Page 1

Installation Guide

Overflowing Bath

K-1166

M product numbers are for Mexico (i.e. K-12345M)

Los números de productos seguidos de M corresponden a México

(Ej. K-12345M)

Français, page “Français-1”

Español, página “Español-1”

1054216-2-B

Page 2

Important Information

WARNING: When using electrical products, basic precautions should always be followed,

including the following:

DANGER: Risk of electric shock. Connect only to a circuit protected by a Ground-Fault

Circuit-Interrupter (GFCI) or Earth-Leakage Circuit-Breaker (ELCB).

WARNING: Risk of electric shock. A licensed electrician should make all electrical connections.

WARNING: Risk of electric shock. Disconnect power before servicing.

WARNING: Risk of injury or property damage. Please read all instructions thoroughly before

beginning installation, including the following requirements.

NOTICE: Follow all local plumbing and electrical codes.

Install to permit access for servicing.

A green with yellow stripe lead wire is provided within the wiring compartment. To reduce the risk of

electrical shock, connect this wire to the grounding terminal of your electric service or supply panel with

copper wire equivalent in size to the circuit conductor supplying this equipment.

A pressure wire connector is provided on the exterior of the pump or control within this unit to permit

connection of a bonding conductor between this unit and all other exposed metal in the vicinity, as needed to

comply with local requirements.

Grounding is required. The unit should be installed by a qualified service representative, and grounded.

Building materials and wiring should be routed away from the pump body and other heat-producing

components of the unit.

Important Product Information

Product Notices

WARNING: Unauthorized modification may cause unsafe operation and poor performance of the

bath. Do not relocate the pump, or make other modifications to the circulating system, as this could

adversely affect the performance and safe operation of your bath. Kohler Co. shall not be liable

under its warranty or otherwise for personal injury or damage caused by any such unauthorized

modification.

Product Inspection

Carefully unpack the product, and inspect the unit for damage. Return the unit to the carton during

construction to prevent damage.

Factory-Assembled Features

Factory installed components include pump, level sensors, in-line heater, submerged chromatherapy lights

(optional), control and switch. The pump and piping are factory-assembled.

Connections and Service Access

NOTICE: Provide unrestricted service access to the pump and heater. Provide unrestricted service access

to the pump, in-line heater, adjustable feet, and control box. You must construct an access panel to provide

sufficient clearance for servicing the pump, in-line heater, and control box. The access panel must be

located immediately next to the pump and in-line heater. Study the roughing-in information.

1054216-2-B 2 Kohler Co.

Page 3

Important Product Information (cont.)

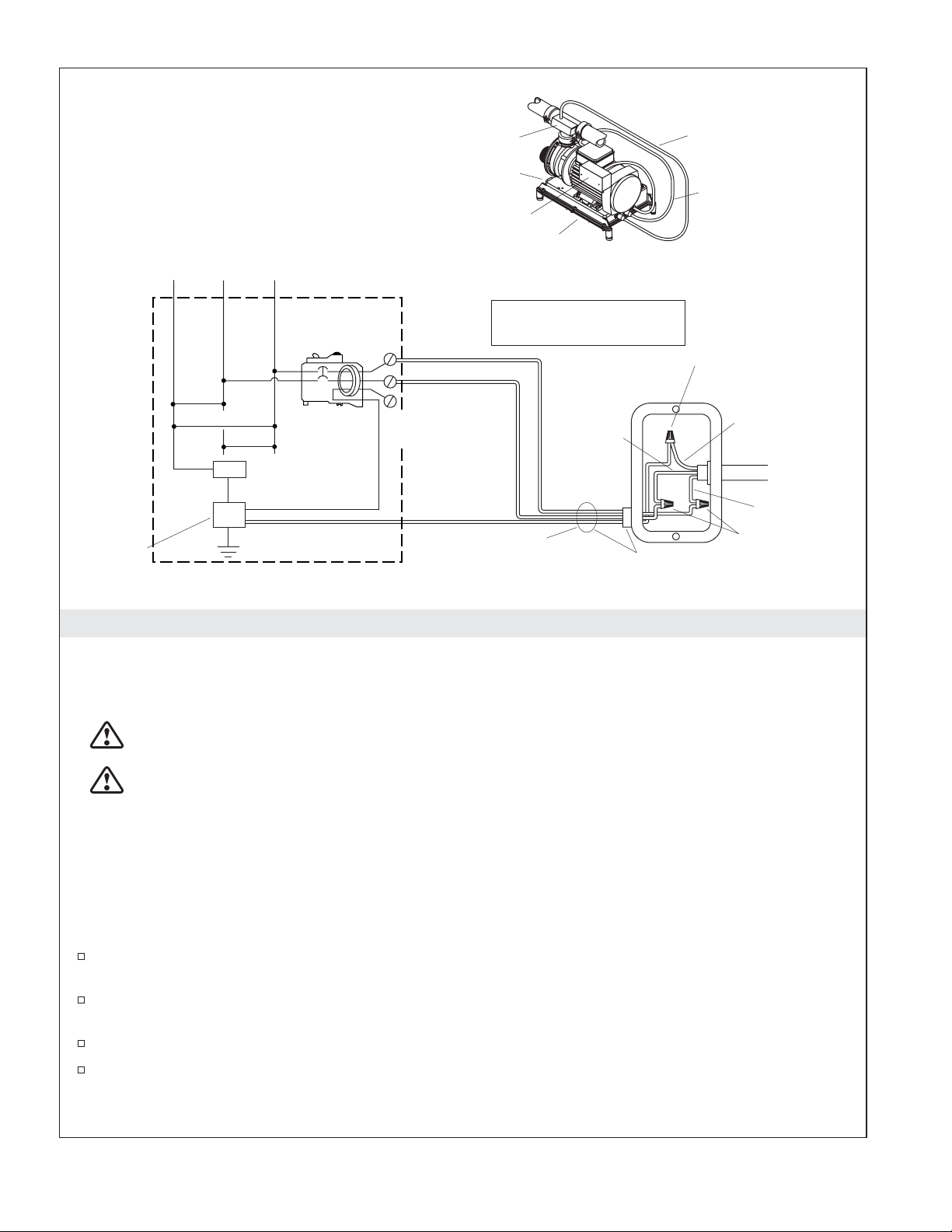

Electrical Requirements

The installation must have two Class A Ground-Fault Circuit-Interrupters (GFCI’s) or Earth-Leakage

Circuit-Breakers (ELCB’s). The GFCI/ELCB protects against line-to-ground shock hazard. Use a 208-240 V, 20

A, 50/60 Hz dedicated service for the pump controls. Use a separate 208-240 V, 20 A, 50/60 Hz dedicated

service for the heater.

An equipment grounding terminal is provided in the field wiring compartment. To reduce the risk of

electrical shock, this terminal must be connected to the grounding means provided in the electrical supply

panel with a conductor equivalent in size to the circuit conductors supplying this equipment.

Install this unit in accordance with the Canadian Electric code, Part I.

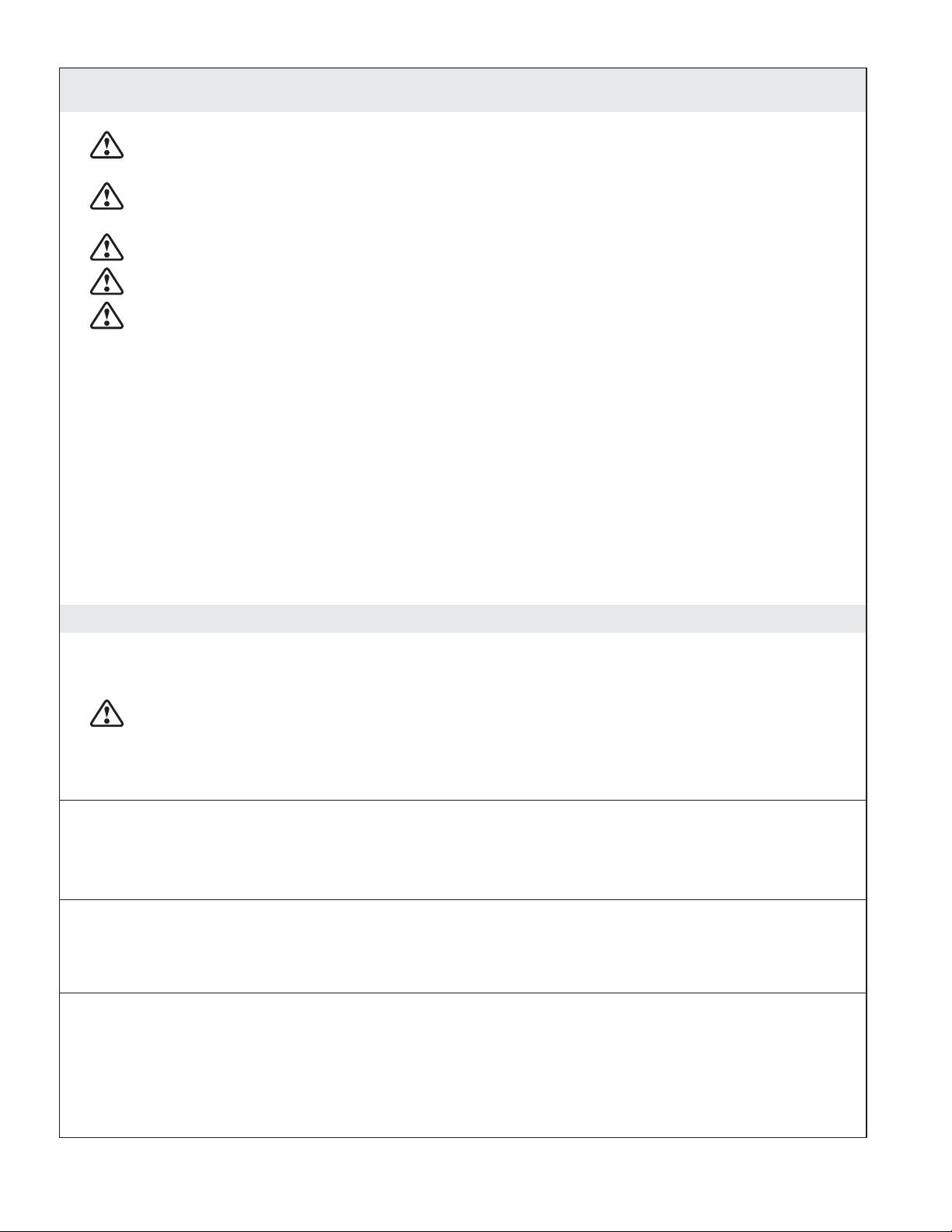

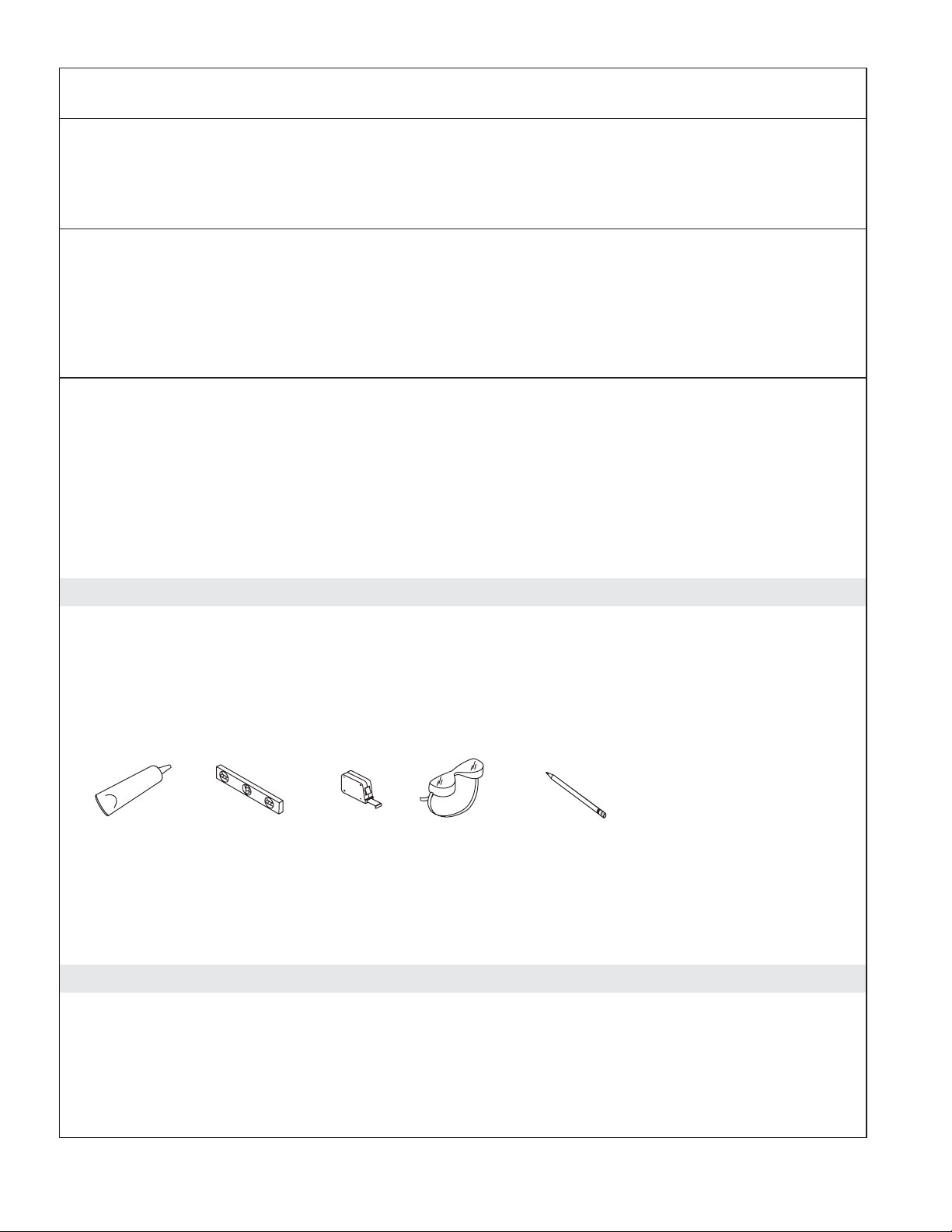

Tools and Materials

• Conventional woodworking

tools and materials

• Drop cloth

Silicon Sealant 4' (1.2 M)

Level

Tape

Measure

Safety

Glasses

Pencil

• 2x4s or 2x6s

Introduction

Please read these instructions carefully to familiarize yourself with the required tools, materials, and

installation sequences. Follow the sections that pertain to your particular installation. This will help you

avoid costly mistakes. In addition to proper installation, read all operating and safety instructions.

All information in this manual is based upon the latest product information available at the time of

publication. At Kohler, we constantly strive to improve the quality of our products; we therefore reserve the

right to make changes in product characteristics, packaging, or availability at any time without notice.

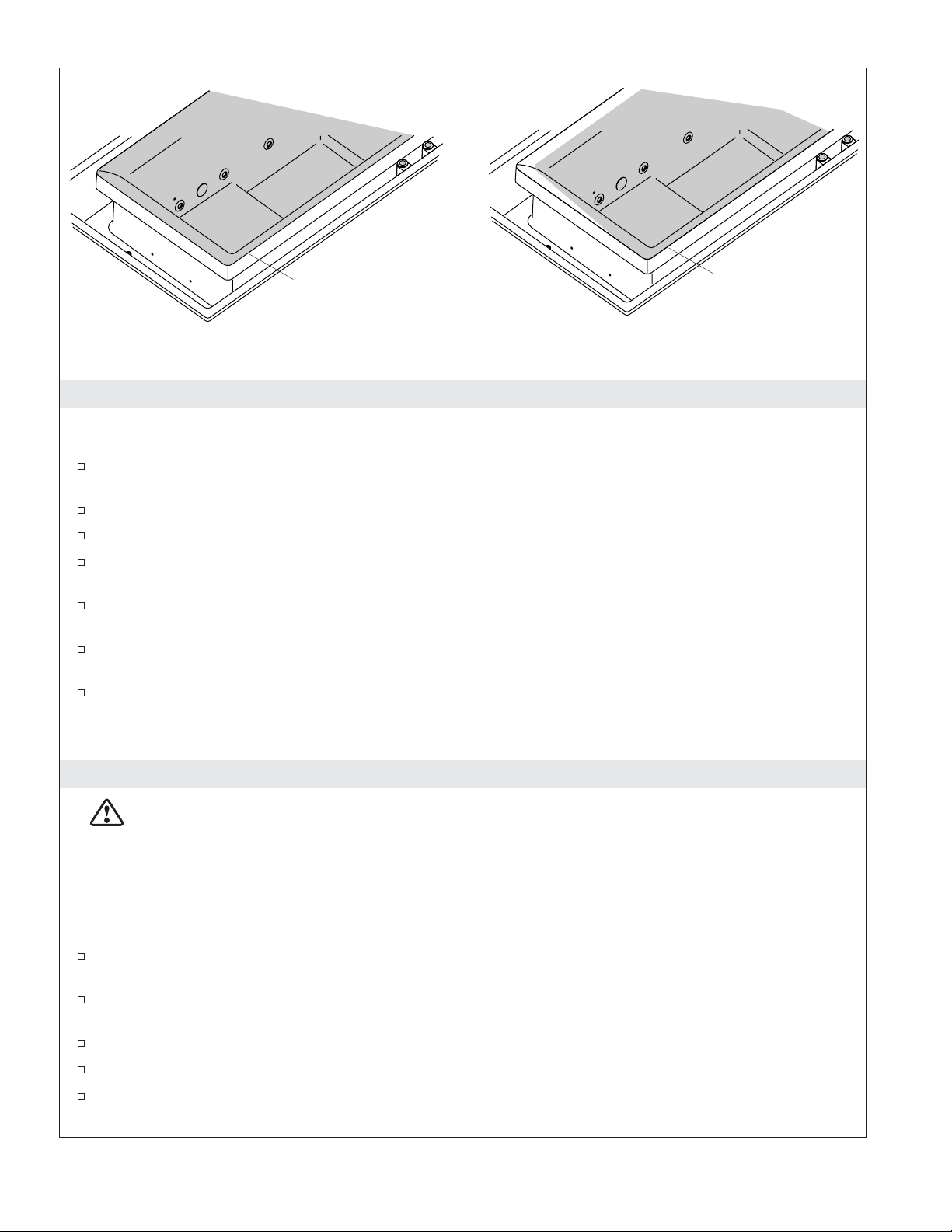

Before You Begin

Your bath is designed for deck mount installations.

You must install the bath onto an adequately supported, level subfloor.

Provide properly dimensioned framing.

Choose a fill spout which will provide adequate reach and a minimum 2″ (5.1 cm) air gap above the

bathing well rim of the overflowing bath. You may need to build up the deck material to obtain

adequate air space because the outer rim may be lower than the bathing well rim depending on the

specific area of the bath.

Follow local plumbing codes.

The bath must be filled with water through the bathing well, not the overflow channel.

Kohler Co. 3 1054216-2-B

Page 4

Before You Begin (cont.)

If you plan to install a deck-mounted, hand-held shower, the diverter vacuum breaker must

maintain a minimum 1″ (2.5 cm) air gap above the bath rim.

When using the K-922 or K-923 Laminar Bath Spout with drip tray K-924, the distance from the

finished wall to the outside wall of overflow channel should not exceed 2″ (5.1 cm).

Kohler Co. reserves the right to make revisions in the design of products without notice, as specified

in the Price Book.

1054216-2-B 4 Kohler Co.

Page 5

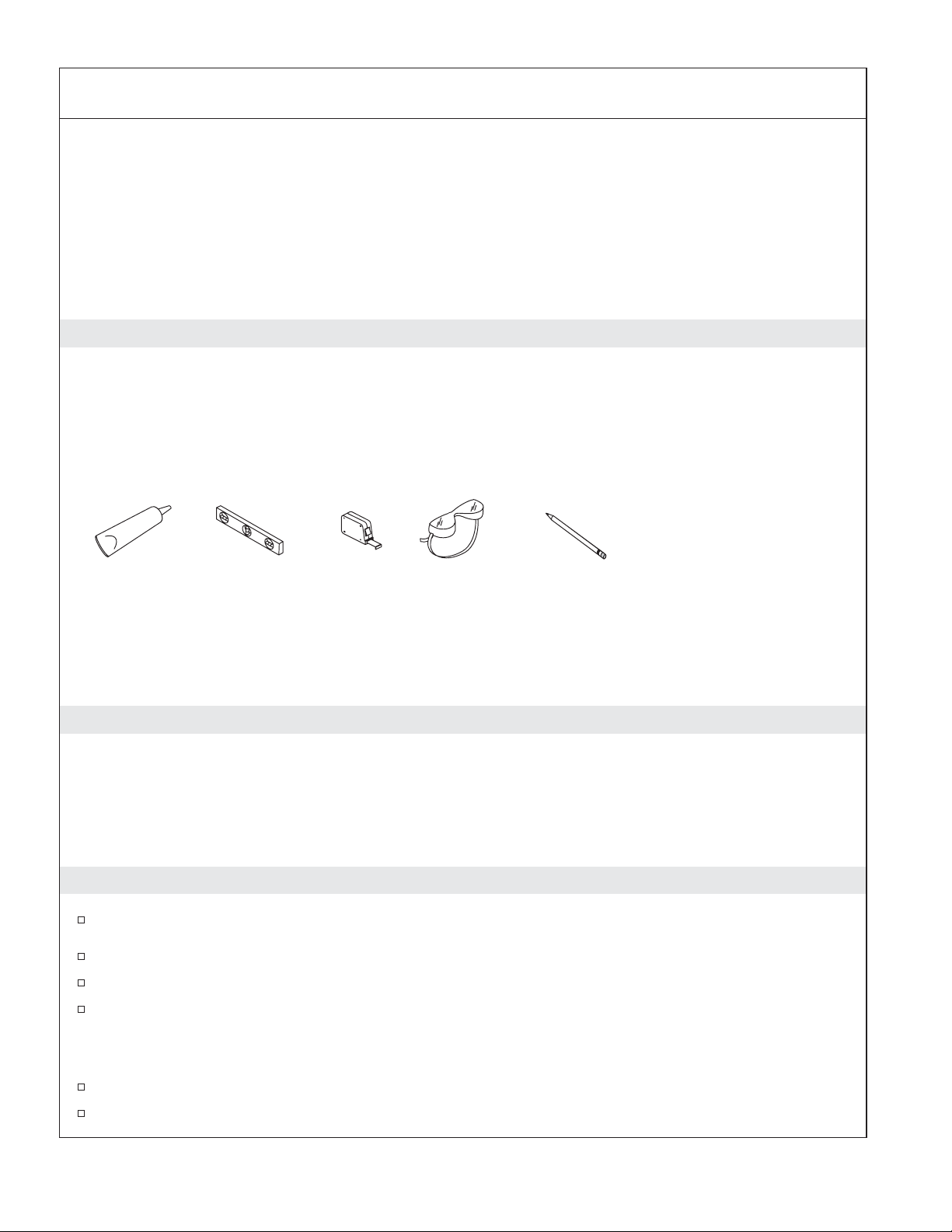

Bathing Well

Bathing Well

Rim

Overflow

Channel

Outer Rim

Overflow Channel

Sensors

Metal Suction

Screen

Plastic

Suction Cover

List of New Terms

Bathing well - The deep portion of the overflowing bath used by the bather.

Bathing well rim - The high rim between the bathing well and the overflow channel. Water will

evenly cascade over the bathing well rim and into the overflow channel during operation.

Cavitation - When air is drawn into the pump instead of water to a point where it impairs or stops

the pump’s ability to circulate water.

Chromatherapy control switch - Turns the chromatherapy lights on and off (if equipped).

Chromatherapy lights - Lights provided in the basin of the bath (if equipped) to enhance your

bathing experience.

Heater - Designed to automatically help maintain the temperature of the water up to 104ºF (40ºC) to

enhance your hydro-massage experience. The heater turns on automatically when the whirlpool is

operating, and turns off when the pump motor is turned off.

Master control - This unit is located beneath the pump. It provides the ″brains″ of the system,

interpreting all incoming and outgoing signals.

Metal suction screen - The removable metal screen located over the plastic suction cover in the

overflow channel. The suction screen must always be clean and in place when the overflowing bath

is running to prevent debris from entering the water intake port and to prevent cavitation and poor

operation.

Outer rim - The rim along the outside of the overflow channel.

Overflow channel - The overflow water collection channel surrounding the bathing well. The

overflow channel collects the water overflowing the bathing well rim during normal operation, and

channels the water back into the piping system for recirculation.

Overflow channel sensors - The two metal probes located in the wall of the overflow channel

beneath the drain overflow hood. These sensors prevent activation of the pump if insufficient water

is available, and will automatically shut off the pump if the water level drops below them. The

pump will only operate when these two sensors are completely submerged.

Pump control switch - Turns the pump on and off.

Plastic suction cover - The plastic guard attached over the water intake port located in the overflow

channel. The suction cover must always be installed during product use to ensure user safety.

Pump - The pump circulates the water.

Wire harness - The wire harness connects all powered peripheral components (valves, pump, heater,

switches, lights) to the master control.

Kohler Co. 5 1054216-2-B

Page 6

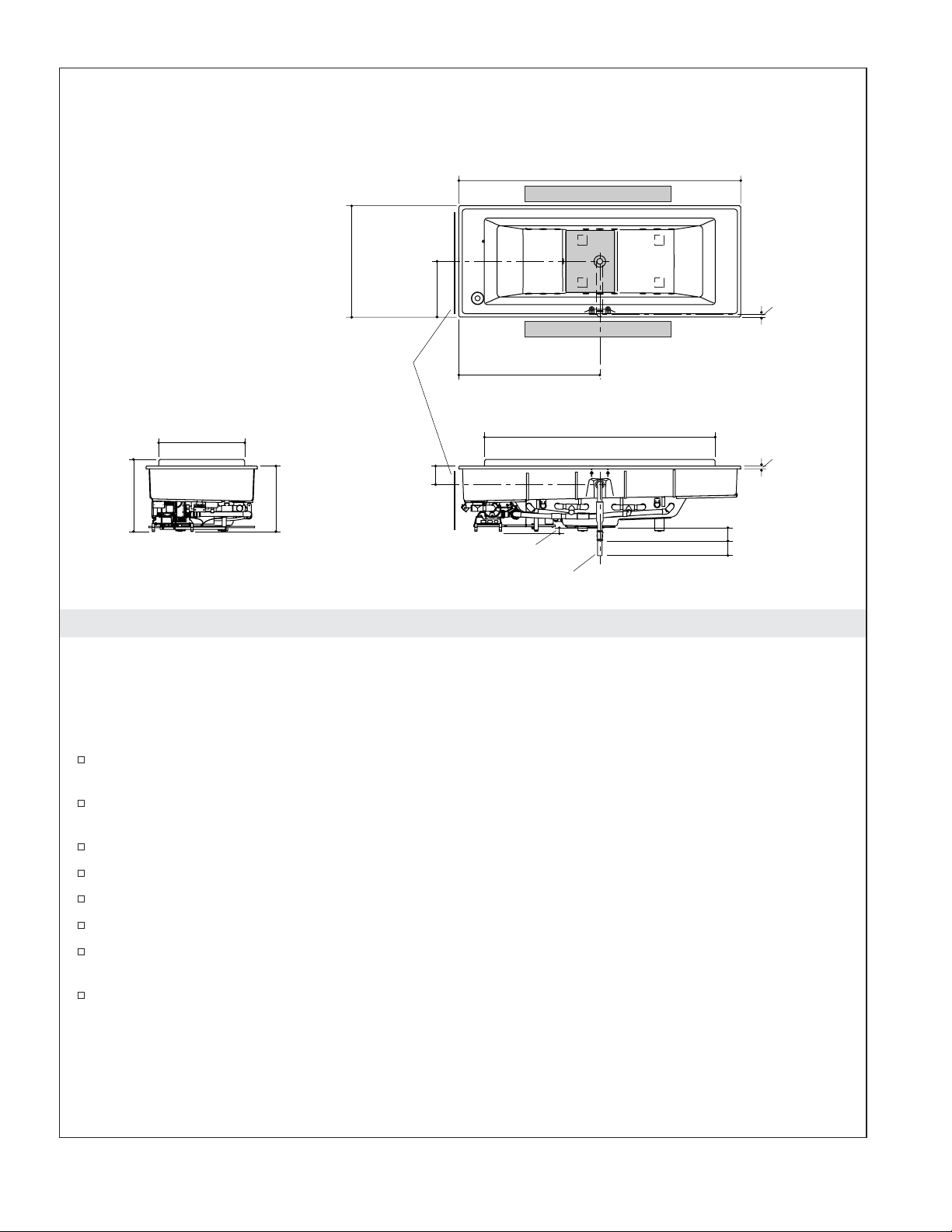

No change in measurements if connected with

drain illustrated. (K-7223 or K-7223M)

Cut-out: 102-1/4" (259.7 cm) x 40" (101.6 cm)

103-3/4" (263.5 cm)

A

B

1" (2.5 cm)

A

85" (215.9 cm)

1" (2.5 cm)

2-7/8" (7.3 cm)

3" (7.6 cm)

26-1/2"

(67.3 cm)

31-13/16"

(80.8 cm)

41"

(104.1 cm)

Pump/Control Access

40" (101.6 cm) W x

15" (38.1 cm) H Min

23-11/16"

(60.2 cm)

20-1/2"

(52.1 cm)

7" (17.8 cm)

51-7/8" (131.8 cm)

1" (2.5 cm)

1-1/2" OD

1. Roughing-In Information

NOTICE: The floor support under the whirlpool must provide for a minimum of 3500 lbs (1588 kg).

NOTICE: The areas labeled ″A″ and ″B″ are recommended installation locations for bath spouts. ″B″

applies to ceiling mounted bath spouts only. For a list of bath spouts for this product, see the specification

sheet.

Two separate 240 V electrical services are required: one for the pump/control, and one for the

heater.

Consult local and national codes for minimum air gap requirements when installing a spout on the

faucet deck.

The overflowing bath must be filled through the bathing well.

Hot water supply should be 70% of the capacity or greater.

The fixture conforms to ANSI Standard Z124.1. All dimensions are nominal.

There is no change in measurements if connected with the drain illustrated (K-7223, K-7223M).

An access panel is required. The recommended dimensions for this access panel are 40″ (101.6 cm)

Wx15″ (38.1 cm) H. Refer to the roughing-in diagram for suggested access panel location.

Make sure the flooring is in good condition and offers adequate support for your bath.

IMPORTANT! Verify that the subfloor is flat and level. This will help minimize the leveling adjustments

necessary for proper product performance.

1054216-2-B 6 Kohler Co.

Page 7

Deck

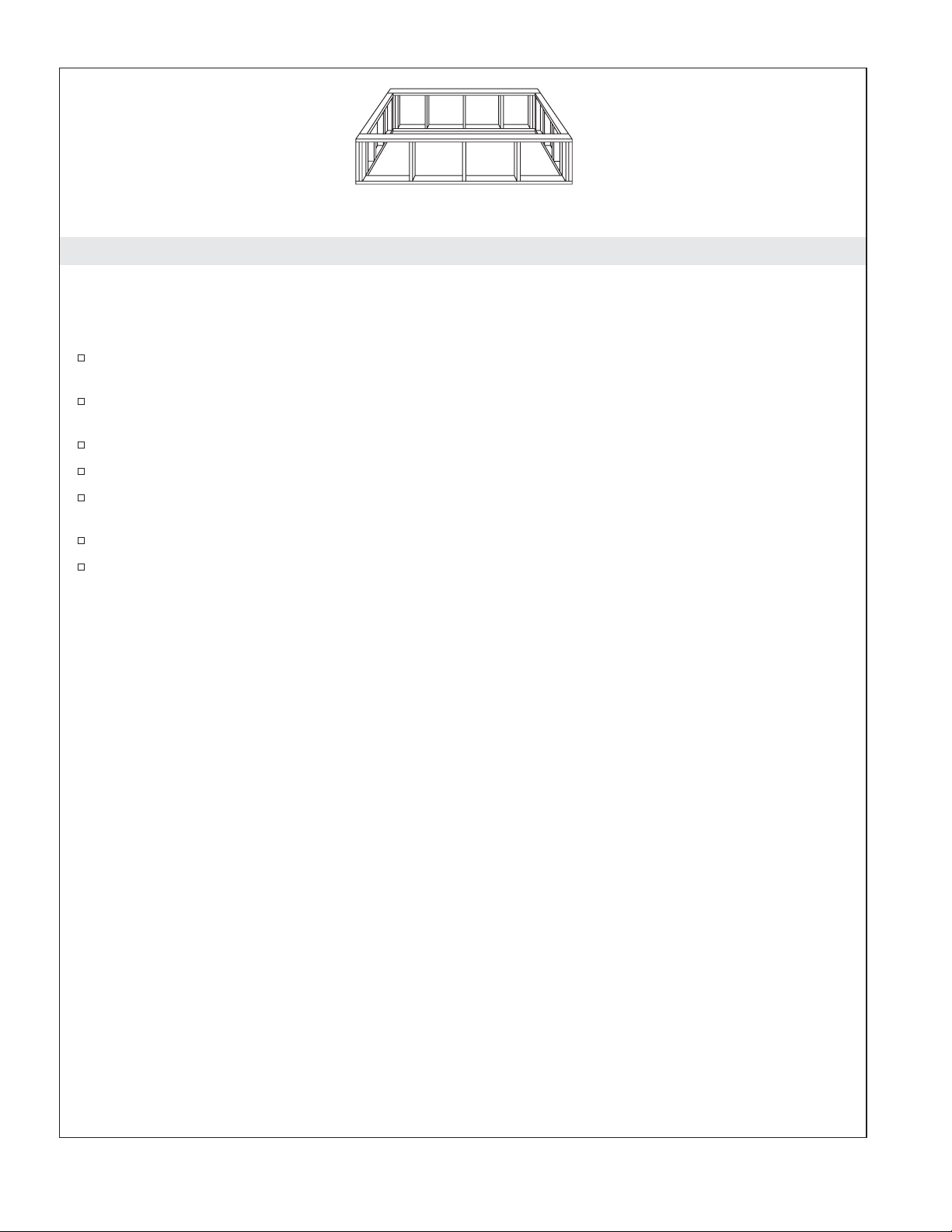

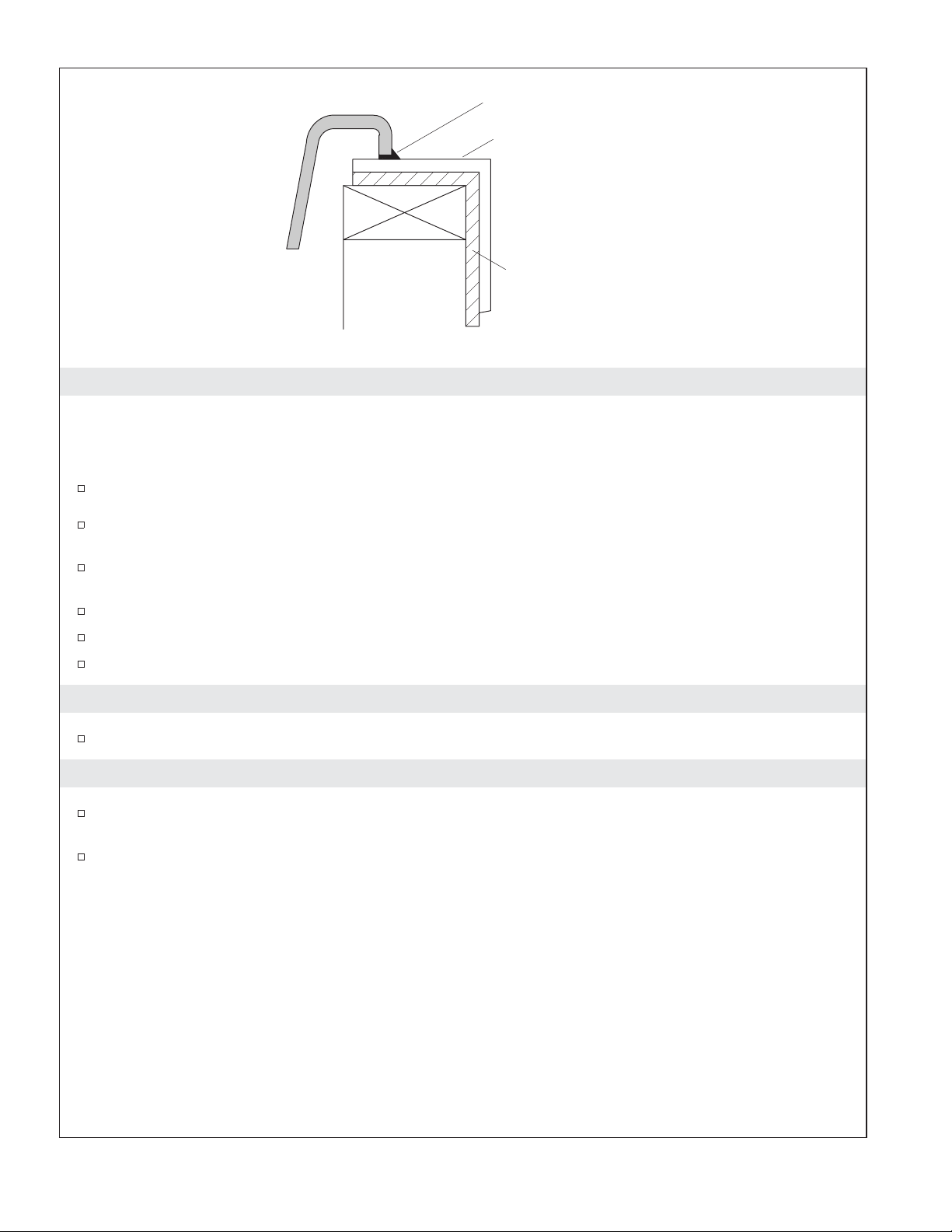

2. Construct the Stud Framing

NOTICE: Provide unrestricted service access to the pump, in-line heater, adjustable feet, and control box.

You must construct an access panel to provide sufficient clearance for servicing the pump, in-line heater,

and control box.

Construct stud framing designed for your particular installation. The overflowing bath can be

installed in a deck mount installation.

Frame the floor, or construct a frame for a raised installation in accordance with the roughing-in

information.

When constructing the framing, allow for the thickness of sub and finished deck materials.

Framing should be of 2x4 construction.

For undermount installation, allow for the thickness of the planned deck material, and provide

proper support.

Do not support the bath by the rim.

When planning the stud framing, take into account the required 2″ (5.1 cm) air gap between the end

of the fill spout and the top of the bathing well rim. Take into account the thickness of your planned

finished deck material, and construct the framing and deck material with this minimum air gap in

mind.

Kohler Co. 7 1054216-2-B

Page 8

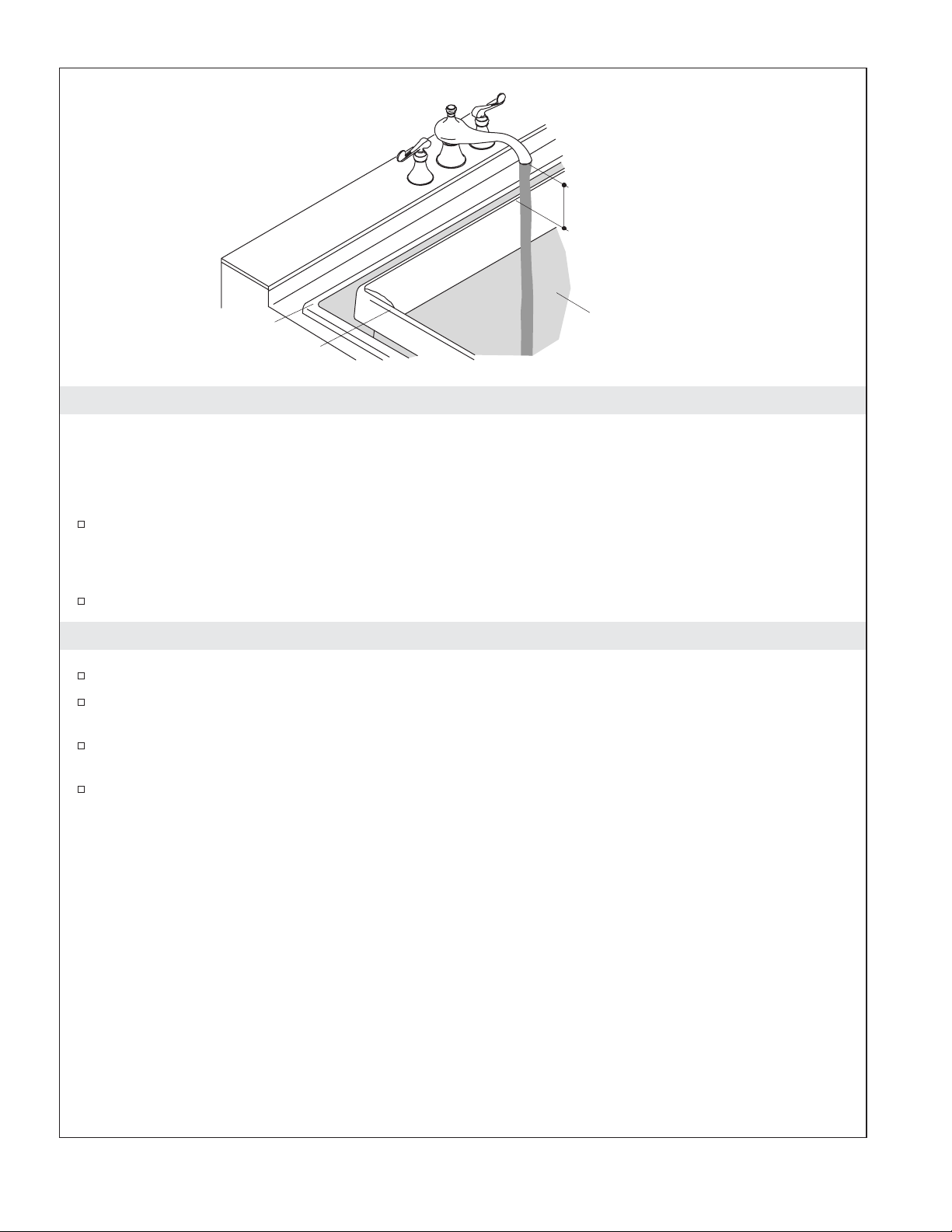

2" (5.1 cm) Min

Outer Rim

Bathing Well Rim

Bathing Well

3. Install the Rough Plumbing

IMPORTANT! Choose a fill spout which will provide a minimum 2″ (5.1 cm) air gap above the basin rim

of the overflowing bath. In addition, if you plan to install a deck-mounted, hand-held shower, the diverter

vacuum breaker must maintain a minimum 1″ (2.5 cm) air gap above the bathing well rim of the

overflowing bath.

Position the plumbing. Position the fill spout supply so the spout will reach beyond both the outer

rim and the bathing well rim. Water from the fill spout must be directed into the bathing well to

fill the overflowing bath. The overflowing bath should never be filled by directing water into the

overflow channel.

Cap the supplies, and check for leaks.

4. Prepare the Unit

Carefully lift the overflowing bath out of the carton.

Identify the box located inside the overflow channel. This box contains the metal suction screen, and

must be saved for use with this product.

Install the drain according to the drain manufacturer’s instructions. Do not connect the trap at this

time.

Position a clean drop cloth or similar material in the bottom of the bath. Be careful not to scratch the

surface of the overflowing bath.

1054216-2-B 8 Kohler Co.

Page 9

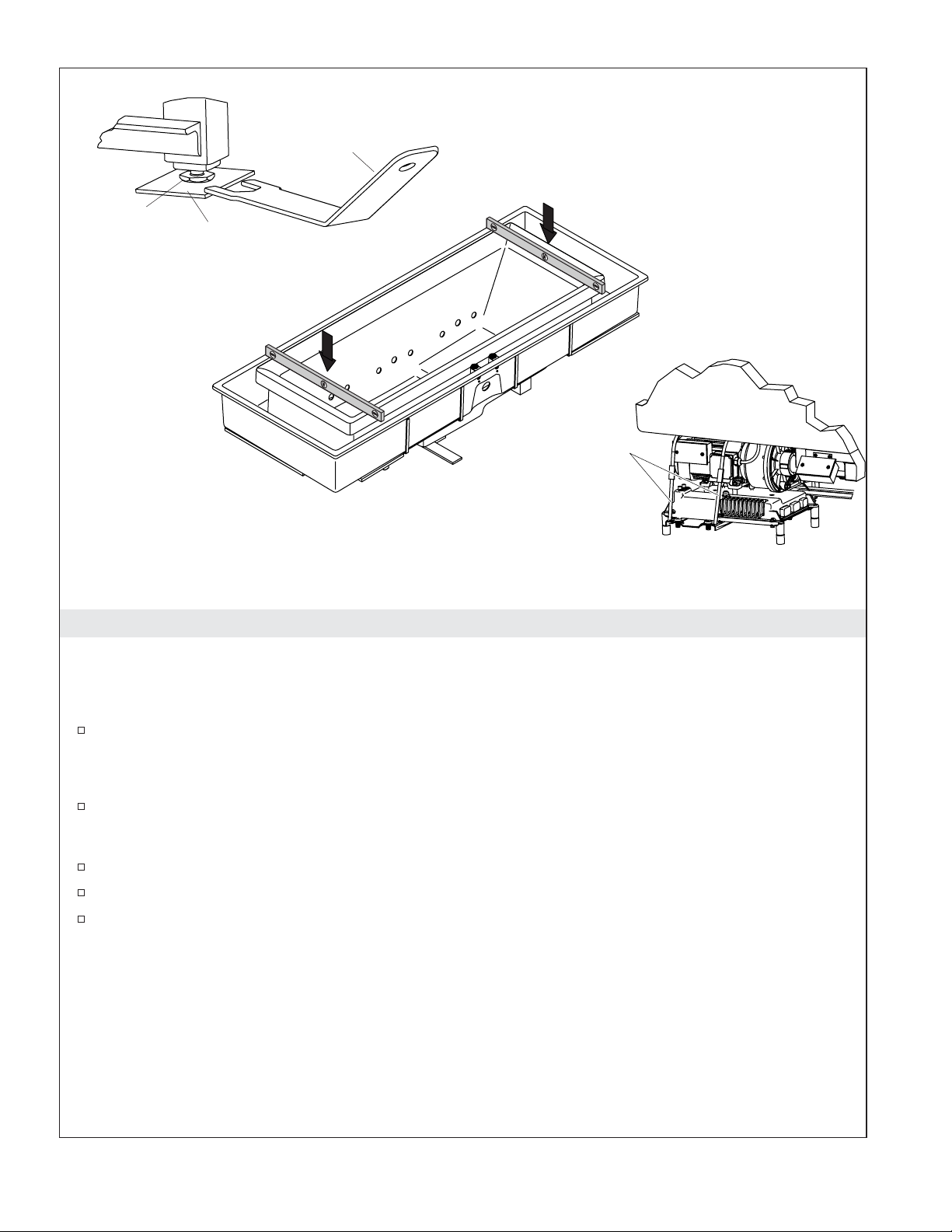

Adjustable

Foot

Wrench

Metal Plate

Adjust Feet

Pump Banding

Straps

Check Level

Cut Straps

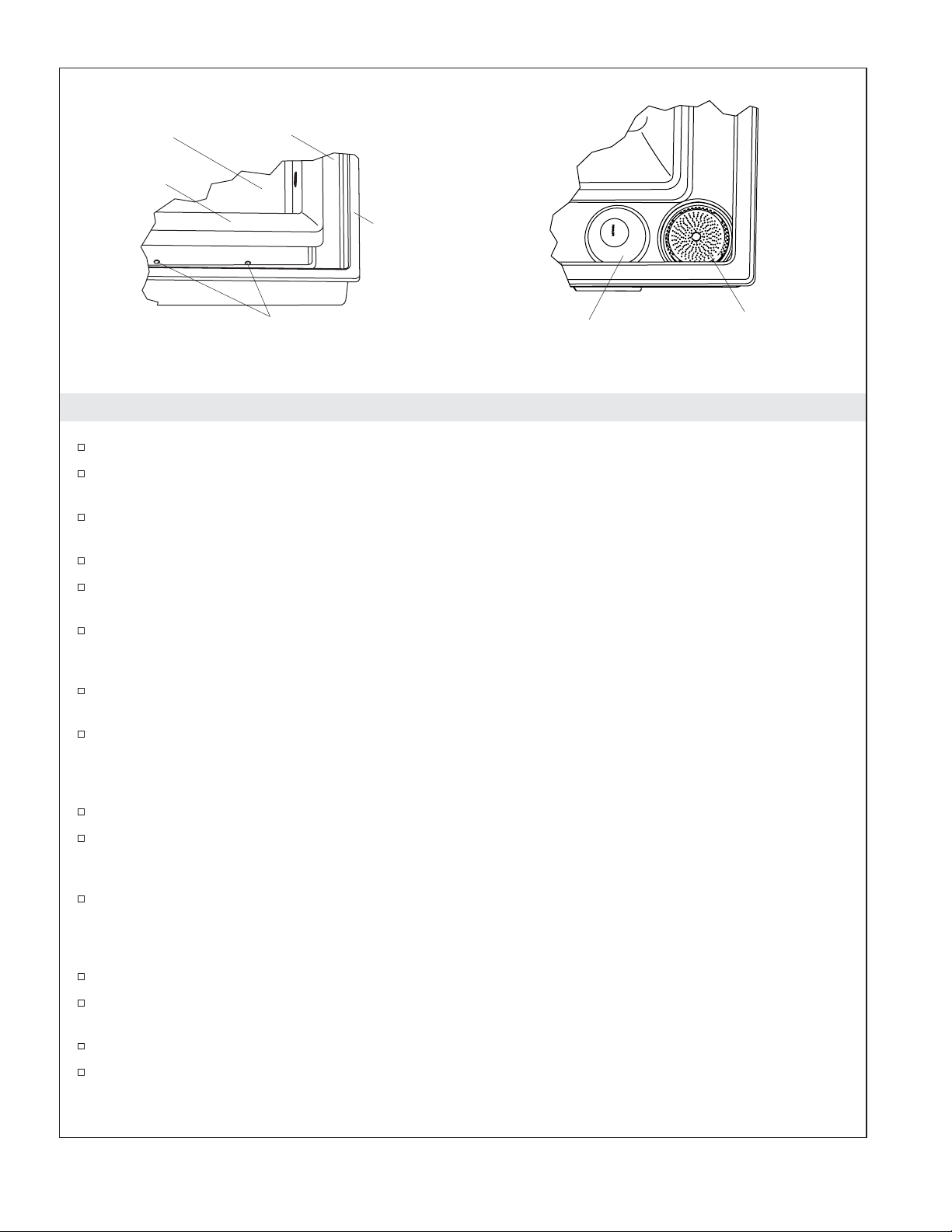

5. Position the Unit

IMPORTANT! Risk of product damage. Do not lift or support the overflowing bath by the pump or

piping.

NOTE: Do not use adhesive or a cement or mortar bed to secure this product to the subfloor.

With help, carefully lift the overflowing bath into place. Using metal plates under the adjustable feet

is recommended and will make leveling the bath easier.

NOTE: If you do not have a 6’ (1.8 m) level, go to the next section.

Level by turning the adjustable feet up or down with the wrench (7/8″) attached to the harness near

the pump. Make sure all six adjustable feet rest directly on the subfloor, and make sure the bathing

well rim is level within 1/8″ (3 mm) in all directions.

Cut and discard the banding straps from the pump.

Make sure the rubber isolation feet are in place.

Insert the drain tailpiece into the trap.

Kohler Co. 9 1054216-2-B

Page 10

Bathing Well Rim

Bathing Well Rim

Level

Not Level

6. Level the Overflowing Bath (without level)

NOTICE: You do not need electrical power for the unit for the following leveling procedure.

Insert the drain tailpiece into the trap, and connect the drain to the trap according to the drain

manufacturer’s instructions.

Close the drain, and plug or cover the suction cover to temporarily make them watertight.

Use a hose and fresh water supply to fill the bathing well to the bathing well rim.

Observe the water level (grey shading in illustration = water level) in relation to the bathing well

rim.

If the water evenly cascades over the entire rim of the overflowing bath, no adjustments are needed.

The overflowing bath is level.

If the water level is uneven and only cascades over sections of the rim, use the wrench to turn the

adjustable feet up or down as needed to obtain a uniform water level.

Open the drain, and unplug the suction cover to drain the bathing well.

IMPORTANT! Allow adequate access to each of the six adjustable feet until after you have test run your

bath.

7. Install the Plumbing

CAUTION: Risk of property damage. Ensure a watertight seal on the drain connections.

IMPORTANT! Choose a fill spout which will provide adequate air space above the bathing well rim of the

bath. You may need to build up the deck material to obtain adequate air space because the outer rim may

be lower than the bathing well rim. In addition, if you plan to install a deck-mounted, hand-held shower,

the diverter vacuum breaker must maintain a minimum 1″ (2.5 cm) air gap above the outer rim.

NOTE: An access panel will simplify future maintenance.

If you have not yet done so, connect the drain to the trap according to the drain manufacturer’s

instructions.

Install the faucet valving according to the faucet manufacturer’s instructions. Do not install the

faucet trim until instructed.

Make sure all butterfly valves and supply connections are tightened securely.

Open the hot and cold water supplies, and check the supply connections for leakage.

Run water into the bathing well, and check the drain connections for leakage.

1054216-2-B 10 Kohler Co.

Page 11

Heater (models may vary) T-style (shown)

or In-line (not shown)

Bond in accordance with national and local codes.

Open bonding lugs are located at the top of the

junction box.

120/240 VAC

Source

L1 L2N

120 V

120 V

240 V

S/N

Breaker Box

Typical Two-Pole

Circuit Breaker

with GFCI

No Connection

(Load Neutral)

* Line Neutral

(White Curly

Wire)

Wiring Harness

Junction Box

Typical Wiring Connection for North America

* Connections to be Made

at the Circuit Breaker

*L2

240 V

*L1

Control

Blue (L1)

Heater Electrical Cord

Pump Electrical Cord

Wire

Connector

Ground

(Green with

Yellow Stripes)

From

Control

Brown (L2)

Wire Connectors

Neutral Bus

(In Breaker Box)

* Equipment Ground

Field Wiring

(From Junction Box

to GFCI Breaker)

Electrician to provide suitable

strain relief cable.

8. Make the Electrical Connections

NOTE: The product model number is printed on a label on the pump side of the overflowing bath. This

label also identifies the electrical rating of the product. These whirlpools come equipped with two wiring

junction boxes and are designed to operate between 208 VAC and 240 VAC at either 50 Hz or 60 Hz.

WARNING: Risk of electrical shock. Make sure the power has been disconnected before

performing the following procedures. Refer to the “Important Information” section.

WARNING: Risk of electrical shock. To reduce the risk of electrical shock, connect the pump to a

properly grounded Ground-Fault Circuit-Interrupter (GFCI) or Earth-Leakage Circuit-Breaker

(ELCB). The heater will also need to be connected to a properly grounded Ground-Fault

Circuit-Interrupter (GFCI) or Earth-Leakage Circuit-Breaker (ELCB). This will provide additional

protection against line-to-ground shock hazard. Two 208-240 V, 20 A, 50/60 Hz dedicated circuits

are required.

IMPORTANT! The load neutral is not used. There should be no connection to the load neutral terminal

on the Ground-Fault Circuit-Interrupter (GFCI) breaker. The green wire with the yellow stripes is the

equipment ground and needs to be connected to the neutral bus in the main circuit breaker box.

The control and heater have been pre-wired at the factory. A licensed electrician should make

routine service connections to each of the junction boxes.

Connect service to the junction boxes. Both junction boxes contain blue, brown, and green with

yellow stripe colored wires.

Follow local electrical codes. Bond in accordance with national and local codes.

A wiring harness has been pre-wired at the factory, allowing communication between the keypad,

all features, and the control. No additional wiring is required, but ensure that all wires are securely

fastened.

Kohler Co. 11 1054216-2-B

Page 12

Make the Electrical Connections (cont.)

NOTE: Your wiring harness included an antenna for the optional remote control. Do not alter or damage

this antenna during installation.

1054216-2-B 12 Kohler Co.

Page 13

Water

Chromatherapy

Control Switch

(Optional)

Bathing Well Rim

Overflow Channel

Sensors

Overflow

Channel Drain

Pump Control

Switch

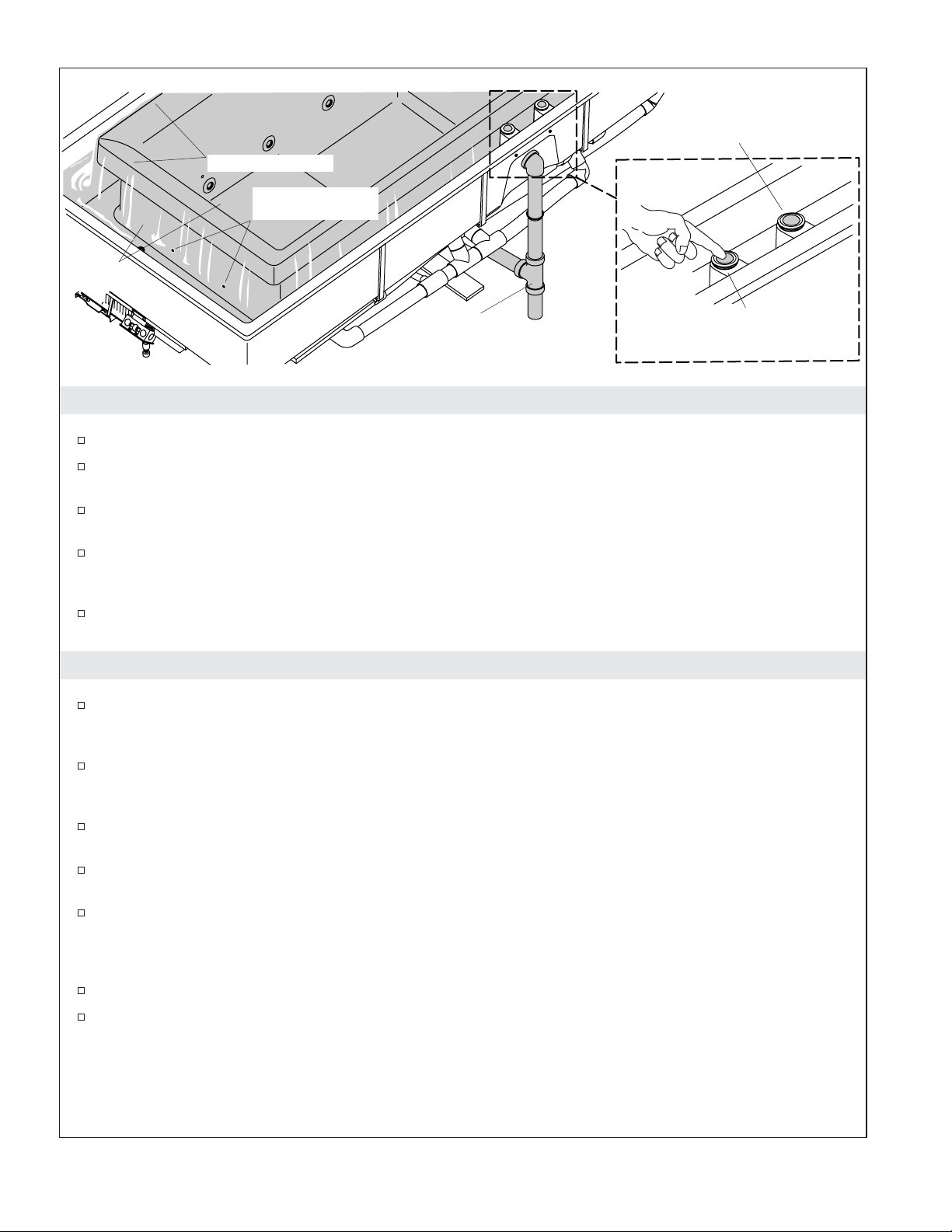

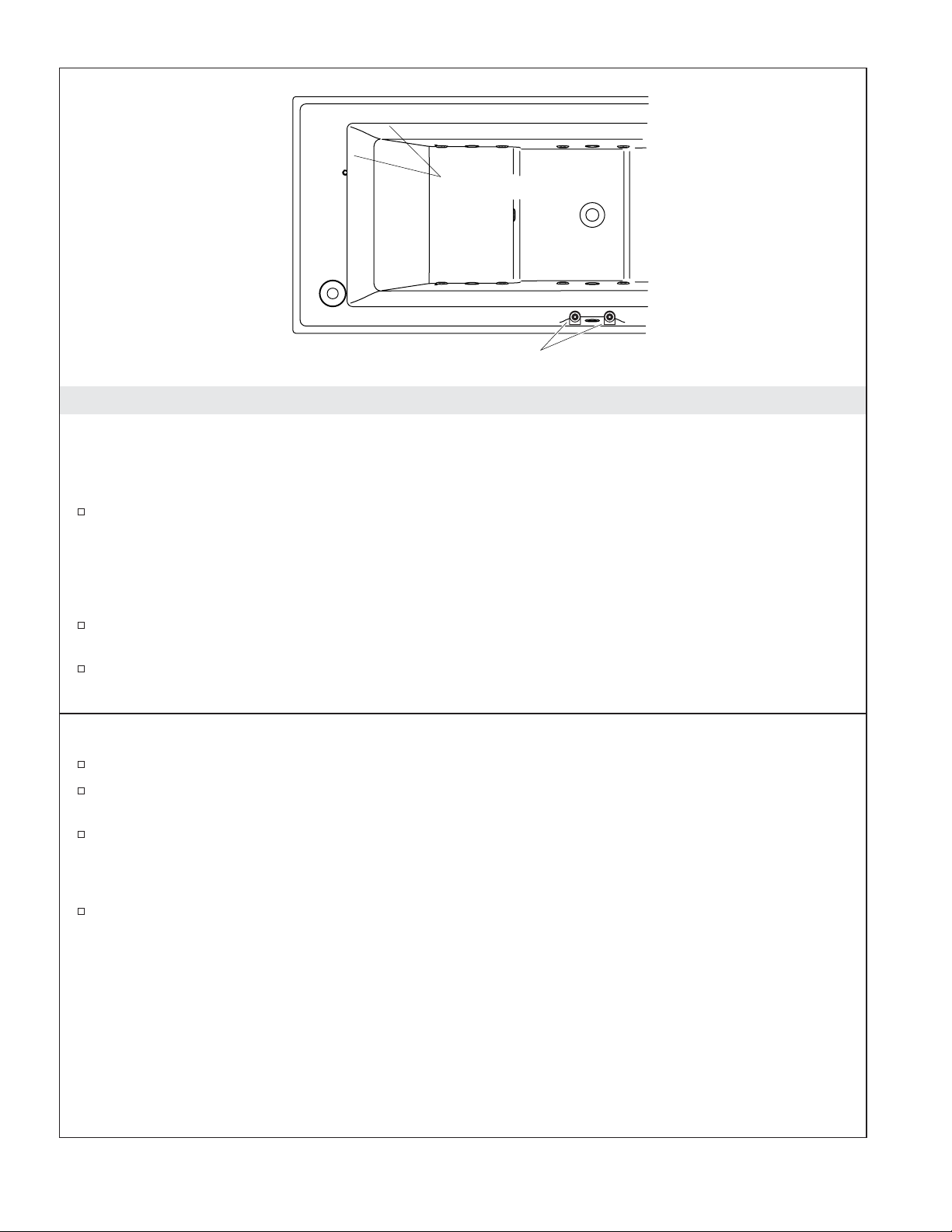

9. Test Run the Overflowing Bath

Check all electrical connections, and make sure the electrical power to the unit is turned on.

Make sure union connections to the pump, butterfly valves, and in-line heater are securely hand

tightened. Make sure the bathing well and overflow channel are clean and free of debris.

Position the metal suction screen over the plastic suction cover. The pump may cavitate if the metal

screen is not in place.

Fill the overflowing bath bathing well with water so it overflows the bathing well rim and flows

into the overflow channel. Continue filling the bathing well until both overflow channel sensors are

completely covered with water, and the water level is at the drain overflow.

Verify that the green light in the pump control switch starts to blink automatically within 1/2

minute after the overflow channel sensors are completely submerged.

10. Test the Control Switch

Press the pump control switch to start the pump/motor and begin the hydro-therapy cycle. As the

pump/motor turns on and the water begins to circulate, the light will turn to constant green, and

will stay on as long as the overflowing bath is running.

With the unit running, check all harness (piping) connections for leaks. Visually observe the

cascading water flow over the bathing well rim to verify that it is smooth and even along all four

sides and corners.

If the water is cascading uniformly over all four sides of the bathing well rim, you do not need to

make further leveling adjustments.

If further leveling is necessary, keep the overflowing bath running and turn the adjustable feet up or

down with the 7/8″ wrench provided. Make sure the unit is resting on all six adjustable feet.

Verify that the chromatherapy lights (if applicable) are operating. Press the chromatherapy control

switch (located next to the power switch) to turn on the lights. Upon start-up, the lights should be

changing through the color sequence. Press the light control switch a second time. The lights should

stop sequencing and stay one color. Press the light control switch again and lights will deactivate.

Check the harness connections for leakage one more time.

Press the pump control switch again to turn off the bath. The green light in the pump control switch

will then start to blink automatically (after approximately 1/2 minute) until the overflowing bath is

drained or restarted.

NOTE: For additional information on operation of your bath, see the ″Using Your Bath″ section.

IMPORTANT! Allow adequate access to each of the six adjustable feet until test run is complete.

Kohler Co. 13 1054216-2-B

Page 14

Power

Heater

On/Off

Power

On/Off

Heater

On/Off

Chromatherapy

Specific Color

Selection

On/Off

Effervescence

Mode

Chromatherapy

Cycle

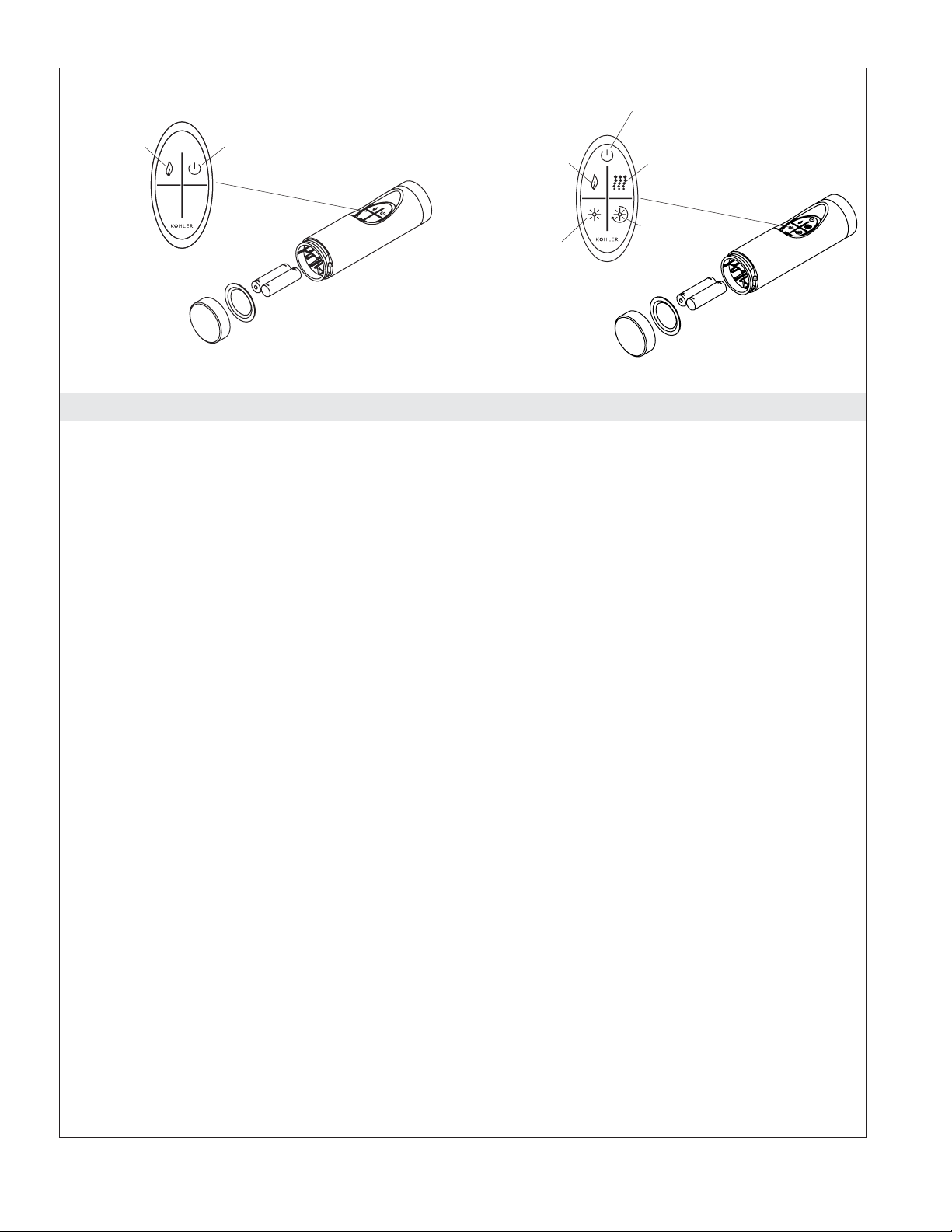

11. Using the Remote Control

NOTE: There are two types of remote controls available: a basic unit and a unit with controls for

chromatherapy and effervescence. Determine which unit you have and follow the corresponding

directions.

NOTE: Your remote requires two AAA batteries. To install or replace them, simply unscrew the base of the

remote.

Your overflowing bath is equipped with a waterproof remote.

To turn the pump and the chromatherapy lights on and off, press the power button.

To reheat the water in the overflowing bath as it circulates, turn the heater on by pressing the heater icon

(the heater defaults to ″On″ when the pump is turned on). Press the heater icon again to turn the heater off.

The heater will not operate if the pump is off. If the heater is on, the pump switch will be dark green. If the

heater is off, it will be yellow-green.

To cycle the chromatherapy lights through the spectrum of colors, press the chromatherapy cycle icon.

To lock an individual chromatherapy color in, press the chromatherapy specific color icon.

1054216-2-B 14 Kohler Co.

Page 15

Silicone Sealant

Finished Deck

2x4 Studding

Deck

Water-Resistant

Wall Material

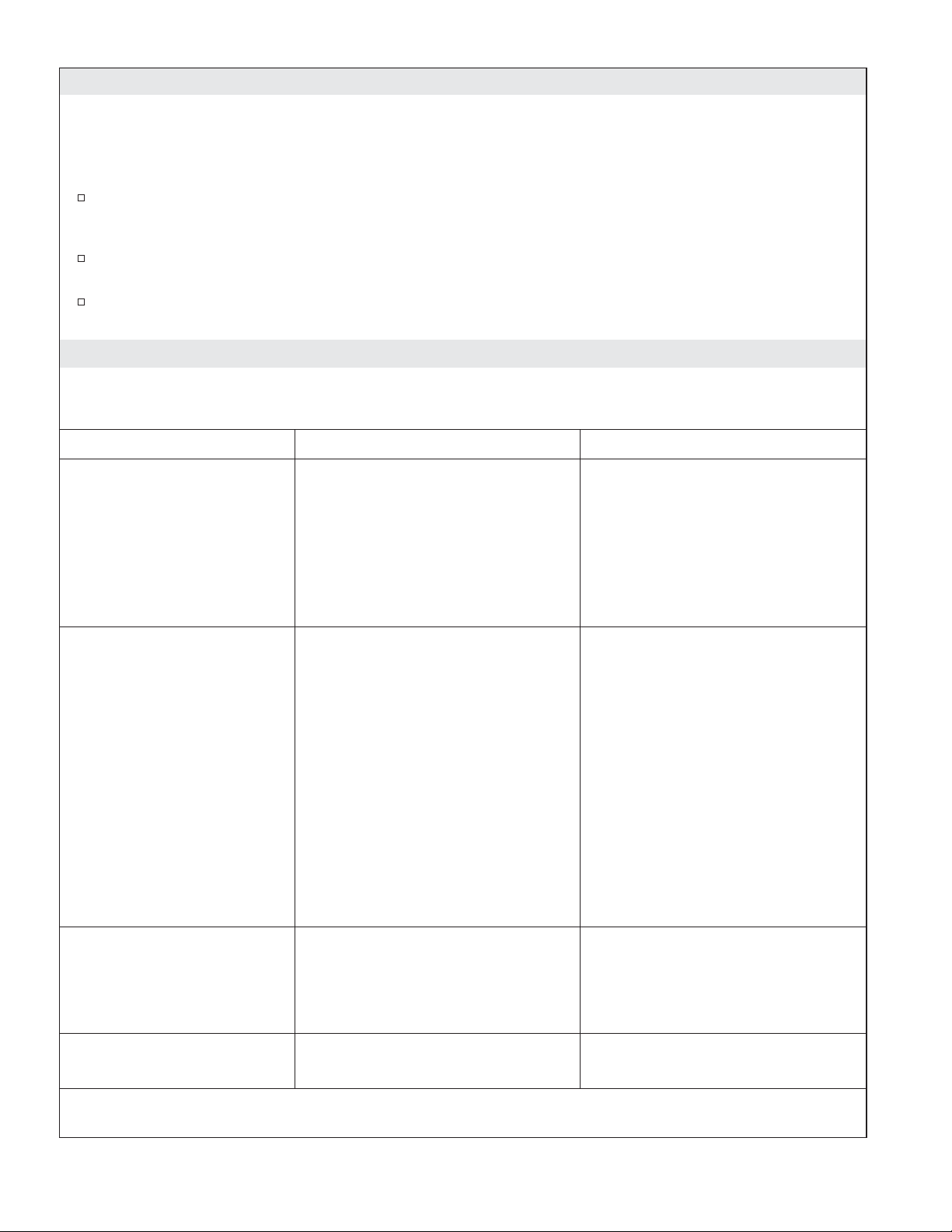

12. Complete the Finished Wall or Deck

NOTICE: Provide unrestricted service access to the pump, in-line heater, adjustable feet, and control box.

You must construct an access panel to provide sufficient clearance for servicing the pump, in-line heater,

and control box.

Protect the product surface. Cover the framing with water-resistant wall material.

Keep the entire overflow channel area exposed to allow access to the drain overflow, and to permit

easy cleaning of the overflow channel surfaces.

Seal the joints between the rim edge and the water-resistant wall or deck material with silicone

sealant.

Tape and mud the water-resistant wall material.

Install the finished wall to the water-resistant wall material.

Seal the joints between the product rim and the finished wall material with silicone sealant.

13. Install the Faucet Trim

Install the faucet trim according to the instructions packed with the trim.

14. Clean-Up After Installation

When cleaning up after installation, do not use abrasive cleansers, as they may scratch and dull the

bath surface. Use warm water and a liquid detergent to clean the surface.

Remove stubborn stains, paint, or tar with turpentine or paint thinner. Do not allow cleaners

containing petroleum distillates to remain in contact with any bath surfaces for long periods of

time. Remove plaster by carefully scraping with a wood edge. Do not use metal scrapers, wire

brushes, or other metal tools. Use a powder-type detergent on a damp cloth to provide mild

abrasive action to any residual plaster.

Kohler Co. 15 1054216-2-B

Page 16

Bathing Well Rim

Control Switches

15. Using Your Bath

Fill the Overflowing Bath

NOTE: Please read these steps carefully before you operate your bath.

Make sure the metal suction screen is clean, and is correctly in place over the plastic suction cover.

NOTE: The water temperature in the bath should not exceed 104°F (40°C) or the heater will not operate.

IMPORTANT! Like any other bath, prevent flooding the area around the unit by entering the filled

bathing well slowly. This will allow the system to properly drain excess water.

Fill the unit with water so the bathing well overflows into the overflow channel to the drain. The

channel sensors should be completely covered with water.

The green light in the pump control switch will start to blink automatically within 1/2 minute after

the sensors are submerged to let you know the unit is ready to start.

Operating Sequence

Press the pump control switch to start the pump/motor and begin operation.

As the pump/motor turns on and water begins to circulate, the light on the pump control switch

will change to solid green, and will stay on as long as the overflowing bath is running.

Verify that the indicator light for the heater is on when the overflowing bath is in operation. This

indicator light is located on the underside of the heater box, and is near the subfloor at the pump

end of overflowing bath. If the light is not on when the overflowing bath is running, try and reset

the GFCI/ELCB.

Press the pump control switch again to turn off the overflowing bath. The green light in the pump

control switch will then start to blink automatically for approximately 1/2 minute until the

overflowing bath is drained below the overflow channel sensors or restarted.

NOTE: A built-in timer automatically stops the bath after approximately 20 minutes of operation.

1054216-2-B 16 Kohler Co.

Page 17

16. Chromatherapy Light Operation

NOTE: These directions pertain to the use of the mounted control switch only. For more information, see

the ″Using the Remote Control″ section.

If the chromatherapy lights are turned off, press the button on the chromatherapy control switch

(located next to the pump control switch). The chromatherapy lights will begin to cycle through

each of the colors (sweep mode).

When the chromatherapy lights are in sweep mode, you can lock in one color light by pressing the

chromatherapy control switch.

When an individual color is locked in, press the chromatherapy control switch to turn the

chromatherapy lights off.

17. Troubleshooting Procedures

For warranty service, contact your dealer or wholesale distributor. This Troubleshooting Guide is for general

aid only. Contact a Kohler Authorized Service Representative or a qualified electrician to correct all electrical

problems. For warranty service, contact your dealer or wholesale distributor.

Symptoms Probable Causes Recommended Action

1. Green light in ″On/Off″

control switch flashes

before the bathing well is

full of water.

2. Product does not start. A. No power to unit. A. Turn on the power to the unit, or

3. Water does not cascade

evenly over the entire

bathing well rim.

4. Unit stops automatically

before 18 minutes.

A. Spout fills directly into overflow

channel.

B. One or both butterfly valves do

not work.

C. Control does not work. C. Check the wiring or replace the

B. Water does not cover the overflow

channel sensors.

C. ″On/Off″ control switch does not

light up or flash when the unit is

running or filled as required.

D. Pump/motor does not work. D. Rebuild or replace the

E. Control does not work. E. Check the wiring or replace the

A. Unit is not level. A. Level the unit by using the

B. Bathing well ports are blocked. B. Remove blockage.

C. Metal suction screen is blocked. C. Clean the metal suction screen.

A. GFCI/ELCB trips. A. Identify the source of the fault

A. Adjust/reinstall the spout to fill

directly into the bathing well.

Refer to the installer/dealer.

B. Check the butterfly valve wiring

or replace the butterfly valves.

Refer to the installer/dealer.

control. Refer to the

installer/dealer.

correct the source of the power

loss. Refer to the installer/dealer.

B. Fill the bathing well until water

flows over the bathing well rim,

into the overflow channel, and

covers the overflow channel

sensors. Suggested fill level is to

the drain overflow.

C. Check the wiring or replace the

″On/Off″ control switch. Refer to

the installer/dealer.

pump/motor. Refer to the

installer/dealer.

control. Refer to the

installer/dealer.

wrench provided to turn the

adjustable feet up or down as

needed.

and correct. Refer to the

installer/dealer.

Kohler Co. 17 1054216-2-B

Page 18

Troubleshooting Procedures (cont.)

Symptoms Probable Causes Recommended Action

B. Motor overheated and protection

device activated.

C. Water level drops below the

overflow channel sensors during

operation (″yellow″ ring will be

flashing on pump switch).

5. Noisy operation. A. Metal suction screen is not in

6. Water temperature drops

significantly over 20

minutes of operation.

7. Chromatherapy lights do

not work.

8. Remote control does not

work.

9. Water does not reach bath

rim upon filling.

place over the plastic suction

cover.

B. Insufficient water level in the

overflow channel.

C. Pump/motor rattles. C. Make sure the pump/motor

A. Heater limit switch tripped.

Indicator light should be ″On″

during operation.

B. Heater does not work. B. Check the wiring or replace the

A. Damaged wiring harness. A. Check the wiring or replace the

B. Control does not work. B. Replace wiring harness. Refer to

A. Batteries improperly installed or

dead.

B. Control does not work. B. Replace wiring harness. Refer to

C. Remote control is not

programmed correctly.

D. Remote control does not work. D. Replace the remote control.

E. Control switch does not work. E. Replace the control.

A. No power to the unit. A. Turn on the power.

B. Level probe wires loose. B. Check/reconnect wires.

C. Butterfly valves does not work. C. Check wiring; replace butterfly

D. Control switch does not work. D. Replace control.

B. Check for blockage of the motor

vent. Allow the motor to cool,

then remove the blockage.

Check for a plugged metal

suction screen, and allow the

motor to cool before restarting.

Check for blockage of the

bathing well ports. Remove the

blockage, and allow the motor to

cool before restarting.

C. Fill the bathing well until water

flows over the bathing well rim,

into the overflow channel, and

covers the overflow channel

sensors. Suggested fill level is to

the drain overflow. Make sure

the bath drain seals properly.

A. Position the metal suction screen

over the plastic suction cover to

prevent cavitation.

B. Fill the bathing well until water

flows over the bathing well rim,

into the overflow channel, and

covers the overflow channel

sensors. Suggested fill level is to

the drain overflow. Make sure

the bath drain seals properly.

banding straps have been cut.

A. Reset the GFCI/ELCB.

heater. Refer to the

installer/dealer.

control. Refer to the

installer/dealer.

the installer/dealer.

A. Replace the batteries.

the installer/dealer.

C. See homeowners guide or service

manual.

valves if necessary.

1054216-2-B 18 Kohler Co.

Page 19

Guide d’installation

Baignoire à déversement

Renseignements importants

AVERTISSEMENT : Lors de l’utilisation des produits électriques, des précautions de base

devraient toujours être observées, incluant ce qui suit:

DANGER : Risque d’électrocution. Raccorder uniquement à un circuit protégé par un Disjoncteur

de fuite de terre (GFCI) ou à un Disjoncteur de mise à la terre (ELCB).

AVERTISSEMENT : Risque d’électrocution. Tous les raccords électriques devraient être réalisés par

un électricien agréé.

AVERTISSEMENT : Risque d’électrocution. Débrancher l’alimentation avant de procéder à

l’entretien.

AVERTISSEMENT : Risque de blessures ou d’endommagement du matériel. Veuillez s’il vous

plaît lire avec attention toutes les instructions avant de commencer l’installation, y compris les

conditions suivantes:

AVIS : Respecter tous les codes de plomberie et électriques locaux.

Installer de façon à permettre l’accès pour l’entretien.

Un câble électrique vert avec une rainure jaune est fournit dans le compartiment du câblage. Afin de réduire

les risques délectrocution, raccorder le câble de sortie à la borne de terre du panneau de service électrique,

avec un câble en cuivre ayant la même calibre que celui du fil conducteur qui alimente cet équipement.

Un connecteur à pression par câble est prévu à l’extérieur de la pompe ou de la commande de cet appareil

afin de permettre la connexion entre l’appareil et toutes autres surfaces de métal avoisinantes, tel que requis

par les normes locales.

Une mise à la terre est requise. L’appareil doit être installé et mis à la terre par un représentant qualifié.

Les matériaux de construction et le câblage devraient être acheminés loin du corps de la pompe et des autres

composants qui dégagent de la chaleur de l’unité.

Renseignements importants sur le produit

Notices du produit

AVERTISSEMENT : Des modifications non authorisées pourraient engendrer une opération

dangereuse et une pauvre performance de la baignoire. Ne pas relocaliser la pompe ou effectuer

d’autres modifications au système de circulation car celà pourrait affecter la performance la sécurité

du fonctionnement. Kohler Co. décline toute responsabilité sous ses garanties quant à toutes

blessures ou dommages causés par des modifications non autorisées.

Inspection du produit

Déballer avec précaution le produit et inspecter pour déceler tout dommage. Remettre l’unité dans le carton

durant la construction pour éviter tout dommage.

Kohler Co. Français-1 1054216-2-B

Page 20

Renseignements importants sur le produit (cont.)

Pièces assemblées en usine

Les composants installés en usine comprennent la pompe, les capteurs de niveau d’eau, le chauffe-eau en

ligne, les lumières de chromathérapie immergées (en option), contrôle et l’interrupteur. La pompe et la

tuyauterie sont assemblées en usine.

Connexions et accès pour l’entretien

AVIS : Prévoir un accès non restraint de maintenance à la pompe et au chauffe-eau. Prévoir un accès de

service non restraint à la pompe, chauffe-eau en ligne, pieds réglables, et boîtier de contrôle. Un panneau

d’accès doit être construit pour suffisamment fournir un dégagement pour l’entretien de la pompe, du

chauffeau en ligne et du boîtier de contrôle. La panneau d’accès doit être placé tout près de la pompe et

du chauffe-eau en ligne. Analyser les informations du plan de raccordement.

Branchements électriques requis

L’installation électrique doit être uniquement raccordée à un disjoncteur coupe-circuit (GFCI) ou disjoncteurs

de fuite à la terre (ELCB). Le GCFI/ELCB protège contre une électrocution par la mise à la terre. Utiliser une

alimentation dediée de 208-240 V, 20 A, 50/60 Hz pour les contrôles de la pompe. Utiliser une alimentation

séparée de 208-240 V, 20 A, 50/60 Hz dédiée au chaffeau.

Une borne de mise à la terre est incluse dans le boîtier du câblage. Afin de réduire le risque d’électrocution,

raccorder la borne de mise à la terre du panneau du service électrique, avec un câble ayant le même calibre

que celui du conducteur qui alimente cet équipement.

Installer l’unité conformément au code électrique Canadien, premiére partie.

Outils et matériels

• Outils conventionnels de

menuiserie et matériels

• Bâche de protection

Mastic à

la silicone

Nivelage 4'

(1,2 m)

Mètre ruban Lunettes de

protection

Crayon à papier

• 2 x 4 ou 2 x 6

Introduction

Veuillez lire avec attention ces instructions pour se familiariser avec les outils et matériels requis, ainsi que

les étapes d’installation. Suivre les étapes qui s’appliquent particulièrement à votre installation. Ceci vous

évitera des erreurs coûteuses. Outre les conseils d’installation appropriée, lire toutes les instructions

d’opération et de sécurité.

Toute l’information dans ce manuel est basée sur la dernière disponible au moment de la publication. Chez

Kohler, nous veillons toujours à améliorer la qualité de nos produits; ainsi nous nous réservons le droit

1054216-2-B Français-2 Kohler Co.

Page 21

Introduction (cont.)

d’apporter des modifications aux caractéristiques des produits, à l’emballage ou à la disponibilité à tout

moment et sans préavis.

Avant de commencer

Votre baignoire est conçue pour des installations sur comptoir.

Cette baignoire doit être installée sur un support adéquat, et sur un sous-sol nivelé.

Prévoir un cadrage aux dimensions appropriées.

Choisir un bec verseur de remplissage d’une longueur adéquate et d’espace d’air d’un minimum de

2″ (5,1 cm) au-dessus du rebord du bassin de la baignoire à déversement. Il est possible qu’il soit

nécessaire d’augmenter la hauteur du plan afin d’obtenir un espace d’air adéquat car le rebord

extérieur pourrait être plus bas que celui du bassin de la baignoire selon la l’emplacement de celle-ci

Suivre les codes locaux de plomberie.

La baignoire doit être remplie par la bassin et non par le canal de trop-plein.

Si une installation de douche à main sur comptoir est planifiée, l’inverseur reniflard doit conserver

un écart anti-retour d’un minimum de 1″ (2,5 cm) au-dessus du rebord de la baignoire.

Si l’on utilise le bec de baignoire à débit laminaire K-922 ou K-923 avec le récipient d’égouttement

K-924, la distance du mur fini à la paroi extérieure du canal de trop-plein ne doit pas excéder 2″ (5,1

cm).

Kohler Co. se réserve le droit d’apporter toutes modifications sur le design des produits et ceci sans

préavis, tel que spécifié dans le catalogue des prix.

Kohler Co. Français-3 1054216-2-B

Page 22

Bassin de

la baignoire

Rebord du

bassin de la

baignoire

Canal de

trop-plein

Rebord

extérieur

Capteurs du canal

du trop-plein

Grille d'aspiration

métallique

Couvercle

d'aspiration en

plastique

Liste de nouveaux termes

Cuve de baignoire -La partie profonde de la baignoire à déversement utilisée par la personne.

Rebord du bassin de baignoire -Rebord élevé entre le bassin de la baignoire et le canal de trop

plein. L’eau tombera en cascade sur le rebord du bassin de la baignoire et dans le canal de trop

plein pendant le fonctionnement.

Cavitation -Lorsque de l’air est conduit dans la pompe au lieu de l’eau au point d’endommager ou

stopper la fonction de circulation de la pompe.

Interrupteur du contrôle de chromathérapie -Allume et éteint les lumières de chromathérapie (si

équipé).

Lumières de chromathérapie -Lumières situées dans le bassin de la baignoire (si équipée) pour

améliorer l’expérience de bain.

Chauffe-eau -Conçu pour aider à maintenir automatiquement la température de l’eau jusqu’à 104ºF

(40ºC) et pour améliorer votre expérience de bain à hydromassage. Le chauffe-eau s’active

automatiquement lorsque la baignoire à hydromassage est en service, et s’éteint lorsque le moteur

de la pompe est arrêté.

Commande principale -Cette unité est localisée sous la pompe. Elle fournit, le ″cerveau″ du

système, interprétant tous les signaux émis et reçus.

Crépine métallique d’aspiration -La crépine métallique amovible située sur le couvercle

d’aspiration en plastique dans le canal de trop plein. La crépine d’aspiration doit toujours être

propre et à sa place pendant le fonctionnement de la baignoire pour éviter que les débris ne rentrent

dans la prise d’eau et provoquer la cavitation et le mauvais fonctionnement.

Rebord extérieur -Le rebord le long de l’extérieur du canal de trop-plein.

Canal de trop-plein -Canal de trop plein qui collecte l’eau autour du bassin de la baignoire. Le

canal du trop plein collecte l’eau du trop plein durant l’opération normale, et l’eau est ensuite

redirigée vers le système et remise en circulation.

Capteurs du canal de trop plein - Les deux capteurs sont situés dans la paroi du canal de trop

plein au-dessous du rebord du trop-plein. Ces capteurs protègent le fonctionnement de la pompe

lorsque le niveau d’eau est insuffisant, et éteindra automatiquement la pompe si le niveau d’eau

descend au-dessous des capteurs. La pompe fonctionnera uniquement lorsque les deux capteurs

sont complètement submergés.

Interrupteur du contrôle de la pompe -Met la pompe en marche/arrêt.

Couvercle d’aspiration en plastique -La protection plastique attachée au port d’entrée d’eau situé

dans le canal de trop plein. Le couvercle d’aspiration doit toujours être installé durant l’utilisation

du produit pour assurer la sécurité.

1054216-2-B Français-4 Kohler Co.

Page 23

Liste de nouveaux termes (cont.)

Pompe -La pompe circule l’eau.

Harnais de câblage -Le harnais du câblage connecte tout les composants périphérique alimentés

(valves, pompe, chauffe-eau, interrupteurs, lumières) à la commande principale.

Kohler Co. Français-5 1054216-2-B

Page 24

Aucun changement des mesures n'est nécessaire

si connecté au drain illustré. (K-7223 ou K-7223M)

Découpe: 102-1/4" (259,7 cm) x 40" (101,6 cm)

103-3/4" (263,5 cm)

A

B

1" (2,5 cm)

A

85" (215,9 cm)

1" (2,5 cm)

2-7/8" (7,3 cm)

3" (7,6 cm)

26-1/2"

(67,3 cm)

31-13/16"

(80,8 cm)

41"

(104,1 cm)

Accès pompe/contrôle

40" (101,6 cm) L x

15" (38,1 cm) H min

23-11/16"

(60,2 cm)

20-1/2"

(52,1 cm)

7" (17,8 cm)

51-7/8" (131,8 cm)

1" (2,5 cm)

Ø Ext. 1-1/2"

1. Information du plan de raccordement

AVIS : Le support de plancher sous la baignoire doit pouvoir soutenir un poids minimal de 3500 lbs (1 588

kg).

AVIS : Les endroits étiquetés″A″ et″B″ sont recommandés pour les emplacements d’installation des becs de

baignoire. ″B″ s’appliquent uniquement aux becs de baignoire montés au plafond. Pour une liste de becs

de baignoire pour ce produit, voir la liste des spécifications.

Deux lignes séparées de 240 V sont nécessaires: une pour la pompe/contrôle, et une pour le

chauffe-eau.

Consulter les codes locaux et nationaux pour les exigences d’espace d’air minimum lors de

l’installation d’un bec sur le comptoir du robinet.

La baignoire à déversement doit être remplie par le bassin.

Le tuyau fournissant l’eau chaude doit être d’une capacité de 70% ou plus.

L’unité est conforme à la norme standard ANSI Z124.1. Toutes dimensions sont nominales.

Il n’y a pas de changement de mesures si connecté au drain illustré (K-7223, K-7223M).

Un panneau d’accès est requis. Les dimensions recommandées pour le panneau d’accès sont de 40″

(101,6 cm) Largeur x 15 ″ (38,1 cm) Hauteur. Se reporter au plan de raccordement pour référer les

emplacements recommandés.

S’assurer que le sol soit en bonne condition et offre un support adéquat pour la baignoire.

IMPORTANT ! S’assurer que le sol soit plat et nivelé. Ceci minimisera les réglages nécessaires de mise à

niveau pour une bonne performance de l’unité.

1054216-2-B Français-6 Kohler Co.

Page 25

Comptoir

2. Construire le cadre du montant

AVIS : Prévoir un accès de service non restreint à la pompe, chauffe-eau en ligne, pieds réglables, et boîtier

de contrôle. Un panneau d’accès doit être construit pour suffisamment fournir un dégagement pour

l’entretien de la pompe, du chauffe-eau en ligne et du boîtier de contrôle.

Construire un cadrage de montant conçu pour votre installation particulière. La baignoire à

débordement peut être installée sur comptoir.

Cadrer le sol, ou construire un cadre pour une installation sur podium, selon le plan de

raccordement.

Lors de la construction du cadre, prévoir l’épaisseur du plancher et des matériaux du plan.

Le cadre devrait être de 2x4.

Pour une installation par dessous, prévoir l’épaisseur du plancher et des matériaux du plan, et

prévoir un support en conséquence.

Ne pas soulever la baignoire par le rebord.

Lors de la planification du cadrage, prendre en compte les 2″ (5,1 cm) d’espace d’air entre

l’extrémité du bec de remplissage et le rebord supérieur de la baignoire. Prendre en compte

l’épaisseur du matériau du plancher, et construire le cadre et le plancher en gardant en tête l’espace

d’air minimum.

Kohler Co. Français-7 1054216-2-B

Page 26

2" (5,1 cm) Min.

Rebord extérieur

Rebord du bassin de la baignoire

Bassin de la baignoire

3. Installer la plomberie de raccordement

IMPORTANT ! Choisir un bec de remplissage avec 2″ (5,1 cm) d’espace d’air au-dessus du rebord du

bassin de la baignoire à déversement. Si une installation de douchette est envisagée, le reniflard inverseur

doit maintenir un écart minimum de 1″ (2,5 cm) au-dessus du rebord du bassin de la baignoire à

déversement.

Positionner la plomberie. Positionner le bec de remplissage de façon à ce qu’il dépasse du rebord

extérieur et du rebord du bassin de la baignoire. L’eau provenant du bec de remplissage doit

s’écouler directement dans le bassin de la baignoire pour remplir celle-ci. La baignoire à

déversement devrait jamais être remplie en dirigeant l’eau vers le canal de trop-plein.

Boucher les alimentations et vérifier s’il y a des fuites.

4. Préparer l’unité

Déballer avec précaution la baignoire à déversement.

Idéntifier la boîte située dans le canal du trop plein. Cette boîte contient la crépine d’aspiration

métallique et doit être gardée pour être utilisée avec ce produit.

Installer le drain conformément aux instructions du fabricant. Ne pas connecter le siphon à ce

moment.

Positionner un chiffon propre ou matière similaire à la base de la baignoire. Faire attention de ne

pas rayer la surface de la baignoire déversante.

1054216-2-B Français-8 Kohler Co.

Page 27

Pied

ajustable

Pattes ajustables

Clé

Plaque

métallique

Sangles de la

pompe

Vérifier le niveau

Découper les sangles

5. Positionner l’unité

IMPORTANT ! Risque d’endommagement du produit. Ne pas soulever ou supporter l’unité par la pompe

ou la tuyauterie.

REMARQUE : Ne pas utiliser d’adhésifs, ciment ou mortier pour sécuriser le produit au sol.

Avec de l’aide, positionner la baignoire à déversement à sa place. L’utilisation de plaques

métalliques sous les pieds réglables est recommandée et facilitera le nivelage de la baignoire.

REMARQUE : Si vous n’avez pas un niveau de 6’ (1,8 m), se reporter à la section suivante.

Niveler en pivotant les pieds réglables vers le haut et le bas avec la clé de 7/8″ attachée au harnais

près de la pompe. S’assurer que les six pieds réglables reposent directement sur le plancher et que

le rebord du bassin de la baignoire soit nivelé à 1/8″ (3 mm) dans toutes les directions.

Couper et jeter les sangles de retenue de la pompe.

S’assurer que les pieds d’isolation en caoutchouc soient en place.

Insérer la pièce de raccordement du drain dans le siphon.

Kohler Co. Français-9 1054216-2-B

Page 28

Rebord du bassin

de la baignoire

Rebord du bassin

de la baignoire

Niveau à bulle

Non nivelé

6. Niveler la baignoire à déversement (sans niveau)

AVIS : L’alimentation électrique n’est pas nécessaire pour les procédures de nivelage suivantes.

Introduire la pièce de raccordement dans le siphon et y raccorder le drain selon les instructions du

fabricant.

Fermer le drain et boucher ou couvrir le couvercle d’aspiration pour créer une étanchéité

temporaire.

Remplir d’eau fraîche le bassin de la baignoire à l’aide d’un flexible jusqu’au rebord.

Observer le niveau d’eau (couleur grise sur l’illustration = niveau d’eau) en relation avec le rebord

du bassin de la baignoire.

Si l’eau se met en cascade de manière égale sur tout le rebord de la baignoire à déversement, aucun

réglage n’est nécessaire. La baignoire à déversement est nivelée.

Si le niveau d’eau n’est pas régulier et ne se met en mode cascade que sur des sections du rebord,

utiliser une clé pour pivoter les pieds réglables vers le haut ou le bas afin d’obtenir un niveau

uniforme d’eau.

Ouvrir le drain et retirer le couvercle d’aspiration pour évacuer l’eau du bassin de la baignoire.

IMPORTANT ! Prévoir suffisamment d’accès aux six pieds réglables jusqu’à effectuer un essai de

fonctionnement de la baignoire.

7. Installer la plomberie

ATTENTION : Risque d’endommagement du matériel. Assurer un joint étanche sur les connexions

de drain.

IMPORTANT ! Choisir un bec de remplissage qui permettra suffisamment de dégagement au-dessus du

rebord du bassin de la baignoire. Il sera peut-être nécessaire de hausser la construction du comptoir afin

d’obtenir un espacement adéquat d’air parce que le rebord extérieur pourrait être plus bas que celui du

bassin de la baignoire. En plus, si un montage mural de douchette est envisagé, le reniflard inverseur doit

maintenir un espacement d’air d’un minimum de 1″ (2,5 cm) au-dessus du rebord extérieur.

REMARQUE : Un panneau d’accès facilitera une maintenance future.

Si cela n’a pas déjà été fait, raccorder le drain au siphon selon les instructions du fabricant.

Installer les valves du robinet conformément aux instructions du fabricant. Ne pas installer la

garniture du robinet avant l’instruction de le faire.

S’assurer que toutes les vannes papillon et les connexions d’alimentation soient bien serrées.

Ouvrir les alimentations d’eau chaude et froide et vérifier qu’il n’y ait pas de fuites.

1054216-2-B Français-10 Kohler Co.

Page 29

Installer la plomberie (cont.)

Laisser couler l’eau dans la baignoire et vérifier s’il y a des fuites dans les connexions du drain.

Kohler Co. Français-11 1054216-2-B

Page 30

Chauffe-eau (modèles peuvent varier) de

style T (illustré) ou en-ligne (non-illustré)

Câble du chauffe-eau

électrique

Raccorder selon les codes nationaux et locaux.

Harnais câblage

Des cosses d'ouverture sont localisées au-dessus

du boÎtier de jonction.

Source

120/240 VAC

L1 L2N

120 V

120 V

240 V

S/N

Module

neutre

(Dans le

boîtier de

disjoncteur)

Boîtier du

disjoncteur

Disjoncteur

typique à deux

pôles avec GFCI

Pas de connexion

(Neutre)

* Ligne neutre

(Câble blanc

bouclé)

* Equippement de

mise à la terre

Câble de la pompe

électrique

Boîte de

jonction

Câblage typique pour l'Amérique du Nord

* Connexions à faire au

disjoncteur

*L2

240 V

*L1

Câblage site

(Du boîtier de jonction

au disjoncteur GFCI)

Contrôle

Connecteur câble

Bleu (L1)

L'électricien doit

fournir un câble réducteur de tension.

Terre

(Vert à rayures

jaunes)

Depuis le

contrôle

Brun (L2)

Connecteurs

câbles

8. Faire les connexions électriques

REMARQUE : Le numéro de modèle du produit est imprimé sur une étiquette placée du côté de la pompe

de la baignoire à déversement. Cette étiquette identifie aussi le calibrage électrique du produit. Ces les

baignoires à hydromassage sont équipées de deux boîtes de jonction et sont conçues pour opérer entre 208

VACet240VACsoità50HZou60Hz.

AVERTISSEMENT : Risque d’électrocution. S’assurer que l’alimentation ait été débranchée avant

d’effectuer les procédures suivantes. Se référer à la section “Information Importante.

AVERTISSEMENT : Risque d’électrocution. Pour réduire les risques d’électrocution, connecter

proprement la pompe à un disjoncteur coupe-circuit (GFCI) ou à un coupe-circuit de fuite à la terre

(ELCB). Le chauffe-eau devra aussi être connecté proprement à un disjoncteur coupe-circuit (GFCI)

ou à un coupe-circuit de fuite à la terre (ELCB). Ceci fournira une mesure de protection

additionnelle contre le risque d’électrocution. Deux circuits dédiés de 208V/240V, 20A, 50/60Hz.

sont nécessaires.

IMPORTANT ! Le neutre n’est pas utilisé. Il ne devrait pas y avoir de connexion au neutre du disjoncteur

coupe-circuit (GFCI). Le câble vert à rayures jaunes est le conducteur de terre et doit être connecté au

neutre de la boîte du disjoncteur.

Le contrôle et le chauffe-eau ont été pré-câblés en usine. Un électricien agréé devrait faire les

connexions de service ordinaire à chaque boîte de jonction.

Connecter le service aux boîtiers de jonction. Les boîtes de jonction contiennent des câbles bleus,

marrons et verts à rayures jaunes.

Suivre tous les codes électriques locaux. Raccorder selon les codes nationaux et locaux.

Un harnais a été pré-câblé en usine, permettant la communication entre le clavier, toutes les

caractéristiques, et le contrôle. Aucun câblage supplémentaire n’est nécessaire, mais s’assurer que

tous les câbles soient bien sécurisés.

1054216-2-B Français-12 Kohler Co.

Page 31

Faire les connexions électriques (cont.)

REMARQUE : Votre harnais de câblage comprend une antenne pour la télécommande optionnelle. Ne pas

modifier ni endommager cette antenne pendant l’installation.

Kohler Co. Français-13 1054216-2-B

Page 32

Eau

Rebord du bassin

de la baignoire

Capteurs du canal

du trop-plein

Interrupteur de contrôle

de chromathérapie

(Optionnel)

Drain du

canal de

trop-plein

9. Tester le fonctionnement de la baignoire à déversement

Contrôler toutes les connexions électriques, et s’assurer que l’alimentation électrique soit en marche.

S’assurer que toutes les connexions à la pompe, les vannes papillon et le chauffe-eau en ligne soient

bien serrés à la main. S’assurer que le bassin de la baignoire et le canal de trop plein soient propres

et exempts de débris.

Positionner la crépine d’aspiration métallique sur le couvercle d’aspiration en plastique. La pompe

pourrait caviter si la crépine métallique n’est pas mise en place.

Remplir le bassin de la baignoire à déversement de manière à ce que l’eau déborde par le bord et

s’écoule dans le canal de trop-plein. Remplir le bassin de la baignoire jusqu’à ce que les capteurs du

canal de déversement soient complètement sous l’eau et que le niveau d’eau ait atteint le trop-plein

de drain.

S’assurer que la lumière verte de l’interrupteur de commande clignote automatiquement environ 30

secondes après que les capteurs du canal de débordement soient complètement submergés.

10. Tester l’interrupteur de contrôle

Appuyer sur l’interrupteur de commande de la pompe pour activer la pompe/moteur et

commencer le cycle d’hydrothérapie. Quand le moteur de pompe s’active et l’eau commence à

circuler, la lumière deviendra verte, et le restera pendant tout le fonctionnement de la baignoire à

déversement.

Pendant que l’unité soit en marche, vérifier s’il y a des fuites dans les raccords de la tuyauterie.

S’assurer que la cascade sur le rebord du bassin s’écoule de façon égale aux quatre côtés.

Des nivelages ultérieurs ne seront pas nécessaires si la cascade s’écoule pas de façon uniforme.

Si un nivelage supplémentaire est nécessaire, maintenir la baignoire à déversement en marche et

pivoter les pieds réglables vers le haut ou le bas avec la clé de 7/8″ fournie. S’assurer que l’unité

repose sur les six pieds réglables.

Vérifier que les lumières chromatiques fonctionnent. Appuyer sur l’interrupteur des lumières

chromatiques (situé à côté de l’interrupteur de courant) pour allumer les lumières. Au démarrage,

les lumières devraient se mettre en cycle de couleurs. Appuyer sur l’interrupteur de contrôle des

lumières une deuxième fois. Le cycle de lumières devrait s’arrêter et rester à la même couleur.

Presser l’interrupteur des lumières une deuxième fois pour éteindre les lumières.

Vérifier encore une fois s’il y a des fuites dans les raccords de tuyauterie.

Appuyer sur l’interrupteur de la pompe encore une fois pour arrêter la baignoire. La lumière verte

de l’interrupteur de la pompe clignotera alors automatiquement (après environ 30 secondes) jusqu’à

ce que la baignoire à déversement soit vidée ou remise en marche.

Interrupteur

du contrôle de

la pompe

1054216-2-B Français-14 Kohler Co.

Page 33

Tester l’interrupteur de contrôle (cont.)

REMARQUE : Pour plus d’information concernant le fonctionnement de la baignoire, consulter la section

″Utilisation de la baignoire″.

IMPORTANT ! Prévoir suffisamment d’accès aux six pieds réglables jusqu’à la finition des tests.

Kohler Co. Français-15 1054216-2-B

Page 34

Chauffeau

marche/arrêt

Marche/arrêt

Alimentation marche/arrêt

Chauffe-eau

marche/arrêt

Mode effervescence

Cycle chromathérapie

Couleur

spécifique de la

sélection de

chromathérapie.

11. Utiliser la télécommande

REMARQUE : Il y a deux types de télécommandes disponibles: une basique et une avec contrôle de

lumières chromatiques et d’effervescence. Déterminer quel type de télécommande vous avez et suivre les

étapes d’installation correspondantes.

REMARQUE : Votre télécommande nécessite deux piles AAA. Pour les installer ou les remplacer,

simplement dévisser la base de la télécommande.

La baignoire à déversement est équipée d’une télécommande étanche.

Pour mettre la pompe et les lumières chromatiques en marche et arrêt, appuyer sur le bouton d’alimentation.

Pour réchauffer l’eau dans la baignoire à déversement, mettre le chauffe-eau en marche en pressant sur

l’icône chauffage (par défaut le chauffage est en position ″On″ quand la pompe est en marche). Appuyer sur

l’icône de chauffage une deuxième fois pour l’arrêter. Le chauffe-eau ne fonctionnera pas si la pompe est

arrêtée. Si le chauffe-eau est en marche, l’interrupteur de la pompe deviendra vert foncé. Si le chauffe-eau est

en arrêt, l’interrupteur deviendra jaune-vert.

Pour cycler les lumières de chromathérapie à travers le spectre de couleurs, presser sur l’icône du cycle de

chromathérapie.

Pour verrouiller une couleur de chromathérapie individuelle, appuyer sur l’icône de couleur de

chromathérapie correspondante.

1054216-2-B Français-16 Kohler Co.

Page 35

Joint en silicone

Comptoir fini

Montant 2x4

Comptoir

Matériau

hydrorésistant du

mur

12. Compléter le mur ou le comptoir fini

AVIS : Prévoir un accès de service non restreint à la pompe, chauffe-eau en ligne, pieds réglables, et boîtier

de contrôle. Un panneau d’accès doit être construit pour suffisamment fournir un dégagement pour

l’entretien de la pompe, du chauffe-eau en ligne et du boîtier de contrôle.

Protéger la surface du produit. Recouvrir le cadrage avec du matériau hydrorésistant.

Laisser le canal de trop-plein exposé pour permettre l’accès au trop-plein du drain et le nettoyage

des surfaces du canal.

Sceller les joints entre le rebord de la baignoire et le matériau hydrorésistant du mur ou du

comptoir à l’aide d’un mastic à la silicone.

Poser et appliquer le matériau hydrorésistant du mur.

Installer le mur fini sur le matériau hydrorésistant.

Fixer les joints entre le rebord du produit et le mur fini à l’aide de mastic à la silicone.

13. Installer la garniture du robinet

Installer la garniture du robinet suivant les instructions emballées avec celle-ci.

14. Nettoyage après installation

Lors du nettoyage après l’installation, ne pas utiliser de nettoyant abrasif, car ils pourraient rayer

et abîmer la surface de la baignoire. Utiliser de l’eau tiède et un savon doux pour nettoyer la

surface.

Retirer les taches résistantes, peinture, ou goudron avec de l’essence de térébenthine ou un diluant

pour peinture. Ne pas laisser de liquide à base de pétrole en contact avec les surfaces de la

baignoire pour de longues périodes. Retirer les résidus de plâtre en raclant au moyen d’un bord en

bois. Ne pas utiliser de grattoirs en métal, une brosse en fer ou d’autres outils en métal. Utiliser des

nettoyants en poudre sur un chiffon humide pour une action abrasive douce sur les résidus de

plâtre.

Kohler Co. Français-17 1054216-2-B

Page 36

Rebord du bassin de la

baignoire

Interrupteurs de contrôle

15. Utiliser la baignoire

Remplir la baignoire à déversement

REMARQUE : Veuillez lire avec attention cette section avant de faire fonctionner la baignoire.

S’assurer que la grille d’aspiration métallique soit propre et correctement placée sur le couvercle

d’aspiration en plastique.

REMARQUE : La température de la baignoire ne devrait pas excéder 104° F (40° C), sinon le chauffe-eau

ne fonctionnera pas.

IMPORTANT ! Comme pour toute autre baignoire, éviter de déborder l’eau de l’unité en entrant dans le

bassin lentement. Cela permettra au système d’évacuer correctement tout excès d’eau.

Remplir l’unité avec de l’eau de façon à ce que le bassin déborde dans le canal de trop-plein vers le

drain. Les capteurs du canal devraient être complétement submergés d’eau.

La lumière verte de l’interrupteur de la pompe clignotera automatiquement 30 secondes après que

les capteurs soient submergés pour préciser que la baignoire est prête à l’utilisation.

Séquence d’opération

Appuyer sur l’interrupteur de contrôle pour activer la pompe/moteur et commencer l’opération.

Quand le moteur de la pompe s’active et l’eau commence à couler, la lumière du voyant de la

pompe deviendra verte foncée, et le restera pendant tout le fonctionnement de la baignoire à

déversement.

S’assurer que la lampe témoin du chauffe-eau soit allumée pendant le fonctionnement de la

baignoire à déversement. La lampe témoin est située en-dessous du boîtier du chauffe-eau, près du

plancher à l’extrémité côté pompe de la baignoire à déversement. Si la lampe est éteinte pendant le

fonctionnement de la baignoire à déversement, essayer et réinitialiser le bouton de la remise en

circuit GFCI/ELCB.

Appuyer sur ’interrupteur de la pompe une deuxième fois pour arrêter la baignoire. La lumière

verte de l’interrupteur de la pompe clignotera automatiquement pendant approximativement 30

secondes jusqu’à ce que la baignoire soit vidée sous les capteurs ou redémarrée.

REMARQUE : Une minuterie intégrée arrêtera automatiquement la baignoire après environ 20 minutes de

fonctionnement.

1054216-2-B Français-18 Kohler Co.

Page 37

16. Fonctionnement de la lumière de chromathérapie

REMARQUE : Ces directions sont uniquement relatives à l’utilisation de l’interrupteur de contrôle monté.

Pour plus d’information, voir la section ″Utiliser la télécommande″.

Si les lumières de chromathérapie sont éteintes, presser le bouton de contrôle de chromathérapie

(situé à côté de l’interrupteur de contrôle de la pompe). Les lumières de chromathérapie

commenceront le cycle de chaque couleur (mode balayage).

Quand les lumières de chromathérapie sont en mode balayage, il est possible de verrouiller une

couleur en pressant le bouton de contrôle de chromathérapie.

Quand une couleur est verrouillée, presser le bouton de contrôle de chromathérapie pour éteindre

les lumières de chromathérapie.

17. Procédures de dépannage

Pour une réparation sous garantie, contacter le vendeur ou distributeur. Ce guide de dépannage est destiné à

une aide générale uniquement. Contacter un technicien agréé Kohler ou un électricien qualifié pour réparer

tout problème électrique. Pour une réparation sous garantie, contacter le vendeur ou distributeur.

Symptômes Causes probables Action recommandée

1. La lumière verte de

l’interrupteur de contrôle

″Marche/Arrêt″ s’active

avant que le bassin de la

baignoire ne soit plein

d’eau.

2. Le produit ne démarre

pas.

3. L’eau ne tombe pas en

cascade de façon égale sur

le rebord du bassin de la

baignoire.

A. Le bec verse l’eau directement

dans le canal de trop-plein.

B. Une ou les deux valves papillon

ne fonctionnent pas.

C. Le contrôle ne fonctionne pas. C. Vérifier le câblage ou remplacer

A. Pas d’alimentation à l’unité. A. Alimenter l’unité ou corriger la

B. L’eau ne couvre pas les capteurs

de canal de trop-plein.

C. L’interrupteur ″Marche/Arrêt″ ne

s’allume pas quand l’unité est

activée ou remplie tel que requis.

D. La pompe/moteur ne fonctionne

pas.

E. Le contrôle ne fonctionne pas. E. Vérifier le câblage ou remplacer

A. L’unité n’est pas nivelée. A. Niveler l’unité avec la clé fournie

B. Les orifices du bassin sont

bloqués.

A. Régler/réinstaller le bec pour

écouler l’eau directement dans le

bassin de la baignoire. Contacter

l’installateur/vendeur.

B. Vérifier le câblage de valves

papillon ou remplacer celles-ci.

Contacter l’installateur/vendeur.

le contrôle. Contacter

l’installateur/vendeur.

perte de courant. Contacter

l’installateur/vendeur.

B. Remplir le bassin de manière à ce

que l’eau circule par dessus le

rebord du bassin dans le canal de

trop-plein, et submerge les

capteurs. Le niveau de

remplissage conseillé est jusqu’au

trop-plein du drain.

C. Vérifier le câblage ou remplacer

l’interrupteur de contrôle

″Marche/Arrêt″. Contacter

l’installateur/vendeur.

D. Reconstruire ou remplacer la

pompe/moteur. Contacter

l’installateur/vendeur.

le contrôle. Contacter

l’installateur/vendeur.

en pivotant les pieds réglables

vers le haut ou le bas selon le

besoin.

B. Retirer le blocage.

Kohler Co. Français-19 1054216-2-B

Page 38

Procédures de dépannage (cont.)

Symptômes Causes probables Action recommandée

C. La crépine d’aspiration métallique

est bloquée.

4. L’unité s’arrête

automatiquement avant

18 minutes.

5. Fonctionnement bruyant. A. La crépine d’aspiration métallique

6. La température de l’eau

baisse considérablement

dans les 20 minutes de

fonctionnement.

7. Les lumières de

chromathérapie ne

fonctionnent pas.

A. Le GFCI se déclenche. A. Identifier la source du problème

B. Moteur surchauffé et système de

protection activé.

C. Le niveau d’eau descend

en-dessous des capteurs du canal

de trop-plein pendant le

fonctionnement (Le voyant ″jaune″

de la pompe clignote)

n’est pas à sa place sur le

couvercle d’aspiration en

plastique.

B. Le niveau d’eau est insuffisant

dans le canal de trop-plein.

C. La pompe/moteur est bruyante. C. S’assurer que les sangles qui

A. L’interrupteur de la chaleur

maximum est déclenché. La

lumière indicatrice devrait être

allumée pendant le

fonctionnement.

B. Le chauffe-eau ne fonctionne pas. B. Vérifier le câblage ou remplacer

A. Harnais de câblage électrique

endommagé.

B. Le contrôle ne fonctionne pas. B. Remplacer le harnais de câblage

C. Nettoyer la crépine d’aspiration

métallique.

puis y remédier. Contacter

l’installateur/vendeur.

B. Vérifier s’il y a blocage du

ventilateur du moteur. Laisser

refroidir le moteur, puis retirer

l’obstruction.

S’assurer que la crépine

d’aspiration métallique ne soit

pas bloquée, puis laisser refroidir

avant de relancer le moteur.

Vérifier qu’il n’y ait pas

d’obstruction dans les orifices du

bassin. Retirer le blocage, puis

laisser refroidir le moteur avant

de le relancer.

C. Remplir le bassin de manière à ce

que l’eau circule par dessus le

rebord du bassin dans le canal de

trop-plein, et submerge les

capteurs. Le niveau de

remplissage conseillé est jusqu’au

trop-plein du drain. S’assurer que

le drain de la baignoire soit bien

étanche.

A. Positionner la crépine

d’aspiration métallique sur le

couvercle d’aspiration en

plastique pour éviter la

cavitation.

B. Remplir le bassin de manière à ce

que l’eau circule par dessus le

rebord du bassin dans le canal de

trop-plein, et submerge les

capteurs. Le niveau de

remplissage conseillé est jusqu’au

trop-plein du drain. S’assurer que

le drain de la baignoire soit bien

étanche.

retiennent la pompe/moteur ont

été sectionnés.

A. Réinitialiser le disjoncteur

différentiel GFCI/ELCB.

le chauffe-eau. Contacter

l’installateur/vendeur.

A. Vérifier le câblage ou remplacer

le contrôle. Contacter

l’installateur/vendeur.

électrique. Contacter

l’installateur/vendeur.

1054216-2-B Français-20 Kohler Co.

Page 39

Procédures de dépannage (cont.)

Symptômes Causes probables Action recommandée

8. La télécommande ne

fonctionne pas.

A. Les piles sont mal installées ou

épuisées.

A. Remplacer les piles.

B. Le contrôle ne fonctionne pas. B. Remplacer le harnais de câblage

électrique. Contacter

l’installateur/vendeur.

C. La télécommande n’est pas

correctement programmée.

C. Consulter le guide du

propriétaire ou le manuel de

service.

D. La télécommande ne fonctionne

D. Remplacer la télécommande.

pas.

E. La commande de l’interrupteur ne

E. Remplacer le contrôle.

fonctionne pas.

9. L’eau n’atteint pas le

rebord de la baignoire

A. Pas d’alimentation à l’unité. A. Brancher l’alimentation

électrique.

pendant le remplissage.

B. Câbles de la sonde de niveau

B. Vérifier/reconnecter les câbles.

desserrés.

C. Les valves papillon ne

fonctionnent pas.

D. La commande de l’interrupteur ne

C. Vérifier le câblage ou remplacer

les valves papillons si nécessaire.

D. Remplacer le contrôle.

fonctionne pas.

Kohler Co. Français-21 1054216-2-B

Page 40

Guía de instalación

Bañera rebosante

Información importante

ADVERTENCIA: Al usar aparatos eléctricos, siga siempre las precauciones básicas, incluyendo

las siguientes:

PELIGRO: Riesgo de descarga eléctrica. Conecte la unidad solamente a un circuito protegido por

un interruptor de circuito con pérdida a tierra (GFCI) o un disyuntor de fuga a tierra (ELCB).

ADVERTENCIA: Riesgo de descarga eléctrica. Un electricista calificado debe realizar todas las

conexiones eléctricas.

ADVERTENCIA: Riesgo de descarga eléctrica. Desconecte el suministro eléctrico antes de dar

servicio.

ADVERTENCIA: Riesgo de lesiones personales o daños a la propiedad. Lea atentamente todas las

instrucciones antes de comenzar la instalación, incluyendo los requisitos detallados a continuación.

AVISO: Cumpla con todos los códigos locales de electricidad y de plomería.

Instale la unidad de manera que se permita el acceso para darle servicio.

Se ha incluido un cable conductor verde con raya amarilla en el compartimento de cables. Para reducir el

riesgo de descarga eléctrica, conecte el cable al terminal de tierra de su servicio eléctrico o panel de

suministro con un cable de cobre del mismo tamaño que los conductores del circuito que alimentan este

equipo.

En el exterior de la bomba o control de esta unidad se incluye un conector de presión para permitir la

conexión de un conductor de puesta a tierra entre esta unidad y el metal expuesto en las proximidades, tal

como lo requieran las normas locales.

La conexión a tierra es un requisito. Un representante de servicio autorizado debe instalar esta unidad y

conectarla a tierra.

El material de construcción y el cableado se deben colocar lejos del cuerpo de la bomba y de otros

componentes que produzcan calor.

Información importante sobre el producto

Avisos sobre el producto

ADVERTENCIA: Las modificaciones no autorizadas pueden causar el funcionamiento peligroso y

el bajo rendimiento de la bañera. No cambie la ubicación de la bomba, ni haga otras

modificaciones al sistema, pues esto podría tener un efecto adverso en el rendimiento y en el

funcionamiento seguro de su bañera. Kohler Co. no se hace responsable bajo esta garantía o de

ninguna otra forma, de las lesiones personales o los daños provocados por modificaciones no

autorizadas.

Inspección del producto

Con cuidado saque el producto del embalaje y revise que no tenga daños. Para evitar daños durante la

construcción, vuelva a colocar la unidad en el cartón de embalaje.

Kohler Co. Español-1 1054216-2-B

Page 41

Información importante sobre el producto (cont.)

Componentes ensamblados en fábrica

Los componentes instalados en fábrica incluyen la bomba, los sensores de nivel, el calentador en línea, las

luces sumergidas de cromoterapia (opcional), el control y el interruptor. La bomba y las tuberías están

ensambladas en fábrica.

Acceso de servicio y a las conexiones

AVISO: Provea acceso sin restricciones para dar servicio a la bomba y el calentador. Provea acceso sin

restricciones para dar servicio a la bomba, el calentador en línea, las patas ajustables y la caja de control.

Se debe construir un panel de acceso que provea suficiente espacio para dar servicio a la bomba, del

calentador en línea y de la caja de control. El panel de acceso debe colocarse junto a la bomba y el