Page 1

R

Builder Portfolio Whirlpool Baths:

K-1200-AC

K-1201-AC

K-1205-AC

K-1206-AC

K-1210-AC

Optional Aprons:

K-1507-AA

K-1515-AA

K-1211-AC

K-1215-AC

K-1216-AC

K-1220-AC

K-1221-AC

106548-CA (9437)

Copyright E1994 Kohler Co.

Page 2

IMPORTANT SAFETY INSTRUCTIONS

ATTENTION INSTALLER: INSTRUCTIONS PERTAINING TO RISK OF FIRE, ELECTRIC

SHOCK OR INJURY TO PERSONS

READ AND FOLLOW ALL INSTRUCTIONS

WARNING: When using this unit, always follow basic precautions, including the following:

DANGER: RISK OF ELECTRICAL SHOCK.

The installation must have a Class A

Ground-Fault Circuit-Interrupter (GFCI) for the

whirlpool system.

This will provide additional protection against

line-to-ground shock hazard.

Such a GFCI should be provided by the installer and

should be tested on a routine basis.

T o test the GFCI, press the test button. The GFCI should

interrupt power. Press the reset button. Power should be

restored.

If the GFCI fails to operate in this manner, there is a

ground current flowing or the GFCI is defective. The

possibility of an electric shock may exist. DO NOT use

this unit. Disconnect the unit and have the problem

corrected by a qualified licensed electrician.

DO NOT operate this unit without the guard on the

suction fitting.

Never drop or insert any object into any opening.

For -J1 and -JA models only: A green colored terminal

(or a wire connector marked “G”, “GR”, “GROUND”, or

“Grounding”) is provided within the terminal

compartment. To reduce the risk of electric shock,

connect this terminal or connector to the grounding

terminal of your electric service or supply panel with a

conductor equivalent in size to the circuit conductors

supplying this equipment.

All models: A pressure wire connector is provided on

the exterior of the pump or control box within this unit to

permit connection of a No. 8 AWG (8.4 mm2) solid

copper bonding conductor between this unit and all other

electrical equipment and exposed metal in the vicinity , as

needed to comply with local requirements.

Use this unit only for its intended use as denoted in this

manual. DO NOT use attachments not recommended

by the Kohler Co.

DANGER: To reduce the risk of injury, do not

permit children to use this unit unless they are

closely supervised at all times.

106548-CA (9437)

SAVE THESE INSTRUCTIONS

2

Kohler Co., Kohler WI

Page 3

TABLE OF CONTENTS

IMPORTANT SAFETY INSTRUCTIONS 2. . . . . . . .

INTRODUCTION 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ROUGHING-IN: K-1200-AC, K-1201-AC 5. . . . . . . .

Ordering Information 5. . . . . . . . . . . . . . . . . . . . . . .

Required Electrical Service 5. . . . . . . . . . . . . . . . . .

Product Information 5. . . . . . . . . . . . . . . . . . . . . . . .

Installation Notes 5. . . . . . . . . . . . . . . . . . . . . . . . . .

ROUGHING-IN: K-1205-AC, K-1206-AC 6. . . . . . . .

Ordering Information 6. . . . . . . . . . . . . . . . . . . . . . .

Required Electrical Service 6. . . . . . . . . . . . . . . . . .

Product Information 6. . . . . . . . . . . . . . . . . . . . . . . .

Installation Notes 5. . . . . . . . . . . . . . . . . . . . . . . . . .

ROUGHING-IN: K-1210-AC, K-1211-AC 7. . . . . . .

Ordering Information 7. . . . . . . . . . . . . . . . . . . . . . .

Required Electrical Service 7. . . . . . . . . . . . . . . . . .

Product Information 7. . . . . . . . . . . . . . . . . . . . . . . .

Installation Notes 7. . . . . . . . . . . . . . . . . . . . . . . . . .

ROUGHING-IN: K-1215-AC, K-1216-AC 8. . . . . . . .

Ordering Information 8. . . . . . . . . . . . . . . . . . . . . . .

Required Electrical Service 8. . . . . . . . . . . . . . . . . .

Product Information 8. . . . . . . . . . . . . . . . . . . . . . . .

Installation Notes 8. . . . . . . . . . . . . . . . . . . . . . . . . .

ROUGHING-IN: K-1220-AC, K-1221-AC 9. . . . . . . .

Ordering Information 9. . . . . . . . . . . . . . . . . . . . . . .

Required Electrical Service 9. . . . . . . . . . . . . . . . . .

Product Information 9. . . . . . . . . . . . . . . . . . . . . . . .

Installation Notes 9. . . . . . . . . . . . . . . . . . . . . . . . . .

PRODUCT NOTICES 10. . . . . . . . . . . . . . . . . . . . . . . . .

Installer Hazard Notification 10. . . . . . . . . . . . . . . . .

Factory-Assembled Features 10. . . . . . . . . . . . . . . .

PRODUCT REQUIREMENTS 11. . . . . . . . . . . . . . . . .

Summary of Key Requirements 11. . . . . . . . . . . . . .

Plumbing Specifications 11. . . . . . . . . . . . . . . . . . . . .

Product Inspection 11. . . . . . . . . . . . . . . . . . . . . . . . .

Connections and Service Access 11. . . . . . . . . . . . .

Electrical Requirements 11. . . . . . . . . . . . . . . . . . . . .

INSTALLATION REQUIREMENTS 12. . . . . . . . . . . . .

Tools Required 12. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Materials Required 12. . . . . . . . . . . . . . . . . . . . . . . . .

Clearance Requirements 12. . . . . . . . . . . . . . . . . . . .

New Or Replacement Installation Requirements 12

SITE REQUIREMENTS 13. . . . . . . . . . . . . . . . . . . . . . .

Remove Old Bath 13. . . . . . . . . . . . . . . . . . . . . . . . . .

Subfloor Preparation 13. . . . . . . . . . . . . . . . . . . . . . . .

Stud Pocket Preparation 13. . . . . . . . . . . . . . . . . . . .

Plumbing Preparation 14. . . . . . . . . . . . . . . . . . . . . . .

BEFORE INSTALLING UNIT 14. . . . . . . . . . . . . . . . . .

Tiling-In Bead Installation 14. . . . . . . . . . . . . . . . . . . .

Partially Install Bath Drain 14. . . . . . . . . . . . . . . . . . .

Protect Bath Unit 14. . . . . . . . . . . . . . . . . . . . . . . . . . .

INSTALL WHIRLPOOL 15. . . . . . . . . . . . . . . . . . . . . . .

Whirlpool Set-In 15. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Height Adjustment 16. . . . . . . . . . . . . . . . . . . . . . . . .

Secure Whirlpool 16. . . . . . . . . . . . . . . . . . . . . . . . . . .

Install Plumbing 16. . . . . . . . . . . . . . . . . . . . . . . . . . . .

ELECTRICAL CONNECTIONS -

AIR ACTUATOR VERSIONS 17. . . . . . . . . . . . . . . . . .

Identify Electrical Requirements 17. . . . . . . . . . . . . .

Wiring Information - 120 V, 60 Hz 17. . . . . . . . . . . .

Locate Field Wiring Compartment - 120 V, 60 Hz 18

Field Wiring Diagram - 120 V, 60 Hz 18. . . . . . . . . .

Field Wiring Control Box Compartment -

230 V, 50 Hz 19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Connect Control Box - 230 V, 50 Hz 19. . . . . . . . . .

ELECTRICAL CONNECTIONS -

WALL TIMER VERSIONS 20. . . . . . . . . . . . . . . . . . . . .

Identify Electrical Requirements 20. . . . . . . . . . . . . .

Wiring Infromation - 120 V, 60 Hz -

Wall Timer Versions 20. . . . . . . . . . . . . . . . . . . . . . . .

WATER TEST WHIRLPOOL AND ELECTRONICS 21

COMPLETE FINISH WALL 21. . . . . . . . . . . . . . . . . . . .

OPTIONAL K-1507 APRON INSTALLATION 22. . . . .

OPTIONAL K-1515 APRON INSTALLATION 23. . . . .

COMPLETE INSTALLATION 24. . . . . . . . . . . . . . . . . .

CLEAN-UP AFTER INSTALLATION 24. . . . . . . . . . . .

CONFIRM PROPER OPERATION 25. . . . . . . . . . . . .

Start-Up Whirlpool 25. . . . . . . . . . . . . . . . . . . . . . . . .

Operating Sequence 25. . . . . . . . . . . . . . . . . . . . . . . .

Troubleshoot Whirlpool System 26. . . . . . . . . . . . . .

Kohler Co., Kohler WI

3

106548-CA (9437)

Page 4

INTRODUCTION

Please read these instructions carefully to familiarize

yourself with the required tools, materials, and

installation sequences. Follow the sections that pertain

to your particular installation. This will aid you in avoiding

the unnecessary expense associated with improper

installation. In addition to proper installation, read all

operating and safety instructions.

The variety of installations possible with this whirlpool

may require framing procedures other than those

described in this manual.

All information in this manual is based on the latest

product information available at the time of publication.

Kohler Co. reserves the right to make changes in

product characteristics, packaging, or availability at any

time without notice.

Identify and record below the model and serial number (found at the pump end of the whirlpool):

Model No. Serial No. Date of Manufacture

106548-CA (9437)

4

Kohler Co., Kohler WI

Page 5

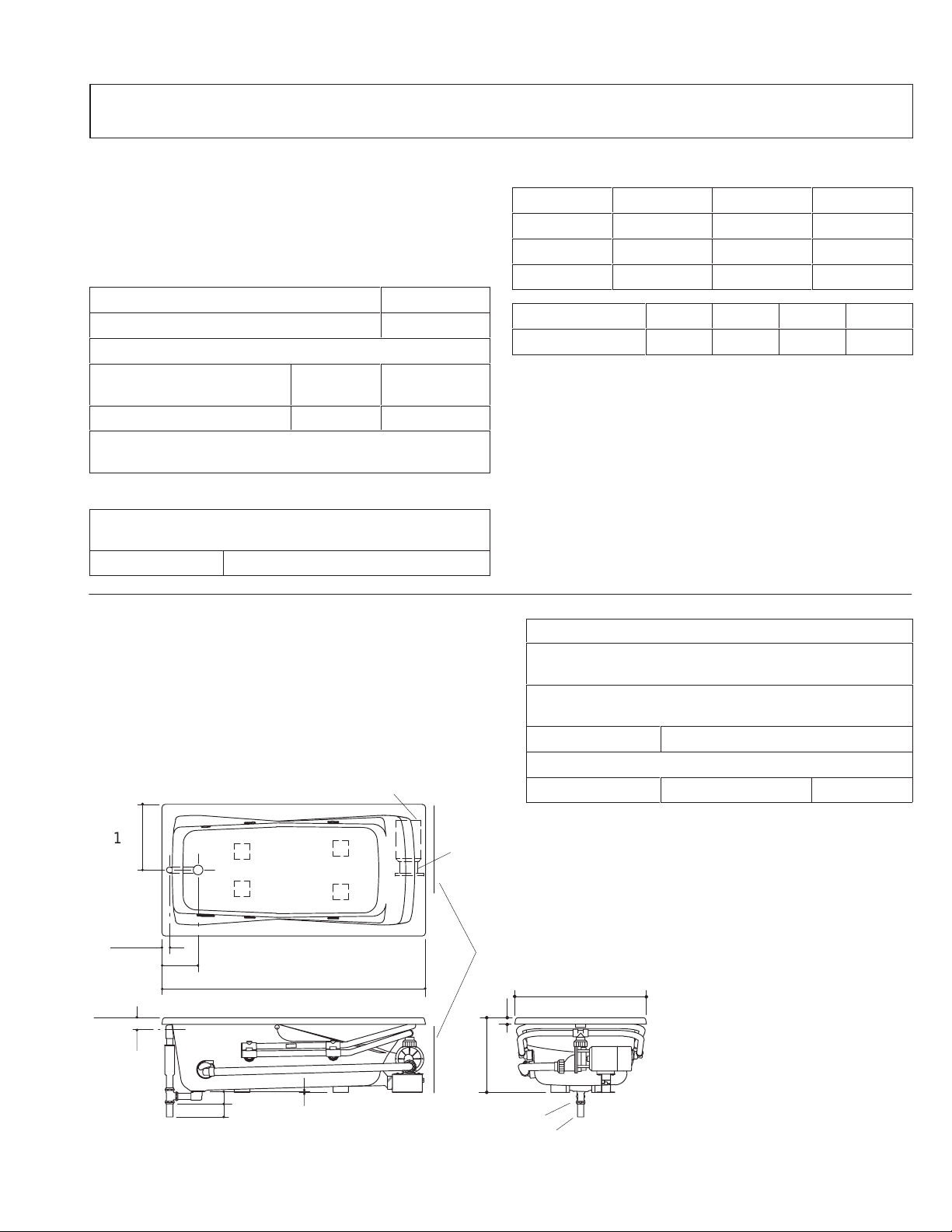

1. ROUGHING-IN: K-1200-AC, K-1201-AC

A. ORDERING INFORMA TION

Factory installed components include pump and air switch

transmitter.

Information contained in this roughing-in also applies to

K-1201-J1-AA, K-1201-J1-AB and K-1201-JA-AA.

Whirlpool with wall timer K-1200-AC

Whirlpool with air actuator (shown) K-1201-AC

Accessories/hardware:

Drain K-7161-AF recom-

mended

Vinyl tiling-in bead* K-1177 optional

*Use K-1177 vinyl bead when wall material contacts any

top surface of bath.

B. REQUIRED ELECTRICAL SERVICE

Dedicated circuits required, protected with Class A

Ground-Fault Circuit-Interrupter (GFCI):

Pump/control 120 V., 15 A, 60 Hz

C. PRODUCT INFORMA TION

Fixture: basin area top area weight

Bathing well 42” x 17” 55” x 25” 93 lbs.

water depth capacity

To overflow 12-1/8” 50 gals.

Pump: hp V Hz A

60 Hz 1/2 120 60 8

D. INST ALLATION NOTES

Refer to installation instructions included with fixture before

beginning installation.

15”

1-1/2”

2-3/4”

FIELD WIRING COMPARTMENT

8-1/2”

60”

ROUGHING-IN NOTES

Fixture dimensions are nominal and conform to tolerances in ANSI Standard Z124.1.

No change in measurements if connected with drain

illustrated.

Cut-out 28-1/2” x 58-1/2”

Minimum access:

Pump/control box 20” W x 15” H panel required

PUMP

PUMP/CONTROL ACCESS

30”

1-1/2”

17”

1.25>132

Kohler Co., Kohler WI

2-7/8”

3”

3/16”

1-1/2” I.P.S. THR’D

1-1/2” O.D.

5

106548-CA (9437)

Page 6

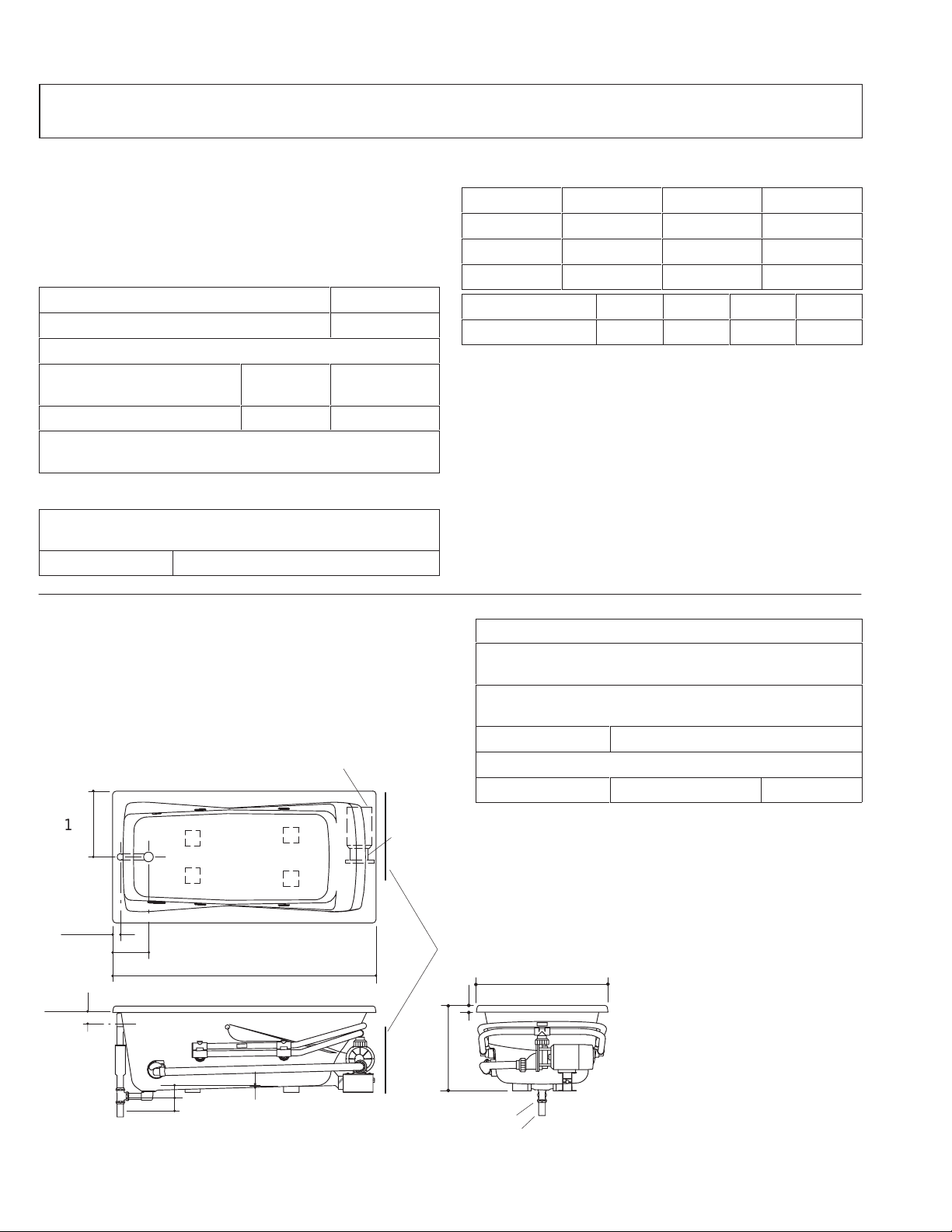

2. ROUGHING-IN: K-1205-AC, K-1206-AC

A. ORDERING INFORMA TION

Factory installed components include pump and air switch

transmitter.

Information contained in this roughing-in also applies to

K-1206-J1-AA, K-1206-J1-AB and K-1206-JA-AA.

Whirlpool with wall timer K-1205-AC

Whirlpool with air actuator (shown) K-1206-AC

Accessories/hardware:

Drain K-7161-AF recom-

mended

Vinyl tiling-in bead* K-1177 optional

*Use K-1177 vinyl bead when wall material contacts any

top surface of bath.

B. REQUIRED ELECTRICAL SERVICE

Dedicated circuits required, protected with Class A

Ground-Fault Circuit-Interrupter (GFCI):

Pump/control 120 V., 15 A, 60 Hz

C. PRODUCT INFORMA TION

Fixture: basin area top area weight

Bathing well 44” x 22” 55” x 25” 100 lbs.

water depth capacity

To overflow 15-1/8” 60 gals.

Pump: hp V Hz A

60 Hz 1/2 120 60 8

D. INST ALLATION NOTES

Refer to installation instructions included with fixture before

beginning installation.

16”

1-3/8”

2-3/4”

FIELD WIRING COMPARTMENT

8-3/8”

60”

ROUGHING-IN NOTES

Fixture dimensions are nominal and conform to tolerances in ANSI Standard Z124.1.

No change in measurements if connected with drain

illustrated.

Cut-out 30-1/2” x 58-1/2”

Minimum access:

Pump/control box 20” W x 15” H panel required

PUMP

PUMP/CONTROL ACCESS

32”

1-1/2”

20”

1.25>132

106548-CA (9437)

2-7/8”

3”

3/8”

1-1/2” I.P.S. THR’D

1-1/2” O.D.

6

Kohler Co., Kohler WI

Page 7

3. ROUGHING-IN: K-1210-AC, K-121 1-AC

A. ORDERING INFORMA TION

Factory installed components include pump and air switch

transmitter.

Information contained in this roughing-in also applies to

K-1211-J1-AA, K-1211-J1-AB and K-1211-JA-AA.

Whirlpool with wall timer K-1210-AC

Whirlpool with air actuator (shown) K-1211-AC

Accessories/hardware:

Drain K-7161-AF recom-

mended

Vinyl tiling-in bead* K-1179 optional

*Use K-1179 vinyl bead when wall material contacts any

top surface of bath.

B. REQUIRED ELECTRICAL SERVICE

Dedicated circuits required, protected with Class A

Ground-Fault Circuit-Interrupter (GFCI):

Pump/control 120 V., 15 A, 60 Hz

C. PRODUCT INFORMA TION

Fixture: basin area top area weight

Bathing well 39” x 22” 54” x 27” 85 lbs.

water depth capacity

To overflow 15-1/2” 65 gals.

Pump: hp V Hz A

60 Hz 1/2 120 60 8

D. INST ALLATION NOTES

Refer to installation instructions included with fixture before

beginning installation.

*Some K-1179 tiling-in beads may require trimming of the

bottom edge for proper fit.

18”

1-7/8”

3-1/4”

FIELD WIRING COMPARTMENT

8-7/8”

59-9/16”

ROUGHING-IN NOTES

Fixture dimensions are nominal and conform to tolerances in ANSI Standard Z124.1.

No change in measurements if connected with drain

illustrated.

Cut-out 34-1/2” x 58-1/2”

Minimum access:

Pump/control box 20” W x 15” H panel required

PUMP

PUMP/CONTROL ACCESS

1-3/4”

21”

36”

1.25>132

Kohler Co., Kohler WI

2-7/8”

3”

1-1/8”

1-1/2” I.P.S. THR’D

1-1/2” O.D.

7

106548-CA (9437)

Page 8

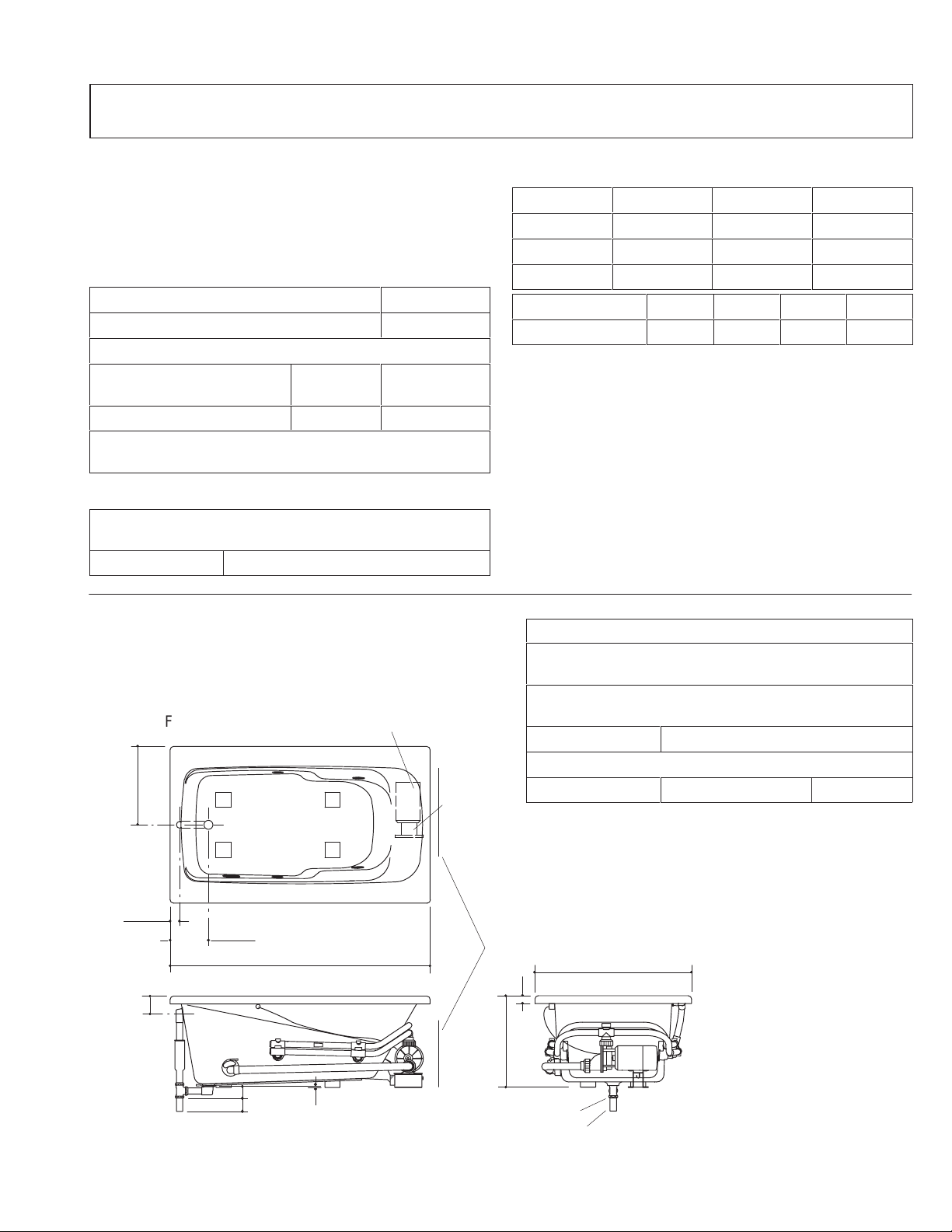

4. ROUGHING-IN: K-1215-AC, K-1216-AC

A. ORDERING INFORMA TION

Factory installed components include pump and air switch

transmitter.

Information contained in this roughing-in also applies to

K-1216-J1-AA and K-1216-JA-AA.

Whirlpool with wall timer K-1215-AC

Whirlpool with air actuator (shown) K-1216-AC

Accessories/hardware:

Drain K-7161-AF recom-

mended

Vinyl tiling-in bead* K-1179 optional

*Use K-1179 vinyl bead when wall material contacts any

top surface of bath.

B. REQUIRED ELECTRICAL SERVICE

Dedicated circuits required, protected with Class A

Ground-Fault Circuit-Interrupter (GFCI):

Pump/control 120 V., 15 A, 60 Hz

C. PRODUCT INFORMA TION

Fixture: basin area top area weight

Bathing well 52” x 23” 65-1/2” x

26-1/2”

water depth capacity

To overflow 15-1/2” 76 gals.

Pump: hp V Hz A

60 Hz 3/4 120 60 10

95 lbs.

D. INST ALLATION NOTES

Refer to installation instructions included with fixture before

beginning installation.

*Some K-1179 tiling-in beads may require trimming of the

bottom edge for proper fit.

18”

1-7/8”

3”

FIELD WIRING COMPARTMENT

PUMP

8-7/8”

71-3/16”

ROUGHING-IN NOTES

Fixture dimensions are nominal and conform to tolerances in ANSI Standard Z124.1.

No change in measurements if connected with drain

illustrated.

Cut-out 34-1/2” x 70”

Minimum access:

Pump/control box 20” W x 15” H panel required

PUMP/CONTROL ACCESS

36”

1-3/4”

21”

1.25>132

106548-CA (9437)

2-7/8”

3”

15/16”

1-1/2” I.P.S. THR’D

1-1/2” O.D.

8

Kohler Co., Kohler WI

Page 9

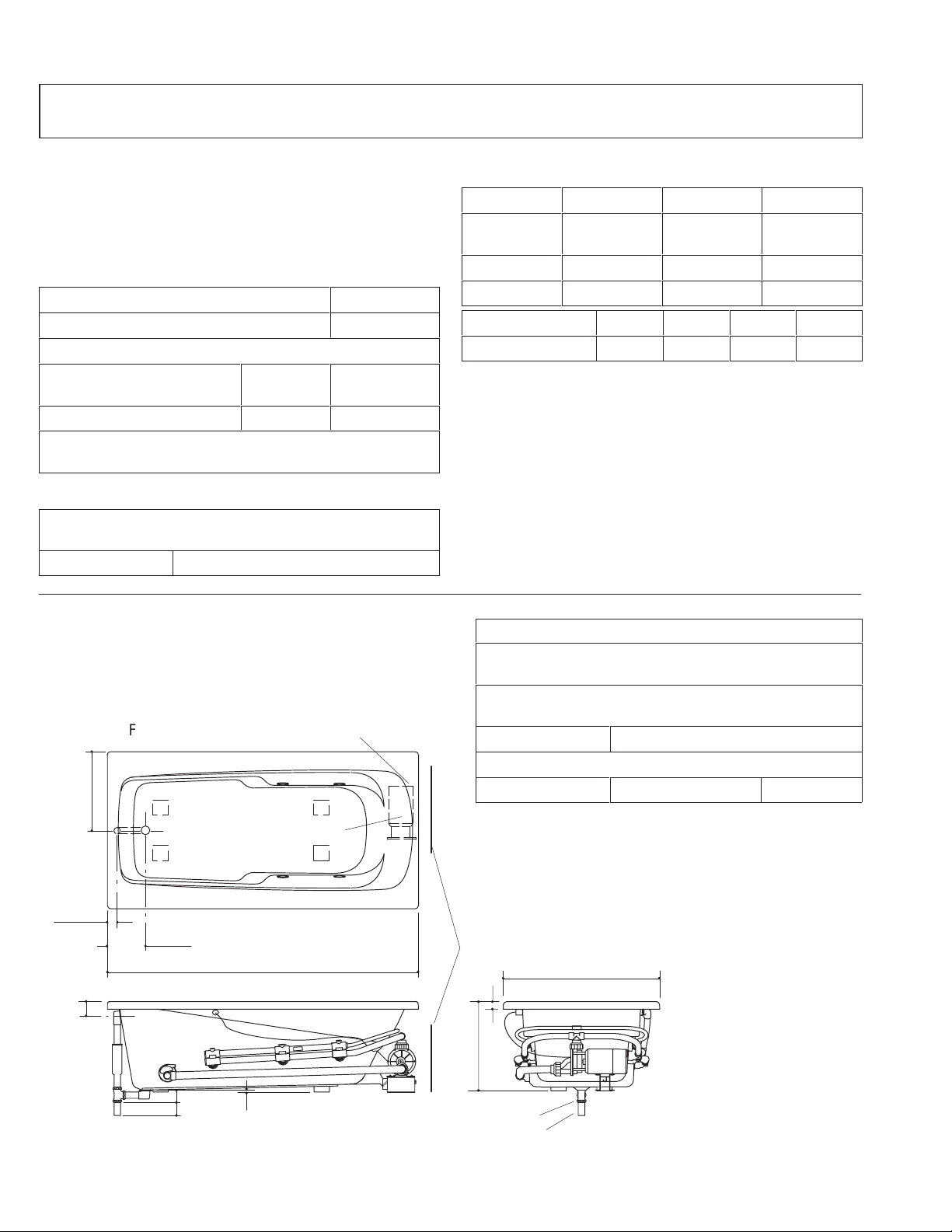

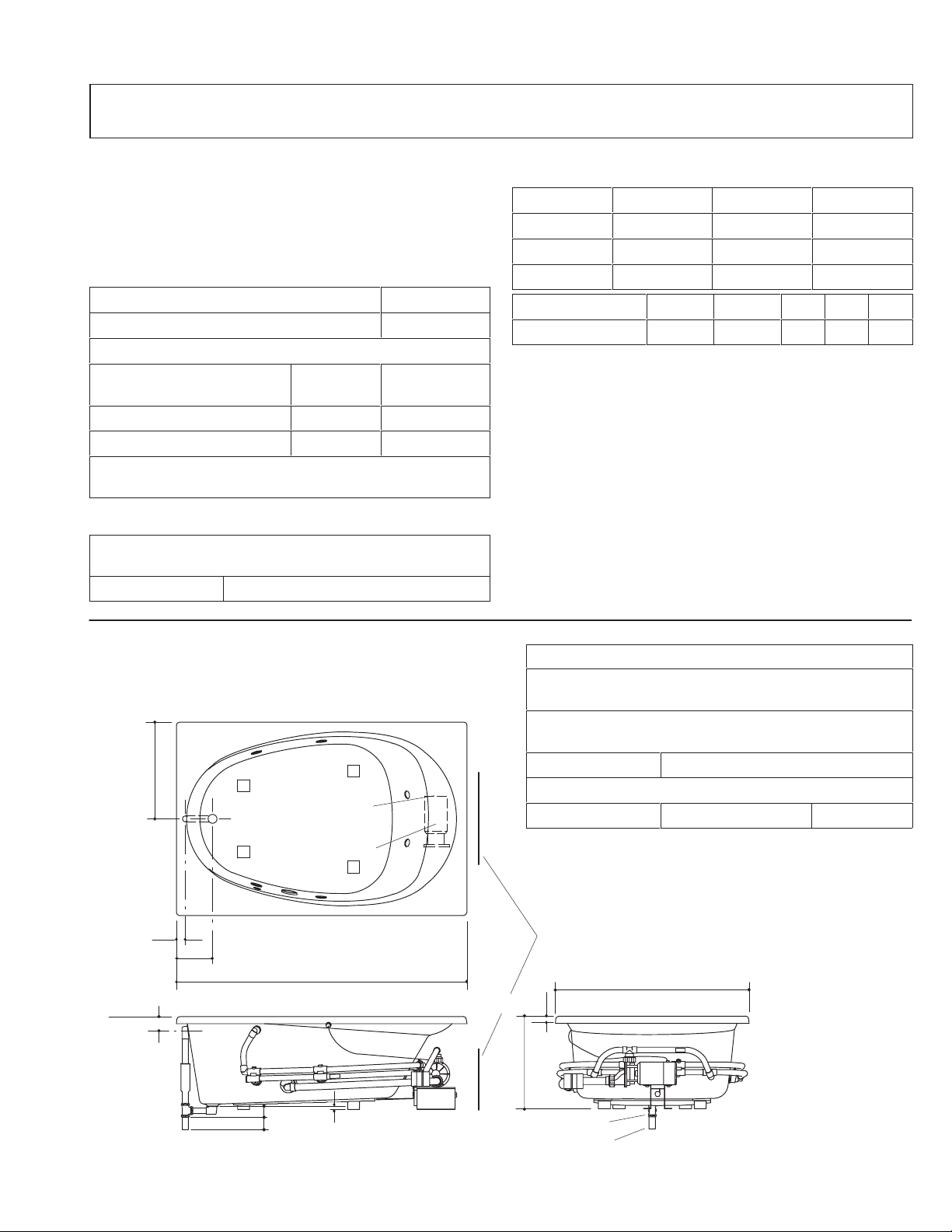

5. ROUGHING-IN: K-1220-AC, K-1221-AC

A. ORDERING INFORMA TION

Factory installed components include pump and air switch

transmitter.

Information contained in this roughing-in also applies to

K-1221-J1-AA and K-1221-JA-AA.

Whirlpool with wall timer K-1220-AC

Whirlpool with air switch (shown) K-1221-AC

Accessories/hardware:

Drain K-7161-AF recom-

mended

Apron K-1223 optional

Vinyl tiling-in bead* K-1179 optional

*Use K-1179 vinyl bead when wall material contacts any

top surface of bath.

B. REQUIRED ELECTRICAL SERVICE

Dedicated circuits required, protected with Class A

Ground-Fault Circuit-Interrupter (GFCI):

Pump/control 120 V., 15 A, 60 Hz

C. PRODUCT INFORMA TION

Fixture: basin area top area weight

Bathing well 47” x 37” 67” x 32” 120 lbs.

water depth capacity

To overflow 16-7/8” 117 gals.

Pump, 1 phase hp RPM V Hz A

60 Hz 3/4 3450 120 60 10

D. INST ALLATION NOTES

Refer to installation instructions included with fixture before

beginning installation.

*Some K-1179 tiling-in beads may require trimming of the

bottom edge for proper fit.

24”

3-1/2”

2”

9”

FIELD WIRING

COMPARTMENT

PUMP

72”

ROUGHING-IN NOTES

Fixture dimensions are nominal and conform to tolerances in ANSI Standard Z124.1.

No change in measurements if connected with drain

illustrated.

Cut-out 46-1/4” x 70-1/4”

Minimum access:

Pump/control box 20” W x 15” H panel required

PUMP/CONTROL ACCESS

48”

1-3/4”

23”

Kohler Co., Kohler WI

2-7/8”

3”

13/16”

1-1/2” I.P.S. THR’D

1-1/2” O.D.

9

1.15>132

106548-CA (9437)

Page 10

6. PRODUCT NOTICES

A. INSTALLER HAZARD NOTIFICA TION

DANGER: Risk of fire, electric shock, or injury

to persons. Read important safety instructions on

inside front cover of these instructions.

WARNING: Risk of electrical shock. A licensed

electrician should make all electrical connections.

WARNING: Risk of electrical shock. Connect

only to a circuit protected by a Ground-Fault

Circuit-Interrupter (GFCI).

WARNING: Risk of electrical shock.

Disconnect power before servicing.

WARNING: Risk of injury or property damage.

Please read all instructions thoroughly before

beginning installation, including the following

Product Requirements.

NOTICE: Follow all local plumbing and electrical

codes.

B. F ACTORY -ASSEMBLED FEATURES

K-1201, K-1206, K-1211, K-1216, K-1221: Factory

installed components include pump and air switch

transmitter. No installation is needed.

K-1200, K-1205, K-1210, K-1215, K-1220: Factory

installed components include pump. Wall timer is

shipped attached to whirlpool harness.

The whirlpool pump and piping are factory-assembled.

WARNING: Unauthorized modification may

cause unsafe operation and poor performance

of the whirlpool. Do not relocate the whirlpool

pump or make other modifications to the whirlpool

system, as this could adversely affect the

performance and safe operation of the whirlpool.

Kohler Co. shall not be liable under its warranty or

otherwise for personal injury or damage caused by

any such unauthorized modification.

106548-CA (9437)

10

Kohler Co., Kohler WI

Page 11

7. PRODUCT REQUIREMENTS

A. SUMMAR Y OF KEY REQUIREMENTS

S Install unit to level subfloor.

S Provide properly dimensioned framing.

S Bath can be installed in a corner. Recess, penin-

sular or sunken installation is also possible.

C. PRODUCT INSPECTION

Carefully uncrate and inspect your product for damage.

Leave all materials in carton during construction to

prevent damage.

NOTICE: Make sure both connections to the

whirlpool pump are securely tightened.

E. ELECTRICAL REQUIREMENTS

B. PLUMBING SPECIFICA TIONS

If using a rim mounted bath faucet, flexible connections

between the valves and spout may be required. Confirm

adequate mounting and connection space of specified

faucet for your installation.

Confirm adequate support for faucet; large faucets that

may be inadvertently used as a means of support are not

appropriate or safe for this installation.

D. CONNECTIONS AND SERVICE ACCESS

Before installation, ensure proper access to the final

connections.

NOTICE: Provide unrestricted service access to

the pump. An access panel 20” W x 15” H minimum

must be constructed to allow for sufficient clearance for

servicing the pump or controls. The access panel must

be located at the pump end of the whirlpool, through an

adjoining wall.

The optional apron is removable to allow limited service

access.

K-1200-AC, K-1201-AC, K-1205-AC, K-1206-AC,

K-1210-AC, K-1211-AC, K-1215-AC, K-1216-AC,

K-1220-AC, K-1221-AC: The installation must have a

Class A Ground-Fault Circuit-Interrupter (GFCI). The

GFCI protects against line-to-ground shock hazard. Use

a 120 V, 15 A, 60 Hz separate service for the whirlpool.

Provide a separate equipment grounding conductor for

the inside grounding lug. Ground must not be connected

to any current-carrying conductor except at the main

service breaker box.

All 50 Hz models: The installation must have an Earth

Leakage Circuit Breaker (ELCB). This will provide

additional protection against line-to-ground shock

hazard. A 230 V, 50 Hz separate circuit that provides15

A of continuous service is required.

Kohler Co., Kohler WI

11

106548-CA (9437)

Page 12

8. INSTALLATION REQUIREMENTS

A. TOOLS REQUIRED

S Conventional woodworking tools

S Arc pliers or 14” pipe wrench

S Rule

S Level

S Safety shoes

S Safety glasses

S Square

S Screwdriver

S Pliers

S Utility knife

C. CLEARANCE REQUIREMENTS

Check roughing-in and room dimensions in order to

provide adequate available space for the bath unit.

B. MA TERIALS REQUIRED

S Plumbers putty

S Water-resistant sealer

S Wall coverings, as necessary

S RTV silicone sealant

S Four 1/4” x 1” lag screws

D. NEW OR REPLACEMENT INSTALLA TION

REQUIREMENTS

This bath unit can be installed in new or existing

bathrooms.

For new installations: Position plumbing according to

roughing-in dimensions beginning on page 5. Cap

supplies and check for leaks.

For replacement installations: Remove old bath,

remove old wall material and remove old floor covering

from area. Remove old plumbing which does not

conform to roughing-in requirements.

106548-CA (9437)

12

Kohler Co., Kohler WI

Page 13

9. SITE REQUIREMENTS

A. OLD BA TH REMOVAL

Disconnect the drain at the trap. Remove old wall

material. Slip boards under old bath feet to protect

floor and slide old bath out of recess as illustrated.

B. SUBFLOOR PREP ARA TION

Check flooring under the bath and repair if necessary.

Make sure that the subfloor is level. Seal subfloor to

reduce the risk of water damage.

C. STUD POCKET PREP ARA TION

Construct a recess designed for your particular

installation. Framing is of 2 x 4 construction. Make sure

you allow for access to the pump or power panel in the

event the unit requires service. When constructing

framing allow for thickness of sub and finished wall

materials.

If an apron wall without a ledge is desired, the finished

apron wall surface must be 1/32” under the bath rim.

Bath can be installed in a corner. Recess, peninsular or

sunken installation is also possible. Possible studding

arrangements are illustrated in 1. through 2. below;

modifications may be needed for other types of

construction.

Old Bath

Floor

Protection

Boards

1. Sunken Installation: For sunken installation,

refer to Roughing-In notes located in Roughing-In

section beginning on page 5 for cut-out detail. Make

sure the bath is supported by the supporting blocks

at the bottom of the bath.

Kohler Co., Kohler WI

13

106548-CA (9437)

Page 14

2. Recessed Installation: Suggested stud

construction is illustrated.

D. PLUMBING PREP ARA TION

Position plumbing according to roughing-in dimensions.

Cap supplies and check for leaks.

10. BEFORE INSTALLING UNIT

A. TILING-IN BEAD INST ALLA TION

Before setting bath, an optional tiling-in bead is

recommended to be applied to whatever side of the bath

contacts the wall. Refer to Ordering Information located

in Roughing-In section beginning on page 5. This bead

prevents water from seeping between the bath and the

wall. Install this bead now. Refer to Installation

Instructions packed with the tiling-in bead.

B. P ARTIALL Y INSTALL BA TH DRAIN

Install drain on bath/whirlpool according to

manufacturer’s instructions.

C. PROTECT BA TH UNIT

Place a drop cloth or similar material in bath/whirlpool

bottom. Be careful not to scratch product.

106548-CA (9437)

14

Kohler Co., Kohler WI

Page 15

11. INSTALL WHIRLPOOL

A. WHIRLPOOL SET -IN

Choose one of the three recommended options below

that is best for your particular installation as described in

1., 2., or 3. Follow the appropriate instructions.

If subfloor is not level, some shimming of the bath and

pump will be necessary. See 11.B. for height

adjustment.

1. Sunken Installation: Set unit into sunken

installation. Make sure the bath/whirlpool is level

and is resting on all blocks. Insert the tailpiece into

the trap. Apply a bead of RTV sealant under rim of

the bath unit.

2. Install Using Gypsum: Place a 2” thick layer of

gypsum cement (such as Gyp-Crete 2000) on the

floor where the whirlpool is to be set. This will help

secure, level and support the bath. Set bath into

position. Clear any excess cement from vicinity of

the pump.

NOTE: Pump bracket must sit flat on the floor.

Insert tailpiece into trap. Make sure bath is level

and resting on all supporting blocks.

3. Install Using 1 x 2 Strips: Set whirlpool in desired

location and level. Nail 1 x 2 wood strips around

blocks under the whirlpool to firmly hold it in

position. It is not necessary to use strips on all

blocks. They are only needed on blocks that are to

the outside edges of your installation.

Insert tailpiece into trap. Make sure bath is level and

resting on all supporting blocks.

Whirlpool

Blocks

Wood

Strips

Wood

Strips

Kohler Co., Kohler WI

15

106548-CA (9437)

Page 16

B. HEIGHT ADJUSTMENT

É

É

NOTICE: Steps B. and C. are necessary for making

your Kohler Whirlpool operate more quietly.

If the subfloor is level, no adjustment is necessary;

proceed to Step C. If the subfloor is not level, shim

beneath pump bracket (plywood is recommended). Do

not change the elevation of the pump relative to the

whirlpool bath since this may affect performance. Use

a 5 x 7 (minimum) piece of plywood.

Drainage

Shim if necessary, using 5” x 7”

(minimum) plywood

C. SECURE WHIRLPOOL

Using four 1/4” x 1” lag screws, secure pump bracket to

subfloor. Predrilling is recommended.

CAUTION: Risk of product damage. Do not

use the piping or pump for structural support or

positioning of whirlpools.

Use a 1/2” wrench to remove the long bolt securing the

bracket to the bath.

D. INST ALL PLUMBING

CAUTION: Risk of damage to whirlpool

bottom and subfloor. Ensure watertight seal on

bath drain connections.

1. When whirlpool is securely positioned, connect

drain into trap. An access panel will simplify future

maintenance.

2. Install the faucet valving and spout tee. If faucets

are deck-mounted, the deck must be finished

before handle trim and spout can be installed. Open

hot and cold valves and check all supply

connections for leaks.

Spacer

Plywood

(if required)

Lag Screw

Bracket

Bolt

Connect Here

3. Run water in whirlpool and check drain connection

106548-CA (9437)

for leaks.

16

Kohler Co., Kohler WI

Page 17

12. ELECTRICAL CONNECTIONS - AIR ACTUATOR VERSIONS

A. IDENTIFY ELECTRICAL REQUIREMENTS

The model number is printed on a plate at the pump end

of the module.

The model number identifies electrical rating. Electrical

connections for each model vary.

S K-1201-AC, K-1206-AC, K-1211-AC,

K-1216-AC, K-1221-AC: 60 Hz

(Follow Step B. below.)

S K-1201-J1-AA, K-1201-J1-AB, K-1206-J1-AA,

K-1206-J1-AB, K-1211-J1-AA, K-1211-J1-AB,

K-1216-J1-AA, K-1221-J1-AA: 60 Hz

(Follow Steps C. and D. below.)

S K-1201-JA-AA, K-1206-JA-AA, K-1211-JA-AA,

K-1216-JA-AA, K-1221-JA-AA: 50 Hz

(Follow Steps E. and F. below.)

See Electrical Requirements section on page 11 of

Product Requirements.

B. WIRING INFORMATION - 120 V , 60 HZ

(EXCLUDING -J1 MODELS)

WARNING: Risk of electrical shock. T o reduce

the risk of electric shock, connect only to a properly

grounded, grounding-type receptacle, protected

by a Ground-Fault Circuit-Interrupter (GFCI). Do

not remove the plug’s grounding pin. Do not use a

grounding adapter.

Your Kohler Whirlpool bath is equipped with a cord and

plug. All wiring of the pump and control has been

completed at the factory. A licensed electrician must

install a GFCI protected, 120 Volt, 15 Amp, grounded

outlet. Your whirlpool may then be plugged into this

outlet. No other load should be on this circuit. Locate the

outlet within reach of the 36” cord.

Kohler Co., Kohler WI

17

106548-CA (9437)

Page 18

C. LOCA TE FIELD WIRING COMP ARTMENT -

)

120 V, 60 HZ (-J1 MODELS ONLY)

WARNING: Risk of electrical shock. Make sure

the power has been disconnected before

performing the following procedures. Refer to

Important Safety Instructions located on page 2.

CAUTION: Risk of electrical shock. All services

must have a Class A Ground-Fault

Circuit-Interrupter (GFCI) which will provide

additional protection against line-to-ground shock

hazard.

A licensed electrician should make a routine service

connection to the field wiring compartment of the pump

containing black and white wires and ground screw.

NOTE: The electrician must supply a listed strain/relief

bushing in accordance with local codes.

Remove air actuator tubing from pump by gently pulling.

Next, remove the screw at the top of the pump near the

strain relief bushing. Save screw. Loosen screw at

bottom of pump. Remove pump cover to reveal field

wiring compartment.

* For bonding in accordance with National and Local

Codes.

Air

Actuator

Air

Actuator

Tubing

Field Wiring

Compartment

Bonding

(Earthing)

Screw*

Pump

D. FIELD WIRING DIAGRAM - 120 V , 60 HZ (-J1

MODELS ONL Y)

The factory has prewired the whirlpool control system.

A 120 V, 15 A separate circuit is required. Provide a

separate equipment grounding conductor for the inside

grounding conductor for the inside grounding screw (14

AWG minimum). Ground must not be connected to any

current-carrying conductor except at the main service

breaker box (per National Electrical Code, Article

250-61-b).

Replace pump cover over field wiring compartment.

Fasten screw through cover at hole near strain relief at

top of pump. Tighten screw at bottom of pump. Snip off

approximately 1” of air actuator tubing and reattach to

pump. Make sure tubing is securely attached to pump.

Green (Ground)

Black (Line)

To Electrician: Provide enough wire to

allow motor removal

upon servicing.

Strain Relief Bushing

(Not Provided)

Air Actuator Tubing

Connection

White

(Neutral

106548-CA (9437)

18

Kohler Co., Kohler WI

Page 19

E. FIELD WIRING CONTROL BOX

COMPARTMENT - 230 V, 50 HZ

WARNING: Risk of electrical shock. Make sure

the power has been disconnected before

performing the following procedures. Refer to

Important Safety Instructions located on page 2.

CAUTION: Risk of electrical shock. All services

must have an Earth Leakage Circuit Breaker

(ELCB) which will provide additional protection

against line-to-ground shock hazard. A separate

service is required for the whirlpool.

The whirlpool controls and system have been prewired

at the factory. A licensed electrician should make a

routine service connection to the field wiring

compartment of the control box containing blue and

brown wires and earth lug.

* For bonding in accordance with National and Local

Codes.

Air

Actuator

Tube

Pump

Air

Actuator

Control

Box

Field Wiring

Compartment

Bonding

(Earthing) Lug*

F . CONNECT CONTROL BOX - 230 V, 50 HZ

Connect service to the field wiring compartment of the

control box. The 50 Hz model control box contains blue

and brown wires and earth lug.

A 230 V, 15 A, 50 Hz dedicated circuit is required.

Provide an Earth Leakage Circuit Breaker.

Provide a separate equipment earthing conductor for the

inside earth lug. The earthing conductor must not be

connected to any current carrying conductor. Follow

local electrical codes. A 230 V, 15A, 50 Hz separate

circuit is required.

Blue

(Neutral)

Brown

(Phase)

Wire Connectors

Neutral

Earth

(Ground) Lug

Earth

(Ground)

Phase (Line)

Earthing Lug (for

bonding in accordance with national

and local codes)

Kohler Co., Kohler WI

19

106548-CA (9437)

Page 20

13. ELECTRICAL CONNECTIONS - WALL TIMER VERSIONS

A. IDENTIFY ELECTRICAL REQUIREMENTS

The model number is printed on a plate at the pump end

of the module.

The model number identifies electrical rating. Electrical

connections for each model vary.

S K-1200-AC, K-1205-AC, K-1210-AC,

K-1215-AC, K-1220-AC: 60 Hz

See Electrical Requirements section on page 11 of

Product Requirements.

B. WIRING INFORMA TION - 120 V, 60 HZ –

W ALL TIMER VERSIONS

DANGER: Risk of electrical shock. Do not

mount timer within reach of whirlpool user.

WARNING: Risk of electrical shock. T o reduce

the risk of electric shock, connect only to a properly

grounded, grounding-type receptacle, protected

by a Ground-Fault Circuit-Interrupter (GFCI). Do

not remove the plug’s grounding pin. Do not use a

grounding adapter.

Your Kohler Whirlpool bath is equipped with a cord and

plug. All wiring of the pump and control has been

completed at the factory. A licensed electrician must

install a GFCI protected, 120 Volt, 15 Amp, grounded

outlet. Your whirlpool may then be plugged into this

outlet. No other load should be on this circuit. Locate the

outlet within reach of the 36” cord.

Black (Line)

White (Neutral)

G

F

C

I

Green (Ground)

White

Green

Black

TIMER

Black

PUMP

White

Green

Install wiring from the GFCI to the wall timer location.

Use a switch box with adequate capacity.

106548-CA (9437)

20

Kohler Co., Kohler WI

Page 21

14. WATER TEST WHIRLPOOL & ELECTRONICS

Check all electrical connections. Make sure both

connections to the pump are securely tightened.

Fill bath to a level at least 2” above the top of the highest

jet.

Operate whirlpool for 5 minutes and check all whirlpool

harness (piping) connections for leaks.

For additional information on whirlpool operation, see

Whirlpool Start-Up Instructions on page 25.

15. COMPLETE FINISH WALL

CAUTION: Risk of product damage. Do not

support the weight of the whirlpool by the rim.

Protect whirlpool surface. Make sure the vinyl bead is

attached securely to the sides being built into the wall.

Cover framing and walls with gypsum wallboard.

Tape and mud drywall...seal drywall and joints under

bath rim. Install finished wall material to subwall. Seal

joints between the whirlpool rim and finished wall using

silicone sealant.

Gypsum Wallboard Subwall

Finished Wall Material

Water-Resistant Sealant

2 x 4 Studding

Vinyl Tiling-In Bead

Bath Rim

Kohler Co., Kohler WI

21

106548-CA (9437)

Page 22

16. OPTIONAL K-1507 APRON INSTALLATION

NOTE: For use with K-1205 and K-1206 models.

NOTICE: Before installing the optional K-1507

Apron: verify that both the finished floor and the bath

rim are level (and therefore parallel to each other). This

is necessary to ensure proper fit and appearance of the

apron. This apron should be installed after the finished

wall material is applied.

On one of the pieces of vinyl extrusion, use a hacksaw

and trim away or notch about 1” (25 mm) of the top end

rigid portion, leaving the flexible portion fully intact.

Repeat operation for the extrusion which will be installed

on opposite side of the apron. This procedure will

provide a better fit upon final installation.

Install the vinyl extrusions on the right and left side of the

apron.

Flexible

1”

Rigid

Vinyl Extrusion

Cut a 4’ length (approx.) of 2 x 2 batten board. Position

the board on the floor so that it will be centered between

the right and left sides of the apron, parallel with the bath

rim (apron side), and 3-3/4” (95 mm) inboard of the bath

rim outer edge (vertically-projected to the floor). Anchor

the 2 x 2 board to the floor.

Remove the mating half of each velcro strip from the

bottom of the apron. Staple the velcro strips to the front

face of the 2 x 2 board.

Carefully insert the top lip of the apron into the extrusions

on the underside of the bath rim. Press the base of the

apron securely onto the velcro strips of the 2 x 2 board.

NOTE: The apron is removable to allow limited service access, if required.

Bath Rim

Extrusion

3-3/4”

Carpenter’s Square

Apron

Velcro Strip

2 x 2 Board

106548-CA (9437)

22

Kohler Co., Kohler WI

Page 23

17. OPTIONAL K-1515 APRON INSTALLATION

NOTE: For use with K-1200 and K-1201 models.

Make sure the bath is installed according to the

instructions. Provide backing on each of the recessed

walls for the nailing-in flange.

Silicone Adhesive

After bath is leveled and set, apply the vinyl trim strip to

the bath. Carefully apply a 1/16” bead of clear silicone

adhesive (provided) onto the vinyl strip as illustrated.

Apply vinyl strip to the underside of the bath rim, being

careful to align the lip of the strip to the bath rim as shown

in the inset. Immediately wipe off any excess sealant.

Tilt apron and carefully slip apron into groove on

underside of rim.

Temporarily tack a nail in the top hole of the nailing-in

flange on each side of the apron and ensure that the

apron is positioned as close to the bath rim as possible.

Plumb the apron and secure the nailing-in flange using

#6d large-head galvanized nails.

Vinyl Trim

Strip

Nailing-in

Flange

Apron

Apron

Vinyl Trim

Strip

Bath

Rim

Kohler Co., Kohler WI

23

106548-CA (9437)

Page 24

18. COMPLETE INSTALLATION

INSTALL HANDLES AND SPOUT

After the deck is finished, attach the handles and spout

to complete faucet installation per manufacturer’s

instructions.

19. CLEAN-UP AFTER INSTALLATION

When cleaning up after installation, do not use

abrasive cleaners as they may scratch and dull the

module surface. Use warm water and one of the liquid

detergents to clean the surface.

Stubborn stains, paint, or tar can be removed with

turpentine or paint thinner. Do not allow cleaners

containing petroleum distillates to remain in

contact with whirlpool surfaces for long periods of

time. Plaster can be removed by scraping with a wood

edge. Do not use metal scrapers, wire brushes, or other

metal tools. One of the powder-type detergents may be

used on a damp cloth to provide mild abrasive action to

the residual plaster.

106548-CA (9437)

24

Kohler Co., Kohler WI

Page 25

20. CONFIRM PROPER OPERATION

A. ST ART-UP WHIRLPOOL

Refer to Important Safety Instructions on page 2

before operating this whirlpool.

Please perform the following so that the owner may

safely receive the benefits of whirlpool bathing.

1. Rotate jets so they are facing down toward basin.

2. Fill the whirlpool bath to a water level at least 2”

above the top of the highest jet.

Water temperature in the whirlpool should not

exceed 104_F (40_C).

B. OPERA TING SEQUENCE

Refer to chart for proper operating sequence.

1. Turn on the whirlpool jets. Adjust each jet for

optimum air/water mixture.

2. A built-in timer automatically stops the motor after

20 minutes of operation.

Bath

Wall

TO METHOD OBSERVE

Turn on whirlpool massage.

Add air to whirlpool action, rotate

flange counterclockwise. To

reduce air, turn

clockwise.

2” Minimum

Jet Trim

Reduce

Air

Water Line

Add

Air

Shut off whirlpool.

Restart whirlpool

after 20 minute

cycle is complete.

Kohler Co., Kohler WI

25

106548-CA (9437)

Page 26

C. TROUBLESHOOT WHIRLPOOL SYSTEM

is um ing, but

before 18 minutes

This troubleshooting guide is for general aid only . A Kohler Authorized Service Representative or a qualified electrician

should correct all electrical problems. For warranty service, contact your dealer or wholesale distributor.

SYMPTOMS PROBABLE CAUSES RECOMMENDED ACTION

1. Whirlpool does not

start/stop.

2. Motor starts, all jets

are not functioning.

3. Motor turns, water

is pumping, but

there is no air

injection.

4. Whirlpool stops

automatically

before 18 minutes.

A. No power to pump/power module. A. Set/Reset GFCI/ELCB breaker; check

wiring to power module.

B. Air actuator tubing disconnected,

loose, kinked, plugged or damaged.

C. Faulty air actuator. C. Replace air actuator.

D. Faulty motor/pump assembly. D. Rebuild or replace motor and pump

A. Jet is closed. A. Rotate jets counterclockwise to open.

B. Trim kit installed incorrectly. B. Reinstall trim kit, checking for damage

C. Jets are blocked. C. Remove blockage.

A. No aspiration at jets. A. Rotate jets counterclockwise.

B. Jet O-Rings are missing. B. Replace jet O-Rings.

A. GFCI/ELCB trips. A. Identify source of fault and correct.

B. Suction blocked. B. Remove obstruction.

.

C. Jets are blocked. C. Remove blockage.

D. Motor overheated and protection

device activated.

B. Connect, straighten, clean or replace

tubing.

assembly.

to O-Ring.

D. Check for blockage at motor vents.

Remove blockage and allow motor to

cool. Check for suction blockage.

Remove blockage and allow motor to

cool. Check for jet blockage. Remove

blockage and allow motor to cool.

5. Whirlpool does not

automatically stop

after 22 minutes.

p

A. Faulty timer mechanism. A. Replace timer board.

B. Wiring error. B. Refer to dealer.

106548-CA (9437)

26

Kohler Co., Kohler WI

Page 27

Kohler Co., Kohler WI

27

106548-CA (1093)

Page 28

R

106548-CA (1093)

Kohler Co., Kohler WI

Loading...

Loading...