Kohler 14RESA, 20RESA, 14RESAL, 20RESAL Installation Manual

Installation (EN)

Installation (FR)

Instalación (ES)

Installation (DE)

Installatie (NL)

Установка (RU)

安装 (ZH)

14/20RESA

14/20RESAL

TP-6803-CMP 1/15j

Installation

Residential/Commercial Generator Sets

Models:

14/20RESA

14/20RESAL

Controllers:

RDC2

DC2

TP-6803 1/15j

California Proposition 65

WARNING

Engine exhaust from this product contains chemicals

known to the State of California to cause cancer, birth

defects, or other reproductive harm.

Product Identification Information

Generator Set Identification Numbers

Record the product identification numbers from the

generator set nameplate(s).

Model Designation

Specification Number

Serial Number

Accessory Number Accessory Description

Engine Identification

Record the product identification information from the

engine nameplate.

Manufacturer

Model Designation

Serial Number

Controller Identification

Record the controller description from the generator set

operation manual, spec sheet, or sales invoice.

Controller Description

Table of Contents

Product Identification Information 2.............................................................

Safety Precautions and Instructions 5.........................................................

Introduction 9...............................................................................

Startup and Registration 9.....................................................

Service Assistance 10.........................................................................

Section 1 Installation 11......................................................................

1.1 Introduction 11...........................................................

1.2 Lifting 11................................................................

1.3 Generator Set Inspection 12...............................................

1.4 Location and Mounting 12.................................................

1.4.1 Mounting Area 12................................................

1.4.2 Concrete Mounting Pads 12.......................................

1.4.3 Exhaust Requirements 12.........................................

1.5 Dimension Drawings 13...................................................

1.6 Access the Air Intake Area 13..............................................

1.7 Fuel Requirements 14.....................................................

1.7.1 Fuel Supply 14...................................................

1.7.2 Fuel Pipe Size 15.................................................

1.7.3 Connecting the Fuel Supply 15.....................................

1.8 Fuel Conversion 16.......................................................

1.8.1 Fuel Conversion, 14RESA/RESAL Equipped with Fuel Block 16........

1.8.2 Fuel Conversion, 14RESA/RESAL Equipped with Fuel Orifice Fittings 18

1.8.3 Fuel Conversion, 20RESA/RESAL 20...............................

1.8.4 Regulator Vent Hose 20...........................................

1.9 Electrical Connections 21..................................................

1.9.1 Grounding 22....................................................

1.9.2 Electrical Lead Entry 22...........................................

1.9.3 Field-Connection Terminal Block 22.................................

1.9.4 AC Power Supply 24..............................................

1.10 ATS and Accessory Connections 25........................................

1.10.1 Transfer Switch Connection 25.....................................

1.10.2 Communication Cable Specifications 26.............................

1.10.3 System Connections with Accessory Modules 26.....................

1.11 Battery 30...............................................................

1.12 Generator Set Accessories 32..............................................

1.12.1 Programmable Interface Module (PIM) 32...........................

1.12.2 Load Control Module (LCM) 33.....................................

1.12.3 Load Shed Kit 34.................................................

1.12.4 Regulator Heater 35..............................................

1.12.5 Carburetor Heater 37.............................................

1.12.6 Battery Heater 39.................................................

1.12.7 OnCue Plus Generator Management System 40......................

1.13 Prestart Installation Check 41..............................................

1.14 Set the Exerciser 42......................................................

1.14.1 RDC2 Controller 42...............................................

1.14.2 DC2 Controller 42................................................

1.14.3 Loaded Exercise 42

Section 2 Drawings and Diagrams 43..........................................................

...............................................

Appendix A Abbreviations 55................................................................

Appendix B Electrical Lead Entry Template 57.................................................

TP-6803 1/15 Table of Contents 3

Notes

TP-6803 1/154

Safety Precautions and Instructions

IMPORTANT SAFETY INSTRUCTIONS.

Electromechanical equipment,

including generator sets, transfer

switches, switchgear, and accessories,

can cause bodily harm and pose

life-threatening danger when

improperly installed, operated, or

maintained. To prevent accidents be

aware of potential dangers and act

safely. Read and follow all safety

precautions and instructions. SAVE

THESE INSTRUCTIONS.

This manual has several types of safety

precautions and instructions: Danger,

Warning, Caution, and Notice.

DANGER

Danger indicates the presence of a

hazard that will cause severe

personal i njury, death,orsubstantial

property damage.

WARNING

Warning indicates the presence of a

hazard that can cause severe

personal injury, death, or substantial

property damage.

CAUTION

Caution indicates the presence of a

hazard that will or can cause minor

personal injury or property damage.

NOTICE

Notice communicates installation,

operation, or maintenance information

that is safety related but not hazard

related.

Safety decals affixed to the equipment

in prominent places alert the operator

or service technician to potential

hazards and explain how to act safely.

The decals are shown throughout this

publication to improve operator

recognition. Replace missing or

damaged decals.

Accidental Starting

WARNING

Accidental starting.

Can cause severe injury or death.

Disconnect the battery cables before

working on the generator set.

Remove the negative (--) lead first

when disconnecting the battery.

Reconnect the negative (--) lead last

when reconnecting the battery.

Disabling the generator set.

Accidental starting can cause

severe injury or death. Before

working on the generator set or

equipment connected to the set,

disable the generator set as follows:

(1) Press the generator set off/reset

button to shut down the generator set.

(2) Disconnect the power to the battery

charger, if equipped. (3) Remove the

battery cables, negative (--) lead first.

Reconnect the negative (--) lead last

when reconnecting the battery. Follow

these precautions to prevent the

starting of the generator set by the

remote start/stop switch.

Battery

WARNING

Sulfuric acid in batteries.

Can cause severe injury or death.

Wear protective goggles and

clothing. Battery acid may cause

blindness and burn skin.

WARNING

Explosion.

Can cause severe injury or death.

Relays in the battery charger

cause arcs or sparks.

Locate the battery in a well-ventilated

area. Isolate the battery charger from

explosive fumes.

Battery electrolyte is a diluted

sulfuric acid. Battery acid can cause

severe injury or death. Battery acid

can cause blindness and burn skin.

Always wear splashproof safety

goggles, rubber gloves, and boots

when servicing the battery. Do not

open a sealed battery or mutilate the

battery case. If battery acid splashes in

the eyes or on the skin, immediately

flush the affected area for 15 minutes

with large quantities of clean water.

Seek immediate medical aid in the case

of eye contact. Never add acid to a

battery after placing the battery in

service, as this may result in hazardous

spattering of battery acid.

Battery acid cleanup. Battery acid

can cause severe injury or death.

Battery acid is electrically conductive

and corrosive. Add 500 g (1 lb.) of

bicarbonate of soda (baking soda) to a

container with 4 L (1 gal.) of water and

mix the neutralizing solution. Pour the

neutralizing solution on the spilled

battery acid and continue to add the

neutralizing solution to the spilled

battery acid until all evidence of a

chemical reaction (foaming) has

ceased. Flush the resulting liquid with

water and dry the area.

TP-6803 1/15 5Safety Precautions and Instructions

Battery gases. Explosion can cause

severe injury or death. Battery gases

can cause an explosion. Do not smoke

or permit flames or sparks to occur near

a battery at any time, particularly when

it is charging. Do not dispose of a

battery in a fire. To prevent burns and

sparks that could cause an explosion,

avoid touching the battery terminals

with tools or other metal objects.

Remove all jewelry before servicing the

equipment. Discharge static electricity

from your body before touching

batteries by first touching a grounded

metal surface away from the battery. To

avoid sparks, do not disturb the battery

charger connections while the battery

is charging. Always turn the battery

charger off before disconnecting the

battery connections. Ventilate the

compartments containing batteries to

prevent accumulation of explosive

gases.

Battery short circuits. Explosion

can cause severe injury or death.

Short circuits can cause bodily injury

and/or equipment damage.

Disconnect the battery before

generator set installation or

maintenance. Remove all jewelry

before servicing the equipment. Use

tools with insulated handles. Remove

the negative (--) lead first when

disconnecting the battery. Reconnect

the negative (--) lead last when

reconnecting the battery. Never

connect the negative (--) battery cable

to the positive (+) connection terminal

of the starter solenoid. Do not test the

battery condition by shorting the

terminals together.

Engine Backfire/Flash

Fire

WARNING

Fire.

Can cause severe injury or death.

Servicing the air cleaner. A sudden

backfire can cause severe injury or

death. Do not operate the generator

set with the air cleaner removed.

Servicing the fuel system. A flash

fire can cause severe injury ordeath.

Do not smoke or permit flames or

sparks near the carburetor, fuel line,

fuel filter, fuel pump, or other potential

sources of spilled fuels or fuel vapors.

Catch fuels in an approved container

when removing the fuel line or

carburetor.

Combustible materials. A fire can

cause severe injury or death.

Generator set engine fuels and fuel

vapors are flammable and explosive.

Handle these materials carefully to

minimize the risk of fire or explosion.

Equip the compartment or nearby area

with a fully charged fire extinguisher.

Select a fire extinguisher rated ABC or

BC for electrical fires or as

recommended by the local fire code or

an authorized agency. Train all

personnel on fire extinguisher

operation and fire prevention

procedures.

Exhaust System

WARNING

Carbon monoxide.

Can cause severe nausea,

fainting, or death.

The exhaust system must be

leakproof and routinely inspected.

Generator set operation. Carbon

monoxide can cause severe nausea,

fainting, or death. Carbon monoxide

is an odorless, colorless, tasteless,

nonirritating gas that can cause death if

inhaled for even a short time. Avoid

breathing exhaust fumes when working

on or near the generator set. Never

operate the generator set inside a

building. Never operate the generator

set where exhaust gas could seep

inside or be drawn into a potentially

occupied building through windows, air

intake vents, or other openings.

Carbon monoxide detectors.

Carbon monoxide can cause severe

nausea, fainting, or death. Install

carbon monoxide detectors on each

level of any building adjacent to the

generator set. Locate the detectors to

adequately warn the building’s

occupants of the presence of carbon

monoxide. Keep the detectors

operational at all times. Periodically

test and replace the carbon monoxide

detectors according to the

manufacturer’s instructions.

Carbon monoxide symptoms.

Carbon monoxide can cause severe

nausea, fainting, or death. Carbon

monoxide is a poisonous gas present in

exhaust gases. Carbon monoxide is an

odorless, colorless, tasteless,

nonirritating gas that can cause death if

inhaled for even a short time. Carbon

monoxide poisoning symptoms include

but are not limited to the following:

D Light-headedness, dizziness

D Physical fatigue, weakness in

joints and muscles

D Sleepiness, mental fatigue,

inability to concentrate

or speak clearly, blurred vision

D Stomachache, vomiting, nausea

If experiencing any of these symptoms

and carbon monoxide poisoning is

possible, seek fresh air immediately

and remain active. Do not sit, lie down,

or fall asleep. Alert others to the

possibility of carbon monoxide

poisoning. Seek medical attention if

the condition of affected persons does

not improve within minutes of breathing

fresh air.

Do not smoke or permit flames or

sparks near fuels or the fuel system.

TP-6803 1/156 Safety Precautions and Instructions

Fuel System

WARNING

Natural Gas—Adequate ventilation is

mandatory. Because natural gas rises,

install natural gas detectors high in a

room. Inspect the detectors per the

manufacturer’s instructions.

WARNING

Explosive fuel vapors.

Can cause severe injury or death.

Use extreme care when handling,

storing, and using fuels.

The fuel system. Explosive fuel

vapors can cause severe injury or

death. Vaporized fuels are highly

explosive. Use extreme care when

handling and storing fuels. Store fuels

in a well-ventilated area away from

spark-producing equipment and out of

the reach of children. Never add fuel to

the tank while the engine is running

because spilled fuel may ignite on

contact with hot parts or from sparks.

Do not smoke or permit flames or

sparks to occur near sources of spilled

fuel or fuel vapors. Keep the fuel lines

and connections tight and in good

condition. Do not replace flexible fuel

lines with rigid lines. Use flexible

sections to avoid fuel line breakage

caused by vibration. Do notoperate the

generator set in the presence of fuel

leaks, fuel accumulation, or sparks.

Repair fuel systems before resuming

generator set operation.

Gas fuel leaks. Explosive fuel

vapors can cause severe injury or

death. Fuel leakage can cause an

explosion. Check the LPG vapor or

natural gas fuel system for leakage by

using a soap and water solution with

the fuel system test pressurized to

6--8 ounces per square inch

(10--14 inches water column). Do not

use a soap solution containing either

ammonia or chlorine because both

prevent bubble formation. Asuccessful

test depends on the ability of the

solution to bubble.

Explosive fuel vapors can cause

severe injury or death. Ta ke

additional precautions when using the

following fuels:

Propane (LPG)—Adequate ventilation

is mandatory. Because propane is

heavier than air, install propane gas

detectors low in a room. Inspect the

detectors per the manufacturer’s

instructions.

Hazardous Noise

CAUTION

Hazardous noise.

Can cause hearing loss.

Never operate the generator set

without a muffler or with a faulty

exhaust system.

Engine noise. Hazardous noise can

cause hearing loss. Generator sets

not equipped with sound enclosures

can produce noise levels greater than

105 dBA. Prolonged exposure to noise

levels greater than 85 dBA can cause

permanent hearing loss. Wear hearing

protection when near an operating

generator set.

Hazardous Voltage/

Moving Parts

DANGER

Hazardous voltage.

Will cause severe injury or death.

This equipment must be installed and

serviced by qualified electrical

personnel.

WARNING

Hazardous voltage.

Can cause severe injury or death.

Operate the generator set only when

all guards and electrical enclosures

areinplace.

Moving parts.

Hazardous voltage.

Backfeed to the utility system can

cause property damage, severe

injury, or death.

If the generator set is used for

standby power, install an automatic

transfer switch to prevent inadvertent

interconnection of standby and

normal sources of supply.

CAUTION

Welding the generator set.

Can cause severe electrical

equipment damage.

Never weld components of the

generator set without first

disconnecting the battery, controller

wiring harness, and engine electronic

control module (ECM).

Grounding electrical equipment.

Hazardous voltage can cause

severe injury or death. Electrocution

is possible whenever electricity is

present. Ensure you comply with all

applicable codes and standards.

Electrically ground the generator set,

transfer switch, and related equipment

and electrical circuits. Turn off the main

circuit breakers of all power sources

before servicing the equipment. Never

contact electrical leads or appliances

when standing in water or on wet

ground because these conditions

increase the risk of electrocution.

Welding on the generator set. Can

cause severe electrical equipment

damage. Before welding on the

generator set perform the following

steps: (1) Remove the battery cables,

negative (--) lead first. (2) Disconnect

all engine electronic control module

(ECM) connectors. (3) Disconnect all

generator set controller and voltage

regulator circuit board connectors.

(4) Disconnect the engine batterycharging alternator connections.

(5) Attach the weld ground connection

close to the weld location.

TP-6803 1/15 7Safety Precautions and Instructions

Connecting the battery and the

battery charger. Hazardous voltage

can cause severe injury or death.

Reconnect the battery correctly,

positive to positive and negative to

negative, to avoid electrical shock and

damage to the battery charger and

battery(ies). Have a qualified

electrician install the battery(ies).

Short circuits. Hazardous

voltage/current can cause severe

injury or death. Short circuits can

cause bodily injury and/or equipment

damage. Do not contact electrical

connections with tools or jewelry while

making adjustments or repairs.

Remove all jewelry before servicing the

equipment.

Electrical backfeed to the utility.

Hazardous backfeed voltage can

cause severe injury or death. Install

a transfer switch in standby power

installations to prevent the connection

of standby and other sources of power.

Electrical backfeed into a utility

electrical system can cause severe

injury or death to utility personnel

working on power lines.

Hot Parts

WARNING

Hot engine and exhaust system.

Can cause severe injury or death.

Do not work on the generator set until

it cools.

Servicing the exhaust system. Hot

parts can cause severe injury or

death. Do not touch hot engine parts.

The engine and exhaust system

components become extremely hot

during operation.

Servicing the engine heater. Hot

parts can cause minor personal

injury or property damage. Install the

heater before connecting it to power.

Operating the heater before installation

can cause burns and component

damage. Disconnect power to the

heater and allow it to cool before

servicing the heater or nearby parts.

Notice

NOTICE

Canadian installations only.For

standby service connect the output of

the generator set to a suitably rated

transfer switch in accordance with

Canadian Electrical Code, Part 1.

Heavy Equipment

WARNING

Unbalanced weight.

Improper lifting can cause severe

injury or death and equipment

damage.

Do not use lifting eyes.

Lift the generator set using lifting bars

inserted through the lifting holes on

the skid.

TP-6803 1/158 Safety Precautions and Instructions

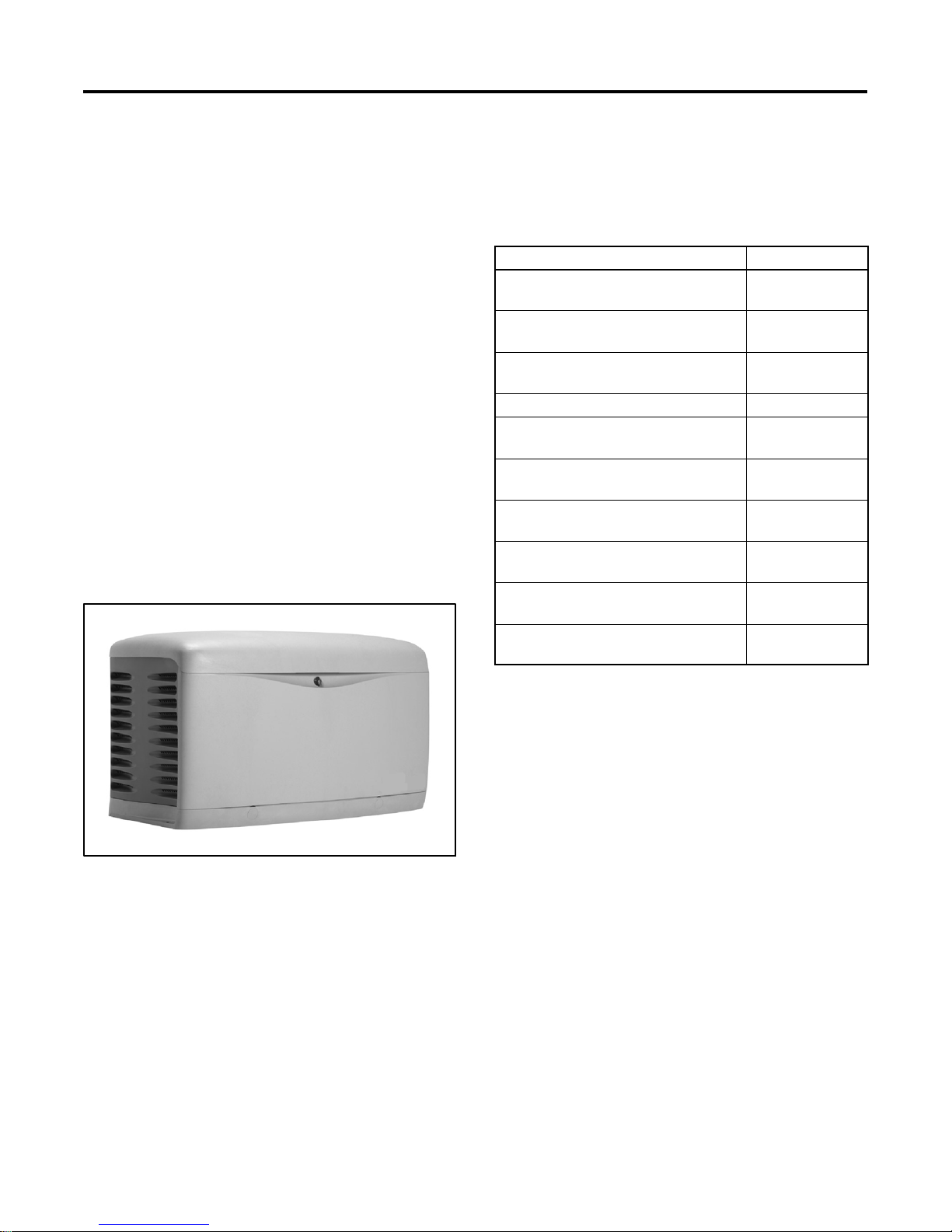

Introduction

This manual provides installation instructions for

Residential/Commercial Model generator sets. See

Figure 1. Refer to TP-6804, Operation Manual, for

generator set operation and maintenance instructions.

The generator set is approved for use in stationary

applications in locations served by a reliable utility

power source.

Have a Kohlerr authorized distributor/dealer install the

generator set outdoors according to the instructions in

this manual. The generator set installation must comply

with the National Electrical Code (NEC) and local code

requirements. Do not install this generator set indoors.

Information in this publication represents data available

at the time of print. Kohler Co. reserves the right to

change this publication and the products represented

without notice and without any obligation or liability

whatsoever.

Read this manual and carefully follow all procedures

and safety precautions to ensure proper equipment

operation and to avoid bodily injury. Read and followthe

Safety Precautions and Instructions section at the

beginning of this manual.

List of Related Literature

Figure 2 identifies related literature available for the

generator sets covered in this manual. Only trained and

qualified personnel should install or service the

generator set.

Literature Type Part Number

Operation Manual,

14/20RESA/RESALGenerator Set

Operation/Installation Manual, Model

RXT Automatic Transfer Switch

Service Manual,

14/20RESA/RESAL Generator Set

Operation Manual, OnCue Plus TP-6928

Operation/Installation Manual,

Model RDT Transfer Switch

Installation Manual,

Model RSB Transfer Switch

Operation Manual,

Model RSB Transfer Switch

Installation Instructions,

Load Control Module (LCM)

Installation Instructions,

Programmable Interface Module (PIM)

Installation Instructions,

Concrete Mounting Pads

Figure 2 Related Literature

TP-6804

TP-6807

TP-6735

TP-6345

TP-6486

TP-6487

TT-1574

TT-1584

TT--1619

Startup and Registration

When the generator set is installed, complete the

startup and installation checklists supplied with the

startup notification form. Complete and sign the startup

notification form and register the unit using the Kohler

zaa28533

Figure 1 14/20RESA/RESAL Generator Set

TP-6803 1/15 9

online Warranty Processing System.

Service Assistance

For professional advice on generator set power

requirements andconscientious service, pleasecontact

your nearest Kohler distributor or dealer.

D Consult the Yellow Pages under the heading

Generators—Electric.

D Visit the Kohler Power Systems website at

KOHLERPower.com.

D Look at thelabels and stickers onyour Kohler product

or review the appropriate literature or documents

included with the product.

D Call toll free in the US and Canada 1-800-544-2444.

D Outside the US and Canada, call the nearest regional

office.

Headquarters Europe, Middle East, Africa

(EMEA)

Kohler Power Systems Netherlands B.V.

Kristallaan 1

4761 ZC Zevenbergen

The Netherlands

Phone: (31) 168 331630

Fax: (31) 168 331631

Asia Pacific

Power Systems Asia Pacific Regional Office

Singapore, Republic of Singapore

Phone: (65) 6264-6422

Fax: (65) 6264-6455

China

North China Regional Office, Beijing

Phone: (86) 10 6518 7950

(86) 10 6518 7951

(86) 10 6518 7952

Fax: (86) 10 6518 7955

East China Regional Office, Shanghai

Phone: (86) 21 6288 0500

Fax: (86) 21 6288 0550

India, Bangladesh, Sri Lanka

India Regional Office

Bangalore, India

Phone: (91) 80 3366208

(91) 80 3366231

Fax: (91) 80 3315972

Japan, Korea

North Asia Regional Office

Tokyo, Japan

Phone: (813) 3440-4515

Fax: (813) 3440-2727

Latin America

Latin America Regional Office

Lakeland, Florida, USA

Phone: (863) 619-7568

Fax: (863) 701-7131

TP-6803 1/1510

Section 1 Installation

1.1 Introduction

DANGER

Hazardous voltage.

Will cause severe injury or death.

This equipment must be installed and

serviced by qualified electrical

personnel.

WARNING

Carbon monoxide.

Can cause severe nausea,

fainting, or death.

The exhaust system must be

leakproof and routinely inspected.

Generator set operation. Carbon monoxide can cause

severe nausea, fainting, or death. Carbon monoxide is an

odorless, colorless, tasteless, nonirritating gas that can cause

death if inhaled for even a short time. Avoid breathing exhaust

fumes when working on or near the generator set. Never

operate the generator set inside a building. Never operate the

generator set where exhaust gas could seep inside or be

drawn into a potentially occupied buildingthrough windows, air

intake vents, or other openings.

The generator set must be installed outdoors. The

exhaust systems on enclosed units are designed for

outdoor installation only.

Note: DO NOT install these generator sets inside a

building.

Note: Install carbon monoxide (CO) detector(s) on

each level of any building adjacent to a generator

set. Locate the detectors to adequately warn the

building’s occupants of the presence of carbon

monoxide.

Obtain a building permit and contact your local utility

companies to mark the locations of underground pipes

and cables.

Read and follow the safety precautions in this manual

and observe the decals on the equipment. Refer to the

diagrams and drawings in this manual for dimensions

and electrical connections during the installation

procedure. Read the entire installation procedure and

obtain the accessories and tools needed before

beginning installation. Perform the steps in the order

shown.

To install optional accessories, follow the instructions

provided with each kit.

1.2 Lifting

WARNING

Carbon monoxide detectors. Carbon monoxide can

cause severe nausea, fainting, or death. Install carbon

monoxide detectors on each level of any building adjacent to

the generator set. Locate the detectors to adequately warn the

building’s occupants of the presence of carbon monoxide.

Keep the detectors operational at all times. Periodically test

and replace the carbon monoxide detectors according to the

manufacturer’s instructions.

Have thegenerator set installed by an authorized Kohler

distributor/dealer or authorized representative. For all

locations, ensure that the installation complies with

applicable national and local codes. In the United

States, the installation must comply with the National

Electrical Code (NEC) and local codes. For Canadian

installations, refer to the Canadian Electrical Code

(CEC).

TP-6803 1/15 11Section 1 Installation

Unbalanced weight.

Improper lifting can cause severe

injury or death and equipment

damage.

Do not use lifting eyes.

Lift the generator set using lifting bars

inserted through the lifting holes on

the skid.

Model Weight, kg (lb.)

14RESA/RESAL

20RESA/RESAL

191 (420)

243 (535)

Figure 1-1 Approximate Weights

Approximate generator set weights are shown in

Figure 1-1. Uselifting bars inserted through the holes in

the skid to lift the unit. See the dimension drawings in

Section 2 for lifting hole locations.

1.3 Generator Set Inspection

Complete a thorough inspection of the generator set.

Check for the following:

1. Inspect the generator set for loose or damaged

parts or wires. Repair or tighten any loose parts

before installation.

2. Check the engine oil. Fill, if necessary, with the

recommended viscosity and grade of oil. Use

synthetic oil, API (American Petroleum Institute)

Service Class SG or higher. See TP-6804,

Operation Manual, for additional information.

1.4 Location and Mounting

Install the generator set outdoors near the incoming gas

service. The generator set location must allow easy

access for maintenance and service. The

recommended distance from a structure is dependent

on state and local codes. See the dimension drawing in

Section 2 for the recommended clearance from

structures and non-combustible materials.

Locate the generator set so that the hot exhaust does

not blow on plants or other combustible materials. No

plants, shrubs, or other combustible materials are

allowed within 1.2 m (4 ft.) of the exhaust end of the

generator set.

Do not installthe generator set where exhaust gas could

accumulate and seep inside or be drawn into a

potentially occupied building. Furnace and other similar

intakes must be at least 3 m (10 ft.) from the exhaust

end of the generator set.

Notice

DO NOT locate the generator set near patios,

decks, play areas, o r animal shelters. Keep items

such as lawn furniture, toys, sports equipment,

and all combustible materials away from the

generator set exhaust outlet.

Remind family members, children, and visitors to

use caution near the generator set. Generator

sets connected to automatic transfer switches

start automatically during exercise periods and

power outages. Some generator set components

become hot when the generator set is running and

remain hot for a time after the generator set shuts

down.

1.4.1 Mounting Area

The generator set is shipped on an engineered

composite mounting pad. Prepare a flat, level mounting

area covered with a weed barrier and gravel or a

concrete mounting pad. Set the composite mounting

pad directly on the gravel or concrete.

Do not install the composite mounting pad directly on

grass, wood, or other combustible materials. Clear all

combustible materials, including plants and shrubs,

building materials, and lawn furniture, from an area at

least 1.2 m (4 ft.) beyond the exhaust end of the

generator set. See the dimension drawing in Section 2.

1.4.2 Concrete Mounting Pads

Kohler Co. offers optional concrete mounting pads that

are custom-designed for Model 14RESA/RESAL and

20RESA/RESAL generator sets. Three-inch and

four-inch thick pads are available. Four-inch pads are

recommended for storm-prone areas. See TT-1619 for

instructions to install the mounting pad, if necessary.

1.4.3 Exhaust Requirements

WARNING

Hot engine and exhaust system.

Can cause severe injury or death.

Do not work on the generator set until

it cools.

TP-6803 1/1512 Section 1 Installation

Figure 1-2 gives the exhaust temperature at rated load.

The engine exhaust mixes with the generator set

cooling air at the exhaust end of the enclosure. Mount

the generator set so that the hot exhaust does not blow

on plants or other combustible materials. Maintain the

clearances shown in the dimension drawing in

Section 2.

Temperature,

Exhaust

Exhaust gas exiting the enclosure

at rated kW, _C(_F)

_C(_F)

260 (500)

Figure 1-2 Exhaust Flow and Temperature

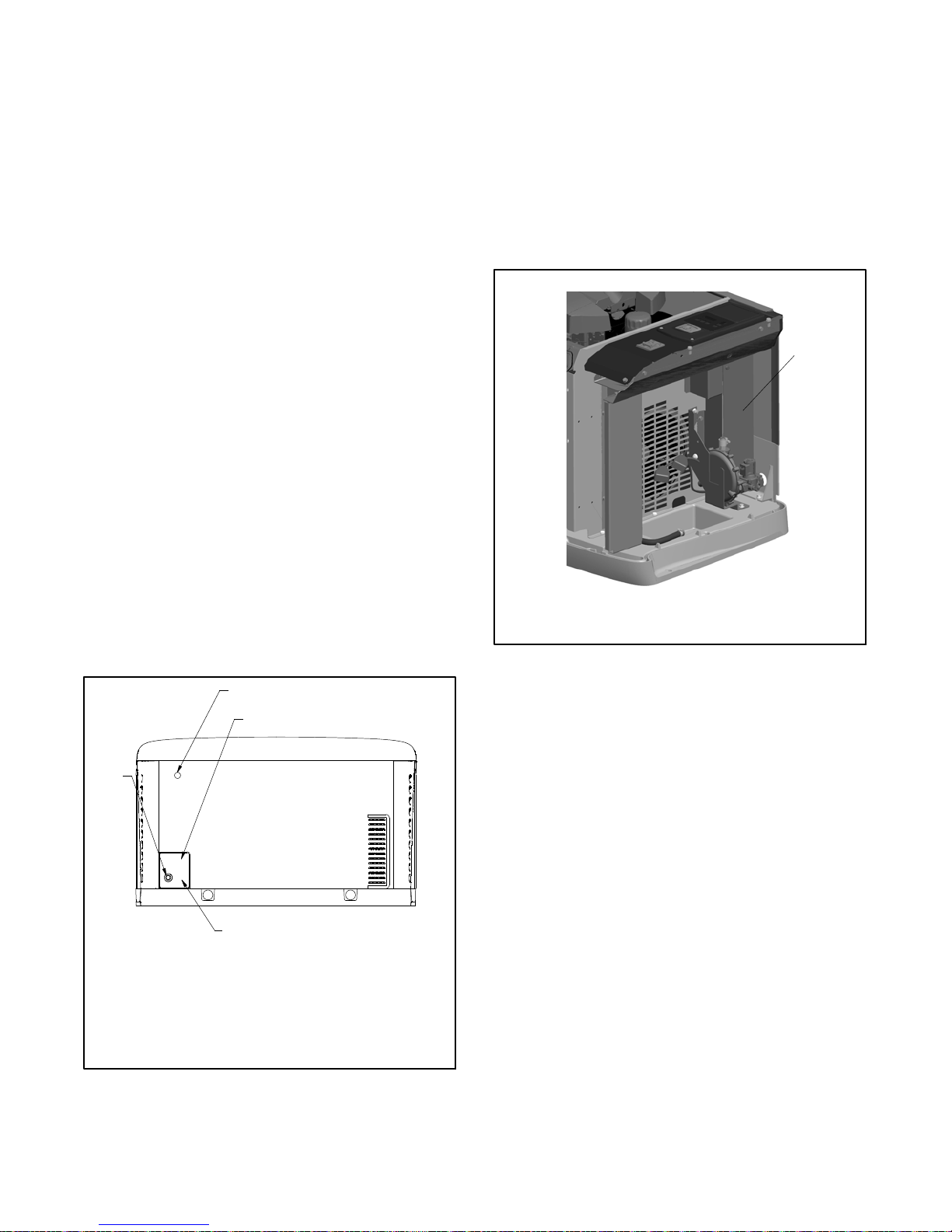

1.6 Access the Air Intake Area

The battery, fuel system, and electrical connections are

located in theair intake area. Raise the roof and remove

the enclosure panel to access the air intake area during

installation as described below.

1. Remove two screws from the top of the air intake

panel. Pull the the panel up and off. See

Figure 1-4.

2. To make the electrical connections, you will also

need to remove the cover panel over the terminal

block as shown in Section 1.9.3.

The generator set requires correct air flow for cooling

and combustion. The inlet and outlet openings in the

sound enclosure provide the cooling and combustion

air. Figure 1-3 shows the locations of the cooling air

intake and exhaust vents. Inspect the air inlet and outlet

openings inside and outside the enclosure to ensure

that the air flow is not blocked.

1

REAR VIEW

1. Air intake

2. Exhaust outlet

1

2

tp6733

Figure 1-3 Cooling Air Intake and Exhaust

The generator set is designed to operate with all

enclosure panels and internal baffling in place. If during

installation, maintenance or repair the unit must be

operated without the complete enclosure and baffling as

shipped from the factory make sure the exhaust panel is

removed as well.

3. Reinstall the panels after all electrical connections

are complete and the battery is installed and

connected.

1. Remove 2 screws.

ADV-8424

Figure 1-4 Removing the Air Intake Panel

1

1.5 Dimension Drawings

See the dimension drawings in Section 2 for the

generator set dimensions, fuel and electric inlet

locations, and recommended clearance.

TP-6803 1/15 13Section 1 Installation

1.7 Fuel Requirements

1.7.1 Fuel Supply

The generator set operates using natural gas or LPG

fuel. The generator set is EPA-certified for both natural

gas and LPG fuels.

The fuel system installation must comply with the NEC

and local codes.

WARNING

Explosive fuel vapors.

Can cause severe injury or death.

Use extreme care when handling,

storing, and using fuels.

Explosive fuel vapors can cause severe injury or death.

Take additional precautions when using the following fuels:

Propane (LPG)—Adequate ventilation is mandatory.

Because propane is heavier than air, install propane gas

detectors low in a room. Inspect the detectors per the

manufacturer’s instructions.

Natural Gas—Adequate ventilation is mandatory. Because

natural gas rises, install natural gas detectors high in a room.

Inspect the detectors per the manufacturer’s instructions.

Because of variable climates and geographical

considerations, contact the local fuel supplier for fuel

system planning and installation. Figure 1-5 lists the

recommended fuel ratings and other fuel supply

information for natural gas and LPG fuels.

Verify that the output pressure from the primary gas

utility pressure regulator is within the range shown in

Figure 1-5 and that the utility gas meter flow rate is

sufficient to supply the generator set at rated load plus

all other gas-consuming appliances. For LPG tanks,

verify that the output pressure is as shown in Figure 1-5.

See Figure 1-6 for fuel consumption. Contact the fuel

supplier for flow rate information or a gas meter

upgrade, if necessary.

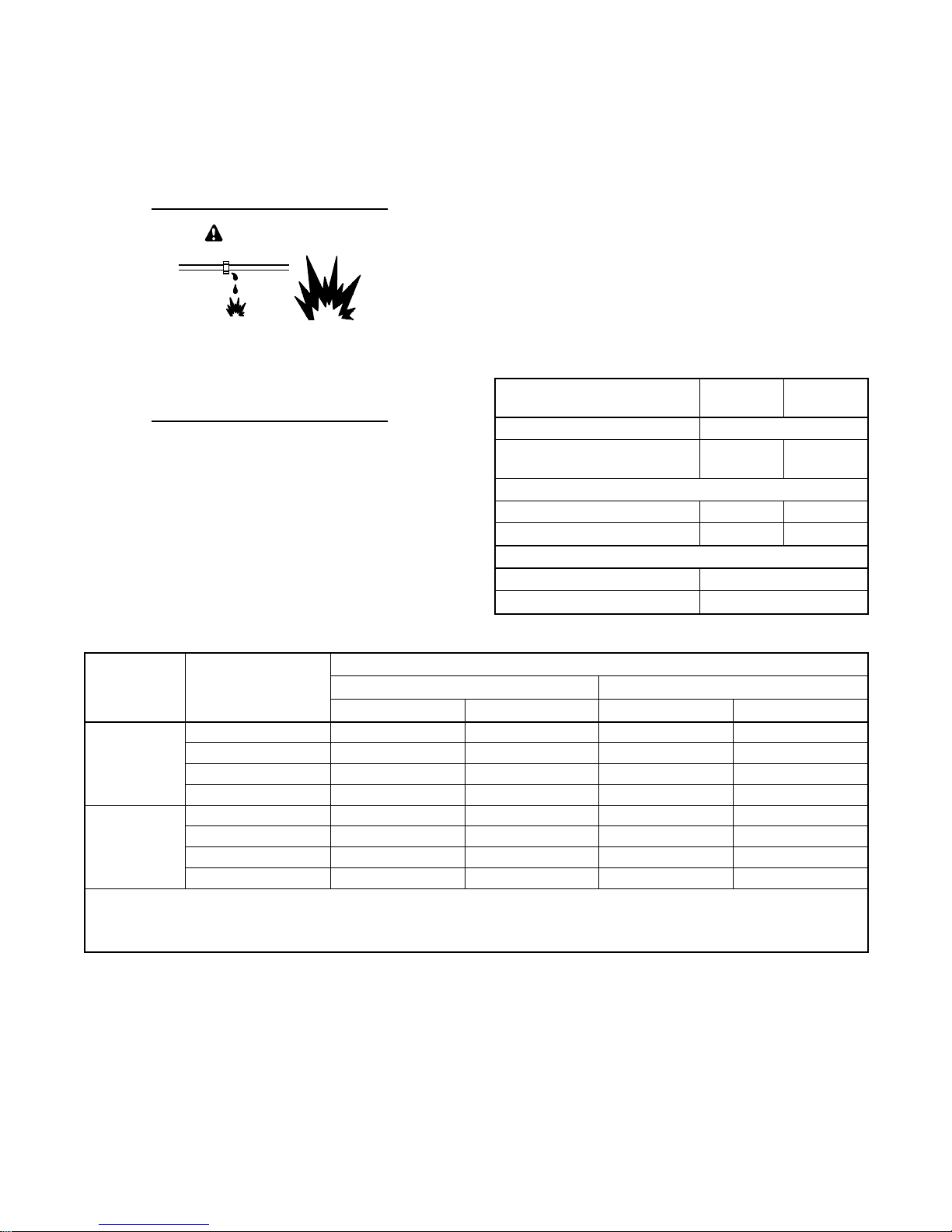

Natural

3

Gas

1.3--2.7

(5--11)

LPG

1.7--2.7

(7--11)

Fuel type

Fuel supply inlet 1/2 NPT

Fuel supply pressure,

kPa (in. H

O)

2

Fuel flow rate, maximum, Btu/hr.:

14RESA/RESAL 193,000 203,000

20RESA/RESAL 281,000 340,000

Nominal Fuel Rating, Btu/ft.

Natural gas 1000

LPG 2500

Fuel Type % Load

100% 5.4 (193) 4.9 (175) 8.0 (281) 6.4 (225)

Natural Gas

LPG

LPG conversion factors:

8.58 ft.

0.535 m

36.39 ft.

3

=1lb.

3

3

=1kg

= 1 gal.

75% 4.7 (163) 4.2 (148) 6.9 (243) 5.4 (189)

50% 3.5 (124) 3.1 (108) 4.6 (161) 3.9 (139)

25% 2.6 (93) 2.4 (84) 3.6 (127) 2.9 (103)

100% 2.3 (81) 2.1 (74) 3.9 (136) 2.9 (102)

75% 2.1 (75) 1.9 (68) 3.1 (109) 2.4 (85)

50% 1.8 (60) 1.5 (53) 2.3 (82) 1.8 (63)

25% 1.2 (45) 1.1 (40) 1.7 (59) 1.3 (47)

Figure 1-6 Fuel Consumption

Figure 1-5 Fuel Supply

Fuel Consumption, m3/hr. (cfh)

14RESA/RESAL 20RESA/RESAL

60 Hz 50 Hz 60 Hz 50 Hz

Nominal fuel rating:

Natural gas: 37 MJ/m

LPG: 93 MJ/m

3

(1000 Btu/ft.3)

3

(2500 Btu/ft.3)

TP-6803 1/1514 Section 1 Installation

1.7.2 Fuel Pipe Size

Ensure that the fuel pipe size and length meet the

specifications in Figure 1-7. Measure the pipe length

from the primary gas pressure regulator to the pipe

connection on the generator set fuel inlet. Add 2.4 m

(8 ft.) to the measured length for each 90 degree elbow.

Compare the total pipe length with the chart in

Figure 1-7 to find the required pipe size.

Contact local LPG provider for LPG installation

information.

Minimum Gas Pipe Size Recommendation, in. NPT

14RESA/RESAL 20RESA/RESAL

Pipe

Length,

m (ft.)

8 (25) 3/4 3/4 1 3/4

15 (50) 1 3/4 1 1

30 (100) 1 1 11/4 1

46 (150) 11/4 1 11/4 11/4

61 (200) 11/4 1 11/4 11/4

Natural

Gas

(193,000

Btu/hr.)

LPG

(203,000

Btu/hr.)

Figure 1-7 Fuel Pipe Size Recommendations

Natural

Gas

(281,000

Btu/hr.)

LPG

(340,000

Btu/hr.)

Apply pipe sealant thatis approved for fuel connections.

Hold the fuel solenoid valve with a wrench when

tightening the fuel connections.

Note: Do not hold the fuel solenoid valve coil when

tightening the fuel connections. See Figure 1-8

for the recommended wrench locations.

1

Note: Do NOT hold the valve

coil when tightening

connections.

IMG_0351

1. Hold valve with wrench on flats of valve body

2. Alternate wrench location

2

1.7.3 Connecting the Fuel Supply

The dimension drawing in Section 2 shows the location

of the fuel inlet connection. Have the fuel supplier install

rigid gas piping and a manual fuel shut-off valve. The

fuel supply line should line up with the generator set fuel

inlet and end about 12 inches away to allow connection

with asection of flexible fuel line. Use flexible sections to

prevent fuel line breakage caused by vibration.

Note: Do not bend the flexible fuel line to make up for

misalignment of the fuel supply line and the

generator set fuel inlet.

Figure 1-8 Holding Fuel Valve to Tighten Fuel

Connections

Open the manual fuel valves and test all fuel

connections using soapy water. If a leak is found, close

the fuel valves, clean the fittings, and apply fresh

sealant. Check for fuel leaks again with the generator

set running.

Protect all fuel lines from machinery or equipment

contact, adverse weather conditions, and environmental

damage.

TP-6803 1/15 15Section 1 Installation

1.8 Fuel Conversion

The multi-fuel system allows conversion from natural

gas to LPG (or vice-versa) in the field while maintaining

emissions-standard compliance. A trained technician

or an authorized distributor/dealer can convert the fuel

system.

After converting the fuel system, change the Fuel Type

setting on the controller. See the Operation Manual for

instructions to change settings at the controller, or use a

personal (laptop) computer and Kohlerr SiteTecht

software to change the setting.

Rating Change

Converting the fuel will change the generator set rating.

See the generator set specification sheet for ratings with

natural gas and LP. Order a new nameplate with the

updated rating and fuel information from an authorized

distributor/dealer, if necessary. Provide the following

information from the original nameplate:

WARNING

Explosive fuel vapors.

Can cause severe injury or death.

Use extreme care when handling,

storing, and using fuels.

Explosive fuel vapors can cause severe injury or death.

Take additional precautions when using the following fuels:

Propane (LPG)—Adequate ventilation is mandatory.

Because propane is heavier than air, install propane gas

detectors low in a room. Inspect the detectors per the

manufacturer’s instructions.

Natural Gas—Adequate ventilation is mandatory. Because

natural gas rises, install natural gas detectors high in a room.

Inspect the detectors per the manufacturer’s instructions.

D Model Number D kVA

D Spec Number D Amps

D Serial Number D Volts

D Fuel (original and new) D Hz

D kW

Attach the new nameplate over the old one. Do NOT

cover the UL listing information on the old nameplate.

WARNING

Accidental starting.

Can cause severe injury or death.

Disconnect the battery cables before

working on the generator set.

Remove the negative (--) lead first

when disconnecting the battery.

Reconnect the negative (--) lead last

when reconnecting the battery.

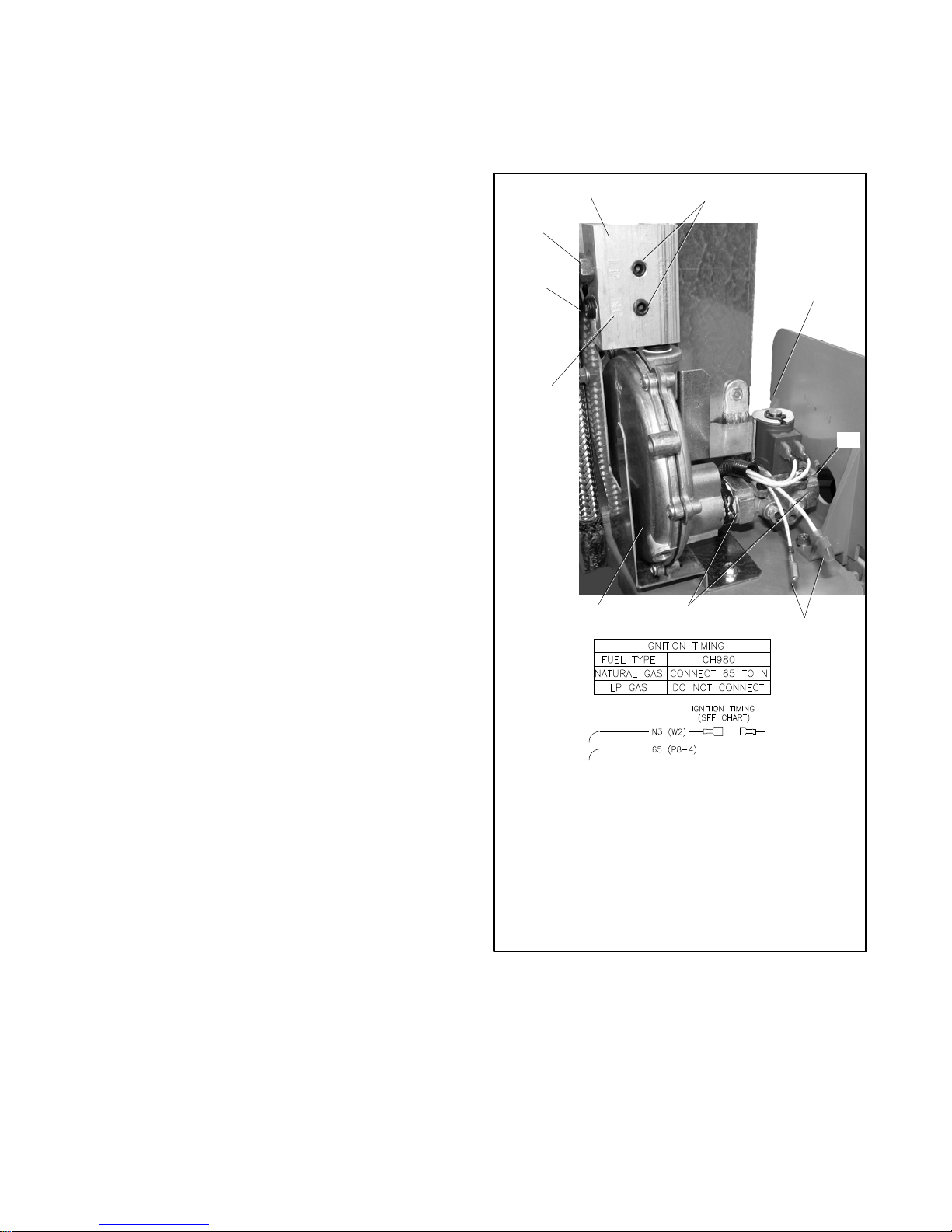

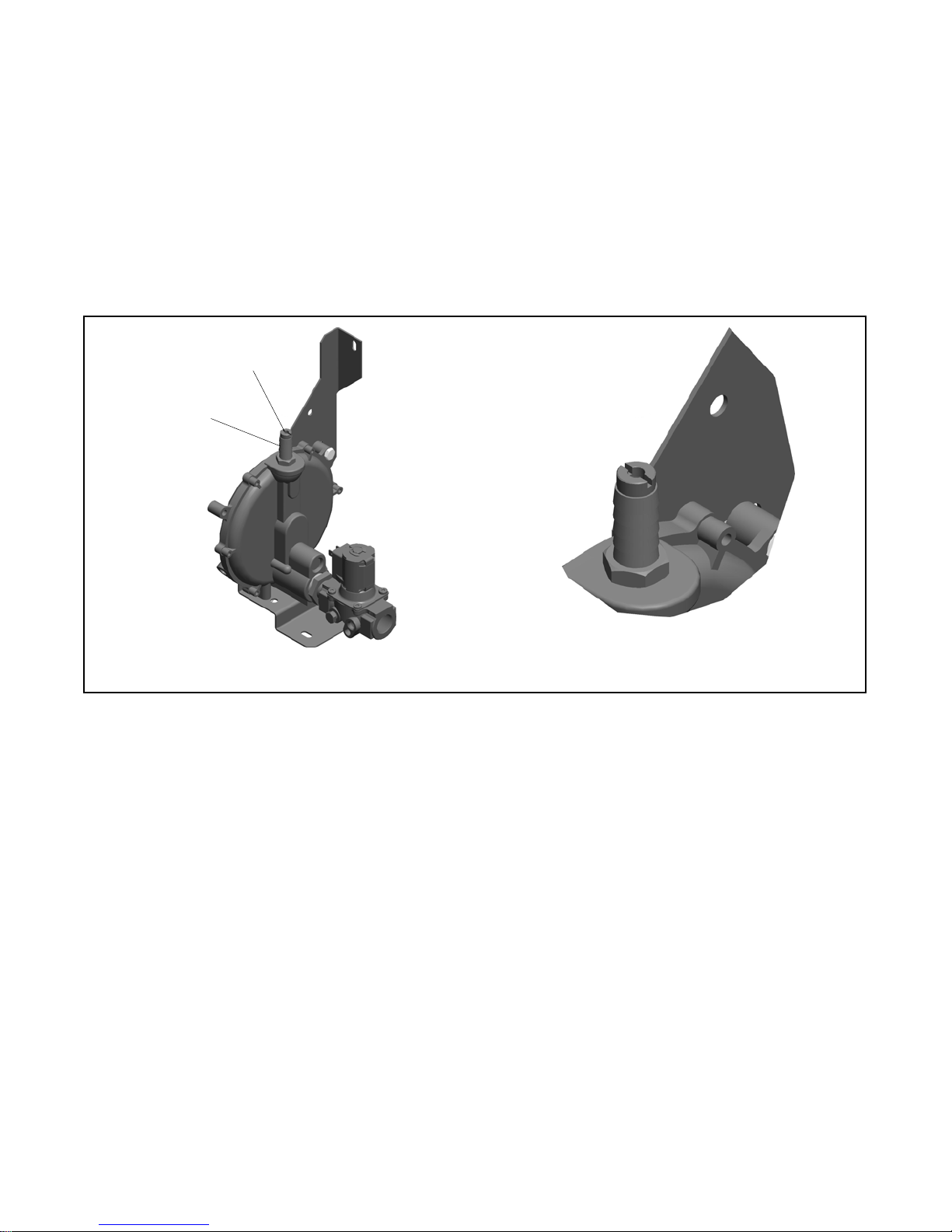

1.8.1 Fuel Conversion, 14RESA/RESAL

Equipped with Fuel Block

Note: Model 14RESA/RESAL generator sets built

before June 26, 2014 use a fuel block for the fuel

type selection. See Figure 1-9 and use the

instructions in this section for fuel conversion.

Model 14RESA/RESAL generators built June 26,

2014, or later are not equipped with the fuel block.

These units use fuel orifice fittings installed in the

hose fitting at the fuel regulator. See Section

1.8.2 for fuel conversion instructions.

Two fuel connections on the fuel block allow fieldconversion between natural gas and LPG. The fuel

metering valves are factory-set and sealed to comply

with applicable e mission standards and to provide the

best possible hot and cold starting.

Note: Do not adjust the factory-sealed fuel-metering

adjustments on the fuel block. Changing the fuelmetering adjustmentsmay violate federalor state

laws.

Disabling the generator set. Accidental starting can

cause severe injury or death. Before working on the

generator set or equipment connected to the set, disable the

generator set as follows: (1) Press the generator set off/reset

button to shut down the generator set. (2) Disconnect the

power to the battery charger, if equipped. (3) Remove the

battery cables, negative (--) lead first. Reconnect the negative

(--) lead last when reconnecting the battery. Follow these

precautions to prevent the starting of the generator set by the

remote start/stop switch.

Use the following procedure to convert from natural gas

(NG) to LPG. See Figure 1-9 for the fuel system

component locations.

TP-6803 1/1516 Section 1 Installation

Procedure to convert from NG to LPG,

14RESA/RESAL with fuel block

1. Press the OFF button on the generator set

controller.

2. Disconnect the power to the battery charger.

3. Disconnect the generator set engine starting

battery, negative (--) lead first.

4. Turn off the fuel supply.

Conversion from LPG to Natural Gas

To convert from LPG to natural gas, follow the fuel

conversion procedure above, moving the hose fitting to

the natural gas port and plugging the LP port. Connect

the DSAI leads for natural gas. See Figure 1-9.

1

10

2

LPG setup

shown

5. Remove the hose clamp and fuel hose from the

hose fitting in the fuel block. See F igure 1-9.

6. Remove the hose fitting from the natural gas outlet

port in the fuel block. See Figure 1-9.

7. Remove the plug from the LP port in the fuel block.

SeeFigure1-9.

8. Clean the plug with a dry cloth or brush, apply fresh

pipe sealant, and install the plug into the natural

gas outlet port.

9. Clean the hose fitting with a dry cloth or brush,

apply fresh pipe sealant to the threads, and install

the fitting into the LP port.

Note: Do not adjust the fuel metering valves.

10. Slide the hose onto the hose fitting and secure it

with the clamp.

11. Disconnect digital spark-advance ignition (DSAI)

leads 65 and N3 for LPG. The DSAI leads are

located near the fuel solenoid valve. See

Figure 1-9.

9

8

7

6

3

4

photo223

5

12. Connect and turn on the new fuel supply.

DSAI Lead Connection

13. Reconnect the generator set engine starting

battery leads, negative (--) lead last.

14. Reconnect power to the battery charger.

15. Start the generator set by pressing the RUN button

on the generator set controller.

16. Check for leaks using a gas leak detector.

17. Run the generator set and check the operation.

1. Fuel block (14RES only)

2. Fuel metering valves—factory -sealed, do not adjust

3. Fuel solenoid valve coil

4. Fuel inlet, 1/2 in. NPT

5. DSAI leads 65 and N3

6. Recommended holding points for tightening fuel connection

7. Fuel regulator

8. Ports are labeled LP and NG

9. Plug

10. Hose fitting

Figure 1-9 Fuel System, 14RESA/RESAL Equipped

with Fuel Block (built before June 26,

18. Press the OFF button to to shut down the generator

2014)

set.

TP-6803 1/15 17Section 1 Installation

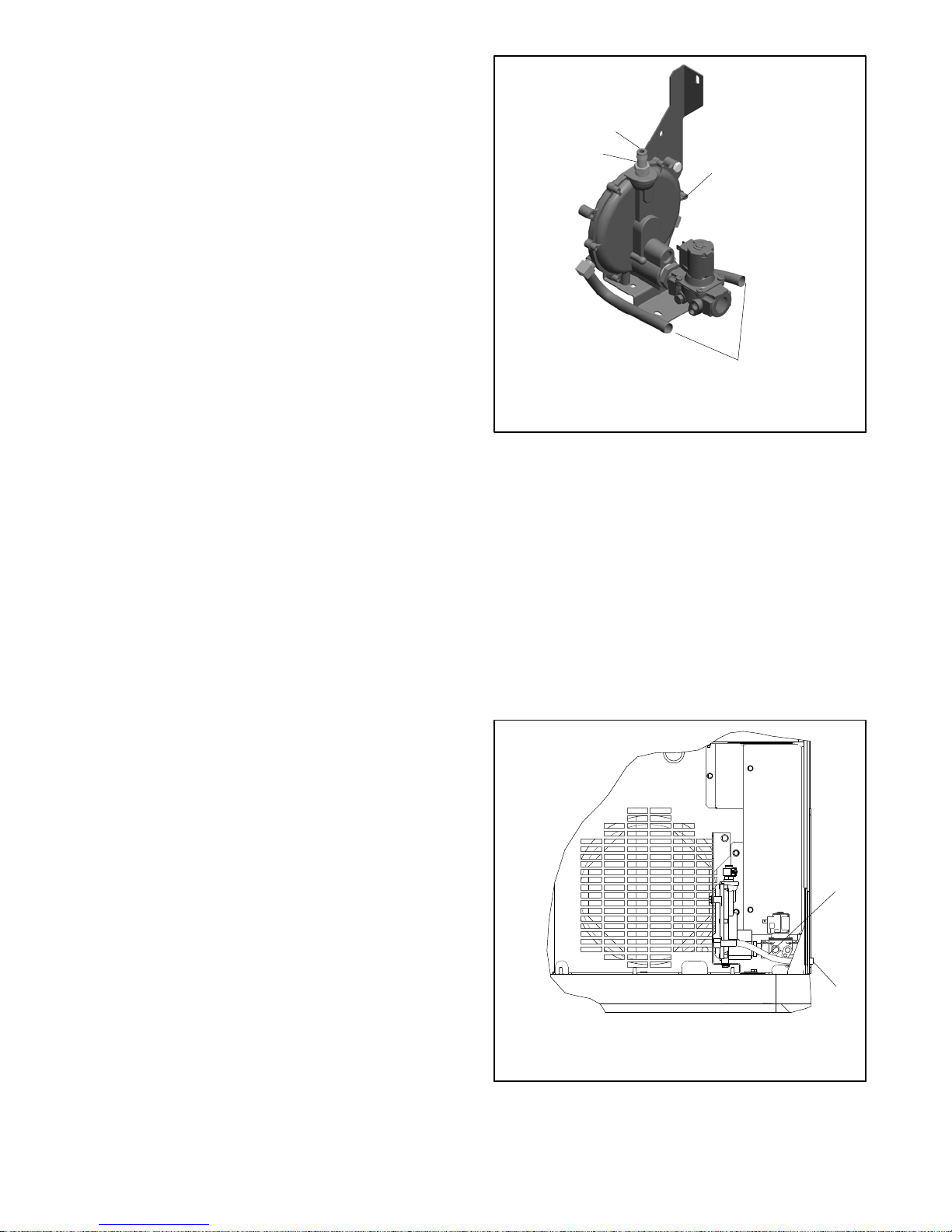

1.8.2 Fuel Conversion, 14RESA/RESAL

Equipped with Fuel Orifice

Fittings

Note: Model 14RESA/RESAL generator sets built

before June 26, 2014, use a fuel block for the fuel

type selection. See Figure 1-9 and use the

instructions Section 1.8.1 for fuel conversion.

Model 14RESA/RESALgenerators built June 26,

2014, or later are not equipped with the fuel block.

These units use fuel orifice fittings installed in the

hose fitting at the fuel regulator. See Figure 1-11

and use the instructions in this section for fuel

conversion.

For natural gas and LPG fuel, orifice fittings are used in

the fuel line. See Figure 1-10. The natural gas orifice

fitting is silver in color and stamped NG. The LPG fitting

is gold in color and stamped LPG. The fittings are

threaded. A straight-blade screwdriver is required to

remove and replace the fittings.

1

2

NG LPG

Figure 1-10 NG and LPG Fuel Orifice Fittings

The unit is typically shipped set up for natural gas, with

the LPG fitting tied near the fuel solenoid valve. To

convert to LPG, remove the NG fitting and install the

LPG fitting as described below. See Figure 1-11 for the

fuel system component locations.

Procedure to Convert from NG to LPG,

14RESA/RESAL with fuel orifice fittings

1. Press the OFF button on the generator set

controller.

2. Disconnect the utility power to the generator.

3. Disconnect the generator set engine starting

battery, negative (--) lead first.

4. Turn off and disconnect the fuel supply.

5. Remove the hose clamp and fuel hose from the

hose fitting. See Figure 1-11.

3

DSAI Lead Connection

1. LPG fitting tied to bracket for shipping

2. Fuel hose and clamp

3. DSAI Leads

Figure 1-11 Fuel System, As Shipped (Model

14RESA/RESAL built after June 26,

2014)

6. Use a straight-blade screwdriver to remove the NG

orifice from the hose fitting. See Figure 1-12.

7. Insert the LPG orifice into the hose fitting. Use a

straight-blade screwdriver to tighten the fitting until

it is snug.

8. Slide the hose onto the hose fitting and secure it

with the clamp.

9. Disconnect digital spark-advance ignition (DSAI)

leads 65 and N3 for LPG. The DSAI leads are

TP-6803 1/1518 Section 1 Installation

located near the fuel solenoid valve. See

Figure 1-11.

10. Connect and turn on the new fuel supply.

15. Run the generator set and check the operation.

16. Press the OFF button to shut down the generator

set.

11. Reconnect the generator set engine starting

battery leads, negative (--) lead last.

12. Reconnect the utility power to the generator.

13. Start the generator set by pressing the RUN button

on the generator set controller.

14. Check for leaks using a gas leak detector.

1

2

Conversion from LPG to Natural Gas

To convert from LPG to natural gas, repeat the steps

above, removing the LPG fuel orifice and installing the

NG fitting. Connect DSAI leads 65 and N3 together for

natural gas.

ORIFICE FITTING DETAIL

1. Orifice fitting (see detail)

2. Hose barb fitting

Figure 1-12 14RESA/RESAL Fuel System Showing Orifice Fittings (generators built after June 26, 2014)

GM84143

TP-6803 1/15 19Section 1 Installation

1.8.3 Fuel Conversion, 20RESA/RESAL

For LPG fuel, an orifice is used in the fuel line. The unit is

typically shipped set up for natural gas, with the loose

orifice tied near the fuel solenoid valve. To convert to

LPG, install the LPG orifice as described below. See

Figure 1-13 for the fuel system component locations.

Note: The generator set harness may contain a pair of

DSAI leads near the fuel solenoid valve.

Connecting or disconnecting these leads has no

effect on the 20RESA/RESAL operation.

Procedure to Convert from NG to LPG,

20RESA/RESAL

LPG setup

shown

1

2

3

1. Press the OFF button on the generator set

controller.

2. Disconnect the power to the battery charger.

3. Disconnect the generator set engine starting

battery, negative (--) lead first.

4. Turn off the fuel supply.

5. Remove the hose clamp and fuel hose from the

hose fitting. See Figure 1-13.

6. Insert the LPG orifice into the hose fitting. See

Figure 1-13.

7. Slide the hose onto the hose fitting and secure it

with the clamp.

8. Connect and turn on the new fuel supply.

9. Reconnect the generator set engine starting

battery leads, negative (--) lead last.

10. Reconnect power to the battery charger.

1. LPG orifice

2. Hose fitting

3. Regulator

4. Regulator vent tubes (vent to the outside of the controller)

4

GM84143

Figure 1-13 Fuel Regulator and LPG Orifice,

20RESA/RESAL

1.8.4 Regulator Vent Hose

Model 20RESA/RESAL generators are equipped with

fuel regulator vent hoses. Drill or punch two holes in the

enclosure at the locations shown on the template in

Appendix B. It may be convenient to cut openings forthe

electrical leads at the same time as shown on the

template and in Section 1.9.2.

Insert the open ends of the hoses through the holes to

the outside of the enclosure as shown in Figure 1-14.

11. Start the generator set by pressing the RUN button

on the generator set controller.

12. Check for leaks using a gas leak detector.

13. Run the generator set and check the operation.

14. Press the OFF button to shut down the generator

set.

Conversion from LPG to Natural Gas

To convert from LPG to natural gas, repeat the steps

above to remove the LPG fuel orifice.

1

2

sb722

1. Fuel regulator vent tubes, qty. 2

2. Drill or punch two holes and route both hoses to the outside

of the enclosure

Figure 1-14 Fuel Regulator Vent Hoses

TP-6803 1/1520 Section 1 Installation

1.9 Electrical Connections

DANGER

Hazardous voltage.

Will cause severe injury or death.

This equipment must be installed and

serviced by qualified electrical

personnel.

Grounding electrical equipment. Hazardous voltage can

cause severe injury or death. Electrocution is possible

whenever electricity is present. Ensure you comply with all

applicable codes and standards. Electrically ground the

generator set, transfer switch, and related equipment and

electrical circuits. Turn off the main circuit breakers of all

power sources before servicing the equipment. Never contact

electrical leads or appliances when standing in water or on wet

ground because these conditions increase the risk of

electrocution.

Electrical backfeed to the utility. Hazardous backfeed

voltage can cause severe injury or death. Install a transfer

switch in standby power installations to prevent the connection

of standby and other sources of power. Electrical backfeed

into a utility electrical system can cause severe injury or death

to utility personnel working on power lines.

NOTICE

Canadian installations only. For standby service connect

the output of the generator set to a suitably rated transfer

switch in accordance with Canadian Electrical Code, Part 1.

Have an authorized distributor/dealer or a licensed

electrician make the following electrical connections.

The electrical installation must comply with the National

Electrical Coder (NEC) class 1 wire designation and all

applicable local codes. Canadian installations must

comply with the Canadian Electrical Code (CEC) and

applicable local codes.

AC circuit protection. All AC circuits must include

circuit breaker or fuse protection. The circuit breaker

must be rated for a maximum of 125% of the rated

generator set output current. The circuit breaker must

open all ungrounded connectors. The generator set is

equipped with a factory-installed circuit breaker.

For customer-supplied wiring, select the wire

temperature rating in Figure 1-15 based upon the

following criteria:

D Select row 1, 2, 3, or 4 if the circuit rating is

110 amperes or less or requires #1 AWG (42.4 mm

2

or smaller conductors.

D Select row 3 or 4 if the circuit rating is greater than

110 amperes or requires #1 AWG (42.4 mm

2

)or

larger conductors.

)

Row Temp. Ra t i n g Copper (Cu) Only Cu/Aluminum (Al) Combinations Al Only

1

60_C (140_F)

or

75_C (167_F)

2

60_C (140_F) Use No. * AWG, 60_Cwire Use 60_C wire, either No. * AWG Cu or No. *

3

75_C (167_F) Use No. *[ AWG, 75_Cwire Use 75_C wire, either No. *[ AWG Cu or No.

4

90_C (194_F) Use No. *[ AWG, 90_Cwire Use 90_C wire, either No. *[ AWG Cu or No.

* The wire size for 60_C (140_F) wire is not required to be included in the marking. If included, the wire size is based on ampacities for the

wire given in Table 310-16 of the National Electrical Coder, in ANSI/NFPA 70, and on 115% of the maximum current that the circuit carries

under rated conditions. The National Electrical Coder is a registered trademark of the National Fire Protection Association, Inc.

[ Use the larger of the following conductors: the same size conductor as that used for the temperature test or one selected using the

guidelines in the preceding footnote.

Use No. * AWG, 60_Cwireor

use No. * AWG, 75_Cwire

Use 60_C wire, either No. * AWG Cu, or No. *

AWG Al or use 75_C wire, either No. * AWG

Cu or No. * AWG Al

AWG Al

*[ AWG Al

*[ AWG Al

Use 60_Cwire,No.*AWGor

use 75_Cwire,No.*AWG

Use 60_Cwire,No.*AWG

Use 75_Cwire,No.*[ AWG

Use 90_Cwire,No.*[ AWG

Figure 1-15 Terminal Markings for Various Temperature Ratings and Conductors

The National Electrical Coder is a registered trademark of the National Fire Protection Association, Inc.

TP-6803 1/15 21Section 1 Installation

1.9.1 Grounding

1.9.3 Field-Connection Terminal Block

Ground the generator set. The grounding method

must comply with NEC a nd local codes. Connect the

grounding cable to the generator set ground terminal

GND on the field-connection terminal block.

Generator sets are shipped with the generator neutral

bonded (connected) to the generator ground in the

junction box. The requirement for having a bonded

(grounded) neutral orungrounded neutral is determined

by the type of installation. At installation, the neutral can

be grounded at the generator set or lifted from the

ground stud and isolated if the installation requires an

ungrounded neutral connection at the generator. The

generator setwill operate properlywith the neutral either

bonded to ground or isolated from ground at the

generator.

Various regulations andsite configurations including the

National Electrical Code (NEC), local codes, and the

type of transfer switch used in the application determine

the grounding of the neutral at the generator. NEC

Section 250 is one example that has a very good

explanation of the neutral grounding requirements for

generators.

The generator set is equipped with a field-connection

terminal block located in the air intake area near the

junction box. Leads have been factory-installed from

the junction box to the terminal block for easy field

wiring.

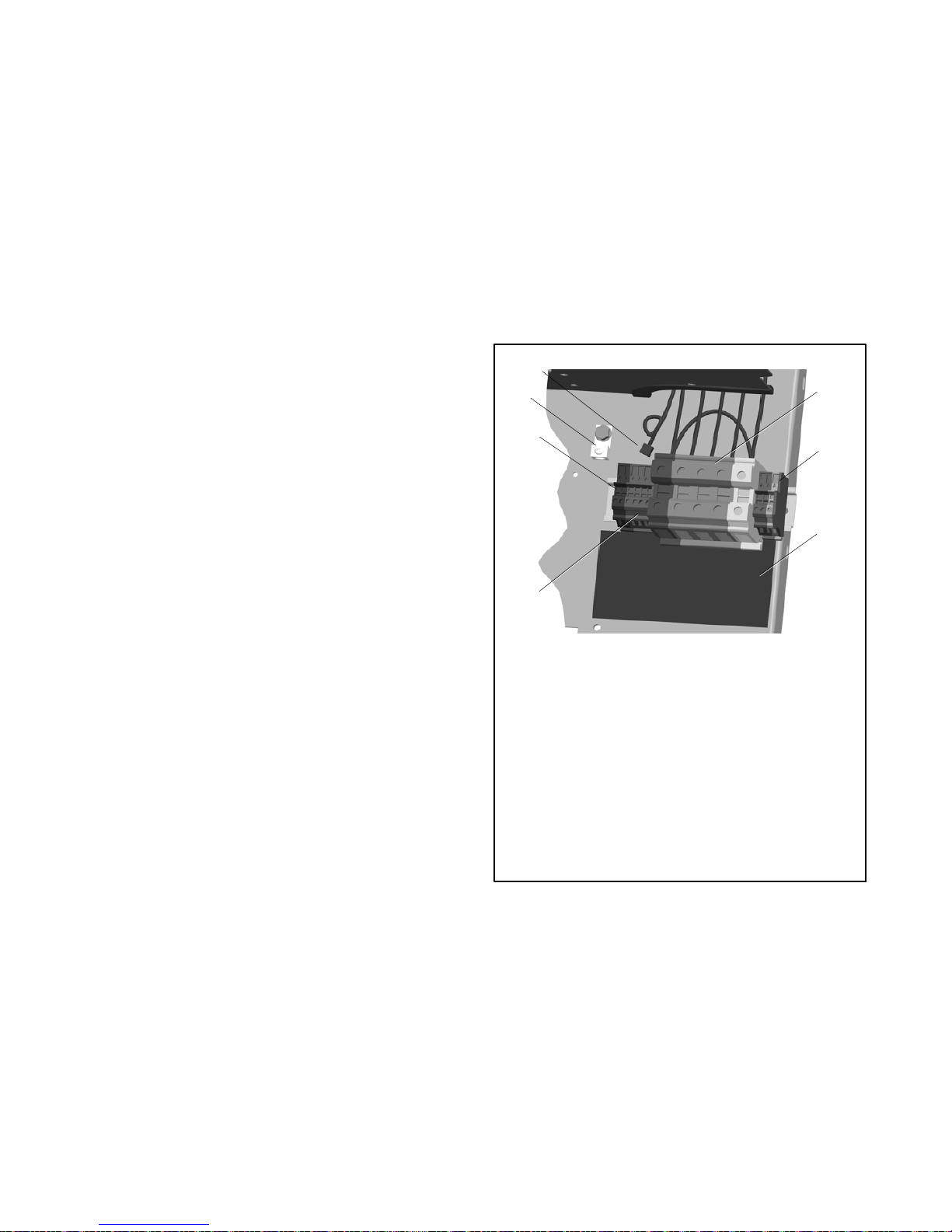

See Figure 1-17 for the terminal block location.

Remove the cover panel for access to the field

connections.

1

1.9.2 Electrical Lead Entry

Drill or punch holes in the enclosure for the electrical

conduit in the locations shown in Figure 1-16. A

full-scale dimensioned template for the hole locations is

printed in Appendix B. See page 57.

1

2

4

ADV--8424

3

Note: See Appendix B for a full-scale template

with dimensions.

1. Optional emergency stop switch location. Do not use to

route wiring.

2. Utility voltage electrical lead entry point

3. ATS signal electrical lead entry point

4. 1/2 NPT female fuel inlet

adv-8424

1. Cover panel. Remove for access to field-connection terminal

block.

Figure 1-17 Field-Connection Terminal Block

Location

Figure 1-16 Electrical Lead Entry Locations

TP-6803 1/1522 Section 1 Installation

See Figure 1-18 for terminal block details. Refer to the

terminal block decal shown in Figure 1-19 for

connections and cable sizes. Also see the wiring

diagram in Section 2.

Route AC leads through flexible conduit. Ensure that

the leads and conduit do not interfere with the operation

of the generatorset or obstruct the serviceareas. Route

low-voltage communication leads through separate

conduit.

Procedure

a. Route the network cable with other low-voltage

signal wiring (for example, the RBUS

communication leads or engine start leads to

the transfer switch), in separate conduit from

the ACload leads. If the networkcable is longer

than 100 meters (328 ft.), use a repeater or

switch.

b. Use an RJ45 inline coupler to connect the

Ethernet cable to the cable in the customer

connection box. See Figure 1-18. The inline

coupler is included with the OnCue Plus kit.

1. Drill holes for the conduit fittings. See Figure 1-16

and Appendix B for the recommended electrical

inlet locations. Feed the cables through the

openings.

2. Connect the leads from the transfer switch

emergency source lugs to the L1, L2, and L3

connections on the generator set terminal block as

applicable for single or three-phase applications.

See Figure 1-18 and Figure 1-19.

3. Connect the neutral ( L0) and ground (GRD) leads

from the ATS and the main panel to the

corresponding connection points on the terminal

block. See Section 1.9.1, Grounding.

4. Connect AC power source leads to the terminal

block connections labeled LINE, NEUTRAL and

GROUND. Connect the circuit to the load side of

the transfer switch. See Section 1.9.4 for more

information about the AC power requirement.

Note: AC power must be connected to maintain

the charge on the engine starting battery.

5. For connection of optional transfer switches, the

programmable interface module (PIM), and/or a

load control module ( LCM) or load shed kit, see

Section 1.10.1.

6. If the OnCuer Plus Generator Management

System will be used with the generator set, run

category 5E network cable from the generator set

to the customer’s router or modem.

7. When connections to the terminal block are

complete, replace the cover plate.

4

3

2

1

GM84094

Note: The number of terminals varies for 1-phase

and 3-phase models. See Figure 1-19.

1. Low voltage RBUS communication to RXT ATS, PIM, LCM

or load shed kit, and/or APM.

2. Engine start connections from transfer switches other than

theRXT,ifused.

3. Ground connection for communication cable shield

4. Ethernet cable for optional OnCue Plus connection

5. AC load connections

6. AC power connections required for battery charging and

accessories

7. Connection decal; see Figure 1-19.

Figure 1-18 Field Connection Terminal Blocks

5

6

7

Note: The OnCue Plus Wireless kit allows

connection of the generator controller to the

customer’s wireless router without running a

network cable from the generator to the

customer’s router or modem. If the OnCue

Plus Wireless is used, follow the instructions

provided with the kit to install and set up the

wireless kit and proceed to step 7.

TP-6803 1/15 23Section 1 Installation

1-Phase, 1-Pole Circuit Breaker

1-Phase, 2-Pole Circuit Breaker

1.9.4 AC Power Supply

The installer must connect AC power for the battery

charger (which is integral to the RDC2 controller) and

the optional accessories shown in Figure 1-20. The

power source must comply with state and local codes.

The power to the battery charger and accessories must

be backed upby the generator so thatpower is available

at all times.

Be sure to disconnect power at the distribution panel

before makingthe connections. Connect power leadsto

the AC power connection points labeled LINE,

NEUTRAL, and GROUND on the field-connection

terminal block. Connect the circuit to the load side of the

transfer switch so that it is backed up by the generator.

See Figure 1-18 and the wiring diagrams in Section 2 for

connection details.

Power Requirement, Max.

Equipment

Battery charger

(standard)

Carburetor heater

(optional)

Battery heater (optional)

Fuel regulator heater

(optional; available for

20RESA/RESAL only)

Figure 1-20 Power Requirements

Watts Volts at 50/60 Hz

50 100--120 VAC

50 200--250 VAC

37

37

50

50

60 100--120 VAC

100 200--250 VAC

100--120 VAC

200--250 VAC

100--120 VAC

200--250 VAC

3-Phase

Figure 1-19 Terminal Block Connection Decals

TP-6803 1/1524 Section 1 Installation

1.10 ATS and Accessory

Connections

The following sections cover electrical connections of

the automatic transferswitches and RBUS accessories,

including the programmable interface module (PIM) and

the load control module (LCM) or load shed kit.

1.10.1 Transfer Switch Connection

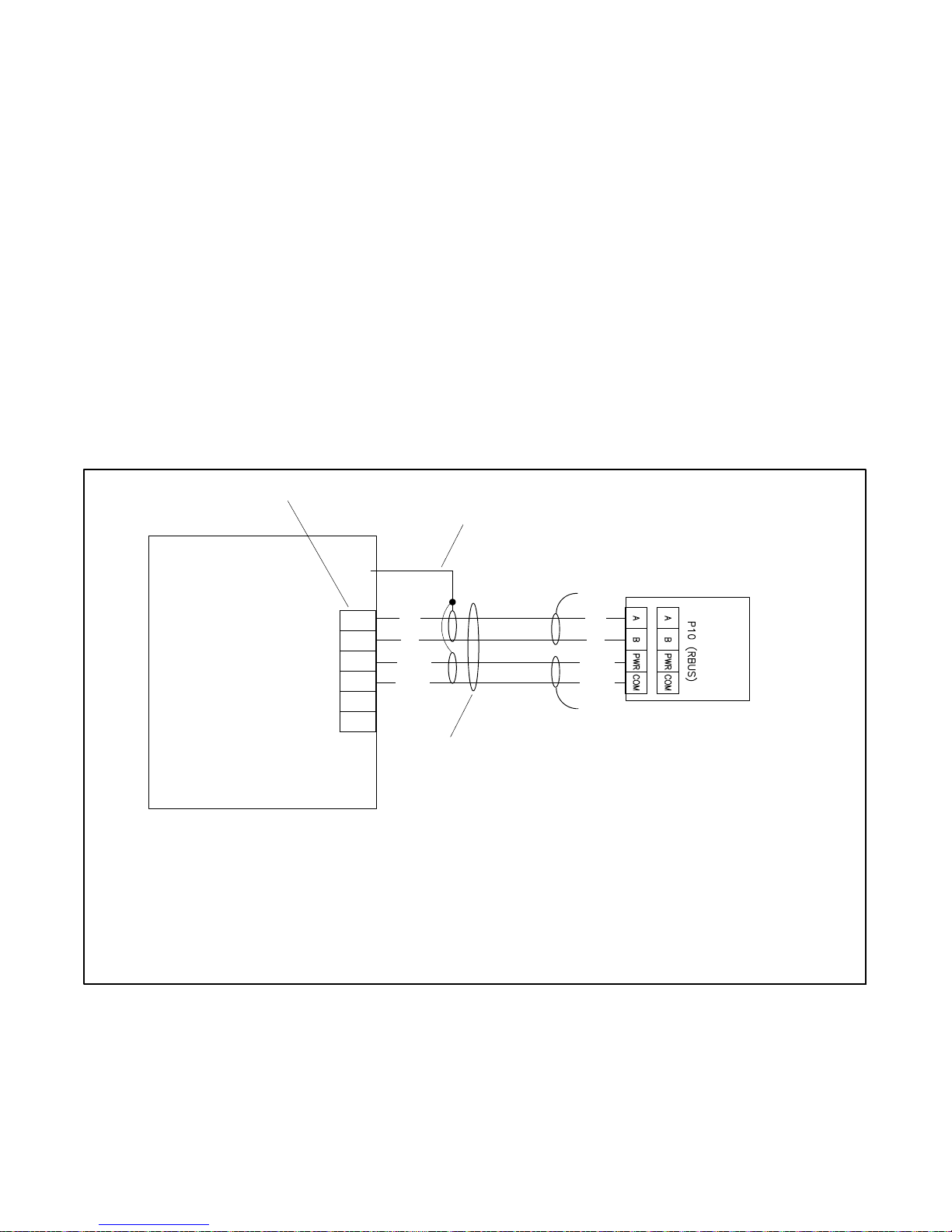

Communication connections for a Kohlerr

Model RXT transfer switch

One Model RXT transfer switch can be connected to the

generator set. See Figure 1-21. Use shielded,

twisted-pair communication cable to connect P10-1

through P10-4 on the transfer switch interface module to

the generatorset terminal block connections A, B, PWR,

and COM. See Section 1.10.2 for the communication

cable recommendations and maximum cable length.

Connect the ATS or remote start/stop switch. Connect

the load leads from the generator set to the Emergency

source lugs on the ATS. Route low-voltage

communication leads through separate conduit fromthe

AC power and load leads. All connections must comply

with applicable state and local codes.

Note: Do not use the Kohlerr Model RRT transfer

switch with the 14/20RESA or 14/20RESAL

generator set.

1

Generator Set

GND

A

B

PWR

COM

3

RBUS

12 VDC

A

B

PWR

COM

4

3

Note: Connections 3 and 4 on the generator set are not

used with the Model RXT transfer switch.

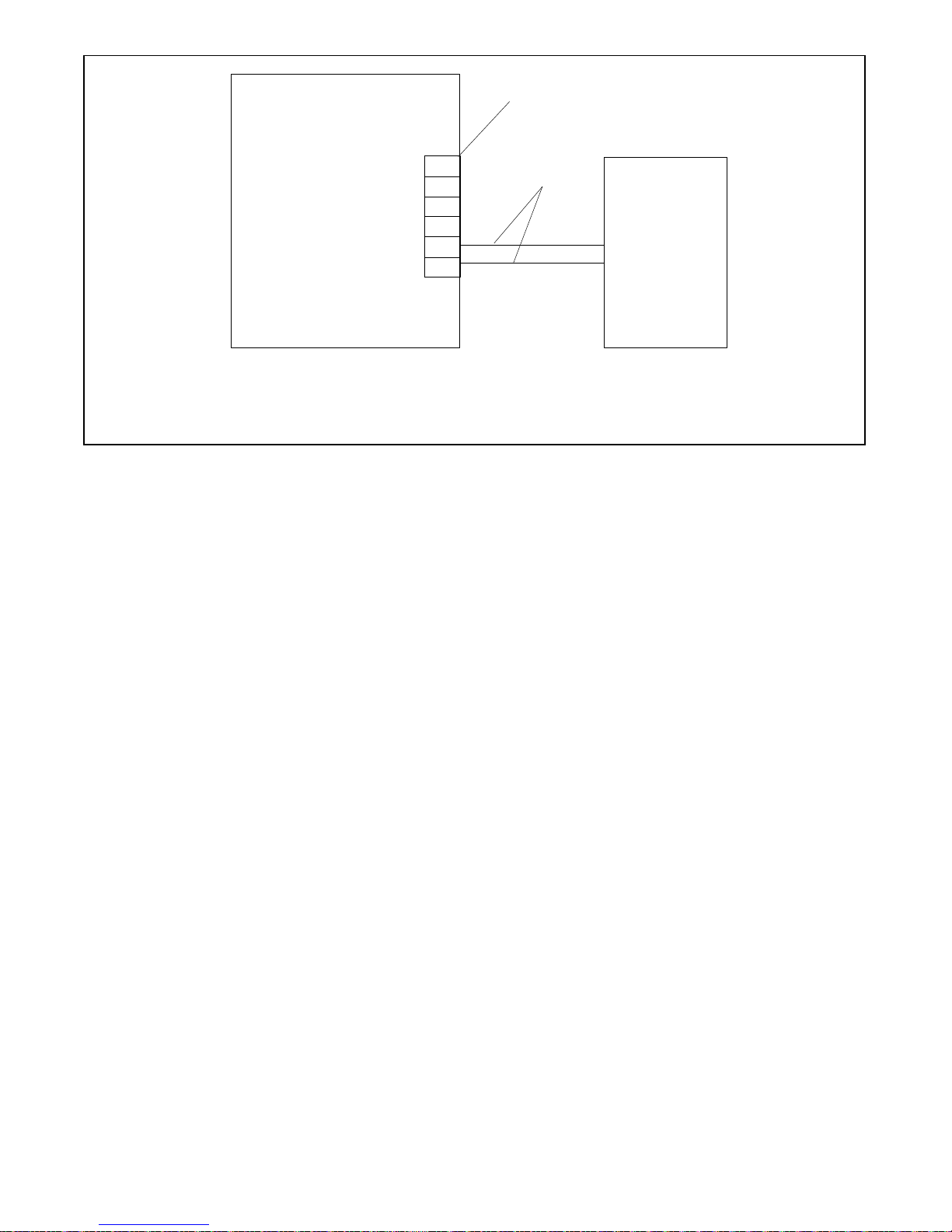

Engine start connection for other transfer

switches or a remote start/stop switch

Connect the engine start leads from the transfer switch

or remote start switch to terminals 3 and 4 on the

terminal block. See Figure 1-22. Route the engine start

leads through separate conduit from the AC power and

load leads.

2

Interface Board on the

Model RXT Transfer Switch

4

A

B

PWR

COM

4

RXT

Note: Generator set terminal block connections 3 and 4 are NOT USED with the Model RXT ATS.

1. Generator set terminal block. See Figure 2-4 for location. Check the decal on the generator set for terminal block connections.

2. Connect one end of each cable shield to GROUND at the generator set.

3. Communication cable Belden #9402 or equivalent 20 AWG shielded, twisted-pair cable. See Section 1.10.2, Cable Specifications.

4. Leave one end of each cable shield disconnected. If accessory modules (PIM, LCM or load shed kit) are connected, see Section

1.10.3.

Figure 1-21 Model RXT Transfer Switch Communication Connection to Generator Set Terminal Block

TP-6803 1/15 25Section 1 Installation

Generator Set

1

A

B

PWR

COM

4

3

1. Generator Set Terminal Block. See the dimension drawings in Section 2 for location. Check the decal on the generator set for terminal

block connections.

2. Engine start leads 3 and 4. See the ATS manual for cable size specifications.

2

ATS

(with engine

start contacts)

Figure 1-22 Engine Start Connections with Transfer Switch Models other than Model RXT

1.10.2 Communication Cable

Specifications

RBUS Connections A and B

For the RBUS communication connections A and B to

the Model RXT transfer switch, optional PIM and/or

optional LCM or load shed kit, use 20 AWG shielded,

twisted-pair communication cable. Belden #9402

(two-pair) or Belden #8762 (single-pair) or equivalent

and use the second pair for the PWR and COM

connections.

D For the longercable runs shownin the lasttwo rows of

Figure 1-23, use 12 or 14 AWG cable for PWR and

COM, and use the 20 AWG communication cable

specified above for the A and B connections only. In

this case, single-pair communication cable such as

Belden #8762 can be used for the A and B

connections.

cable is recommended.

For outdoor installations, including those with buried

cables and/or conduit, use outdoor-rated Belden

#1075A or equivalent 20 AWG shielded, twisted-pair

communication cable.

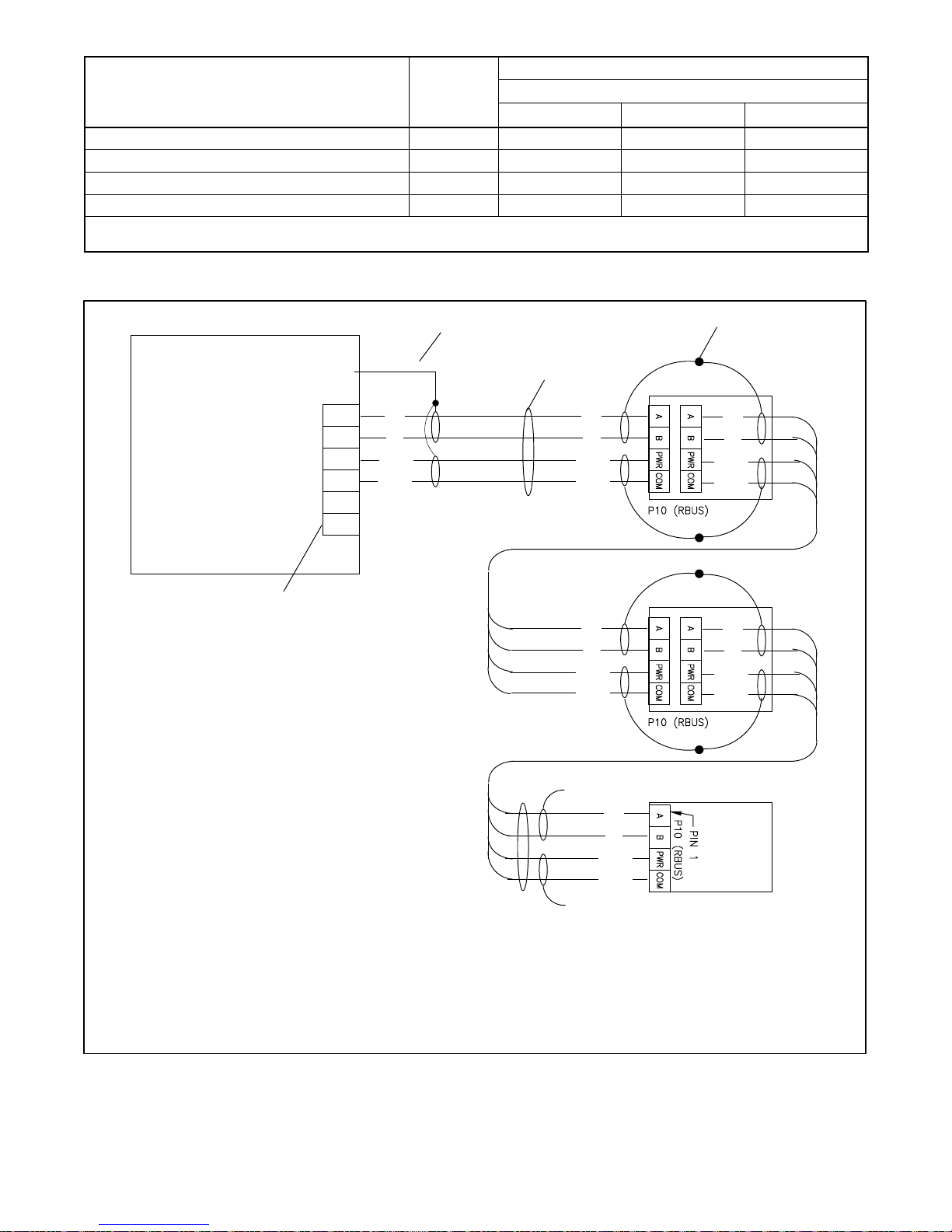

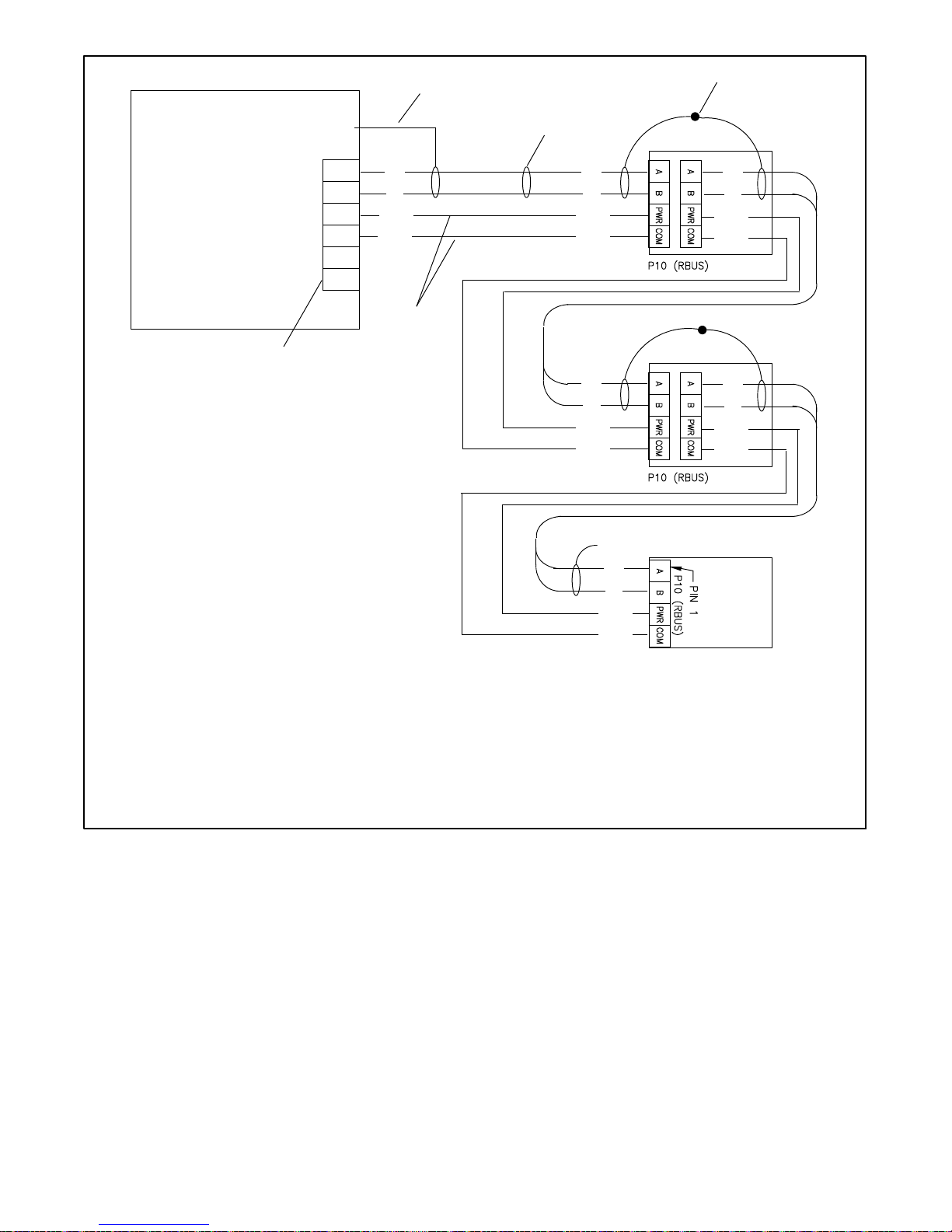

1.10.3 System Connections with

Accessory Modules

See Figure 1-24 through Figure 1-28 for connection

options with accessory modules. Accessory modules

can include one Model RXT transfer switch, one

PWR and COM Connections

For the PWR and COM connections, the cable size and

maximum cable length depends on the number of

modules connected. See Figure 1-23.

D For short cable runs shown in the first two rows of

Figure 1-23, use one pair in the two-pair

communication cable for the A and B connections,

programmable interface module (PIM) and/or one load

control module (LCM) or load shed kit. Note the cable

shield connections shown in Figure 1-24.

The maximum cable length depends on the number of

optional modules connected. See Figure 1-23 for the

maximum cablelengths with 1,2, or 3modules per cable

run.

tp6803

TP-6803 1/1526 Section 1 Installation

Maximum length per run, meters (ft.)

Indoor or

Outdoor

Cable Size for PWR and COM Connections

Installation

20 AWG Belden #9402 or equivalent, two-pair Indoor

20 AWG Belden #1075A or equivalent, two-pair Outdoor

14 AWG * —

12 AWG * —

* Use 12 or 14 AWG cable for PWR and COM connections only. For RBUS connections A and B, use shielded, twisted pair communication

cable specified in Section 1.10.2.

1 Module 2 Modules 3 Modules

61 (200) 31 (100) 21 (67)

61 (200) 31 (100) 21 (67)

152 (500) 152 (500) 122 (400)

152 (500) 152 (500) 152 (500)

Number of Modules per Run

Figure 1-23 Total Cable Lengths for PWR and COM Connections

Generator Set

RBUS

12 VDC

1

GND

A

B

PWR

COM

4

3

A

B

PWR

COM

2

4

3

RXT

A

B

PWR

COM

A

B

PWR

COM

PIM

A

B

PWR

COM

A

B

PWR

COM

Note: See Section 1.10.2, Cable Specifications.

1. Generator set terminal block. See Figure 2-4 for location. Check the decal on the generator set for terminal block connections.

2. Connect one end of each cable shield to GROUND at the generator set.

3. Communication cable Belden #9402 or equivalent 20 AWG shielded, twisted-pair cable.

4. Connect shields together as shown.

5. Leave one end of each cable shield disconnected at the last device.

Figure 1-24 Accessory Module Communication Connection Details

TP-6803 1/15 27Section 1 Installation

5

A

B

PWR

COM

LCM

or load

shed kit

5

2

4

Generator Set

RBUS

12 VDC

1

GND

A

B

PWR

COM

4

3

A

B

PWR

COM

3

RXT

A

B

PWR

COM

6

A

B

PWR

COM

PIM

A

B

PWR

COM

5

A

B

PWR

COM

A

B

PWR

COM

LCM

or load

shed kit

Note: See Section 1.10.2, Cable Specifications.

1. Generator set terminal block. See Figure 2-4 for location. Check the decal on the generator set for terminal block connections.

2. Connect one end of each cable shield to GROUND at the generator set.

3. Communication cable Belden #8762 or equivalent 20 AWG shielded, twisted-pair cable (one pair).

4. Connect shields together as shown.

5. Leave one end of each cable shield disconnected at the last device.

6. 12 AWG or 14 AWG leads for PWR and COM.

Figure 1-25 Accessory Module Connections with 12--14 AWG Power Leads

TP-6803 1/1528 Section 1 Installation

Loading...

Loading...