Page 1

Installation

Marine Generator Sets

Models:

3.5EFOZ/4EOZ, 4EFOZ/5EOZ

6.5EFOZ/8EOZ, 8.5EFOZ, 9EFOZ/10EOZ

11EFOZ/13EOZ, 11.5EFOZ/14EOZ

13EFOZ/15.5EOZ, 16EFOZ/20EOZ

17.5EFOZ/20EOZ, 19EFOZ/23EOZ

20EFOZ/24EOZ, 23EFOZ/28EOZ

27EFOZ/32EOZ, 33EFOZ/40EOZ

40EFOZ/50EOZ, 55EFOZ/65EOZ

70EFOZ/80EOZ, 80EFOZ/99EOZ

100EFOZ/125EOZ, 125EFOZ/150EOZ

TP-6069 6/03d

Page 2

Page 3

Table of Contents

Safety Precautions and Instructions I........................................................

Section 1 Introduction 1.....................................................................

Section 2 Location and Mounting 3..........................................................

2.1 General Considerations 3................................................

2.2 Location 3.............................................................

2.3 Mounting 3.............................................................

Section 3 Cooling System 5.................................................................

3.1 Ventilation 5............................................................

3.2 Cooling System Components 5...........................................

3.2.1 Intake Through-Hull Strainer (Seacock Cover) 5.....................

3.2.2 Seacock 6.....................................................

3.2.3 Seawater Strainer 6.............................................

3.2.4 Water Lines 6..................................................

3.2.5 Closed Heat Exchanger (4--125EFOZ/5--150EOZ Models) 6..........

3.2.6 Direct Water Cooled (3.5EFOZ/4EOZ Models) 6.....................

Section 4 Exhaust System 11.................................................................

4.1 Types 11...............................................................

4.2 Exhaust Lines 11........................................................

4.3 Exhaust System Location, Mounting, and Installation 12.......................

4.3.1 Above-Waterline Installation 12....................................

4.3.2 Mid/Below-Waterline Installation 14.................................

Section 5 Fuel System 17.....................................................................

5.1 Fuel Tank 17............................................................

5.2 Fuel Lines 18............................................................

5.3 Fuel Filters 18...........................................................

5.4 Fuel Pump Lift 18........................................................

5.5 Fuel Consumption 18.....................................................

Section 6 Electrical System 19................................................................

6.1 AC Voltage Connections 19...............................................

6.2 Circuit Protection 19......................................................

6.2.1 Circuit Breaker Considerations 19..................................

6.2.2 Circuit Breaker Installation (4--27EFOZ and 5--32EOZ Models) 21......

6.2.3 Circuit Breaker Installation (33--125EFOZ and 40--150EOZ Models) 22..

6.3 Installation In Steel or Aluminum Vessels 23.................................

6.4 Installation Recommendations 23..........................................

6.5 Battery 24...............................................................

6.6 Wiring 24...............................................................

6.7 Remote Start Switch Connection 25........................................

Section 7 Installation Drawings 29............................................................

Section 8 Reconnection/Adjustments 67.......................................................

8.1 Four-Lead Reconnection 67...............................................

8.1.1 100--120-Volt Configurations 67....................................

8.1.2 100--120/200--240-Volt Configurations 67............................

8.1.3 200--240-Volt Configurations 68....................................

8.2 Twelve-Lead Reconnection 68.............................................

8.3 Decision-Maker 3+ Controller Overvoltage Shutdown Adjustment 69............

8.4 Voltage Regulator Adjustment (4--27EFOZ and 5--32EOZ Models) 72...........

Appendix A Generator Selection and Wattage Requirements A-1................................

Appendix B Abbreviations A-2................................................................

Appendix C Generator Set Output Ratings Procedure A-4.......................................

TP-6069 6/03 Table of Contents

Page 4

Page 5

Safety Precautions and Instructions

IMPORTANT SAFETY

INSTRUCTIONS. Electromechanical

equipment, including generator sets,

transfer switches, switchgear, and

accessories, can cause bodily harm

and pose life-threatening danger when

improperly installed, operated, or

maintained. To prevent accidents be

aware of potential dangers and act

safely. Read and follow all safety

precautions and instructions. SAVE

THESE INSTRUCTIONS.

This manual has several types of safety

precautions and instructions: Danger,

Warning, Caution, and Notice.

DANGER

Danger indicates the presence of a

hazard that will cause severe

personal injury, death,orsubstantial

property damage.

WARNING

Warning indicates the presence of a

hazard that can cause severe

personal injury, death,or substantial

property damage.

CAUTION

Caution indicates the presence of a

hazard that will or can cause minor

personal injury or property damage.

NOTICE

Notice communicates installation,

operation, or maintenance information

that is safety related but not hazard

related.

Safety decals affixed to the equipment

in prominent places alert the operator

or service technician to potential

hazards and explain how to act safely.

The decals are shown throughout this

publication to improve operator

recognition. Replace missing or

damaged decals.

Accidental Starting

WARNING

Accidental starting.

Can cause severe injury or death.

Disconnect the battery cables before

working on the generator set.

Remove the negative (--) lead first

when disconnecting the battery.

Reconnect the negative (--) lead last

when reconnecting the battery.

Disabling the generator set.

Accidental starting can cause

severe injury or death. Before

working on the generator set or

connected equipment, disable the

generator set as follows: (1) Move the

generator set master switch to the OFF

position. (2) Disconnect the power to

the battery charger. (3) Remove the

battery cables, negative (--) lead first.

Reconnect the negative (--) lead last

when reconnecting the battery. Follow

these precautions to prevent startingof

the generator set by an automatic

transfer switch, remote start/stop

switch, orengine startcommand from a

remote computer.

Disabling the generator set.

Accidental starting can cause

severe injury or death. Before

working on the generator set or

equipment connected to the set,

disable the generator set as follows:

(1) Place the generator set start/stop

switch in the STOP position.

(2) Disconnect the power to the battery

charger, if equipped. (3) Remove the

battery cables, negative (--) lead first.

Reconnect the negative (--) lead last

when reconnecting the battery. Follow

these precautions to prevent the

starting of the generator set by the

remote start/stop switch.

Disabling the generator set.

Accidental starting can cause

severe injury or death. Before

working on the generator set or

equipment connected to the set,

disable the generator set as follows:

(1) Press the generator set on/off

button to shut down the generator set.

All indicator lamps dim. (2) Disconnect

the power to the battery charger, if

equipped. (3) Remove the battery

cables, negative (--) lead first.

Reconnect the negative (--) lead last

when reconnecting the battery. Follow

these precautions to prevent the

starting of the generator set by the

remote start/stop switch.

Battery

WARNING

Sulfuric acid in batteries.

Can cause severe injury or death.

Wear protective goggles and clothing.

Battery acid may cause blindness and

burn skin.

Battery electrolyte is a diluted

sulfuric acid. Battery acidcan cause

severe injury or death. Battery acid

can cause blindness and burn skin.

Always wear splashproof safety

goggles, rubber gloves, and boots

when servicing the battery. Do not

open a sealed battery or mutilate the

battery case. If battery acid splashes in

the eyes or on the skin, immediately

flush the affected area for 15 minutes

with large quantities of clean water.

Seek immediate medical aid inthe case

of eye contact. Never add acid to a

battery after placing the battery in

service, asthis mayresult inhazardous

spattering of battery acid.

TP-6069 6/03 ISafety Precautions and Instructions

Page 6

Battery acid cleanup. Battery acid

can cause severe injury or death.

Battery acid is electrically conductive

and corrosive. Add 500 g (1 lb.) of

bicarbonate of soda (baking soda) to a

containerwith4L(1gal.)ofwaterand

mix the neutralizing solution. Pour the

neutralizing solution on the spilled

battery acid and continue to add the

neutralizing solution to the spilled

battery acid until all evidence of a

chemical reaction (foaming) has

ceased. Flush the resulting liquid with

water and dry the area.

Engine Backfire/Flash

Fire

WARNING

Fire.

Can cause severe injury or death.

Do not smoke or permit flames or sparks

near fuels or the fuel system.

Exhaust System

WARNING

Carbon monoxide.

Can cause severe nausea,

fainting, or death.

The exhaust system must be leakproof

and routinely inspected.

Battery gases. Explosion can cause

severe injury or death. Battery gases

can cause an explosion. Do not smoke

or permit flames or sparks to occur near

a battery at any time, particularly when

it is charging. Do not dispose of a

battery in a fire. To prevent burns and

sparks that could cause an explosion,

avoid touching the battery terminals

with tools or other metal objects.

Remove alljewelry beforeservicing the

equipment. Discharge static electricity

from your body before touching

batteries by first touching a grounded

metal surface away from the battery. To

avoid sparks, do not disturb the battery

charger connections while the battery

is charging. Always turn the battery

charger off before disconnecting the

battery connections. Ventilate the

compartments containing batteries to

prevent accumulation of explosive

gases.

Battery short circuits. Explosion

can cause severe injury or death.

Short circuits can cause bodily injury

and/or equipment damage.

Disconnect the battery before

generator set installation or

maintenance. Remove all jewelry

before servicing the equipment. Use

tools with insulated handles. Remove

the negative (--) lead first when

disconnecting the battery. Reconnect

the negative (--) lead last when

reconnecting the battery. Never

connect the negative (--) battery cable

to the positive (+) connection terminal

of the starter solenoid. Do not test the

battery condition by shorting the

terminals together.

Servicing the fuel system. A flash

fire can cause severe injury or death.

Do not smoke or permit flames or

sparks near the carburetor, fuel line,

fuel filter, fuel pump, or other potential

sources of spilled fuels or fuel vapors.

Catch fuels in an approved container

when removing the fuel line or

carburetor.

Servicing the air cleaner. A sudden

backfire can cause severe injury or

death. Do not operate the generator

set with the air cleaner/silencer

removed.

Combustible materials. A sudden

flash fire can cause severe injury or

death. Do not smoke or permit flames

or sparks near the fuel system. Keep

the compartment and the generator set

clean and free of debris to minimize the

risk of fire. Wipe up spilled fuels and

engine oil.

Combustible materials. A fire can

cause severe injury or death.

Generator set engine fuels and fuel

vapors are flammable and explosive.

Handle these materials carefully to

minimize the risk of fire or explosion.

Equip the compartment or nearby area

with a fully charged fire extinguisher.

Select a fire extinguisher rated ABC or

BC for electrical fires or as

recommended by the local fire code or

an authorized agency. Train all

personnel on fire extinguisher

operation and fire prevention

procedures.

Carbon monoxide symptoms.

Carbon monoxide can cause severe

nausea, fainting, or death. Carbon

monoxide is a poisonous gas present in

exhaust gases. Carbon monoxide

poisoning symptoms include but are

not limited to the following:

D Light-headedness, dizziness

D Physical fatigue, weakness in

joints and muscles

D Sleepiness, mental fatigue,

inability to concentrate

or speak clearly, blurred vision

D Stomachache, vomiting, nausea

If experiencing any of these symptoms

and carbon monoxide poisoning is

possible, seek fresh air immediately

and remain active. Do not sit, lie down,

or fall asleep. Alert others to the

possibility of carbon monoxide

poisoning. Seek medical attention if

the condition of affected persons does

not improvewithin minutesof breathing

fresh air.

Copper tubing exhaust systems.

Carbon monoxide can cause severe

nausea, fainting, or death. Do not

use copper tubing in diesel exhaust

systems. Sulfur in diesel exhaust

causes rapid deterioration of copper

tubing exhaust systems, resulting in

exhaust/water leakage.

TP-6069 6/03II Safety Precautions and Instructions

Page 7

Inspecting the exhaust system.

Carbon monoxide can cause severe

nausea, fainting, or death. For the

safety of the craft’s occupants, install a

carbon monoxidedetector. Consult the

boat builder or dealer for approved

detector location and installation.

Inspect the detector before each

generator set use. In addition to routine

exhaust system inspection, test the

carbon monoxide detector per the

manufacturer’s instructions and keep

the detector operational at all times.

Operating thegenerator set. Carbon

monoxide cancause severenausea,

fainting, or death. Carbon monoxide

is an odorless, colorless, tasteless,

nonirritating gasthat cancause death if

inhaled for even a short time. Use the

following precautions when installing

and operating the generator set. Do not

install the exhaustoutlet where exhaust

can be drawn in through portholes,

vents, or air conditioners. If the

generator set exhaust discharge outlet

is near the waterline, water could enter

the exhaust discharge outlet and close

or restrict the flow of exhaust. Never

operate the generator set without a

functioning carbon monoxide detector.

Be especially careful if operating the

generator set when moored or

anchored under calm conditions

because gases may accumulate. If

operating the generator set dockside,

moor the craft so that the exhaust

discharges on the lee side (the side

sheltered from the wind). Always be

aware of others, making sure your

exhaust is directed away from other

boats and buildings. Avoid overloading

the craft.

Fuel System

WARNING

The fuel system. Explosive fuel

vapors can cause severe injury or

death. Vaporized fuels are highly

explosive. Use extreme care when

handling and storing fuels. Store fuels

inawell-ventilatedareaawayfrom

spark-producing equipment and out of

the reach of children. Never add fuel to

the tank while the engine is running

because spilled fuel may ignite on

contact with hot parts or from sparks.

Do not smoke or permit flames or

sparks to occur near sources of spilled

fuel or fuel vapors. Keep the fuel lines

and connections tight and in good

condition. Do not replace flexible fuel

lines with rigid lines. Use flexible

sections to avoid fuel line breakage

caused by vibration. Do notoperate the

generator set in the presence of fuel

leaks, fuel accumulation, or sparks.

Repair fuel systems before resuming

generator set operation.

Draining the fuel system. Explosive

fuel vapors can cause severe injury

or death. Spilled fuel can cause an

explosion. Use acontainer tocatch fuel

when draining the fuel system. Wipe up

spilled fuel after draining the system.

Installing the fuel system. Explosive

fuel vapors can cause severe injury

or death. Fuel leakage can cause an

explosion. Do not modify the tank or

the propulsion engine fuel system.

Equip the craft with a tank that allows

one of the two pickup arrangements

described in the installation section.

The tank and installation must conform

to USCG Regulations.

Pipe sealant. Explosive fuel vapors

can cause severe injury or death.

Fuel leakage can cause an explosion.

Use pipesealant onall threadedfittings

to prevent fuel leakage. Use pipe

sealant that resists gasoline, grease,

lubrication oil, common bilge solvents,

salt deposits, and water.

Ignition-protected equipment.

Explosive fuel vapors can cause

severe injury or death. Gasoline

vapors can cause an explosion.

USCG Regulation 33CFR183 requires

that all electrical devices (ship-to-shore

transfer switch, remote start panel,

etc.) must be ignition protected when

used in a gasoline and gaseous-fueled

environment. The electrical devices

listed above are not ignition protected

and are not certified to operate in a

gasoline and gaseous-fueled

environment such as an engineroom or

near fuel tanks. Acceptable locations

are the wheelhouse and other living

areas sheltered from rain and water

splash.

Hazardous Noise

CAUTION

Hazardous noise.

Can cause hearing loss.

Never operate the generator set

without a muffler or with a faulty

exhaust system.

Engine noise. Hazardous noise can

cause hearing loss. Generator sets

not equipped with sound enclosures

can produce noise levels greater than

105 dBA. Prolonged exposure to noise

levels greater than 85 dBA can cause

permanent hearing loss. Wear hearing

protection when near an operating

generator set.

Hazardous Voltage/

Electrical Shock

WARNING

Explosive fuel vapors.

Can cause severe injury or death.

Use extreme care when handling, storing,

and using fuels.

TP-6069 6/03 IIISafety Precautions and Instructions

Hazardous voltage.

Can cause severe injury or death.

Operate the generator set only when

all guards and electrical enclosures

areinplace.

Moving rotor.

Page 8

CAUTION

Welding the generator set.

Can cause severe electrical

equipment damage.

Never weld components of the

generator set without first

disconnecting the battery, controller

wiring harness, and engine electronic

control module (ECM).

Grounding electrical equipment.

Hazardous voltage can cause

severe injury or death. Electrocution

is possible whenever electricity is

present. Open the main circuit

breakers of all power sources before

servicing theequipment. Configure the

installation to electrically ground the

generator set, transfer switch, and

related equipment and electrical

circuits to complywith applicablecodes

and standards. Never contact

electrical leads or appliances when

standing in water or on wet ground

because these conditions increase the

risk of electrocution.

Disconnecting the electrical load.

Hazardous voltage can cause

severe injury or death. Disconnect

the generator set from the load by

opening the line circuit breaker or by

disconnecting the generator set output

leads from the transfer switch and

heavily taping the ends of the leads.

High voltage transferred to the load

during testing may cause personal

injury and equipment damage. Do not

use the safeguard circuit breaker in

place of the line circuit breaker. The

safeguard circuit breaker does not

disconnect the generator set from the

load.

Welding the generator set. Can

cause severe electrical equipment

damage. Before welding the generator

set perform the following steps:

(1) Remove the battery cables,

negative (--) lead first. (2) Disconnect

all engine electronic control module

(ECM) connectors. (3) Disconnect all

generator set controller and voltage

regulator circuit board connectors.

(4) Disconnect the engine batterycharging alternator connections.

(5) Attach the weld ground connection

close to the weld location.

Short circuits. Hazardous

voltage/current can cause severe

injury or death. Short circuits can

cause bodily injury and/or equipment

damage. Do not contact electrical

connections with tools or jewelry while

making adjustments or repairs.

Remove alljewelry beforeservicing the

equipment.

Testing the voltage regulator.

Hazardous voltage can cause

severe injury or death. High voltage

is present at the voltage regulator heat

sink. Toprevent electrical shock do not

touch the voltage regulator heat sink

when testing the voltage regulator.

(PowerBoostt, PowerBoostt III, and

PowerBoostt V voltage regulator

models only)

Electrical backfeed to the utility.

Hazardous backfeed voltage can

cause severe injury or death.

Connect the generator set to the

building/marina electrical system only

through an approved device and after

the building/marina main switch is

opened. Backfeed connections can

cause severe injury or death to utility

personnel working on power lines

and/or personnel near the work area.

Some states and localities prohibit

unauthorized connection to the utility

electrical system. Install a

ship-to-shore transfer switch to prevent

interconnection of the generator set

power and shore power.

Testing live electrical circuits.

Hazardous voltage or current can

cause severe injury or death. Have

trained and qualified personnel take

diagnostic measurements of live

circuits. Use adequately rated test

equipment with electrically insulated

probes and followthe instructions of the

test equipment manufacturer when

performing voltage tests. Observe the

following precautions when performing

voltage tests: (1) Remove all jewelry.

(2) Stand on a dry, approvedelectrically

insulated mat. (3) Do not touch the

enclosure or components inside the

enclosure. (4) Be prepared for the

system to operate automatically.

(600 volts and under)

Hot Parts

WARNING

Hot coolant and steam.

Can cause severe injury or death.

Before removing the pressure cap, stop

the generator setand allowit to cool. Then

loosen the pressure cap to relieve

pressure.

WARNING

Hot engine and exhaust system.

Can cause severe injury or death.

Do not work on the generator set until it

cools.

Checking the coolant level. Hot

coolant can cause severe injury or

death. Allow the engine to cool.

Release pressure from the cooling

system before removing the pressure

cap. To release pressure, cover the

pressure capwith a thick cloth and then

slowly turn the cap counterclockwiseto

the first stop. Remove the cap after

pressure has been completely

released and the engine has cooled.

Check thecoolant levelat thetank ifthe

generator set has a coolant recovery

tank.

TP-6069 6/03IV Safety Precautions and Instructions

Page 9

Servicing the exhaust system. Hot

parts can cause severe injury or

death. Do not touch hot engine parts.

The engine and exhaust system

components become extremely hot

during operation.

Moving Parts

WARNING

Hazardous voltage.

Can cause severe injury or death.

Operate the generator set only when

all guards and electrical enclosures

areinplace.

WARNING

Rotating parts.

Can cause severe injury or death.

Operate the generator set only when

all guards, screens, and coversare in

place.

WARNING

Airborne particles.

Can cause severe injury or

blindness.

Wear protective goggles andclothing

when using power tools, hand tools,

or compressed air.

Moving rotor.

Tightening the hardware. Flying

projectiles can cause severe injury

or death. Loose hardware can cause

the hardware or pulley to release from

the generator setengine and can cause

personal injury. Retorque all

crankshaft and rotor hardware after

servicing. Do notloosen thecrankshaft

hardware or rotor thrubolt when making

adjustments or servicing the generator

set. Rotate the crankshaft manually in

a clockwise direction only. Turning the

crankshaft bolt or rotor thrubolt

counterclockwise can loosen the

hardware.

Servicing the generator set when it

is operating. Exposed moving parts

can cause severe injury or death.

Keep hands, feet, hair, clothing, and

test leads away from the belts and

pulleys when the generator set is

running. Replace guards, screens, and

covers before operating the generator

set.

Sound shield removal. Exposed

moving parts can cause severe

injury or death. The generator set

must be operating in order to perform

some scheduled maintenance

procedures. Be especiallycareful if the

sound shield has been removed,

leaving the belts and pulleys exposed.

(Sound-shield-equipped models only)

Notice

NOTICE

This generator set has been

rewired fromits nameplate voltage

to

246242

NOTICE

Voltage reconnection. Affix a notice

to the generator set after reconnecting

the set to a voltage different from the

voltage on the nameplate. Order

voltage reconnection decal 246242

from an authorized service

distributor/dealer.

NOTICE

Hardware damage. The engine and

generator set may use both American

Standard and metric hardware. Use

the correct size tools to prevent

rounding of the bolt heads and nuts.

NOTICE

When replacing hardware, do not

substitute with inferior grade

hardware. Screws and nuts are

available in different hardness ratings.

To indicate hardness, American

Standard hardware uses a series of

markings, and metric hardware uses a

numeric system. Check the markings

on the bolt heads and nuts for

identification.

NOTICE

Electrostatic discharge damage.

Electrostatic discharge (ESD)

damages electronic circuit boards.

Prevent electrostatic discharge

damage by wearing an approved

grounding wrist strap when handling

electronic circuit boards or integrated

circuits. An approved grounding wrist

strap provides a high resistance (about

1 megohm), not a direct short,to

ground.

NOTICE

Fuse replacement. Replace fuses

with fuses of the same ampere rating

and type (for example: 3AB or 314,

ceramic). Do not substitute clear

glass-type fuses for ceramic fuses.

Refer to the wiring diagram when the

ampere rating is unknown or

questionable.

NOTICE

Saltwater damage. Saltwater quickly

deteriorates metals. Wipe up saltwater

on and around the generator set and

remove salt deposits from metal

surfaces.

TP-6069 6/03 VSafety Precautions and Instructions

Page 10

Notes

TP-6069 6/03VI Safety Precautions and Instructions

Page 11

Section 1 Introduction

Information in this publication represents data available

at the time of print. Kohler Co. reserves the right to

change this publication and the products represented

without notice and without any obligation or liability

whatsoever.

x:in:001:002:a

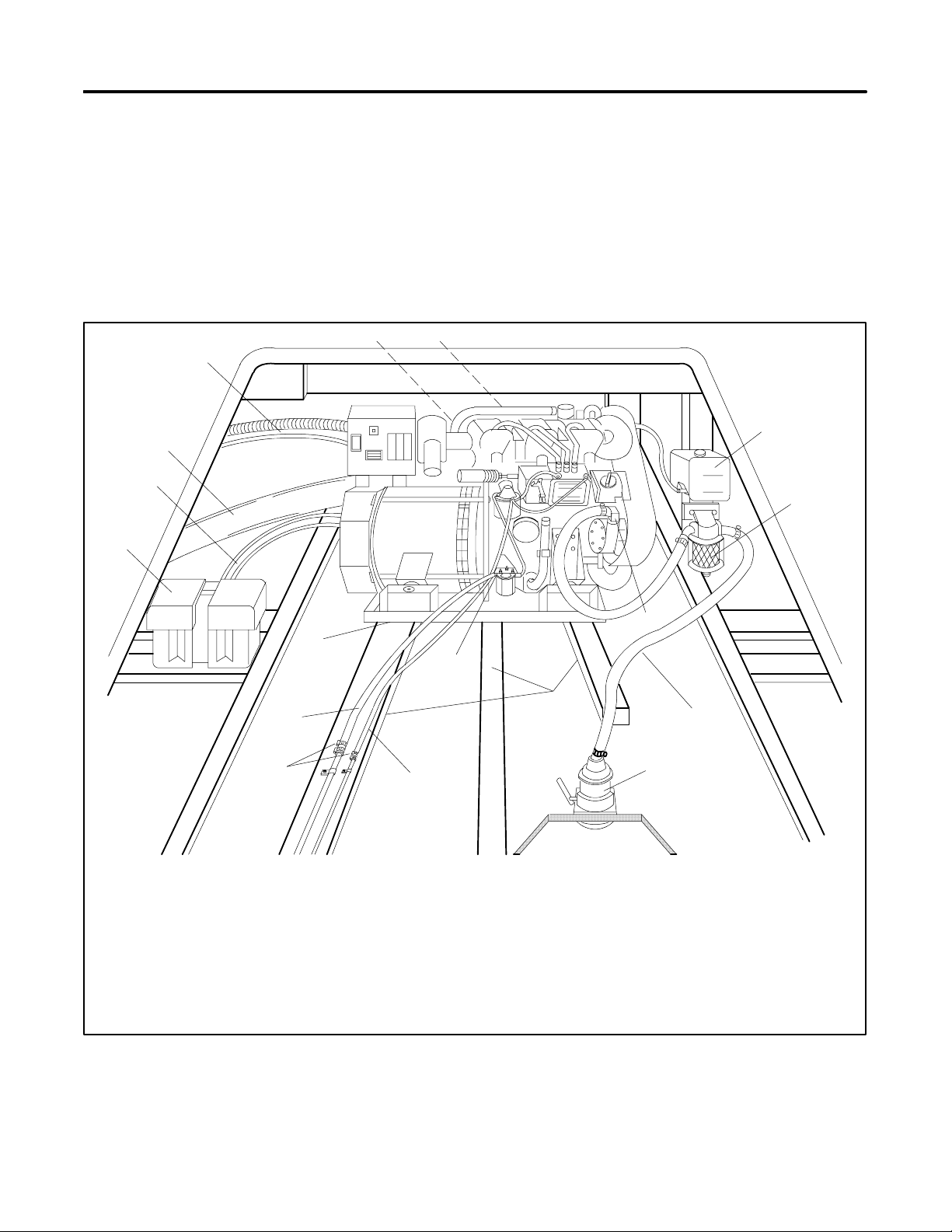

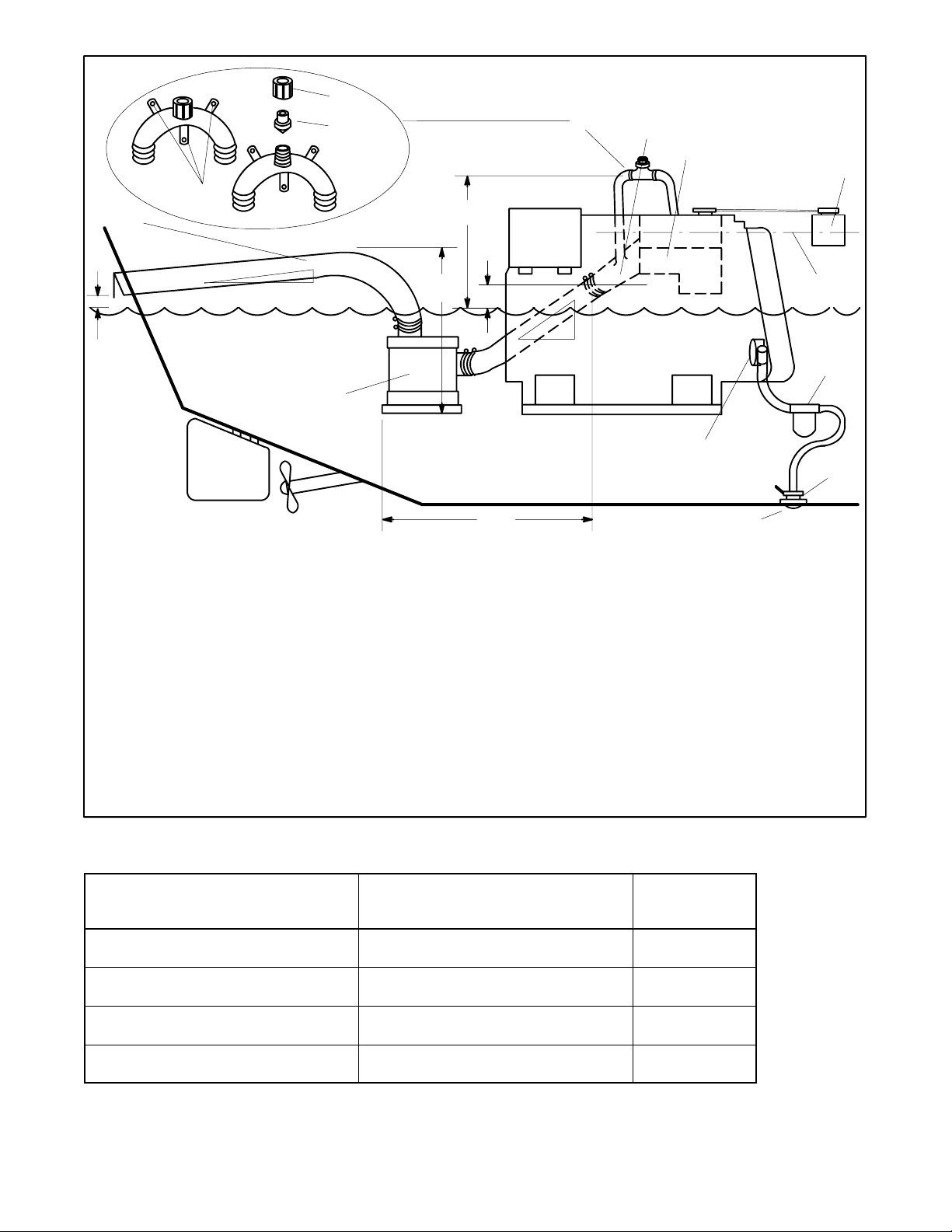

The safe and successful operation of a marine power

system depends primarily on the installation. See

Figure 1-1. Use this manual as a guide to install the

2

14

15

1

17

16

KOHLER

marine generator set. For operating instructions, refer

to the operation manual.

Marine generator set installations must comply with all

applicable regulations and standards.

Use the specification sheets as a guide in planning your

installation. Use current dimension drawings and wiring

diagrams.

3

4

13

9

12

11

1. Exhaust mixer elbow (exhaust/water outlet) (not shown)

2. Heat exchanger (not shown)

3. Coolant recovery tank (locatedon the unit on some models)

4. Seawater strainer *

5. Seawater pump (seawater inlet)

6. Seawater line *

7. Seacock *

8. Craft stringers

9. Fuel feed pump (fuel inlet) *

10

Figure 1-1 Typical Generator Set Location and Mounting

5

8

6

7

585711

10. Fuel return line *

11. Hose clamps

12. Fuel supply line *

13. Mounting tray (mounting skid on 33--150 kW models)

14. Battery/battery storage box

15. Battery cables

16. Exhaust hose or exhaust line *

17. Electrical leads (AC output leads/remote start panel leads)

* Indicated components must conform to USCG regulations.

Note: See text for complete explanation of installation

requirements.

TP-6069 6/03 1Section 1 Introduction

Note: Use two hose clamps on each end of all flexible

exhaust hose connections.

Page 12

Notes

TP-6069 6/032 Section 1 Introduction

Page 13

Section 2 Location and Mounting

2.1 General Considerations

The key to installation is location. Before making final

plans for locating a generator set, consider the

following.

Installation Location Considerations

1. Choose a location that allows adequate space for

cooling and exhaust system installation, fuel

system installation, ventilation, and service access

to the generator set (engine and generator).

2. Use craft stringers or other available structural

members capable of supporting the generator set’s

weight.

3. Seal the generator set compartment from the cabin

to prevent exhaust gases and fuel vapors from

entering the cabin.

See the current generator set specification sheet or

Section 7 of this manual for generator set dimensions

and weights. See Figure 1-1 for a typical installation.

m:is:101:001

2.2 Location

Locate the generator set to allow easy service access to

the generator set’s engine, controller, cooling, and fuel

system components. The engine compartment is often

the ideal location for the generator set if the propulsion

engine(s) does not obstruct access to the generator set

and controller.

Allow clearance for vibration and cooling during

operation. Allow a minimum of 38 mm (1.5 in.)

clearance on all sides (top, front, rear, and sides) of a

generator set without an optional sound shield. Refer to

the instruction sheet for minimum clearances for

sound-shielded units. Also, allow space for the power

takeoff (PTO) option, if equipped.

Diesel generator sets are not ignition-protected. USCG

Regulation 183.410 requires ignition-protected devices

only in gasoline/gaseous-fueled environments.

2.3 Mounting

Mount the generator set as high as possible to avoid

contact with bilge splash and lower-lying vapors and to

allow for downward pitch of the exhaust line toward the

exhaust outlet.

Craft stringers generally provide the best generator set

support. Ensure that the structural members can

support the generator set’s weight and withstand its

vibration.

The generator set includes vibration mounts and a

mounting tray or skid. If desired, install additional

vibration isolating pads underneath the generator set’s

base.

Use the four mounting holes in the mounting tray to

mount the generator set securely to the craft.

For angular operating limits, consult the operation

manual.

Marine Generator Set Installations in

European Union Member Countries

This generator set is specifically intended and approved

for installation below the deck in the engine

compartment. Installation above the deck and/or

outdoors would constitute a violation of European Union

Directive 2000/14/EC noise emission standard.

TP-6069 6/03 3Section 2 Location and Mounting

Page 14

Notes

TP-6069 6/034 Section 2 Location and Mounting

Page 15

3.1 Ventilation

Engine combustion, generator cooling, and expulsion of

flammable and lethal fumes require ventilation. Provide

ventilation compliant with USCG Regulations governing

sizing of vents and other considerations.

As a rule, size each inlet- and outlet-vent area to a

minimum of 13 sq. cm/30.5 cm (2 sq. in. per ft.) of the

craft’s beam. Should this rule conflict with USCG

Regulations, follow USCG Regulations. For applications

with screened inlets, double the size (4 sq. in. per ft.) of

the hull/deck openings. Extend the vent ducts to bilges to

expel heavier-than-air fumes.

Section 3 Cooling System

1

2

3

For generator sets mounted in the engine compartment,

increase the air flow to allow for the generator set’s

requirements. Install optional detection devices to

cause alarm, warning, or engine shutdown should

dangerous fumes accumulate in the compartment.

See the generator set specification sheet that shipped

with the generator set for air requirements. The air intake

silencer/cleaner provides combustion air to the engine.

Do not compromise the recommended minimum

clearance of 38 mm (1.5 in.) between a duct opening and

enclosure wall. The engine/generator performance will

decline if you compromise these guidelines. See

Figure 3-1 for allowable intake restriction.

Note: ISO 3046 derates apply. See Appendix C.

Model Allowable Intake Restriction

3.5EFOZ/4EOZ 200 mm H2O (1.96 kPa or less)

4--125EFOZ/5--150EOZ 635 mm H2O (6.23 kPa or less)

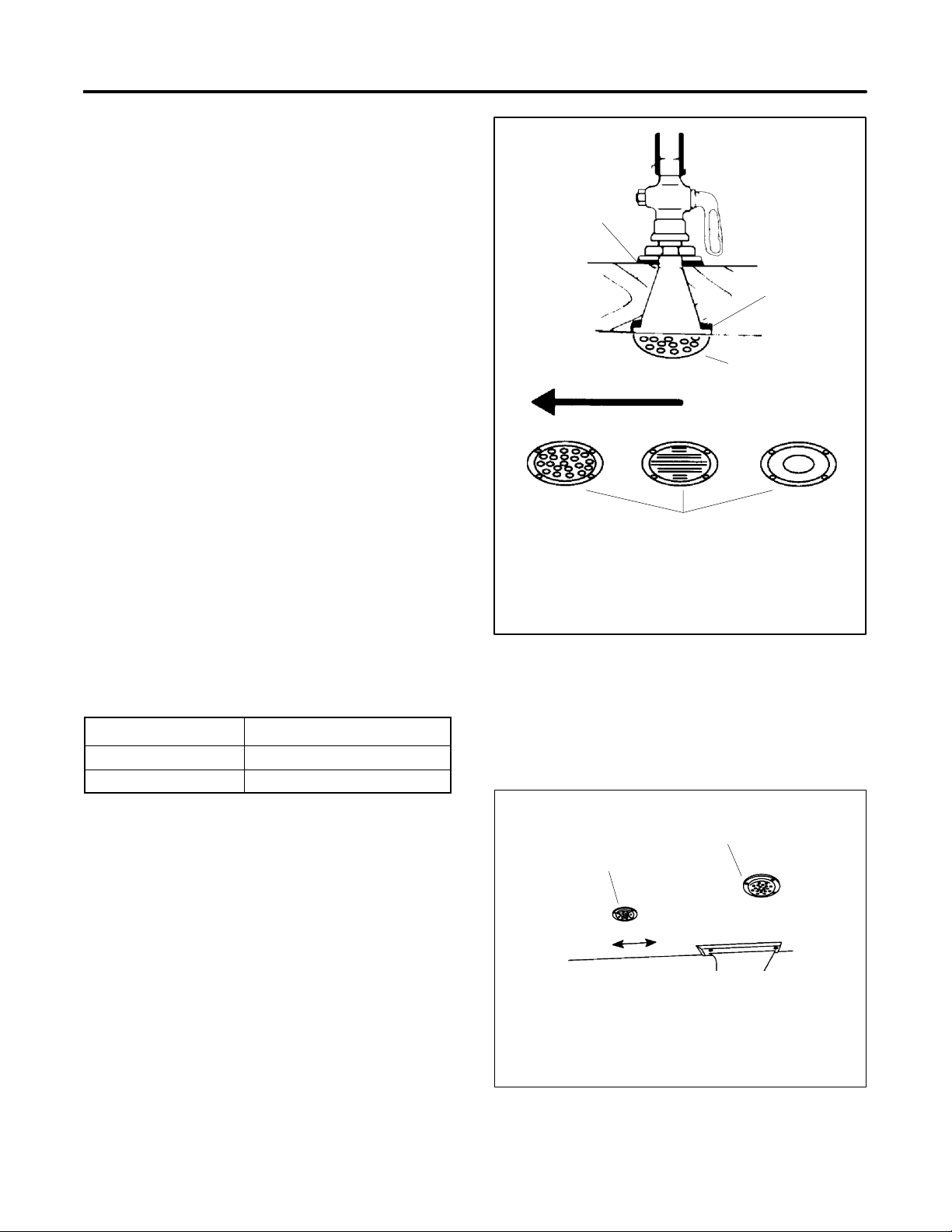

Figure 3-1 Combustion Air Intake Restriction

4

5

1. Inside packing

2. Outside packing

3. Seacock cover

4. Direction of vessel movement

5. Typical intake through-hull strainers

1-789

Figure 3-2 Seacock Installation

Do not align the strainer (in relation to the craft’s direction

of travel) with any other through-hull intakes. See

Figure 3-3. Flush mount the recommended through-hull

strainer. Install slotted-hole-design strainers with the

slots parallel to the direction of the vessel’s movement.

2

3.2 Cooling System Components

1

The marine generator set’s cooling system requires the

following components.

4 3

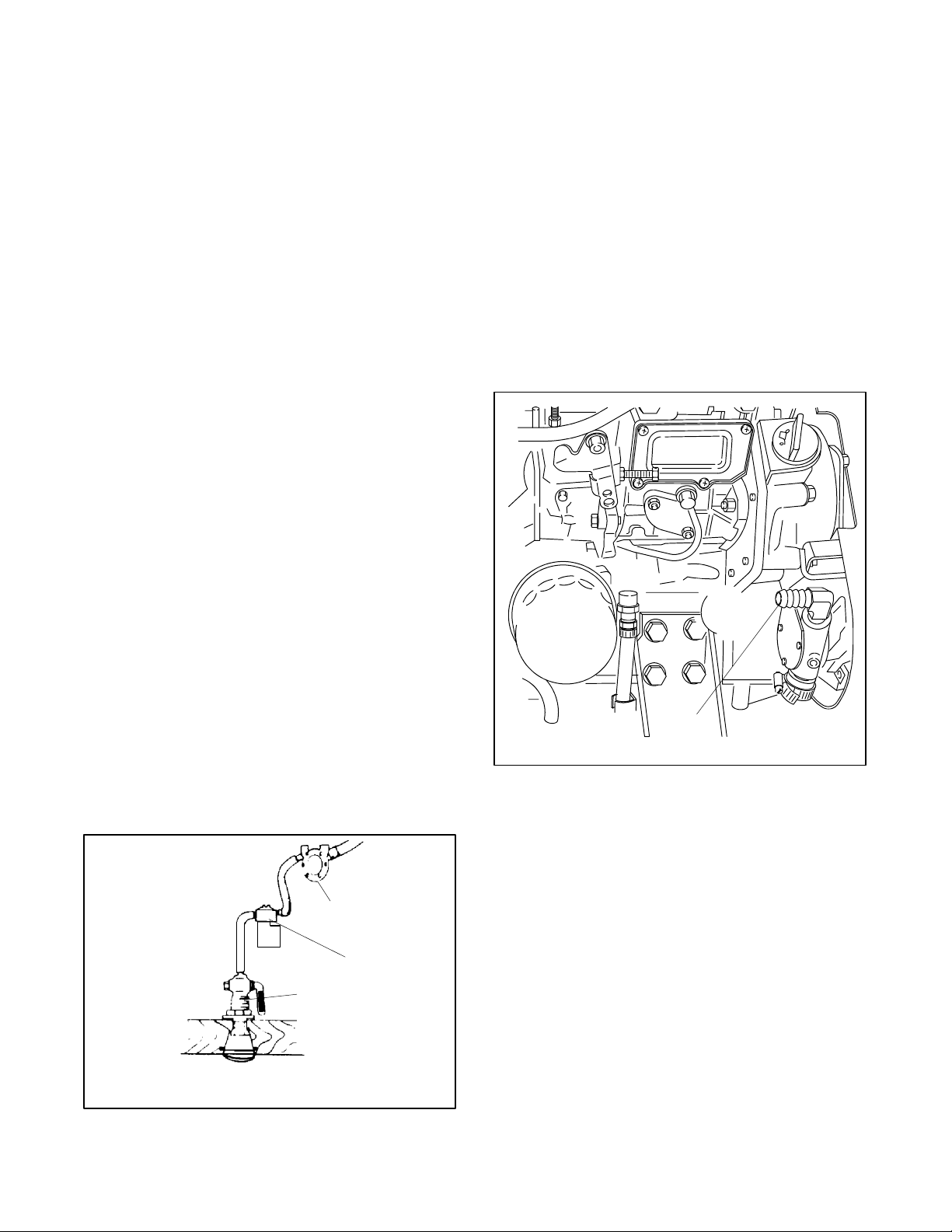

3.2.1 Intake Through-Hull Strainer

(Seacock Cover)

Install a screened-intake, through-hull strainer to

prevent entry of foreign objects. Use perforated,

slotted-hole, or unrestricted-hole design strainers. See

Figure 3-2 for examples of typical strainers. The inner

diameter of the strainer opening must be equal to or

greater than the inner diameter of the water-line hose to

the seawater pump.

TP-6069 6/03 5Section 3 Cooling System

Note: Position the intakes in relation to the vessel’s

travel so neither is in the wake of the other.

1. Generator set intake

2. Main engine intake

3. Aft (rearward)

4. Fore (forward)

Figure 3-3 Intake Strainer

1-789

Page 16

Do not use a speed scoop or cup design intake

through-hull strainer because it can cause a ramming

effect and force water upward, past the seawater pump,

and into the engine cylinders when the vessel is moving

and the generator set is shut down.

Do not use hulls incorporating sea chests or other

designs that provide a positive pressure to the raw water

pump for the intake through-hull strainers. Positive

pressure forces water past the raw water pump and into

the engine. A sea chest is a concave molded-in-the-hull

chamber that aligns to the vessel’s direction of travel. A

sea chest configuration applies positive pressure similar

to a scoop-type through-hull strainer.

3.2.2 Seacock

Mount the seacock to the hull, assemble it to the intake,

and ensure that it is accessible for operation. Figure 3-2

shows a typical installation.

Avoid overcaulking the seacock. Excess caulk reduces

water flow and, in some cases, develops a barrier that

can force water upward, past the seawater pump, and

into the engine cylinders when the vessel is moving and

the generator set is shut down.

3.2.4 Water Lines

Water lines from the seacock to the engine-driven

seawater pump are usually constructed of flexible hose.

Connect a flexible section of hose to the seawater pump

to allow the generator set to vibrate during operation.

Support a nonflexible water line within 102 mm (4 in.) of

its connection to the flexible section.

Keep the seawater hose as straight and short as

possible. If the hose is too long, usually over 4.6 m

(15 ft.), water draw problems may occur. See Section 7

for the inlet water line hose size and the seawater

connection to the seawater pump inlet. Avoid running

the inlet pipe above the generator. See Figure 3-5 for

the seawater hose connection to the seawater pump

inlet.

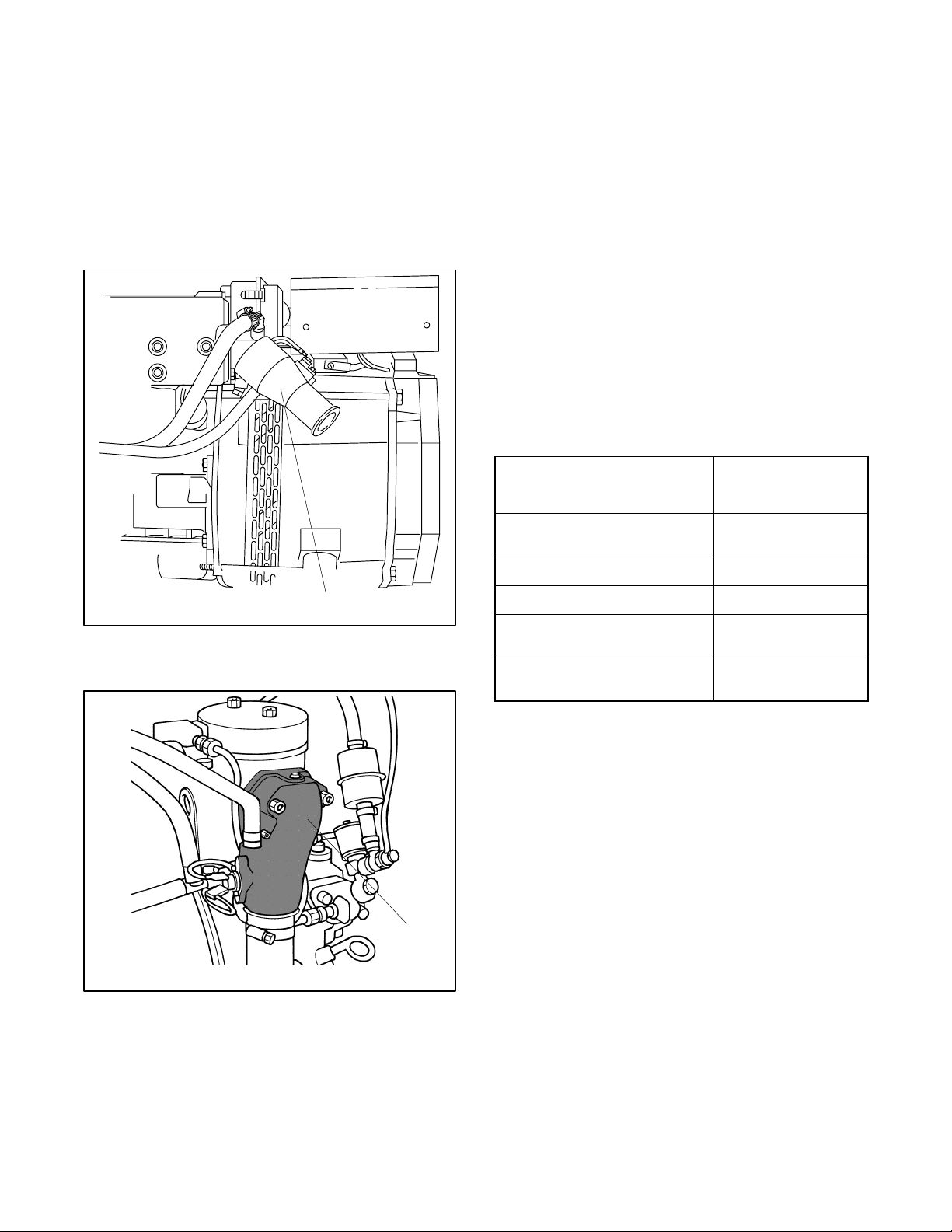

3.2.3 Seawater Strainer

Mount the seawater strainer to the seacock or

permanent structure at a point not higher than the

seawater pump. Ensure that the strainer is accessible

for service. See Figure 3-4 for a typical installation.

Some seawater strainers include a seacock and an

intake through-hull strainer.

Maximum seawater inletpressure at the seawater pump

is 34.5 kPa (5 psi). Excessive pressure will cause water

ingestion.

1

2

3

1

1. Seawater pump inlet

TP-5586-6

Figure 3-5 Seawater Inlet Connection, Typical

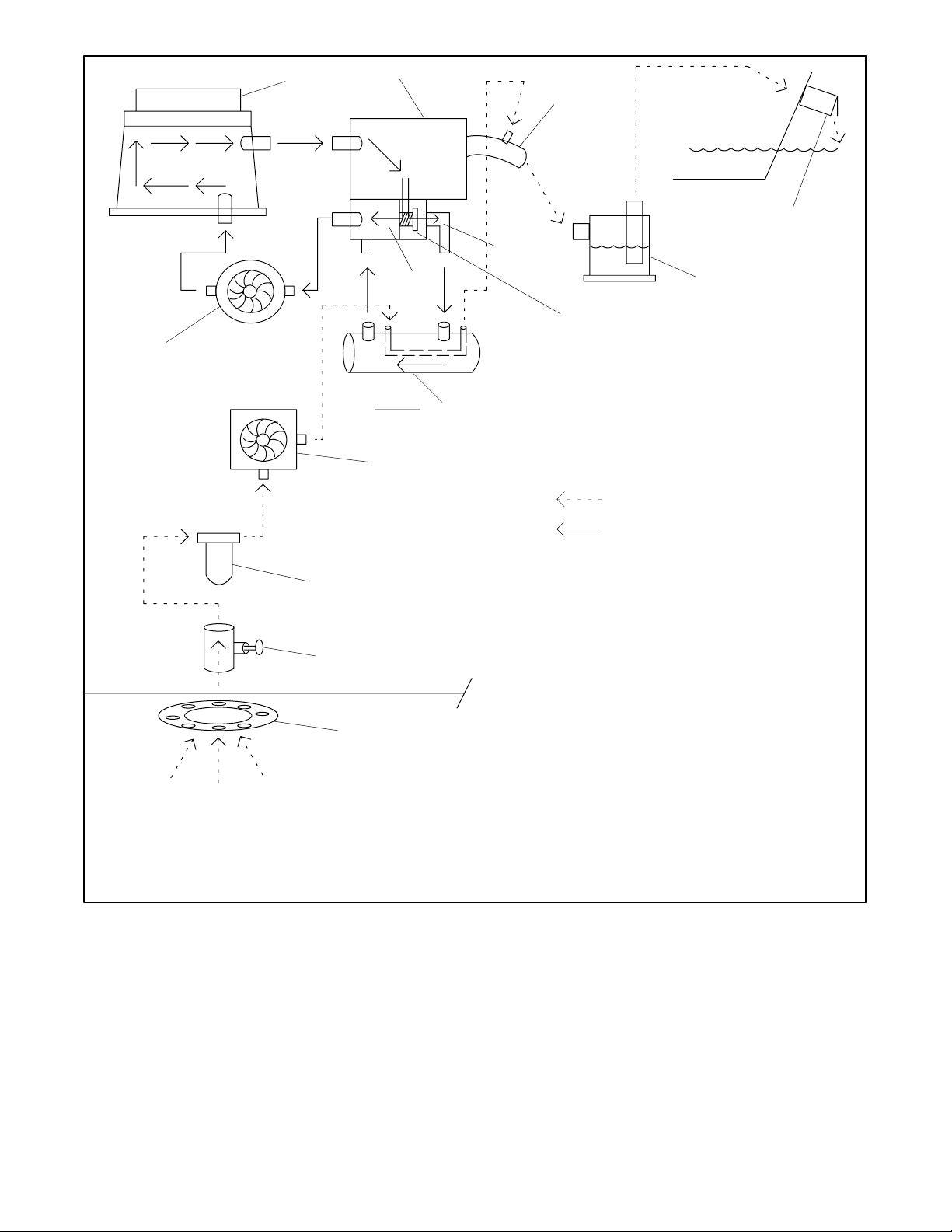

3.2.5 Closed Heat Exchanger

(4--125EFOZ/5--150EOZ Models)

A closed heat exchanger is the best cooling method for

most applications. See Figure 3-6 or Figure 3-7 for a

typical installation. Provide space to access the

water-cooled exhaust manifold pressure cap.

3.2.6 Direct Water Cooled

(3.5EFOZ/4EOZ Models)

1. Seawater pump

2. Seawater strainer

3. Seacock

Figure 3-4 Seawater Strainer

1-789

In a direct seawater cooling system, the impeller pump

circulates the seawater around the cylinder and through

the cylinder head. A thermostat controls the cooling water

circuit temperature. Consult Figure 3-8 and the engine

operation manual for the cooling water circuit diagrams.

TP-6069 6/036 Section 3 Cooling System

Page 17

1

2

3

4

6

14

11

12

10

8

5

7

9

Arrow Description

Direction of Flow

Seawater

Freshwater (Coolant/Antifreeze)

13

1. Engine block

2. Exhaust manifold

3. Exhaust mixer elbow

4. Outlet flapper (exhaust/water discharge)

5. Silencer (customer supplied)

6. Thermostat open

7. Thermostat

8. Thermostat closed

9. Heat exchanger

10. Engine-driven seawater pump

11. Seawater strainer

12. Seacock

13. Intake strainer

14. Engine-driven water pump

Figure 3-6 Typical Closed/Heat Exchanger Cooling System (4/6.5/8.5/9/23/27EFOZ and 5/8/10/28/32EOZ

Models)

TP-6069 6/03 7Section 3 Cooling System

TP-5586-6

Page 18

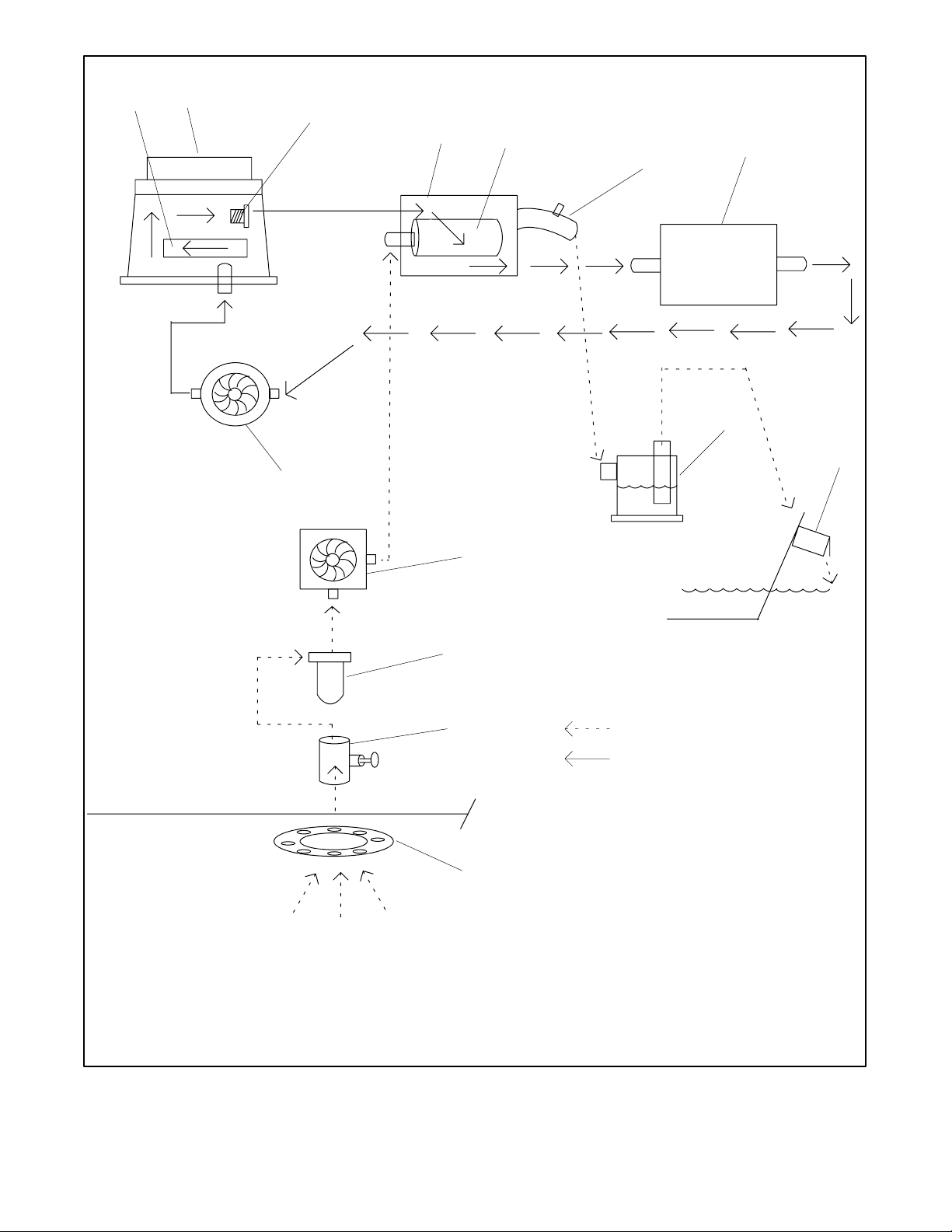

1

2

3

4

5

7

6

8

9

14

1. Oil cooler

2. Engine block

3. Thermostat

4. Water-cooled manifold

5. Heat exchanger

6. Exhaust mixer elbow

7. Water-cooled turbocharger

13

12

11

10

8. Silencer (customer-supplied)

9. Exhaust outlet

10. Intake strainer

11. Seacock

12. Seawater strainer

13. Engine-driven seawater pump

14. Engine-driven water pump

Seawater

Freshwater (Coolant/Antifreeze)

TP-5592-6

Figure 3-7 Typical Closed/Heat Exchanger Cooling System (11--20EFOZ,13--24EOZ, 33--125EFOZ and

40--150EOZ Models)

TP-6069 6/038 Section 3 Cooling System

Page 19

7

6

8

9

10

3

5

4

2

1

1. Intake strainer

2. Seacock

3. Seawater strainer

4. Engine-driven seawater pump

5. Oil exchanger

6. Zinc plug

7. Exhaust manifold elbow

8. Exhaust hose

9. Silencer (customer supplied)

10. Outlet flapper (exhaust/water discharge)

Figure 3-8 Direct Water-Cooled Cooling System (3.5EFOZ and 4EOZ Models)

TP-6069 6/03 9Section 3 Cooling System

TP-6134-

Page 20

Notes

TP-6069 6/0310 Section 3 Cooling System

Page 21

Section 4 Exhaust System

WARNING

Carbon monoxide.

Can cause severe nausea,

fainting, or death.

The exhaust system must be leakproof

and routinely inspected.

Carbon monoxide symptoms. Carbon monoxide can

cause severe nausea, fainting, ordeath. Carbon monoxide

is a poisonous gas present in exhaust gases. Carbon

monoxide poisoning symptoms include but are not limited to

the following:

D Light-headedness, dizziness

D Physical fatigue, weakness in

joints and muscles

D Sleepiness, mental fatigue,

inability to concentrate

or speak clearly, blurred vision

D Stomachache, vomiting, nausea

If experiencing any of these symptoms and carbon monoxide

poisoning is possible, seek fresh air immediately and remain

active. Do not sit, lie down, or fall asleep. Alert others to the

possibility of carbon monoxide poisoning. Seek medical

attention if the condition of affected persons does not improve

within minutes of breathing fresh air.

Inspecting the exhaust system. Carbon monoxide can

cause severe nausea, fainting, or death. For the safety of

the craft’s occupants, install a carbon monoxide detector.

Consult the boat builder or dealer for approved detector

location and installation. Inspect the detector before each

generator set use. In addition to routine exhaust system

inspection, test the carbon monoxide detector per the

manufacturer’s instructions and keep the detector operational

at all times.

Operating thegenerator set. Carbon monoxidecan cause

severe nausea, fainting, or death. Carbon monoxide is an

odorless, colorless,tasteless, nonirritating gas that can cause

death if inhaled for even a short time. Use the following

precautions when installing and operating the generator set.

Do not install the exhaust outlet where exhaust can be drawn

in through portholes,vents, or airconditioners. If the generator

set exhaust discharge outlet is near the waterline, watercould

enter the exhaust discharge outlet and closeor restrictthe flow

of exhaust. Never operate the generator set without a

functioning carbonmonoxide detector. Be especially careful if

operating the generator set when moored or anchored under

calm conditions because gases may accumulate. If operating

the generator set dockside, moor the craft so that the exhaust

discharges on the lee side (the side sheltered from the wind).

Always be aware of others, making sure your exhaust is

directed away from other boats and buildings. Avoid

overloading the craft.

4.1 Types

Kohlerr generator sets covered in this manual use

either wet or dry exhaust systems. Dry exhaust systems

are common in commercial applications. See the

engine manual for specifications.

4.2 Exhaust Lines

Use water-cooled exhaust lines in all marine

installations. Keep the lines as short and straight as

possible. NFPA 302 Fire Protection Standard for

Pleasure and Commercial Motor Craft, Clause 4-3,

recommends using two corrosion-resistant hose

clamps with a minimum width of 13 mm (1/2 in.) on each

end of the flexible exhaust hose connections.

Kohler Co. requires a downward pitch of at least 13 mm

per 30.5 cm (1/2 in. per running foot). Use a flexible

exhaust hose that conforms to UL Standard 1129 for the

engine’s wet exhaust components between the mixer

elbow and the exhaust outlet.

TP-6069 6/03 11Section 4 Exhaust System

Page 22

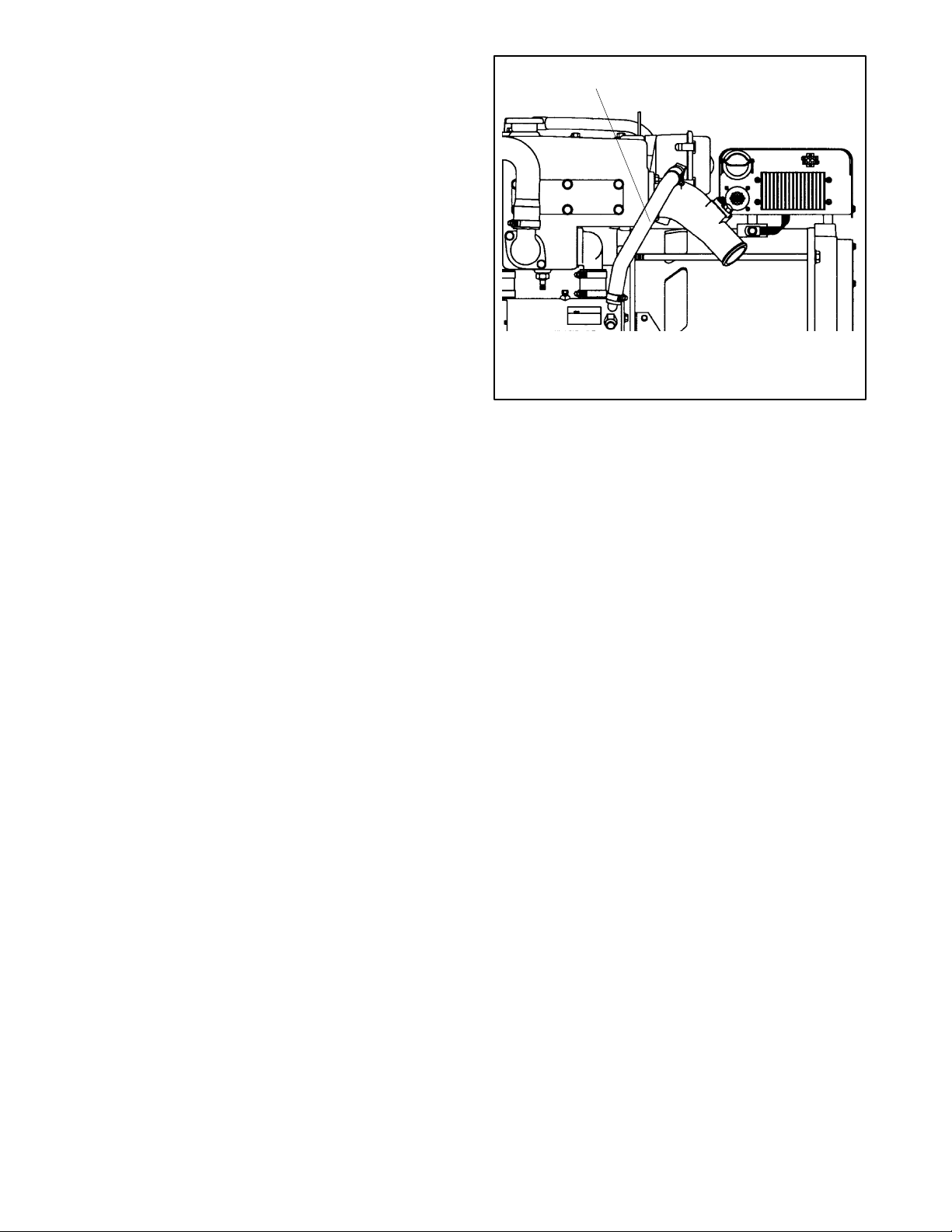

4.3 Exhaust System Location,

Mounting, and Installation

Mount the silencer independently to eliminate stress on

the exhaust system and the exhaust manifold/mixer

elbow. See Section 7 for the mixer elbow water line hose

size. See Figure 4-1 for the exhaust connection to the

mixer elbow. Provide an adequate hose length from the

exhaust mixer to the silencer to allow for generator set

movement.

Locate the exhaust outlet at least 10 cm (4 in.) above the

waterline when the craft is loaded to maximum capacity.

Install an exhaust port with the flap at the exhaust

(transom) outlet to prevent water backup in following

seas or when moving astern (backward). A lift in the

exhaust piping before the piping exits the craft prevents

backwash. See Figure 4-4, item 1. Support the exhaust

lines to prevent the formation of water pockets.

Exhaust system installation guidelines for various

generator set locations follow. Information and

illustrations of stern- (rear) exhaust installations also

apply to side-exhaust installations. Where exhaust lines

require passage through bulkheads, use port (left)- or

starboard (right)- side exhaust outlets, also in

applications in which long exhaust lines to the transom

(rear) could cause excessive back pressure. See

Figure 4-3 for allowable back pressures. Should any

information regarding installation conflict with USCG

Regulations, follow USCG Regulations.

Allowable Exhaust

Back Pressure,

kPa (mm H2O)

Model

≤

1. Water/exhaust outlet

1

Figure 4-1 Mixer Elbow/Exhaust Connection,

Typical

1. Water/exhaust outlet

Figure 4-2 Mixer Elbow/Exhaust Connection,

3.5EFOZ/4EOZ Model Only

TP-5586-6

1

TP-6134-

4/8.5/9/23/27EFOZ and

5/10/28/32EOZ

6.5EFOZ and 8EOZ 11.77 (1200)

11/16/17.5EFOZ and 13/20EOZ 6.37 (650)

3.5/11.5/13/19/20EFOZ and

4/14/15.5/23/24EOZ

33/40/55/70/80/100/125EFOZ

and 40/50/65/80/99/125/150EOZ

9.81 (1000)

4.90 (500)

7.47 (762)

Figure 4-3 Allowable Exhaust Back Pressures

4.3.1 Above-Waterline Installation

Install a customer-supplied silencer with the silencer’s

outlet at a maximum of 3 m (10 horizontal ft.) from the

center of the engine’s exhaust outlet. See Figure 4-4.

Mount a typical silencer with the inlet and outlet

horizontal and with the drain plug down. Use an exhaust

hose pitch of at least 13 mm per 30.5 cm (0.5 in. per

running foot). Some silencers require two support

brackets or hanger straps for installation to stringers or

other suitable structure. Follow the instructions

provided with the silencer. Install any lift (see

Figure 4-4, item 1) in the exhaust line below the engine

exhaust manifold outlet.

TP-6069 6/0312 Section 4 Exhaust System

Page 23

4

5

3

6

2

1

7

8

15

Waterline

16

1. Slight lift improves silencing and prevents water backwash

into the silencer (keep below the level of the exhaust

manifold outlet)

2. Silencer (customer-supplied)

3. Exhaust manifold outlet

4. Exhaust mixer elbow

5. Heat exchanger (locations vary by model)

6. Coolant recovery tank (located on the unit on some models)

7. Locate the coolant recovery tank at the same height as the

heat exchanger

8. Maximum seawater pump lift of 1 m (3 ft.)

9. Seawater strainer

10. Seacock

11. Intake strainer

12. Engine-driven seawater pump

13

12

14

11

13. Minimum exhaust hose pitch of 1.3 cm per 30.5 cm (0.5 in.

per ft.)

14. Maximum distance between silencer and exhaust mixer

elbow of 3 m (10 ft.)

15. Minimum exhaust hose pitch of 1.3 cm per 30.5 cm (0.5 in.

per ft.)

16. Minimum exhaust outlet distance above waterline of 10 cm

(4 in.). Note: Vessel fully loaded.

Note: Data applies to both rear- and side-exhaust installations.

Note: Use two hose clamps on each end of all flexible exhaust

hose connections.

Note: Read the text for complete explanation of dimensions

and other installation considerations.

9

10

TP-5856-4

Figure 4-4 Typical Above-Waterline Installation

TP-6069 6/03 13Section 4 Exhaust System

Page 24

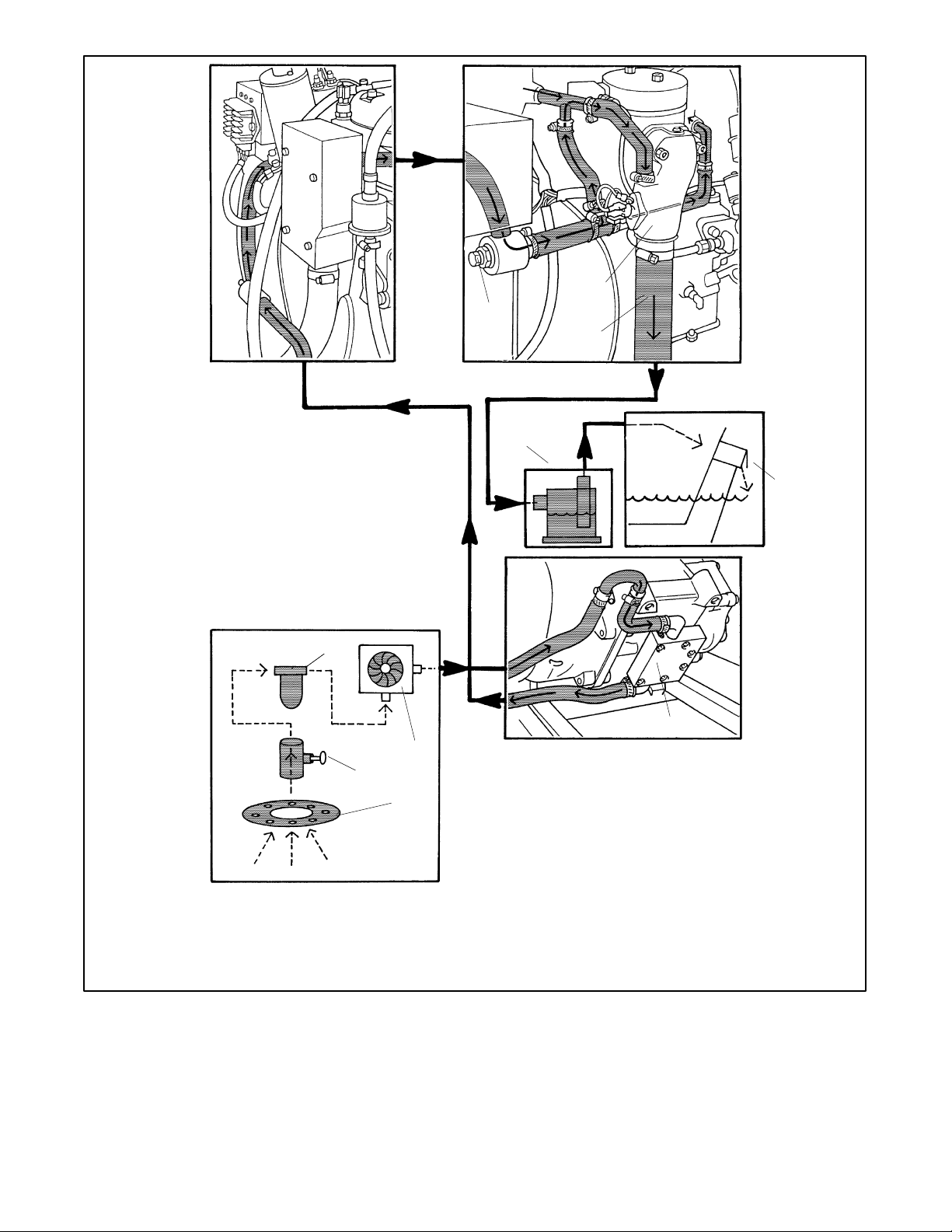

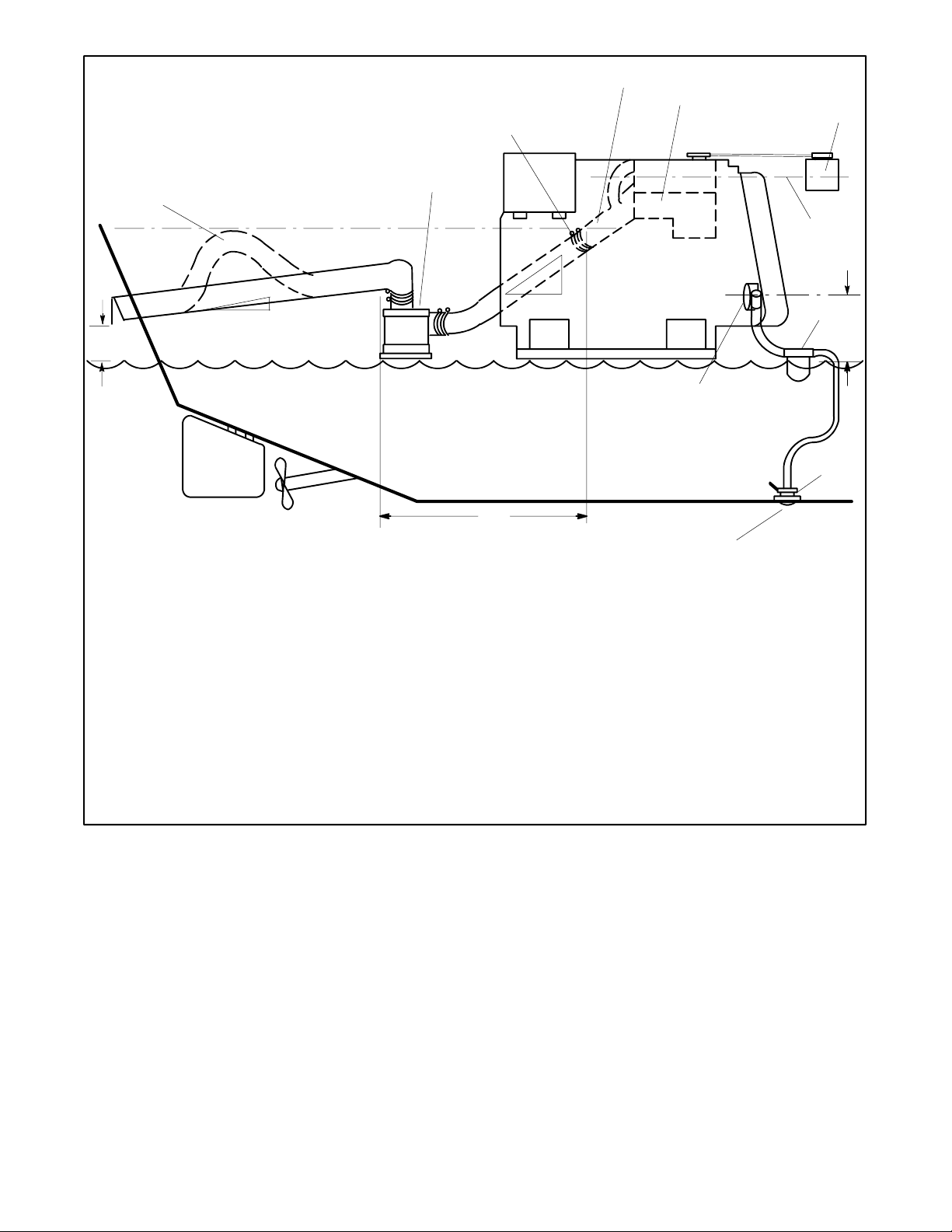

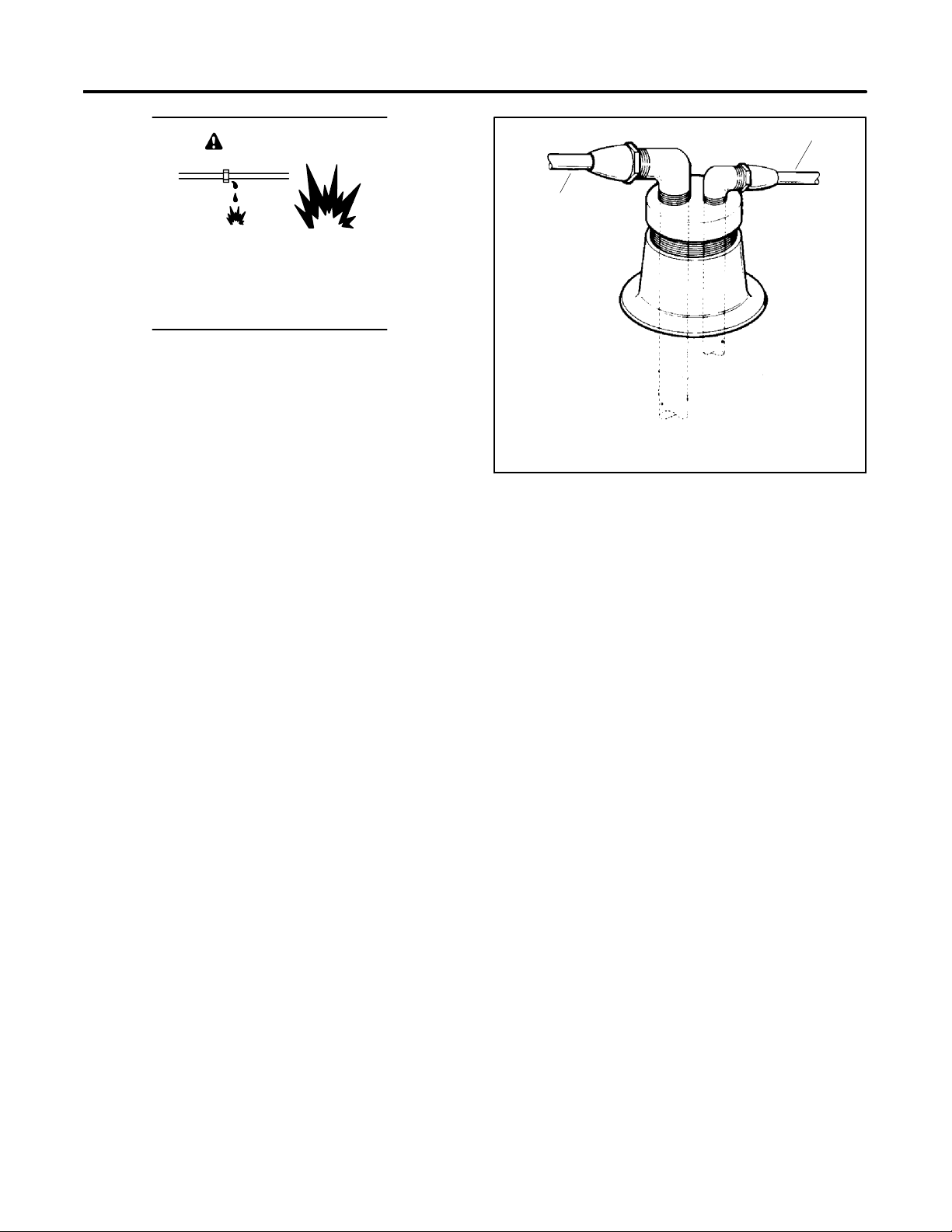

4.3.2 Mid/Below-Waterline Installation

Follow USCG Regulations for installing an antisiphon

provision to prevent raw water entry into the engine.

Use the siphon break if the exhaust manifold outlet is

located less than 23 cm (9 in.) above the waterline when

the craft is loaded to maximum capacity. Install the

siphon break at least 31 cm (1 ft.) above the waterline

using the instructions provided with the siphon break kit.

Note: An improperly installed siphon break will cause

engine damage and may void the warranty.

Install the siphon break above the highest point in the

exhaust line between the heat exchanger and the

exhaust mixer. See Figure 4-5 for the siphon break

connection. Support the siphon break and hoses to

maintain their position and function. Allow a slight offset

to clear the stringers or other permanent structures.

Protect the siphon break air inlet from dirt and debris.

Note: Toprevent water leakage on the generator set, do

not mount the siphon break directly over the

generator set.

1

TP-5586-6

1. Cut hose and connect siphon break and hardware

Figure 4-5 Siphon Break Connection (4EFOZ/5EOZ

model shown)

Mount a typical silencer’s base no morethan 1.2 m (4 ft.)

below the highest point in the exhaust line. Attach a

separate wood mounting base to the hull stringers or

other suitable structures. Use the silencer

manufacturer’s recommendation for securing the

silencer to the hull. Mount the silencer with the outlet not

more than 3 m (10 horizontal ft.) from the engine’s

exhaust manifold outlet. Use a USCG-type certified

marine exhaust hose.

TP-6069 6/0314 Section 4 Exhaust System

Page 25

21

2

3

7

8

9

10

1

6

5

Waterline

19

20

18

1. Mounting base

2. Retaining cap

3. Reed valve assembly

4. Maximum silencer vertical lift of 1.2 m (4 ft.)

5. Exhaust mixer elbow distance above waterline; if less than

23 cm (9 in.), a siphon break is required

6. Minimum siphon break distance above waterline of 30.5 cm

(1 ft.)

7. Siphon break

8. Exhaust mixer elbow

9. Heat exchanger (locations vary by model)

10. Coolant recovery tank (located on the unit on some models)

11. Indicates thecoolant recovery tank isat the same heightas the

heat exchanger

12. Seawater strainer

13. Seacock

14. Intake strainer

4

16

11

12

15

13

17

15. Engine-driven seawater pump

16. Minimum exhaust hose pitch of 1.3 cm per 30.5 cm (0.5 in. per ft.)

17. Maximum distance betweensilencer andexhaust mixer elbow

of 3 m (10 ft.)

18. Silencer (customer-supplied)

19. Minimum exhaust hose pitch of 1.3 cm per 30.5 cm

(0.5 in. per ft.)

20. Minimum exhaust outlet distance above waterline of 10 cm

(4 in.)

21. Exhaust hose (see Figure 4-7 for hose sizes)

Note: Read the text for complete explanation of dimensions and

other installation considerations.

Note: Use two hose clamps on each end of all flexible exhaust

hose connections.

Note: Data applies to both rear- and side-exhaust installations.

14

TP-5856-4

Figure 4-6 Typical Mid and Below Waterline Installation

Exhaust Hose

Diameter

Models without Sound Shield Models with Sound Shield

3.5/4/6.5/8.5/9EFOZ

4/5/8/10EOZ

11/11.5/13/16/17.5/19/20/23/27EFOZ

13/14/15.5/20/23/24/28/32EOZ

33EFOZ

40EOZ

40/55/70/80/100/125EFOZ

50/65/80/99/125/150EOZ

4/6.5/8.5/9/11/11.5/13/16/17.5/19/20EFOZ

5/8/10/13/14/15.5/20/23/24EOZ

27EFOZ

32EOZ

33EFOZ

40EOZ

40/55/70/80/100/125EFOZ

50/65/80/99/125/150EOZ

mm (in.)

51 (2.0)

76 (3.0)

89 (3.5)

102 (4.0)

Figure 4-7 Exhaust Hose Sizes

TP-6069 6/03 15Section 4 Exhaust System

Page 26

Notes

TP-6069 6/0316 Section 4 Exhaust System

Page 27

Section 5 Fuel System

WARNING

Explosive fuel vapors.

Can cause severe injury or death.

Use extreme care when handling, storing,

and using fuels.

Installing the fuel system. Explosive fuel vapors can

cause severe injury or death. Fuel leakage can cause an

explosion. Do not modify the tank orthe propulsion engine fuel

system. Equip the craft with a tank that allows one of the two

pickup arrangements describedin theinstallation section. The

tank and installation must conform to USCG Regulations.

Note: Fuel system installations must conform to USCG

Regulations.

5.1 Fuel Tank

Most marine generator sets draw fuel fromthe same fuel

tank as the craft’s propulsion engine(s). If the tank’s fuel

pickup opening allows a multiple dip tube, use a multiple

dip tube arrangement. See Figure 5-1. The multiple dip

tube arrangement incorporates a shorter dip tube for the

generator set and a longer dip tube for the propulsion

engine. With this arrangement, the generator set runs

out of fuel before the propulsion engine during a low fuel

supply situation. Equip the fuel system with a fuel/water

separator to remove any accumulated dirt and water.

2

1

1-788

1. Fuel line to propulsion engine

2. Fuel line to generator set

Figure 5-1 Multiple Dip Tube Arrangement

m:is:102:001

TP-6069 6/03 17Section 5 Fuel System

Page 28

5.2 Fuel Lines

5.3 Fuel Filters

Locate the fuel return line as far as practical from the fuel

pickup to allow the tank fuel to cool the return fuel before

delivery back to the fuel injectors. Incoming fuel cools

the injectors to achieve maximum engine efficiency.

Note: Do not tee into the main propulsion engine’s fuel

line.

Under no circumstances should the propulsion engine

and generator set share pickup or return lines (through a

tee arrangement) that would allow the larger engine to

starve fuel from the smaller engine. It is possible that the

operation of either engine could completely drain the

fuel line of the other engine and make starting difficult.

Use a flexible hose section to connect the metallic line

from the fuel tank to the engine’s fuel pump inlet

connection point. Also, use a flexible hose section to

connect the metallic line from the fuel tank to the fuel

return connection point. The flexible section allows the

generator set to vibrate during operation.

Fuel Line

ID Size

Model

mm (in.)

Conform to USCG Regulations regarding inline fuel

filters or strainers.

5.4 Fuel Pump Lift

See Figure 5-3 for fuel pump lift capabilities.

Fuel

Pump

Model

3.5/4/6.5/8.5/9/11/11.5/13/16/17.5/19/20/23/

27EFOZ and

4/5/8/10/13/14/15.5/20/23/24/28/32EOZ

33/40/55/70/80/100/125EFOZ

and 40/50/65/80/99/125/150EOZ

Lift

m (ft.)

1.2 (4)

0.9 (3)

Figure 5-3 Fuel Pump Lift

5.5 Fuel Consumption

Consult the current generator set specification sheets

for generator set fuel consumption rates.

3.5EFOZ and 4EOZ 6.4 (1/4)

4--125EFOZ and 5--150EOZ 9.7 (3/8)

Figure 5-2 Fuel Line ID Size

See Figure 5-2 for the ID size of the customer-supplied

fuel line that connects to the fuel pump and fuel return.

Route the fuel lines from the fuel tank in a gradual incline

to the engine—do not exceed the height of the generator

set and do not route fuel lines above the generator set.

Comply with USCG Regulation 46CFR182.20

regarding fuel lines and supports.

See Section 7 for fuel feed pump inlet connection and

fuel return line connection.

TP-6069 6/0318 Section 5 Fuel System

Page 29

Section 6 Electrical System

WARNING

Hazardous voltage.

Can cause severe injury or death.

Operate the generator set only when

all guards and electrical enclosures

areinplace.

Electrical backfeed to the utility. Hazardous backfeed

voltage can cause severe injury or death. Connect the

generator set to the building/marina electrical system only

through an approved device and after the building/marina

main switch is opened. Backfeed connections can cause

severe injury or death to utility personnel working on power

lines and/or personnel near the work area. Some states and

localities prohibit unauthorized connection to the utility

electrical system. Install a ship-to-shore transfer switch to

prevent interconnection of the generator set power and shore

power.

1

Moving rotor.

2

3

4

6.1 AC Voltage Connections

Make AC connections to the generator set inside the

controller box (4--27EFOZ and 5--32EOZ models) or

inside the junction box (33--125EFOZ and 40--150EOZ

models). Typically, the generator set connects to a

ship-to-shore transfer switch that allows the use of

shore/utility power when docked or generator set power

when docked or at sea. The wiring then connects to a

main circuit breaker box (panel board) that distributes

branch circuits throughout the craft. See Figure 6-1 for

AC voltage connections to the generator set. See

Section 8 for reconnection of the generator set.

6.2 Circuit Protection

The AC circuit breakers (optional) protect the wiring

from the AC circuit breakers to the vessel’s distribution

panel. AC circuit breakers trip when they detect a faultin

the output circuit.

After correcting the fault, reset the AC circuit breaker(s)

by placing them in the ON position. Restart the unit. Do

not start the unit under load. See Figure 6-2 or

Figure 6-3 for AC circuit breaker ratings. The unit’s

voltage configuration determines the circuit breaker

selection.

Note: Circuit breaker ampere rating and availability are

subject to change.

6.2.1 Circuit Breaker Considerations

Mounting location. Mount the circuit breakers in the

5

6

1. Line side

2. AC circuit breaker

3. Load side

4. L1/L2 phase (black) leads

5. GRD ground (green) lead

6. L0 neutral (white) lead

585771

Figure 6-1 AC Voltage Connections in Controller

Box (5--32EOZ Models, Typical)

TP-6069 6/03 19Section 6 Electrical System

generator set’s controller (4--27EFOZ and 5--32EOZ

models) or the generator set’s junction box

(33--125EFOZ and 40--150EOZ models). See

Section 6.2.2 or Section 6.2.3.

Note: 3.5EFOZ and 4EOZ models already have circuit

breakers installed.

Sizing. Use the generator set voltage/frequency

configuration to determine the circuit breaker

amperage. If the generator set voltage configuration

changes, change the circuit breaker to provide optimum

protection.

For circuit breaker application and selection

information, contact an authorized distributor/dealer.

Have a qualified electrician or technician install circuit

breakers and reconnect the generator set. Comply with

all governing standards and codes.

Page 30

Amps

2

0

250

3

0

35250

2

250

240

240

240

0

8

0

1

25600

22 250 2 4EFOZ, 5EOZ

25 250 2 5EOZ

33 250 2 8EOZ

40

4

50

55 250 1 5EOZ

60

7

80

85 250 1 9EFOZ, 10EOZ

90

100

150 600 2

175 600 2 32EOZ—1 phase

Max.

Voltage

250 1 4EFOZ

600 3 8.5/11.5EFOZ, 14EOZ

600 3

250 1 5EOZ

600 3

250 2 9EFOZ, 10EOZ

480 3

250 1 6.5EFOZ

600 3

250 1 6.5EFOZ, 8EOZ

600 3 20/24EOZ—3 phase

240

250 1 8EOZ

480 3 23EFOZ—3 phase

240

480 3 27EFOZ—3 phase

240 2 23EOZ

480 3

Number

of Poles

1 6.5EFOZ

2 6.5EFOZ

1 4EFOZ

2 8EOZ

1 9EFOZ

2 9EFOZ, 8/10EOZ

1 11/13EFOZ

2 11/11.5/17.5EFOZ

1 13EFOZ

2 11/13EFOZ, 13/14EOZ

20/24/28/32EOZ—3 phase

1 16EFOZ

2 13/20EFOZ, 15.5EOZ

1 16/19EFOZ

16EFOZ, 20EOZ—1 phase,

2

1 19EFOZ

2

2

1 phase, 27EFOZ—3 phase

3

Model(s)

11.5/17.5/20EFOZ,

14/20/24EOZ—3 phase

11. 5 EFOZ,

14/20/24EOZ—3 phase

20/23/27EFOZ,

20/28/32EOZ—3 phase

17.5/20EFOZ,

20/24EOZ—3 phase

19EFOZ—1 phase

20/23EOZ

23/27EFOZ,

28/32EOZ—3 phase

23/27EFOZ, 28EOZ—

23/27EFOZ,

28/32EOZ—3 phase

28/32EOZ—1 phase,

32EOZ— 3 phase

Figure 6-2 AC Circuit Breaker Ratings (4--27EFOZ

and 5--32EOZ Models), Listed By Amps

Amps

100--125 600 3 IEC

100--125 600 3 IEC 70EFOZ, 80EOZ

128--160 600 3 IEC

128--160 600 3 IEC

160--400 600 3 UL

160--400 600 3 IEC

200--250 600 3 IEC

200--250 600 3 IEC

240--600 600 3 UL

250--630 600 3 IEC

Max.

Voltage

60 600 3 UL/IEC 33EFOZ, 40EOZ

70 600 3 UL/IEC 40EFOZ, 40EOZ

80 480 3 UL/IEC 40EFOZ, 50EOZ

100 480 3 UL/IEC 55EFOZ, 50/65EOZ

125 600 3 UL

125 600 3 UL 70EFOZ, 80EOZ

150 600 3 UL

150 600 3 UL

200 600 3 UL

200 600 3 UL

250 600 3 UL 55EFOZ, 65EOZ

250 600 3 UL

Number

of Poles

Typ e Model(s)

33/55EFOZ,

40/65EOZ

33/55EFOZ,

40/65EOZ

33/40EFOZ,

40/50EOZ

70/80EFOZ,

80/99EOZ

33/40EFOZ,

40/50EOZ

70/80EFOZ,

80/99EOZ

70/80/100EFOZ,

80/99/125/150EOZ

70/80/100/125EFOZ,

80/99/125/150EOZ

40/55EFOZ,

50/65EOZ

100EFOZ,

99/125EOZ

40/55EFOZ,

50/65EOZ

70/100/125EFOZ,

80/125/150EOZ

125EFOZ,

125/150EOZ

70/125EFOZ,

80/125/150EOZ

125EFOZ,

125/150EOZ

Figure 6-3 AC Circuit Breaker Ratings (33--150 kW

Models), Listed By Amps

WARNING

Accidental starting.

Can cause severe injury or death.

Disconnect the battery cables before

working on the generator set.

Remove the negative (--) lead first

when disconnecting the battery.

Reconnect the negative (--) lead last

when reconnecting the battery.

TP-6069 6/0320 Section 6 Electrical System

Page 31

Disabling the generator set. Accidental starting can

cause severe injury or death. Before working on the

generator set or equipment connected to the set, disable the

generator set asfollows: (1) Place thegenerator setstart/stop

switch in the STOP position. (2) Disconnect the power to the

battery charger, if equipped. (3) Remove the battery cables,

negative (--) lead first. Reconnect the negative (--) lead last

when reconnecting the battery. Follow these precautions to

prevent the starting of the generator set by the remote

start/stop switch.

WARNING

3. Remove the controller cover screws and remove

the access cover.

4. Remove the screws and nuts to remove the circuit

breaker cover plate. Save the mounting hardware.

5. Install the circuit breaker from the inside of the

cutout panel and mount it using existing screws

removed in step 4. Position the circuit breaker with

the ON in the normal upright position or to the left

side. Cover the cutout opening, if applicable, with

the circuit breaker cover plate. Use existing screws

to mount the cover plate.

6. See Section 8 for voltage reconnection.

Hazardous voltage.

Can cause severe injury or death.

Operate the generator set only when

all guards and electrical enclosures

areinplace.

Grounding electrical equipment. Hazardous voltage can

cause severe injury or death. Electrocution is possible

whenever electricity is present. Open the main circuit

breakers of all power sources before servicing the equipment.

Configure the installation to electrically ground the generator

set, transfer switch, and related equipment and electrical

circuits tocomply withapplicable codesand standards. Never

contact electrical leads or appliances when standing in water

or on wet ground because these conditions increase the risk of

electrocution.

Short circuits. Hazardous voltage/current can cause

severe injury or death. Short circuits can cause bodily injury

and/or equipment damage. Do not contact electrical

connections with tools or jewelry while making adjustments or

repairs. Remove all jewelry before servicing the equipment.

Electrical backfeed to the utility. Hazardous backfeed

voltage can cause severe injury or death. Connect the

generator set to the building/marina electrical system only

through an approved device and after the building/marina

main switch is opened. Backfeed connections can cause

severe injury or death to utility personnel working on power

lines and/or personnel near the work area. Some states and

localities prohibit unauthorized connection to the utility

electrical system. Install a ship-to-shore transfer switch to

prevent interconnection of the generator set power and shore

power.

Moving rotor.

6.2.2 Circuit Breaker Installation

(4--27EFOZ and 5--32EOZ Models)

1. Place the generator set start/stop switch in the

STOP position.

2. Disconnect the generator set engine starting

battery, negative (--) lead first.

Note: Kohlerr marine diesel generator sets are

fully frequency adjustable and voltage

reconnectable. To determine reconnection

options, check the model’s specification

sheet.

7. Install insulation boots over stator lead terminals if

the kit includes insulation boots.

Note: See Section 8 for wiring instructions.

8. Make the recommended connections for the

following four reconnection systems using circuit

breakers:

Two-pole circuit breaker with a single-voltage

system (example: 120-volt, 3-wire). Attach

stator leads marked 2 and 4 to the side of the circuit

breaker marked LINE. Install the jumper lead

across the LINE side of circuit breaker terminals

(see Section 8). Attach stator leads 1 and 3 to L0.

Single-pole circuit breaker with a 120-volt,

2-wire, single-voltage system. Attach stator

leads marked 2 and 4 to the side of the circuit

breaker marked LINE (see Section 8). Attach stator

leads 1 and 3 to L0.

Two-pole circuit breaker with a dual-voltage

system (example: 120/240-volt, 3-wire). Attach

stator leads marked 1 and 4 to the side of the circuit

breaker marked LINE. Do not use a jumper lead

(see Section 8). Attach stator leads 2 and 3 to L0.

Single-pole circuit breaker with a 240-volt,

2-wire, single-voltage system. Attach the stator

lead marked 2 to the side of the circuit breaker

marked LINE (see Section 8). Bolt together leads 1

and 4 and tape to insulate from ground. Attach the

stator lead marked 3 to L0.

9. Connect the stator lead(s) used for neutral

connection to the L0 stud. See the illustrations in

Section 8.

TP-6069 6/03 21Section 6 Electrical System

Page 32

10. Connect the side of the circuit breaker marked

LOAD to the ship-to-shore switch or craft wiring.

Attach insulation boots to the black leads if the kit

includes insulation boots. With a single-pole circuit

breaker use one black lead (L1). With a two-pole

circuit breaker use two black leads, L1 and L2.

Connect the neutral (white) lead to the L0 stud.

Connect the equipment ground (green) lead to

GRD stud.

Note: Wire material. Use stranded copper for all

wiring. Use wire gauges and insulation,

conductor temperature ratings, sheath

stripping, conductor support and protection,

conductor terminals and splices, and

overcurrent protection (circuit breakers,

fuses) that conform to standards and codes.

Note: Follow USCG Regulations CFR33, Part 183

(Pleasurecraft) and CFR46 (Commercial

Craft) for marine applications.

Note: Wire protection. Use rubber grommets

and cable ties as necessary to protect and

secure wiring from sharp objects, the

exhaust system, and any moving parts.

11. Replace the controller cover or circuit breaker box

access panel.

12. Reconnect the generator set engine starting

battery, negative (--) lead last.

13. Make voltage or frequency adjustments according

to Section 8.

6.2.3 Circuit Breaker Installation

(33--125EFOZ and 40--150EOZ

Models)

1. Place the generator set master switch in the OFF

position.

2. Disconnect the generator set engine starting

battery, negative (--) lead first.

3. Remove the six screws from the right side junction

box panel and remove the panel.

4. Install the circuit breaker on the new panel with the

screws and washers. Position the ON side of the

circuit breaker toward the rear of the junction box.

See Figure 6-4.

5. Attach stator leads L1, L2, and L3 to the extension

leads (if supplied) or to the line side of the circuit

breaker. See Figure 8-5.

Note: Insulate leads with electrical tape after

connecting extension leads to stator leads.

6. Connect the neutral connection stator leads to the

L0 stud.

Note: Verify that terminal positions and previously

made line lead connections allow room for

load connections to load studs.

7. Connect the load side of the circuit breaker to

customer-supplied craft wiring. Connect the

neutral lead to the L0 stud. See Figure 8-5.

8. Attach the new panel to the junction box using the

original six screws. See Figure 6-4.

Note: Voltage/frequency adjustable. Some

four-lead generator sets are not

voltage/frequency adjustable. To determine

adjustment possibilities, check the model’s

specification sheet or service manual. If you

are reconnecting the generator set from a

single-voltage to a dual-voltage

configuration (example: from 120-volt to

120/240-volt) or a dual voltage to a single

voltage (example: from 120/240-volt to

120-volt) with the same primary voltage, do

not adjust the voltage/frequency

adjustment. Adjust the voltage/frequency

for frequency changes or setting changes of

the primary voltage (example: from 120-volt

to 100-volt). Refer to the model’s

specification sheet for reconnection

capability.

9. Check that the generator set master switch is in the

OFF position. Reconnect the generator set engine

starting battery, negative (--) lead last.

TP-6069 6/0322 Section 6 Electrical System

Page 33

8

9

12 3 4 56

1. Existing mounting hardware

2. Load lead access panel

3. Screw

4. Hang tag

5. Circuit breaker

ASSEMBLY VIEW C-C

7

ASSEMBLY VIEW A ASSEMBLY VIEW B

6. Circuit breaker panel

7. Extension leads, if equipped

8. Rear connection used on 125-250 amp circuit breaker

9. Spacer used on 125-250 amp circuit breaker

156

DX-250000-B

Figure 6-4 Circuit Breaker Mounting

6.3 Installation In Steel or

Aluminum Vessels

Installation of a generator set in a vessel constructed of

a material capable of conducting current (e.g., steel or

aluminum) is subject to considerations not normally

encountered in fiberglass or wood vessels. These

differences include equipment grounding, grounding of

neutral conductors, ground-fault protection, and

isolation of galvanic currents.

The scope of these topics is too extensive to be fully

discussed here. Consult your local marine authority for

more information.

Before installing the generator set, check the available

wiring diagrams in the operation manual to become

familiar with the electrical system.

6.4 Installation Regulations

The U.S. Coast Guard governs generator set

installation in U.S. pleasurecraft and commercial

vessels. Refer to the applicable regulations below:

U.S. Pleasurecraft Installation

Regulations

Title 33CFR, Chapter I, U.S. Coast Guard, Part 183

1. Subpart I—Electrical Equipment

2. Subpart J—Fuel Systems

U.S. Commercial Vessel Installation

Regulations

Title 46CFR, Chapter I, U.S. Coast Guard

1. Part 111—Electrical Systems

2. Part 182—Machinery Installation

m:sc:001:001

TP-6069 6/03 23Section 6 Electrical System

Page 34

6.5 Battery

Distancebetween

Batteries and their installation must conform to USCG

Regulations 183.420 (a) through (g). Provide generator

sets with batteries separate from the propulsion

engine’s whenever possible. The starting/charging

systems of both the generator set and the engine must

have a common negative (--) ground.

USCG Regulation 183.415, Grounding, requires

connection of a common conductor to each grounded

cranking-motor circuit. Size the conductor to match the

larger of theengine’s two battery cables. Figure 6-5 lists

cable sizes for generator set battery connections at

various ambient temperatures. Connecting a common

conductor to each grounded cranking motor circuit