ION WIPER

"Separate Type"

X904484

(DTY-WB01)

(DTY-WBM01-S/DTY-WBM01-L)

Operating Instructions (Ver. 1. 0)

Introduction

This device uses the input air. When turning on this device, always input the air.

Never disassemble, repair, or modify this device. Otherwise, it can lead to an accident or device failure.

Do not point the nozzle tip to a person.

When this product is unusable or no longer necessary, the product should be disposed of as a piece of industrial

Please wire properly. Incorrect or inappropriate wiring can cause a functional failure.

This device has a high voltage generator. Do not cause abnormal discharge by moving a metal piece to the

Air contaminated with oil and/or solid matters cannot be used. For the supplied fluid, use the cleaned air (use a

To prevent dew condensation and freeze due to the blow from the product, maintain a dew-point temperature of

Thank you for purchasing "ION WIPER, Separate Type".

Although this device is not subject for the standards for electric installation as a high voltage apparatus,

this device uses 2000 V AC voltage. Please read this Operating Instructions manual and the Operating

Instructions of Ionizer Air blow Type [DTY-ELK01] for appropriate handling and operation of this device.

Please keep this manual for your reference and consult it as needed.

1. Safety Precaution

Warning

This device is not for explosion-proof or water-proof. Do not install this device in a location where combustible

gases and/or solvents are used (in a coating booth, for example). Otherwise, there is a risk of ignition and/or

explosion.

When cleaning the discharge needle, always turn off the device. Also, the tip of the discharge needle is sharp, pay

attention when handling the discharge needle. Otherwise, there is a risk of injury.

As high voltage is applied to the discharge needle equipped to the ionizer, do not move the fingers, body, and

metal pieces such as wires and tools close to the discharge needle. Otherwise, it can lead to an electric shock or

device failure. This device is a high voltage equipment. Do not install this device in a place exposed to water or oil,

high temperature, or high humidity. Especially, avoid a place with high humidity and a chance of dew

condensation.

The fluid used for the ionizer is the air. Do not use any other fluid.

Always turn off the device before performing the wiring, installation, and inspection tasks. Otherwise, it can lead to

an accident, electric shock, or device failure.

Wear the protective glasses and ear plugs to prevent scattering objects by the air blow from entering eyes and

noise induced deafness.

Install a shut-off valve on the supply side to ensure safety in case of a leak or breakdown.

Caution

Always ground the wire. Otherwise, it can lead to poor static charge removal characteristic or failure.

waste.

For the worker to be able to cut the power immediately, install a switch or a circuit breaker and label it properly.

For the DC power source, use output voltage DC 24 V with double or reinforced insulation.

Due to the EN specification, wiring should be within 30 m.

discharge needle while current is applied. Otherwise, it can lead to failure or damages of peripherals or this

device.

The ionizer generates ozone in the air. Ventilate the room when the ozone odor is felt.

Do not move your face closer to the ion outlet to check the ozone odor. Otherwise, there is a risk to damage the

nose and throat.

This product cannot be used if the following substances are included in the fluid used :

Organic solvent, phosphate hydraulic operating fluid, sulfurous acid gas, chlorine gas, acids.

Do not use this device in a location exposed to direct sunlight (ultra-violet ray); with dust, salt, or iron powder; high

humidity; or atmosphere with organic solvent, phosphate hydraulic operating fluid, sulfurous acid gas, chlorine

gas, or acids. Otherwise, it can lead to loss of function in short period, rapid decrease in performance or shorter

life span.

The life of the discharge needle varies depending on the operating environment. A poor operating environment

(atmosphere with high humidity, for example) and/or unclean discharge needle can degrade the performance. A

periodical maintenance is required.

Please be advised that inrush current would be applied when turning on this product and when the built-in DC fan

in the dust collecting unit starts.

filter with a nominal filtration rating of 40 μm or less). Drain or dust entered inside the product can cause an

operational failure.

the supplied fluid lower than the ambient atmosphere temperature using a refrigeration air dryer and/or an after

cooler.

Do not drop, step on, or hit the product. Otherwise, the product may be damaged.

Walls or objects near the exhaust slot of the dust collecting unit affects the exhaust ventilation. Please keep

enough spaces when installing the product.

For other warning and caution items, refer to the “Safety Precautions” in the general catalog.

- 26 -

2. Overview

ION WIPER Separate Type is an out-of-box static eliminator/particle removing apparatus to remove particles adhered on the workpiece

(charged material).

Ionized air coming out from the ionizer built into the blow unit neutralizes the static electricity on the charged material.

At the same time, the air blow from the blow nozzle blows out the particles on the material.

In addition, the dust collecting unit collects dusts and the filter catches the dust, exhausting from the rear of the project.

A unit type product for flexible installation to a device and a process and a box type product for installing on a workbench are available.

Verify that all the contents below are included in the package. If any item is missing, please contact your dealer (distributor) or a nearest

Koganei office.

[DTY-WB01]

Blow unit……x1 / L-shaped brackets and mounting (M4 x 0.5, length 6 mm) … 4 pieces each

[DTY-ZMW01]

Dust collecting unit…… x1 / L-shaped bracket … x4 *Four mounting screws (M4 x 0.5, length 6 mm) are fixed to the dust collecting

unit.

[DTY-WBM01-S/DTY-WBM01-L]

Box unit body…… x1 / Micro screw driver… x1 *Use the micro screw driver for operating the photoelectronic sensor switches.

21. System Configuration

[DTY-WB01]

Install the blow unit to a device to remove static charge/particles.

Connect the additional parts to the blow unit, as needed.

PC

Blow unit:

DTY-WB01-□-□

(Additional parts)

Control circuit

(such as PLC)

DC power/AC adapter

[DTY-WBM01]

The Box type product can be installed to a workbench to remove static charge/particles and collect particles.

PC

Control circuit

(such as PLC)

Nozzle:

DTY-NZW-□

Blow unit

Photoelectronic sensor

Photoelectronic

sensor:

DTY-ZSP□L-WB

Dust collecting unit:

DTY-ZMW01-□-□

Electrostatic potential

sensor:

DTY-EPS01-EA-□LWB

Housing (aluminum frame)

Dust collecting unit

DC power/AC adapter

Clear cover

(PET anti-electricity type)

Box type: DTY-WBM01-S/DTY-WBM01-L

- 27 -

3. Device Configuration and Features

Ionized air regulator

0.5 MPa using

the

Connector for the

The blow unit consists of various functional parts, including the ionizer (DTY-ELK01) and valves, as well as the electric/air control circuits

that operate these functional parts.

For collecting dusts, an additional part -- dust collecting unit (DTY-ZMW01) -- is available.

31. Terms and Functions of Each Part

[Blow unit: DTY-WB01-□-□]

Pressure gauge (for ionized air)

Setting pressure range: 0.05 - 0.5 MPa

LED indicators

Setting switches

Nozzle (ionized air outlet)

Power switch

[Dust collecting unit: DTY-ZMW01-□-□]

Dust collecting cable

Throttle valve for air blow

*) set to a value within a

range of 0.05 the pressure gauge (fo r

ioni zed air)

Communication

Nozzle (blow air outlet)

I/O connectors

photoelectronic

Air IN port (φ8 quick joint)

Impressed pressure range:

0.2 - 0.7 MPa

sensor

Connector for

electrostatic

potential sensor

Connector for the dust

collecting unit 2

Connector for the dust

collecting unit 1

Power connector

Fan filter (OUT)

Fan filter (IN)

Unit Term Feature Reference Section

Blow unit Power connector Power 24 V/0 V/FG is connected. 4-2-1. Power and ground

I/O connectors These connectors are used to connect PLC and other components to control

the blow unit.

Connectors for the dust

These connectors are used to connect to the dust collecting units. 4-2-3. Connecting the dust

collecting units 1 & 2

Connector for the

This connector is used to connect the photoelectronic sensor. 4-2-4. Connecting the

photoelectronic sensor

Connector for the

This connector is used to connect the electrostatic potential sensor. 4-2-5. Connecting the

electrostatic potential

sensor

Communication This port is used to connect to an external device such as a PC, and to

retrieve various settings and information.

Air IN port This is a piping port for the air blow and ionized air. 4-3. Air Piping

Nozzle (ionized air outlet) This is the nozzle from which the ionized air (for static charge removal) is

blown out.

Nozzle (blow air outlet) This is the nozzle from which the blow air (for static charge removal) is blown

out.

Throttle valve for air blow This valve adjusts the flow rate of the blow air (for static charge removal). 5-1. Operation Procedures (2)

Ionized air regulator This component adjusts the impressed pressure of the ionizer. 5-1. Operation Procedures (2)

Pressure gauge (for ionized

air)

This component displays the pressure applied to the built-in ionizer.

(Configured on the ionized air regulator)

Setting switches These switches are used to set the blow time/blow intermittent frequency. 5-1. Operation Procedures (3)

Power switch This switch is used to turn on/off the blow unit and the additional parts. 5-1. Operation Procedures (4)

LED indicators These indicators indicate the status of the blow unit and the additional parts. 5-2. LED Indicators

Dust

collecting

unit

Dust collecting cable This cable is connected to the blow unit. 4-2-3. Connecting the dust

Fan filter (IN) This is the filter on the suction side.

(This filter is designed to prevent foreign objects such as screws from entering

inside the product)

Fan filter (OUT) T his is the filter on the exhaust side. 4-4. Exhaust Ventilation

connection

4-2-2. Connecting to external

devices

collecting unit

photoelectronic sensor

electrostatic potential sensor

4-2-6. Connecting

communication devices

6. Communication

4-3. Air Piping

4-3. Air Piping

5-1. Operation Procedures (2)

collecting unit

4-4. Exhaust Ventilation

- 28 -

4. Installation and Wiring/Piping

41. Installation Precaution

• This product s hould be used an indoor environment. When ins talling this product, pay attention to the pollution by water and oil,

high temperature, and high humidity.

• Especially, a void a place where dew condensation is anticipated.

• Use the L-shaped bracket to securely fix the product. Do not install this product to an unstab le place.

The fi xing screws for the L-shaped bracket are M4 x length 5 mm. When the screws are prepared at the customer site, use

screws of M4 x length 5 mm to 10 mm.

• Box type DTY-WBM01 should be installed on a robust and flat place like a workbench. Do not install this product to an unstable

place.

• For the blow unit side operation area/air piping (φ8 tube), keep a space larger than 100 mm when installing this product.

Also, for the exhaus t from the dust collecting unit, keep a space larger than 100 mm when installing this produc t.

42. Wiring

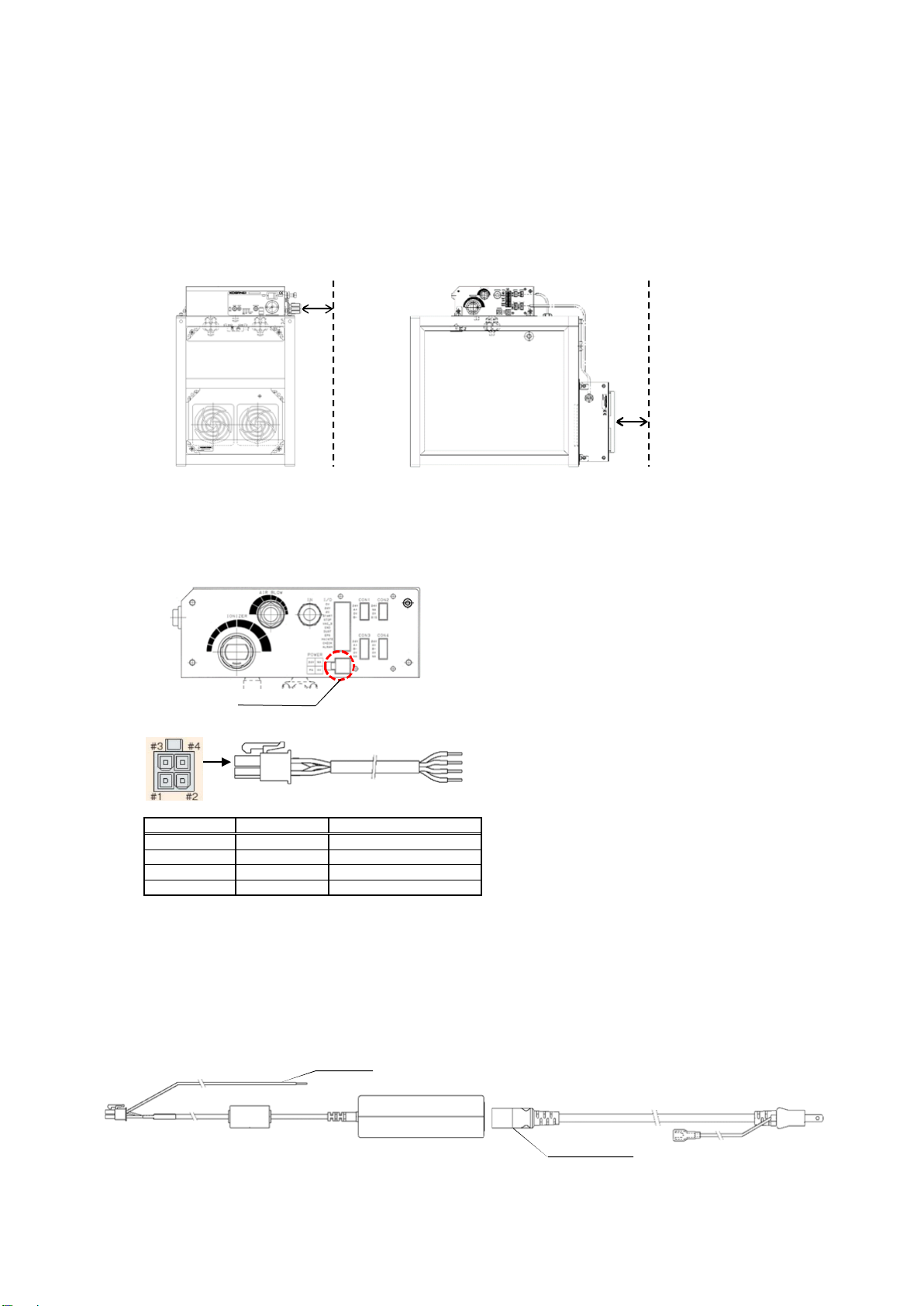

4-2-1. Power and ground connection

Connect the power cable (DTY-ZDW-□) or the AC adapter (DTY-ZPS4) to the power connector POWER.

Connect the cable securely b y inserting the cable until the lock lever locks on the power connector. To disconnect the cable push

down the lock lever fully and hold the connector and remove the cable. Do not apply excessive force to the lead wire.

Connect to the power (DC 24 V). The ground wire (green) o f the power cable must be grounded.

Power connector

(Connection using the power cable: DTY-ZDW-□)

Power cable: DTY-ZDW-□

Terminal No. Symbol Connecting cable color

1 NA White

2 0 V Black

3 24 VDC Red

4 FG Green

Connect the red power cable (terminal No.3) to the 24 V DC power.

Connect the black power cable (terminal No.2) to the 0 V power.

Ground the green power cable (terminal No.4).

Note: Connect the red and black power cables correctly.

As the reverse connection protective circuit is built-in, the product would not be damaged but does not operate correctly.

(Connection using the adapter: DTY-ZPS4)

Connect the AC adapter cable to the AC adapter, and connect to the AC outlet (100 VAC - 240 VAC, 50 Hz/60 Hz).

Ensure to ground the ground wire (green).

Ground wire

To the AC outlet

AC adapter: DTY-ZPS4

Note: Always ground the ground wire (green) to prevent static charge and to achieve full performance of the ionizer.

Incomplete grounding would degrade the discharge performance.

Note: 0 V and FG (ground terminal) are internally connected.

AC adapter cable

- 29 -

4-2-2. Connecting to external devices

Electrostatic

potential sensor

Main ci rcuit

Main ci rcuit

Main ci rcuit

Main ci rcuit

(Brown) 24V

(Brown) 24V

(Brown) 24V

(Brown) 24V

Photoelectronic

Dust collecting

unit (1)

Dust collecting

Signal connector

DC

power/AC

adapter

Communication

connector (485 IN)

connector (485

Communication

cable

Communication

cable

Communication

Load

Load

Load

Main ci rcuit

The fo llowing table shows the I/O connector specification. Refer to this table when connecting external devices such as PLC.

● Inp ut specification

Item Specification

Input voltage DC 24 V ± 5% (Common to DC 24 V power)

Input current 4.8 mA at DC 24 V

Input response time ≥ 30 ms

Input impedance 4.7 kΩ

● Output specification

Item Specification

Output s ystem Transisto r output, NPN open collector

(with overcurrent protection)

Output vo ltage 24 V DC ± 5%

Output c urrent 50 mA Max

Leakage current when the power is OFF 0.10 mA Ma x

Residual voltage when the powe r is ON 0.3 V Max at 5 mA; 1.0 V at 50 mA Max

Output response time ≥ 30 ms

PIN No.

DC 24 V output

Load

(White) A(+)

(Blue) 0V

(Black) B(-)

(Blue) 0V

(Black) SIG

(White) A(+)

(Blue) B(-)

Load

Load

Load

(Black) 0V

(White) A(+)

(Blue) B(-)

(Black) 0V

Communication

Internal circuit

External connection example

(White) A(+)

(Pink) B(-)

(Yellow) GN D

(White) A(+)

(Pink) B(-)

(Yellow) GN D

device

Next unit

[I/O connector terminal list]

Terminal No. Term I/O Description

1 ALARM Output

2 CHECK Outp ut

3 MAINT Output

4 EPS Output

5 DUST Output

6 END Output

7 VAC_START Output

8 STOP Inp ut

9 START Input

ZC

10

(Zero

Input

calibration)

11 DC24 V -

Output abnormality (refer to "8. Troubleshooting" for details)

Io nizer discharge abnormality (1 shot pulse of 200 ms is output at abnormality)

Maintenance output (air valve for blow/ionizer discharge needle)

Electrostatic potential sensor decision output (output when the output is below the setting

value)

Dust sensor decision output (output when the output is below the setting value)

Blow operation finish o utput (1 shot pulse of 200 ms is output when the operation finishes)

External device operation output

Operation stop input

Operation start input

Electrostatic potential sensor zero calibration input

This is a feature to calibrate the reference potential where the measured value equals to 0 V.

0 V potential is read while facing to the grounded metal plate or a space without charged

objects.

Power DC 24 V output

It is connected to the 24 V power of, for example, an external sensor. (Capacity 24 V/100 m A

Max)

12 0V -

I/O 0 V (common to the power connector 0 V)

Note: 0 V and FG (ground terminal) are internally connected.

Note: Value of the dust sensor is just a guide. It does not guarantee removal of dust from the workpiece.

- 30 -

4-2-3. Connecting the dust collecting unit

electrostatic

(Connect the round terminal)

Connect the dust co llecting unit connector CON3/CON4 when collecting dust using the dust collecting unit (DTY-ZMW01-□-□).

Up to two dust collecting units can be connected to a single blow unit.

(When the dust collecting units equipped with the dust sensors are connected to both of CON3 and CON4, the display and

output are based on the higher value of the dust sensors.

Connector for dust collecting unit 1

CON3

[Te rminal array]

Connector for dust collecting unit 2

CON4

Dust collecting unit: DTY-ZMW01-□-□

Terminal No. Symbol Connecting cable color

1 24 VDC Brown

2 A(+) White

3 B(-) Blue

4 0 V Black

5 NA(FG) -

4-2-4. Connecting the photoelectronic sensor

When the photoelectronic sensor (DTY-ZSP□L-WB) is used, connect it to the photoelectronic sensor connector CON2.

Connector for the

electrostatic potential

sensor

CON2

Photoelectronic sensor:

DTY-ZSP□L-WB

[Te rminal array]

Terminal No. Symbol Connecting cable color

1 24 VDC Brown

2 NA 3 0 V Blue

4 SIG Black

The photoelectronic sensor can be installed to the no zzle surface of the blow unit. Use the enclosed screws to mount the

sensor. (Eit her of 2 positions)

Photoelectronic sensor installation positions

(M3 screw)

4-2-5. Connecting the electrostatic potential sensor

When the electrostatic potential sensor (DTY-EPS01-EA-□LWB) is used, connect it to the electrostatic potential sensor connector

CON1.

Remove the coat of the tip of the electrostatic potential sensor cable (6 mm removal is recommended), crimp a rod terminal and

connect to CON1.

Ground the round te rminal of the cable. (Connect it to a L-shape bracket fixing screw.)

For the specification details/use method of the electrostatic potential sensor, refer to the operating instructions of [Electrostatic

potential sensor DTY-EPS01].

Connector for the electrostatic potential sensor

CON1

Ground

Electrostatic potential sensor:

DTY-EPS01-EA-□LWB

Connect to the

potential sensor

Communication

connector 4-pin

Power connector 5-pin

[Terminal array]

Terminal No. Symbol Connecting cable color

Connect to the blow unit

←

Round terminal

Electrostatic potential

sensor cable

1 24VDC Brown

2 A(+) White

3 0V Blue

4 B(-) Black

- 31 -

Note: Connect the 24 VDC and 0 V to their correc t connectors. Otherwise, the device does not function normally.

Communication connector

In addition, wrong wiring ma y cause operation failure and damage of the product. Always check wiring before turning on the device.

When connecting the electrostatic potential sensor: DTY-EPS01-EA-□LWB for the first time, connect the powe r connector only and

ensure that the green LED of the sensor body is correctly turned on. Then, turn off the device and connect the communication

connector.

If the device is turned on when the power of the electrostatic potential sensor has a reverse connection, the device may be

damaged.

Note: When inserting a cable to each screwless terminal connector, use a Phoenix contact's screw driver SZS 0,4X2,0 (size: 0.4 x 2.0 x

60 mm) or an equivalent product.

Note: Do no t connect to the terminal symbol NA (FG) connectors. If diffe rent voltage is supplied, the product may be damaged,

Note: Measurement value may be affected if dust adheres to the dust passage hole of the dust sensor. If dust is adhered to the dust

passage hole, remo ved the fan filter on the OUT side and clean the hole section with air. Life span of the LED used in the dust

sensor is limited. Light output will weaken over time when turned on (by less than 5% per 5 years).

4-2-6. Connecting communication devices

When a communication device such as a PC is connected, connect a USB-RS458 converter (IBM2A-H1 -□) to the

communication connector (485IN),

When a daisy-chain connection is used, connect a daisy-chain cable (DTY-EPP-CG-□) to the communication connector

(485OUT), and connect to the communication connector of the next blow unit (485IN).

Connect a terminating resistor connector (IBFL-K-TR) to the communication connector of the last blow unit (485OUT).

For details of communication, refer to "6. Communication".

Communication connector

(485IN)

(485OUT)

Next blow unit

PC

USB-RS485 converter

IBM2A-H1-□

Daisy-chain cable

DTY-EPP-CG-□

Terminating resistor connector

IBFL-K-TR

Note: When connecting the communication cable for the first time, ensure that the Power (green) LED of the blow unit successfully

turns on and turn off the light before connecting the cable. If the device is turned on when the communication cable or USBRS485 converter is connected while the power has a reverse connection, the device may be damaged.

- 32 -

43. Air piping

• Use a urethane or nylon tube of a φ8 outer dimension for the air piping.

• Use clean air through a dryer or filter for the air supply.

• Connecting the nozzle

Select a nozzle to attach to the blow unit according to the workpiece to remove static charge/particles.

Nozzle piping bore: Rc1/8

Do not use nozzles other than the following nozzles. Do not close the ionized air outlet with a plug, etc.

Recommended tightening torque:5 N・m

[Front] [Side]

Air piping joint

Air IN port

Note:Prepare sufficientai n supply to minimize the pressure drop during operation

Nozzle (ionized air outlet)

Nozzle (blow air outlet)

Nozzle joint: DTY-N ZW-NJ01

(For pinpoint removal of static charge/particles)

Nozzle: DTY-NZW-PP02 nozzle bore φ2.0 mm (It is dedicated particles removal nozzle)

DTY-NZW-PP03 nozzle bore φ3.0 mm

DTY-NZW-PP04 nozzle bore φ4.0 mm

(For removal of static charge/particles in a large area)

Nozzle: DTY-NZW-SW60 nozzle shower 60°

DTY-NZW-SW90 nozzle shower 90°

DTY-NZW-FT01 nozzle flat

To adjust the nozzle angle, use in co njunction with the nozzle joint: DTY-NZW- NJ01.

After adjus ting the nozzle angle, lock it and use it.

Angle adjustable range of the nozzle joint: ±25°

Recommended tightening torque: Body 1 N・m / Nozzle 0.3 N・m

44. Exhaust Ventilation

• Dust collecting unit (DTY-ZMW01-□-□) has a dust collection filter in it.

There is a fan inside the unit. Be careful about an injury due to the fan and the fan damage.

The fi lter on the fan filter (OUT) side collects particles.

(The filter on the fan filter (IN) side is a filter to prevent larger particles from entering inside the dust collecting unit.)

The fi lters are consumables. Replace the filter (DTY-ZFF-WB/ DTY- ZFR-WB) when the filter is clogged or contaminated.

Exhaust direction

Inhalation irection

Filter

IN side: DTY-ZFF-WB

Fan fi lter (OUT)

OUT side: DTY-ZFR-WB

Fan fi lter (IN)

• The exhaust duct outer diameter is φ76.3 if the dust collecting unit is not used but the duct attaching bracket (DTY-ZBRB-WB)

(additional part) is used,

When connecting exhaust hose, pay a ttention to the exhaust resistance. (Recommended exhaust hose nominal diameter: φ75)

- 33 -

5. Operation

Ionized air regulator

frequen cy s witch N o.

[Hz ]

Increase

Lock

51. Operation procedures

(1) Ensure the power connection, gro unding, air piping, wiring, and exhaust ventilation (dust collecting unit/duct piping).

(Working pressure range: 0.2 - 0.7 MPa)

(2) Open the va lve source of the air device (installed by the customer) and adjust the throttle valve for the ionized air regulator/air

blow.

Adjust the ionizer supply air pressure to be within a range of 0.05 - 0.5 MPa. When turning on this device, always input the

air.

Throttle valve for air blow

(Ionized air regulator)

Rotate the regulator handle with the handle securely pulled out. Rotate clockwise to increase the pressure, and rotate counterclockwise to decrease the pressure.

After the adjustment completes, push the handle to lock it.

Check the p ressure with the pressure gauge at the front of the blow unit. (Setting range: 0.05 - 0.5 MPa)

pressure

Handle < 0.5 MPa

Unlock

Decrease

pressu re

> 0.05 MPa

(Throttle valve for air blow)

Rotate the throttle valve needle from the fully open position to the counter-clockwise direction to increase the blow flow rate.

When the desired flow rate is achieved, always fasten the locknut to secure the setting.

When the needle is rotated too much (the flow rate is too high), ro tate the handle clockwise to decrease the flow rate.

Needle

Locknut

(3) Set the blow time and blow intermittent frequency using the blow time switch TIME/blow intermittent frequency switch FREQ.

For the blow time, either use the timer setting (0.5 - 10.0 seconds) or select the blow time switch No. from the continuous setting.

When the timer setting is used (blow time setting switch No.0 - A), the prod uct blows the air for the configured time.

When the continuous setting is used (blow time setting switch No. B - F), the product blows the air when the photoelectronic sensor

detects the workpiece.

For the continuous setting, the sensor OFF delay time can also be selected. When removing particles manually, for example, the

products keeps blowing the air during the OFF delay time if the target workpiece is out of the range of the photoelec tronic sensor. If

the workpiece is detected again during the OFF delay time, the OFF delay time is reset.

When the blow intermittent frequency setting is used, the product provides intermittent blow at the frequency specified by the blow

intermittent freq uency switch No.

Set the switch No. to "0" to disable intermittent blow.

The blo w intermittent frequency switch No.8/No.9 are the user area that a llows the customer to set desired behaviors .

There are two areas. The blow time/intermittent frequency/operation interval time can be configured according to the user

environment.

For details, refer to Section 6-3-4. (Setting via communication is required.)

Blow time switch

TIME

Blow intermittent frequency s witch

Note: The i ntermittent operation is available for air blow only. Intermittent blow is not available for the ionized air.

FREQ

(Blow time switch) (Blow inte rmittent frequency switch)

Blow t ime swit ch Blow t ime Remark

No. [second]

0 0.5 1 1.0 2 2.0 3 3.0 4 4.0 5 5.0 6 6.0 7 7.0 8 8.0 9 9.0 A 10.0 B Continue Sens or OFF_d elay tim e 0 .1 se cond

C Continue Sens or OFF_de lay time 0.5 seco nd

D Continue

E Continue

F Continue

Sen sor OFF_delay tim e 1.0 s econd

Se nsor OFF_dela y time 2.0 sec onds

Se nsor OFF_dela y time 3.0 sec onds

Blow intermi ttent

Bl ow frequen cy

0 0

1 1 2 2 -

3 3 4 4 -

5 6 -

6 8 7 10 -

8 User area 1 9 User area 2 -

Re mark

No int ermitte nt

operat ion

- 34 -

[Time chart]

Operation starts when the photoelectronic sensor or external inpu t

T2

Dust collecting operation time prior to blow

200

Dust collecting operation time prior to air blow

T3

Ionized air time prior to blow

100

Ionized air time prior to air blow

Set by the blow time

T5

Ionized air time after blow

0

Ionized air blow time after air blow

T6

Dust collecting operation time after blow

200

Dust collecting operation time after air blow

T7

External output [END] time

200

External output time (1 s hot puls e)

The subsequent operation is accepted when the photoelectronic

Operation starts w hen the photoelectronic sensor or external input

T2

Dust collecting operation time prior to blow

200

Dust collecting operation time pr ior to air blow

T3

Ionized air time prior to blow

100

Ionized air time prior to air blow

Photoelectronic sensor or external input [START]

T5

Ionized air time after blow

0

Ionized air blow time after air blow

T6

Dust collecting operation time after blow

200

Dust collecting operation time after air blow

T7

External output [END] ti me

200

External output time (1 shot pulse)

Air blow operation stops w hen the setting is greater than T8 (OFF)

T3

T5

• When the blow time is specified (blo w time setting switch No.0 - A)

OFF

OFF

OFF

T1

ON

T2 T6

ON

ON

T8

T7

Photoelectronic sensor or

externa l input [START]

External output

[VAC_S]

External output [END]

External input [STOP]

OFF

Dust collecting unit

(DC fan)

OFF

Io nized air

OFF

Air blow

OFF

Symbol Term Time [ms ] Rem ark

T1 Input signal ON delay time 100

T4 Air blow time

ON

T3 T5

ON

ON

T4

Set by the blow intermittent frequency switch No.

[START] is greater than T1

setting switch

Air blow time

T1

ON

T8 Input signal OFF delay time 100

sensor or external input [START] is greater than T8

• Continuous blow is specified (Setting switch No . B - F)

T1 T1

Photoelectronic sensor or

externa l input [START]

External output

[VAC_S]

External output [END]

External input [STOP]

Dust collecting unit

(DC fan)

Io nized air

Air blow

Symbol Term Time [ms] Remark

T1 Input signal ON delay time 100

OFF

OFF

OFF

OFF

OFF

OFF

OFF

ON

T2 T6

ON

ON

ON

T4

ON

Set by the blow intermittent frequency switch No.

T8

T7

ON

ON

[START] is greater than T1

T4 Air blow time

T8 Input signal OFF delay time Set by the blow time setting switch

Note: When the external input [STOP] is set to ON, the photoelectronic sensor/external input [START] is not accepted.

To enable the operation again, set the external input [STOP] and the photoelectronic sensor/external input [START] to OFF, and

then activa te the operation.

When ON (excluding T2/T3, including T8)

- 35 -

Air blow time

The operation continues when the photoelectronic sensor or the

external input [START] is OFF once and back to ON again w ithin T8.

• At the external input [STOP]

Photoelectronic sensor or

externa l input [START]

External output

[VAC_S]

T1 T1

ON

OFF

T2

ON

OFF

External output [END]

OFF

External input [STOP]

Dust collecting unit

(DC fan)

Io nized air

Air blow

OFF

OFF

OFF

OFF

ON

T3

ON

ON

Set by the blow intermittent frequency switch No.

ON

(4) Press the "-" side of the power switch to turn on the device. The device turns on. If the power LED (green) and the

photoelectronic sensor are equipped, ensure tha t the power LED (green) of the photoelectronic sensor is turned on before

enteri ng the workpiece.

The photoelectronic sensor detects the ente red workpiece and the device starts the operation.

Power LED (green)

Power switch

(5) The blow operation is performed with the blow time/blow intermittent frequenc y set in Step (3), and then the operation stops.

This is the end of the static charge/particle removal process.

Note: When adjusting the nozzle angle usi ng the nozzle joint, if the air flow nozzle is directed to the ionized air nozzle, the static charge

remova l performance may be affected.

Use the product with the air blow nozzle facing the vertical direction or the opposite direction of the ionized air nozzle.

Static charge removal performance may be affected if the ionized air pressure (set value o f the ionized air regulator) is low

compared to the air blow pressure (impressed pressure).

(Recommended nozzle direction)

Ionized air nozzle

Air blow nozzle

Static charge

removal

Particle removal

[Air blow nozzle vertical direction] [Air blo w nozzle opposite direction]

Ionized air nozzle

Static charge

removal

Target workpiece

Air blow nozzle

Particle removal

Target workpiece

Dust

collection

Dust collecting unit, etc.

- 36 -

52. LED Indicators

These indicators (turned on/flash/turned off) indicate the status of the blow unit and the additional parts.

For the details, refer to the LED status table.

Maintenance LED MAINT (yellow)

Alarm LED ALM (red)

Power LED POWER (green)

Io n blow LED ION BLOW (blue)

Electrostatic potential sensor LED EPS (yellow)

Dust sensor LED DUST (Blue/green/red)

(LED status table)

LED

Item

Power OFF

While s tarting up from the power ON

Power ON

Blowing the i onized air

*1)

Maintenance

Alarm Ionizer

Elect rostatic

potential sensor

Dust sensor Dust amount: little

Ioni zer discharge needle

Air blow valve

Ioni zer discharge needle/

Air blow valves (both)

Blow unit

Dust collecting unit:

Electrostatic potential

sensor

Judgment output ON

Zero-point calibration

execution

Outside the measurement

range

Dust amount: medium

Dust amount: high

Dust sensor not equipped

POWER

(green)

○ ○ ○ ○ ○ ○

◎ ○ ○ ○ ○ ○

● - - - - -

● - - ● - -

● -

● -

● - ● - - -

● ● - - - -

●

●

●

● - - - ● -

● - - -

● - - -

● - - - -

● - - - -

● - - - -

● - - - - ○

ALM

(red)

◎

(4Hz )

◎

(2Hz )

◎

(1Hz )

MAINT

(yellow)

◎

(2Hz )

◎

(4Hz )

- - - -

- - - -

- - - -

ION BLOW

(blue)

- - -

- - -

: On

●

◎

EPS

(yellow)

◎

(2s,2Hz)

◎

(4Hz)

: Flash

DUST

(red/green/

blue)

-

-

(Blue)

●

(Green)

●

(Red)

●

: Off

○

*1) To e nable maintenance, enable the piano dip switch SW1/2 on the front of the blow unit.

(Refer to "7. Maintenance and Precautions" fo r details)

(Initial value) Ionizer discharge time: 300 [time]/frequency of air blow valve ON/OFF: 10 million times

Note: While the ion wiper is in operation, ensure that air is supplied to the equipped ionizer.

If the pressure setting of the ionized air regulator is less than 0.05 MPa, the device and the environment would receive harmful

effect.

Note: The particle removal effect by the ion wiper varies depending on the shape and the amount of charge of the workpiece (charged

material), air pressure, blow time, and blow i ntermittent frequenc y.

When this device is used, configure the ionized air pressure, blow flow rate/time/frequency appropriate to the workpiece.

Note: Value o f the dust sensor is just a guide. It does not guarantee removal of dust from the workpiece.

- 37 -

6. Communication

61. Address Setting

To communicate with the blow unit, it is necessary to configure the unit address for each blow unit.

Use the address setting switch to set the address. Up to 15 units can be connected in a daisy-chain.

Ensure tha t there are no duplicated addresses. Duplicated addresses prevent correct communication.

Also, do not set the address switch No. to "0". This setting disables communication.

Address setting switch

ADDRESS

62. Communication Specification

(Communication settings specification)

Communication protocol Modbus-RTU

Physical laye r RS-485

Communication method Half duplex, start-stop

Maximum number o f

connected units

Address Setting

Communication speed 115.2 kbps

Data bit 8 bit

Start bit 1 bit

Stop bit 1 bit

Parity Odd number

Flow control None

(Communication frame configuration)

Silent i nterval with 3.5

characte rs (350 s) or more

(Corresponding function code)

Item Description

15 Max

1-F[15] (use the rotary switch on the front body)

Communication is disabled when set to 0.

Start

Address

1 byte 1 byte n byte 2 byte

Function code Function term Description

1 Read Coil Status DO state (0/1) read

2 Read Input Status DI state (0/1) read

3 Read Holding Register Retention register read

4 Read Input Register Input register read

5 Force Single Coil DO state (0/1) overwrite

6 Preset Single Register Retention register overwrite

(1-15)

ADDRESS Address Rem ark

Switch No.

0 0 Do not configure

1 1 2 2 3 3 4 4 5 5 -

6 6 7 7 8 8 9 9 A 10 B 11 C 1 2 -

D 1 3 E 14 F 15 -

Function code

(1-6)

Data

Error check

CRC

End

Silent i nterval with 3.5

characte rs (350 us) o r more

63. Communication Data Address

Use the data address when reading or modifying (writing) data in Modbus communication.

6-3-1. Read Coil Status (function code: 1)/ Force Single Coil (function code: 5)

Read by the function code 1, and overwrite by the function code 5.

(Readable and overwritable binary data , such as ON/OFF, is dep loyed)

Data address Term Description

0 Stop

1 Start

2 ZC

Operation stop (equivale nt to I/O connector terminal No.8: STOP)

Operation stops when toggled to 0 -> 1

* The operation status is reset before starting the operation.

Operation start signal (equivalent to I/O connector terminal No.9: START)

Operation starts when toggled to 0 -> 1

Electrostatic potential sensor zero calibration execution (equivalent to I/O connector

termina l No.10: ZC)

Calibration is executed when toggled to 0 -> 1

* Automatically cleared to 0 when the execution successfully completes. If zero

calibration does not complete after 100 ms, the process is not complete

successfully. Check the co nnection state and the electric potential, etc.

- 38 -

6-3-2. Read Input Status (function code: 2)

Read by the function code 2.

(Readable binary data, such as ON/OFF, is deployed)

Data address Term Description

0 ALARM

1 CHECK

2 MAINT

3 EPS

4 DUST

5 END

6 VAC_START

7 STOP

8 START

9

10 To uch Sensor

11 EPS Connect

12 DUST1 Connect

13 DUST2 Connect

14 DUST1 FAN Error

15 DUST2 FAN Error

16 ELK CHECK

17 ELK ALARM

18 ELK HV

19 ELK Maint

20 Blow Valve Maint

24 Current Over ALARM

25 Current Over CHECK

26 Current Over MAINT

27 Curre nt Over EPS

28 Curre nt Over DUST

29 Current Over END

30 Current Over START

ZC

(Zero calibration)

This indicates the same state as the I/O connector terminal No.1: ALARM.

0: OFF, 1: ON

This indicates the same state as the I/O connector terminal No.2: CHECK.

0: OFF, 1: ON

This indicates the same state as the I/O connector terminal No.3: MAINT.

0: OFF, 1: ON

This indicates the same state as the I/O connector terminal No.4: EPS.

0: OFF, 1: ON

This indicates the same state as the I/O connector terminal No.5: DUST.

0: OFF, 1: ON

This indicates the same state as the I/O connector terminal No.6: END.

0: OFF, 1: ON

This indicates the same state as the I/O connector terminal No.7:

VAC_START.

0: OFF, 1: ON

This indicates the same state as the I/O connector terminal No.8: STOP.

0: OFF, 1: ON

This indicates the same state as the I/O connector terminal No.9: START.

0:OFF, 1:ON

This indicates the same state as the I/O connector terminal No.10: ZC.

0:OFF, 1:ON

This indicates the detection state of the photoelec tronic sensor.

0:OFF, 1:ON

Connection state of the elec trostatic potential sensor.

0: not co nnected, 1: connected

Connection state of the dust collecting unit 1

0: not co nnected, 1: connected

* Dust collecting unit connected to the dust collecting unit 1 connector

CON3

Connection state of the dust collecting unit 2

0: not co nnected, 1: connected

* Dust collecting unit connected to the dust collecting unit 2 connector

CON4

Fun error state of the dust collecting unit 1

0: normal, 1: error

Fun error state of the dust collecting unit 2

0: normal, 1: error

CHECK state of the ionizer (DTY-ELK01)

0: OFF, 1: ON

ALARM state of the ionizer (DTY-ELK01)

0: OFF, 1: ON

Discharge state of the ionizer (DTY-ELK01)

0: OFF, 1: ON

Maintenance signal of the ionizer (DTY-ELK01)

0: OFF, 1: ON

Maintenance signal for blow valve

0: OFF, 1: ON

Ove rcurrent error state of the I/O connector terminal No.1: ALARM

0: normal, 1: overcurrent error

Ove rcurrent error state of the I/O connector terminal No.2: CHECK

0: normal, 1: overcurrent error

Ove rcurrent error state of the I/O connector terminal No.3: MA INT

0: normal, 1: overcurrent error

Ove rcurrent error state of the I/O connector terminal No.4: EPS

0: normal, 1: overcurrent error

Ove rcurrent error state of the I/O connector terminal No.5: DUST

0: normal, 1: overcurrent error

Ove rcurrent error state of the I/O connector terminal No.6: END

0: normal, 1: overcurrent error

Ove rcurrent error state of the I/O connector terminal No.7: START

0: normal, 1: overcurrent error

- 39 -

6-3-3. Read Input Register (function code: 4)

Read by the function code 4.

(Read-only 16-bit data is deployed)

Data address Term Description Unit

0 EPS Data

8 DUST1 Sensor

9 DUST1 Fan1 SP

10 DUST1 Fan2 SP

11 DUST2 Sensor

12 DUST2 Fan1 SP

13 DUST2 Fan2 SP

24 RSW Addr Current value of the ADDRESS switch (0 - 15)

25 RSW Freq Current value o f the FREQ switch (0 - 9)

26 RSW Blow Curre nt value of the TIME switch blow time (0 - 15)

27 PIANO SW Curre nt values of the SW 1/2 switches (0 - 3)

40 BLOW Unit Major Ver Main unit major version

41 BLOW Unit Minor Ver Main unit minor version

42 EPS Major Ver Electrosta tic potential sensor major version

43 EPS Minor Ver Electrosta tic potential sensor minor version

44 DUSTUnit1 Major Ver Dust collecting unit 1 major version

45 DUSTUnit1 Minor Ver Dust collecting unit 1 minor version

46 DUSTUnit2 Major Ver Dust collecting unit 2 major version

47 DUSTUnit2 Minor Ver Dust collecting unit 2 minor version

50 Error History1 Error history 1 (clear not allowed, retention) [New]

51 Error History2 Error history 2 (clear not allowed, retention) ↑

52 Error History3 Error history 3 (clear not allowed, retention) |

53 Error History4

54 Error Histor5

55 Error Histor6 Error history 6 (clear not allowed, retention) |

56 Error History7 Error history 7 (clear not allowed, retention) |

57 Error History8

58 Error History9 Error history 9 (clear not allowed, retention) ↓

59 Error History10 Error history 10 (clear not allowed, retention) [Old]

Electrostatic potential sensor measurement electric potential

value (-20000 - 20000)

30000: + over range, -30000: - over range

The data is a 16-bit signed integer.

In the s tandard mode: -2000 - 2000, resolution 1

In the high voltage mode: -20000 - 20000, resolution 10

Dust collecting unit 1 dust sensor measurement value (0 - 1000)

If the value immediately after turning the power on is -1000 and

a dust sensor is used, the value of -1000 continues to be used.

Disconnected: -1

Dust collecting unit 1 fan 1 rotation speed (2500 to 8250)

Disconnected: -1000, On error: -1

Dust collecting unit 1 fan 2 rotation speed (2500 to 8250)

Disconnected: -1000, On error: -1

Dust collecting unit 2 dust sensor measurement value (0 - 1000)

If the value immediately after turning the power on is -1000 and

a dust sensor is used, the value of -1000 continues to be used.

Disconnected: -1

Dust collecting unit 2 fan 1 rotation speed (2500 to 8250)

Disconnected: -1000, On error: -1

Dust collecting unit 2 fan 2 rotation speed (2500 to 8250)

Disconnected: -1000, On error: -1

Error history 4 (clear not allowed, retention) |

Error history 5 (clear not allowed, retention) |

Error history 8 (clear not allowed, retention) |

V

rpm

rpm

rpm

rpm

- 40 -

6-3-4. Read Ho lding Register (function code: 3)/ Preset Single Register (function code: 6)

Read by the function code 3, and overwrite by the function code 6.

(Readable and overwritable 16-bit data is deplo yed. The value of the retention register is maintained after the main unit is

turned off.)

Data

address

0 EPS Work size Workpiece size setting for the electrostatic potential sensor 300 400 20 mm

1 EPS Distance

2 EPS CP Thers

3 EPS CP Hys

4 EPS Mod e

8 FAN1 SPEED Fan rotation speed setting for Dust collecting unit 1 8250 8250 2500 rpm

9 FAN2 SPEED Fan rotation speed setting for Dust collecting unit 2 8250 8250 2500 rpm

10 FAN1 Mode

11 FAN2 Mode

16 DUST Thres

17 DUST Hys

18 DUST Led DH

19 DUST Led DL

21 End Count H Operation completion count upper 0 3000 0 0

22 End Count L Operation completion count lower 0 9999 0 time(s)

23 ELK Clean H

24 EKL Cle an S

25

26

27

28

32 UA1 ON Delay User area 1 ON delay time: T1 100 3000 0 ms

33 UA1 ON FAN User area 1 pre-blow blow time: T2 200 3000 0 ms

34 UA1 O N ELK User area 1 pre-blow discharge time: T3 100 3000 0 ms

35 UA1 B low Time User area 1 blow time: T4 1000 6000 0 500 ms

36 UA1 OFF ELK User area 1 post-blow discharge time: T5 0 3000 0 ms

37 UA1 OFF FAN User ar ea 1 post-blow blow time: T6 200 3000 0 ms

38

39 UA1 Blow Freq

40 UA1 Mode

48 UA2 ON Delay User area 2 ON delay time: T1 100 3000 0 ms

49 UA2 ON FAN User area 2 pre-blow blow time: T2 200 3000 0 ms

50 UA2 O N ELK User area 2 pre-blow discharge time: T3 100 3000 0 ms

51 UA2 B low Time User area 2 blow time: T4 1000 6000 0 500 ms

52 UA2 OFF ELK User area 2 post-blow discharge time: T5 0 3000 0 ms

53 UA2 OFF FAN User ar ea 2 post-blow blow time: T6 200 3000 0 ms

54

55 UA2 Blow Freq

56 UA2 Mode

Term Description

Measurement distance setting f or the electrostatic potential

sensor

Threshold setting for the electrostatic potential sensor

* "EPS CP Thers > EPS CP Hys" must be satisfied.

Hysteresis setting for the electrostatic potential sensor

* "EPS CP Thers > EPS CP Hys" must be satisfied.

Mode setting for the electrostatic potential sensor

0: standard mode, 1: high voltage mode

Operation mode setting for Fan 1

0: normal, 1: continuous (not turned OFF after the operation)

Operation mode setting for Fan 2

0: normal, 1: continuous (not turned OFF after the operation)

Dust sensor DUST signal t hreshold

* "DUST Thres >DUST Hys" must be satisfied.

Dust sensor DUST signal hysteresis

* "DUST Thres >DUST Hys" must be satisfied.

Dust sensor LED threshold DH

Detected value >= DH: red LED turned on

DH > Detected value > DL: green LED turned on

Detected value <= DL: blue LED turned on

Dust sensor LED threshold DL

Detected value >= DH: red LED turned on

DH > Detected value > DL: green LED turned on

Detected value <= DL: blue LED turned on

Ionizer discharge time (hour)

Automatic count at discharge

Ionizer discharge time (second)

Automatic count at discharge

ELK Clean

Thres

Blow Valve

CntH

Blow Valve

CntL

Blow Valve Cnt

Thres

UA1 OFF

Delay

UA2 OFF

Delay

* Ensure to clear to 0 after a maintenance task completes.

Discharge needle maintenance time setting

(for MAINT output)

Blow valve actuating cycle upper 0 1000 0

Blow valve actuating cycle lower

* Ensure to clear to 0 after a maintenance task completes.

Blow valve replacement (for MAINT output) 1000 1000 0 0

User area 1 OFF delay time: T8 100 3000 0 ms

User area 1 blow frequency

0: continuous, 10 - 100: pulse blow

User area 1 operation mode

0: blow time specifying mode, 1: continuous mode

User area 2 OFF delay time: T8 100 3000 0 ms

User area 2 blow frequency

0: continuous, 10 - 100: pulse blow

User area 2 operation mode

0: blow time specifying mode, 1: continuous mode

Initial

Maximum

value

value

50 100 6 mm

100 20000 0 V

10 1000 0 V

0 1 0

0 1 0

0 1 0

50 1000 0 -

10 100 0 -

200 1000 0 -

50 1000 0 -

0 3000 0 0 h

0 3599 0 s

300 30000 0 h

0 9999 0 time(s)

0 100 0 x0.1 Hz

0 1 0

0 100 0 x0.1 Hz

0 1 0

Minimum

value

Unit

x10,000

times

x10,000

times

x10,000

times

*) Data addresses 32 - 40 and data addresses 48 - 56 are enabled when the blow intermittent frequency switch [FRE Q]No.8 and the

glow intermittent frequency switch [FREQ]No.9 are set, respectively. For their behavior, refer to the [time chart] on page 11.

- 41 -

7.Maintenance and Caution Items

R

ed

B

ck

• While this device is installed to a place where no water or oil splashes over, if water, oil, paint, or other fluids splashes over the

device, wipe it out using a piece of cloth.

• Dirt contamination on the tip of the discharge needle of the equipped ionizer degrades the static charge removal performance.

If gradual degradation of the static charge removal effect is experienced, clean the tip of the discharge needle using an appropriate

tool such as a nylon brush. (Never use a wire brush.)

Clean the discharge needle and the area nearby using a swab.

When cleani ng the discharge needle of the ionizer, remove the cover from the blow unit body.

Blow unit upper side

Screw locations x2

Blow unit cover

Blow unit rear side

Screw location x1

For additional maintenance and precautions regarding the ionizer, refer to the operating instructions of DTY-ELK01.

• The blow intermittent operation of this ion wiper is controlled by an electromagnetic valve. The electromagnetic value has a product life.

The electromagnetic value is a consumable item. When it reaches the end of the product life, replace it. Model: 230E1-SR-26W DC24V

10 million ON/OFF cycles are considered as a milestone for replacement.

When replacing the electromagnetic valve , remove the cover from the blow unit body.

The electromagnetic valve is fixed with two screws.

Remove the screws and re move the electromagnetic valve from the blow unit body. Tilt the electromagnetic valve for easier

remova l.

Disconnect the cables (red/black) from the electromagnetic valve connectors. Push down the white protrusion at the

electromagnetic valve connector and p ull out the cable to disconnect the cable.

Align a new electromagnetic valve to the board silk and connect the cables (red/black) of the new electromagnetic valve.

Insert the cables while pressing down the white protrusion.

Ensure to set the electromagnetic valve O-rings (x3) to the specified locations.

After connecting the cable and attaching the O-rings, fix the electromagnetic valve with the screws. Recommended tightening torque: 0.5 [N・

m]

Ionizer (DTY-ELK01) Discharge needle

Electromagnetic valve

(230E1-SR-26W

DC24 V)

Fixing screw (x2)

Tilt the valve and remove it

O-ring mounting position (x3)

Enlarge

• Setting the maintenance time/count

The blo w unit measures the discharge time of the ionizer. When the discharge time reaches the specified discharge time, the

maintenance LED MAINT (yellow) flashes (2 Hz) and I/O connector terminal No.3: MAINT is output.

The ON/OFF cycle of the air blow valve is also counted. When the number of cycle reach the specified count, the maintenance

LED MAINT (yellow) flashes (4 Hz) and I/O connector terminal No.3: MAINT is output.

When the flash/I/O connector terminal No.3: MAINT is ackno wledged, replace the relevant parts.

To enable the count, SW1 or SW2 on the blow unit front must be set to ON. (They are set to OFF at the time of shipping)

ON: Count enabled

OFF: Count disabled

Cable slot

la

White protrusion

OFF => ON: Count starts

Io nizer discharge time

Count switch SW1

Blow valve ON/OFF

Count switch SW2

ON => OFF: Count reset

Warning: Ensure to turn off the power before performing the inspection, cleaning, or maintenance task. Also, shut the connection to the

air completely.

When cleani ng the discharge needle, pay attention to handle the needle as the tip of the discharge needle is sharp.

Otherwise, there is a risk of injury.

- 42 -

8. Troubleshooting

overcurrent

81. When a Problem Occurs

When contacting us for a problem, please inform us about the following items as specific as possible:

Item Description (e xample)

What Model (blow unit: DTY-WB01/Box type DTY-WBM01-S/-L)

When Purchase date (serial No.)

In what situation During operation

What happened The unit does not function

Frequency Always occurs

82. When Alarms Are Issued and Their Resolution

When the I/O connector ALARM signal output is ON, it is considered that an alarm is issued.

Also, the blow unit ALM (red) LED turns on/flashes. (For the details, refer to "5-2. LED Indicators".)

When an a larm is issued, refer to the solutions in "8-3. Alarm List".

83. Alarm List

Alarm

Alarm S ubject Descr iption B eh avior Po ssible Cause Resolution

Code

1001 I/O c onnect or terminal No.1 ALARM overc urrent S top

1002 I/O c onnect or terminal No.2 CHECK o vercurrent Stop

1003 I/O c onnect or terminal No.3 MAINT overc urrent Stop

1004 I/O c onnect or terminal No.4 EPS overc urrent Stop

1005 I/O c onnect or terminal No.5 DUST overcurrent S top

1006 I/O c onnect or terminal No.6 END overcurrent S top

Blow un it

1007

1020 Memory failure Stop

1030 Communic at ion error (CRC m is match occ urred) Con tinue

1031

2010 Dust coll ec ting unit 1

2020 Dust coll ec ting unit 2

3010 Zero calibration error Continue

Elec trostati c

potentia l sensor

3020 Elect rostati c pot ential se nsor Stop

4010 Feature failure S top The piezo electric transformer is broke n.

Ionizer

4020 Disch arge failure Continue

I/O c on ne ctor terminal N o.7 VAC START

Comm unic ation error (excepti on response

oc curred)

Internal DC fan failure Sto p

Others

Period of service, operating condition

When the power is on; One hour after the power is on

During configuration

An error occurs

Once in an hour

The problem is not reproduced

・ The lo ad connec ted to the I/O o ut put got sh ort

cir cuited.

・ DC 24 V i s applied with out the load.

Stop

Error in the com munica tion set tings

・

・ The p ower was turned ON while c ommunicatin g wi th

su pport software

Continue

・ E ffe ct by the noise

A foreign object s tuck in the DC fan stopped th e

・

rotati on of the fan.

DC fan is bro ken.

・

Zero calibrat io n was performed wit hin the range (within

・

±200 V)

(±2000 V in the hi gh volt age mode)

The sens or is broken Remove the se ns or fro m the unit a nd attach it again.

Abnorma l discha rge occ ur red

Shut the power, and check t he load.

After rem oving th e caus e o f t he alarm, tu rn on the devi ce.

Check the commu ni cation setti ngs.

Connect be fo re applying th e power.

Turn off the power, and re move the foreign object fro m t he

DC fan, if any.

If the problem persist s, contac t us.

Perform c alibration within th e r ange (within ±2 00 V)

(± 2000 V in the high voltage m od e)

If the problem persist s, contac t us.

Shut the power, and check for any issues on the

disc harge needle, such as contaminati on with dust.

If the problem persist s, contac t us.

- 43 -

9. Specification/External Dimension

91. Specification

Item

Type

Input voltage 24 VDC±5%

Current consumption Blow uni t: 0.6 A Max

Equipped ionizer DTY-ELK01 (x1)

Ion balance *1) ±15 V (0.5 MPa, 50 mm)

Discharge time *1) 1 sec (1000 V → 100 V, 0.5 MPa, 50 mm)

Fluid used Air (Clean air free from water and oil)

Working pressure range 0.2 to 0.7 MPa

Ionized air setting pressure range 0.05 to 0.5 MPa

Piping connection bore φ8 quick joint

Air blow time Rotary switch TIME 16-

point

Blow intermittent frequency Rotary switch FREQ 10-

point

Switches Locker switch

Piano dip switch: SW1 Ionizer discharge time count enabled/disabled

Piano dip switch: SW2 Blow valve ON/OFF cycle count enabled/disabled

Indicators POWER (green, turns on when the power is on)

External output Output ALARM ( Output on error)

Input STOP (Operation stop input)

Connectability sensor Photoelectronic sensor: DTY-ZSP□L-WB

Nozzle Shower type: 60°, 90°, flat (three types)

Consumed air flow rate *2) Air blow side 330 L/min (ANR)

Ionized air side 170 L/min (ANR)

Dust collecting fan exhaust flow rate 2000 L/min at no load

Filter collec tion capability *3) OUT side 62%

Communication RS485 communication

Number of communication connections 15

Operating environment Indoor 0 - 40°C, 15 -65% RH (no condensation)

Weight Blow uni t: 2.1 kg (no photoelectronic sensor/power unit)

Mount 4 L-shaped brackets (screws) enclosed with each unit

Box type A4 type DTY-WBM01-S-□-□

A3 type DTY-WBM01-L-□-□

*1) The values are based on Koganei’s measurement criteria They are not guaranteed values.

*2) No zzle: Pinpoint φ2 x 2, with the conditions of a nozzle shower 60°/slop valve fully open/supply pressure 0.7 MPa/ionized air regulator

setting pressure 0.5 MPa

*3) Test method: ASHRAE 52.1-1992 (weighing method) test dust: ASHRAE TEST DUST

*4) Value of the dust sensor is just a guide. It does not guarantee removal of dust from the workpiece.

Dust collecting unit x1: 1.0 A Max (2.0 A Max at start-up)

0.5 - 10 s/continuous (sensor OFF_delay: 0.1 s - 3.0 s)

1, 2, 3, 4, 6, 8, 10 Hz/continuous (no intermittent)

MAINT (yellow, turns on when a maintenance required)

ION BLOW (blue, turns on during blow operation)

EPS (yellow, turns on at electrostatic potential sensor judgment)

DUST (blue/ green/ red, indicating the dust sensor status)

CHECK (Ionizer discharge abnormal output)

EPS (Electrostatic potential sensor judgment output)

VAC START (External device operation output)

ZC (Electrostatic potential sensor zero calibration input)

Electrostatic potential sensor: DTY-EPS01-EA-□LWB

(Dust collecting unit: built into DTY- ZMW01-□-DS)

Dust collecting unit: 1.3 kg (with a dust sensor)

(with a nozzle and a dust sensor/without a power unit)

(with a nozzle and a dust sensor/without a power unit)

Blow uni t: DTY-WB01-□-□

Dust collecting unit: DTY- ZMW01-□-□

User setting 2 area

Power ON/OFF (○: OFF / -: ON)

(ON: count enabled/OFF: count di sabled)

(ON: count enabled/OFF: count di sabled)

ALM (red, turns on/flashes on error)

MAINT (Maintenance timing output)

DUST (Dust sensor judgment output)

END (Blow operation end output)

Start (Operation start input)

Dust sensor

Pinpoint type: φ2, φ3, φ4 (three types)

Weight: 7.5 Kg

Weight: 9.5 Kg

- 44 -

92. Outline Drawing

sensor

[Blow unit: DTY-WB01]

Nozzle joint (additional part)

Nozzle (additional part, ionized air outlet)

L-shaped brackets

mounting holes (M4)

(The other side is the same)

Blow intermitte nt frequency switch

Blow time switch

Maintenance LED (yellow)

Alarm LED (red)

Power LED (green)

Nozzle (additional part, air blow outlet)

Address setting switch

Regulator

(For ionized air)

Power

connector

Connector 1 for the

dust collecting unit

Connector 2 for the

dust collecting unit

L-shaped bracketsPhotoelectronic sensor mounting holes (M3)

Power switch

Pressure gauge (for ionized air)

Throttle valve

(For air blow)

Air IN port φ8

I/O connectors

Connector for the

electrostatic potential

sensor

Connector for the

photoelectronic

Ionizer discharge time count switch

Blow valve ON/OFF count switch

Dust sensor LED (blue/green/red)

Electrostatic potential sensor LED (yellow)

Ionized air LED (blue)

Indicator/setting area details

- 45 -

[Dust collecting unit: DTY-ZMW01]

L-shaped brackets

mounting holes (M4)

(The other side is the same)

Type L dimension [mm]

DTY-ZMW01-1L-□ 1000

DTY-ZMW01-3L-□ 3000

[Photoelectronic sensor: DTY-ZSP□L-WB]

Detective part

Power LED (green)

Workpiece detection LED (green)

Mode selection switch

Detection output settings switch

Setting trimmer

Type L dimension [mm]

DTY-ZSP1L-WB 1000

DTY-ZSP3L-WB 3000

- 46 -

[Box type A4 size: DTY-WBM01-S]

Aperture

Aperture

Depth ( )

- 47 -

[Box type A3 size: DTY-WBM01-L]

Aperture

Aperture

Depth

- 48 -

[Memo]

- 49 -

内容についてのご不明な点や技術的なご質問がございましたら、下記へお問い合わせください。

《 問い合わせ 》

株式会社コガネイ 技術サービスセンター

住所:東京都小金井市緑町3-11-28

TEL:042-383-7172

FAX:042-383-7206

JUST CONSULT US

KOGANEI CORPORATION

OVERSEAS DEPARTMENT

3-11-28, Midoricho, Koganei City, Tokyo 184-8533, Japan

TEL : 042-383-7271 FAX : 042-383-7276

イオンワイパー

“セパレートタイプ”

ION WIPER

“Separate Type”

取扱説明書

Owner's Manual

2018年12月 Ver.1.0 X904484

December 2018 Ver.1.0 X904484

© 株式会社コガネイ

© Koganei Corp.

本書の内容の一部もしくは、全てを無断で

複写・転写することを禁じます。

Any copy or reproduction of part or all of

the content of this manual is prohibited.

2018 年 12 月 Ver.1.0 KG ©KOGA NEI CORP. PRINT ED IN JAPA

Loading...

Loading...