Page 1

Operation and

Installation Manual

Marine Generator Sets

Models:

3.5CFZ

4CZ

5CFZ

6.5CZ

TP-5695 12/93

Page 2

California Proposition 65

WARNING

Engine exhaust from this product contains

chemicalsknowntotheState of Californiato cause

cancer, birth defects, or other reproductive harm.

Page 3

Table of Contents

SUBJECT PAGE SUBJECT PAGE

Safety Precautions and Instructions i. . . . . . .

Reference Material viii. . . . . . . . . . . . . . . . . . . . . . .

Routine Service Parts x. . . .. . . .. . . .. . . .. . . .. .

Glossary of Abbreviations xi. . . . . . . . . . . . . . . .

Section 1. Specifications 1-1. . . . . . . . . . . . . . . . . .

Introduction 1-1. . . .. . . .. . . .. . . .. . . .. . . .. . . .. . .

Specifications 1-1. . . .. . . .. . . .. . . .. . . .. . . .. . . ..

General Specifications 1-1. . . .. . . .. . . .. . . .. . .

Generator 1-2. . . .. . . .. . . .. . . .. . . .. . . .. . . .. .

Engine 1-3. . . .. . . .. . . .. . . .. . . .. . . .. . . .. . . ..

Accessories 1-5. . . .. . . .. . . .. . . .. . . .. . . .. . . .. .

Service Views 1-6. . . .. . . .. . . .. . . .. . . .. . . .. . . ..

Section 2. Operation 2-1. . . . . . . . . . . . . . . . . . . . . .

Prestart Checks 2-1. . . .. . . .. . . .. . . .. . . .. . . .. . .

Controller 2-2. . . .. . . .. . . .. . . .. . . .. . . .. . . .. . . .

Starting 2-3. . . .. . . .. . . .. . . .. . . .. . . .. . . .. . . .. .

Stopping 2-3. . . .. . . .. . . .. . . .. . . .. . . .. . . .. . . ..

Circuit Protection 2-4. . . .. . . .. . . .. . . .. . . .. . . .. .

Engine Safety Shutdown Switches 2-4. . . .. . . .. . .

Remote Panels (Optional) 2-6.. . . . . . . . . . . . . . . . .

Section 3. Scheduled Maintenance 3-1. . . . . . . . .

Service Schedule 3-2. . . .. . . .. . . .. . . .. . . .. . . .. .

Lubrication System 3-4. . . .. . . .. . . .. . . .. . . .. . . .

Specifications 3-4. . . .. . . .. . . .. . . .. . . .. . . .. . .

Oil Check 3-4.. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Adding Oil 3-5. . . .. . . .. . . .. . . .. . . .. . . .. . . .. .

Oil Change/Oil Filter Change 3-5. . . .. . . .. . . .. .

Fuel System 3-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Specifications 3-6. . . .. . . .. . . .. . . .. . . .. . . .. . .

Fuel Pump Screen 3-7. . . .. . . .. . . .. . . .. . . .. . .

Carburetor/Choke Lubrication 3-8. . . .. . . .. . . ..

Carburetor Adjustments 3-8.. . . . . . . . . . . . . . . . .

Ignition System 3-9. . . .. . . .. . . .. . . .. . . .. . . .. . . .

Ignition System Service 3-9. . . .. . . .. . . .. . . .. .

Spark Plugs 3-9. . . .. . . .. . . .. . . .. . . .. . . .. . . .

Cooling Systems—Closed/Heat Exchanger 3-12. . .

Filling and Checking 3-12. . . .. . . .. . . .. . . .. . . ..

Flushing and Cleaning 3-14. . . .. . . .. . . .. . . .. . .

Anticorrosion Zinc 3-16. . .. . . .. . . .. . . .. . . .. . . .

Pressure Cap 3-17. . . . . . . . . . . . . . . . . . . . . . . . . . .

Siphon Break 3-17.. . . .. . . .. . . .. . . .. . . .. . . .. .

Air Cleaner and Mixing Elbow 3-17. . . .. . . .. . . .. . .

Servicing Air Cleaner 3-17. . . .. . . .. . . .. . . .. . . .

Servicing Mixing Elbow 3-17.. .. . . .. . . .. . . .. . . .

Battery 3-18. . . .. . . .. . . .. . . .. . . .. . . .. . . .. . . .. . .

Cleaning 3-18. . .. . . .. . . .. . . .. . . .. . . .. . . .. . . .

Checking Electrolyte Level 3-18. . . .. . . .. . . .. . . .

Checking Specific Gravity 3-18. . . .. . . .. . . .. . . .

Charging 3-19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Valve Adjustment 3-20. . . .. . . .. . . .. . . .. . . .. . . .. .

Governor 3-22. . . .. . . .. . . .. . . .. . . .. . . .. . . .. . . ..

Lubrication 3-22.. . . .. . . .. . . .. . . .. . . .. . . .. . . .

Governor Adjustment 3-22. . . . . . . . . . . . . . . . . . . .

Wattage Requirements 3-23. . . .. . . .. . . .. . . .. . . ..

Generator Service 3-23. . . .. . . .. . . .. . . .. . . .. . . ..

General 3-23. . .. . . .. . . .. . . .. . . .. . . .. . . .. . . ..

Storage Procedure 3-24. . . .. . . .. . . .. . . .. . . .. . . .

Section 4. Troubleshooting 4-1. . . . . . . . . . . . . . . .

Engine 4-1. . . .. . . .. . . .. . . .. . . .. . . .. . . .. . . .. . .

Electrical System 4-3.. . . . . . . . . . . . . . . . . . . . . . . . .

Generator 4-4. . . .. . . .. . . .. . . .. . . .. . . .. . . .. . . .

Section 5. Wiring Diagrams 5-1.. . . . . . . . . . . . . .

Section 6. Installation 6-1. . . . . . . . . . . . . . . . . . . . .

Introduction 6-1. . . .. . . .. . . .. . . .. . . .. . . .. . . .. . .

Generator Selection and

Wattage Requirements 6-1. . . .. . . .. . . .. . . .. . . ..

Lighting Load 6-1. . . .. . . .. . . .. . . .. . . .. . . .. . .

Motor Loads 6-1. . . .. . . .. . . .. . . .. . . .. . . .. . . .

Appliance Loads 6-2. . . . . . . . . . . . . . . . . . . . . . . .

Kilowatt Derating 6-2. . . . . . . . . . . . . . . . . . . . . . . .

Location 6-4.. .. . . .. . . .. . . .. . . .. . . .. . . .. . . .. . .

General 6-4. . . .. . . .. . . .. . . .. . . .. . . .. . . .. . . .

Space 6-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Mounting 6-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Ventilation 6-4. . . .. . . .. . . .. . . .. . . .. . . .. . . .. . . .

Fuel Systems 6-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fuel Supply 6-5. . . .. . . .. . . .. . . .. . . .. . . .. . . .

Anti-Siphon Provisions 6-6.. .. . . .. . . .. . . .. . . .

Fuel Lines 6-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fuel Pump Lift Capabilities and

Fuel Consumption 6-6. . . .. . . .. . . .. . . .. . . .. . .

Cooling Systems 6-7. . . .. . . .. . . .. . . .. . . .. . . .. .

General 6-7. . . .. . . .. . . .. . . .. . . .. . . .. . . .. . . .

Closed/Heat Exchanger 6-8. . . . . . . . . . . . . . . . . .

Exhaust Systems 6-9. . . . . . . . . . . . . . . . . . . . . . . . . .

General 6-9. . . .. . . .. . . .. . . .. . . .. . . .. . . .. . . .

Above Waterline 6-11. . . . . . . . . . . . . . . . . . . . . . . .

Mid/Below Waterline 6-11.. .. . . .. . . .. . . .. . . .. .

Electrical Systems 6-12. . .. . . .. . . .. . . .. . . .. . . .. .

AC Voltage Connections 6-12. . . . . . . . . . . . . . . . . .

Installation in Steel or Aluminum Vessels 6-12.. .

Battery 6-13. . . .. . . .. . . .. . . .. . . .. . . .. . . .. . . ..

Wiring 6-13. .. . . .. . . .. . . .. . . .. . . .. . . .. . . .. . .

Remote Start Switch Connection 6-14. . . .. . . .. .

Section 7. Installation Drawings 7-1. . . . . . . . . . .

Section 8. Parts Ordering Instructions 8-1. . . . .

Section 9. Operating Hour Service Log 9-1. . . . .

TP-5695 12/93 Table of Contents

Page 4

Safety Precautions and Instructions

A generator set, like any other electro-mechanical

device, can pose potential dangers to life and limb if

improperly maintained or imprudently operated. The

best way to prevent accidents is to be aware of the

potential dangers and to always use good common

sense. In the interest of safety, some general

precautions relating to the operation of a generator set

follow. Keep these in mind. This manual contains

several types of safety precautions which areexplained

below.

DANGER

Dangerisusedtoindicatethepresenceofahazardthat

will cause severe personal injury, death, or substantial

property damage if the warning is ignored.

WARNING

Warning is used to indicate the presence of a hazard

that can cause severe personal injury, death, or

substantial property damage if the warning is ignored.

CAUTION

Cautionis used to indicate thepresence of a hazardthat

will or can cause minor personal injury or property

damage if the warning is ignored.

Safety decals are affixed to the generator set in

prominent places to advise the operator or service

technician of potentially hazardous situations. The

decals are reproduced here to improve operator

recognition and thereby increase decal effectiveness.

Forafurtherexplanation of decal information, reference

theaccompanying safety precautions. Before operating

or servicing the generator set, be sure you understand

the message of these decals. Replacedecals if missing

or damaged.

NOTE

Noteis used to notify people ofinstallation,operation,or

maintenance information that is important but not

hazard-related.

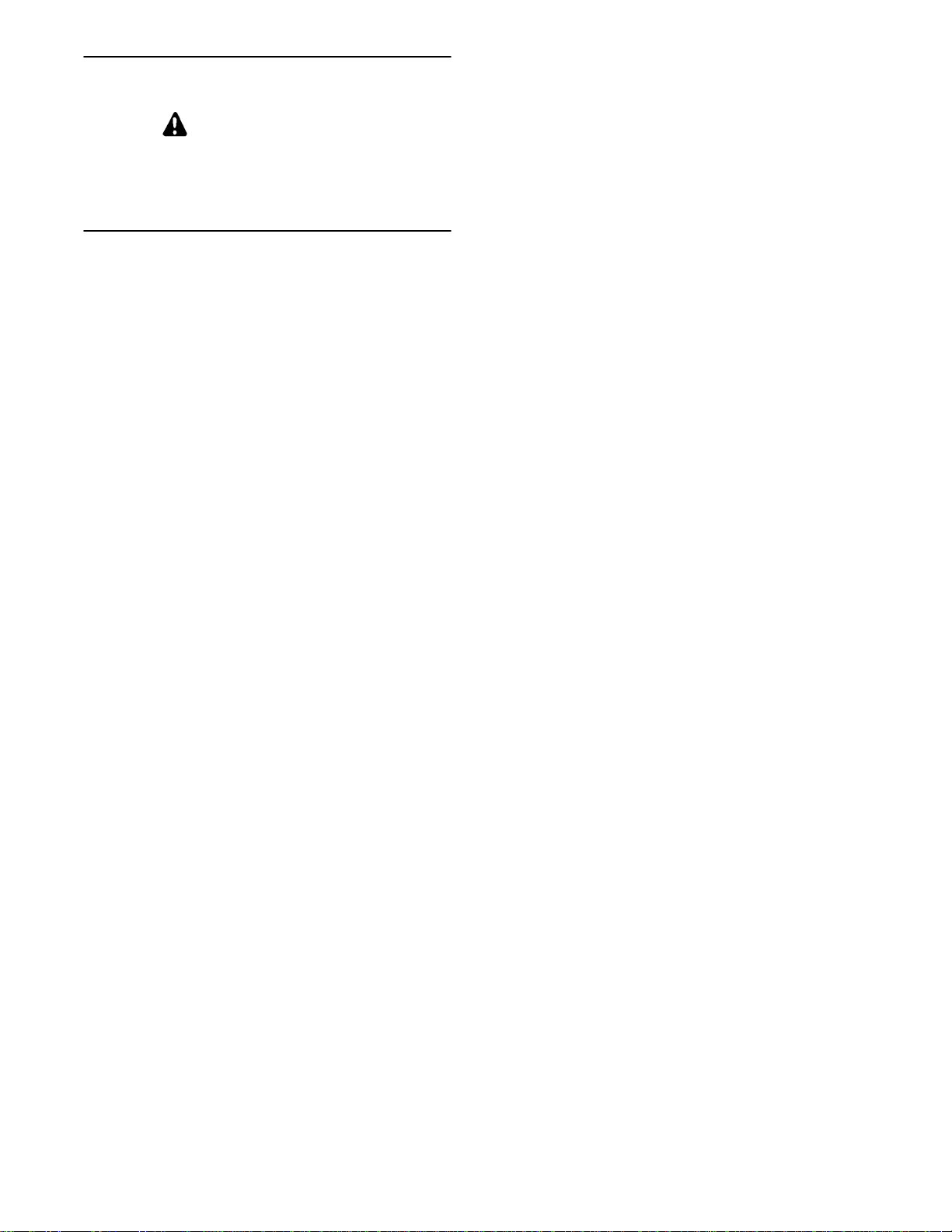

HAZARDOUS VOLTAGE/

ELECTRICAL SHOCK

WARNING

Hazardous voltage.

Can cause severe injury or death.

Do not operate generator set without all guards

and electrical enclosures in place.

Hazardous voltage can cause severe injury or

death. Wherever electricity is present, there is the

hazardof electrocution. Take thesameprecautionswith

electrical appliances in your craft that you would

observe in your home. Open main circuit breaker on all

power sources before servicing equipment. Make sure

unqualified persons, especially children, cannot gain

access to your set—keep thecompartment door locked

orsecurely latched at all times.Besure that generator is

properly grounded. Never touch electrical leads or

appliances with wet hands, when standing in water, or

on wet ground as the chance of electrocution is

especially prevalent under such conditions.

Hazardous voltage can cause severe injury or

death. Use caution when handling the capacitor;

possible electrical shock can result. Discharge

capacitor by shorting terminals together.

Hazardous voltage can cause severe injury or

death. Short circuits can cause bodily injury and/or

equipment damage. Do not contact electrical

connections with tools or jewelry while adjustments are

made. Remove wristwatch, rings, and jewelry that can

cause short circuits.

Hazardous “backfeed” voltage can cause severe

injury or death. Donot connect to anybuilding/marina

electrical system without connecting through an

approved device and afterbuilding mainswitch is open.

Backfeedconnections can causeseriousinjury or death

to utility personnel working to repair a power outage

and/or personnel in the vicinity. Unauthorized

connection may be unlawful in some states and/or

localities. A ship-to-shore transfer switch must be

installed to prevent interconnection of generator set

power and shore power.

Moving rotor.

TP-5695 12/93 Safety Precautions and Instructions i

Page 5

EXHAUST SYSTEM

WARNING

Carbon monoxide.

Can cause severe nausea, fainting, or death.

The exhaust system must be leakproof and

routinely inspected.

Carbon monoxide can cause severe nausea,

fainting, or death. Use the following precautions when

installing and operating generator set. Carbon

monoxide is particularly threatening in that it is an

odorless, colorless, tasteless, nonirritating gas. Be

especially careful if operating the generator when

moored or anchored under calm conditions as gases

may accumulate. If operating the set dockside, moor

yourcraftsothatthe exhaust discharges on the lee side

(the side sheltered from the wind), and always be

mindful of others—make sure your exhaust is directed

away from other boats and occupied buildings. Do not

install exhaust outlet where exhaust can be drawn

through portholes, vents, or air conditioners. If

generator set’s exhaust discharge hole is near to your

craft’swater line, DO NOTOVERLOAD CRAFT so asto

close or restrict exhaust discharge hole.

Carbon monoxide can cause severe nausea,

fainting, or death. In addition to routine inspection of

theexhaust system,acarbon monoxidedetectorshould

be considered. Consult your boat builder or marina for

installation of approved detectors. It is essential that all

detectors be routinely inspected for proper operation.

TP-5695 12/93ii Safety Precautions and Instructions

Page 6

BATTER Y

WARNING

Sulfuric acid in batteries.

Can cause severe injury or death.

Use protective goggles and clothes. Can cause

permanent damage to eyes, burn skin, and eat holes

in clothing.

Sulfuric acid in batteries can cause severe injury or

death. Sulfuric acid in battery can cause permanent

damage to eyes, burn skin, and eat holes in clothing.

Alwayswearsplash-proof safety goggles when working

around the battery. If battery electrolyte is splashed in

the eyes or on skin, immediately flush the affected area

for15 minutes with large quantities of clean water.In the

caseofeyecontact,seek immediate medical aid. Never

addacid toabattery oncethebattery hasbeenplaced in

service. Doing so may result in hazardous spattering of

electrolyte.

Explosion can cause severe injury ordeath. Battery

gases can cause an explosion. Do not smoke or permit

flame or spark to occur near a battery at any time,

particularly when it is being charged. Avoid contacting

terminalswith tools, etc. to prevent burns and toprevent

sparks that could cause an explosion. Remove

wristwatch,rings,andanyotherjewelry before handling

battery. Never connect negative (--) battery cable to

positive (+) connection terminal of starter solenoid. Do

not test battery condition by shorting terminals together

or sparks could ignite battery gases or fuel vapors. Any

compartment containing batteries must be well

ventilated to prevent accumulation of explosive gases.

To avoid sparks, do not disturb battery charger

connections while battery is being charged and always

turn charger off before disconnecting battery

connections. When disconnecting battery, remove

negative lead first and reconnect it last.

TP-5695 12/93 Safety Precautions and Instructions iii

Page 7

FUEL SYSTEM

WARNING

Explosive fuel vapors can cause severe injury or

death. Additional precautions must be taken when

using the following fuels:

Gasoline—Store gasoline only in approved red

containers clearly marked GASOLINE. Do not store

gasoline in any occupied building.

Explosion.

Gasoline vapors can cause explosion and

severe injury or death.

Before starting generator set, operate blower 4

minutes and check engine compartment for

gasoline vapors.

WARNING

Explosive fuel vapors.

Can cause severe injury or death.

Useextreme care when handling, storing,

and using fuels.

Explosive fuel vapors can cause severe injury or

death.Allfuelsarehighlyexplosiveinavapor state.Use

extreme care when handling, storing, and using fuels.

Store fuel in a well-ventilated area away from

spark-producing equipment and out of the reach of

children. Never add fuel to the tank while the engine is

running since spilled fuel may ignite on contact with hot

parts or from ignition spark. Do not smoke or permit

flame or spark to occur near potentialsources of spilled

fuelorfuelvapors.Keepfuellinesand connections tight

and in good condition—don’t replace flexible fuel lines

with rigid lines. Flexible sections are used to avoid

breakage due to vibration. Should any fuel leakage, fuel

accumulation, or electrical sparks be noted, DO NOT

OPERATE GENERATOR SET.Have systems repaired

before resuming generator operation.

Explosive fuel vapors can cause severe injury or

death. Gasoline vapors can explode and can cause

death or severe injury. USCG Regulation 33CFR183

requires all electrical devices (ship-to-shore transfer

switch,remotestartpanel, etc.)to be“ignitionprotected”

whenusedinagasoline(gaseous)-fueledenvironment.

These electrical devices are not “ignition protected” and

are not certified to operate in a gasoline

(gaseous)-fueled environment such as engine room or

near fuel tanks. Acceptable locations would be

wheelhouseor otherliving areasshelteredfrom rainand

water splash.

Explosive fuel vapors can cause severe injury or

death. Spilled fuel can cause an explosion. Use a

container to catch fuel when draining fuel system. Wipe

up all spilled fuel after draining system.

Explosive fuel vapors can cause severe injury or

death. Fuel leakage can cause an explosion. Do not

modify the tank or propulsion engine fuel system. Craft

must be equipped with a tank allowing one of the two

pickup arrangements described. Tank and installation

must conform to U.S.C.G. Regulations.

Explosive fuel vapors can cause severe injury or

death. Fuel leakage can cause an explosion. To

prevent fuel leakage, use pipe sealant on all threaded

fittings. Pipe sealant must be suitable for use in marine

applications having oil and gasoline environments.

TP-5695 12/93iv Safety Precautions and Instructions

Page 8

ACCIDENTAL STARTING

WARNING

Exposed moving parts can cause severe injury or

death. Keep hands, feet, hair, clothing, and test leads

away from belts and pulleys when unit is running.

Replace guards, covers, and screens before operating

generator set.

Accidental starting.

Can cause severe injury or death.

Disconnect battery cables before working on

generator set (negative lead first and reconnect it

last).

Accidental starting can cause severe injury or

death. Disconnect battery cables (remove negative

lead first and reconnect it last) to disable generator set

before working on any equipment connected to

generator. The generator set can be started by remote

start/stop switch unless this precaution is followed.

MOVING PARTS

WARNING

Rotating parts.

Can cause severe injury or death.

HOT PARTS

WARNING

Hot engine and exhaust system.

Can cause severe injury or death.

Donotworkongeneratorsetuntilunitis allowed to

cool.

Hot parts can cause severe injury or death. Do not

touchhot engine parts. Anenginegets hot whilerunning

and exhaust system components get extremely hot.

WARNING

Do not operate generator set without all guards,

screens, or covers in place.

Flying projectiles can cause severe injury or death.

Retorque all crankshaft and rotor hardware after

servicing. When making adjustments or servicing

generator set, do not loosen crankshaft hardware or

rotor thru-bolt. If rotating crankshaft manually, direction

should be clockwise only. Turning crankshaft bolt or

rotor thru-bolt counterclockwise can loosen hardware

and result in serious personal injury from hardware or

pulley flying off engine while unit is running.

Exposed moving parts can cause severe injury or

death. Additional Precautions Regarding Sound Shield

Equipped Models:

Some scheduled maintenance procedures require the

generator set to be running while performing service. If

the sound shield has been removed leaving belts and

pulleys exposed, be especially careful of this area.

Hot coolant and steam.

Can cause severe injury or death.

Before removing pressure cap stop generator,

allow to cool and loosen pressure cap to relieve

pressure.

Hot coolant can cause severe injury or death. Allow

engine to cool and release pressure from cooling

system before opening pressure cap. To release

pressure, cover thepressure cap with a thick cloth then

turn it slowly counterclockwise to the first stop. After

pressure has been completely released and the engine

has cooled, remove cap. If generator set is equipped

witha coolantrecoverytank, checkcoolantlevel at tank.

TP-5695 12/93 Safety Precautions and Instructions v

Page 9

ENGINE BACKFIRE/FLASH FIRE

Asudden backfire cancause severeinjury or death.

Do not operate with air cleaner/silencer removed.

WARNING

Fire.

Can cause severe injury or death.

Do not smoke or permit flame or spark to occur

near fuel or fuel system.

A flash fire can cause severe injury or death. Donot

smokeor permitflameor sparktooccur nearcarburetor,

fuel line, fuel filter,fuel pump, or other potential sources

of spilled fuel orfuel vapors. When removing fuel line or

carburetor, use a proper container to catch all fuel.

A suddenbackfire can cause severe injury or death.

Do not operate with backfire flame arrestor removed.

Asudden flashfire cancause severeinjury ordeath.

Donot smokeorpermit flameorspark tooccur nearfuel

system.Keepthecompartmentandgeneratorsetclean

and free of debris to minimize chances of fire. Wipe up

all spilled fuel and engine oil.

HAZARDOUS NOISE

CAUTION

Hazardous noise.

Can cause loss of hearing.

Never operate generator without a muffler or with

faulty exhaust system.

TP-5695 12/93vi Safety Precautions and Instructions

Page 10

NOTES

NOTE

NOTICE

HARDWARE DAMAGE! Engine and generator may

make use of both American Standard and metric

hardware. Be sure to use the correct size tools to

prevent rounding of bolt heads and nuts.

NOTE

Special attention should be given when checking for

propercoolant level. After the coolanthas been drained,

it normally requires some time before complete refill of

the engine water jacket takes place.

NOTE

When replacing hardware, do not substitute with

inferior grade hardware. Screws and nuts are

available in different hardness ratings. American

Standard hardware uses a series of markings and

metric hardware uses a numeric system to indicate

hardness. Check markings on bolt head and nuts for

proper identification.

This generator set has been rewired from its

nameplate voltage to:

246242

NOTICE

This is a positive terminal only.

Do not attach negative lead!

NOTICE

Checkzinc anode every100 hours or 3months.

NOTICE

NOTE

When a fuse replacement is required, be sure fuse has

the same ampere rating and is the same type (for

example: ABC or 3AB, ceramic). Do not substitute

“clear” glass-type fuses for ceramic fuses. If ampere

rating is unknown orquestionable, see Wiring Diagram.

NOTE

High-mineral content sea water (salt water) can cause

rapid destruction of all metals. Wipe up all salt water

spillage on and around generator set and keep metal

surfaces free from accumulated salt deposits.

Do not use as a step.

Standing on genset could impair operation of unit.

NOTE

Split lock washers may be supplied with some kits. If

split lock washers are supplied with kit, their use is

optional.

TP-5695 12/93 Safety Precautions and Instructions vii

Page 11

Reference Material

It is recommended that the following Regulations and

Standards be followed when installing Marine

Generator Sets.

Pleasure Craft

Designed and manufactured to meet U.S. Coast Guard

Title 33.

U.S. Coast Guard Code of Federal Regulations

Title 33

Subparts I--Electrical Systems

Subparts J--Fuel Systems

Title 46

Subchapter F--Marine Engineering

Part 58--Main and Auxiliary Machinery and Related

Systems

Order the above publications from:

Superintendent of Documents

U.S. Government Printing Office

Washington, DC 20402

1-202-783-3238

Boating Safety Circular Commandant (G-BC)

Boating Statistics (G-BP-1)

U.S. Coast Guard Headquarters

2100 Second Street, S.W.

Washington, DC 20593-0001

Boating Safety Hotline: 1-800-368-5647

Lloyds Registry of Shipping

“Rules for Classification of Ships”

17 Battery Place

New York, N.Y. 10004

212-425-8050

Underwriters Laboratories, Inc. (UL)

Publications Stock

333 Pfingsten Road

Northbrook, IL 60062

Marine Department: 1-919-549-1400

NFPA 302

National Fire Protection Association

60 Batterymarch Park

Quincy, MA 02269

Customer Service

Society of Automotive Engineer’s (SAE)

400 Commonwealth Drive

Warrendale, PA 15096

1-412-776-4970

American Boat and Yacht Council, Inc. (ABYC)

3069 Solomon’s Island Rd.

Edgewater, MD 21037

1-410-956-1050

1-410-974-8112

1-410-956-2737 FAX

American Bureau of Shipping

“Rules for Building and Classing Steel Vessels”

45 Eisenhower Drive

Paramus, N.J. 07652

201-368-9100

IEEE 45

The Institute of Electrical and

Electronics Engineer’s Inc.

345 East 47th Street

New York, NY 10017

TP-5695 12/93viii Reference Material

Page 12

Commercial Vessels

In order to use these generator sets for commercial

applicationswhere U.S. Coast GuardTitle46Certificate

is required, additional modifications will be necessary.

U.S. Coast Guard Code of Federal Regulations

Title 46

Subchapter F--Marine Engineering

Part 58--Main and Auxiliary Machinery and Related

Systems

Subchapter J--Electrical Engineering

Part111--ElectricalSystems--GeneralRequirements

Part 112--Emergency Lighting and Power Systems

Subchapter T--Small Passenger Vessels

(Under 100 Gross Tons)

Part 182--Machinery Installation

Part 183--Electrical Installation

Order the above publications from:

Superintendent of Documents

U.S. Government Printing Office

Washington, DC 20402

1-202-783-3238

American Bureau of Shipping (ABS)

65 Broadway

New York, NY 10006

Order ABS publications from:

American Bureau of Shipping

Book Order Section

45 Eisenhower Drive

P.O. Box 910

Paramus, NJ 97653-0910

Lloyd’s Register of Shipping

71 Fenchurch Street

London, EC3M 4BS England

Midwest Office:

Lloyd’s Register of Shipping

100 South York Street, Room 226

Elmhurst, IL 60126

1-312-279-5414

Additional References

The following organizations provide a service which

may be useful to the generator set installer. These

organizations are not regulatory in nature but rather

provide guidelines and assistance. They are listed only

as a source for additional information. No solicitation or

representation is hereby given.

Yacht Corrosion Consultants, Inc.

2970 Seaborg Ave.

Ventura, CA 93003

1-805-644-1886

Ward’s Marine Electric, Inc.

630 S.W. Flagler Ave.

Ft. Lauderdale, FL 33301

1-305-523-2815

1-800-545-9273

1-305-523-1967 FAX

TP-5695 12/93 Reference Material ix

Page 13

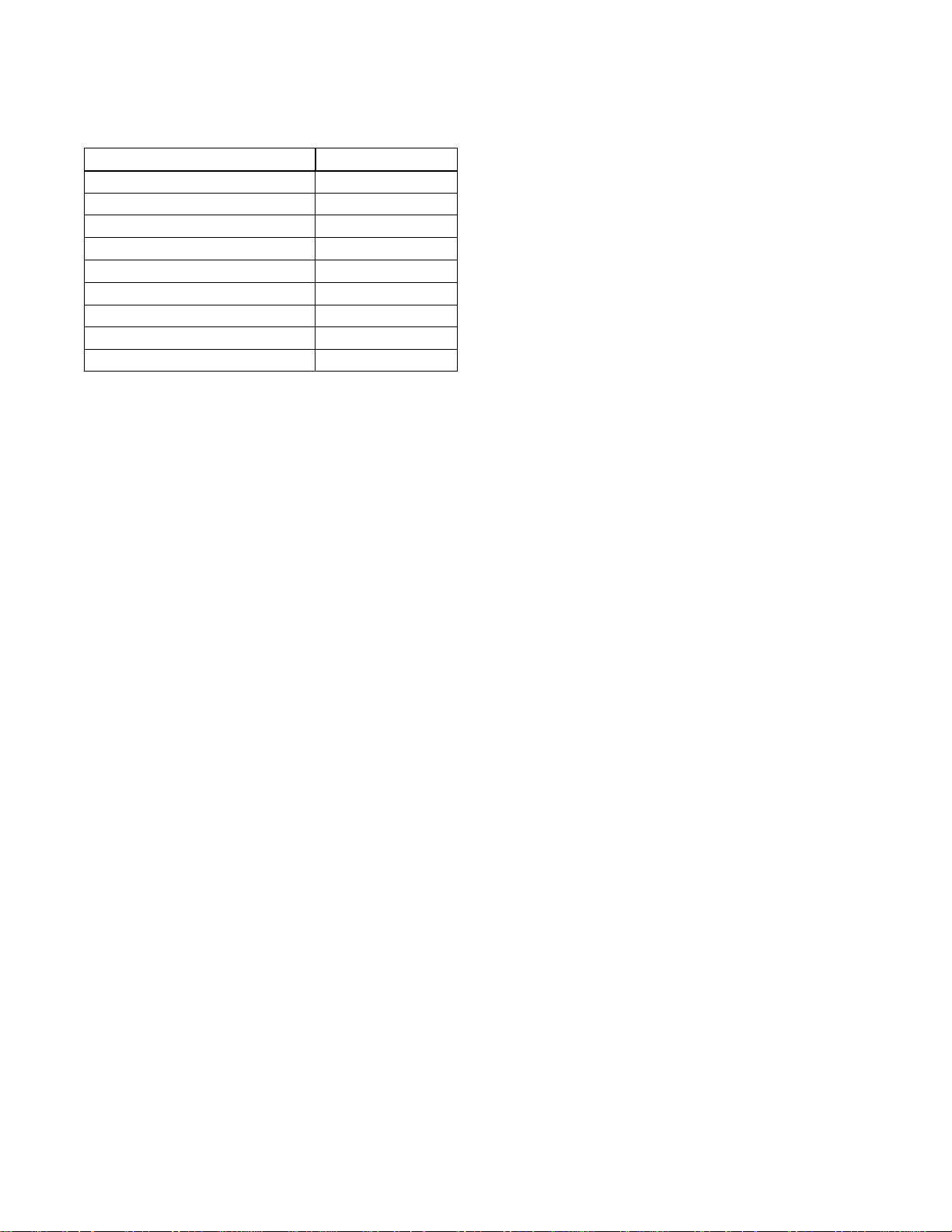

Routine Service Parts

Contact your Kohler generator dealer/distributor for a

complete listing of service parts for your generator set.

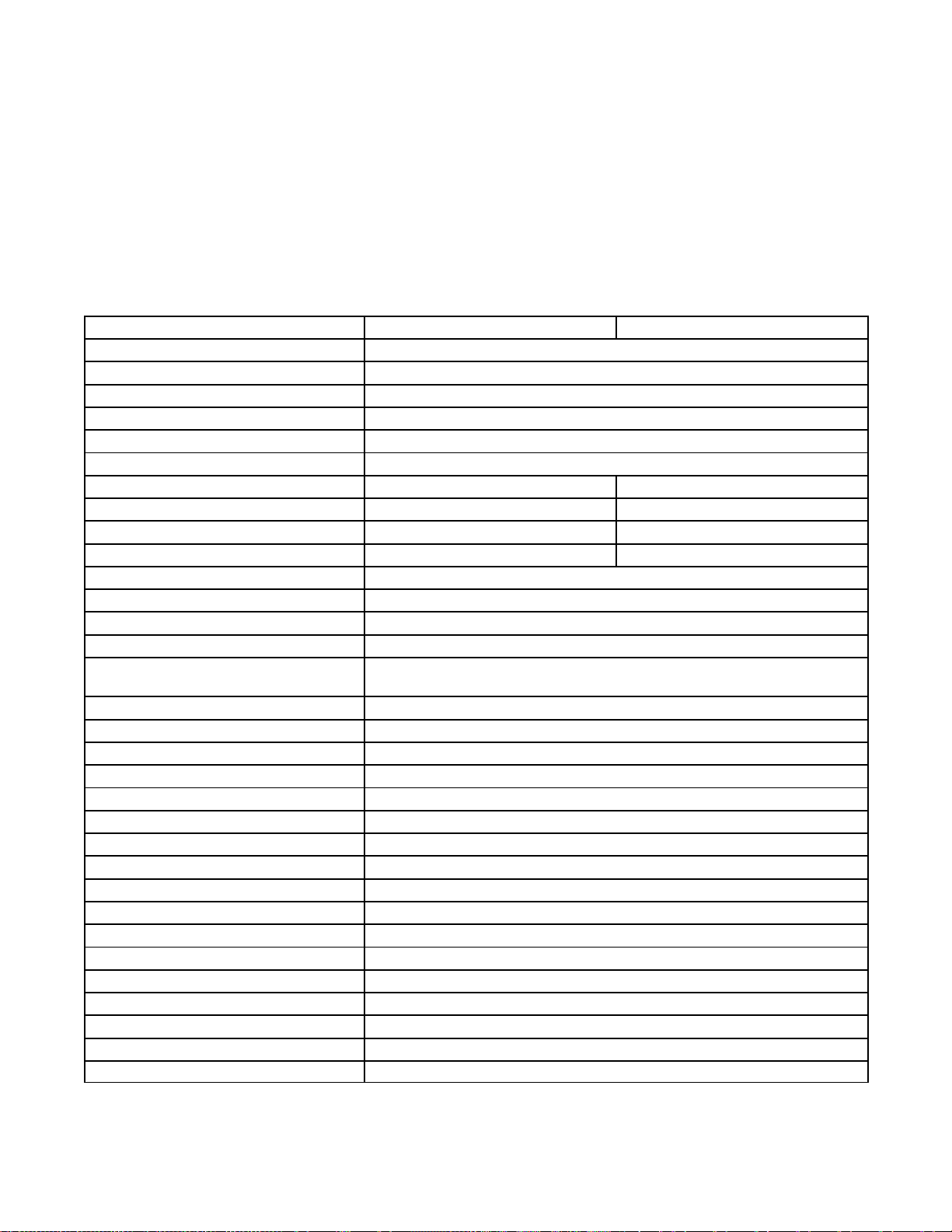

Part Description Kohler Part No.

Engine:

Air Filter 278612

Oil Filter 267714

Belt, Timing 267722

Ignition System:

Spark Plug 267713

Sea Water Pump Impeller 229826

Zinc Anode 267928

White Spray Paint 221318

x Routine Service Parts TP-5695 12/93

Page 14

Glossary of Abbreviations

Abbreviations are used throughout this manual. Normally in the text they will appear in complete form with the

abbreviation following in parenthesis the first time they are used. After that they will appear in the abbreviated form.

The commonly used abbreviations are shown below.

Abbreviation Description

AC alternating current

AHWT anticipatory high water temp.

ALOP anticipatory low oil pressure

AM amplitude modulation

Amp ampere

Amps amperes

ANSI American National Standard Institute

API American Petroleum Institute

approx. approximate, approximately

A/R as required, as requested

A/S as supplied, as stated, as suggested

ASA American Standards Association

assy. assembly

ASTM American Society for Testing Materials

ATDC after top dead center

ATS automatic transfer switch

aux. auxiliary

AWG American Wire Gauge

AWM appliance wiring material

bhp brake horsepower

bmep brake mean effective power

Btu British thermal unit

°C Celsius degree

cc cubic centimeter

CCA cold cranking Amps.

CEC Canadian Electrical Code

cfh cubic feet per hour

cfm cubic feet per minute

CID cubic inch displacement

cm centimeter, centimeters

cmm cubic meters per minute

co. company

cont’d. continued

C.S.A. Canadian Standards Association

cu. in. cubic inch, cubic inches

cyl. cylinder

dBA decibels

DC direct current

DCR direct current resistance

deg. degree

dept. department

dia. diameter

e.g. example given

EMI electromagnetic interference

etc. etcetera, (and so forth)

ext. external

°F Fahrenheit degree

fl. oz. fluid ounce, fluid ounces

Abbreviation Description

FM frequency modulation

fs full scale

ft. foot, feet

ft. lbs. foot pound, foot pounds

ga. gauge

gal., gals. gallon, gallons

gal./hr. gallons per hour

gph gallons per hour

gpm gallons per minute

gr. grade

grd. ground

HCHT high cylinder head temperature

HET high exhaust temperature

Hg mercury (element)

H2O water

hp horsepower

hr, hrs hour

HWT high water temperature

Hz hertz (cycles per second)

ID inside diameter

in. inch(es)

inc. incorporated

in. lbs. inch pounds

int. internal

int.-ext. internal-external

ISO International Standards Organization

J joule, joules

JIS Japanese Industry Standard

kg kilogram, kilograms

2

kg/cm

kgm kilogram meter(s)

km kilometer, kilometers

kPa kiloPascal, kiloPascals

kph kilometers per hour

kV kilovolt

kVA kilovolt amperes

kW kilowatt, kilowatts

kWH kilowatt hour

L liter, liters

LxWxH length x width x height

LED, LEDs light emitting diode

lb., lbs. pound, pounds

L/hr. liter per hour, liters per hour

L/min. liter(s) per minutes

LOP low oil pressure

LP liquefied petroleum

LWT low water temperature

m meter, meters

kilograms per square centimeter

TP-5695 12/93 Glossary of Abbreviations xi

Page 15

Abbreviation Description

3

m

cubic meter, cubic meters

max. maximum

MCM one thousand circular mils.

mi. mile, miles

mil one one-thousandth of an inch

min. minimum

mJ millijoule, millijoules

MJ mega joule, mega joules

mm millimeter, millimeters

m3/min cubic meters per minute

MPa megaPascal

mph miles per hour

MS military standard

mW milliwatt, milliwatts

MW megawatt, megawatts

N/A not available

NEC National Electrical Code

NEMA National Electrical

Manufacturers Association

NFPA National Fire Protection Association

Nm Newton meter, Newton meters

no., nos. number, numbers

NPT National Standard taper pipe

thread per general use

N/R not required

OC overcrank

OD outside diameter

OEM original equipment manufacturer

OS overspeed, oversize

OV overvoltage

oz. ounce, ounces

Abbreviation Description

PF power factor

pot. potentiometer

ppm parts per million

psi pounds per square inch

pt., pts. pint, pints

qt., qts. quart, quarts

qty. quantity

ref. reference

RFI radio frequency interference

rms root mean square

rpm revolutions per inch

SAE Society of Automotive Engineers

sec. second, seconds

SCR silicon controlled rectifier

spec, specs specification

sq. square

sq. cm square centimeters

sq. in. square inch, square inches

tach tachometer

TDC top dead center

temp. temperature

TIF telephone influence factor

turbo turbocharger

UNC Unified coarse thread (was NC)

UNF Unified fine thread (was NF)

UL Underwriter’s Laboratories, Inc.

US undersize

V volt, volts

VAC Volts alternating current

VDC volts direct current

W watt, watts

xii Glossary of Abbreviations TP-5695 12/93

Page 16

Section 1. Specifications

Introduction

The craft is equipped with a dependable 110 volt

(reconnectable to 110/220 volt), 50 Hz; or 120 volt

(reconnectable to 120/240 volt), 60 Hz single-phase

alternating current marine generator set. Service

requirements are minimal but are very important to the

safe and efficient operation of the generator set;

therefore, inspect associated parts often. It is

recommended that an authorized service

dealer/distributor perform required servicing to assure

the unit continues to meet U.S.C.G. requirements.

Please take a few moments to read this manual, then

carefullyfollow all service recommendations tokeepthe

set in top condition. Keep this manual aboard the craft

for future reference. See Figure 1-1 for identification

and location of components.

Specifications

General Specifications

3.5CFZ 5CFZ

Dimensions--L x W x H--in. (mm) 27.87 x 17.50 x 16.60

(708 x 445 x 422)

with Sound Shield 31.07 x 18.10 x 17.50

(789 x 460 x 445)

Weight--(wet), lbs. (kg) 208 (94) 231 (104)

with Sound Shield 231 (104) 231 (104)

Air Requirements--cfm (L/min.) 18 (510) 18 (510)

Fuel Consumption U.S. gal./hr. (L/hr.)

Load

25% 0.42 (1.59) 0.44 (1.67)

50% 0.50 (1.89) 0.54 (2.04)

75% 0.59 (2.23) 0.66 (2.50)

100% 0.68 ( 2.57) 0.80 (3.03)

4CZ 6.5CZ

Dimensions--L x W x H --in. (mm) 27.87 x 17.50 x 16.60

(708 x 445 x 422)

with Sound Shield 31.07 x 18.10 x 17.50

(789 x 460 x 445)

Weight--(wet), lbs. (kg) 190 (86) 231 (104)

with Sound Shield 213 (96) 231 (104)

Air Requirements--cfm (L/min.) 18 (510) 18 (510)

Fuel Consumption U.S. gal./hr. (L/hr.)

Load

25% 0.48 (1.81) 0.53 (2.00)

50% 0.55 (2.08) 0.62 (2.34)

75% 0.62 (2.34) 0.86 (3.25)

100% 0.68 (2.57) 1.02 (3.86)

31.07 x 18.10 x 17.50

(789 x 460 x 445)

31.07 x 18.10 x 17.50

(789 x 460 x 445)

31.07 x 18.10 x 17.50

(789 x 460 x 445)

31.07 x 18.10 x 17.50

(789 x 460 x 445)

TP-5695 12/93 Specifications 1-1

Page 17

Generator

3.5CFZ 5CFZ

Rated kW 3.5 5

Frequency--Hz 50 50

Rated Voltage 110 Volt, 2&3 Wire, Single Phase or 110/220 Volt, 3 Wire, Single Phase

Rated Amps (110 Volt) 31.8 45.5

Rated Amps (220 Volt) 15.9 22.7

Rotor Resistance (cold) (ohms) 4--5 4--5

Stator Resistance (cold) (ohms)*

Leads:

1--2, 3--4 0.8 0.8

55--66 4.2 4.2

B1--B2 0.08 0.08

4CZ 6.5CZ

Rated kW 4 6.5

Frequency--Hz 60 60

Rated Voltage 120 Volt, 2&3 Wire, Single Phase or 120/240 Volt, 3 Wire, Single Phase

Rated Amps (120 Volt) 33.3 54.2

Rated Amps (240 Volt) 16.7 27.1

Rotor Resistance (cold) (ohms) 3--4 4--5

Stator Resistance (cold) (ohms)*

Leads:

1--2, 3--4 0.06 0.04

55--66 1.9 2.4

B1--B2 0.09 0.06

3.5CFZ/4CZ 5CFZ/6.5CZ

Generator Type Two-Pole, Rotating Field

Voltage Regulation ±5%

Frequency Regulation ±5%

Angular Operation (Max.)

(in all directions)

Excitation Method Brushless, Exciter Winding/Capacitor

Coupling Type Tapered Shaft--Thru-Bolt

Stator Bolt Torque in. lbs. (Nm) 260 (29)

Thru-Bolt Torque ft. lbs. (Nm) 37 (50)

Number of Output Leads 4, Reconnectable

Insulation (Rotor and Stator) Class F, Epoxy Varnish, Vacuum Impregnated

Winding Material Copper

Bearing, Number and Type 1, Replaceable Ball

Circuit Protection:

Controller Replaceable 10-Amp Fuse

Battery Charging Replaceable 10-Amp Fuse

AC Circuit Breakers Optional

* Most ohmmeters will not give accurate readings when measuring less than 1 ohm. The stator can be

considered good if a low resistance reading (continuity) is obtained and there is no evidence of shorted

windings (discoloration). Do not confuse a low resistance reading with a reading indicating a shorted winding.

20° Continuous

TP-5695 12/931-2 Specifications

Page 18

DERATING: Allunits are rated 1.0 powerfactor.Derateapproximately 3.5% per 1000 ft.(300 m) above 500ft. (150 m)

above sea level.

3.5CFZ, 50 Hz: 3.5 kW at 77° F (25° C) and 3.5 kW at 122° F (50° C).

4CFZ, 60 Hz: 4 kW at 77° F (25° C) and 3.5 kW at 122° F (50° C).

5CFZ, 50 Hz: 5 kW at 77° F (25° C) and 4.85 kW at 122° F (50° C).

6.5CZ, 60 Hz: 6.5 kW at 77° F (25° C) and 6 kW at 122° F (50° C).

Engine

Some general engine specifications are listed below.Refer to the appropriate service section and the engineservice

manual for specific service details.

3.5CFZ/4CZ 5CFZ/6.5CZ

Manufacturer Honda

Model GX360EV

Cycle 4

Number Cylinders 2

Compression Ratio 8:5:1

Displacement--cu. in. (L) 21.9 (359)

Rated Horsepower--50 Hz 10.7 (3.5CFZ) 10.7 (5CFZ)

--60 Hz 12.8 (4CZ) 12.8 (6.5CZ)

RPM--50 Hz 3000 (3.5CFZ) 3000 (5CFZ)

--60 Hz 3600 (4CZ) 3600 (6.5CZ)

Bore x Stroke--in. (mm) 2.28 x 2.68 (58 x 68)

Valve Material Steel Alloy (JIS SUH3)

Valve Clearance--in. (mm) (cold) 0.004--0.006 (0.10--0.14)

Cylinder Block Material Aluminum

Cylinder Head Cover Tightening

Torque--ft. lbs. (Nm)

Cylinder Head Material Aluminum

Connecting Rod Material Steel

Piston Rings 2 Compression/1 Oil Control

Crankshaft Bearings Replaceable Inserts

Governor Gear-Driven Centrifugal

Lubrication System Pressure

Oil Capacity (with filter)--U.S. qts. (L) 1.48 (1.4)

Oil Type (API) SF, SF/CC, or SF/CD

Oil Pressure--psi (kPa) 30--50 (207--345)

Fuel Type Gasoline, 86 or Higher, Octane Unleaded

Fuel System Single-Barrel, Horizontal Carburetor

Carburetor Choke Automatic, Electric

Fuel Pump Electric

Fuel Pump Lift (max.) 3 ft. (0.9 m)

Battery Voltage 12

Battery Ground Negative

Battery Recommendation 250 Cold Cranking Amps (Min.)

7(10)

TP-5695 12/93 Specifications 1-3

Page 19

Engine (Continued)

3.5CFZ/4CZ 5CFZ/6.5CZ

Spark Plug Type Resistor, Radio Suppression, 14 mm

BPR4HS (NGK)

Kohler Part Number L92YC (Champion)

R43CFS (AC-Delco)

Spark Plug Gap--in. (mm) 0.028--0.031 (0.7--0.8)

Spark Plug Tightening Torque--

ft. lbs. (Nm)

Ignition System Transistorized, Breakerless

Starter Motor Bendix Automotive Type

Cooling System Water-Cooled, Closed/Heat Exchanger

Cooling System Capacity--U.S. qts. (L) 1.10 (1.00)

Coolant Recovery Tank--U.S. qts. (L) 0.38 (0.35)

Thermostat 180 °F (82° C)

Pressure Cap Rating 15 psi (103 kPa)

Engine Firing Order 1--2

Ignition Timing B.T.D.C. 24° ± 2 degrees

Exhaust Manifold to Cylinder

Head Torque

Water Pump Assembly to

Cylinder Block Torque

Cooling Fan Torque 16 ft. lbs. (22 Nm)

Air Cleaner Elbow to Carburetor

Stud Torque

Timing Belt Cover Torque 6 ft. lbs. (8 Nm)

Governor Arm Shaft Nut Torque 7 ft. lbs. (10 Nm)

Governor Case to Cylinder Head

Torque

Fuel Pump Pressure Rating 2.0--3.5 psi (13.8--24.1 kPa)

Battery Charging Winding

Resistance--10 Amp

Ignition Coil Primary Wire

Resistance

Ignition Coil Secondary

(Spark Plug Wire Side) Resistance

Transistorized Ignition Air Gap 0.016 ±0.008 in. (0.4 ±0.2 mm)

Timing Belt Deflection 0.16--0.20 in. (4.5 mm) @ 4.4 lbs. (2 kg)

(With Spark Plug Boot/Cap Removed)

15--22 (20--30)

16 ft. lbs. (22 Nm)

7 ft. lbs. (10 Nm)

6 ft. lbs. (8.5 Nm)

7 ft. lbs. (10 Nm)

0.16--0.24 Ohms

0.9--1.1 Ohms

0.9--1.1 Ohms

TP-5695 12/931-4 Specifications

Page 20

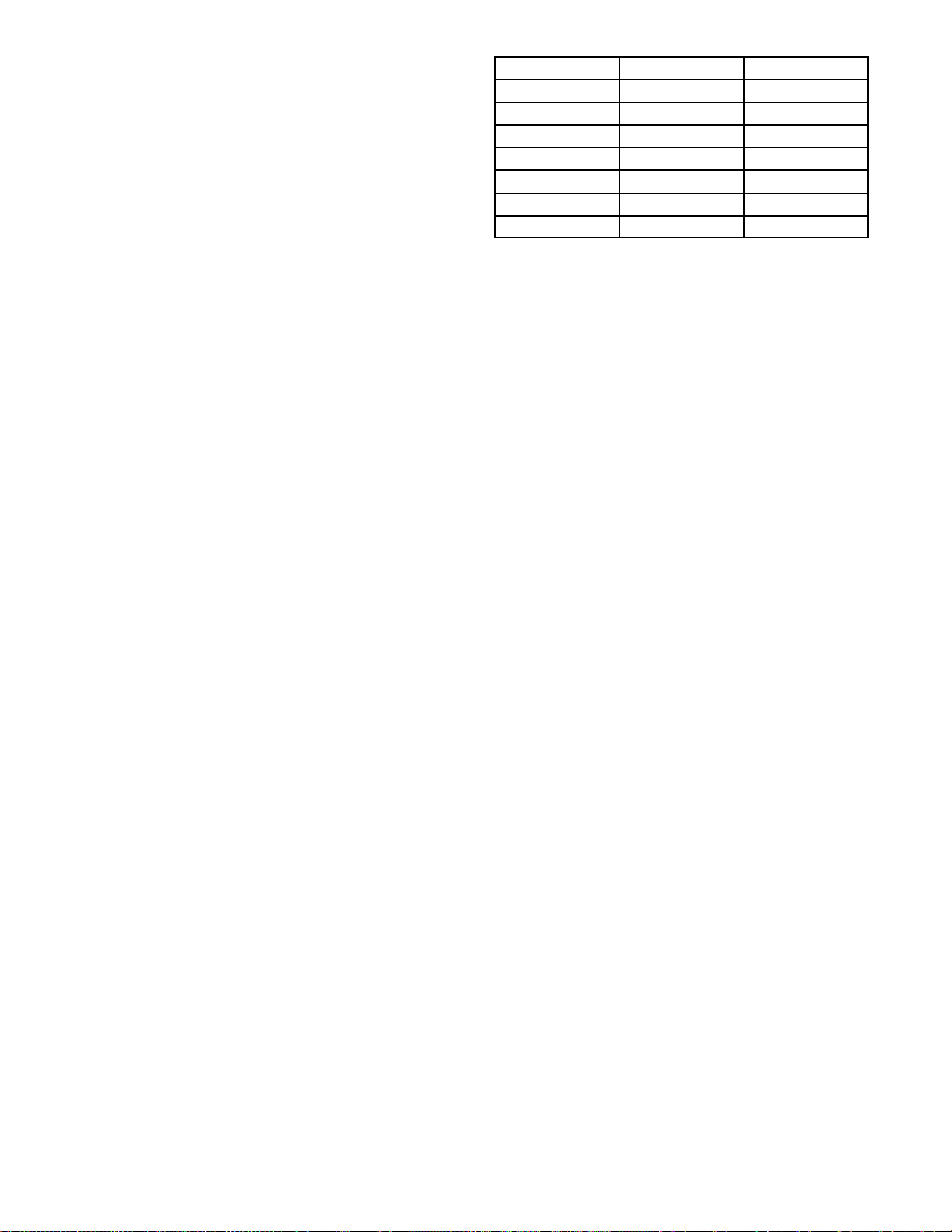

Accessories

Several accessories are available to finalize the

installation or to add convenience to operation and

service.All themost currentinformationcan beobtained

by contacting the local authorized Kohler

dealer/distributor. Available accessories at the time of

print of this publication are as follows.

Model Amps Poles

4CZ/3.5CFZ 18 2

4CZ/3.5CFZ 35 1

4CZ/3.5CFZ 20 1

6CZ/5CFZ 30 2

6CZ/5CFZ 55 1

6CZ/5CFZ 25 2

6CZ/5CFZ 20 1

Sound Shield

(Optional on 3.5CFZ/4CZ;

Standard on 5CFZ/6.5CZ)

Provides for highly effective silencing, ease of access

for engine/generator servicing, low maintenance,

excellent durability, and safety.

Seawater Strainer

The seawater strainer with clear viewing container,

allows easy cleaning and maintenance. Threaded for

1/2 NPT fittings.

Ship-to-Shore Transfer Switch

The ship-to-shore transfer switch allows immediate

switching to generator set power or shore power

protecting the electrical system from the possibility of

simultaneous connection of both power sources.

Remote Start and

Four-Meter Panel Kit

Allows starting/stopping from a location remote of the

generator set. The illuminated meters/gauges include a

DC voltmeter, engine oil pressure gauge, water

temperature gauge, and an hourmeter which records

total generator set operating hours. Overall dimensions

are 9 in. (229 mm) by 6 in. (152 mm) with a minimum

mounting depth of 4 in. (102 mm). Requires remote

connection/extension harness and sender kit.

Remote Start and

Two-Meter Panel Kit

Allows starting/stopping from a location remote of the

generatorset. The illuminated gaugesincludeengine oil

pressure gauge and water temperature gauge. Overall

dimensions are 6 in. (152 mm) by 6 in. (152 mm) with a

minimum mounting depth of 2 3/4 in.(70 mm). Requires

remote connection/extension harness and sender kit.

Remote Connection/

Remote Start Panel

Allows starting/stopping from a location remote of the

generator set. Supplied with 15 foot (4.6 m) connection

harness. Overall mounting dimensions are 4 1/16 in.

(103mm) by 2 1/8 in.(54mm) with a minimum mounting

depth of 2 1/4 in. (57 mm).

Sender Kit

Provides gauge senders for the remote start and

two-meter panel kit andthe remote start andfour-meter

panel kit. The gauge sender kit is required to make the

oil pressure and water temperature gauges functional.

Provides additional wiring between all remote panels

and controller connector. One required for each remote

meter panel kit. Available in 15 ft. (46 m) and 25 ft.

(76 m) lengths. Extension limited to a total of four kits

and 75 ft. (23 m).

12-Inch Remote Wiring Harness

This one foot (0.3 m) wiring harness has a 6-pin

connector on one end which is keyed to controller box

connector. The other end has pigtails for connection to

customer-supplied start switch, generator “on” light,

hourmeter, etc.

Circuit Breakers

See price list or dealer/distributor for proper application

of circuit breakers.

TP-5695 12/93 Specifications 1-5

Prevents the siphoning of water into the engine on

generator sets installed below the waterline.

Extension Harness

Siphon Break

Page 21

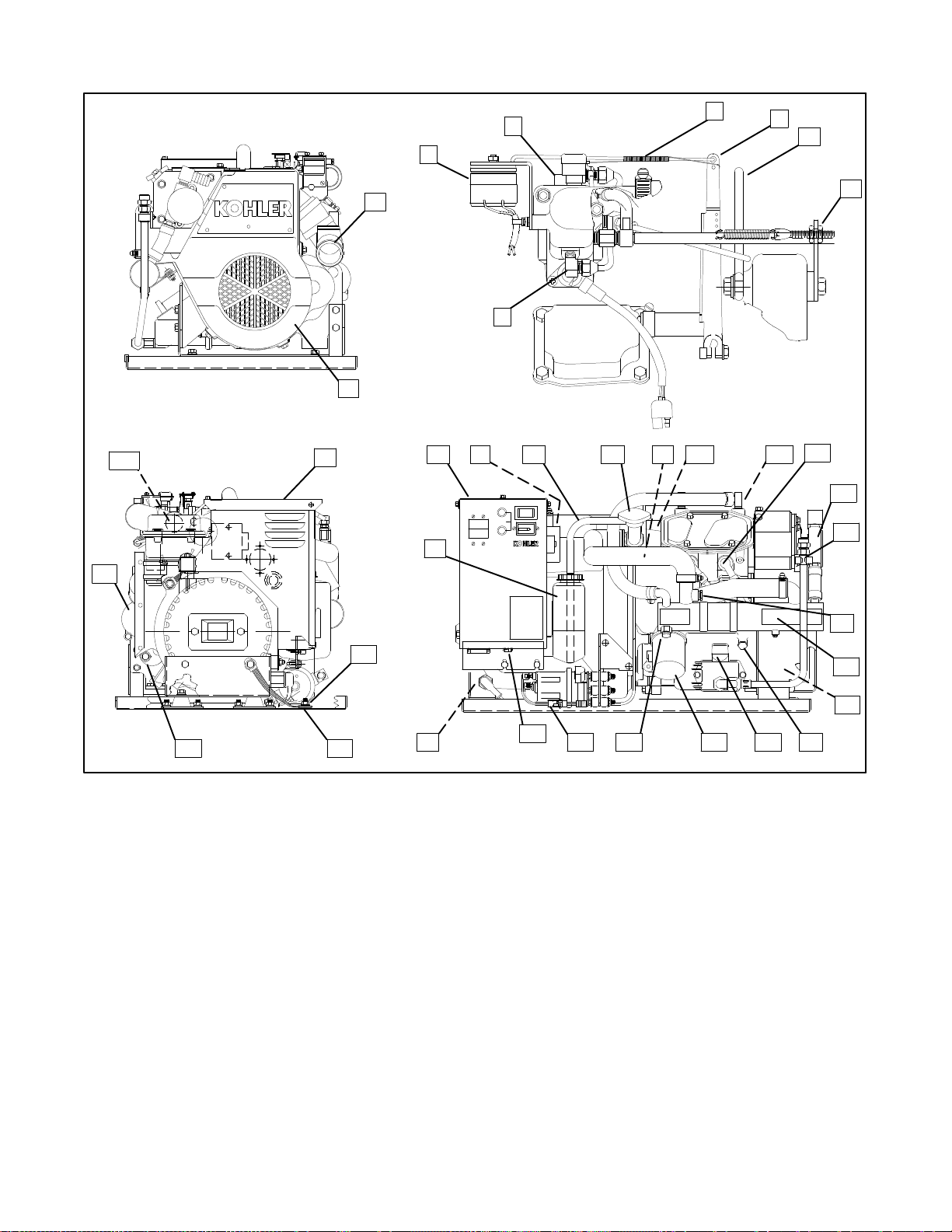

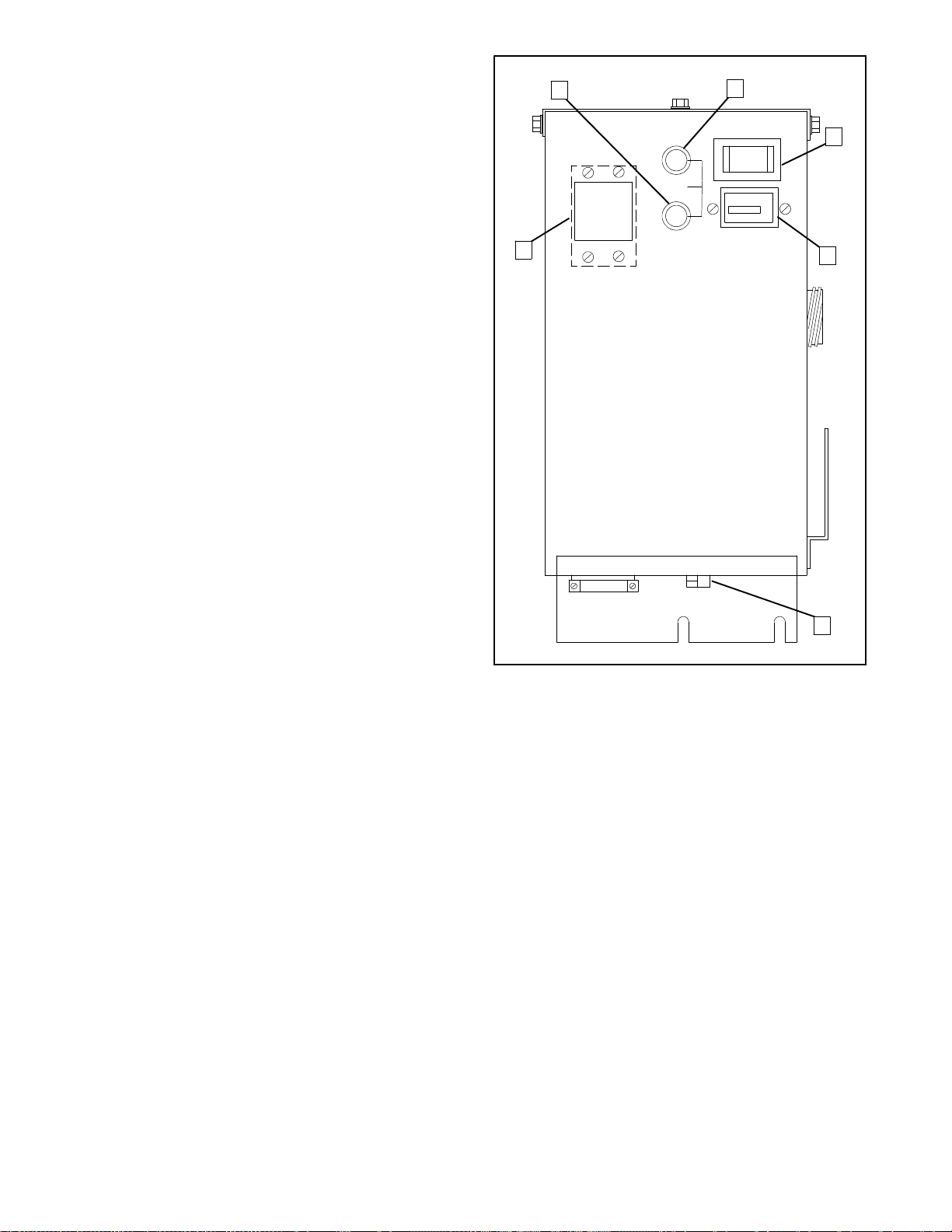

Service Views

36

32

4

5

6

7

3

8

1

9

2

10

30

INPUT

FUSE

CHRG.

STOP START

10A

1/10

00 0E00

TOTALHOURS

BATT.

17

16131211 143115

18

19

33

35

34

Figure 1-1. Service Views (typical)

1. Mixer Elbow (Exhaust Water Outlet)

2. Belt Guard

3. Electric Choke Rotary Solenoid

4. Carburetor

5. Governor Linkage

6. Governor Arm

7. Lifting Eye

8. Speed Adjustment (Idle Speed)

9. Antidieseling Solenoid

10. Controller

11. Battery Charger Voltage Regulator

12. Coolant Overflow Hose

13. Cooling System Pressure Cap

14. High Water Temperature Safety Shutdown

Switch

15. Thermostat

16. High Exhaust Temperature Shutdown

Switches (2)

17. Spark Plugs

18. Seawater Pump

29

28

27 26 25 24 23

258000-D

19. Oil Drain

20. Water Temperature Sender (Optional)

21. Heat Exchanger

22. Ignition Coil/Module

23. Low Oil Pressure Shutdown Switch/Sender

(Sender Optional)

24. Oil Dipstick (Oil Check/Oil Fill)

25. Oil Filter

26. Anticorrosion Zinc

27. Electric Fuel Pump

28. Remote Panel Connector

29. Positive Battery Lead Connection

30. Coolant Recovery Tank

31. Air Filter

32. Nameplate

33. Negative Battery Lead Connection

34. Equipment Ground Lug

35. Starter Solenoid

36. Starter Motor

20

21

22

TP-5695 12/931-6 Specifications

Page 22

Section 2. Operation

Prestart Checks

Toinsure continued satisfactory operation, the following

items should be checked before each start-up.

BACKFIRE FLAME ARRESTOR: Air cleaner must be

cleanand properlyinstalledto preventunfiltered airfrom

entering engine. See Maintenance--Air Cleaner.

BATTERY: Remove caps and check the electrolyte

level of each cell (batteries with filler caps only); add

distilled water if necessary. Check to make sure it is

connected correctly. Battery installation and

connections must meet Coast Guard Standards.

Battery should be serviced by authorized personnel

only. See Maintenance--Battery.

COMPARTMENT: Keep the engine room or

compartment clean and dry. Check for fuel or oil leaks.

Check the condition of fuel system, exhaust piping,

hoses, and muffler; have any faulty components

repaired before getting underway. Open hatch to air out

compartment and use “ignition-protected” bilge

blowers, if required, to clear fumes from area before

each start-up. If fuel leaks, fumes, exhaust gases, or

electrical sparks are noted, arrange for qualified

personnel to make necessary repairs before operating

generator set.

FUEL LEVEL: Make sure the fuel tanks are full and the

fuel system primed for operation. See

Maintenance--Fuel System.

OIL LEVEL: Should be ator nearMax. mark. Add oil as

neededtobringlevelupto this range. See Maintenance

Lubrication System.

COOLING: The coolant level on closed-type heat

exchanger systems can be checked using the coolant

recoverytank, if used. The MIN markindicatesfullwhen

coldandtheMAXmarkindicatesfullwhen hot. Maintain

the coolant level between these marks. It is

recommended that coolant level on closed systems be

periodically checked by removing pressure cap. Do not

solely rely on level in coolant recovery tank.

Add fresh coolant until level is just below overflow tube

opening. See Maintenance--Cooling Systems.

SEAWATER PUMP PRIMING: The seawater pump

must be primed before initial start-up. To prime pump,

close seacock and remove the hose from water filter

outlet. Fill hose and pump with clean water. Replace

hose and open seacock. Check for pump operating on

start-up by observing water discharge from exhaust

outlet.

TP-5695 12/93 Operation 2-1

Page 23

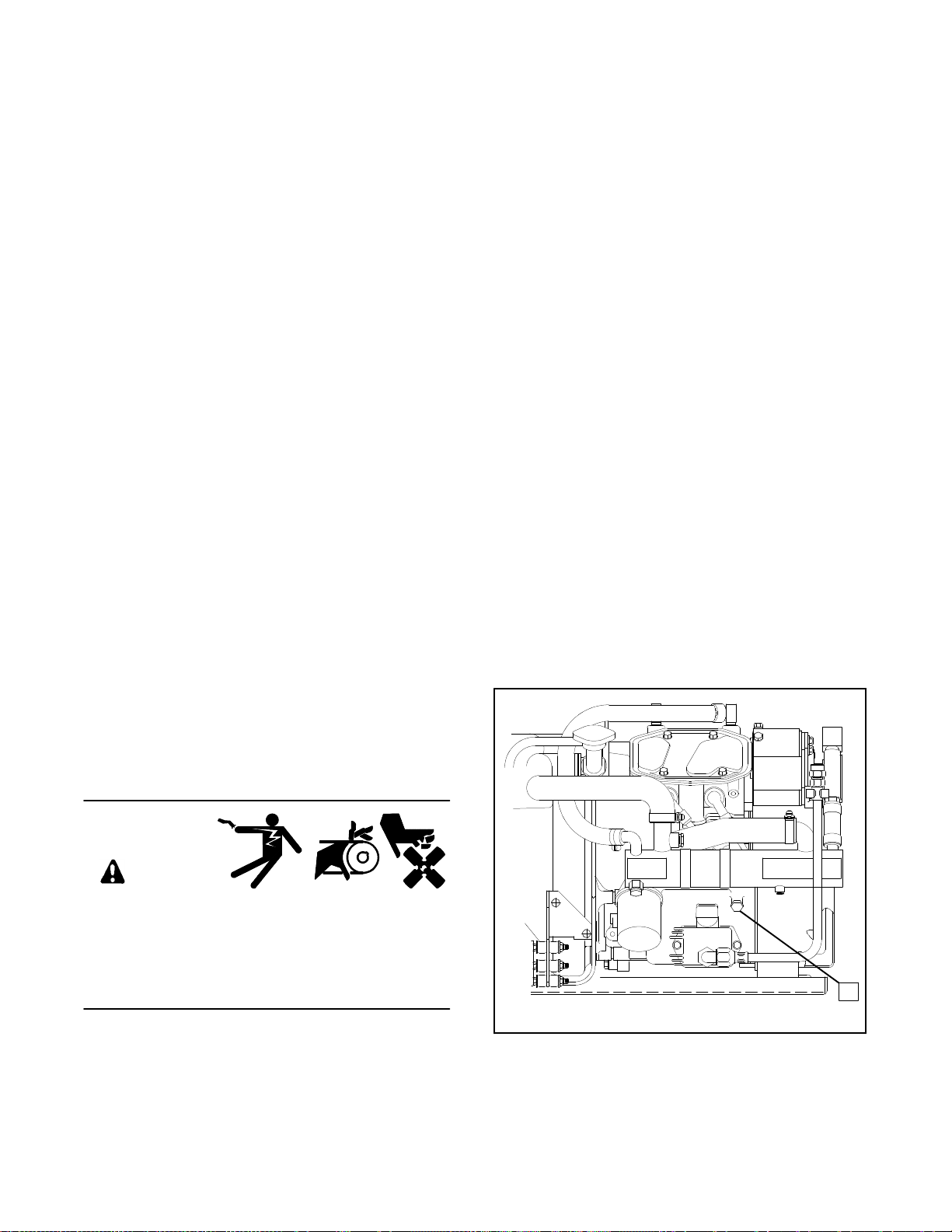

Controller

For identification and location of controller operating

features, refer to the text below and Figure 2-1.

1. Battery Charging Fuse protects battery charging

circuitry from short circuits.

2. Input (Controller) Fuse protects controller

circuitry from short circuits.

3. Start/Stop Switch is used to stop and start

generator set. Rock to start or stop position and

hold to start or stop engine. Switch automatically

returns to neutral center position when released.

4. Hourmeter records total generator set operating

hours. Use as a reference to schedule

maintenance.

5. Remote Start Connector provides connection

point for optional remote start kits.

6. Optional AC Circuit Breaker(s) protects

generator set from short circuits in load. Also used

to disconnect generator set from loads during

maintenance. To close circuit breaker,place in ON

position.

1

2

3

6

4

1. Battery Charging Fuse

2. Input (Controller) Fuse

3. Start/Stop Switch

Figure 2-1. Controller

5

A-246486-D

4. Hourmeter

5. Remote Start Connector

6. Optional AC Circuit

Breaker(s)

TP-5695 12/932-2 Operation

Page 24

Starting

WARNING

Explosion.

Gasoline vapors can cause explosion and

severe injury or death.

Iftheenginefailstostart after the first attempt, close the

seacock before a second start-up attempt. This action

will help prevent seawater from entering the engine

cylinders through the exhaust valve. Once the engine

starts,the seacock must be re-opened to allow passage

of cooling water.

NOTE

Failure to open the seacock after the generator set is

running will result in serious engine damage due to

overheating.

Before starting generator set, operate blower 4

minutes and check engine compartment for

gasoline vapors.

NOTE

For reliable starting, allow at least 30 seconds after

shutdown before restarting a hot engine.

Ensurethat the manual fuelshutoffvalve (if equipped)is

open. Then rock the master Start/Stop Switch on

controller (or use Start/Stop Switch on remote panel) to

theStartpositionfor amaximum of7 secondsoruntil the

engine starts.

NOTE

Do not crank the engine continuously for more than 7

seconds at a time. Allow a 5-second period between

starting attempts if the engine does not start. If the

engine fails to start after three attempts, contact an

authorized Kohler dealer/distributor for repair.Failure to

follow these guidelines may result in burn-out of the

starter motor from overheating.

NOTE

Ensure that the marine ship-to-shore transfer switch, if

used, is in proper position.

Stopping

Disconnectthe loadfrom thegenerator setandallow the

generator set to run at no-load for 5 minutes to cool

down the engine. Then rock the master Start/Stop

switch on the controller (or the Start/Stop Switch on a

remotepanel)totheStoppositionandhold it in the Stop

position until the generator set comes to a complete

stop.

NOTE

Allow unit to cometo a complete stop beforeattempting

to start the generator set again.

TP-5695 12/93 Operation 2-3

Page 25

Circuit Protection

AC Circuit Breaker (Optional)

before working on any equipment connected to

generator. The generator set can be started by remote

start/stop switch unless this precaution is followed.

The optional AC circuit breaker(s) located on the front

panel of the controller protect the generator output

windings.Ifaloadcircuit loses power,the cause may be

atrippedAC circuit breaker.If a tripped circuit breaker is

reset and then trips again, find and correct the short in

the load circuit that is causing the problem.

Input (Controller) Fuse (10 Amp)

The input fuse protects the controller circuitry. If the

generator set engine will not crank and the battery and

battery connections appear okay, the input fuse may be

blown. If this fuse, located on the front panel of the

controller, is replaced and then blows again, find and

correct the short that is causing the problem.

Battery-Charging Fuse (10 Amp)

The battery-charging fuse protects the battery-charging

circuit. If the battery goes dead and the battery and

battery-charging alternator are otherwise normal, the

battery-chargingfusemaybeblown. If this fuse, located

onthe front panelof the controller,isreplacedand blows

again, find and correct the short in the charging circuit

that is causing the problem.

NOTE

When a fuse replacement is required, be sure fuse has

the same ampere rating and is the same type (for

example: ABC or 3AB, ceramic). Do not substitute

“clear” glass-type fuses for ceramic fuses. If ampere

rating is unknown orquestionable, see Wiring Diagram.

Engine Safety

Shutdown Switches

The engine is protected by three engine safety

shutdown switches. Activating any of these switches

while the generator set is running, results in an

immediate, automatic shutdown. During start-up, the

engine safety shutdown feature is inhibited until a

generatoroutputissensedinordertoallowthe oil pump

output to reach normal operating pressure.

Low Oil Pressure Shutdown Switch

The low oil pressure shutdown switch protects the

engineagainst internaldamage,if the oilpressuredrops

below20 psi(138kPa), duetoan engineoilpump failure

or other engine malfunction. The location of the low oil

pressure shutdown switch is shown in Figure 2-2.

NOTE

The low oil pressure shutdown switch does not act as a

low oil level switch. The only way to protect against

engine damage due to low oil level is to check the oil

level regularly.

WARNING

Accidental starting.

Can cause severe injury or death.

Disconnect battery cables before working on

generator set (negative lead first and reconnect it

last).

Accidental starting can cause severe injury or

death. Disconnect battery cables (remove negative

lead first and reconnect it last) to disable generator set

1

258000-D

1. Low Oil Pressure Shutdown Switch

Figure 2-2. Low Oil Pressure Shutdown Switch

TP-5695 12/932-4 Operation

Page 26

High Water Temperature

High Exhaust Temperature

Shutdown Switch

The high water temperature shutdown switch protects

the engine against internal damage if the cooling water

temperature in the engine block is too high due to

cooling water or coolant circulation problems. The

switch is set to trip at 248--266° F (120--130° C). The

location of the high water temperature shutdown switch

is shown in Figure 2-3.

1 (hidden)

STARTSTOP

INPUT

10A

FUSE

1/10

00 000

TOTALHOURS

BATT.

CHRG.

258000-D

1. High Water TemperatureShutdown Switch

Figure 2-3. High Water Temperature

Shutdown Switch

Shutdown Switches

The two high exhaust temperature shutdown switches

protect the engine against internal damage due to

excessive exhaust temperatures. The switches are set

at 210--220° F (99--105° C). The locations of the high

exhaust temperature shutdown switches are shown in

Figure 2-4.

1

STARTSTOP

INPUT

10A

FUSE

1/10

00 000

TOTALHOURS

BATT.

CHRG.

258000-D

1. High Exhaust Temperature Shutdown Switches

(one located on each manifold)

Figure 2-4. High Exhaust Temperature

Shutdown Switches

TP-5695 12/93 Operation 2-5

Page 27

Remote Panels (Optional)

Remote Start Panel

Remote start panel allows starting-stopping from a

locationremoteofthegeneratorset.Generator sets are

equippedwitha6-pinconnectoroncontrollerbottomfor

connection of the kit. See Figure 2-5.

KOHLER

GENERATOR

1

2

START

1

STOP

1. “ON” Light 2. Start/Stop Switch

Figure 2-5. Remote Panel Features

2

1-656

Remote Start and

Two-Meter Panel Kit

Allows starting-stopping from a location remote of the

generator set. The illuminated gauges include an

engine oil pressure gauge and a water temperature

gauge. Generator sets come equipped with a 6-pin

connector on controller bottom for connection of the kit.

See Figure 2-6 for remote start and meter panel kit.

4 3

1-762

1. Engine Oil Pressure

2. Water Temperature

Figure 2-6. Remote Start and Two-Meter

Panel Features

Start/Stop Switch is a rocker-type switch with “ON”

light used to start and stop generator set.

Engine Oil Pressure Gauge measures engine oil

pressure. Normal engine operating range is 30--50 psi

(207--345 kPa).

NOTE

During the engine break-in period, it is normal for the

engine to produce higher oil pressure readings.

Water Temperature Gauge measures engine coolant

temperature. Normal engine operating range is

170--195_ F (77--91_ C).

3. Start/Stop Switch

4. “On” Light

TP-5695 12/932-6 Operation

Page 28

Remote Start and Four-Meter

Panel Kit

Allows starting-stopping from a location remote of the

generator set. The illuminated gauges include a DC

voltmeter, engine oil pressure gauge, water

temperature gauge, and generator running time

hourmeter.Generator sets come equipped with a 6-pin

connector on controller bottom for connection of the kit.

See Figure 2-7 for remote start and four-meter panel

features.

DC Voltmeter measuresvoltage of starting battery(ies).

Normalbattery operating range is 12--14 volts.

Engine Oil Pressure Gauge measures engine oil

pressure. Normal engine operating range is 30--50 psi

(207--345 kPa).

NOTE

During the engine break-in period, it is normal for the

engine to produce higher oil pressure readings.

Water Temperature Gauge measures engine coolant

temperature. Normal engine operating range is

170--195_ F (77--91_ C).

Start/Stop Switch is a rocker-type switch with “ON”

light used to start and stop the generator set.

1

6

5

Hourmeter records total generator set operating hours

for reference in maintenance scheduling.

2

3

4

1-830

1. Engine Oil Pressure

2. Hourmeter

3. Voltmeter

4. Water Temperature

5. Start/Stop Switch

6. “ON” Light

Figure 2-7. Remote Start and Four-Meter Features

TP-5695 12/93 Operation 2-7

Page 29

Section 3. Scheduled Maintenance

Use the following service schedule and the hourmeter

on the controller to schedule routine maintenance. In

addition to the routine services listed in this manual,

there are other important steps that should be taken to

keep a generator set in top condition. Usually tools and

instruments required for these additional steps are not

availableto thegeneratorset owner.Forthis reason,the

set should be returned periodically to an authorized

service dealer/distributor for complete servicing and

tune-up. The benefits of such service will be improved

performance and continuous satisfactory operation

duringa long trouble-free servicelife.Use the Operating

HourService Loginthe backofthis manualto document

services performed.

Service intervals are located on the top rows of the

Service Schedule chart. It indicates how often

maintenance tasks need to be done. Each service item

is to be repeated at the specified interval. For example,

an item required at 50 hours will again need to be

performed at 100 hours, 150 hours, etc.

Forcontinued satisfactoryoperation andlongevity ofthe

engine and generator set, proper maintenance and

eventual overhaul by a competent mechanic/technician

are essential. While it is not possible to anticipate

component failure, rough operation, metallic noises,

and excessive oil loss are among the indicators of

potential problems. Do not ignore these conditions!

NOTE

Operate the generator set with load applied at least

oncea month. Allow generator settorun about onehour

to reach operating temperature. This prevents the

formation of corrosion on internal engine components

when exposed to the breakdown of exhaust gases and

seawaterfor long periods ofgenerator inactivity.If unitis

to be out of service for several months, see Storage

Procedure.

WARNING

Accidental starting.

Can cause severe injury or death.

Disconnect battery cables before working on

generator set (negative lead first and reconnect it

last).

Accidental starting can cause severe injury or

death. Disconnect battery cables (remove negative

lead first and reconnect it last) to disable generator set

before working on any equipment connected to

generator. The generator set can be started by remote

start/stop switch unless this precaution is followed.

NOTE

HARDWARE DAMAGE! Engine and generator make

useof bothAmerican Standardandmetric hardware.Be

sure to use the correct size tools to prevent rounding of

bolt heads and nuts.

NOTE

High-mineral content seawater (salt water) can cause

rapid destruction of metals. Wipe up all salt water

spillage on and around generator set and keep metal

surfaces free from accumulated salt deposits.

TP-5695 12/93 Scheduled Maintenance 3-1

Page 30

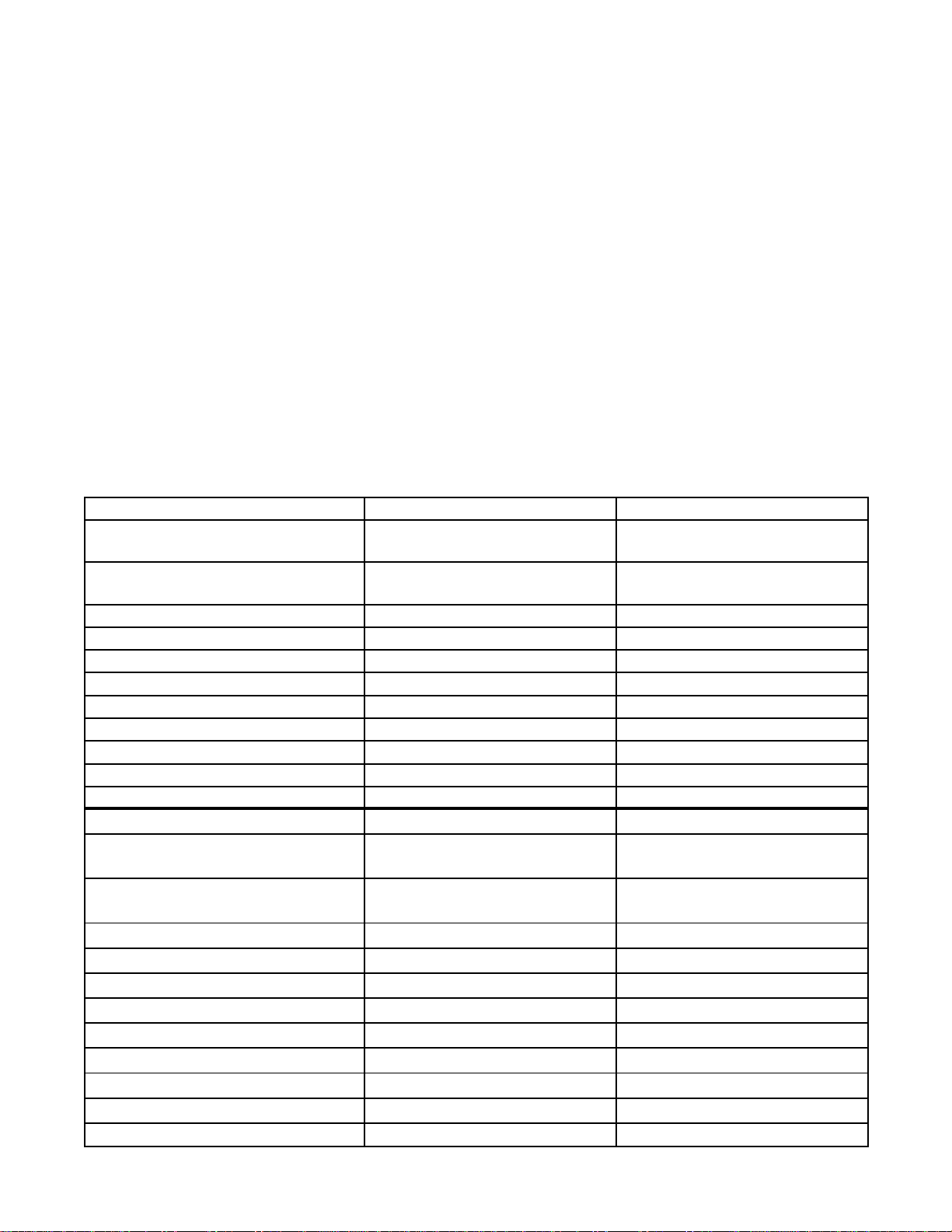

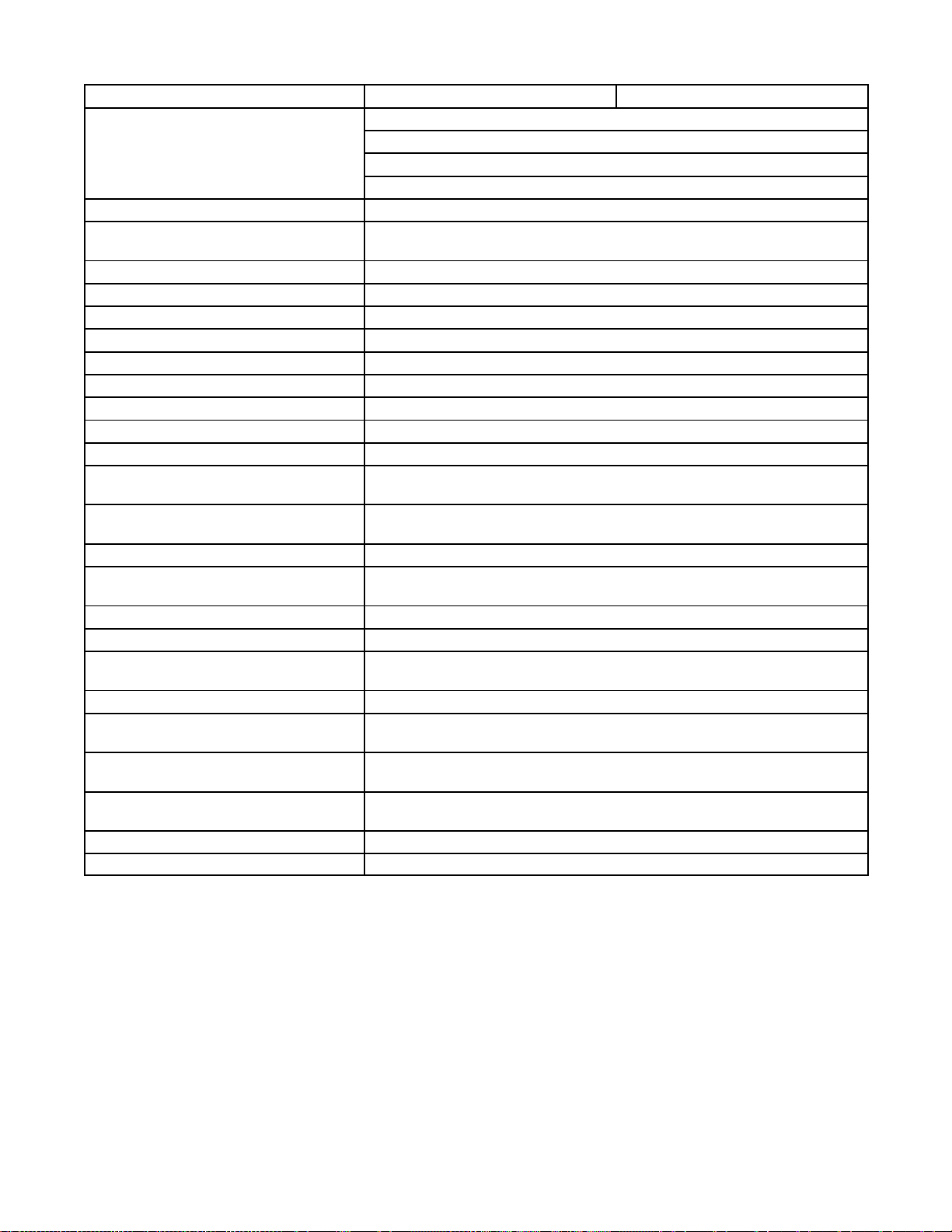

Service Schedule

After 20

Hrs. or

Before

Starting

LUBRICATION SYSTEM

Check oil level X

Change oil

Change oil filter X

FUEL SYSTEM

Check the fuel level X

Fill fuel tank X

Lubricate carburetor and choke

linkage

Clean fuel screen X

Service fuel lines X

IGNITION SYSTEM

Replace spark plugs X

COOLING SYSTEM

Check coolant level X

Check seawater outlet

Inspect exhaust system

components for cracks and

corrosion (exhaust manifold,

mixing elbow, exhaust line,

hose clamps, silencer, and

outlet flapper)

Check function of siphon break

(if equipped)

Check condition of heat

exchanger anticorrosion zinc

Replace heat exchanger

anticorrosion zinc

Replace the impeller of

seawater pump

Check thermostat function X

INTAKE/EXHAUST SYSTEM

Check exhaust gas condition

Clean the exhaust/water mixing

elbow

Clean air filter element X

X (During

Operation)

X X

X (During

Operation)

One

Month

X (Break-in

Period)

X (Break-in

Period)

Every 50

Hrs. or 3

Months

X

Every

100 Hrs.

or 6

Months

X (100 Hrs.

or 3

Months)

X

Every

200 Hrs.

or Yearly

X

X

X

Every

300 Hrs.

or 2 Years

X

TP-5695 12/933-2 Scheduled Maintenance

Page 31

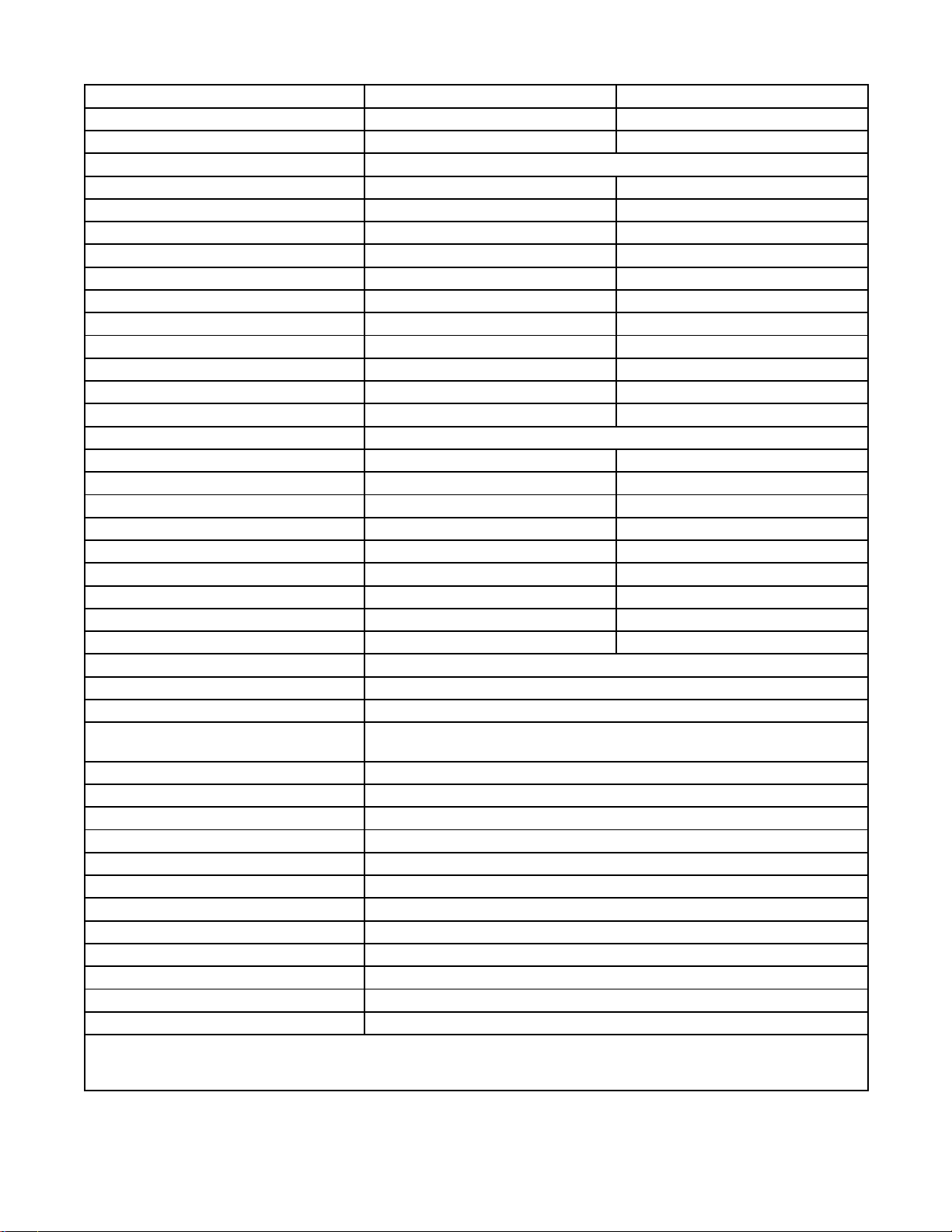

Service Schedule (Continued)

After 20

Hrs. or

Before

Starting

ELECTRICAL SYSTEM

Check electrolyte level

(Batteries with filler caps only)

Check and tighten electrical

connections

Check specific gravity

(Batteries with filler caps only)

Clean battery cables X

ENGINE AND MOUNTING

Check for leakage of water, fuel,

or oil

Lubricate governor linkage

Retighten all major nuts and

bolts

Check and tighten mounting

bolts and vibromounts

Check intake/exhaust

valve clearance

REMOTE CONTROL SYSTEM,

ETC.

Check compartment condition

(fuel, oil, or water leaks)

Check the remote control

operation

Test run generator set

GENERATOR

Blow dust out of generator X

X X

X X

X

One

Month

X (Break-in

Period)

X (Break-in

Period)

X (Break-in

Period)

X

(Monthly)

Every 50

Hrs. or 3

Months

Every

100 Hrs.

or 6

Months

X

X

Every

200 Hrs.

or Yearly

X

X

X

Every

300 Hrs.

or 2 Years

X

TP-5695 12/93 Scheduled Maintenance 3-3

Page 32

Lubrication System

Specifications

Use high quality detergent oil of API (American

PetroleumInstitute) service class SF,SF/CC, or SF/CD.

This information can be found on most oil containers,

see Figure 3-1. The symbol illustratedidentifies theAPI

service class in the upper portion. The center indicates

the SAE (Society of Automotive Engineers) viscosity

grade. The bottom portion (when used) signifies the oil

is intended to improve fuel economy and displays the

phrase “Energy Conserving.” Select viscosity based on

the air temperature at the time of operation. (See

Figure 3-2.)

SAE 10W40 is the preferred oil for general use where

temperatures permit.

Oil Check

Checkoillevelincrankcasedaily or before each startup

to insure that the level is in the safe range.

NOTE

Do not check oil level when unit is running. Generator

set must be stopped and level to get an accurate

reading.

If generator set has just been run, allow a few minutes

for the oil to return to the oil pan before checking level.

To check oil level, remove dipstick and wipe the end

clean, place bottom thread of dipstickagainst oil fill hole

and remove. Do not screw in dipstickwhen checking oil

level. Level should bebetween MIN and MAX marks on

dipstick. See Figure 3-3.

NOTE

Do not operate the set if thelevel isbelow the MIN mark

or above the MAX mark. Oil above the MAX mark is

wasted due to increased oil consumption.

1--792

Figure 3-1. Oil Service Class and

SAE Viscosity Grade Symbol

When Outside Temperature

is Consistently:

Below 5_ F (--15_ C)

--5_ F (--21_ C) to

90_ F (32_ C)

Above 15_ F (--10_ C)

Above --5_ F (--21_ C)

Figure 3-2. Recommended SAE

Viscosity Grades

Using other than the appropriate service class oil or

extended oil change intervals could cause engine

damage which is not covered by the engine warranty.

Do not mix oils of different viscosities. It is also best not

to mix different brands of oils. Possible incompatibility

could cause a breakdown of lubricating ingredients and

reduce engine protection.

Use SAE

Viscosity Grade:

5W30

10W30

20W40 or 20W50

10W40 (Preferred)

1. MAX Limit

2. MIN Limit

Figure 3-3. Checking Oil Level

1

3. Safe Range

2

3

1-826

TP-5695 12/933-4 Scheduled Maintenance

Page 33

Adding Oil

It is normal to add some oil between oil changes. The

amountwill vary with the usage.Openfill cap and pour a

small amount of oil using a funnel or other suitable

pouring device. See Figure 3-4. Wait a few minutesand

check level. If necessary, add more oil and then check

again. Each time be sure to add small quantities and

check to prevent overfilling.

1. Place oil drain hose in a proper container. Remove

oil drain cap. If a drain pump is used, remove oil

draincap and connect oil drainhoseto drain pump.

2. Allow ample time for all oil to drain into container. If

drain pump is used, activate pump until oil is

removed.

3. Loosen oil filter by turning in a counterclockwise

direction. Oil filter is 2 1/2 in. (64 mm) dia. with 14

flutes. Use oil filter wrench, if necessary. See

Figure 3-6. Use rags to handle hot oil filter and

clean up spilled oil. Remove filter from oil filter

adapter on engine and discard oil filter in a proper

container.

4. Clean contact surface of oil filter adapter.

5. Lightly lubricate the gasket surface of new oil filter

with fresh engine oil. Thread oil filter onto oil filter

adapter until gasket makes contact; then

hand-tighten oil filter an additional 3/4 turn.

1-826

Figure 3-4. Adding Oil

Oil Change/Oil Filter Change

Change oil and oil filter every 200 hours or yearly.

Change oil more frequently under dirty, dusty

conditions.Changeoilwhile theengine isstill warm.See

Figure 3-5 and use the following procedure.

1

STARTSTOP

INPUT

10A

FUSE

1/10

00 000

TOTALHOURS

BATT.

CHRG.

258000-D

1. Oil Drain Cap

Figure 3-5. Oil Drain Cap

NOTE

If an automatic oil drain/oil fill pump is used, omit

Step 6. Fill with proper amount and type of oil, see

Step 6. When complete, replace cap and

disconnect pump.

6. Replace oil drain cap. Remove oil fill cap. Add oil

usinga funnelorother suitablepouring device.See

Specifications—Engine for oil capacity and

Lubrication System—Specifications for proper

service class and SAE viscosity of oil. Replace oil

fill cap.

7. Start generator set and check for leaks at oil drain

cap and oil filter.

8. Stop generator set. Wait a few minutes for oil to

return to oil pan. Remove dipstick and wipe clean,

reinsert as far as possible and remove to check oil

level. Add oil, as necessary, to bring level up to

MAX mark.

TP-5695 12/93 Scheduled Maintenance 3-5

Page 34

1

1. Oil Filter Wrench 2 1/2 in. (64 mm) Dia.

Figure 3-6. Removing Oil Filter

1-826

Fuel System

Specifications

For best results, use only clean fresh, regular grade

unleaded gasoline. Use fuel with a minimum octane

rating as designated by the following:

Antiknock Index (Average of Research 86

Octane Number and Motor Octane Number)

Unleaded fuel is recommended since it leaves less

combustion chamber deposits. Oil must not be mixed

with fuel.

If using a gasoline containing alcohol (gasohol), be sure

the octane rating is at least 86(Antiknock Index). There

are two types of gasohol: one containing ethanol, and

another containing methanol.

Do not use gasohol that contains more than 10%

ethanol. Do not use gasohol containing methanol

(methyl or wood alcohol) that does not also contain

cosolvents and corrosion inhibitorsfor methanol. Never

usegasoline containing more than 5%methanol,even if

it has cosolvents and corrosion inhibitors.

NOTE

Fuel system damage and engine performance

problems resulting from the use of such fuels are not

coveredunderWarranty.Hondacannot endorsethe use

offuels containingmethanolsince evidenceofsuitability

is as yet incomplete. Before purchasing fuel from an

unfamiliar station, try to confirm whether the fuel

contains alcohol, and to what percentage. If any

undesirableoperating symptoms are noticed after using

a gasoline that contains alcohol, or one that contains

alcohol, switch to a gasoline that does not contain

alcohol.

NOTE

Discontinue use of any gasohol or alcohol/gasoline

blend if engine performance or fuel system problems

occur. Do not use such fuel unless it is UNLEADED.

Usefresh gasoline to ensure itisblended for the season

and to prevent the formation of gum deposits which

could clog the fuel system. Do notuse gasolineleft over

from the previous season.

TP-5695 12/933-6 Scheduled Maintenance

Page 35

Fuel Pump Screen

3. Remove the three nuts that secure the electric fuel

pump to the mounting bracket.

4. Remove the three mountingstuds from theelectric

fuel pump.

WARNING

Explosive fuel vapors.

Can cause severe injury or death.

Useextreme care when handling, storing,

and using fuels.

Explosive fuel vapors can cause severe injury or

death.Allfuelsarehighlyexplosiveinavapor state.Use

extreme care when handling, storing, and using fuels.

Store fuel in a well-ventilated area away from

spark-producing equipment and out of the reach of

children. Never add fuel to the tank while the engine is

running since spilled fuel may ignite on contact with hot

parts or from ignition spark. Do not smoke or permit

flame or spark to occur near potentialsources of spilled

fuelorfuelvapors.Keepfuellinesand connections tight

and in good condition—don’t replace flexible fuel lines

with rigid lines. Flexible sections are used to avoid

breakage due to vibration. Should any fuel leakage, fuel

accumulation, or electrical sparks be noted, DO NOT

OPERATE GENERATOR SET.Have systems repaired

before resuming generator operation.

5. Remove the cover plate and inspect the screen.

Remove any debris orresidue. Be sure the screen

is intact. If the screen is damaged, replace the fuel

pump.

6. Check the O-ring seal. Replace the O-ring if it is

nicked or eroded.

7. Reinstall the cover plate and secure it to the fuel

pump by reinstalling the three mounting studs.

8. Insert the three mounting studs on the fuel pump

through the mating holes in the mounting bracket.

Reinstall the three nuts to secure the fuel pump in

place.

9. Reconnect the fuel lines to the fuel pump.

10. Open fuel line at tank or in-line shutoff valve and

check for leaks from the fuel pump at fuel line

connections and cover plate.

Gasoline—Store gasoline only in approved red

containers clearly marked GASOLINE. Do not store

gasoline in any occupied building.

The electric fuel pump includes a screen. (See

Figure 3-7.) At the recommended interval or when

clogging is suspected, inspect and clean the screen as

follows:

1. Shut off fuel flow to electric fuel pump at tank or at

in-line shutoff valve. Disconnect harness plug(see

Figure 3-7 for location).

2. Disconnect fuel lines from electric fuel pump,

drainingfuel fromthelines andpumpinto asuitable

container to prevent spillage into the bilge.

1

2 (enclosed)

258000-D

1. Harness Plug 2. Fuel Pump Screen

Figure 3-7. Fuel Pump Screen

TP-5695 12/93 Scheduled Maintenance 3-7

Page 36

Carburetor/Choke Lubrication

Theonly maintenancerequiredis to lubricatecarburetor

and choke linkage at the specified interval using white

lithium grease or lubriplate.

WARNING

Carburetor Adjustments

The carburetor is a single-barrel, horizontal design and

uses an electric choke.

Lack of power usually indicates that the fuel mixture is

too rich. An overrich mixture may also be caused by a

clogged air intake (backfire flame arrestor)—check this

before readjusting carburetor. Fuel mixture may be too

lean if engine skips or backfires. Minor carburetor

adjustment may be necessary to compensate for

differences in altitude, fuel, and temperature.

1. With ENGINE STOPPED, turn fuel mixture screw

in (clockwise) until it seats lightly. DO NOT

FORCE! Turn fuel mixture screw out 2 to

2 1/2 turns. See Figure 3-8.

2. Start engine and let it run at no load for about 5

minutes. Before making adjustments engine

should be thoroughly warmed up running at

governed speed, and connected to full load.

Fire.

Can cause severe injury or death.

Do not smoke or permit flame or spark to occur

near fuel or fuel system.

Asudden flashfire cancause severeinjury ordeath.

Donot smokeorpermit flameorspark tooccur nearfuel

system.Keepthecompartmentandgeneratorsetclean

and free of debris to minimize chances of fire. Wipe up

all spilled fuel and engine oil.

2

1

3. Turn low speed mixture screw in until engine

instability (hunting) develops and then screw out

until engine instability is again apparent. Turn

screwbackin until it is positioned halfway between

the points of increasing stability. When properly

adjusted, engine will operate with steady governor

action.