Kohler DTV+ Installation And Care Manual

Installation and Care Guide

Digital Thermostatic Valve for DTV+

Français, page ″Français-1″

Español, página ″Español-1″

1240338-2-B

IMPORTANT INSTRUCTIONS

WARNING: When using electrical products, basic precautions should always be followed,

including the following:

WARNING: Risk of electric shock. A qualified electrician should route all electrical wiring.

WARNING: Risk of electric shock. Disconnect power before servicing.

WARNING: Unauthorized modification may cause poor performance of the valve. Do not make

modifications to the valve as this could adversely affect the performance of the valve and void the

warranty. Kohler Co. shall not be liable under its warranty or otherwise for personal injury or

damage caused by any such unauthorized modification.

DANGER: Risk of injury or property damage. If the power cord gets damaged, it must be

replaced by the manufacturer, its authorized service agent, or qualified personnel to avoid danger.

WARNING: Risk of injury. This device is not intended for use by persons (including children)

with different or reduced physical, sensory, or mental abilities, or who lack experience or

knowledge, unless they are under the supervision of or receive training for the use of the device by

a person responsible for their safety. Children should be under supervision to ensure that they do

not use devices as toys.

WARNING: Risk of injury or property damage. Please read all instructions thoroughly before

beginning installation.

NOTICE: Follow all plumbing, electrical, and building codes.

NOTICE: Some electrical codes require a circuit protected by a GFCI*.

NOTICE: For K-557-K1: If a GFCI outlet is required, connect only one valve per outlet.

NOTICE: Provide unrestricted service access to the valve.

NOTICE: The minimum flow rate of this valve is 1.6 gal/min (6 l/min).

*Outside North America, this device may be known as a Residual Current Device (RCD).

___________________________________________________________________________________________________

Operation with DTV+

To connect the valve to the DTV+ system, the K-99695 system controller is required.

The provided data cable is used to connect the valve to the system controller.

Refer to the ″DTV+ System Layout″ section in this guide.

Before Operating the System for the First Time:

Download and install the latest software for connected components. This may take an hour or more to

complete based on system configuration and internet connection speed. Do not disconnect the power from

any components during software download and installation.

Specifications

Pressures

Maximum Static Pressure 125 psi, 862 kPa, 8.6 bar

Supply Pressure Differential* Max 5 psi, 34.5 kPa, 0.34 bar (Equal pressures recommended.)

1240338-2-B 2 Kohler Co.

Specifications (cont.)

Pressures

Minimum Flow Rate 1.6 gal/min (Less than 72 psi dynamic pressure.)

Temperatures

Programmable Temperature Max 120°F (49°C) Min 86°F (30°C) Full cold may also be selected.

Default Temperature at Start-up 100°F (38°C)

Minimum Mixed Temperature Differential

from Hot Supply

Temperature Stability at Recommended

Supply Conditions

Ambient Temperature Greater than 34°F (1°C), Max 104°F (40°C)

Maximum Relative Humidity 95% noncondensing

Electrical

Electrical Rating 120 V, 0.16 A, 60 Hz

Data Cable Length 25’ (7.6 m)

*In commercial applications where there is a large difference in hot and cold supply pressures or frequent

fluctuation in either supply line is anticipated, it is strongly recommended that pressure regulators be

installed.

6 l/min (Less than 500 kPa maintaining pressure.)

2.1 gal/min (Greater than 72 psi dynamic pressure.)

8 l/min (Greater than 500 kPa maintaining pressure.)

3.6°F (2°C)

+/- 1.6°F (1°C)

Tools and Materials

Plus:

• (2) 1/2" Union Connectors

• Wood and Framing Materials

• PEX Tubing, Copper Tubing, or PVC

• (2) Water Hammer Arrestors (Recommended)

• (2) Supply Shut-Off Valves

Hacksaw or Tube Cutter Sealant

Tape

Solder Propane

Torch

Before You Begin

NOTICE: Do not install the valve under a whirlpool surround or any location where the temperature may

exceed 104°F (40°C). The valve and its integrated power supply are rated to operate in temperatures up to

104°F (40°C).

NOTICE: Do not apply excessive heat near the valve or apply flux or acids directly onto the valve. This

valve contains plastic and rubber components that will melt if heat is directly applied.

NOTICE: Do not apply petroleum-based lubricants to the valve components. Doing so will damage the

valve components.

NOTICE: Do not use oil-based, nonsetting compounds, such as plumbers putty, on the threaded

connections.

Kohler Co. 3 1240338-2-B

Before You Begin (cont.)

NOTICE: Do not remove the check valves from the inlets as this can damage the product.

NOTICE: If the valve will be used for a bath/shower application, the bath fill supply line must be routed

from the #1 outlet port.

Read these instructions and determine the locations of all required components before beginning

installation. For shower configuration options, refer to the guide on the K-99695 controller product

page at us.kohler.com.

If possible, flush all piping thoroughly before installing the valve. If the pipes are flushed after the

valve is installed, clean the inlet screens before using the system.

A qualified electrician should install a 120 V electrical outlet, within the stud framing, close to the

valve. A GFCI outlet may be required in certain applications.

If possible, install the electrical outlet before installing the valve.

Multiple Valve Applications

Showering configurations using large water volumes require supply piping and drain systems that

will sufficiently accommodate the actual total flow rate at any one time.

Hot water generation: Use a water heating system capable of handling large flow rates. Tankless

(on-demand) water heaters and recirculating pumps may not be adequate for your showering

configuration.

1240338-2-B 4 Kohler Co.

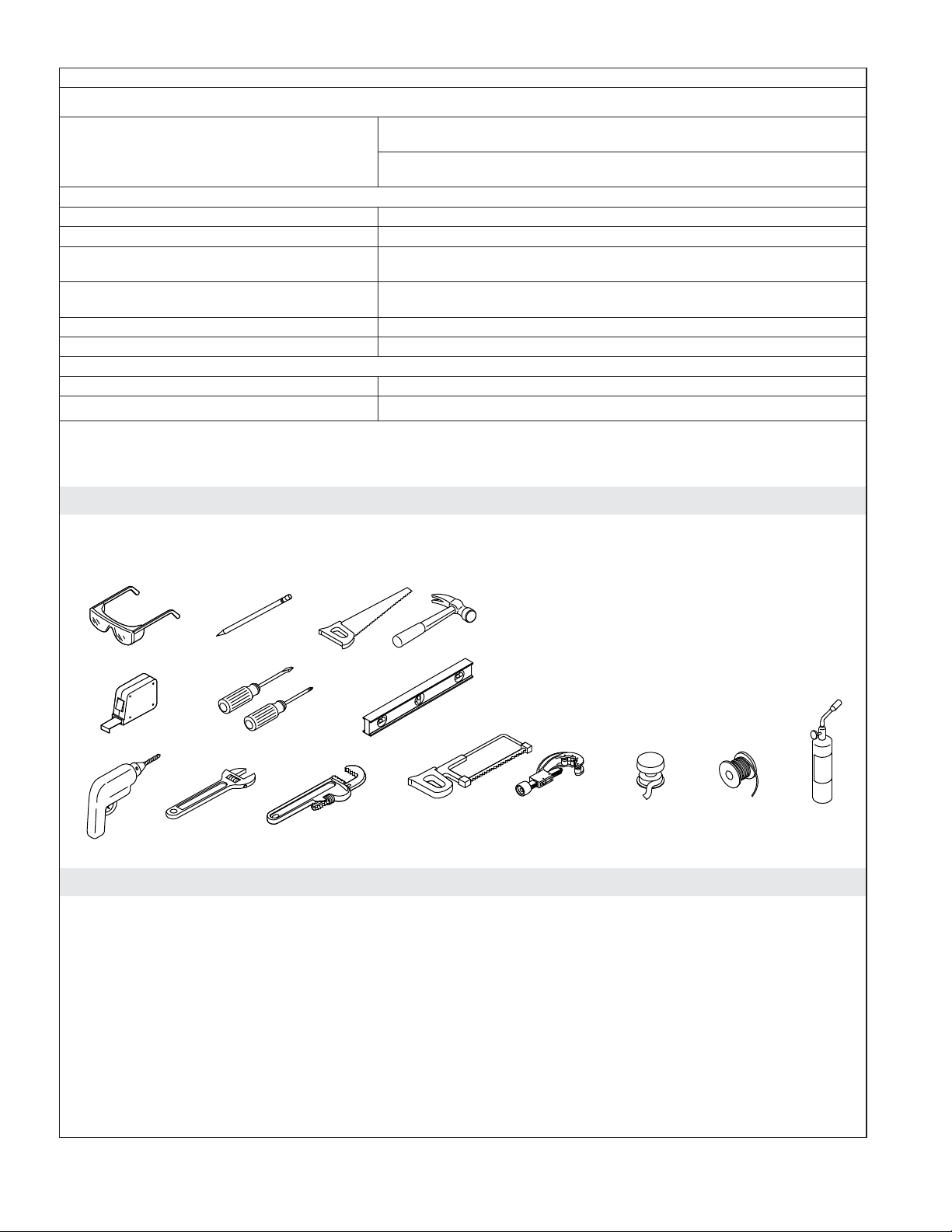

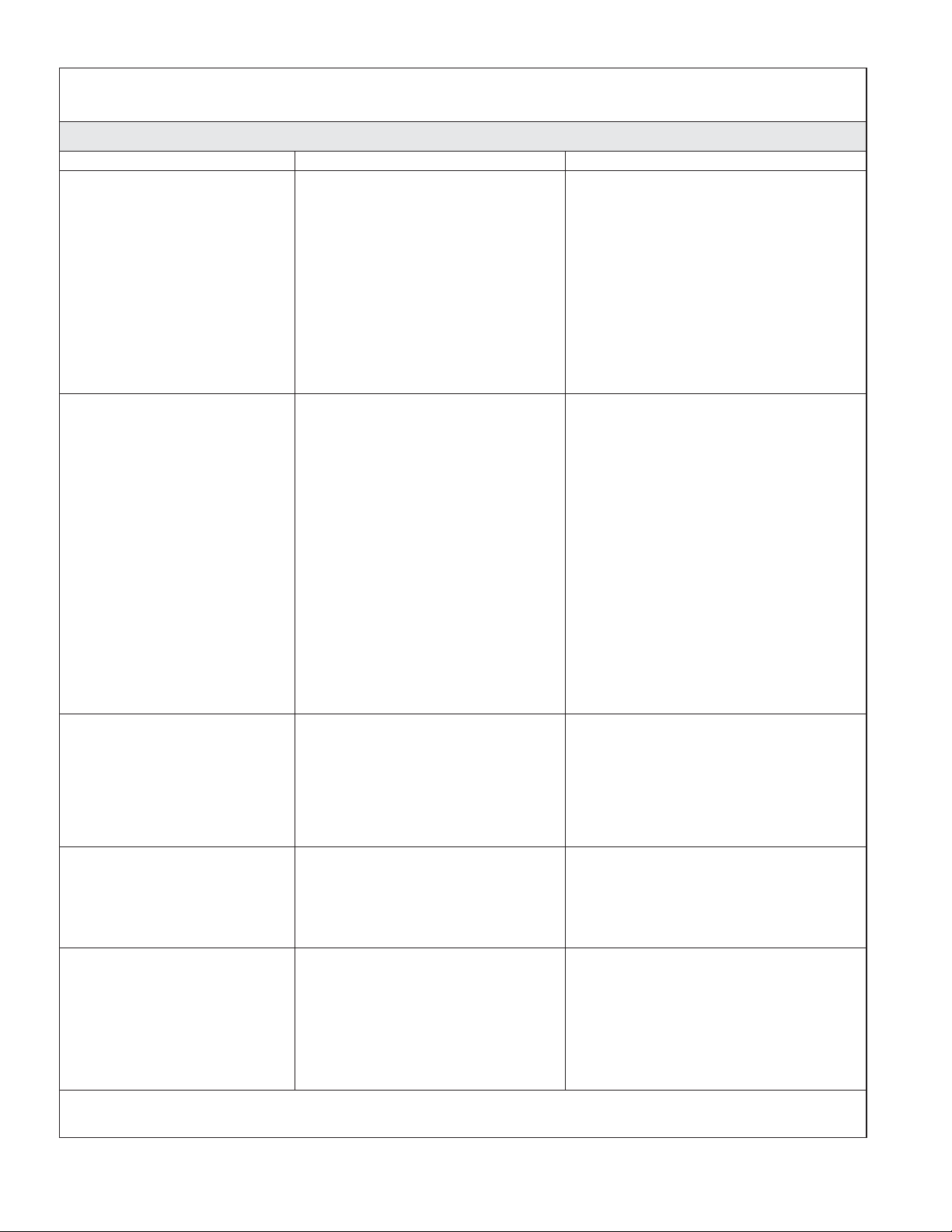

AC Power

Router

Interface

(Up to Three)

Component Cable

Connections

Controller

Digital

Valve

25' (7.6 m)

Data Cable

Digital

Valve

AC Power

Water InletsShower Fittings

1. DTV+ System Layout

The K-99695 system controller powers the interface(s) and controls the digital valve(s) and other system

components. The controller is required to configure the valve(s).

NOTICE: If the valve will be used for a bath/shower application, the bath fill supply line must be routed

from the #1 outlet port.

NOTICE: Custom shower configurations may not allow certain features to be enabled. For shower

configuration options, refer to the guide on the K-99695 controller product page at us.kohler.com.

Determine the locations of all required components, including shower fittings.

A data cable is provided to connect the valve to the controller. If the valve is not within 25’ (7.6 m)

of the controller, obtain a longer telephone-style cable or add an extension cable.

When routing piping, make sure that each shower fitting will connect to the appropriate valve

outlet for your configuration.

Before Operating the System for the First Time:

Download and install the latest software for connected components. This may take an hour or more to

complete based on system configuration and internet connection speed. Do not disconnect the power from

any components during software download and installation.

Kohler Co. 5 1240338-2-B

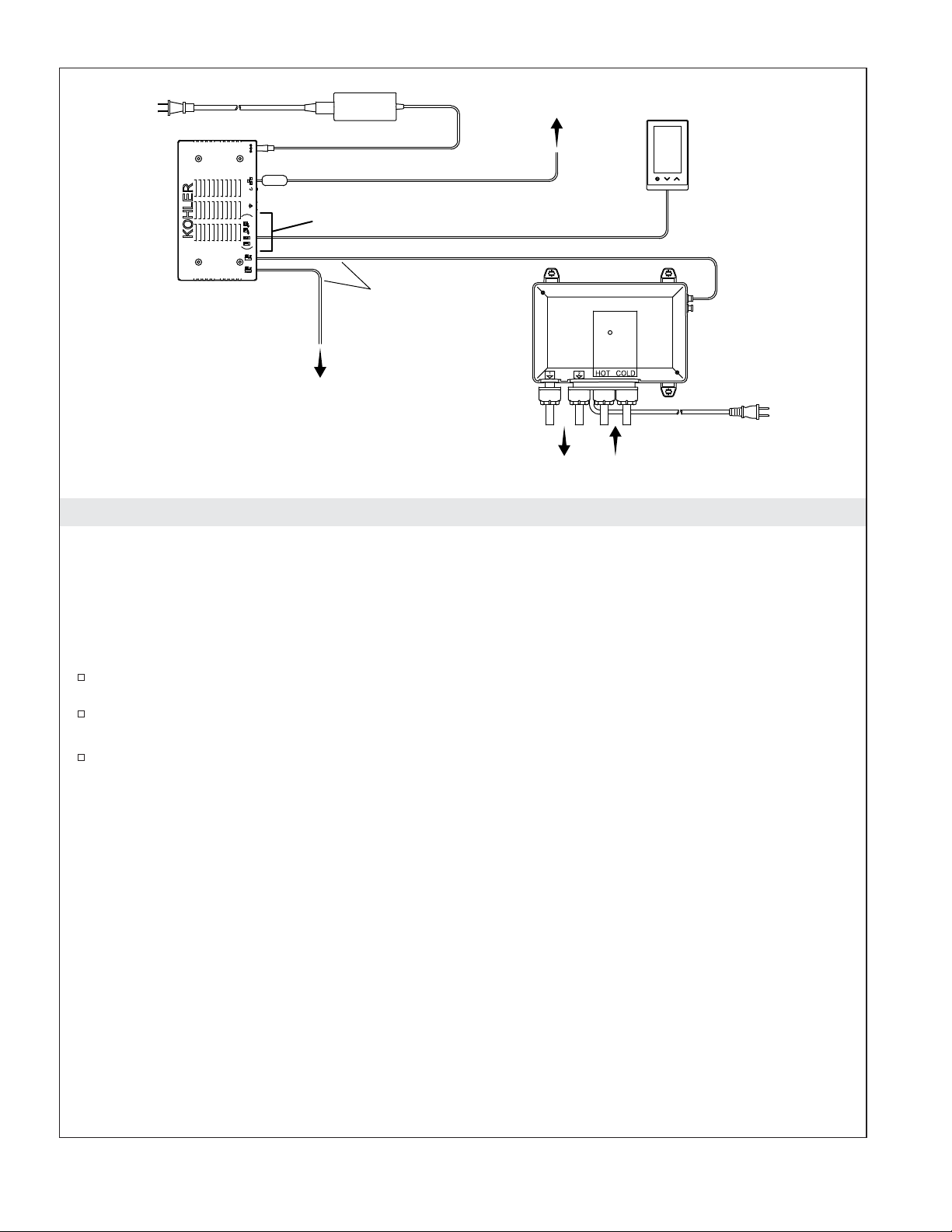

Inlets

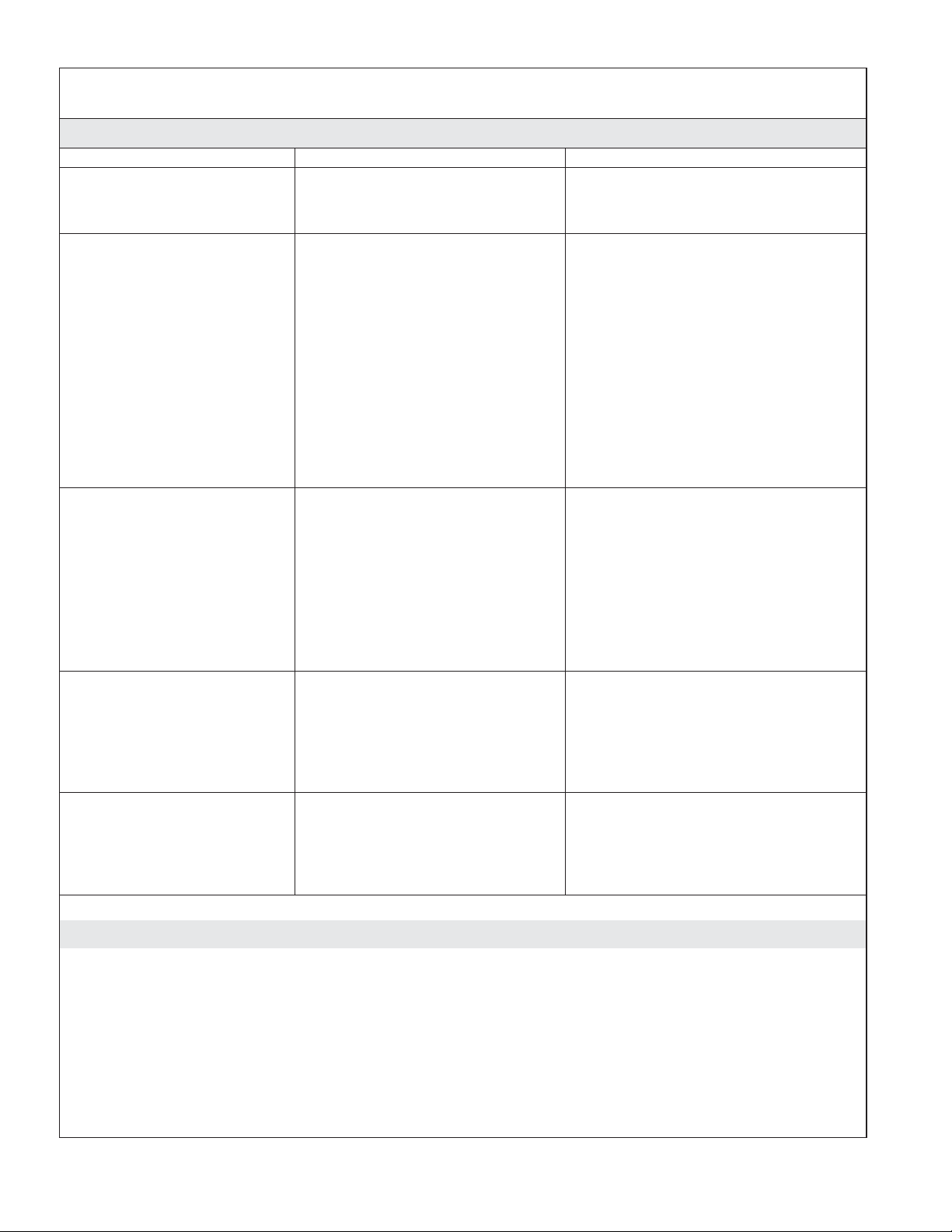

Mounting on a Horizontal SurfaceMounting on a Vertical Surface

Cable

Sockets

Inlets

2. Mounting Configurations

NOTICE: Do not mount the valve with the inlets pointing up or positioned above the outlet ports. Doing

so will damage this product.

The two-port valve is shown above. The same vertical or horizontal mounting configurations apply

for the three-port valve.

1240338-2-B 6 Kohler Co.

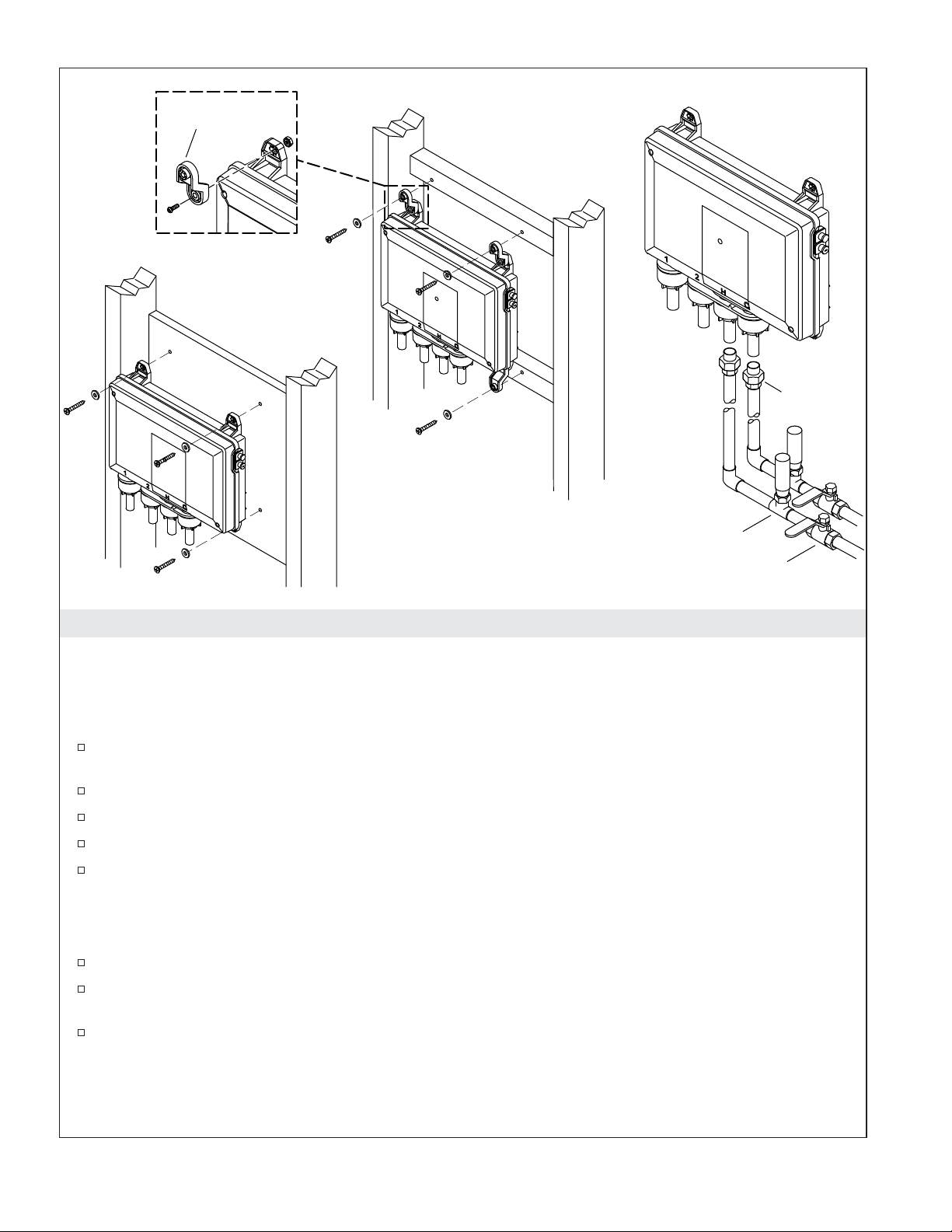

Cross Brace MountBoard Mount

2-3/4"

(70 mm)

Min

Drip Loop

K-528-K1: 14-1/2"

(368 mm) Min

K-557-K1:

18" (457 mm) Min

Place the outlet

higher than

the valve.

9-1/2"

(241 mm)

Notch bottom brace.

K-528-K1:

14-1/2" (368 mm) Min

K-557-K1:

18" (457 mm) Min

11-5/8"

(295 mm)

12-1/2"

(318 mm)

3. Prepare the Site

NOTICE: Do not install the valve under a whirlpool surround or any location where the temperature may

exceed 104°F (40°C).

NOTE: Horizontal installation within a stud cavity is shown. The valve can also be mounted vertically or

mounted to a horizontal surface. Refer to the ″Mounting Configurations″ section.

K-528-K1: This product is designed to fit within a minimum 14-1/2″ (368 mm) 2x4 stud cavity.

K-557-K1: This product will not fit within a standard stud cavity. Construct a minimum 18″ (457

mm) wide 2x4 stud cavity.

Install adequate bracing for mounting the valve. Notch the bracing as needed to accommodate the

inlets and outlets.

Install a 120 V electrical outlet within the stud framing, close to the valve. Locate the outlet above

the valve. A GFCI outlet may be required in some applications.

Kohler Co. 7 1240338-2-B

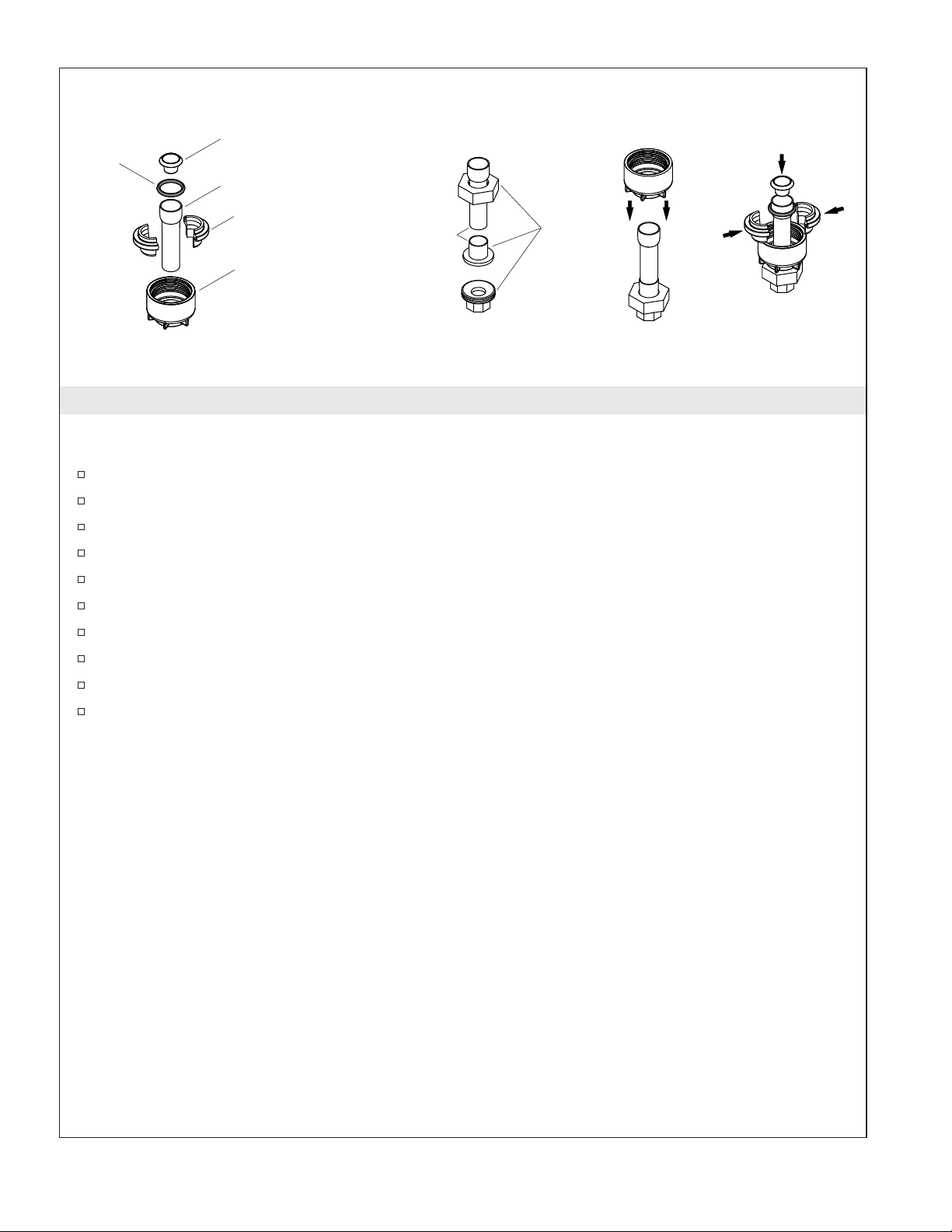

O-Ring

Screen (Inlets Only)

Inlet/Outlet Tube

Adapter Lock

Solder this connection.

Adapter Nut

1/2" Union

4. Assemble the Adapters and Unions

NOTICE: Do not apply excessive heat near the valve or apply flux or acids directly onto the valve. This

valve contains plastic and rubber components that will melt if heat is directly applied.

Disassemble the adapter. Ensure that all rubber and plastic components are removed.

Slide the union nut onto the inlet/outlet tube.

Solder the inlet/outlet tube to the union. Allow to cool completely.

Assemble the union.

Slide the adapter nut onto the inlet/outlet tube.

Assemble the adapter lock onto the inlet/outet tube and slide the assembly into the adapter nut.

Slide the O-ring onto the inlet/outlet tube.

For inlet tubes only: Insert the screen into the end of the inlet tube.

Reinstall the adapter assembly to the valve.

Repeat for all inlet/outlet tubes as required.

1240338-2-B 8 Kohler Co.

Offset Foot

Board Mount

Cross Brace Mount

1/2" Union

Water-Hammer Arrestor

Shut-Off Valve

5. Install the Valve

NOTICE: Do not apply excessive heat near the valve or apply flux or acids directly onto the valve. This

valve contains plastic and rubber components that will melt if heat is directly applied.

IMPORTANT! If your water supply has high amounts of particulates, install wye strainers in the supply

lines.

Route the water supply lines. Use unions to install removable pipe segments to the valve inlets to

allow access for periodic cleaning of the inlet screens.

Install shut-off valves and water-hammer arrestors in the supply lines before the valve.

Hold the valve up to the installation location. Verify fit and mark the hole locations.

Predrill the holes.

Secure the valve with the washers and screws. Do not overtighten.

IMPORTANT! Make sure that each shower fitting is connected to the appropriate valve outlet for your

shower configuration. For shower configuration options, refer to the guide on the K-99695 controller

product page at us.kohler.com.

Route the piping from the valve outlets to the appropriate shower fitting.

Connect the hot and cold supply lines to the appropriate valve inlets. Hot is red and marked with

″HOT,″ cold is blue and marked with ″COLD.″

Secure all piping to the framing.

Kohler Co. 9 1240338-2-B

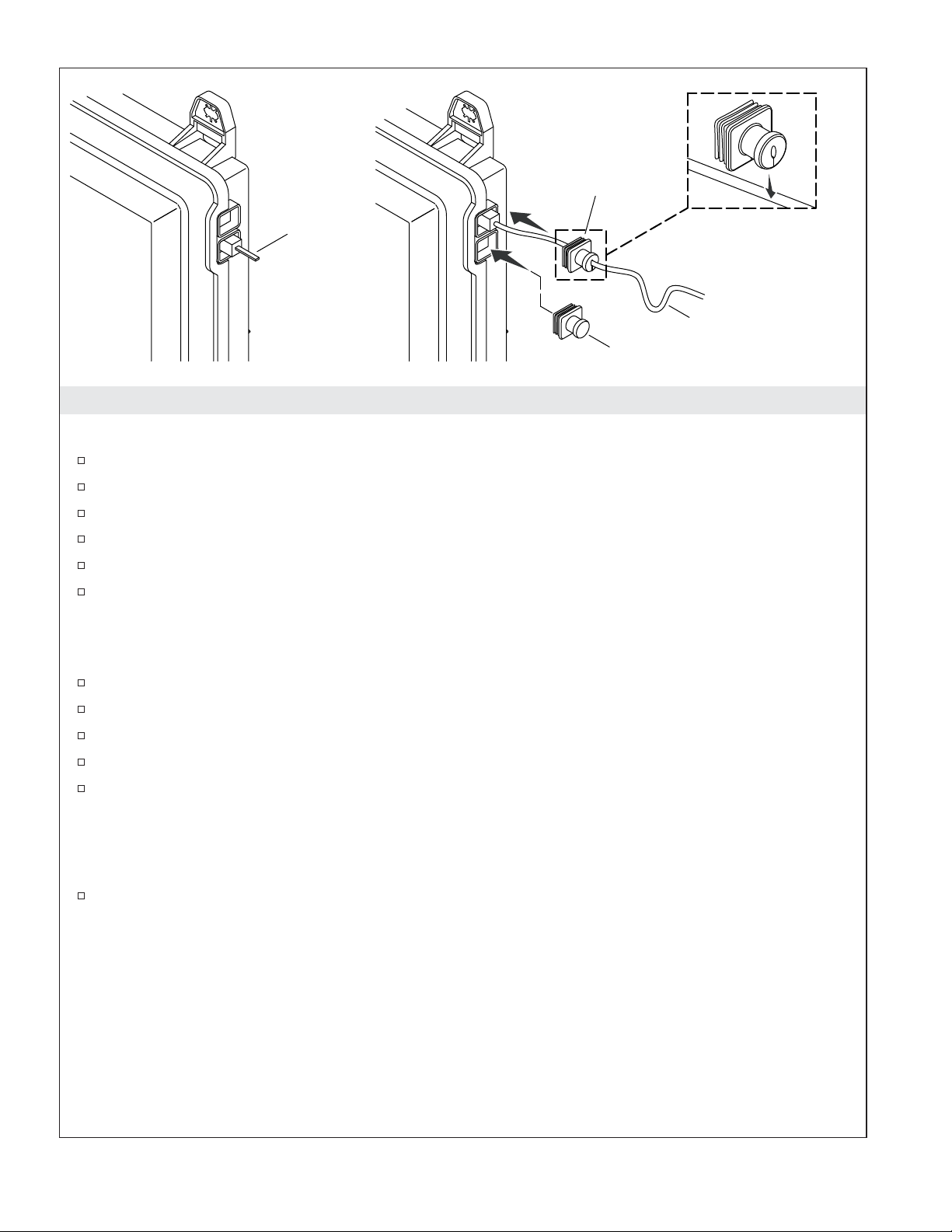

Split

Boot

Jumper

Slide the split boot

onto the cable.

Drip Loop

Solid Boot

6. Installation Checkout

Test for Leaks

Turn on the water supply to the valve.

Connect the jumper to the valve.

Verify that there is power to the 120 V electrical outlet, then plug the power cord into the outlet.

Wait 10 seconds for the valve to initialize; the outlets will activate.

Check all connections for leaks.

Disconnect the power, then remove the jumper.

Connect the Cables

NOTE: Make drip loops in all cables and cords.

Install the K-99695 system controller according to the instructions packed with the product.

Route the data cable in the wall between the controller and valve installation location.

Attach a split boot to the data cable, toward the end that will connect to the valve.

Connect the cable to the valve. Press the boot over the connection in the valve socket.

Insert a solid boot into the unused socket.

Configure the Valve (Requires an Installed Controller)

NOTE: Valves that have been recently installed, or have not been used for some time should be exercised

before running tests or setting the maximum temperature.

To configure valve setup, refer to the guide on the K-99695 controller product page at us.kohler.com.

Before Operating the System for the First Time:

Download and install the latest software for connected components. This may take an hour or more to

complete based on system configuration and internet connection speed. Do not disconnect the power from

any components during software download and installation.

1240338-2-B 10 Kohler Co.

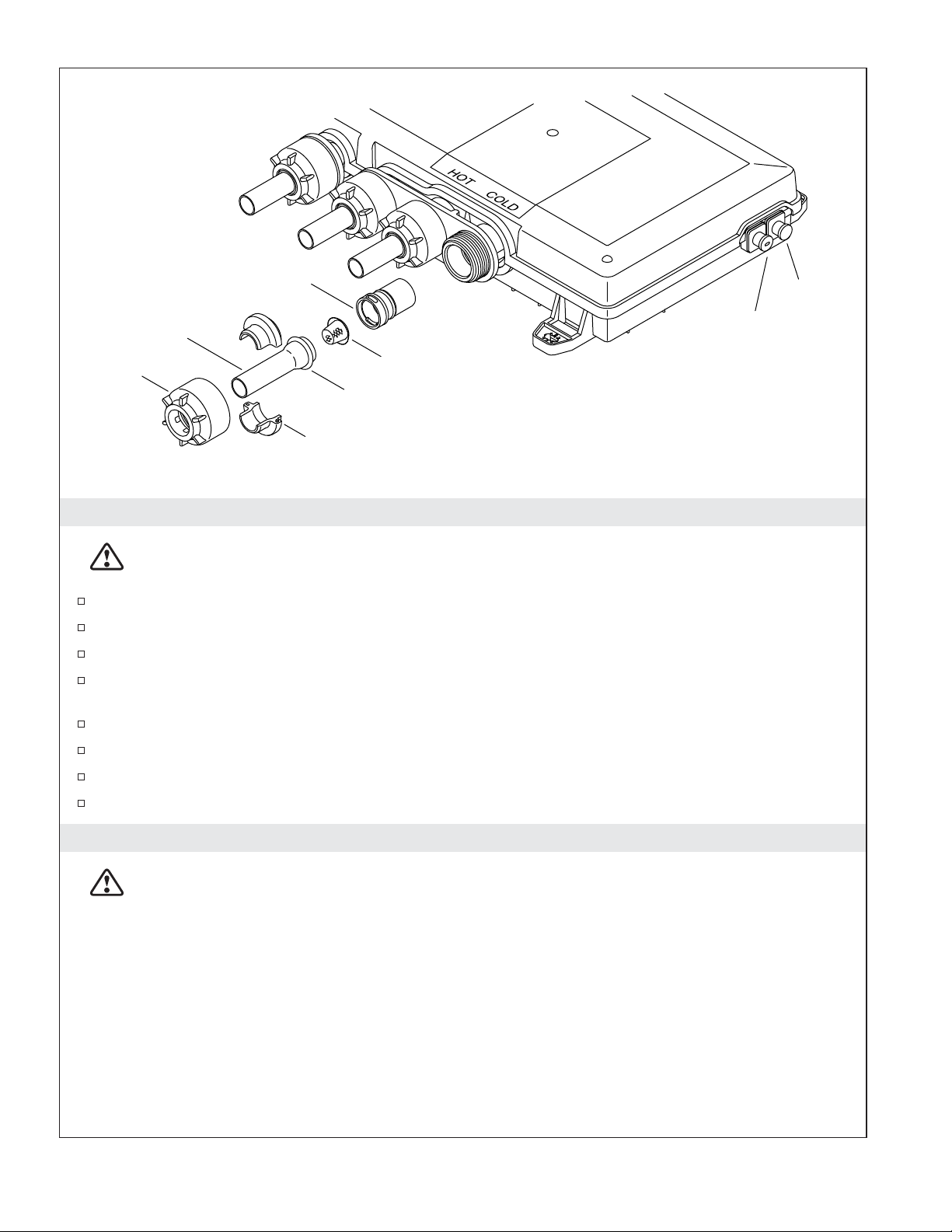

Check Valve

Boot

Copper Tube

Nut

Screen

O-Ring

Seal

Split

Boot

7. Clean the Inlet Screens

CAUTION: Risk of personal injury. The valve may contain hot water; be careful when draining

any residual water.

Disconnect the power and turn off the water supply.

Unthread the plastic nuts from the hot and cold inlets.

Remove the copper tubes. The O-ring and screen may be attached to the end of the tube.

If the screen remains in the check valve, use a small flat-blade screwdriver to gently pull the check

valve from the valve inlet.

Remove the screens from the copper tubes or check valves.

Clean the screens to remove any dirt or debris.

Rinse or replace the check valves and screens.

Reassemble the inlet connections.

Troubleshooting

WARNING: Risk of electric shock. Disconnect power before servicing.

NOTICE: Valve maintenance should be performed by a KOHLER Authorized Service Representative

(ASR).

NOTE: For DTV+ system troubleshooting, refer to the guide on the K-99695 controller product page at

us.kohler.com.

NOTE: For service parts information, visit your product page at kohler.com/serviceparts.

This troubleshooting guide is for general aid only. For service and installation issues or concerns, call

1-800-4KOHLER.

Kohler Co. 11 1240338-2-B

Troubleshooting (cont.)

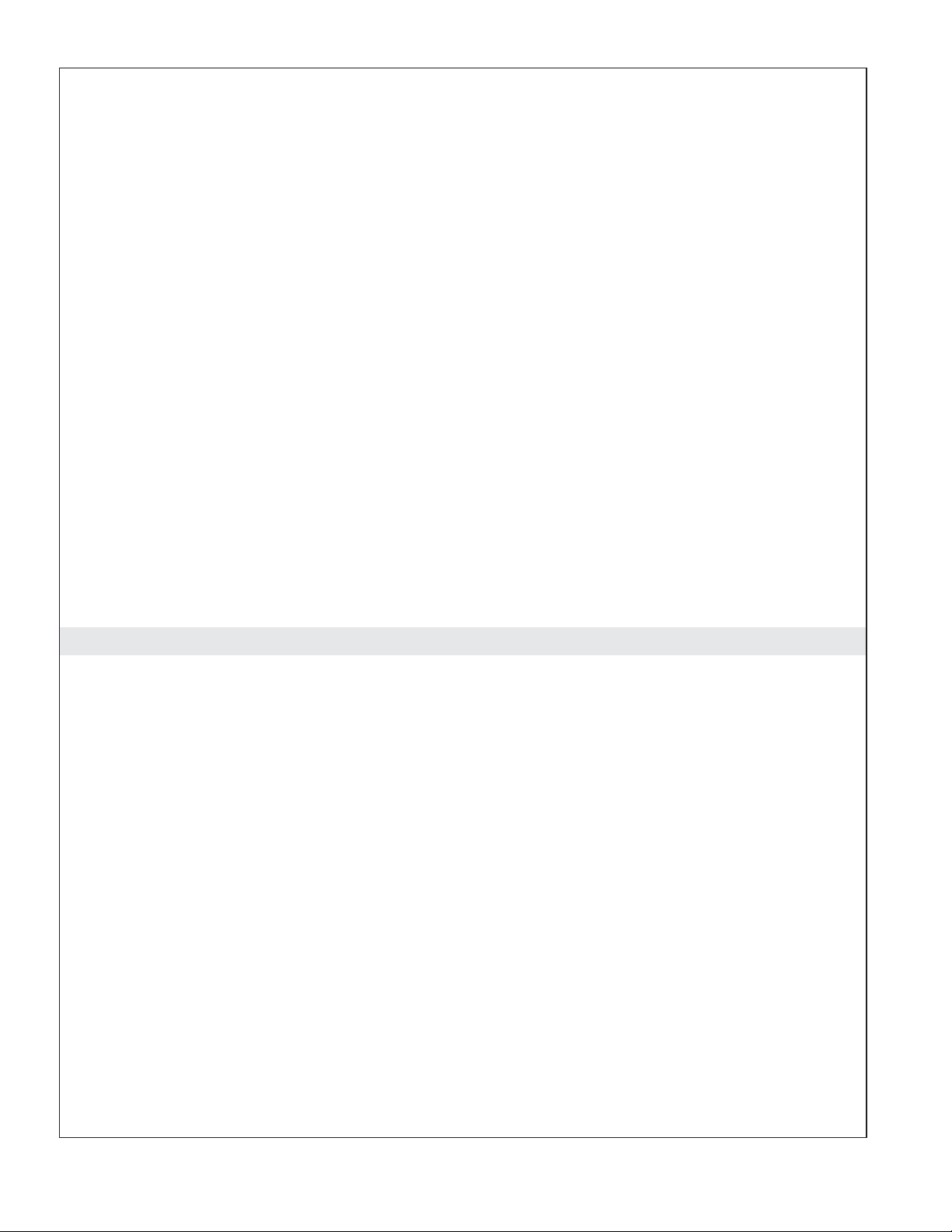

Troubleshooting Table

Symptoms Probable Cause Recommended Action

1. Valve will not turn on. A. Valve is not plugged into the

2. The interface functions

normally but no water

flows from the shower

fittings.

3. Maximum blend

temperature too hot or

too cold.

4. Continuous flow. A. System will not switch off. A. Turn off the water and power

5. Only cold water flows

from the outlets.

outlet.

B. Data cable connection may be

loose or disconnected.

C. Circuit breaker has been

tripped.

D. The valve memory may require

resetting.

E. If none of the recommended

actions for the above issues

correct the symptom, the valve

or interface requires servicing.

A. Valve outlets may be blocked. A. Check the valve outlets for

B. Fittings/sprayfaces may be

blocked.

C. Hot and cold water supplies are

not turned on.

D. The valve memory may require

resetting.

E. System error. E. Check the user interface for an

F. If none of the recommended

actions for the above issues

correct the symptom, the valve

requires servicing.

A. Incorrect maximum temperature

setting.

B. If the above recommended

action does not correct the

symptom, the interface or valve

requires servicing.

B. Flow rate exceeds 10 gal/min

(45.5 l/min) from one outlet.

A. Hot water supply is either not

turned on or not connected to

the valve inlet.

B. Hot water inlet is blocked. B. Check the hot water inlet screen for

C. The hot water supply is

exhausted.

A. Plug the valve into an outlet.

B. Check the data cable connection,

connect if needed.

C. Reset the circuit breaker.

D. Disconnect and reconnect the valve

power cord from the electrical

outlet.

E. Contact your Kohler Co.

Authorized Service Representative

(ASR).

blockage or debris. Clean the outlet

screens.

B. Clean the sprayfaces and any

screens in your fittings.

C. Turn on the water supply to the

valve.

D. Disconnect and reconnect the valve

power cord from the electrical

outlet.

error code. Refer to the guide on

the K-99695 controller product page

at us.kohler.com.

F. Contact your Kohler Co.

Authorized Service Representative

(ASR).

A. Set the maximum temperature.

Refer to the guide on the K-99695

controller product page at

us.kohler.com.

B. Contact your Kohler Co.

Authorized Service Representative

(ASR).

supply and contact your Kohler Co.

Authorized Service Representative

(ASR).

B. Ensure that flow restrictors are

installed in both outlets.

A. Check if the hot water supply is

turned on and connected to the

valve inlet.

blockage. Clean or replace the inlet

screen.

C. Allow time for the water heater to

come up to temperature.

1240338-2-B 12 Kohler Co.

Troubleshooting (cont.)

Troubleshooting Table

Symptoms Probable Cause Recommended Action

6. Fluctuating or reduced

flow rate. Valve is

functioning properly.

7. Blend temperature drift or

temperature cycling.

8. Water leaking from the

valve.

CAUTION: Risk of

personal injury or

product damage. Turn off

the main power and

water supply.

9. Hot water only, the valve

shuts down.

D. If none of the recommended

actions for the above issues

correct the symptom, the valve

requires servicing.

A. Valve inlets may be blocked. A. Check the valve inlets for blockage

B. Fittings/Sprayfaces may be

blocked.

C. Water outlet pressure is low. C. Check that the flow rate is at or

D. Fluctuating supply pressure. D. Verify that the dynamic inlet

E. Water supply temperatures are

not within the recommended

range.

A. Fluctuating water supply

temperature.

B. Pressure difference greater than

5 psi (34.5 kPa) between the hot

and cold supply lines.

C. If none of the recommended

actions for the above issues

correct the symptom, the valve

requires servicing.

A. Connections are not secure. A. Check all connections. Make

B. Seals are worn or damaged. B. Order a seal service pack and

C. Internal leak. C. Unit requires overhaul. Contact

A. Hot and cold lines are reversed. A.

D. Contact your Kohler Co.

Authorized Service Representative

(ASR).

or debris. Clean the inlet screens.

Refer to the ″Clean the Inlet

Screens″ section.

B. Clean the sprayfaces and any

screens in your fittings.

above the minimum rate required.

Refer to ″Specifications″ section.

pressures are within specifications.

Refer to ″Specifications″ section.

E. Check if inlet water temperatures

are within the recommended range.

A. Check the inlet temperature

differentials and verify that they

are sufficient. Refer to

″Specifications″ section.

B. Install pressure regulators to bring

the supplies within 5 psi (34.5 kPa)

of each other.

C. Contact your Kohler Co.

Authorized Service Representative

(ASR).

adjustments as needed.

replace all seals.

your Kohler Co. Authorized Service

Representative (ASR).

Switch hot and cold water supply

connections. Verify that the hot

water supply is connected to the

″Hot″ inlet and the cold water

supply is connected to the ″Cold″

inlet.

FCC, IC, and CE Compliance

Contains: Kohler Company, Model: K-528-PM-NA, FCC ID: SH6MDBT40, IC: 8017A-MDBT40

FCC Interference Statement

This device complies with Part 15 of the FCC Rules. Operation is subject to the following two conditions:

1. This device may not cause harmful interference, and

2. This device must accept any interference received, including interference that may cause undesired

operation.

Kohler Co. 13 1240338-2-B

FCC, IC, and CE Compliance (cont.)

Changes or modifications not expressly approved by the party responsible for compliance could void the

user’s authority to operate the equipment.

This equipment has been tested and found to comply with the limits for a Class B digital device, pursuant to

Part 15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful

interference in a residential installation. This equipment generates, uses, and can radiate radio frequency

energy and, if not installed and used in accordance with the instructions, may cause harmful interference to

radio communications. However, there is no guarantee that interference will not occur in a particular

installation. If this equipment does cause harmful interference to radio or television reception, which can be

determined by turning the equipment off and on, the user is encouraged to try to correct the interference by

one or more of the following measures:

•

Reorient or relocate the receiving antenna.

•

Increase the separation between the equipment and receiver.

•

Connect the equipment into an outlet on a circuit different from that to which the receiver is

connected.

•

Consult the dealer or an experienced radio/TV technician for help.

Industry Canada Statement

This device complies with Industry Canada licence-exempt RSS standard(s). Operation is subject to the

following two conditions:

1. This device may not cause interference, and

2. This device must accept any interference, including interference that may cause undesired operation of the

device.

CAN ICES-3(B) /NMB-3(B)

CE2200

Warranty

KOHLER®Electronic Faucets, Valves and Controls

FIVE-YEAR LIMITED WARRANTY

Kohler Co. warrants that its electronic faucets, valves and controls will be free of defects in material and

workmanship during normal residential use for five years from the date the product is installed. This

warranty applies only to electronic faucets, valves and controls installed in the United States of America,

Canada and Mexico (″North America″).

If a defect is found in normal residential use, Kohler Co. will, at its election, repair, provide a replacement

part or product, or make appropriate adjustment where Kohler Co.’s inspection discloses any such defect.

Damage caused by accident, misuse, or abuse is not covered by this warranty. Improper care and cleaning

will void the warranty*. Proof of purchase (original sales receipt) must be provided to Kohler Co. with all

warranty claims. Kohler Co. is not responsible for labor charges, installation, or other incidental or

consequential costs other than those noted above. In no event shall the liability of Kohler Co. exceed the

purchase price of the faucet, valve or control.

If the electronic faucets, valves or controls are used commercially or are installed outside of North America,

Kohler Co. warrants that the faucet, valve or control will be free from defects in material and workmanship

for one (1) year from the date the product is installed, with all other terms of this warranty applying except

duration.

If you believe that you have a warranty claim, contact your Home Center, Dealer, Plumbing Contractor or

E-tailer. Please be sure to provide all pertinent information regarding your claim, including a complete

description of the problem, the product, model number, the date the product was purchased, from whom the

product was purchased and the installation date. Also include your original invoice. For other information,

or to obtain the name and address of the service and repair facility nearest you, write Kohler Co., Attn:

Customer Care Center, Kohler, Wisconsin 53044 USA, or by calling 1-800-4-KOHLER (1-800-456-4537) from

within the USA and Canada, and 001-800-456-4537 from within Mexico, or visit www.kohler.com within the

1240338-2-B 14 Kohler Co.

Warranty (cont.)

USA, www.ca.kohler.com from within Canada, or www.mx.kohler.com in Mexico.

THE FOREGOING WARRANTIES ARE IN LIEU OF ALL OTHER WARRANTIES, EXPRESS OR

IMPLIED, INCLUDING BUT NOT LIMITED TO THE IMPLIED WARRANTIES OF

MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE.

KOHLER CO. AND/OR SELLER DISCLAIM ANY LIABILITY FOR SPECIAL, INCIDENTAL OR

CONSEQUENTIAL DAMAGES. Some states/provinces do not allow limitations on how long an implied

warranty lasts or the exclusion or limitation of such damages, so these limitations and exclusions may not

apply to you. This warranty gives the consumer specific legal rights. You may also have other rights that

vary from state/province to state/province. This warranty is to the original consumer purchaser only, and

excludes product damage due to installation error, product abuse, or product misuse, whether performed

by a contractor, service company, or the consumer.

This is Kohler Co.’s exclusive written warranty.

*Never use cleaners containing abrasive cleansers, ammonia, bleach, acids, waxes, alcohol, solvents or

other products not recommended for chrome. This will void the warranty.

Kohler Co. 15 1240338-2-B

Loading...

Loading...