Page 1

Installation and Care Guide

Bath with Airjets

Retain serial number for reference:

Numéro de série du produit:

Número de serie del producto:__________________________

Français, page “Français-1”

Español, página “Español-1”

1199249-2-A

Page 2

Installation Instructions

WARNING: When using electrical products, basic precautions should always be followed,

including the following:

DANGER: Risk of electric shock. Connect only to a circuit protected by a Ground-Fault

Circuit-Interrupter (GFCI)*.

Building materials and wiring should be routed away from the blower body and other heat-producing

components of the unit.

Install to permit access for servicing.

A pressure wire connector marked ″Earth/Ground″ is provided within the wiring compartment. To reduce

the risk of electric shock, connect this connector to the grounding terminal of your electric service or supply

panel with copper wire equivalent in size to the circuit conductor supplying this equipment.

Pressure wire connectors are provided on the exterior of the junction box or control within this unit to permit

connection of a bonding conductor between this unit and all other exposed metal in the vicinity, as needed to

comply with local requirements.

An equipment grounding terminal is provided in the field wiring compartment. To reduce the risk of electric

shock, this terminal must be connected to the grounding means provided in the electric supply panel with a

conductor equivalent in size to the circuit conductors supplying this equipment.

Grounding is required. The unit should be installed by a qualified service representative, and grounded.

WARNING: Risk of injury or property damage. Please read all instructions thoroughly before

beginning installation, including the following requirements.

WARNING: Risk of electric shock. A qualified electrician should make all electrical connections.

WARNING: Risk of electric shock. Disconnect power before servicing.

NOTICE: Follow all local plumbing and electrical codes. In Canada, install this unit in accordance with

the Canadian Electrical Code, Part 1.

*Outside North America, this device may be known as a Residual Current Device (RCD).

Product Information

Electrical Requirements

The installation must have a Class A Ground-Fault Circuit-Interrupter (GFCI) or Residual Current Device

(RCD). The GFCI or RCD protects against line-to-ground shock hazards. Use a 220 - 240 V, 20 A, 50/60 Hz

dedicated service for the bath.

Product Notices

WARNING: Risk of personal injury or property damage. Unauthorized modification may cause

unsafe operation or affect performance of the bath. Do not relocate the blower motor, or make other

modifications to the bath system in the absence of kit or other published instructions, as this could

adversely affect the performance and safe operation of the product. Kohler Co. shall not be liable

under its warranty or otherwise for personal injury or damage caused by any such unauthorized

modification. Refer to the ″Prepare the Blower (Remote Site)″ section for blower motor relocation

requirements, recommendations, and section coverage information.

NOTICE: Keep the area around the blower motor clean and free of debris. Ensure that the area around

the blower motor is free of sawdust, insulation, dirt, or other small loose debris. Such material could plug

the blower motor air intake and reduce the air flow through the blower.

1199249-2-A 2 Kohler Co.

Page 3

Product Information (cont.)

Features

Factory assembled components include a blower motor, air harness, control, check valve, butterfly valves,

chromatherapy lights (if provided), electrical harnesses, and an illuminated user keypad. Other than power

wiring and plumbing, no assembly is required.

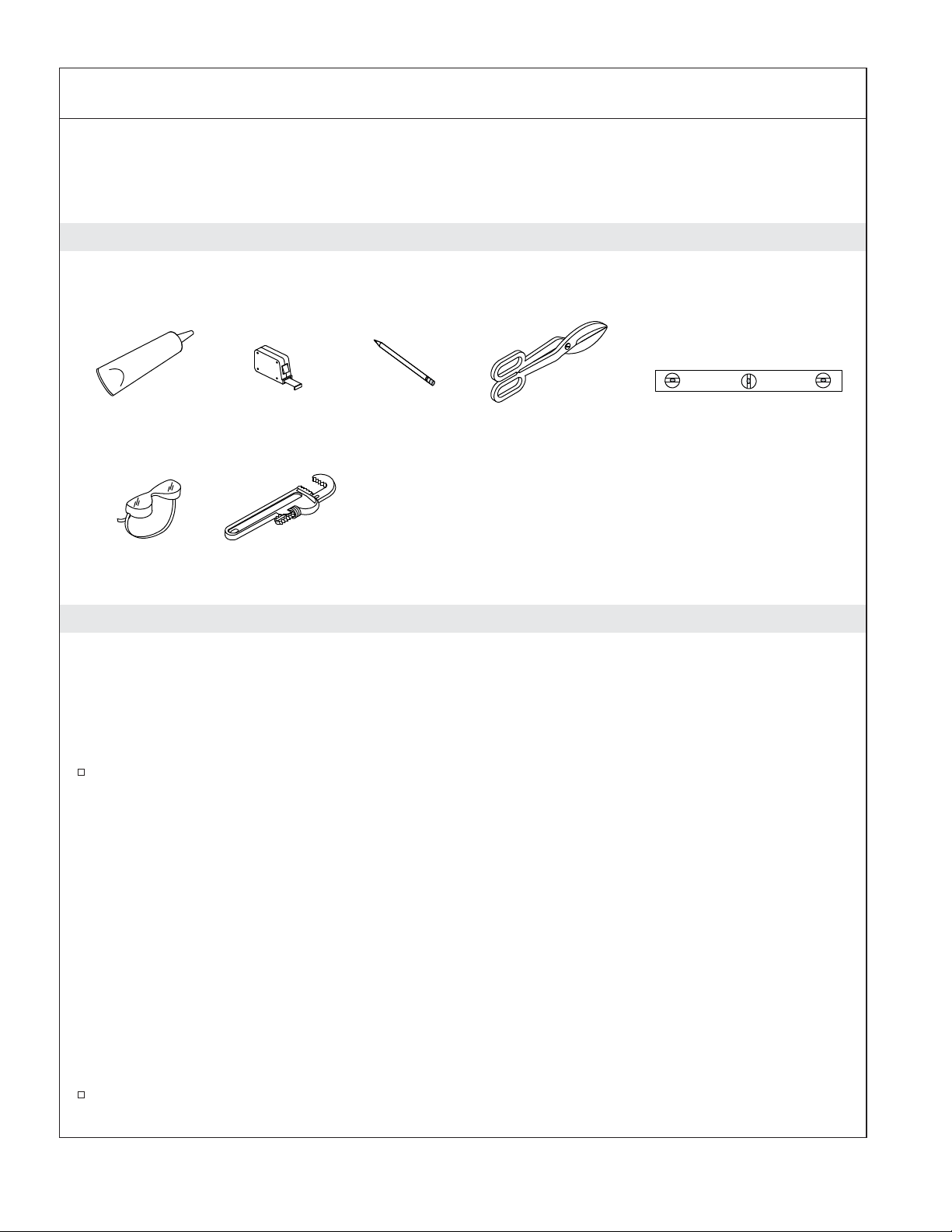

Tools and Materials

Silicone Sealant

Safety Glasses

Measuring Tape

Pipe Wrench

Pencil Tin Snips

Plus:

• Conventional woodworking

tools and materials

• Drop cloth

• Metal shims

• 2x4s

Level

Prepare the Blower (Remote Site)

NOTICE: The blower motor and the check valve must be relocated together. Do not relocate one

without the other.

NOTE: This bath can be installed as received or with the blower motor and check valve relocated to

another location. Refer to the appropriate sections throughout this manual for instructions related to your

particular installation. Read this section before relocating your blower.

Relocate the blower and check valve as close as possible to the bath to maximize performance. Do

not relocate the blower and check valve more than 15’ (4.5 m) from the bath.

•

Position the blower 1-1/2″ (38 mm) above the floor. Do not mount the blower motor with the

blower motor discharge pointing up.

•

Use 1-1/2″ PVC or equivalent rigid piping.

•

The piping installation must meet the requirements of local plumbing or building codes. Ensure that

the installation does not reduce the fire rating of any walls. Piping must be supported at intervals

along the length in accordance with local codes.

•

Ensure that the blower motor location is clean and free of dust or debris.

•

Install an access panel for blower motor maintenance.

•

The 18 AWG minimum power cable to the blower motor must meet the requirements of all

applicable electrical or building codes. Ensure that the installation does not reduce the fire rating of

any walls.

•

The power cord must be supported at intervals along its length in accordance with local codes.

Power cords must not rest on surfaces or floors that are subject to flooding.

•

All material needed for the relocation must be supplied by the installer.

Additional tools and materials you will need:

Kohler Co. 3 1199249-2-A

Page 4

Prepare the Blower (Remote Site) (cont.)

•

Electrician pliers

•

Assorted screwdrivers

•

Adjustable wrench

•

Drill and bits to install the blower mounting fasteners

•

18 AWG non-metallic sheathed cable, two conductors with ground, with support clips, as required

•

One 4″ (102 mm) x 2″ (51 mm) electrical junction box with cover, gasket, and mounting screws

•

Three strain reliefs - one must fit the blower motor cover with standard National Pipe Thread (NPT)

threads. The other two must fit the holes in the new junction box.

•

Six wire connectors (wire nuts or equivalent)

•

1-1/2″ PVC or other rigid pipe with fittings, unions, PVC cement (or equivalent fastening method),

and support clips, as required

•

Four fasteners (such as flathead wood screws or concrete anchors) to secure the blower motor

•

Solid copper 8-gauge bonding wire, 36″ (914 mm)

1199249-2-A 4 Kohler Co.

Page 5

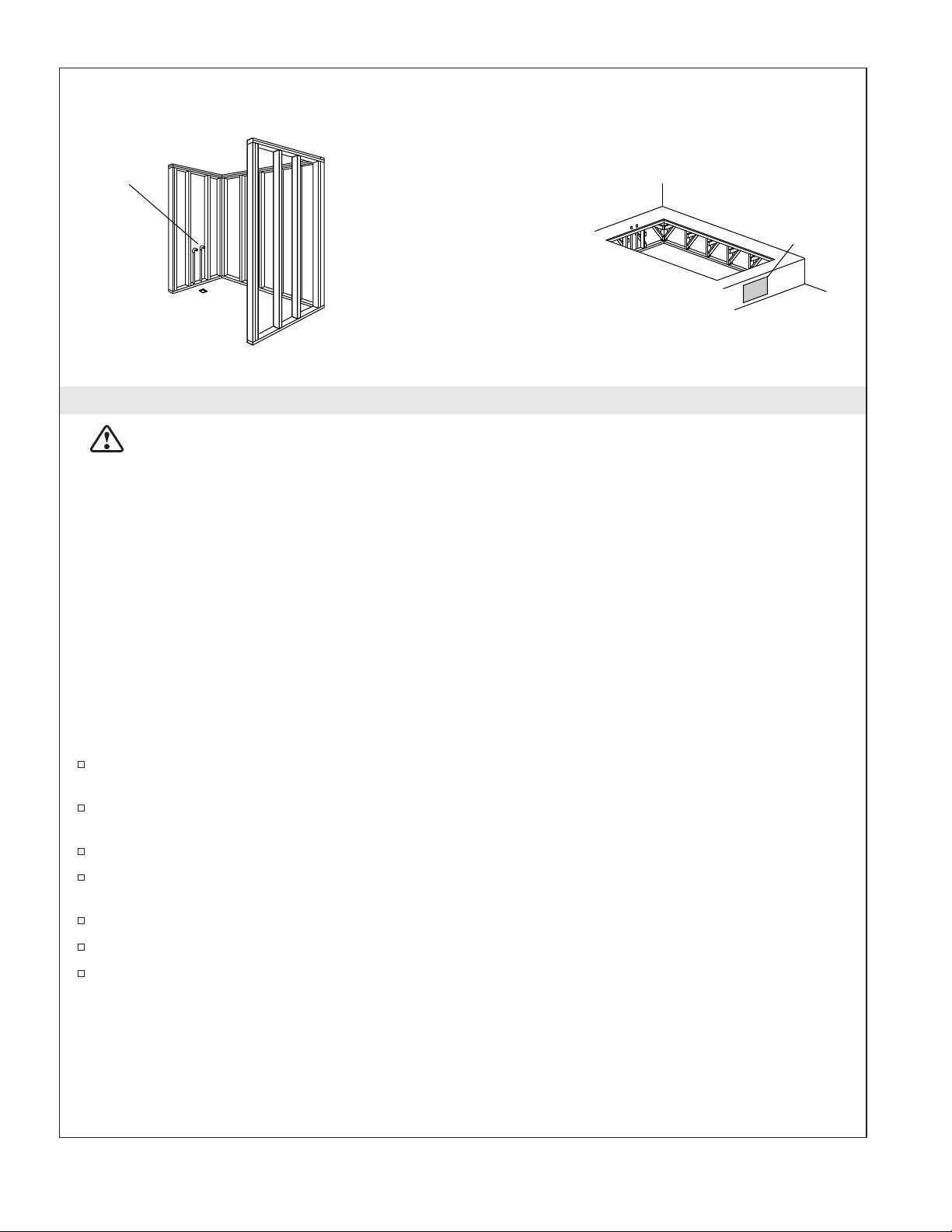

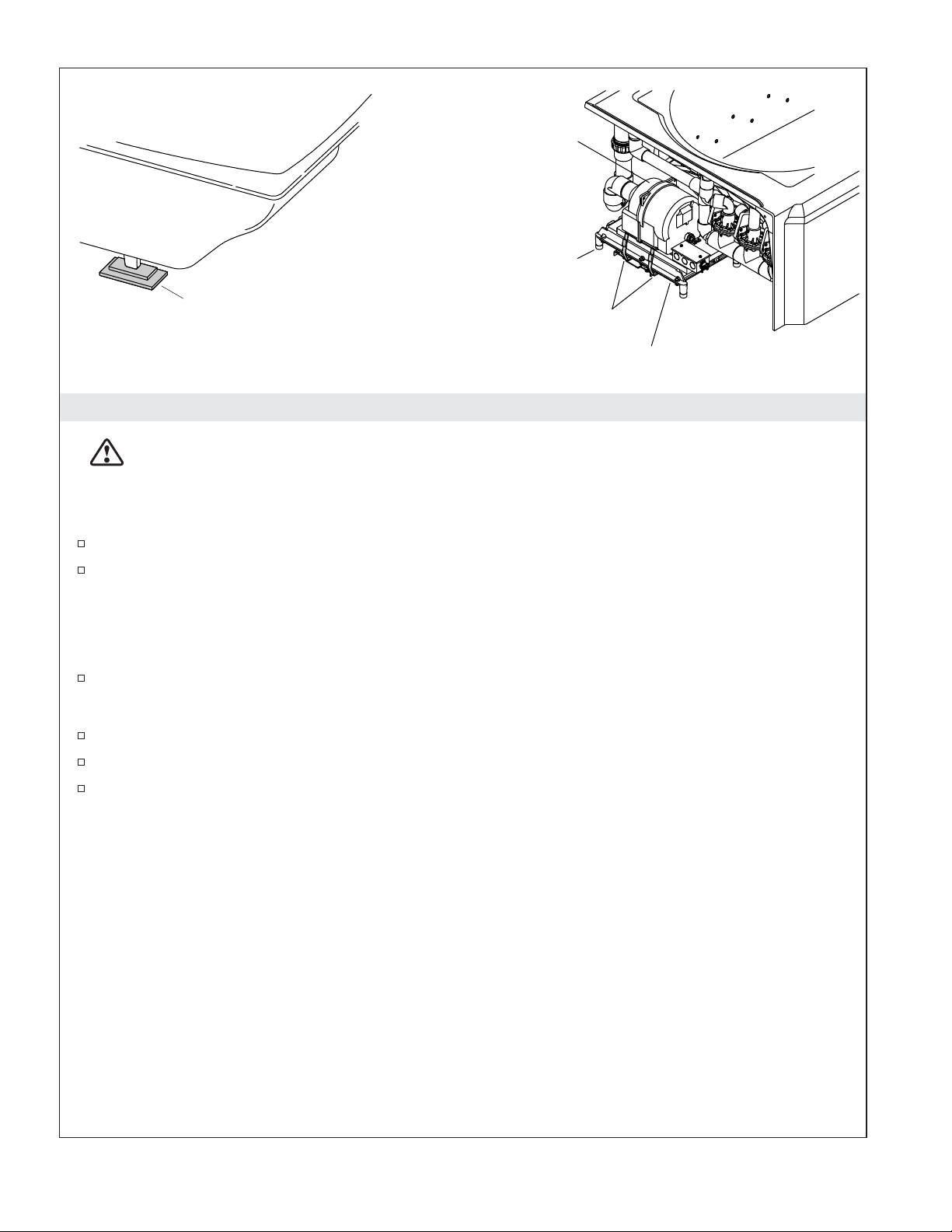

Alcove Drop-In

Position

the rough

plumbing.

Construct 2x4

stud framing

according to the

Position the

rough plumbing.

roughing-in

information.

Construct according

to the product dimensions.

Access

Panel

Verify that the subfloor

offers adequate support,

and is flat and level.

Verify that the subfloor

offers adequate support,

and is flat and level.

1. Prepare the Site

WARNING: Risk of personal injury. This cast iron bath is extremely heavy. Obtain sufficient help

to carefully lift and move it.

NOTICE: Measure your product for site preparation. Note the model number located on the blower, then

visit the product page at www.kohler.com for more information.

NOTICE: Provide adequate ventilation and a minimum 15 cubic feet (.4 cubic meters) air space in the

installed location for cooling the motor and to supply sufficient air for the blower. Do not install the

blower motor closer than 1″ (25 mm) from the wall or other objects.

NOTICE: Provide generous, unrestricted access to the blower. You must provide access for servicing the

blower and controls. The access must be located immediately next to the blower.

NOTICE: Do not lift the bath by the piping or blower, or use the piping or blower for structural support

of the bath. To avoid damage to the bath, lift at the sides of the bath.

NOTICE: Do not support the weight of the bath by the rim.

NOTE: Drop-in, alcove, or corner installation is possible, depending on the product chosen.

Carefully unpack and inspect the new bath for damage before installation. If there is damage do not

install the bath; contact your dealer.

Make sure the flooring offers adequate support for your bath, and verify that the subfloor is flat and

level.

Construct 2x4 stud framing.

Install an access panel for future blower servicing. The access panel must be at least 34″ (864 mm)

wide by 15″ (381 mm) high.

Install the rough plumbing.

Install the drain to the bath according to the drain manufacturer’s instructions.

Protect the bath surface by positioning a clean drop cloth in the basin bottom.

Kohler Co. 5 1199249-2-A

Page 6

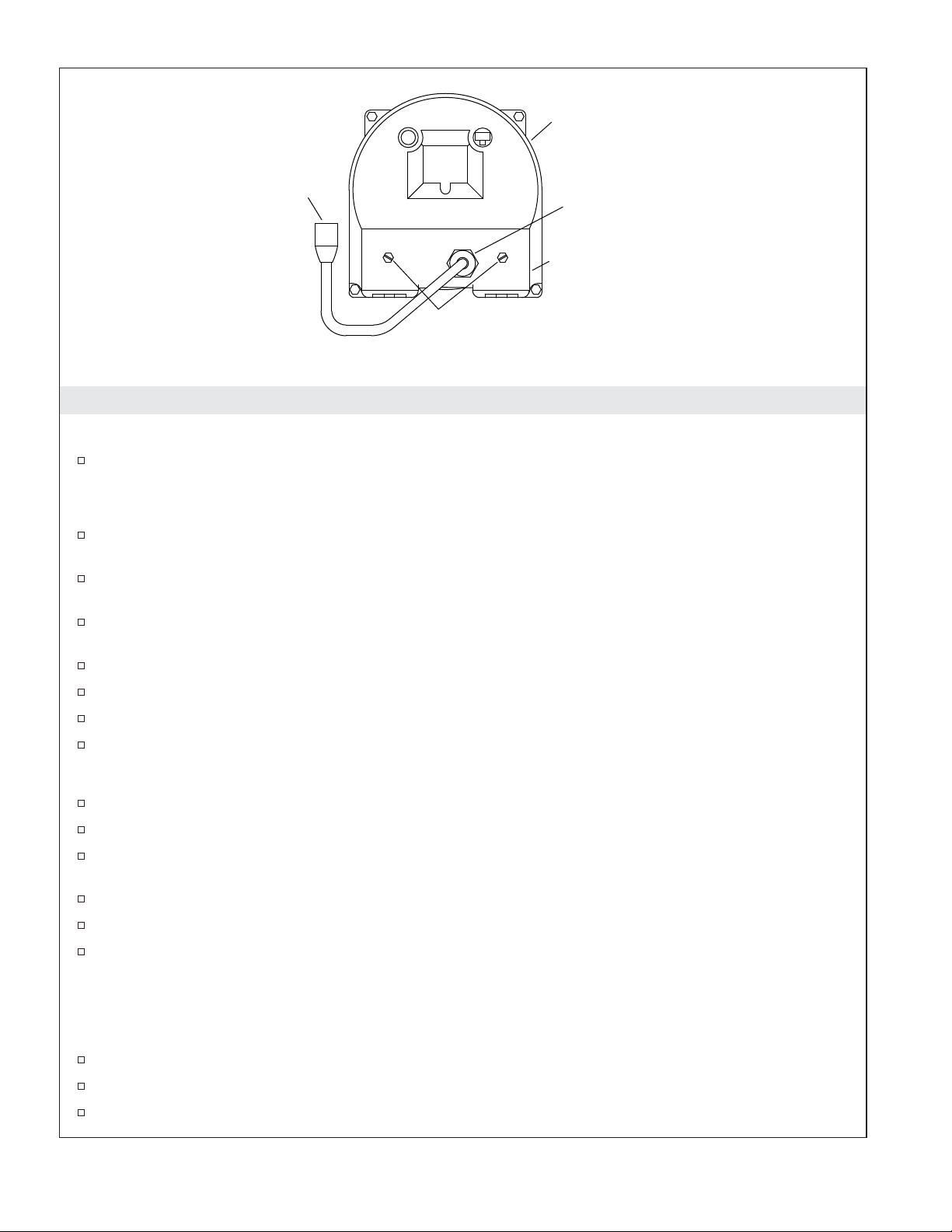

Blower

Motor

Rubber

Isolation

Level by fitting metal shims

under the feet.

Feet

Cut the banding

straps.

Control

2. Install the Bath

WARNING: Risk of personal injury. This cast iron bath is extremely heavy. Obtain sufficient help

to carefully lift and move it.

NOTICE: Do not lift the bath by the piping or blower, or use the piping or blower for structural support

of the bath. To avoid damage to the bath, lift by the rim at the sides of the bath.

Carefully move the bath into position.

Level the bath by fitting metal shims under the feet as needed. Check for level along the rim. Make

sure the bath is resting on all four feet.

Cut the Banding Straps

IMPORTANT! This step is necessary to make the bath operate more quietly.

Cut the two banding straps from the blower.

Install the Plumbing

Insert the drain tailpiece into the trap. Secure the drain tailpiece to the trap.

Install the faucet valve.

Check the drain connections for leakage.

1199249-2-A 6 Kohler Co.

Page 7

Check Valve

Blower Motor Cord

Bond in accordance with national and

local codes. Open bonding lugs are

located at the top of the junction box.

120/240 VAC Source

Neutral Bus

(In Breaker Box)

N

120 V

L1

120 V

L2

Breaker Box

Typical Two-Pole

Circuit Breaker

with GFCI

240 V

* Line Neutral

(White

Curly Wire)

* Equipment Ground

*L2

240 V

*L1

No Connection

(Load Neutral)

Field Wiring

(From Junction Box

to GFCI Breaker)

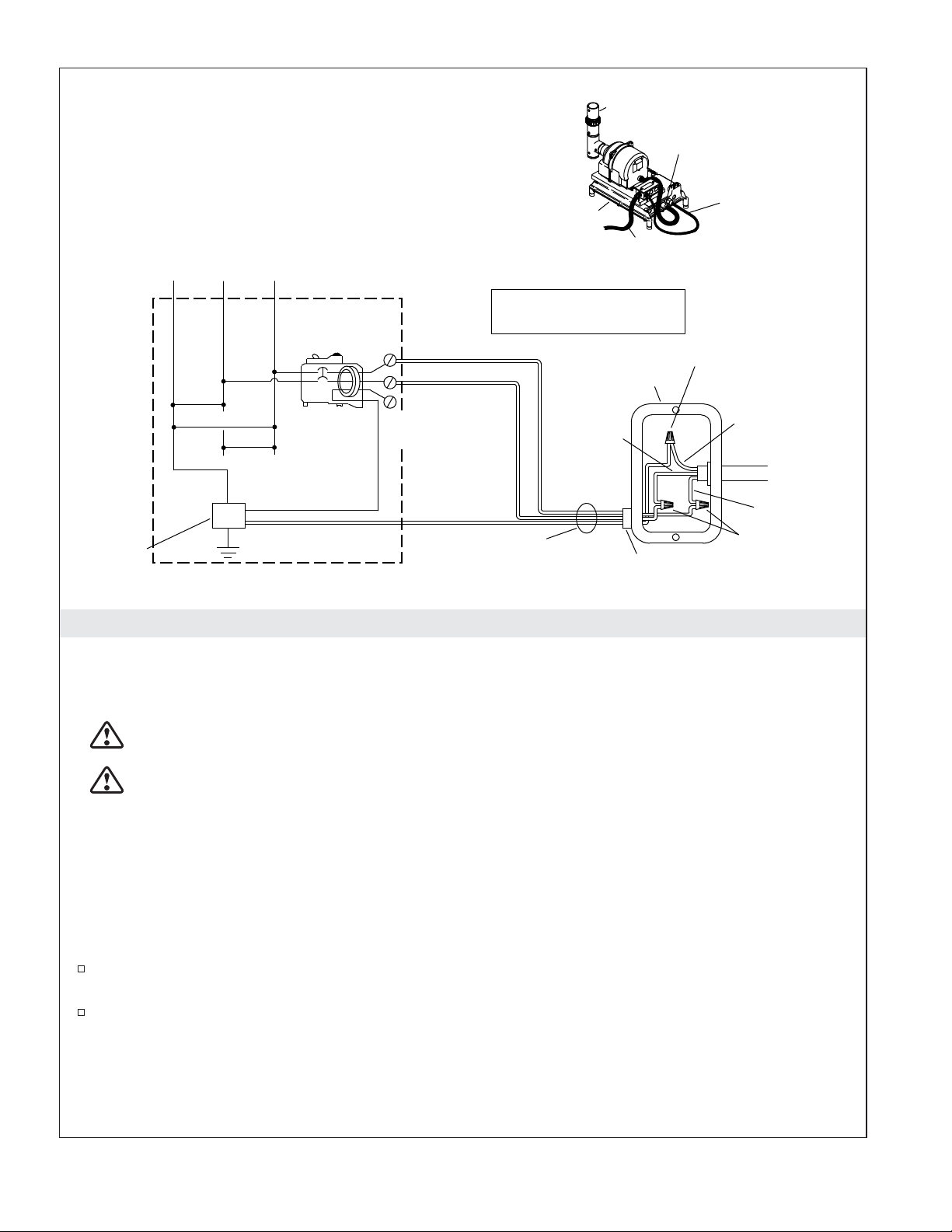

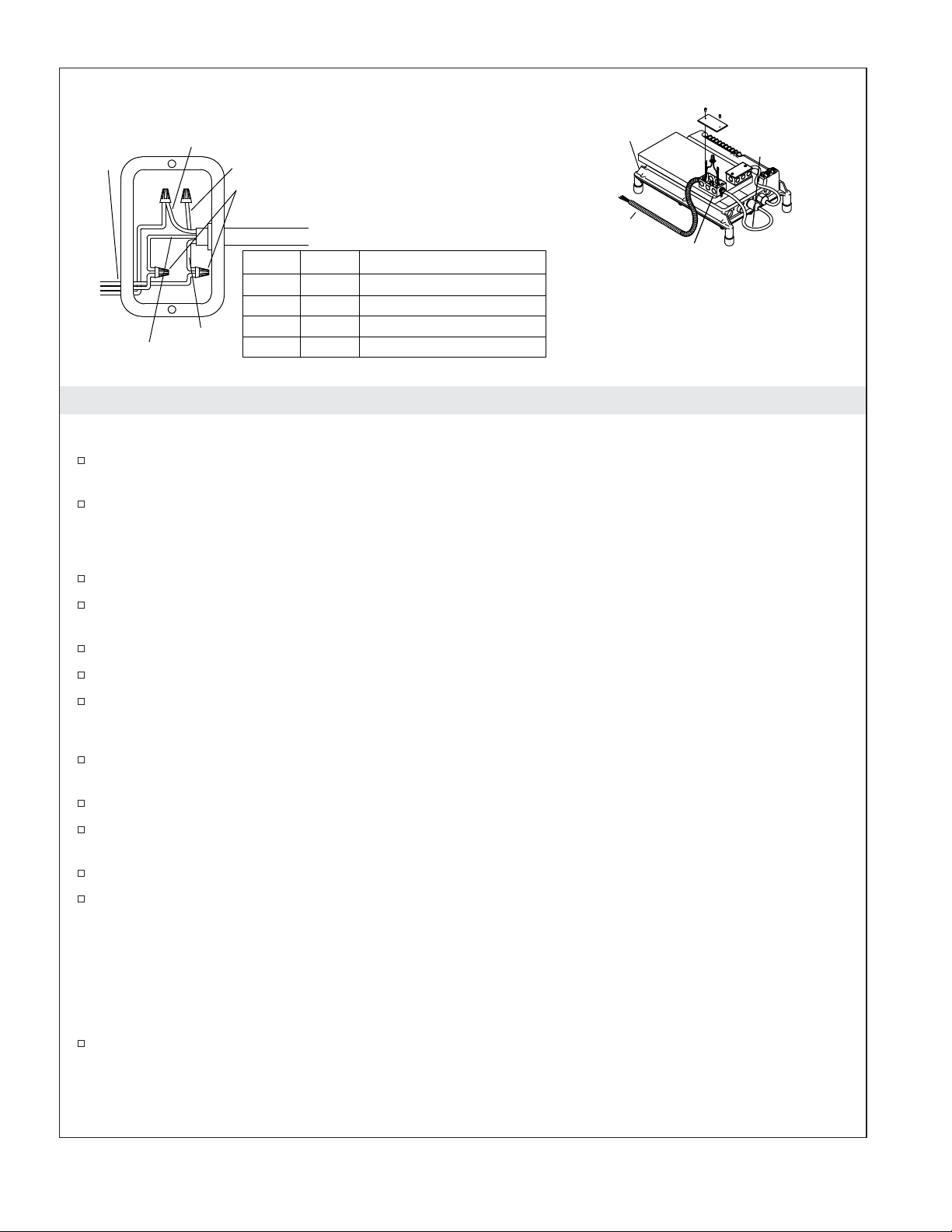

3. Make Electrical Connections - Standard

Control

Power Supply

Control

External Power

Typical Wiring Connection for North America

* Connections to be Made

at the Circuit Breaker

Control Power

Junction Box

Blue (L1)

Wire Connector

Ground

(Green with

Yellow Stripes)

From Control

Brown (L2)

Wire Connectors

Electrician to provide

suitable strain relief.

NOTE: The product model number is printed on a label on the blower side of the bath. This label also

identifies the electrical rating of the product. All baths come equipped with a wiring junction box and

are designed to operate between 220 V and 240 V at either 50 Hz or 60 Hz.

WARNING: Risk of electrical shock. Make sure the power has been disconnected before

performing the following procedures.

WARNING: Risk of electrical shock. Connect the blower to a properly grounded Ground-Fault

Circuit-Interrupter (GFCI) or Residual Current Device (RCD). This will provide additional

protection against line-to-ground shock hazard. A 220-240 V, 20 A, 50/60 Hz dedicated circuit is

required.

IMPORTANT! The load neutral is not used. There should be no connection to the load neutral terminal

on the Ground-Fault Circuit-Interrupter (GFCI) breaker. The green wire with the yellow stripe is the

equipment ground and needs to be connected to the neutral bus in the main circuit breaker box.

NOTE: The wiring harness includes an antenna for the optional remote control. Do not alter or damage

this antenna during installation.

Connect service to the junction box. The junction box contains blue, brown, and green with a yellow

stripe colored wires and a ground lug

Follow local electrical codes. Bond in accordance with national and local codes.

Kohler Co. 7 1199249-2-A

Page 8

Blower Motor

Mounting Screws

Elbow

Check

Valve

Cover

Junction Box

Baseboard

Screw

Control

To Blower Motor

Blower Motor

Electrical Plug

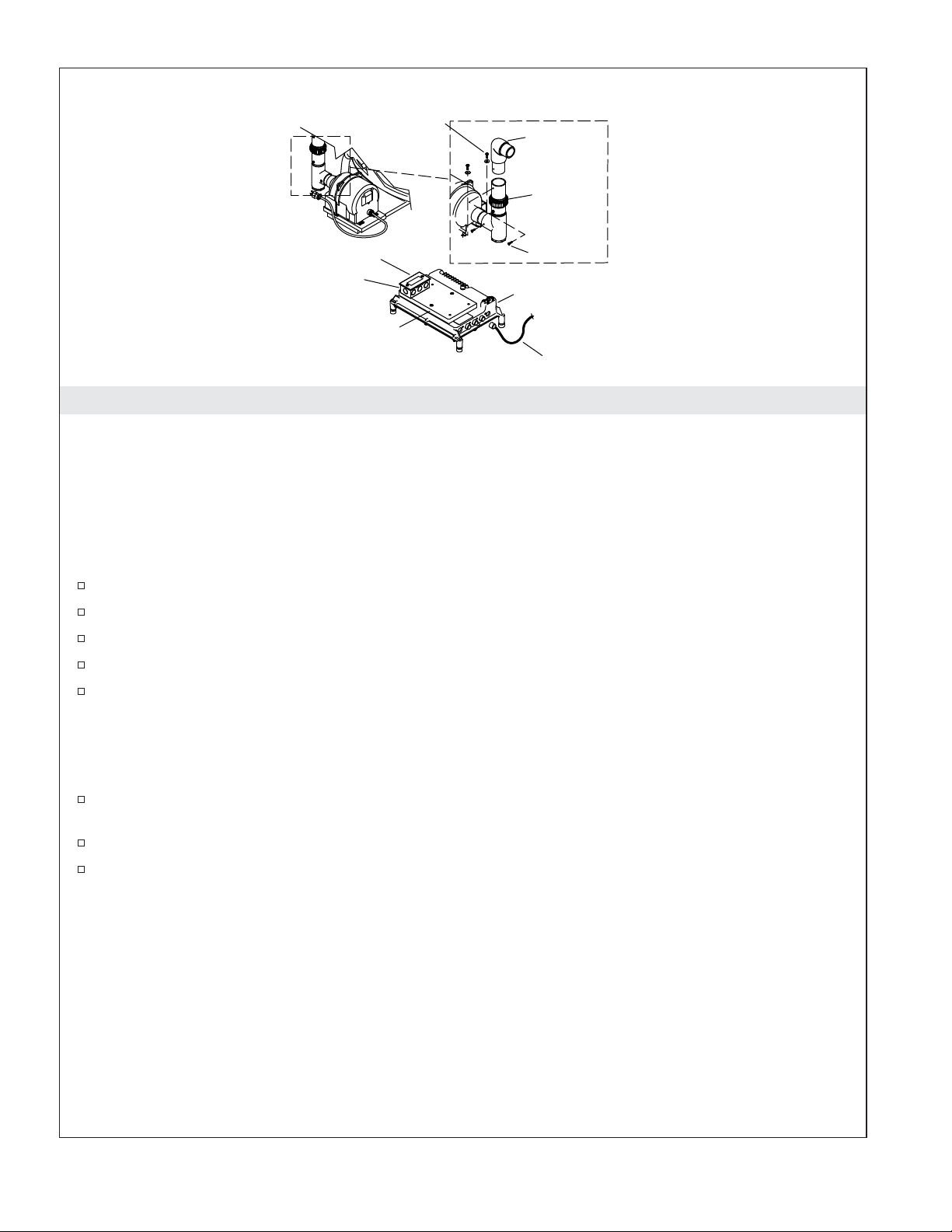

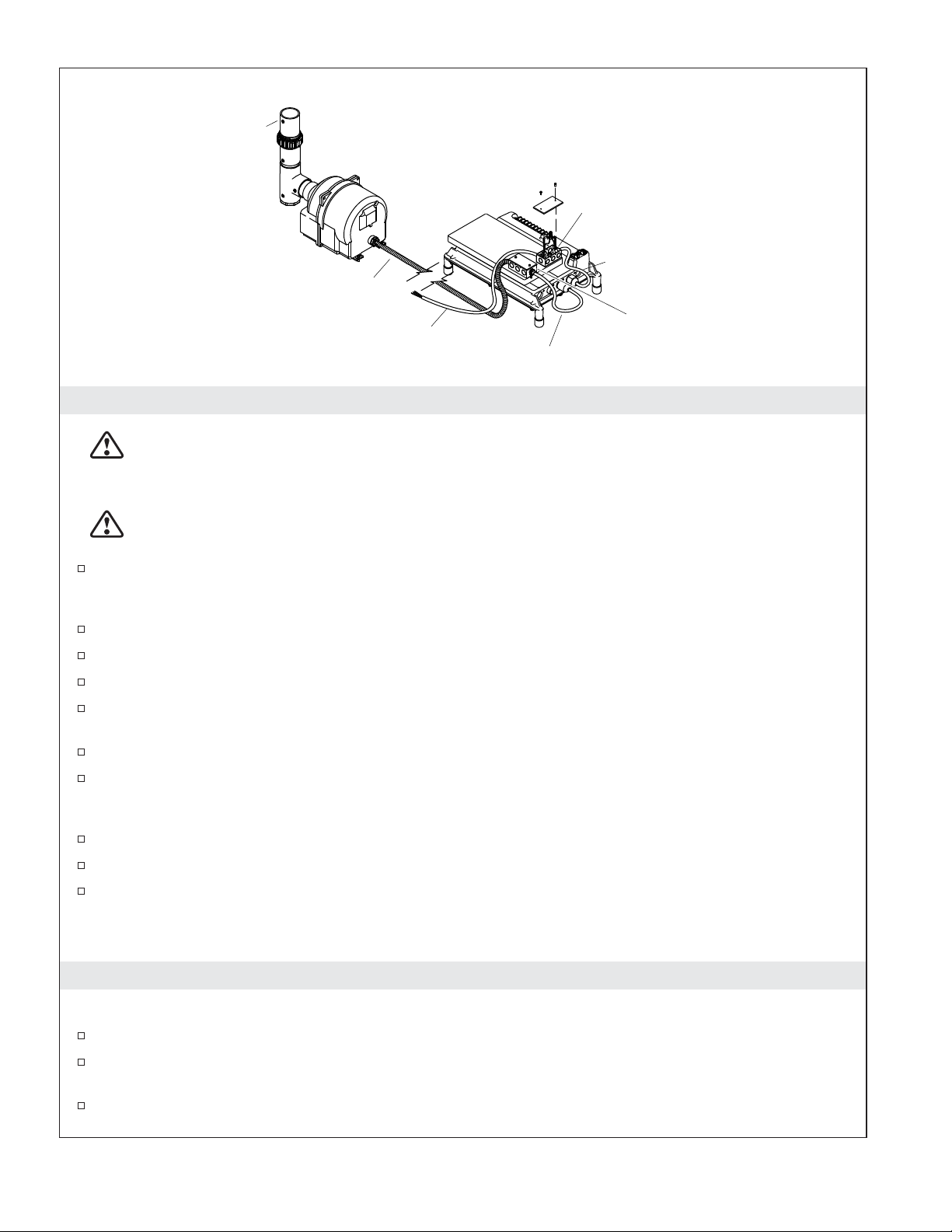

4. Disconnect the Blower Motor - Remote

NOTICE: This section applies only to installations in which the blower motor and check valve are

being relocated.

NOTICE: Do not cut the blower piping for this installation.

NOTICE: You must relocate the check valve with the blower motor. Do not disconnect the check valve

from the tee.

Remove the Blower Motor and Check Valve

Disconnect the blower motor electrical plug from the control.

Remove any cable ties that support the blower motor cord.

Remove and retain the screw holding the check valve to the PVC elbow.

Remove and retain the four screws from the baseboard.

Slide the blower motor and check valve away from the elbow, and remove the blower motor from

the bath.

Prepare the Site

NOTE: Refer to the ″Prepare the Blower (Remote Site)″ section for blower relocation details.

Prepare the site where the blower motor will be installed. The site must be within 15’ (4.5 m) of the

bath.

Install an access panel to service the blower motor.

Prepare the routing paths for the PVC piping and the new blower motor power cable. Follow all

applicable codes.

1199249-2-A 8 Kohler Co.

Page 9

Blower Motor

Mounting Screws

1-1/2" Rigid Piping

(not supplied)

Check Valve

1-1/2" (38 mm) Min

Screw

Screw

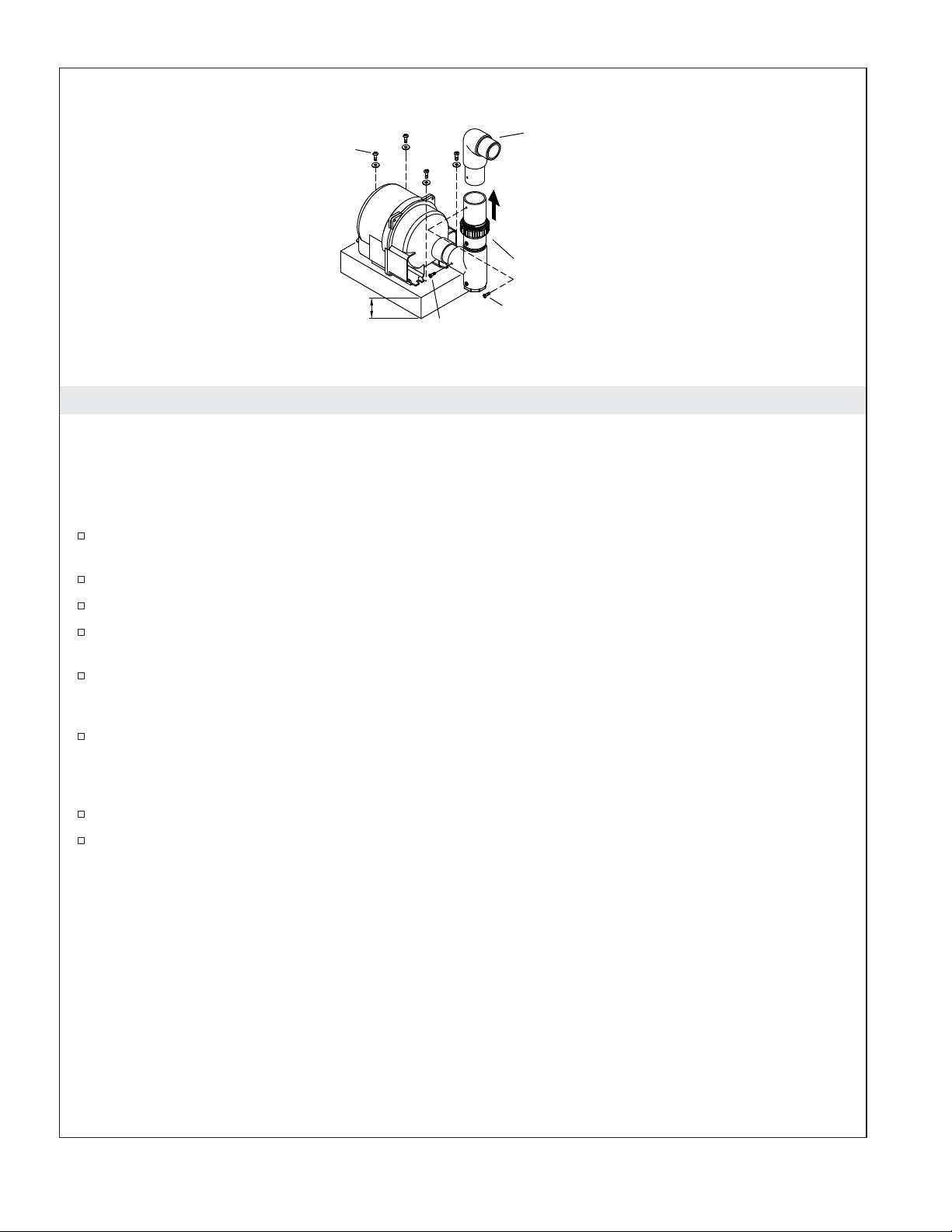

5. Mount the Blower Motor and Check Valve - Remote

NOTE: The blower motor must be mounted horizontally 1-1/2″ (38 mm) above the floor. Do not mount

the blower motor with the discharge pointing up.

NOTE: Refer to the ″Prepare the Blower (Remote Site)″ section for other requirements for the blower

motor relocation.

At the new blower motor location, install a 1-1/2″ (38 mm) high block (not supplied) to support the

blower motor.

Use the blower motor as a template to mark the location of the four mounting bolts or screws.

Drill four 1/8″ (3 mm) pilot holes for the blower motor mounting screws.

Install and support PVC or other 1-1/2″ rigid piping (not supplied) between the blower motor

location and the air harness.

Connect the new piping to the existing air harness without modifying the air harness. Align the new

pipe and secure the connection with PVC cement. Allow the PVC cement to cure according to the

manufacturer’s instructions.

Connect the check valve assembly to the new piping. Align the new pipe with the check valve

assembly and drill a hole for the existing mounting screw. Use silicone or equivalent sealant at the

connections and reuse the screw that was removed previously. Allow the sealant to cure according

to the manufacturer’s recommendations.

Position the motor on the support block. Reinstall the screw on the check valve.

Fasten the blower motor to the new support block with the mounting screws.

Kohler Co. 9 1199249-2-A

Page 10

Blower Motor

Plug

Strain Relief

Access Cover

Remove screws, remove cover,

and cut existing cable about 4"

(102 mm) from the blower motor.

6. Terminate the Cable at the Blower - Remote

Route the Power Cable

Route 18 AWG or equivalent power cable (two conductors with ground) between the bath and

blower. Support and protect the cable. Follow local electrical codes.

Prepare the Blower for Remote Installation

Loosen the cable strain-relief nut on the blower motor. Push the nut back on the cable to provide

clearance for the cover removal.

Remove and retain the two access cover screws from the back of the blower motor. As you are

loosening the screws, check periodically if the cover can be slid back on the electrical cable.

When the cover is loose, use electrician pliers or equivalent to cut the electrical cable at a point

about 4” (102 mm) from where the cable enters into the blower motor housing.

Pull the free end of the electrical cord through the cover, insert, and strain relief nut.

Discard the existing strain relief nut and insert.

Reconnect the blower motor plug to the control.

Install a standard NPT threaded strain relief to the blower motor cover.

Connect the New Power Cable at the Blower Motor

On the 4″ (102 mm) pigtail lead of the blower motor, strip back the cable jacket about 3″ (76 mm).

On the customer-supplied power cable, strip back the cable jacket about 2″ (51 mm).

In the USA, mark white conductors with red or black tape as required by the National Electric Code

(NEC).

Strip the wire insulation 3/8″ (10 mm) from the blower motor pigtail and power cable leads.

Route the new power cable leads through the blower motor access cover and strain relief.

Using wire nuts or other approved termination methods, terminate the conductors as follows:

•

Connect the black pigtail lead to the L1 conductor of the power cable.

•

Connect the blue pigtail lead to the L2 or N conductor of the power cable.

•

Connect the green with yellow stripe pigtail lead to the power cable ground conductor.

With the two screws, reinstall the access cover on the blower motor.

Tighten the strain relief on the power cable at the blower motor.

Remove any dust or debris from the blower motor area.

1199249-2-A 10 Kohler Co.

Page 11

Second Junction Box

Cable to

Blower

Motor

Ground (Green with

Yellow Stripe)

Brown

Wire Nut

Strip back the jackets about

3" (76 mm) on the field cable

and on the blower motor pigtail.

Then cut the unused fourth

conductor brown wire off

Control Power Junction Box

Blower Adapter

Board

at the point that the

cable jacket ends.

From Control50 Hz

L1

N

NC

Black

Blue

Green w/Yellow Stripe

Brown

New Field

Cable To

Blower Motor

Second

Junction Box

Route the cut end of the cord to

the new junction box. Add strain relief.

Install junction box with cover

and bonding lug (not provided).

Blue

From Control

Black

60 Hz

L1

L2

GNDNCGND

7. Install the Blower Cord at the Control - Remote

Install the Second Junction Box on the Control

Install a second junction box with external bonding lug, two strain reliefs, and a cover (not

supplied) on the blower adapter board on the control.

Connect a solid copper 8-gauge bonding wire from the bonding lug on the new junction box to the

spare bonding lug on the control. Follow all local electrical codes.

Reconnect the Blower Motor Power Cord

Blower

Motor Pigtail

If required, reconnect the blower motor power cord at the control.

Route the blower motor power cord through a strain relief on the second junction box. Tighten the

strain relief.

At the end of the cut power cord, strip back the cable jacket about 3″ (76 mm).

Using a wire nut, cap off the unused brown conductor in the cable jacket.

Strip about 3/8″ (10 mm) of wire insulation from the remaining control wires.

Reconnect the Blower New Power Cable

Route the customer-supplied power cable from the blower through the other strain relief on the

second junction box. Tighten the strain relief.

Strip back the cable jacket about 3″ (76 mm).

For installations in the USA, mark the white wire with either red or black electrical tape as required

by the National Electric Code (NEC).

Strip the end of the wires about 3/8″ (10 mm).

Use approved termination devices to terminate the conductors as follows:

•

Connect the black pigtail lead to the L1 conductor of the power cable.

•

Connect the blue pigtail lead to the L2 or N conductor of the power cable.

•

Connect the green with yellow stripe pigtail lead to the grounding or earthing conductor of the

power cable.

•

The brown wire is not used and should be capped with a wire nut.

Install the cover on the new junction box.

Kohler Co. 11 1199249-2-A

Page 12

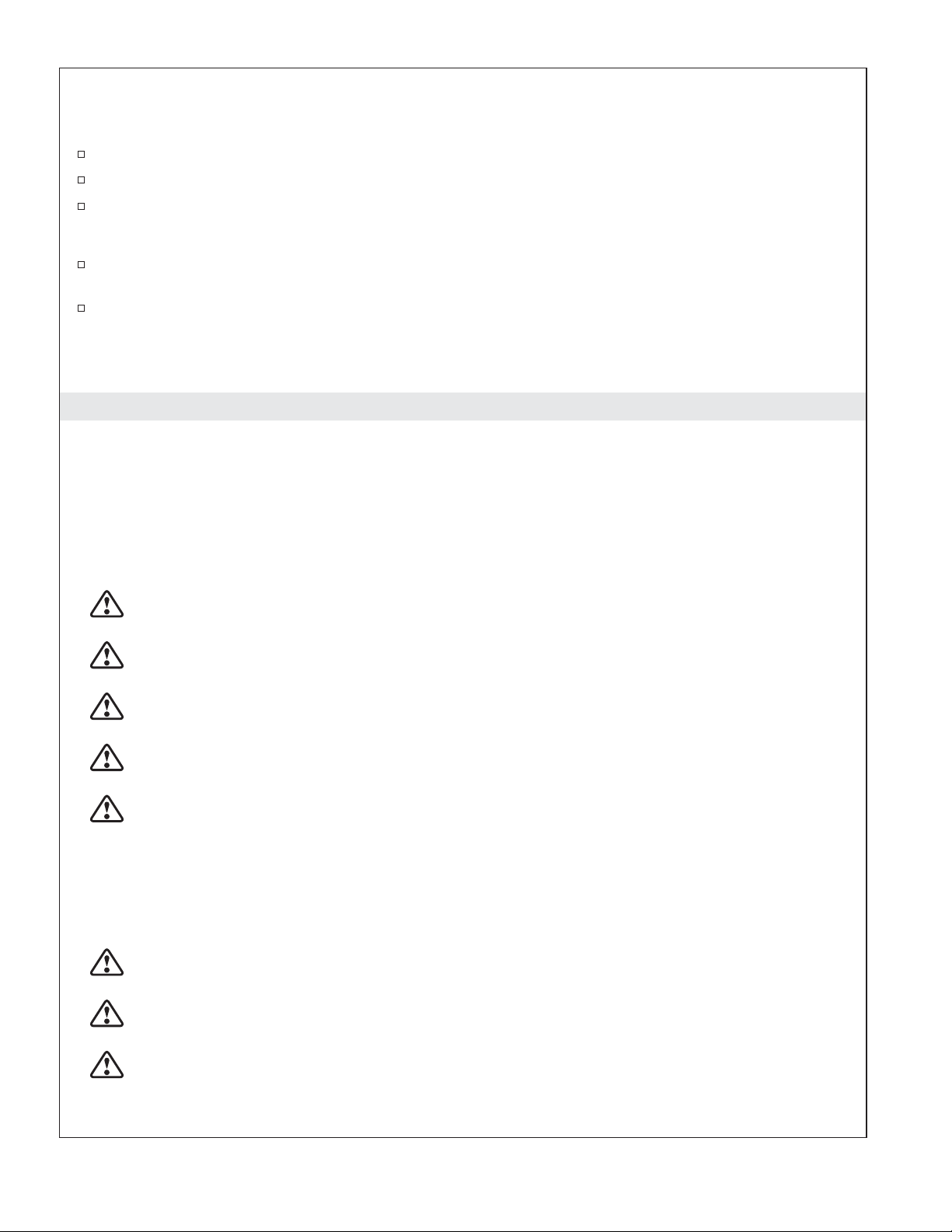

Check Valve

Typical Remote Blower Installation

Control Power Junction Box

Remote Blower

New Field Cable To Blower Motor

Power Supply Cable

Blower Motor Cord

Control Power Supply

Second Junction Box

(added for Remote Blower)

8. Make Power Connections - Remote

WARNING: Risk of electric shock. To reduce the risk of electric shock, connect the control to a

properly grounded Ground-Fault Circuit-Interrupter (GFCI) or Residual Current Device (RCD). This

will provide additional protection against line-to-ground shock hazard. A dedicated 220-240 V, 20 A,

50/60 Hz circuit is required.

WARNING: Risk of electric shock. Make sure the power has been disconnected before performing

the following procedures.

Ensure that the control power supply cord is properly routed to the control power junction box. The

control power supply cord contains a brown wire (Line 1), a blue wire (Line 2), and a green wire

with a yellow stripe (ground or earth).

Install a strain relief (not provided) for the power supply cable to the control power junction box.

Route the power supply cable to the control power junction box.

As required, strip the jacket and wire insulation on both cables to make the connections.

For installations in the USA, mark any white conductor in the supply power wiring with red or

black tape as required by the NEC.

Connect service to the control power junction box.

Provide a separate equipment earthing or grounding conductor to the spare earth/ground lug

located on the control power junction box. This conductor must not be connected to any

current-carrying conductor. Follow local electrical codes.

Bond in accordance with national and local codes.

Clean the area of all dust and debris.

All wiring harnesses have been pre-wired at the factory. Ensure that all wires are securely fastened.

NOTE: Your wiring harness includes an antenna for the optional remote control. Do not alter or damage

this antenna during installation.

9. Complete the Installation

Test Run the Bath

Fill the bath to a level at least 4″ (102 mm) above the top of the highest airjet.

Operate the bath for 5 minutes and check all bath piping connections for leaks. Check for leakage

along the front, sides, and back of the bath.

For additional information on bath operation, see the ″Operating Instructions″ section.

1199249-2-A 12 Kohler Co.

Page 13

Complete the Installation (cont.)

Finish the Installation

Install water-resistant wallboard and all finished wall, deck, and floor materials.

Apply silicone sealant to seal all areas where the bath and finished wall or deck meet.

Install the faucet trim.

Clean-up After Installation

When cleaning up after installation, do not use abrasive cleansers, as they may scratch and dull the

bath surface. Use warm water and a liquid detergent to clean the surface of the bath.

Remove stubborn stains or paint with turpentine or paint thinner. Do not allow cleaners containing

petroleum distillates to remain in contact with any bath surface for long periods of time. Remove

plaster by carefully scraping with a wood edge. Do not use metal scrapers, wire brushes, or other

metal tools. Use a powder-type detergent on a damp cloth to provide mild abrasive action to any

residual plaster.

Important Safety Instructions

READ AND FOLLOW ALL INSTRUCTIONS

SAVE THESE INSTRUCTIONS

INSTRUCTIONS PERTAINING TO A RISK OF FIRE, ELECTRIC SHOCK, OR INJURY TO PERSONS

WARNING: When using electrical products, basic precautions should always be followed,

including the following:

DANGER: Risk of accidental injury or drowning. To reduce the risk of injury, do not permit

children to use this unit unless they are closely supervised at all times.

WARNING: Risk of personal injury. To avoid injury, exercise care when entering or exiting the

bath.

WARNING: Risk of electric shock. Do not permit electric appliances (such as a hair dryer, lamp,

telephone, radio, or television) within 5’ (1.5 m) of this bath.

WARNING: The use of alcohol, drugs, or medication can greatly increase the risk of fatal

hyperthermia. Prolonged immersion in hot water may induce hyperthermia. Hyperthermia occurs

when the internal temperature of the body reaches a level several degrees above the normal body

temperature of 98.6°F (37°C). The symptoms of hyperthermia include an increase in the internal

temperature of the body, dizziness, lethargy, drowsiness, and fainting. The effects of hyperthermia

include: (a) failure to perceive heat, (b) failure to recognize the need to exit the bath, (c)

unawareness of impending hazard, (d) fetal damage in pregnant women, (e) physical inability to

exit the bath, and (f) unconsciousness resulting in the danger of drowning.

WARNING: Risk of fetal injury. Pregnant or possibly pregnant women should consult a physician

before using the bath.

WARNING: Risk of hyperthermia or drowning. Do not use the bath immediately following

strenuous exercise.

WARNING: Risk of hyperthermia or drowning. Water temperature in excess of 100°F (38°C) may

cause injury. Test and adjust the water temperature before use.

Kohler Co. 13 1199249-2-A

Page 14

Important Safety Instructions (cont.)

WARNING: Risk of personal injury. Never drop or insert any object into any opening.

Use this bath only for its intended purpose as described in this guide. Do not use attachments not

recommended by Kohler Co.

The bath must be connected only to a supply circuit that is protected by a Ground-Fault Circuit-Interrupter

(GFCI)*. Such a GFCI should be provided by the installer and should be tested on a routine basis. To test the

GFCI, press the test button. The GFCI should interrupt power. Press the reset button. Power should be

restored. If the GFCI fails to operate in this manner, the GFCI is defective. If the GFCI interrupts power to

the bath without the test button being pressed, a ground current is flowing, indicating the possibility of an

electric shock. Do not use this bath. Disconnect the bath and have the problem corrected by a qualified

service representative before using.

Your new KOHLER bath has been listed by Underwriter’s Laboratories, ensuring safety for you and your

family. This bath also conforms to rigid ANSI and IAPMO standards set within the plumbing industry.

* Outside North America, this device may be known as a Residual Current Device (RCD).

1199249-2-A 14 Kohler Co.

Page 15

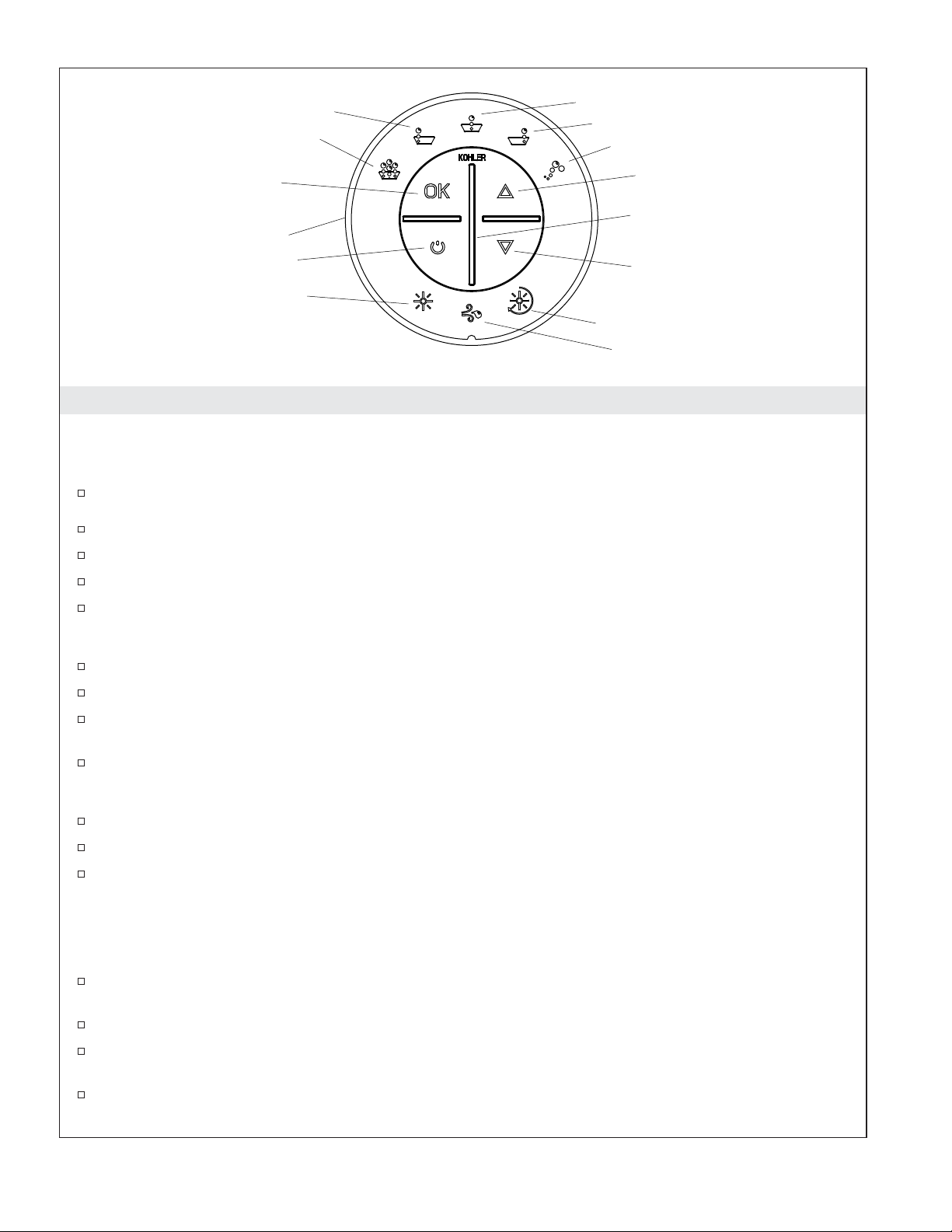

Zone 1

Air Flow Mode

Zone 2

Zone 3

Surge Mode

Activates Mode Selected

Rotate Outer Ring to

Access Desired Mode

Power On/Off

Chromatherapy Specific

Color (if provided)

Increase Flow or Surge

Indicator Bar

Decrease Flow or Surge

Chromatherapy Cycle (if provided)

Purge Mode

Operating Instructions

NOTE: If the unit does not function properly, please refer to the “Troubleshooting” section.

Starting the Unit

Fill the bath to a level at least 4” (102 mm) above the top of the airjets.

Use your hand to test the water temperature for comfort and safety.

Carefully enter the bath basin.

Press the On/Off icon on the user keypad.

If desired, adjust the air flow rate using the up or down buttons.

Selecting Air Flow Modes

Rotate the outer ring to select a desired mode.

Press the ″OK″ icon to activate the mode.

To turn off a mode, rotate the outer ring until the icon is flashing green and then press the “OK”

icon again.

The icon will then turn blue, indicating the mode is off.

Stopping the Bath

When ready, press the On/Off icon a second time to stop the air system.

Carefully exit the bath.

When the bath drains below the level sensors an automatic, two-minute purge cycle occurs. The air

system then operates at low speed to blow any residual water out of the air harness.

Initiating a Manual Purge Cycle (when desired)

NOTE: Follow these steps if you choose to manually purge residual water from the air system.

After stopping the air system and draining the bath, rotate the ring on the user keypad to the

″Purge″ icon.

When the ″Purge″ icon is flashing blue, press the ″OK″ icon once.

The ″Purge″ icon flashes green and the manual purge mode begins. The air system operates at low

speed to blow any residual water out of the air harness.

After two minutes, the air system stops automatically.

Kohler Co. 15 1199249-2-A

Page 16

Care and Cleaning

For best results, keep the following in mind when caring for your KOHLER bath with airjets:

•

Always test your cleaning solution on an inconspicuous area before applying to the entire surface.

•

Wipe surfaces clean and rinse completely with water immediately after applying cleaner. Rinse and

dry any overspray that lands on nearby surfaces.

•

Do not allow cleaners to soak on surfaces.

•

Use a soft, dampened sponge or cloth. Never use an abrasive material such as a brush or scouring

pad to clean surfaces.

•

The ideal cleaning technique is to rinse thoroughly and blot dry any water from the surface after

each use.

•

Use a soft nylon brush on slip-resistant surfaces. Be sure to use a water-soluble cleaner (dissolves

100% in water).

•

Do not use powdered cleaners unless the cleaner is fully dissolved in water. Solid substances can

block the airjets.

•

Do not use full strength bleach or ammonia cleaning solutions. Chemically active cleaning

solutions can damage the surface.

•

Do not use abrasive cleansers or solvents on airjet surfaces. Abrasive cleaners and solvents can

damage the airjet surface.

Maintaining the Airjets

If cleaning the airjets is necessary due to hard water deposits, wet a soft, non-abrasive cloth with

white vinegar and wipe the plugged airjet holes. Immediately rinse the area with clean water to

avoid long-term exposure of the vinegar to the airjet surface.

Fill the bath with water to the top row of airjets. Drain the bath and press the purge button.

Cleaning Your User Keypad and Remote Control

Use a soft cloth to wipe the keypad and remote control after each use. If the surface becomes dirty,

use a non-abrasive soap and warm water to clean.

For detailed cleaning information and products to consider, visit www.kohler.com/clean. To order Care &

Cleaning information, call 1-800-456-4537.

Warranty

Kohler Co. warrants the cast iron components of products manufactured after February 10, 2000, to be free of

defects in material and workmanship during normal residential use for as long as the original consumer

purchaser owns his or her home. Gloss reduction, scratching, staining and alkaline etching of the finish over

time due to use, cleaning practices or water or atmospheric conditions, are not manufacturing defects but are

indicative of normal wear and tear. This warranty applies only for KOHLER Cast Iron products installed in

the United States of America, Canada or Mexico (North America).

If a defect is found in normal residential use, Kohler Co. will, at its election, repair, replace or make

appropriate adjustment. Damage caused by accident, misuse, or abuse is not covered by this warranty.

Improper care and cleaning will void the warranty. Proof of purchase (original sales receipt) must be

provided to Kohler Co. with all warranty claims. Kohler Co. is not responsible for labor charges, installation,

or other incidental or consequential costs. In no event shall the liability of Kohler Co. exceed the purchase

price of the product.

If the cast iron product is used commercially or is installed outside of North America, Kohler Co. warrants

the cast iron product to be free from defects in material and workmanship for one (1) year from the date the

product is installed, with all other terms of this warranty applying except duration. All other components

other than the enameled cast iron carry Kohler Co.’s one-year limited warranty unless otherwise specified.

If you believe that you have a warranty claim, contact Kohler Co., either through your Dealer, Plumbing

Contractor, Home Center or E-tailer, or by writing: Kohler Co., Attn.: Customer Care Center, 444 Highland

Drive, Kohler, WI 53044, USA. Please be sure to provide all pertinent information regarding your claim,

including a complete description of the problem, the product, model number, color, finish, the date the

product was purchased and from whom the product was purchased. Also include your original invoice. For

other information, or to obtain the name and address of the service and repair facility nearest you call

1199249-2-A 16 Kohler Co.

Page 17

Warranty (cont.)

1-800-4-KOHLER (1-800-456-4537) from within the USA and Canada, and 001-800-456-4537 from within

Mexico, or visit www.kohler.com within the USA, www.ca.kohler.com from within Canada, or

www.mx.kohler.com in Mexico.

KOHLER CO. AND/OR SELLER ARE PROVIDING THIS WARRANTY IN LIEU OF ALL OTHER

WARRANTIES, EXPRESSED OR IMPLIED, INCLUDING BUT NOT LIMITED TO THE IMPLIED

WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE. KOHLER CO.

AND/OR SELLER DISCLAIMS ANY LIABILITY FOR SPECIAL, INCIDENTAL OR CONSEQUENTIAL

DAMAGES.

Some states/provinces do not allow limitations on how long an implied warranty lasts, or the exclusion or

limitation of special, incidental or consequential damages, so these limitations and exclusions may not apply

to you. This warranty gives the consumer specific legal rights. You may also have other rights, which vary,

from state/province to state/province. This warranty is to the original consumer purchaser only, and

excludes product damage due to installation error, product abuse, or product misuse, whether performed by

a contractor, service company or the consumer.

This is Kohler Co.’s exclusive written warranty.

Warranty

ONE-YEAR LIMITED WARRANTY

KOHLER plumbing products are warranted to be free of defects in material and workmanship for one year

from date of installation.

Kohler Co. will, at its election, repair, replace or make appropriate adjustment where Kohler Co. inspection

discloses any such defects occurring in normal usage within one (1) year after installation. Kohler Co. is not

responsible for removal or installation costs. Use of in-tank toilet cleaners will void the warranty.

To obtain warranty service contact Kohler Co. either through your Dealer, Plumbing Contractor, Home

Center or E-tailer, or by writing Kohler Co., Attn.: Customer Care Center, 444 Highland Drive, Kohler, WI

53044, USA, or by calling 1-800-4-KOHLER (1-800-456-4537) from within the USA and Canada, and

001-800-456-4537 from within Mexico, or visit www.kohler.com within the USA, www.ca.kohler.com from

within Canada, or www.mx.kohler.com in Mexico.

IMPLIED WARRANTIES INCLUDING THAT OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE ARE EXPRESSLY LIMITED IN DURATION TO THE DURATION OF THIS

WARRANTY. KOHLER CO. AND/OR SELLER DISCLAIM ANY LIABILITY FOR SPECIAL,

INCIDENTAL OR CONSEQUENTIAL DAMAGES. Some states/provinces do not allow limitations on how

long an implied warranty lasts, or the exclusion or limitation of special, incidental or consequential damages,

so these limitations and exclusions may not apply to you. This warranty gives you specific legal rights. You

may also have other rights which vary from state/province to state/province.

This is Kohler Co.’s exclusive written warranty.

Warranty

For Mexico

KOHLER CO.

It is recommended that at the time of purchase, you verify that all accessories and components are complete

in this package.

This Kohler product is warranted to be free of defects in material and workmanship for one (1) year from the

date of purchase as shown on the invoice or receipt.

1. Kohler Co. will only service its commercialized products through its authorized distributors.

2. To obtain warranty service, please present the invoice and corresponding warranty.

3. Through its authorized distributors, Kohler Co. promises to repair the defective product or provide a new

Kohler Co. 17 1199249-2-A

Page 18

Warranty (cont.)

replacement or an equivalent model (in those cases that the model has been discontinued) when the product

is beyond repair, without any charge to the consumer.

4. The time of repair will not exceed six (6) weeks commencing on the date the product is received.

5. It is recommended that the consumer save the invoice or receipt as additional protection, as it may

substitute the warranty in the case that there is a discrepancy in the validity of the warranty.

EXCEPTIONS AND RESTRICTIONS

The Warranty will not be valid in the following cases:

1. When the product is not operated in accordance with the instructions concerning use and operation set

forth in the owner’s manual or installation instructions, and when the recommendations and warnings

included are not observed.

2. When the product has been modified or dismantled partially or totally; or has been used in a negligent

fashion and as a consequence has suffered damages attributable to the consumer, individual, or hardware not

authorized by Kohler Co.

3. This warranty does not cover the damages as a result of disaster such as fire or acts of God, including

flooding, earthquake, or electric storms, etc. To obtain a list of distributors in your area where you can

exercise your rights under this warranty, please call 001-800-456-4537.

KOHLER CO., KOHLER, WI 53044 U.S.A.

IMPORTER:

INTERNACIONAL DE CERÁMICA, S.A.B. DE C.V.

AV. CARLOS PACHECO NO. 7200

CHIHUAHUA, CHIH., MEXICO C.P. 31060

TEL: 52 (14) 29-11-11

Troubleshooting

NOTICE: This section is for general aid only. A Kohler Co. Authorized Service Representative or qualified

electrician should correct any electrical problems. For warranty service, call 1-800-4KOHLER from within

the USA and Canada, or 001-800-456-4537 from within Mexico.

NOTE: The product model number is printed on a label on the blower side of the bath.

NOTE: For service parts information, visit your product page at www.kohler.com/serviceparts.

Troubleshooting the Bath System

Symptoms Probable Causes Recommended Action

1. User keypad does not

illuminate when Power

icon is pressed or the

outer ring is rotated.

A. No power to control. A. Check wiring and connect power.

B. Ground-Fault Circuit-Interrupter

(GFCI) or Residual Current

Device (RCD) tripped.

C. Wiring harness from user

keypad to control is loose,

disconnected or damaged.

D. User keypad does not work. D. Replace the user keypad.

E. Control does not work. E. Replace the control.

B. Reset GFCI or RCD. If it trips

again, refer to ″Ground-Fault

Circuit-Interrupter (GFCI) or

Residual Current Device (RCD)

trips when bath is turned on.″

C. Check wiring for proper

connections. Replace the wiring

harness if necessary.

1199249-2-A 18 Kohler Co.

Page 19

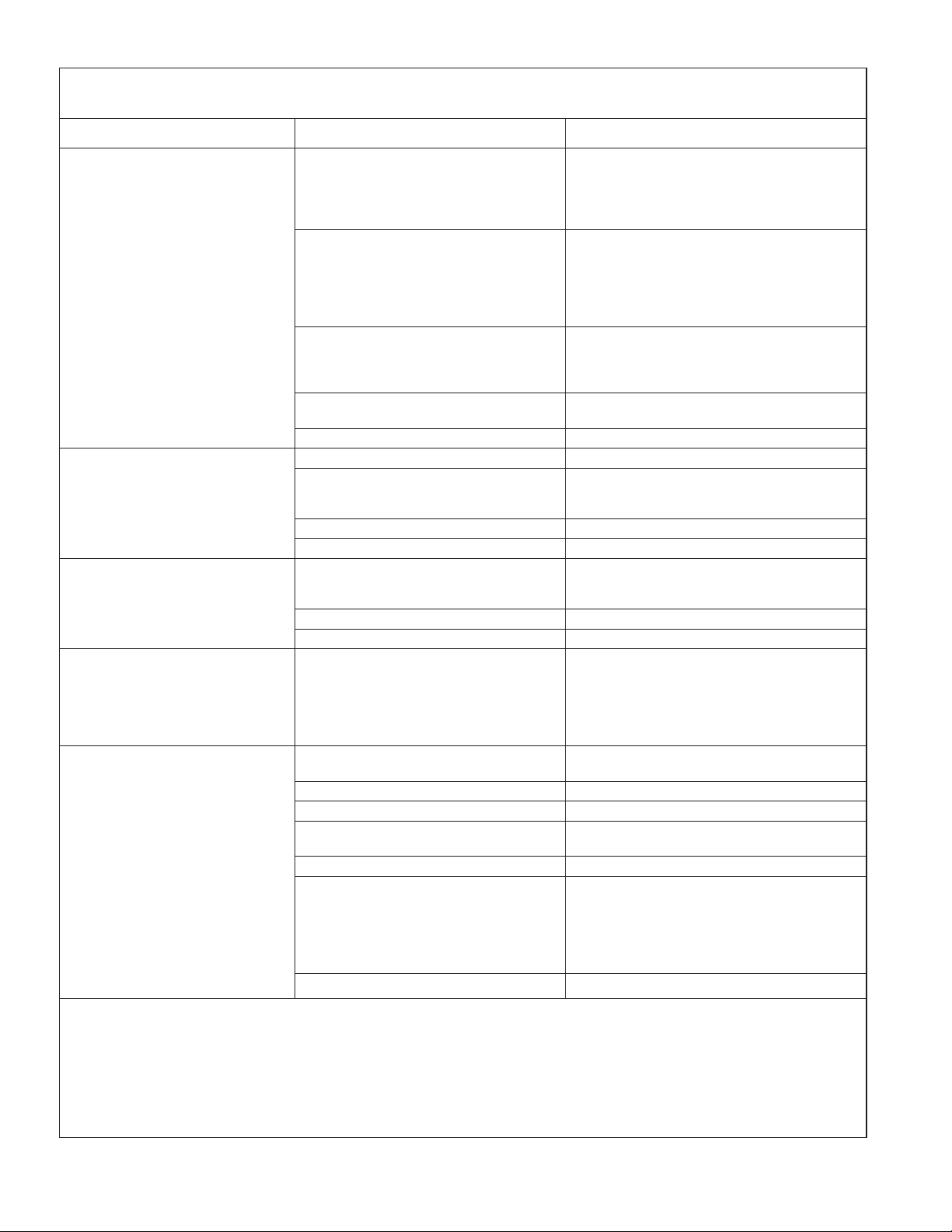

Troubleshooting (cont.)

Symptoms Probable Causes Recommended Action

2. Ground-Fault

Circuit-Interrupter (GFCI)

or Residual Current

Device (RCD) trips when

bath is turned on.

3. User keypad is

illuminated, but does not

respond to icons or outer

ring.

4. Blower motor will not

start.

5. Blower motor stops

running and will not

immediately restart.

Keypad is illuminated.

6. Blower motor starts, some

but not all airjets are

bubbling.

A. Electrical harness is wet or

damaged.

B. Electrical wiring to the bath

junction box is wet or damaged;

or the power amperage is

inadequate.

C. Electrical wiring to the bath

power cord is wet or damaged.

D. Blower motor is shorted

internally.

E. Control is shorted internally. E. Replace the control.

A. Control program is locked. A. Reset GFCI or RCD.

B. P5 plug assembly harness from

user keypad to control is loose,

disconnected, or damaged.

C. User keypad does not work. C. Replace the user keypad.

D. Control does not work. D. Replace the control.

A. Power cord from blower motor

to control is loose, disconnected,

or damaged.

B. Blower motor does not work. B. Replace the blower motor.

C. Control does not work. C. Replace the control.

A. Blower motor overheated and

protection device activated.

A. Blower motor speed is too low. A. Increase speed set point to blower

B. Blower air inlet is blocked. B. Clear blower air inlet.

C. Blower motor does not work. C. Replace the blower motor.

D. Blower motor discharge is

blocked.

E. Check valve does not work. E. Replace the check valve.

F. Airjets are clogged. F. Use a small between-the-teeth

G. Some zones are closed. G. Operate all zones.

A. Check for wet connections. Dry the

connections and repair the leak.

Check for insulation or connector

damage. Replace the harness if

damaged.

B. Have a qualified electrician

diagnose and correct the problem

in accordance with applicable

building and electrical codes; or

increase the power amperage to 20

A.

C. Have a qualified electrician

diagnose and correct the problem

in accordance with applicable

building and electrical codes.

D. Replace the blower motor.

B. Check wiring for proper

connections. Replace the wiring

harness if necessary.

A. Check wiring for proper

connections.

A. Check for blockage at air inlet.

Remove blockage and allow motor

to cool. Refer to ″User keypad is

illuminated, but does not respond

to icons or outer ring. Blower

motor will not start.″

motor.

D. Clear blockage.

dental brush and white vinegar.

Dip the brush in the vinegar, brush

the hole, rinse the brush in clean

water, and then use the wet rinsed

brush to rinse the hole.

Kohler Co. 19 1199249-2-A

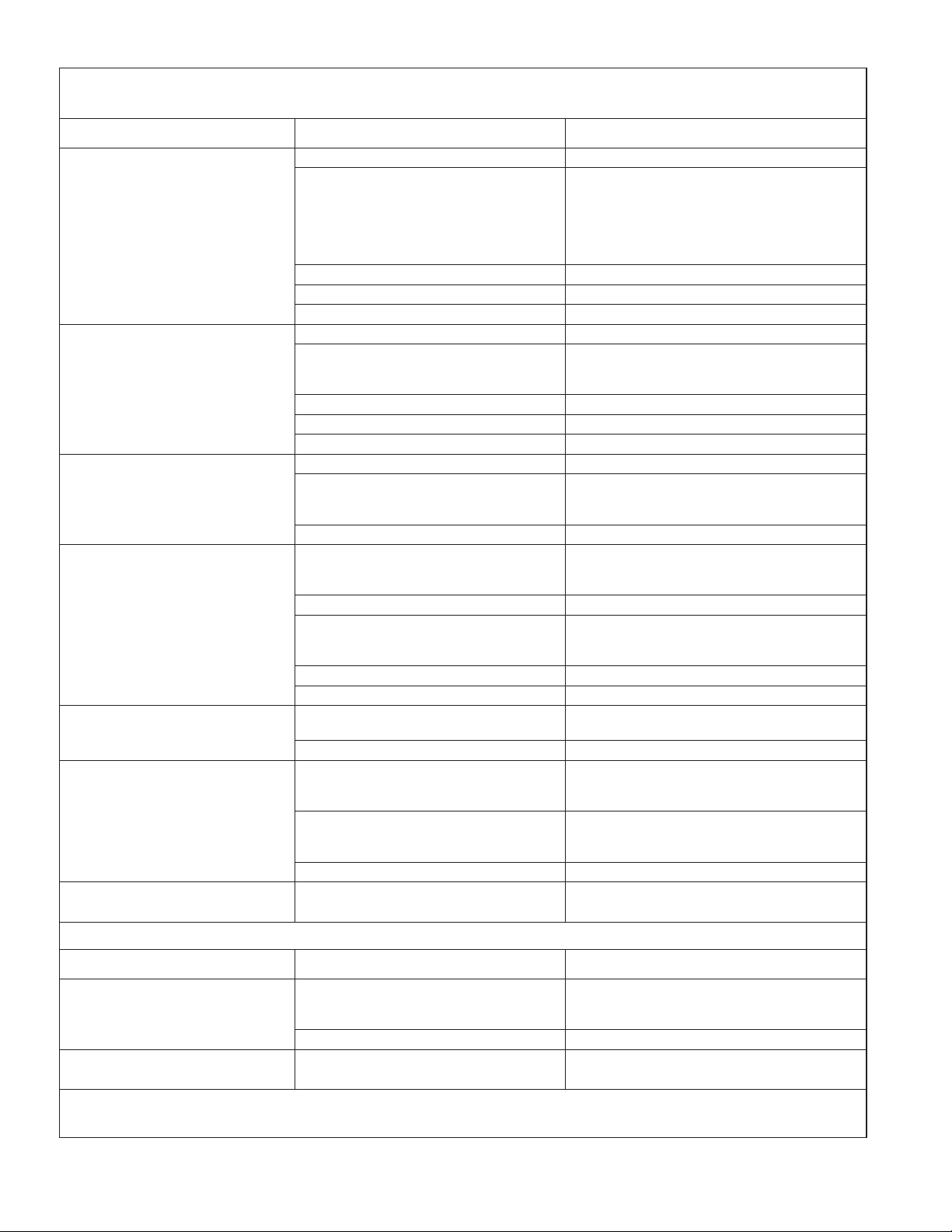

Page 20

Troubleshooting (cont.)

Symptoms Probable Causes Recommended Action

7. Blower motor runs but no

air bubbles are formed.

8. Blower motor operates,

air bubbles are formed,

zone controls work, but

variable speed feature

does not work.

9. Blower motor won’t turn

off when the Power icon

on user keypad is

pressed.

10. A zone does not produce

air bubbles but another

zone operates normally.

11. Surge mode does not

work.

12. Water spillage or damage

observed under the bath.

13. Bath does not purge

automatically.

A. Blower air inlet is blocked. A. Clean blower air inlet.

B. Airjets are clogged. B. Use a small between-the-teeth

C. Check valve does not work. C. Replace the check valve.

D. Blower motor does not work. D. Replace the blower motor.

E. Control does not work. E. Replace the control.

A. Blower air inlet is blocked. A. Clear blower air inlet.

B. Loose, disconnected, or

damaged wiring harness.

C. User keypad does not work. C. Replace the user keypad.

D. Blower motor does not work. D. Replace the blower motor.

E. Control does not work. E. Replace the control.

A. User keypad does not work. A. Replace the user keypad.

B. Loose, disconnected, or

damaged wiring harness.

C. Control does not work. C. Replace the control.

A. Zone is not selected. A. Select the zone according to the

B. Butterfly valve does not work. B. Replace the butterfly valve.

C. Loose, disconnected, or

damaged wiring harness.

D. User keypad does not work. D. Replace the user keypad.

E. Control does not work. E. Replace the control.

A. User keypad does not work. A. Replace the user keypad.

B. Control does not work. B. Replace the control.

A. Drain or overflow leaking. A. Repair or replace the drain

B. Wall, deck, and/or shower door

is improperly sealed.

C. Cracked piping or air channels. C. Refer to the manufacturer.

A. Level sensor wires are

disconnected.

dental brush and white vinegar.

Dip the brush in the vinegar, brush

the hole, rinse the brush in clean

water, and then use the wet rinsed

brush to rinse the hole.

B. Check wiring for proper

connections. Replace the wiring

harness if necessary.

B. Check wiring for proper

connections. Replace the wiring

harness if necessary.

instructions in the ″Operating

Instructions″ section.

C. Check wiring for proper

connections. Replace the wiring

harness if necessary.

assembly according to the

manufacturer’s instructions.

B. Apply silicone sealant at the seams

between the bath and the wall,

deck, or door.

A. Connect the level sensor wires.

Chromatherapy (if equipped)

Symptoms Probable Causes Recommended Action

14. Chromatherapy lights do

not work.

15. Chromatherapy does not

cycle.

1199249-2-A 20 Kohler Co.

A. Loose, disconnected or damaged

wiring/connections.

B. Control does not work. B. Replace control.

A. Chromatherapy harness

assembly does not work.

A. Check wiring for proper

connections. Replace wiring if

necessary.

A. Replace the chromatherapy harness

assembly.

Page 21

Guide d’installation et d’entretien

Baignoire à jets d’air

Instructions d’installation

AVERTISSEMENT: Lors de l’utilisation de produits électriques, toujours observer les

précautions de base, notamment:

DANGER: Risque d’électrocution. Raccorder uniquement à un circuit protégé par un disjoncteur

de fuite de terre (GFCI)*.

Les matériaux de construction et le câblage doivent être acheminés loin du souffleur et des autres

composants qui dégagent de la chaleur de l’appareil.

Installer de façon à permettre l’accès pour l’entretien.

Un connecteur à pression pour câbles marqué ″Earth/Ground″ (Terre/Masse) est fourni dans le

compartiment de câblage. Afin de réduire les risques de choc électrique, raccorder ce connecteur à une borne

de terre du panneau de service électrique ou du panneau d’alimentation avec un câble en cuivre ayant la

même dimension que le conducteur du circuit qui alimente cet équipement.

Des connecteurs à pression par câble sont fournis sur l’extérieur de la boîte de jonction ou de la commande

incluse dans cet appareil afin de permettre la connexion d’un conducteur de mise à la terre entre cet appareil

et toutes les autres surfaces de métal avoisinantes, tel que requis par les normes locales.

Une borne de mise à la terre est incluse dans le boîtier du câblage sur place. Pour réduire les risques

d’électrocution, cette borne doit être raccordée à un dispositif de mise à la terre fourni dans le panneau

d’alimentation électrique, avec un conducteur ayant le même calibre que celui des conducteurs du circuit qui

alimente cet équipement.

Une mise à la terre est requise. L’appareil doit être installé par un représentant qualifié et doit être mis à la

terre.

AVERTISSEMENT: Risque de blessures ou d’endommagement du matériel. Toutes les

instructions doivent être lues avec la plus grande attention avant de commencer l’installation, et

toutes les conditions suivantes doivent être respectées.

AVERTISSEMENT: Risque d’électrocution. Un électricien qualifié doit effectuer toutes les

connexions électriques.

AVERTISSEMENT: Risque d’électrocution. Déconnecter l’alimentation électrique avant d’effectuer

un entretien ou une réparation.

AVIS: Respecter tous les codes de plomberie et électriques locaux. Installer cet appareil conformément

au Code canadien de l’électricité, Partie 1.

*Hors de l’Amérique du Nord, ce dispositif peut être connu sous le nom de dispositif à courant résiduel

(RCD).

Information sur le produit

Installations électriques requises

L’installation doit comprendre un disjoncteur de fuite de terre (GFCI) ou un dispositif à courant résiduel

(RCD) de classe A. Le GFCI ou le RCD protège contre les dangers d’électrocution par une tension

phase-terre. Utiliser une alimentation dédiée de 220 - 240 V, 20 A, 50/60 Hz.

Kohler Co. Français-1 1199249-2-A

Page 22

Information sur le produit (cont.)

Notices du produit

AVERTISSEMENT: Risque de blessures ou d’endommagement matériel. Des modifications non

approuvées pourraient provoquer un fonctionnement dangereux ou affecter la performance de la

baignoire. Ne pas changer l’emplacement du moteur du souffleur et ne pas effectuer d’autres

modifications sur le système de baignoire sans le kit ou sans autres instructions publiées, vu que ce

qui pourrait affecter la performance et l’opération sans danger du produit. Kohler Co. décline toute

responsabilité sous sa garantie et pour toutes blessures ou tous dommages causés par de telles

modifications non autorisées. Se référer à la section ″Préparer le souffleur (site à distance″ pour les

exigences de déplacement du moteur du souffleur, les recommandations, et l’information de

couverture de la section.

AVIS: Garder l’espace autour du moteur du souffleur propre et exempt de débris. S’assurer que l’espace

autour du moteur du souffleur est exempt de sciure, de matériau isolant, de saleté, ou d’autres petits

débris volatiles. De tels matériaux pourraient boucher l’orifice d’admission du moteur du souffleur et

réduire le débit d’air à travers le souffleur.

Caractéristiques

Les composants assemblés en usine incluent un moteur de souffleur, un faisceau d’air, une commande, un

clapet de non retour, des valves papillon, des lumières de chromothérapie (si fournies), des faisceaux

électriques, et un clavier utilisateur illuminé. Aucun montage n’est nécessaire excepté celui du câblage

électrique et de la plomberie.

Outils et matériaux

Mastic à la silicone

Lunettes de protection

Mètre ruban

Clé à tuyau

Crayon Cisailles de ferblantier

Plus:

• Matériaux et outils à bois classiques

• Toile de protection

• Cales de métal

• 2x4

Niveau

Préparer le souffleur (Installation à distance)

AVIS: Le moteur du souffleur et le clapet de non retour doivent être déplacés ensemble. Ne pas

relocaliser l’un sans l’autre.

REMARQUE: Cette baignoire peut être installée telle que reçue, ou avec le moteur du souffleur et le

clapet de non-retour déplacé vers un autre emplacement. Se référer aux sections appropriés dans ce

manuel pour obtenir des instructions relatives à l’installation en question. Lire cette section avant de

déplacer le souffleur.

1199249-2-A Français-2 Kohler Co.

Page 23

Préparer le souffleur (Installation à distance) (cont.)

Déplacer le souffleur et le clapet de non-retour pour l’amener aussi près que possible de la

baignoire, afin d’obtenir une performance maximale. Ne pas déplacer le souffleur et le clapet de

non-retour à une distance de plus de 15’ (4,5 m) de la baignoire.

•

Positionner le souffleur à une distance de 1-1/2″ (38 mm) au-dessus du plancher. Ne pas monter le

moteur du souffleur avec sa décharge dirigée vers le haut.

•

Utiliser un PVC de 1-1/2″ ou un tube rigide équivalent.

•

L’installation de la tuyauterie doit être conforme aux codes de plomberie et de bâtiment locaux.

S’assurer que l’installation ne réduit pas le classement au feu des murs. La tuyauterie doit être

supportée à des intervalles sur la longueur conformément aux codes locaux.

•

S’assurer que l’espace du moteur du souffleur soit propre et exempt de poussière ou de débris.

•

Installer un panneau d’accès pour permettre un entretien du moteur du souffleur.

•

Le câble d’alimentation minimum de 18 AWG au moteur du souffleur doit être conforme aux

exigences de tous les codes d’électricité ou de construction applicables. S’assurer que l’installation ne

réduit pas le classement au feu des murs.

•

Le cordon d’alimentation doit être supporté à des intervalles sur sa longueur, conformément aux

codes locaux. Les cordons d’alimentation ne doivent pas reposer sur des surfaces ou sur des

planchers susceptibles aux inondations.

•

Tous les matériaux nécessaires au déplacement doivent être fournis par l’installateur.

Outils et matériaux supplémentaires dont vous avez besoin:

•

Pinces d’électricien

•

Tournevis variés

•

Clé à molette

•

Perceuse et mèches pour installer les dispositifs de fixation du souffleur.

•

Un câble à gaine 18 AWG non-métallique, deux conducteurs avec terre, et avec clips de support, tel

que requis.

•

Un boîtier de jonction électrique 4″ (102 mm) x 2″ (51 mm) avec couvercle, joint d’étanchéité

statique, et vis de fixation

•

Trois serre-câbles - l’un d’entre eux doit s’adapter sur le couvercle du moteur du souffleur avec les

filets National Pipe Thread (NPT) standard. Les deux autres doit s’adapter aux orifices du nouveau

boîtier de jonction.

•

Six connecteurs de fils (écrous pour fils ou équivalent).

•

PVC 1-1/2″ ou autre tube rigide avec raccords, unions, ciment PVC (ou méthode de fixation

équivalente) et des clips de support, tels que requis

•

Quatre dispositifs d’attache (comme des vis à bois à tête plate ou des dispositifs d’ancrage en béton)

pour fixer le moteur du souffleur.

•

Un fil de fusion de calibre 8 en cuivre solide, 36″ (914 mm)

Kohler Co. Français-3 1199249-2-A

Page 24

Alcôve À encastrer par le dessus

Positionner la

plomberie de

raccordement.

Effectuer la construction

selon les dimensions

du produit.

Construire la

charpente à

montants de 2x4

selon l'information

Positionner la

plomberie de

raccordement.

du plan de

raccordement.

Vérifier que le sous-plancher

Vérifier que le

sous-plancher offre un

offre un support adéquat et

qu'il est plat et nivelé.

support adéquat et qu'il est plat et nivelé.

1. Préparer le site

AVERTISSEMENT: Risque de blessures. Cette baignoire en fonte est très lourde. Obtenir

suffisamment d’aide pour la soulever et la déplacer avec précaution.

AVIS: Mesurer le produit pour la préparation du site. Noter le numéro de modèle se trouvant sur le

souffleur, puis visiter la page des produits sur le site www.kohler.com pour obtenir de l’information

supplémentaire.

AVIS: Fournir une ventilation adéquate et un minimum de 15 pieds cube (0,4 mètre cube) d’espace d’air à

l’endroit d’installation pour le refroidissement du moteur et pour fournir assez d’air au souffleur. Ne pas

installer le moteur du souffleur à une distance plus proche de 1″ (25 mm) du mur ou d’autres objets.

Panneau

d'accès

AVIS: Fournir un large espace non restreint pour pouvoir accéder au souffleur. Un accès doit être prévu

pour l’entretien du souffleur et des commandes. L’accès doit être situé juste à côté du souffleur

AVIS: Ne pas soulever la baignoire par la tuyauterie ou le souffleur, et ne pas utiliser ceux-ci comme

support structurel de la baignoire. Afin d’éviter d’endommager la baignoire, soulever sur les côtés de

celle-ci.

AVIS: Ne pas supporter le poids de charge de la baignoire par le rebord.

REMARQUE: Une installation à encastrer par le dessus, en alcôve ou en coin est possible, selon le produit

choisi.

Déballer et examiner soigneusement la nouvelle baignoire afin d’y déceler tout dommage avant

d’effectuer l’installation. Si des dommages sont notés, ne pas installer la baignoire; contacter le

concessionnaire.

S’assurer que le plancher offre un support adéquat pour la baignoire et vérifier que le sous-plancher

est plat et nivelé.

Construire une charpente avec des montants de2x4.

Installer un panneau d’accès pour permettre un entretien futur de la pompe. Le panneau d’accès

doit avoir une largeur de 34″ (864 mm) et une hauteur de 15″ (381 mm) au moins.

Installer la plomberie de raccordement.

Installer le drain sur la baignoire selon les instructions du fabricant du drain.

Protéger la surface de la baignoire en plaçant une toile de protection propre dans le bas du bassin.

1199249-2-A Français-4 Kohler Co.

Page 25

Moteur

souffleur

Pieds en

caoutchouc

isolant

Mettre de niveau à l'aide

des cales en métal sous les

pieds.

Couper les sangles

de retenue.

Contrôle

2. Installer la baignoire

AVERTISSEMENT: Risque de blessures. Cette baignoire en fonte est très lourde. Obtenir

suffisamment d’aide pour la soulever et la déplacer avec précaution.

AVIS: Ne pas soulever la baignoire par la tuyauterie ou le souffleur, et ne pas utiliser ceux-ci comme

support structurel de la baignoire. Afin d’éviter tout endommagement de la baignoire, soulever celle-ci par

les côtés.

Déplacer soigneusement la baignoire pour la positionner.

Niveler la baignoire en posant des cales métalliques sous les pieds selon les besoins. Vérifier le

niveau le long du rebord. S’assurer que la baignoire repose sur les quatre pieds.

Couper les sangles de retenue

IMPORTANT! Cette étape est nécessaire pour que la baignoire fonctionne plus silencieusement.

Couper les deux sangles de retenue du souffleur.

Installer la plomberie

Insérer la pièce de raccordement du drain dans le siphon. Fixer l’about du drain sur le siphon.

Installer la vanne de robinet.

Rechercher des fuites dans les connexions du drain.

Kohler Co. Français-5 1199249-2-A

Page 26

Raccorder selon les codes nationaux et locaux.

Des cosses d'ouverture sont localisées

au-dessus du boÎtier de jonction.

Valve clapet de non-retour

Cordon du

moteur souffleur

Alimentation

du contrôle

Contrôle

Alimentation externe

Connecteur câble

Terre

(Vert à

rayures jaunes)

Depuis

le contrôle

Brun (L2)

Connecteurs

L'électricien doit

câbles

prévoir un collier de serrage adéquat.

Module

neutre

(Dans le

boîtier de

disjoncteur)

Source 120/240 VAC

N

120 V

L1

120 V

L2

Disjoncteur

typique à deux

pôles avec GFCI

240 V

* Ligne neutre

(Câble

blanc bouclé)

* Equippement

de mise à la terre

Boîtier du

disjoncteur

*L2

240 V

*L1

Pas de

connexion (Neutre)

Câblage site (Du

boîtier de jonction

au disjoncteur GFCI)

Câblage typique pour l'Amérique du Nord

* Connexions à

faire au disjoncteur

Boîtier de jonction

du contrôle

d'alimentation

Bleu (L1)

3. Effectuer les connexions électriques - Standard

REMARQUE: Le numéro de modèle du produit est imprimé sur une étiquette placée du côté souffleur de

la baignoire. Cette étiquette identifie également les caractéristiques électriques du produit. Toutes les

baignoires sont équipées d’un boîtier de jonction de câblage et sont conçues pour fonctionner entre 220

Vet240V,à50HZou60Hz.

AVERTISSEMENT: Risque d’électrocution. S’assurer que l’alimentation a été débranchée avant

d’effectuer les procédures suivantes.

AVERTISSEMENT: Risque d’électrocution. Connecter le souffleur à un disjoncteur de fuite de

terre (GFCI) ou à un dispositif à courant résiduel (RCD) mis à la terre de manière adéquate. Ceci

fournira une mesure de protection supplémentaire contre le risque d’électrocution par tension

phase-terre. Un circuit dédié de 220-240 V, 20 A, 50/60Hz est nécessaire.

IMPORTANT! La charge neutre n’est pas utilisée. Il ne devrait pas y avoir de connexion à la borne de

charge neutre sur le disjoncteur de fuite de terre (GFCI). Le fil vert avec la bande jaune est la terre de

l’équipement et doit être connecté sur le bus neutre dans la boîte du disjoncteur principal.

REMARQUE: Le câblage électrique comprend une antenne pour la télécommande optionnelle. Ne pas

modifier ni endommager cette antenne pendant l’installation.

Effectuer le branchement sur la boîte de jonction. La boîte de jonction contient des fils de couleur

bleue, brune et verte à rayure jaune, ainsi qu’une cosse de mise à la terre.

Suivre tous les codes électriques locaux. Raccorder conformément aux codes nationaux et locaux.

1199249-2-A Français-6 Kohler Co.

Page 27

Vis de montage

du moteur-souffleur

Coude

Valve

clapet de

non-retour

Couvercle

Boîte de

jonction

Plancher

Vis

Contrôle

Au moteur-souffleur

Prise

électrique du

moteur-souffleur

4. Déconnecter le moteur du souffleur - À distance

AVIS: Cette section s’applique uniquement aux installations dans lesquelles le moteur du souffleur et

le clapet de non-retour sont déplacées à un nouvel emplacement.

AVIS: Ne pas couper la tuyauterie du souffleur pour cette installation.

AVIS: Le clapet de non-retour doit être déplacé avec le moteur du souffleur. Ne pas déconnecter le

clapet de non-retour du té.

Retirer le moteur du souffleur et le clapet de non-retour

Déconnecter la prise électrique du moteur du souffleur de la commande.

Retirer tous les serre-câble qui soutiennent le cordon du moteur du souffleur.

Retirer et conserver la vis qui maintient le clapet de non-retour sur le coude PVC.

Retirer et conserver les quatre vis de fixation de la plinthe.

Faire glisser le moteur du souffleur et le clapet de non-retour pour les éloigner du coude, et retirer

le moteur du souffleur de la baignoire.

Préparer le site

REMARQUE: Se référer à la section ″Préparer le souffleur (Site à distance)″ pour obtenir de l’information

détaillée sur le déplacement du souffleur.

Préparer le site d’installation du moteur du souffleur. Le site doit être compris dans un rayon de 15’

(4,5 m) de la baignoire.

Installer le panneau d’accès pour l’entretien du moteur du souffleur.

Préparer les voies d’acheminement pour la tuyauterie PVC et le nouveau câble d’alimentation du

moteur du souffleur. Suivre tous les codes applicables.

Kohler Co. Français-7 1199249-2-A

Page 28

Vis de montage du

moteur souffleur

Tuyauterie rigide de 1-1/2"

(non fournie)

Valve clapet de non-retour

1-1/2" (38 mm) Min

Vis

Vis

5. Monter le moteur du souffleur et le clapet anti-retour - À distance

REMARQUE: Le moteur du souffleur doit être monté horizontalement à 1-1/2″ (38 mm) au-dessus du

plancher. Ne pas monter le moteur du souffleur avec sa décharge dirigée vers le haut.

REMARQUE: Se référer à la section ″Préparer le souffleur (site à distance)″ pour les autres exigences

relatives au déplacement du moteur du souffleur.

Au nouvel emplacement du moteur du souffleur, installer un bloc de 1-1/2″ (38 mm) (non-fourni)

de haut pour supporter le moteur du souffleur.

Utiliser le moteur du souffleur comme gabarit afin de marquer l’emplacement des quatre boulons de

fixation ou vis.

Percer quatre trous pilotes de 1/8″ (3 mm) pour les vis de fixation du moteur du souffleur.

Installer et supporter le PVC ou une autre tuyauterie rigide de 1-1/2″ (non fournie) entre

l’emplacement du moteur du souffleur et le faisceau pneumatique.

Connecter la nouvelle tuyauterie au faisceau pneumatique existant sans modifier ce dernier. Aligner

le nouveau tuyau et sécuriser la connexion avec du ciment PVC. Laisser prendre le ciment PVC

selon les instructions du fabricant.

Connecter l’ensemble du clapet de non-retour à la nouvelle tuyauterie. Aligner le nouveau tuyau

avec l’ensemble du clapet de non retour et percer un trou pour la vis de fixation existante. Utiliser

un mastic à la silicone ou un produit d’étanchéité équivalent au niveau des connexions et réutiliser

la vis qui a été retirée auparavant. Laisser prendre le mastic selon les recommandations du fabricant.

Positionner le moteur sur le bloc de support. Réinstaller la vis sur le clapet de non-retour.

Fixer le moteur du souffleur sur le nouveau bloc de support avec les vis de fixation.

1199249-2-A Français-8 Kohler Co.

Page 29

Moteur

souffleur

Bouchon

Réducteur

de tension

Couvercle

d'accès

Retirer les vis, le couvercle et

couper le câble existant à environ

4 " (102 mm) du moteur souffleur.

6. Finir le câble au souffleur - À distance

Acheminer le câble d’alimentation

Acheminer le câble 18 AWG ou un câble équivalent (deux conducteurs avec terre) entre la baignoire

et le souffleur. Supporter et protéger le câble. Suivre tous les codes électriques locaux.

Préparer le souffleur pour une Installation à distance

Desserrer le réducteur de tension de câble sur le moteur du souffleur. Repousser l’écrou sur le câble

afin de fournir un espace pour le démontage du couvercle.

Retirer et conserver les deux vis du couvercle d’accès de l’arrière du moteur du souffleur. Tout en

desserrant les vis, vérifier périodiquement si le couvercle peut être reglissé sur le câble électrique.

Lorsque le couvercle est desserré, utiliser des pinces d’électricien ou un outil équivalent pour couper

le câble électrique à peu près à 4” (102 mm) de l’endroit où ce dernier entre dans le boîtier du

moteur du souffleur.

Tirer l’extrémité libre du cordon électrique à travers le couvercle, l’insertion et l’écrou de réduction

de tension.

Jeter l’écrou de réduction de tension existant et l’insertion.

Reconnecter la prise du moteur du souffleur à la commande.

Installer un réducteur de tension fileté NPT standard sur le couvercle du moteur du souffleur.

Connecter le nouveau câble d’alimentation au moteur du souffleur

Sur le fil conducteur en queue de cochon de 4″ (102 mm) du moteur du souffleur, dénuder la gaine

de câble d’environ 3″ (76 mm).

Sur le nouveau câble d’alimentation fourni par le client, dénuder la gaine du câble d’environ 2″ (51

mm).

Aux États-Unis, marquer les conducteurs blancs avec du ruban rouge ou noir tel que requis par le

National Electric Code (NEC).

Dénuder l’isolant de 3/8″ (10 mm) environ des fils conducteurs en queue de cochon et des fils

d’alimentation du moteur du souffleur.

Acheminer les nouveaux fils d’alimentation à travers le couvercle d’accès du moteur du souffleur et

le réducteur de tension.

Utiliser des écrous de câble ou d’autres méthodes de terminaison approuvées pour terminer les

conducteurs selon la façon suivante:

•

Connecter le fil en queue de cochon noir au conducteur L1 du câble d’alimentation.

Kohler Co. Français-9 1199249-2-A

Page 30

Finir le câble au souffleur - À distance (cont.)

•

Connecter le fil conducteur bleu en queue de cochon au conducteur L2 ou N du câble

d’alimentation.

•

Connecter le fil conducteur en queue de cochon vert avec rayures jaunes au conducteur de terre du

câble d’alimentation.

Avec les deux vis, réinstaller le couvercle d’accès sur le moteur du souffleur.

Serrer le réducteur de tension sur le câble d’alimentation au niveau du moteur du souffleur.

Retirer toute poussière ou tous débris de l’emplacement du moteur du souffleur.

1199249-2-A Français-10 Kohler Co.

Page 31

Second boîtier de jonction

Câble au

moteursouffleur

Bleu

Terre (vert à

rayures jaunes)

Marron

Écrous câble

Noir

Depuis

le contrôle

60 Hz

L1

L2

TERRE TERRE

NC NC

50 Hz

L1

N

Dénuder la gaine du câble

d'environ 3" (76 mm) du

câble et de la queue de cochon

du moteur-souffleur. Puis couper

le quatrième conducteur

brun non-utilisé à l'extrémité

de la gaine du câble.

Depuis le contrôle

Bleu

Noir

Vert avec rayures jaunes

Marron

Boîtier de jonction du contrôle d'alimentation

Adaptateur

du souffleur

Nouveau

câble au moteur

-souffleur

Second boîtier de jonction

Passer l'extrémité du cordon au nouveau

boîtier de jonction. Ajouter un réducteur

de tension.

Installer le boîtier de jonction avec le

couvercle et cosse (non fournie).

7. Installer le cordon au niveau de la commande - À distance

Installer le deuxième boîtier de jonction sur la commande

Installer un deuxième boîtier de jonction avec une cosse de fusion externe, deux réducteurs de

tension, et un couvercle (non fourni) sur la plaque d’adaptation du moteur du souffleur sur la

commande.

Connecter un fil de fusion solide en cuivre d’un calibre 8 de la cosse de fusion du nouveau boîtier

de jonction à la cosse de fusion restante de la commande. Respecter tous les codes électriques

locaux.

Queue de

cochon du

moteur-souffleur

Reconnecter le cordon d’alimentation du moteur du souffleur

Si requis, reconnecter le cordon d’alimentation du moteur du souffleur au niveau de la commande.

Acheminer le cordon d’alimentation du moteur du souffleur à travers un réducteur de tension sur le

deuxième boîtier de jonction. Serrer le réducteur de tension.

À l’extrémité du cordon d’alimentation sectionné, dénuder la gaine du câble d’environ 3″ (76 mm).

À l’aide d’un coinceur à câble, recouvrir le conducteur brun non utilisé dans la gaine du câble.

Dénuder 3/8″ (10 mm) environ d’isolant de fil des fils de commande restants.

Reconnecter le nouveau câble d’alimentation du souffleur

Acheminer le nouveau câble d’alimentation fourni par le client entre le souffleur et l’autre réducteur

de tension sur le deuxième boîtier de jonction. Serrer le réducteur de tension.

Dénuder la gaine du câble d’environ 3″ (76 mm).

Pour des installations aux États-Unis, marquer le conducteur blanc avec du ruban électrique rouge

ou noir tel que requis par le National Electric Code (NEC).

Dénuder l’extrémité des fils de 3/8″ (10 mm) environ.

Utiliser des dispositifs approuvés pour terminer les conducteurs comme ce qui suit:

•

Connecter le fil en queue de cochon noir au conducteur L1 du câble d’alimentation.

•

Connecter le fil conducteur bleu en queue de cochon au conducteur L2 ou N du câble

d’alimentation.

•

Connecter le fil conducteur en queue de cochon vert à rayures jaunes au conducteur de mise à la

masse ou de mise à la terre du câble d’alimentation.

•

Le câble brun n’est pas utilisé et doit être terminé avec un coinceur à câble.

Installer le couvercle sur le nouveau boîtier de jonction.

Kohler Co. Français-11 1199249-2-A

Page 32

Valve clapet de non-retour

Installation de moteur-souffleur à distance

Boîtier de jonction

du contrôle d'alimentation

Moteur-souffleur à distance

Nouveau câble au moteur-souffleur

Câble d'alimentation électrique

Cordon du moteur-souffleur

Alimentation électrique du contrôle

Second boîtier de jonction

(pour moteur-souffleur à distance)

8. Effectuer les connexions électriques - À distance

AVERTISSEMENT: Risque d’électrocution. Afin de réduire les risques d’électrocution, connecter la

commande à un disjoncteur de fuite de terre (GFCI) ou à un dispositif à courant résiduel (RCD) mis

à la terre de manière adéquate. Ceci fournira une mesure de protection supplémentaire contre le

risque d’électrocution par tension phase-terre. Un circuit dédié de 220-240 V, 20 A, 50/60Hz est

nécessaire.

AVERTISSEMENT: Risque d’électrocution. S’assurer que l’alimentation a été débranchée avant

d’effectuer les procédures suivantes.

S’assurer que le cordon d’alimentation de la commande est acheminé correctement au boîtier de

jonction d’alimentation de la commande. Le cordon d’alimentation de la commande comprend un fil

brun (Ligne 1), un fil bleu (Ligne 2), et un fil vert à rayures jaunes (masse ou terre).

Installer un réducteur de tension (non fourni) pour le câble d’alimentation sur le boîtier de jonction

d’alimentation de la commande.

Acheminer le câble d’alimentation au boîtier de jonction de l’alimentation de commande.

Tel que requis, dénuder la gaine et l’isolant des deux câbles pour effectuer les connexions.

Pour des installations aux États-Unis, marquer tout conducteur blanc avec du ruban rouge ou noir

tel que requis par la norme NEC.

Effectuer le branchement sur le boîtier de jonction de l’alimentation de commande.

Fournir un conducteur séparé de mise à la terre ou à la masse de l’équipement à la cosse de

terre/masse de secours sur le boîtier de jonction d’alimentation de commande. Le conducteur ne

peut pas être raccordé à un autre conducteur d’alimentation électrique. Suivre tous les codes

électriques locaux.

Raccorder conformément aux codes nationaux et locaux.

Nettoyer la surface de toute poussière et de tous débris.

Tous les faisceaux de câblage ont été précâblés en usine. S’assurer que tous les fils sont bien serrés.

REMARQUE: Le faisceau de câblage comprend une antenne pour la télécommande optionnelle. Ne pas

modifier ni endommager cette antenne pendant l’installation.

9. Terminer l’installation

Tester le fonctionnement de la baignoire

Remplir la baignoire à un niveau d’eau se trouvant à au moins 4″ (102 mm) au-dessus du haut du

jet le plus élevé.

1199249-2-A Français-12 Kohler Co.

Page 33

Terminer l’installation (cont.)

Faire fonctionner la baignoire pendant 5 minutes et s’assurer qu’aucun des raccords des tuyaux de

la baignoire ne présente de fuites. Rechercher des fuites le long de l’avant et des côtés de la

baignoire, et à l’arrière de celle-ci.

Pour obtenir de l’information supplémentaire sur le fonctionnement de la baignoire, se reporter à la

rubrique ″Instructions d’utilisation″.

Terminer l’installation

Installer le panneau mural hydrorésistant, ainsi que tous les matériaux du mur fini, de la

plate-forme, et du plancher.

Appliquer un mastic à la silicone pour sceller toutes les zones où la baignoire et le mur fini ou la

plate-forme entrent en contact.

Installer la garniture de robinet.

Nettoyer après l’installation

Lors du nettoyage après l’installation, ne pas utiliser de nettoyants abrasifs, vu que ceux-ci

risqueraient de rayer et d’abîmer la surface de la baignoire. Utiliser de l’eau chaude et un détergent

liquide pour nettoyer la surface de la baignoire.

Enlever les taches résistantes ou la peinture avec de l’essence de térébenthine ou un diluant pour

peinture. Ne pas laisser de nettoyants à base de distillats de pétrole rester en contact avec les

surfaces de la baignoire pendant une longue période. Retirer les résidus de plâtre en raclant avec