Page 1

Service

Marine Generator Sets

Models:

40COZ/33CFOZ, 40EOZ/33EFOZ

50COZ/40CFOZ, 50EOZ/40EFOZ

65COZ/50CFOZ, 65EOZ/55EFOZ

80EOZ/70EFOZ, 99EOZ/80EFOZ

125EOZ/100EFOZ, 150EOZ/125EFOZ

Controllers:

Decision-Makert 3+

Decision-Makert 1 Standard

Decision-Makert 1 Expanded

TP-5737 5/01b

Page 2

Product Identification Information

Product identification numbers determine service parts.

Record the product identification numbers in the spaces

below immediately after unpacking the products so that

the numbers are readily available for future reference.

Record field-installed kit numbers after installing the

kits.

Generator Set Identification Numbers

Record the product identification numbers from the

generator set nameplate(s).

Model Designation

Specification Number

Serial Number

Accessory Number Accessory Description

Engine Identification

Record the product identification information from the

engine nameplate.

Manufacturer

Model Designation

Serial Number

Page 3

Table of Contents

Product Identification Information Inside front cover............................................

Safety Precautions and Instructions I........................................................

Introduction i...............................................................................

Service Assistance i........................................................................

Section 1 Specifications 1...................................................................

1.1 Introduction 1..........................................................

1.2 Specifications 1.........................................................

1.3 Accessories 2..........................................................

1.3.1 Remote Annunciator Kit 2........................................

1.3.2 Safeguard Breaker 3............................................

1.3.3 Line Circuit Breaker 3...........................................

1.3.4 Run Relay Kit 3.................................................

1.3.5 FASTCHECK Diagnostic Tester (Microprocessor Controller Only) 4....

Section 2 Operation 5.......................................................................

2.1 Fast-Responset II Concepts 5...........................................

2.2 Short Circuit Performance 5..............................................

2.3 Prestart Checklist 6.....................................................

2.4 Marine Inspection 6.....................................................

2.5 Angular Operation 6.....................................................

2.6 Exercising the Generator Set 6...........................................

2.7 Decision-Makert 3+ 16-Light Microprocessor Controller Operation 7..........

2.7.1 Controls and Indicators 8........................................

2.7.2 Fuses and Terminal Strips 9......................................

2.7.3 Auxiliary Fault Lamp Conditions 10.................................

2.7.4 Starting the Generator Set 10......................................

2.7.5 Stopping the Generator Set 10.....................................

2.7.6 Prime Power Mode Operation 11...................................

2.7.7 Fault Shutdowns 11..............................................

2.7.8 Controller Resetting Procedure (Following Fault Shutdown) 12.........

2.7.9 Resetting the Emergency Stop Switch 12............................

2.8 Expanded Decision-Makert 1 Controller Operation 13........................

2.8.1 Controls and Indicators 13........................................

2.8.2 Starting the Generator Set 14......................................

2.8.3 Stopping the Generator Set 14.....................................

2.8.4 Fault Shutdowns 14..............................................

2.8.5 Controller Resetting Procedure (Following Fault Shutdown) 14.........

2.9 Standard Decision-Makert 1 Controller Operation 15.........................

2.9.1 Controls and Indicators 15........................................

2.9.2 Starting the Generator Set 15......................................

2.9.3 Stopping the Generator Set 15.....................................

2.9.4 Fault Shutdowns 16..............................................

2.9.5 Controller Resetting Procedure (Following Fault Shutdown) 16.........

Section 3 Scheduled Maintenance 17..........................................................

3.1 General Maintenance 17..................................................

3.2 Generator Bearing 18....................................................

3.3 Storage Procedure 18....................................................

3.3.1 Lubrication System 18............................................

3.3.2 Cooling System 18...............................................

3.3.3 Fuel System 18..................................................

3.3.4 Exterior 18......................................................

3.3.5 Battery 18.......................................................

Section 4 General Troubleshooting 19.........................................................

TP-5737 5/01 Table of Contents

Page 4

Table of Contents, continued

Section 5 Decision-Makert 3+ Troubleshooting 23.............................................

5.1 Decision-Makert 3+ Controller 23.........................................

5.1.1 Decision-Maker 3+ Circuit Board Terminal/Connector Identification 25...

5.1.2 Fault Shutdowns, Decision-Maker 3+ Controller 31...................

5.2 Microprocessor Controller Relay Descriptions 32.............................

5.2.1 K1 Relay, Starter Solenoid 32......................................

5.2.2 K2 Relay, Crank Relay on Main Circuit Board 32.....................

5.2.3 K3 Relay, Run Relay on Main Circuit Board 32.......................

5.2.4 K4 Relay, Emergency Stop Relay on Main Circuit Board 32............

5.2.5 K5 Relay, Governor Control Relay 32...............................

5.3 Microprocessor Controller 32..............................................

5.3.1 Troubleshooting 33...............................................

5.3.2 Fuses 34.......................................................

5.4 FASTCHECK Features and Operation 39...................................

5.4.1 Features 39.....................................................

5.4.2 Application 40...................................................

5.4.3 Connect/Operate Procedure 40....................................

5.4.4 Overcrank 41....................................................

5.4.5 Controller Speed Sensor Circuitry 41...............................

5.4.6 Generator Condition Indicator Terminal (TB1 Terminal Strip) 42.........

Section 6 Decision-Makert 1 Controller Troubleshooting 45....................................

6.1 Decision-Makert 1 and Decision-Makert 1 Expanded Relay Controller 45......

6.2 Relay Controller 52.......................................................

Section 7 Component Testing and Adjustment 57..............................................

7.1 Generator Troubleshooting 57.............................................

7.2 Generator Testing 60.....................................................

7.2.1 No Output On Any Phase 60.......................................

7.2.2 Overvoltage 62..................................................

7.2.3 Fluctuating Voltage 62............................................

7.3 LED Circuit Board Test 62.................................................

7.4 SCR Assembly and Photo Transistor Board 64...............................

7.4.1 Concept and Equipment 64........................................

7.4.2 SCR Assembly and Photo Transistor Board Test 64...................

7.5 Automatic Voltage Regulator (AVR) Operation and Adjustment 66..............

7.6 Stator 68................................................................

7.7 Generator Field 69.......................................................

7.8 Exciter Armature 70......................................................

7.9 End Bracket Removal and Replacement 72..................................

7.10 Speed Sensor Test 73....................................................

7.11 Current Transformers 73..................................................

7.11.1 Function and Application 73.......................................

7.11.2 Testing 74.......................................................

7.12 Reactive Droop Compensator 74...........................................

7.12.1 Function and Application 74.......................................

7.12.2 Initial Adjustment 74..............................................

7.12.3 Final Adjustment 75..............................................

7.12.4 Testing 75.......................................................

7.13 Gauge Senders 76.......................................................

7.13.1 Oil Pressure Sender Testing 76....................................

7.13.2 Water Temperature Sender Testing 76..............................

TP-5737 5/01Table of Contents

Page 5

Table of Contents, continued

7.14 Governor Adjustment 77..................................................

7.14.1 Mechanical Governor 77..........................................

7.14.2 Electronic Governor, Barber-Colman Dyna 2500

7.14.3 Electronic Governor, Barber-Colman Dyna 70025

Section 8 Disassembly/Reassembly 83........................................................

8.1 Disassembly 87..........................................................

8.2 Reassembly 89..........................................................

Section 9 Wiring Diagrams 95................................................................

9.1 Voltage Reconnection 116.................................................

9.1.1 Introduction 116...................................................

9.1.2 Voltage Reconnection Procedure 116................................

9.2 Overvoltage Shutdown Adjustment 119......................................

9.3 Generator Set Frequency Change and Adjustment 121.........................

9.3.1 Frequency Change 121............................................

9.3.2 Frequency Adjustment 121.........................................

Appendix A Abbreviations A-1..................................................................

Appendix B Common Hardware Application Guidelines A-3........................................

Appendix C General Torque Specifications A-4...................................................

Appendix D Common Hardware Identification A-5.................................................

125--150 kW John Deere Engine-Powered 6081 77...................

using Stanadyne D Series Injection Pump

35--99 kW John Deere-Engine Powered 4045 and 6068 80............

Appendix E Common Hardware List A-6.........................................................

Appendix F Operating Hour Service Log A-8.....................................................

TP-5737 5/01 Table of Contents

Page 6

Page 7

Safety Precautions and Instructions

IMPORTANT SAFETY

INSTRUCTIONS. Electromechanical

equipment, including generator sets,

transfer switches, switchgear, and

accessories, can cause bodily harm

and pose life-threatening danger when

improperly installed, operated, or

maintained. To prevent accidents be

aware of potential dangers and act

safely. Read and follow all safety

precautions and instructions. SAVE

THESE INSTRUCTIONS.

This manual has several types of safety

precautions and instructions: Danger,

Warning, Caution, and Notice.

DANGER

Danger indicates the presence of a

hazard that will cause severe

personal injury, death,orsubstantial

property damage.

WARNING

Warning indicates the presence of a

hazard that can cause severe

personal injury, death, or substantial

property damage.

CAUTION

Caution indicates the presence of a

hazard that will or can cause minor

personal injury or property damage.

NOTICE

Notice communicates installation,

operation, or maintenance information

that is safety related but not hazard

related.

Safety decals affixed to the equipment

in prominent places alert the operator

or service technician to potential

hazards and explain how to act safely.

The decals are shown throughout this

publication to improve operator

recognition. Replace missing or

damaged decals.

Accidental Starting

WARNING

Accidental starting.

Can cause severe injury or death.

Disconnect the battery cables before

working on the generator set.

Remove the negative (--) lead first

when disconnecting the battery.

Reconnect the negative (--) lead last

when reconnecting the battery.

Disabling the generator set.

Accidental starting can cause

severe injury or death. Before

working on the generator set or

connected equipment, disable the

generator set as follows: (1) Move the

generator set master switch to the OFF

position. (2) Disconnect the power to

the battery charger. (3) Remove the

battery cables, negative (--) lead first.

Reconnect the negative (--) lead last

when reconnecting the battery. Follow

these precautions to prevent starting of

the generator set by an automatic

transfer switch, remote start/stop

switch, or engine start command from a

remote computer.

Battery

WARNING

Sulfuric acid in batteries.

Can cause severe injury or death.

Wear protective goggles and

clothing. Battery acid may cause

blindness and burn skin.

Battery electrolyte is a diluted

sulfuric acid. Battery acid can cause

severe injury or death. Battery acid

can cause blindness and burn skin.

Always wear splashproof safety

goggles, rubber gloves, and boots

when servicing the battery. Do not

open a sealed battery or mutilate the

battery case. If battery acid splashes in

the eyes or on the skin, immediately

flush the affected area for 15 minutes

with large quantities of clean water.

Seek immediate medical aid in the case

of eye contact. Never add acid to a

battery after placing the battery in

service, as this may result in hazardous

spattering of battery acid.

Battery acid cleanup. Battery acid

can cause severe injury or death.

Battery acid is electrically conductive

and corrosive. Add 500 g (1 lb.) of

bicarbonate of soda (baking soda) to a

containerwith4L(1gal.)ofwaterand

mix the neutralizing solution. Pour the

neutralizing solution on the spilled

battery acid and continue to add the

neutralizing solution to the spilled

battery acid until all evidence of a

chemical reaction (foaming) has

ceased. Flush the resulting liquid with

water and dry the area.

TP-5737 5/01 ISafety Precautions and Instructions

Page 8

Battery gases. Explosion can cause

severe injury or death. Battery gases

can cause an explosion. Do not smoke

or permit flames or sparks to occur near

a battery at any time, particularly when

it is charging. Do not dispose of a

battery in a fire. To prevent burns and

sparks that could cause an explosion,

avoid touching the battery terminals

with tools or other metal objects.

Remove all jewelry before servicing the

equipment. Discharge static electricity

from your body before touching

batteries by first touching a grounded

metal surface away from the battery. To

avoid sparks, do not disturb the battery

charger connections while the battery

is charging. Always turn the battery

charger off before disconnecting the

battery connections. Ventilate the

compartments containing batteries to

prevent accumulation of explosive

gases.

Battery short circuits. Explosion

can cause severe injury or death.

Short circuits can cause bodily injury

and/or equipment damage.

Disconnect the battery before

generator set installation or

maintenance. Remove all jewelry

before servicing the equipment. Use

tools with insulated handles. Remove

the negative (--) lead first when

disconnecting the battery. Reconnect

the negative (--) lead last when

reconnecting the battery. Never

connect the negative (--) battery cable

to the positive (+) connection terminal

of the starter solenoid. Do not test the

battery condition by shorting the

terminals together.

Engine Backfire/Flash

Fire

Servicing the fuel system. A flash

fire can cause severe injury or death.

Do not smoke or permit flames or

sparks near the carburetor, fuel line,

fuel filter, fuel pump, or other potential

sources of spilled fuels or fuel vapors.

Catch fuels in an approved container

when removing the fuel line or

carburetor.

Servicing the air cleaner. A sudden

backfire can cause severe injury or

death. Do not operate the generator

set with the air cleaner/silencer

removed.

Combustible materials. A sudden

flash fire can cause severe injury or

death. Do not smoke or permit flames

or sparks near the fuel system. Keep

the compartment and the generator set

clean and free of debris to minimize the

risk of fire. Wipe up spilled fuels and

engine oil.

Combustible materials. A fire can

cause severe injury or death.

Generator set engine fuels and fuel

vapors are flammable and explosive.

Handle these materials carefully to

minimize the risk of fire or explosion.

Equip the compartment or nearby area

with a fully charged fire extinguisher.

Select a fire extinguisher rated ABC or

BC for electrical fires or as

recommended by the local fire code or

an authorized agency. Train all

personnel on fire extinguisher

operation and fire prevention

procedures.

Exhaust System

WARNING

Carbon monoxide symptoms.

Carbon monoxide can cause severe

nausea, fainting, or death. Carbon

monoxide is a poisonous gas present in

exhaust gases. Carbon monoxide

poisoning symptoms include but are

not limited to the following:

D Light-headedness, dizziness

D Physical fatigue, weakness in

joints and muscles

D Sleepiness, mental fatigue,

inability to concentrate

or speak clearly, blurred vision

D Stomachache, vomiting, nausea

If experiencing any of these symptoms

and carbon monoxide poisoning is

possible, seek fresh air immediately

and remain active. Do not sit, lie down,

or fall asleep. Alert others to the

possibility of carbon monoxide

poisoning. Seek medical attention if

the condition of affected persons does

not improve within minutes of breathing

fresh air.

Copper tubing exhaust systems.

Carbon monoxide can cause severe

nausea, fainting, or death. Do not

use copper tubing in diesel exhaust

systems. Sulfur in diesel exhaust

causes rapid deterioration of copper

tubing exhaust systems, resulting in

exhaust/water leakage.

Inspecting the exhaust system.

Carbon monoxide can cause severe

nausea, fainting, or death. For the

safety of the craft’s occupants, install a

carbon monoxide detector. Consult the

boat builder or dealer for approved

detector location and installation.

Inspect the detector before each

generator set use. In addition to routine

exhaust system inspection, test the

carbon monoxide detector per the

manufacturer’s instructions and keep

the detector operational at all times.

WARNING

Fire.

Can cause severe injury or death.

Do not smoke or permit flames or

sparks near fuels or the fuel system.

Carbon monoxide.

Can cause severe nausea,

fainting, or death.

The exhaust system must be

leakproof and routinely inspected.

TP-5737 5/01II Safety Precautions and Instructions

Page 9

Operating the generator set. Carbon

monoxide can cause severe nausea,

fainting, or death. Carbon monoxide

is an odorless, colorless, tasteless,

nonirritating gas that can cause death if

inhaled for even a short time. Use the

following precautions when installing

and operating the generator set. Do not

install the exhaustoutlet where exhaust

can be drawn in through portholes,

vents, or air conditioners. If the

generator set exhaust discharge outlet

is near the waterline, water could enter

the exhaust discharge outlet and close

or restrict the flow of exhaust. Never

operate the generator set without a

functioning carbon monoxide detector.

Be especially careful if operating the

generator set when moored or

anchored under calm conditions

because gases may accumulate. If

operating the generator set dockside,

moor the craft so that the exhaust

discharges on the lee side (the side

sheltered from the wind). Always be

aware of others, making sure your

exhaust is directed away from other

boats and buildings. Avoid overloading

the craft.

Fuel System

WARNING

Explosive fuel vapors.

Can cause severe injury or death.

The fuel system. Explosive fuel

vapors can cause severe injury or

death. Vaporized fuels are highly

explosive. Use extreme care when

handling and storing fuels. Store fuels

inawell-ventilatedareaawayfrom

spark-producing equipment and out of

the reach of children. Never add fuel to

the tank while the engine is running

because spilled fuel may ignite on

contact with hot parts or from sparks.

Do not smoke or permit flames or

sparks to occur near sources of spilled

fuel or fuel vapors. Keep the fuel lines

and connections tight and in good

condition. Do not replace flexible fuel

lines with rigid lines. Use flexible

sections to avoid fuel line breakage

caused by vibration. Do not operate the

generator set in the presence of fuel

leaks, fuel accumulation, or sparks.

Repair fuel systems before resuming

generator set operation.

Draining the fuel system. Explosive

fuel vapors can cause severe injury

or death. Spilled fuel can cause an

explosion. Use a container to catch fuel

when draining the fuel system. Wipe up

spilled fuel after draining the system.

Installing the fuel system. Explosive

fuel vapors can cause severe injury

or death. Fuel leakage can cause an

explosion. Do not modify the tank or

the propulsion engine fuel system.

Equip the craft with a tank that allows

one of the two pickup arrangements

described in the installation section.

The tank and installation must conform

to USCG Regulations.

Pipe sealant. Explosive fuel vapors

can cause severe injury or death.

Fuel leakage can cause an explosion.

Use pipe sealant on all threaded fittings

to prevent fuel leakage. Use pipe

sealant that resists gasoline, grease,

lubrication oil, common bilge solvents,

salt deposits, and water.

Hazardous Noise

CAUTION

Hazardous noise.

Can cause hearing loss.

Never operate the generator set

without a muffler or with a faulty

exhaust system.

Engine noise. Hazardous noise can

cause hearing loss. Generator sets

not equipped with sound enclosures

can produce noise levels greater than

105 dBA. Prolonged exposure to noise

levels greater than 85 dBA can cause

permanent hearing loss. Wear hearing

protection when near an operating

generator set.

Use extreme care when handling,

storing, and using fuels.

TP-5737 5/01 IIISafety Precautions and Instructions

Page 10

Hazardous Voltage/

Electrical Shock

WARNING

Hazardous voltage.

Can cause severe injury or death.

Operate the generator set only when

all guards and electrical enclosures

areinplace.

Grounding electrical equipment.

Hazardous voltage can cause

severe injury or death. Electrocution

is possible whenever electricity is

present. Open the main circuit

breakers of all power sources before

servicing the equipment. Configure the

installation to electrically ground the

generator set, transfer switch, and

related equipment and electrical

circuits to comply with applicable codes

and standards. Never contact

electrical leads or appliances when

standing in water or on wet ground

because these conditions increase the

risk of electrocution.

Disconnecting the electrical load.

Hazardous voltage can cause

severe injury or death. Disconnect

the generator set from the load by

opening the line circuit breaker or by

disconnecting the generator set output

leads from the transfer switch and

heavily taping the ends of the leads.

High voltage transferred to the load

during testing may cause personal

injury and equipment damage. Do not

use the safeguard circuit breaker in

place of the line circuit breaker. The

safeguard circuit breaker does not

disconnect the generator set from the

load.

Moving rotor.

Testing the voltage regulator.

Hazardous voltage can cause

severe injury or death. High voltage

is present at the voltage regulator heat

sink. To prevent electrical shock do not

touch the voltage regulator heat sink

when testing the voltage regulator.

(PowerBoostt, PowerBoostt III, and

PowerBoostt V voltage regulator

models only)

Electrical backfeed to the utility.

Hazardous backfeed voltage can

cause severe injury or death.

Connect the generator set to the

building/marina electrical system only

through an approved device and after

the building/marina main switch is

opened. Backfeed connections can

cause severe injury or death to utility

personnel working on power lines

and/or personnel near the work area.

Some states and localities prohibit

unauthorized connection to the utility

electrical system. Install a

ship-to-shore transfer switch to prevent

interconnection of the generator set

power and shore power.

Testing live electrical circuits.

Hazardous voltage or current can

cause severe injury or death. Have

trained and qualified personnel take

diagnostic measurements of live

circuits. Use adequately rated test

equipment with electrically insulated

probes and follow the instructions of the

test equipment manufacturer when

performing voltage tests. Observe the

following precautions when performing

voltage tests: (1) Remove all jewelry.

(2) Stand on a dry, approved electrically

insulated mat. (3) Do not touch the

enclosure or components inside the

enclosure. (4) Be prepared for the

system to operate automatically.

(600 volts and under)

Hot Parts

WARNING

Hot coolant and steam.

Can cause severe injury or death.

Before removing the pressure cap,

stop the generator set and allow it to

cool. Then loosen the pressure cap

to relieve pressure.

WARNING

Hot engine and exhaust system.

Can cause severe injury or death.

Do not work on the generator set until

it cools.

Checking the coolant level. Hot

coolant can cause severe injury or

death. Allow the engine to cool.

Release pressure from the cooling

system before removing the pressure

cap. To release pressure, cover the

pressure cap with a thick cloth and then

slowly turn the cap counterclockwise to

the first stop. Remove the cap after

pressure has been completely

released and the engine has cooled.

Check the coolant level at the tank if the

generator set has a coolant recovery

tank.

Servicing the exhaust system. Hot

parts can cause severe injury or

death. Do not touch hot engine parts.

The engine and exhaust system

components become extremely hot

during operation.

Short circuits. Hazardous

voltage/current can cause severe

injury or death. Short circuits can

cause bodily injury and/or equipment

damage. Do not contact electrical

connections with tools or jewelry while

making adjustments or repairs.

Remove all jewelry before servicing the

equipment.

TP-5737 5/01IV Safety Precautions and Instructions

Page 11

Moving Parts

WARNING

Hazardous voltage.

Can cause severe injury or death.

Operate the generator set only when

all guards and electrical enclosures

areinplace.

WARNING

Rotating parts.

Can cause severe injury or death.

Operate the generator set only when

all guards, screens, and covers are in

place.

WARNING

Airborne particles.

Can cause severe injury or

blindness.

Wear protective goggles and clothing

when using power tools, hand tools,

or compressed air.

Moving rotor.

Tightening the hardware. Flying

projectiles can cause severe injury

or death. Loose hardware can cause

the hardware or pulley to release from

the generator set engine and can cause

personal injury. Retorque all

crankshaft and rotor hardware after

servicing. Do not loosen the crankshaft

hardware or rotor thrubolt when making

adjustments or servicing the generator

set. Rotate the crankshaft manually in

a clockwise direction only. Turning the

crankshaft bolt or rotor thrubolt

counterclockwise can loosen the

hardware.

Servicing the generator set when it

is operating. Exposed moving parts

can cause severe injury or death.

Keep hands, feet, hair, clothing, and

test leads away from the belts and

pulleys when the generator set is

running. Replace guards, screens, and

covers before operating the generator

set.

Sound shield removal. Exposed

moving parts can cause severe

injury or death. The generator set

must be operating in order to perform

some scheduled maintenance

procedures. Be especially careful if the

sound shield has been removed,

leaving the belts and pulleys exposed.

(Sound-shield-equipped models only)

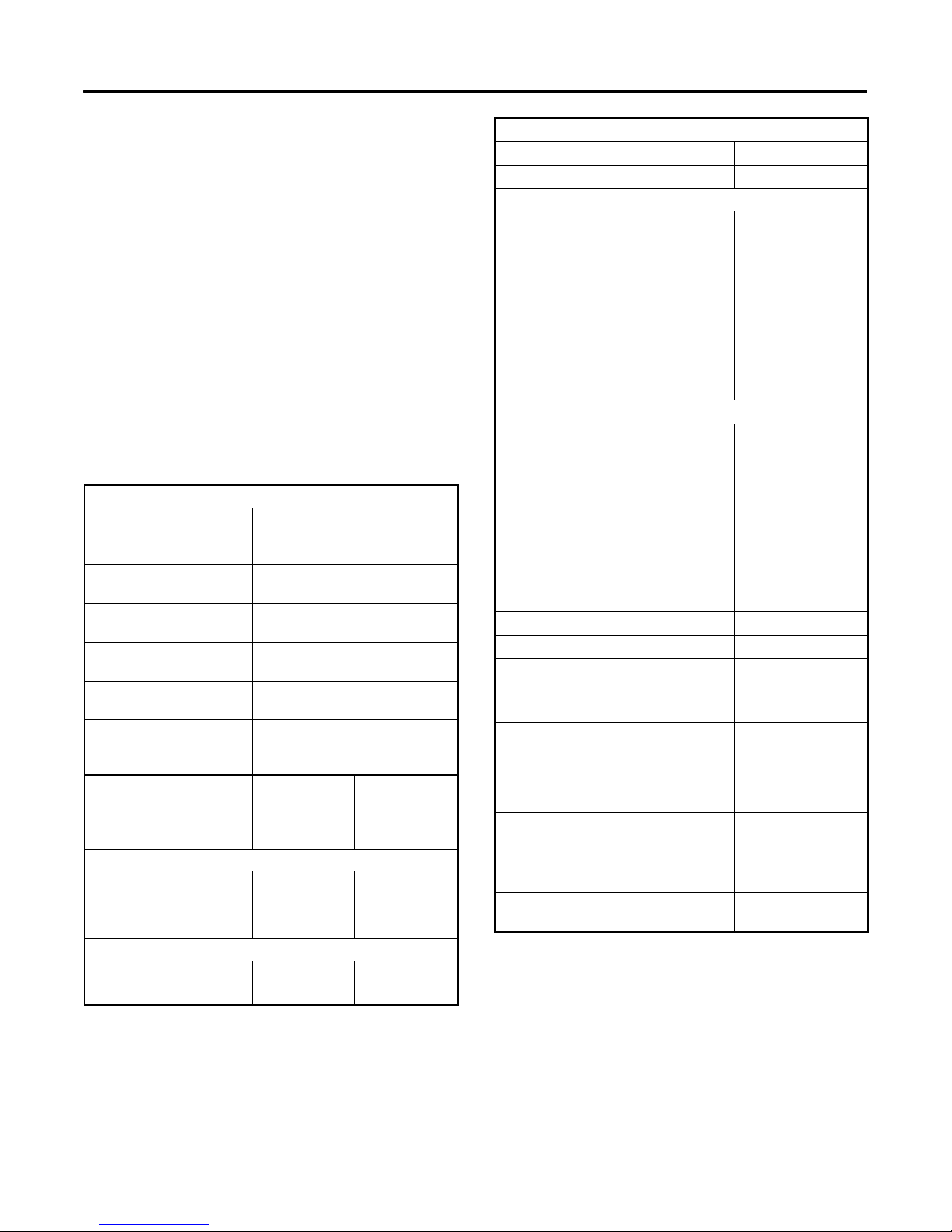

Notice

NOTICE

This generator set has been

rewired from its nameplate voltage

to

246242

NOTICE

Voltage reconnection. Affix a notice

to the generator set after reconnecting

the set to a voltage different from the

voltage on the nameplate. Order

voltage reconnection decal 246242

from an authorized service

distributor/dealer.

NOTICE

Hardware damage. The engine and

generator set may use both American

Standard and metric hardware. Use

the correct size tools to prevent

rounding of the bolt heads and nuts.

NOTICE

When replacing hardware, do not

substitute with inferior grade

hardware. Screws and nuts are

available in different hardness ratings.

To indicate hardness, American

Standard hardware uses a series of

markings, and metric hardware uses a

numeric system. Check the markings

on the bolt heads and nuts for

identification.

NOTICE

Fuse replacement. Replace fuses

with fuses of the same ampere rating

and type (for example: 3AB or 314,

ceramic). Do not substitute clear

glass-type fuses for ceramic fuses.

Refer to the wiring diagram when the

ampere rating is unknown or

questionable.

TP-5737 5/01 VSafety Precautions and Instructions

NOTICE

Saltwater damage. Saltwater quickly

deteriorates metals. Wipe up saltwater

on and around the generator set and

remove salt deposits from m etal

surfaces.

Page 12

Notes

TP-5737 5/01VI Safety Precautions and Instructions

Page 13

Introduction

This manual provides troubleshooting and repair

instructions for 40COZ/33CFOZ, 40EOZ/33EFOZ,

50COZ/40CFOZ, 50EOZ/40EFOZ, 65COZ/50CFOZ,

65EOZ/55EFOZ, 80EOZ/70EFOZ, 99EOZ/80EFOZ,

125EOZ/100EFOZ, and 150EOZ/125EFOZ model

generator sets, controllers, and accessories.

Refer to the engine service manual for generator set

engine service information.

x:in:001:001

This manual may be used for models not listed on the

front cover.

Information in this publication represents data available

at the time of print. Kohler Co. reserves the right to

change this publication and the products represented

Please contact a local authorized distributor/dealer for

sales, service, or other information about Kohler Co.

Generator Division products.

D Look on the product or in the information included

with the product

D Consult the Yellow Pages under the heading

Generators—Electric

D Visit the Kohler Co. Generator Division web site at

www.kohlergenerators.com

D Inside the U.S.A. and Canada, call 1-800-544-2444

D Outside the U.S.A. and Canada, call the nearest

regional office

Africa, Europe, Middle East

London Regional Office

Langley, Slough, England

Phone: (44) 1753-580-771

Fax: (44) 1753-580-036

Australia

Australia Regional Office

Queensland, Australia

Phone: (617) 3893-0061

Fax: (617) 3893-0072

China

China Regional Office

Shanghai, People’s Republic of China

Phone: (86) 21-6482 1252

Fax: (86) 21-6482 1255

without notice and without any obligation or liability

whatsoever.

Read this manual and carefully follow all procedures

and safety precautions to ensure proper equipment

operation and to avoid bodily injury. Read and follow the

Safety Precautions and Instructions section at the

beginning of this manual. Keep this manual with the

equipment for future reference.

The equipment service requirements are very important

to safe and efficient operation. Inspect the parts often

and perform required service at the prescribed intervals.

Obtain service from an authorized service

distributor/dealer to keep equipment in top condition.

x:in:001:002:a

Service Assistance

India, Bangladesh, Sri Lanka

India Regional Office

Bangalore, India

Phone: (91) 80-2284270

(91) 80-2284279

Fax: (91) 80-2284286

Japan

Japan Regional Office

Tokyo, Japan

Phone: (813) 3440-4515

Fax: (813) 3440-2727

Latin America

Latin America Regional Office

Lakeland, Florida, U.S.A.

Phone: (941) 619-7568

Fax: (941) 701-7131

South East Asia

Singapore Regional Office

Singapore, Republic of Singapore

Phone: (65) 264-6422

Fax: (65) 264-6455

X:in:008:001

TP-5737 5/01 iIntroduction

Page 14

Notes

TP-5737 5/01ii Service Assistance

Page 15

Section 1 Specifications

1.1 Introduction

The spec sheets for each generator set provide specific

generator and engine information. Refer to the

respective spec sheet for data not supplied in this

manual. Consult the generator set operation manual,

generator installation manual, engine operation

manual, and engine service manual for additional

specifications.

1.2 Specifications

The generator set consists of a rotating-field generator

combined with a smaller rotating-armature generator

turned by a common shaft. The main rotating-field

generator supplies current to the load circuits while the

rotating-armature (exciter) generator supplies rectified

AC (DC) to excite the main generator’s field.

Engine

Specification

Engine Prealarm and

Shutdown Switches

Anticipatory high engine

temperature switch

Anticipatory low oil

pressure switch

High engine temperature

shutdown switch

Low oil pressure

shutdown switch

High exhaust

temperature switch (wet

exhaust only)

Controller Gauge

Senders

Oil Pressure Sender

0kPa(0psi) 120 (+9/--8) 240 (+17/--15)

172 kPa (25 psi) 76.5 (+6/--7.5) 153 (+12/--15)

690 kPa (100 psi) 16.8 33.5

Water Temperature Sender

54° C (130° F) 100 ±15 180 ±12

82° C (180° F) 40 ±6 71 ±8

COZ/CFOZ and EOZ/EFOZ

Models

96_ C (205_ F) ±7

138 kPa ±14 kPa

(20 psi ±2)

103_ C (218_ F) ±7

103 kPa ±14 kPa

(15 psi ±2)

88--102_ C

(190--215_ F) ±5

Specification

(in ohms)

COZ/CFOZ

Models

Specification

(in ohms)

EOZ/EFOZ

Models

Generator

Component Specification Value

Controller/battery electrical system 12 or 24 volts DC

Generator field resistance (F+/ F--):

40/50COZ and 33/40CFOZ 2.0--2.9 ohms

65COZ and 50CFOZ 1.8--2.2 ohms

40EOZ and 33EFOZ 2.1--2.5 ohms

50EOZ and 40EFOZ 2.7--3.1 ohms

65/80EOZ and 55/70EFOZ 1.7--2.1 ohms

99EOZ and 80EFOZ 2.0--2.4 ohms

125EOZ and100EFOZ 1.4--1.8 ohms

150EOZ and 125EFOZ 1.6--2.0 ohms

Exciter armature resistance:

40/50COZ and 33/40CFOZ 0.13 ohms

65COZ and 50CFOZ 0.27 ohms

40EOZ and 33EFOZ 0.23 ohms

50EOZ and 40EFOZ 0.14 ohms

65/80EOZ and 55/70EFOZ 0.27 ohms

99EOZ and 80EFOZ 0.27 ohms

125EOZ and100EFOZ 0.27 ohms

150EOZ and 125EFOZ 0.27 ohms

SCR assembly terminal nut torque 1.4 Nm (12 in. lbs.)

Fan to rotor flange torque 29 Nm (260 in. lbs.)

Drive disks to rotor shaft torque 61 Nm (45 ft. lbs.)

Speed sensor air gap 0.36--0.71 mm

(0.014--0.028 in.)

Speed sensor voltage 2 (black) &

16 (white)

3--6 volts DC

2 (black) & 24 (red)

8--10 volts DC

Electronic governor magnetic pickup

air gap

Magnetic pickup output voltage

during cranking

Flex plate to flywheel bolt torque

(3/8-16)

0.36--0.71 mm

(0.014--0.028 in.)

2.5 volts AC min.

52.9 Nm

(39 ft. lbs.)

TP-5737 5/01 1Section 1 Specifications

Page 16

1.3 Accessories

1.3.1 Remote Annunciator Kit

Kohler Co. offers several accessories to finalize the

installation and to add convenience to operation and

service. Accessories vary with each generator set

model and controller. Kohler Co. offers accessories

factory-installed and/or shipped loose. Some

accessories are available only with microprocessor

controllers. Obtain current information by contacting

your local authorized service distributor/dealer.

Several accessories available at the time of print of this

publication are detailed in the following subsections.

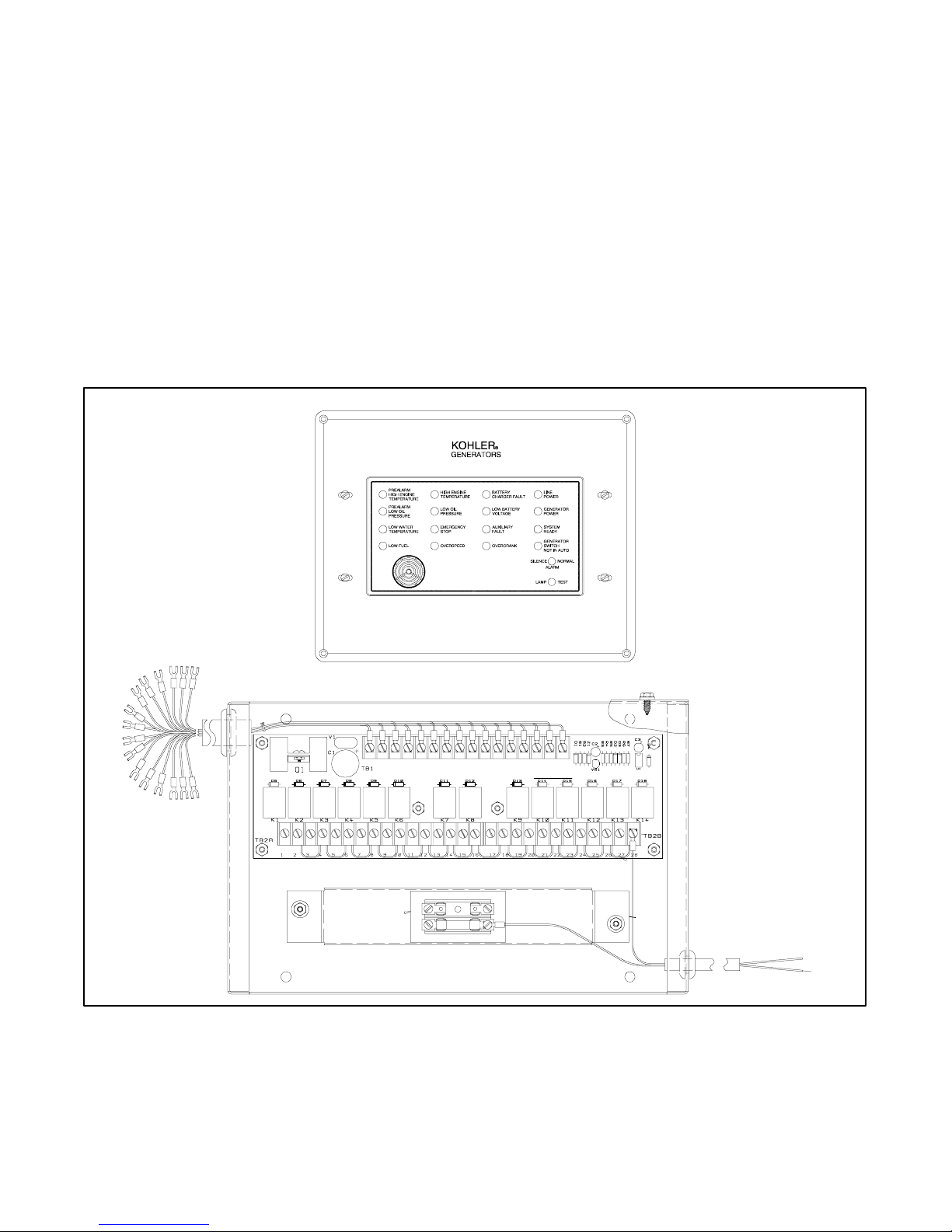

Remote Annunciator

A remote annunciator allows convenient monitoring of

the generator set’s condition from a remote location.

See Figure 1-1. The flush-mounted annunciator panel

extends all of the fault and prealarm lights/audio of the

Decision-Maker 3+ controller. The remote annunciator

includes an alarm horn, an alarm silence switch, a lamp

test, and the same lamp indicators (except air damper

and auxiliary prealarm) as the microprocessor

controller, plus the following:

Line Power. Lamp illuminates to indicate the power

source is shore power.

Generator Power. Lamp illuminates to indicate the

power source is the generator set.

14-Relay Dry Contact Box

42A 2 K1 K2 K3 K4 K5 K6 K7 K8 K9 K10 K11 K13 K14K12

CONTACTRATINGS: 10A@120VAC RES.LOAD

INPUT

NO C CNO CNO CNO CNO CNO CNO CNO CNO CNO CNO CNO CNO CNO

K1 K2 K3 K4 K5 K6 K7 K8 K9 K10 K11 K12 K13 K14

.01A@28VDC MIN.

10A@28VDC MAX.

42B

FBA--1

10 AMP

LOT NO.

P

Figure 1-1 Remote Annunciator with 14-Relay Dry Contact Kit

PCBASSY A--320639

N

P

A-344522TP-5750-1

TP-5737 5/012 Section 1 Specifications

Page 17

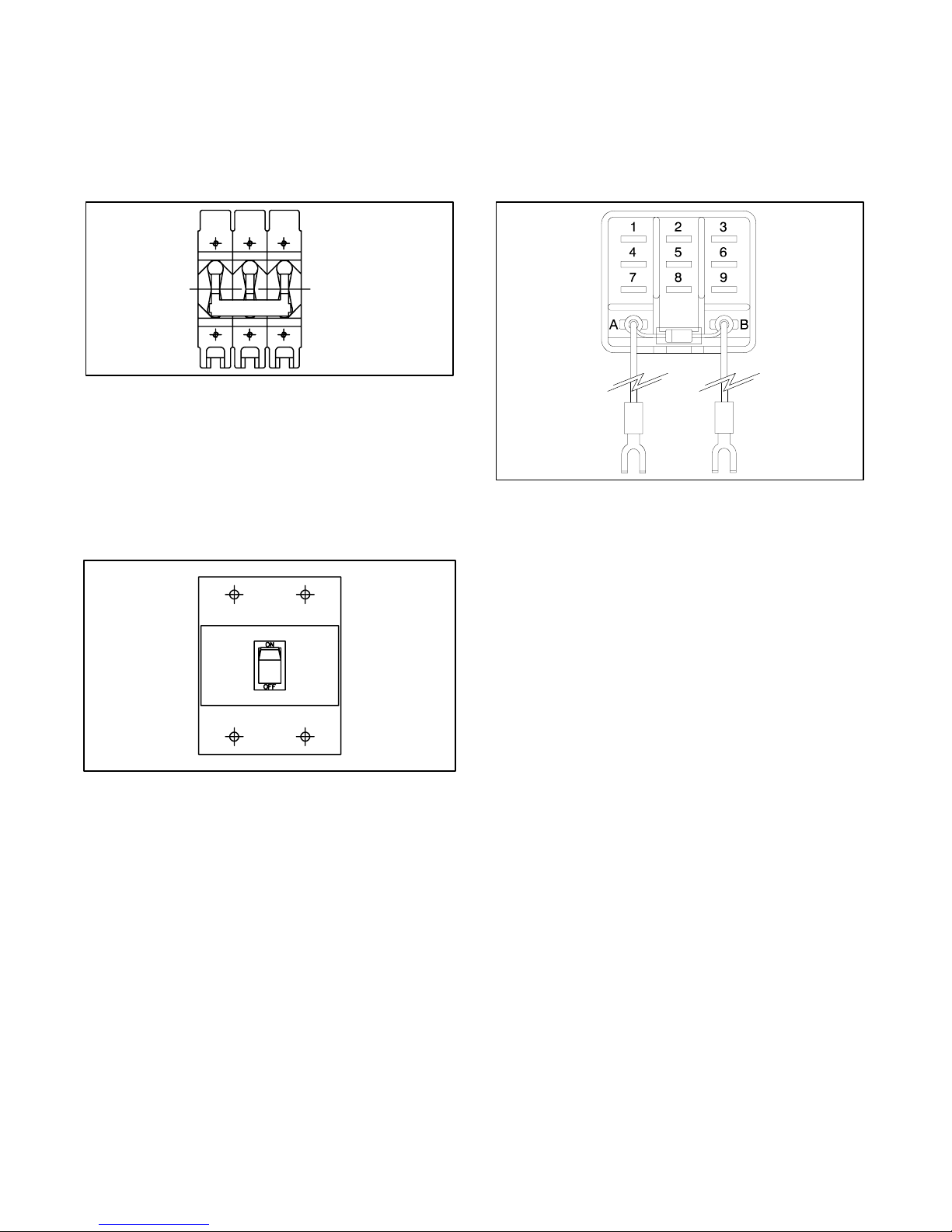

1.3.2 Safeguard Breaker

1.3.4 Run Relay Kit

The safeguard breaker senses output current on each

generator phase and shuts off the AC voltage regulator

in the event of a sustained overload or short circuit. It is

not a line circuit breaker and does NOT disconnect the

generator from the load. See Figure 1-2.

X-796

Figure 1-2 Safeguard Breaker

1.3.3 Line Circuit Breaker

The line circuit breaker interrupts generator output in the

event of an overload or short circuit. Use the kit to

manually disconnect the generator set from the load

when servicing the generator set. See Figure 1-3.

The run relay kit energizes only when the generator set

is running. Typically, the three sets of contacts control

air intake and/or compartment ventilation fans.

However, alarms and other signalling devices can also

connect to the contacts. See Figure 1-4.

273705

Figure 1-4 Run Relay Kit

TP-5352-1

Figure 1-3 Line Circuit Breaker

TP-5737 5/01 3Section 1 Specifications

Page 18

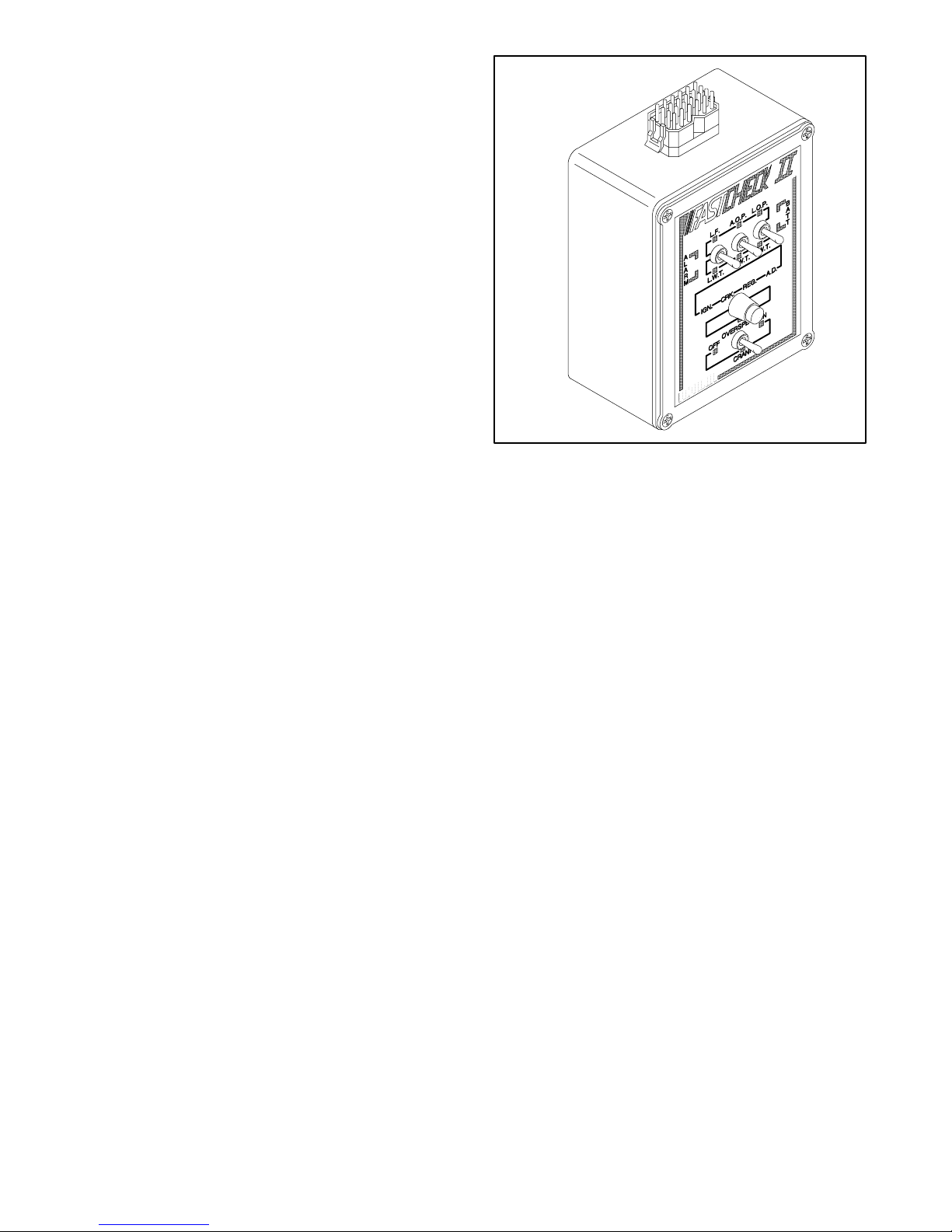

1.3.5 FASTCHECK Diagnostic Tester

(Microprocessor Controller Only)

The FASTCHECKâdiagnostic tester simulates engine

operation to identify faults in the controller and engine

circuitry. Use the FASTCHECK

startup problems or to test and troubleshoot the

controller when the controller is removed from the

generator. Perform tests without starting the generator

set. Functions performed by the FASTCHECKâare

listed below; refer to Figure 1-5 to identify LEDs and

switches.

â

when troubleshooting

LEDs on the FASTCHECK

â

indicate the energizing of

the following circuits:

D Fuel solenoid (diesel)

D Engine crank

D AC voltage regulator

D Battery connection (correct polarity)

D Engine malfunction alarm and/or alarm shutdown

â

Switches on the FASTCHECK

D Engine cranking

D Engine running

D Engine overspeed

D Low fuel

D Low engine coolant temperature

D Anticipatory low engine oil pressure

D Anticipatory high engine coolant temperature

D Low engine oil pressure

D High engine coolant temperature

simulate the following:

B-291930

Figure 1-5 FASTCHECKâDiagnostic Tester

TP-5737 5/014 Section 1 Specifications

Page 19

2.1 Fast-Responset II Concepts

The generator excitation system uses a permanent

magnet exciter with a silicon controlled rectifier (SCR)

assembly that controls the amount of DC current fed to

the generator field. This type of system uses a voltage

regulator that signals the SCR assembly through an

optocoupler. The voltage regulator monitors generator

output voltage and engine speed and signals the SCR

assembly to turn on or off accordingly through the

optocoupler. The optical coupler consists of a light

emitting diode (LED) mounted on the stationary end

bracket and a photo transistor mounted on the rotating

shaft. The photo transistor picks up the infrared signal

from the LED and signals the SCR assembly to turn on

or off, depending upon the need, as dictated by the

voltage regulator. See Figure 2-1.

Section 2 Operation

2

3

1

4

7

5

6

8

The voltage recovery period of this type of generator is

several times faster than the conventionally wound field

brushless generator because the generator set does not

have to contend with the inductance of the exciter field.

The generator set also has better recovery

characteristics than the static-excited machine because

it is not dependent upon the generator set output voltage

for excitation power. Possibly the greatest advantage of

this type of machine is its inherent ability to support

short-circuit current and allow system coordination for

tripping downstream branch circuit breakers.

The generator set systems deliver exciter current to the

main field within 50 milliseconds (0.050 seconds) of a

change in load demand.

2.2 Short Circuit Performance

When a short circuit occurs in the load circuit(s) being

served, output voltage drops and amperage

momentarily rises to 600--1000% of the generator set’s

rated current until removal of the short. The SCR

assembly sends full exciter power to the main field. The

generator then sustains up to 300% of its rated current.

Sustained high current causes correspondingly rated

load circuit fuses/breakers to trip. The safeguard

breaker kit shuts down the excitation system in the event

of a sustained heavy overload or short circuit.

12

11

13

16

1. Main armature

2. Main field

3. Main generator

4. Stator

5. SCR assembly

6. Exciter armature

7. Rotor

8. Exciter generator

9. Exciter field magnets

10. Optical coupler

11. LED board (PCB assembly)

12. Photo transistor board (PCB assembly)

13. AC voltage regulator

14. Starting battery

15. Safeguard breaker (optional)

16. Main output leads

15

Figure 2-1 Alternator Schematic

9

10

14

TP-5353-1

TP-5737 5/01 5Section 2 Operation

Page 20

2.3 Prestart Checklist

To ensure continued satisfactory operation perform the

following checks or inspections before or at each

startup, as designated, and at the intervals specified in

the service schedule. In addition, some checks require

verification after the unit starts.

Air Cleaner. Check for a clean and installed air cleaner

element to prevent unfiltered air from entering the

engine.

Air Inlets. Check for clean and unobstructed air inlets.

Air Shrouding. Check for securely installed and

positioned air shrouding.

Battery. Check for tight battery connections. Consult

the battery manufacturer’s instructions regarding

battery care and maintenance.

Fuel Level. Check the fuel level and keep the tank(s)

full to ensure adequate fuel supply.

Oil Level. Maintain the oil level at or near, not over, the

full mark on the dipstick.

Operating Area. Check for obstructions that could

block the flow of cooling air. Keep the air intake area

clean. Do not leave rags, tools, or debris on or near the

generator set.

Seawater Pump Priming. Prime the seawater pump

before initial startup. To prime the pump: (1) close the

seacock, (2) remove the hose from the water-filter

outlet, (3) fill the hose and seawater pump with clean

water, (4) reconnect the hose to the water filter outlet,

and (5) open the seacock. Confirm sea water pump

operation on startup as indicated by water discharge

from the exhaust outlet.

Coolant Level. Check the coolant level according to

the cooling system maintenance information.

Drive Belts. Check the belt condition and tension of the

water pump and battery charging alternator belt(s).

Exhaust System. Check for exhaust leaks and

blockages. Check the silencer and piping condition and

check for tight exhaust system connections.

Inspect the exhaust system components (exhaust

manifold, mixing elbow, exhaust line, hose c lamps,

silencer, and exhaust outlet) for cracks, leaks, and

corrosion.

D Check the hoses for softness, cracks, leaks, or dents.

Replace the hoses as needed.

D Check for corroded or broken metal parts and replace

them as needed.

D Check for loose, corroded, or missing clamps.

Tighten or replace the hose clamps as needed.

D Check that the exhaust outlet is unobstructed.

D Visually inspect for exhaust leaks (blowby). Check

for carbon or soot residue on exhaust components.

Carbon and soot residue indicates an exhaust leak.

Seal leaks as needed.

D Ensure that the carbon monoxide detector is (1) in the

craft, (2) functional, and (3) energized whenever the

generator set operates.

2.4 Marine Inspection

Kohler Co. recommends that all boat owners have their

vessels—especially the exhaust system attached to the

generator set—inspected at the start of each boating

season by the local Coast Guard Auxiliary. If there is no

Coast Guard Auxiliary in the area, contact an authorized

Kohler distributor/dealer for the inspection.

m:op:001:003

2.5 Angular Operation

See Figure 2-2 for angular operation limits for units

covered in this manual.

Intermittent—

Continuous

25_ 30_

Maximum value for all directions

3 minutes or less

Figure 2-2 Angular Operation

m:op:001:004

2.6 Exercising the Generator Set

Operate the generator set under load once each week

for one hour with an operator present.

The operator should perform all of the prestart checks

before starting the exercise procedure. Start the

generator set according to the starting procedure in the

controller section of this manual. While the generator

set is operating, listen for a smooth-running engine and

visually inspect the generator set for fluid or exhaust

leaks.

x:op:001:005

TP-5737 5/016 Section 2 Operation

Page 21

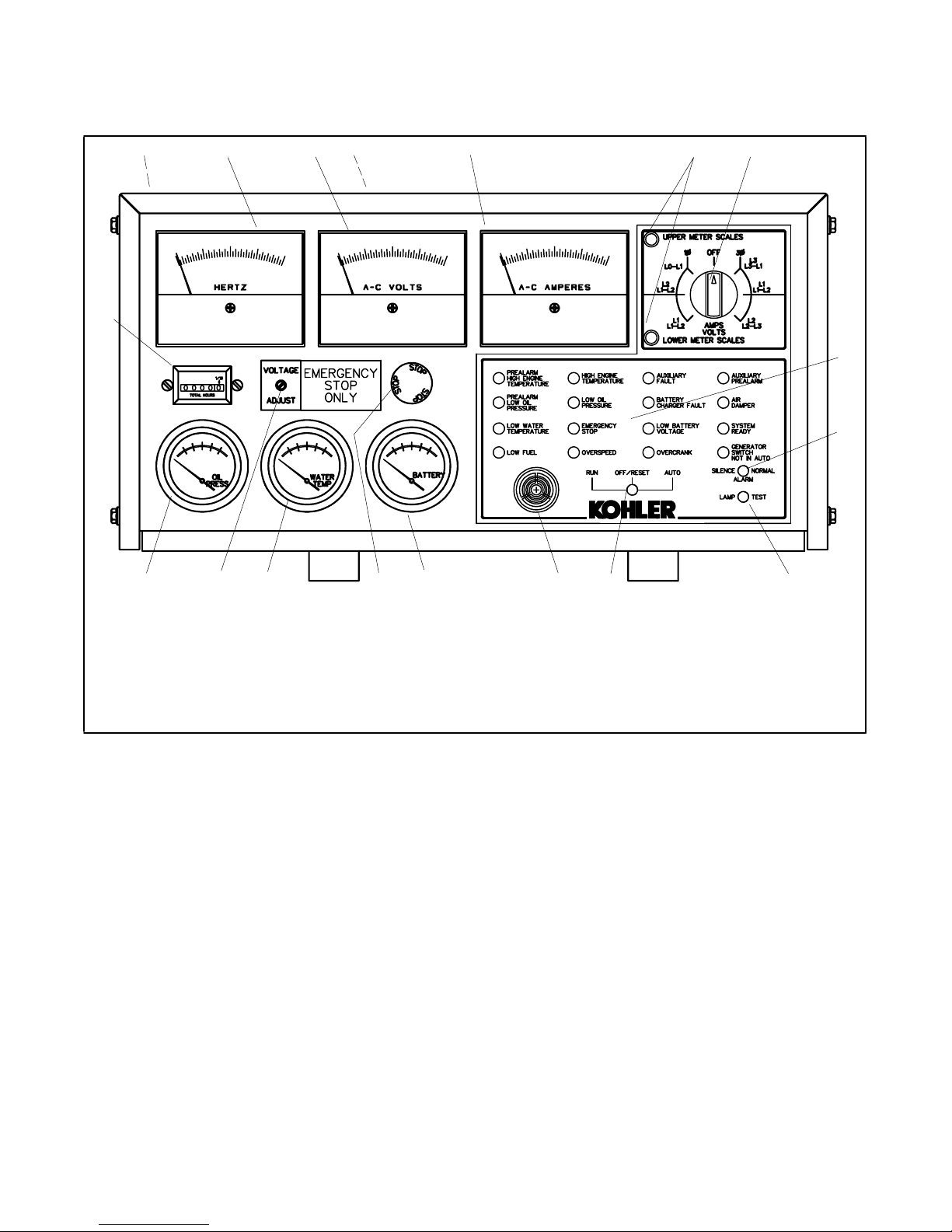

2.7 Decision-Makerä 3+ 16-Light Microprocessor Controller Operation

Figure 2-3 identifies the Decision-Makert 3+ 16-light controller’s indicators and controls and their functions.

12 34 5 6

18

1. Fuses (inside controller)

2. Frequency meter

3. AC voltmeter

4. Controller TB1 and TB2 terminal strips (on circuit board)

5. AC ammeter

6. Scale lamps (upper/lower)

7. Selector switch

8. Annunciator panel lamps

9. Alarm silence switch

10. Lamp test

11. Generator set master switch

12. Alarm horn

13. DC voltmeter

14. Emergency stop switch, if equipped

15. Water temperature gauge

16. Voltage adjustment

17. Oil pressure gauge

18. Hourmeter

7

8

9

1011121314151617

ADV-5849 P1

Figure 2-3 Decision-Makert 3+, 16-Light Microprocessor Controller

TP-5737 5/01 7Section 2 Operation

Page 22

2.7.1 Controls and Indicators

The following table describes the controls and indicators

located on the controller.

Name Description

AC ammeter The meter displays the AC output

AC voltmeter The meter displays the AC output

DC voltmeter The meter displays the voltage of

Alarm horn The horn sounds if any fault or

Alarm silence switch The switch disconnects the alarm

Auxiliary fault lamp The lamp flashes or lights when

Frequency meter The meter displays the frequency

Generator set master

switch

High engine

temperature lamp

Hourmeter The hourmeter records the

amperage. Use the selector

switch to choose the phase

current.

voltage. Use the selector switch to

choose the output lead circuits.

the starting battery(ies).

anticipatory condition exists.

Place the generator set master

switch in the AUTO position before

silencing the horn. See the

Controller Resetting Procedure

later in this section.

during service (place the generator

set master switch in the AUTO

position before silencing the alarm

horn). Restore the alarm horn

switches at all locations (controller,

remote annunciator, and

audio/visual alarm) to normal

positions after correcting the fault

shutdown to avoid reactivating the

alarm horn. See the Controller

Resetting Procedure later in this

section.

the controller detects a fault. See

the lamp conditions section

following.

(Hz) of the generator set output

voltage.

The switch functions as the

controller reset and generator set

operation switch.

The lamp illuminates if the

generator set shuts down because

of high engine temperature.

Shutdown occurs 5 seconds after

the engine reaches temperature

shutdown range.

generator set total operating hours

for reference in maintenance

scheduling.

Lamp test switch The switch tests the controller

Low oil pressure

lamp

Overcrank lamp The lamp illuminates and cranking

Overspeed lamp The lamp illuminates if the

Water temperature

gauge

Oil pressure gauge The gauge displays the engine oil

Scale lamps

(upper/lower)

Selector switch The switch selects the generator

Voltage adjustment

potentiometer

indicator lamps.

The lamp illuminates if the

generator set shuts down because

of low oil pressure. Shutdown

occurs 5 seconds after the engine

reaches oil pressure shutdown

range.

stops if the engine does not start

after 45 seconds of continuous

cranking or 75 seconds of cyclic

cranking.

The cranking stops and overcrank

lamp lights after 15 seconds if the

starter or engine does not turn

(locked rotor).

The overcrank lamp flashes if the

speed sensor signal is absent

longer than one second.

NOTE: The generator set

controller’s automatic restart

function attempts to restart the

generator set if the engine speed

drops below 13 Hz (390 rpm).

Continued decreased engine

speed causes an overcrank

condition.

generator set shuts down because

governed frequency on 50 and

60 Hz models exceeds 70 Hz.

The gauge displays the engine

coolant temperature.

pressure.

The lamps indicate which AC

voltmeter and/or ammeter scales

to read.

set output circuits to measure.

When switched to a position with

two circuit labels, measure

amperage on the lead shown in

the upper label and measure

voltage between the two leads

shown in the lower label. The AC

ammeter and voltmeter function

only with the switch in the ON

position.

The potentiometer fine-tunes

(±5%) the generator set output

voltage.

TP-5737 5/018 Section 2 Operation

Page 23

Name Description

Auxiliary prealarm

lamp

The lamp illuminates when

customer-provided sensing

devices activate the pump.

Emergency stop

lamp

The lamp illuminates and the

generator set shuts down when

energizing the optional emergency

stop switch. The lamp needs the

optional emergency stop switch to

function.

Generator switch not

in auto lamp

The lamp illuminates when the

generator set master switch is in

the RUN or OFF/RESET position.

Low fuel lamp The lamp illuminates when the fuel

level in the tank approaches

empty. The lamp needs a low fuel

sensor in the fuel tank to function.

High water

temperature lamp

The lamp illuminates when the

water temperature approaches

shutdown range. The lamp needs

an optional prealarm sender kit to

function.

Prealarm high engine

temperature lamp

The lamp illuminates when the

engine coolant temperature

approaches shutdown range. The

lamp needs an optional prealarm

sender kit to function.

Prealarm low oil

pressure lamp

The lamp illuminates when the

engine oil pressure approaches

shutdown range. The lamp needs

an optional prealarm sender kit to

function.

System ready lamp The lamp illuminates when the

generator set master switch is in

AUTO position and the system

senses no faults.

Emergency stop

switch

The switch, if activated, instantly

shuts down the generator set in

emergency situations. Use the

emergency stop switch for

emergency shutdowns only. Use

the generator set master switch for

normal shutdowns.

2.7.2 Fuses and Terminal Strips

The following table describes the controller circuit board

fuses and controller terminal strips.

Name Description

3-amp remote

annunciator fuse

3-amp controller fuse The fuse protects the controller

15-amp engine and

accessories fuse

Controller TB1

terminal strip

Controller TB2

terminal strip

The fuse protects the remote

annunciator circuit, A/V alarm, and

isolated alarm kit, if equipped.

circuit board, speed sensor, and

lamp circuit board.

Thefuseprotectsthe

engine/starting circuitry and

accessories.

The terminal strip provides

connection points for

customer-supplied sensing

devices and generator set

accessories such as the

emergency stop switch, remote

start stop/switch, audio/visual

alarms, etc., to the controller.

Figure 2-4 shows the location of

the TB1 terminal strip on the

controller circuit board. Refer to

the wiring diagrams for information

on connecting accessories to the

TB1 terminal strip.

The terminal strip provides

connection points for crank mode

selection (cyclic or continuous)

and remote start/stop switch inputs

of operation. Figure 2-4 shows the

location of the TB2 terminal strip

on the controller circuit board.

Refer to the wiring diagrams for

connection information.

12

TP-5737 5/01 9Section 2 Operation

3

R41

LED4

P2

1. TB1 terminal strip

2. TB2 terminal strip

3. Fuses

P1

Figure 2-4 TB1 and TB2 Terminal Strips on

Decision-Makert 3+ Controller Circuit

Board

A-336415-A

Page 24

2.7.3 Auxiliary Fault Lamp Conditions

2.7.4 Starting the Generator Set

The following descriptions define the possible auxiliary

fault lamp conditions.

Flashing Lamp Conditions

No AC Output. The auxiliary lamp flashes immediately

if the controller senses no AC output while the generator

set runs (except during the first 10 seconds after

startup). The flashing stops and the light goes out when

the controller senses AC output. The controller requires

no manual reset.

Low Battery Voltage. The auxiliary lamp flashes if the

battery power was reconnected or was low and then

restored while the generator set master switch was in

the RUN or AUTO position. A possible cause is a

temporary low battery condition when the battery is

weak or undersized for the application. To clear the low

battery voltage condition, place the generator set

master switch in the OFF/RESET position.

Continuous-On Lamp Conditions

Emergency Stop Switch Energized. Upon activation

of the emergency stop switch, if equipped, the auxiliary

lamp lights and the generator set shuts down

immediately.

Emergency Stop Switch Reset. Resetting the

optional emergency stop switch while the generator set

master switch is in the AUTO or RUN position causes

the auxiliary lamp to light. Place the generator set

master switch in the OFF/RESET position to clear the

auxiliary lamp ON condition.

Note: Auxiliary Delay Shutdown. The auxiliary lamp

lights and the engine shuts down 5 seconds after

the high oil temperature (P1-13) or auxiliary delay

shutdown (P1-15) fault, if equipped, occurs.

Auxiliary Delay Shutdown is inhibited during the

first 30 seconds after crank disconnect.

The following procedures describe starting the

generator set.

Local Starting (Nonautomatic). Move the generator

set master switch to the RUN position to start the

generator set at the controller.

Note: The alarm horn sounds whenever the generator

set master switch is not in the AUTO position.

Automatic (Auto) Starting. Move the generator set

master switch to the AUTO position to allow startup by

the automatic transfer switch or remote start/stop switch

(connected to controller terminals TB1-3 and TB1-4).

Note: The transient start/stop function of the

Decision-Makert3+ controller prevents

accidental cranking of the rotating engine. When

the generator set master switch is momentarily

placed in the OFF/RESET position, then quickly

returned to RUN, the generator set slows to

249 rpm and then recranks before returning to

rated speed.

Note: The Decision-Makert 3+ controller’s automatic

restart function attempts to restart the generator

set if the engine speed drops below 390 rpm

(generator output frequency of 13 Hz).

Continued decreased engine speed causes an

overcrank fault condition.

Crank Mode Selection

The Decision-Makert3+ controller cranks continuously

for up to 45 seconds or cyclically for up to 75 seconds

(crank 15 seconds, rest 15 seconds, crank 15 seconds,

etc.) before overcrank shutdown. Select the crank

mode (cyclic or continuous) on the controller circuit

board terminal strip. For cyclic cranking, leave circuit

board terminal TB2-9 open. For continuous cranking,

attach a jumper between circuit board terminal TB2-9A

(ground) and terminal TB2-9.

Note: Overvoltage Shutdown. If a generator set is

equipped with this kit, the auxiliary lamp lights

and the engine shuts down immediately when an

overvoltage condition occurs.

Note: Auxiliary Immediate Shutdown. The auxiliary

lamp lights and the engine shuts down

immediately when any customer-supplied

sensing devices connected to auxiliary

immediate shutdown ports (P1-17 and P1-18)

activate them.

x:op:005:004

2.7.5 Stopping the Generator Set

The following procedures describe stopping the

generator set.

Normal Stopping

1. Cooldown. Run the generator set at no load for

5 minutes to ensure adequate engine cooldown.

2. Stopping. Move the generator set master switch

to the OFF/RESET position. The engine stops.

TP-5737 5/0110 Section 2 Operation

Page 25

Note: The generator set continues running during

a 5-minute cooldown cycle if a remote

switch or automatic transfer switch signals

the engine to stop.

Emergency Stopping

Move the generator set master switch to the

OFF/RESET position or activate the remote emergency

stop, if equipped, for immediate shutdown. The

controller AUXILIARY lamp lights and the generator set

shuts down on activation of the emergency stop switch.

The remote annunciator and/or A/V alarms, if equipped,

signal an emergency stop.

2.7.6 Prime Power Mode Operation

The Decision-Makert 3+ controller operates in either

the normal mode or the prime power mode. In prime

power mode, the controller draws less current,

minimizing the battery drain. Consider using the prime

power mode for installations that do not have a battery

charger.

Moving the generator set master switch to the

OFF/RESET position disables all controller functions.

Moving the generator set master switch to the AUTO

position restores controller functions.

Enabling and Disabling the Prime Power Mode.

Enable the prime power mode by connecting jumpers

across the following terminals on terminal strip TB2 on

the controller circuit board:

D TB2-1P and TB2-2P

D TB2-3P and TB2-4P

D TB2-3 and TB2-4

See Figure 2-4. Remove the jumpers listed above to

disable the prime power mode.

Prime Power Starting. The prime power mode

provides local starting only at the controller. When the

generator set master switch is in the OFF/RESET

position, the controller functions are inoperative. Move

the generator set master switch to the AUTO position to

start the generator set. Do not start the generator set

with the master switch in the RUN position because the

alarm horn sounds.

Note: Move the generator set master switch to the

AUTO position to return controller functions to

normal.

2.7.7 Fault Shutdowns

The generator set shuts down automatically under the

following fault conditions and cannot be restarted until

the fault condition is corrected. The system

automatically resets when the problem is corrected or

the generator set cools (if high engine temperature was

the fault).

Name Description

High engine

temperature

High exhaust

temperature

Low coolant level

(water-cooled

engines only)

Low oil pressure Shutdown occurs 5 seconds after

Overcrank Shutdown occurs after 45 seconds

Overspeed Shutdown occurs immediately

Overvoltage

(optional)

Shutdown occurs 5 seconds after

the fault. The high engine

temperature shutdown does not

function during the first 5 seconds

after startup.

NOTE: The high temperature

shutdown functions only when the

coolant level is in the operating

range.

Shutdown occurs 5 seconds after

the fault. The high exhaust

temperature shutdown does not

function during the first 5 seconds

after startup.

Shutdown occurs 5 seconds after

fault. The low coolant level

shutdown does not function during

the first 5 seconds after startup.

the fault. The low oil pressure

shutdown does not function during

the first 5 seconds after startup.

NOTE: The low oil pressure

shutdown does not protect against

low oil level. Check the engine oil

level.

of continuous cranking or 75

seconds of cyclic cranking (crank

15 seconds, rest 15 seconds,

crank 15 seconds, etc.).

when governed frequency on 50

and 60 Hz models exceeds 70 Hz.

The generator set shuts down and

the auxiliary lamp lights when

voltage is 15% or more over the

nominal voltage for 2 seconds or

longer.

NOTE: Overvoltage can damage

sensitive equipment in less than

one second. Install separate

overvoltage protection on on-line

equipment requiring faster

shutdown.

x:op:005:007

Prime Power Stopping. Move the generator set

master switch to the OFF/RESET position to stop the

generator set and power down the controller.

TP-5737 5/01 11Section 2 Operation

Page 26

2.7.8 Controller Resetting Procedure

(Following Fault Shutdown)

2.7.9 Resetting the Emergency Stop

Switch

Use the following procedure to restart the generator set

after a fault shutdown. Refer to Resetting the

Emergency Stop Switch in this section to reset the

generator set after an emergency stop.

1. Place the controller alarm horn silence switch in the

SILENCE position. Place the A/V annunciator

alarm switch, if equipped, in the SILENCE position

to stop the alarm horn. The A/V annunciator lamp

stays lit. (The A/V alarm uses one lamp to indicate

a fault shutdown; the respective fault lamp on the

remote annunciator lights to indicate a fault

condition.)

2. Disconnect the generator set from the load using

the line circuit breaker or automatic transfer switch.

3. Correct the cause of the fault shutdown. See the

Safety Precautions at the beginning of this section

before proceeding.

4. Place the generator set master switch in the

OFF/RESET position and then in the RUN position

to start the generator set. The A/V annunciator

alarm horn sounds and the lamp, if equipped,

darkens.

Use the following procedure to restart the generator set

after an emergency stop switch shutdown. Refer to the

Controller Resetting Procedure in this section to restart

the generator set following a fault shutdown. The

generator set does not crank until the operator

completes the resetting procedure.

Note: The controller auxiliary lamp lights when the

generator set master switch is in the RUN or

AUTO position during the resetting procedure.

Procedure to Restart the Generator Set After an

Emergency Stop Shutdown:

1. Determine the cause of the emergency stop and

correct the problem(s).

2. Reset the controller emergency stop switch by

rotating the switch clockwise until the switch

springs back to the original position. See

Figure 2-3.

3. Toggle the generator set master switch to

OFF/RESET and then to RUN or AUTO to restart

the generator set.

5. Test operate the generator set to verify that the

cause of the shutdown has been corrected.

6. Reconnect the generator set to the load via the line

circuit breaker or automatic transfer switch.

7. Place the generator set master switch in the AUTO

position for startup by a remote transfer switch or

remote start/stop switch. Place the A/V

annunciator alarm switch, if equipped, in the

NORMAL position.

8. Place the generator set master switch in the AUTO

position before silencing the alarm horn.

TP-5737 5/0112 Section 2 Operation

Page 27

2.8 Expanded Decision-Makert 1 Controller Operation

For identification of the expanded controller’s indicators and controls and their functions, refer to Figure 2-5.

13

1. Frequency meter

2. AC voltmeter

3. AC ammeter

4. Scale lamps (upper/lower)

5. Selector switch

6. Hourmeter

7. Generator set master switch

1

12

2

11

Figure 2-5 Expanded Decision-Makert 1 Controller

3

10

9

8. Voltage adjustment potentiometer

9. Fault lamp

10. 10-amp controller fuse

11. DC voltmeter

12. Water temperature gauge

13. Oil pressure gauge

4

8

7

5

6

ADV-5849E-B

x:op:002:001

2.8.1 Controls and Indicators

The following table describes the controls and indicators

located on the controller.

Name Description

AC voltmeter The meter displays the AC output

AC ammeter The meter displays the AC output

DC voltmeter The meter displays the voltage of the

Fault lamp The lamp illuminates during engine

Frequency meter The meter displays the frequency (Hz)

Generator set

master switch

Hourmeter The hourmeter records the generator

voltage. Use the selector switch to

choose the output lead circuits.

amperage. Use the selector switch to

choose the phase currents.

starting battery(ies).

shutdown if the engine shuts down

because of one of the following faults:

high engine temperature, low water

level, low oil pressure, overcrank, or

overspeed. See Section 2.8.4, Fault

Shutdowns, for additional shutdown

information.

of the generator set output.

The switch functions as the controller

reset and generator set operation

switch.

set total operating hours for reference

in maintenance scheduling.

Oil pressure

gauge

Scale lamps

(upper/lower)

The gauge displays the engine oil

pressure.

The lamps indicate which AC

voltmeter and/or ammeter scales to

read.

Selector switch The switch selects the generator set

output circuits to measure. When

switched to a position with two circuit

labels, measure amperage on the

lead shown in the upper label and

measure voltage between the two

leads shown in the lower label. The

AC ammeter and voltmeter function

only with the switch in the ON

position.

Voltage

adjustment

The potentiometer fine-tunes (±5%)

the generator set output voltage.

potentiometer

Water

temperature

The gauge displays the engine

coolant temperature.

gauge

10-amp controller

fuse

The fuse protects the controller

circuitry from short circuits and

overloads.

TP-5737 5/01 13Section 2 Operation

Page 28

2.8.2 Starting the Generator Set

The following procedure describes the actions required

to start the generator set.

Local Starting. Move the generator set to the RUN

position to immediately start the generator set.

Auto (Automatic) Starting. Move the generator set

master switch to the AUTO position to allow startup by

the automatic transfer switch or the remote start/stop

switch (connected to controller terminals TB1-3 and

TB1-4).

Note: The controller provides up to 30 seconds of

continuous cranking before overcrank shutdown

occurs.

x:op:002:003

2.8.3 Stopping the Generator Set

2.8.5 Controller Resetting Procedure

(Following Fault Shutdown)

Use the following procedure to restart the generator set

after a fault shutdown.

1. Disconnect the generator set from the load using

the line circuit breaker or automatic transfer switch.

See the Safety Precautions at the beginning of this

section before proceeding.

2. Correct the cause of the fault shutdown. See the

Safety Precautions at the beginning of this section

before proceeding.

3. Start the generator set by moving the generator set

master switch to RESET/OFF and then to RUN.

4. Verify that the cause of the shutdown has been

corrected by test operating the generator set.

The following procedure describe how to stop the

generator set.

Normal Stopping

1. Cooldown. Run the generator set at no load for

5 minutes to ensure adequate engine cooldown.

2. Stopping. Move the generator set master switch

to the OFF/RESET position. The engine stops.

x:op:002:004

2.8.4 Fault Shutdowns

The generator set shuts down automatically under the

following fault conditions and cannot be restarted until

the fault condition is corrected. The system automatically

resets when the problem is corrected or the generator

set cools (if high engine temperature was the fault).

The fault lamp does not stay lit after the generator set

shuts down on a fault condition.

5. Reconnect the generator set to the load using the

line circuit breaker or automatic transfer switch.

6. Move the generator set master switch to the AUTO

position for startup by remote transfer switch or

remote start/stop switch.

Fault Description

High engine

temperature

High exhaust

temperature

Low coolant level Shutdown occurs 5 seconds after the

Low oil pressure Shutdown occurs 5 seconds after the

Overcrank Shutdown occurs after 30 seconds of

Overspeed Shutdown occurs immediately when

Shutdown occurs 5 seconds after the

fault. The high engine temperature

shutdown does not function during the

first 5 seconds after startup.

Note: The high temperature

shutdown functions only when the

coolant level is in the operating range.

Shutdown occurs 5 seconds after the

fault. The high exhaust temperature

shutdown does not function during the

first 5 seconds after startup.

fault. The low coolant level shutdown

does not function during the first

5 seconds after startup.

fault. The low oil pressure shutdown

does not function during the first

5 seconds after startup.

Note: The low oil pressure shutdown

does not protect against low oil level.

Check the oil level at the engine.

continuous cranking. Shutdown

occurs after 30 seconds if the engine

or starter does not turn (locked rotor).

the governed frequency on the 50 and

60 Hz models exceeds 70 Hz.

x:op:002:006