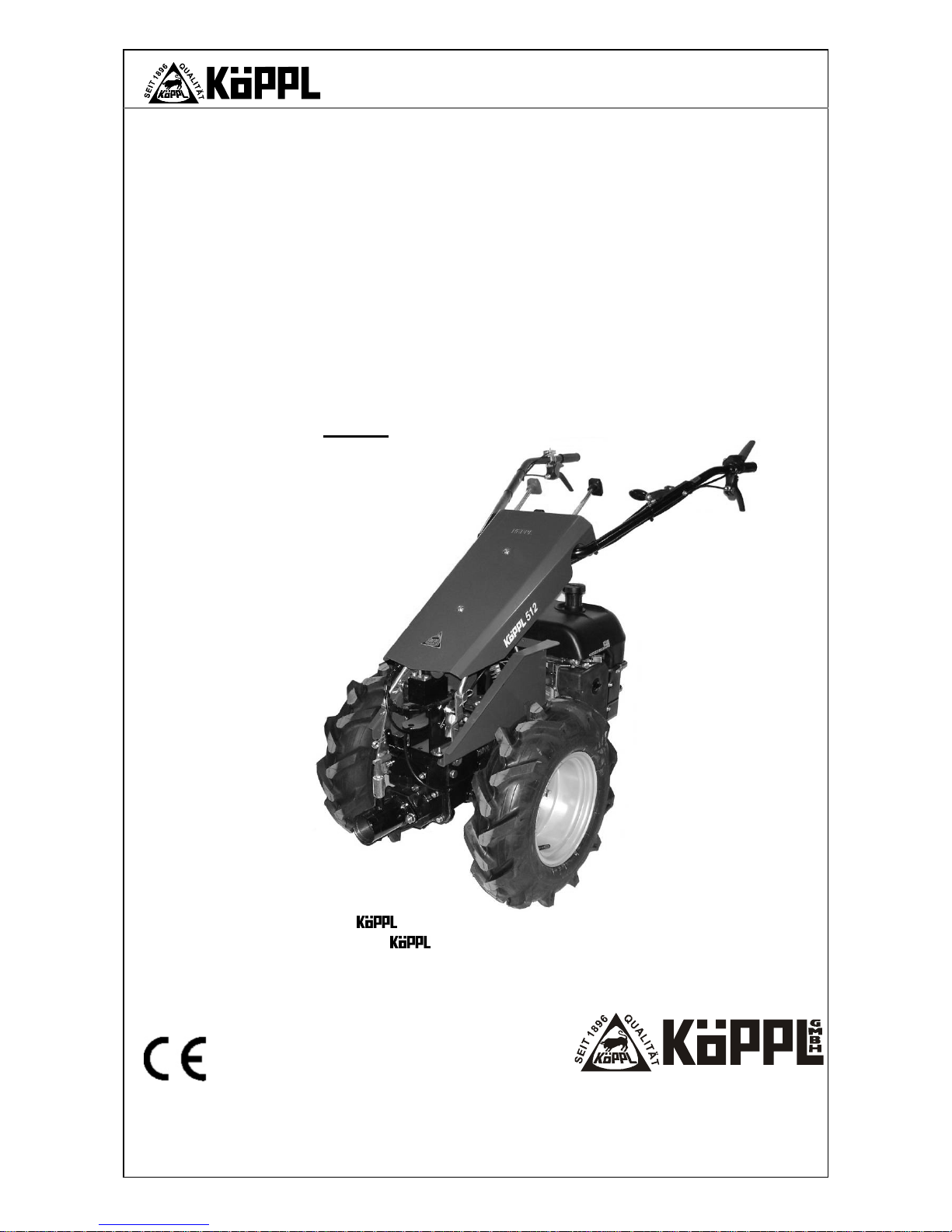

Koeppl 4H 500, 4K 500, 4M 500 Operator's Manual

M O TOR G ER Ä T E F A BR I K

94163 ENTSCHENREUTH

(0 99 07) 89 10-0 ɀ Fax (0 99 07) 10 42

Internet: http://www.koeppl.com

email: info@koeppl.com

Operator manual

for

2-wheel tractor

Series 500

The basis for working with the 2-

wheel tractor is that you read, observe and understand this

operator manual of the utilized accessory equipment and the engine manufacturer.

You may not begin operation before doing so.

Beginning work without observing this manual is prohibited!

Edition / Rev.

- Date

01-2009 ☺ 11/18/09

Store for future usage!

Types 4H 500, 4K 500, 4M 500

N

OTES

Page 2

Version 01-2009

S500K

Translation of the original operator manual

P

REFACE

Page 3

Version 01-2009

S500K

Preface

Before commissioning the

2-wheel tractor it is absolutely necessary to read

and observe the proper usage and the safety notes!

The guarantee is ensured only for proper operation!

Valued customer! You have made the right decision!

Although the selection is great, you have chosen a

2-wheel tractor.

That pleases us greatly. We will make an effort to keep you satisfied over the years.

As of now, you will hopefully be our best advertiser.

The following points distinguish our product:

- The machine is very stable, one can work effortlessly.

- It is equipped with an outstanding engine.

- The maintenance costs are thus very low.

- The gear shift is easy to operate.

- The spare parts supply is guaranteed and occurs quickly.

- An optimal customer service is available to you at all times.

The

2-wheel tractor has resulted from decades of experience and can therefore be

placed into continuous practice.

is constantly working on advancements of machines and devices. We must

therefore reserve the right to make changes to the scope of delivery in form, technology and equipment. Please understand that no claims can be made based on

statements and illustrations in this manual.

LET US KNOW YOUR SUGGESTIONS FOR IMPROVEMENT!

T

ABLE OF CONTENTS

Page 4

Version 01-2009

S500K

Table of contents

PREFACE ........................................................................................................................................... 3

TABLE OF CONTENTS ......................................................................................................................... 4

PROPER USAGE ................................................................................................................................. 5

1

GENERAL SAFETY NOTES ................................................................................................... 6

1.1 Possible hazards during interaction with the 2-wheel tractor.................................................. 6

1.2 Safety notes and hints ............................................................................................................. 6

1.3 Hazards due to accessories ....................................................................................................... 7

1.4 Emissions ............................................................................................................................... 8

1.5 Hazard sources ....................................................................................................................... 9

1.6 Lighting devices on single-axle tractors ....................................................................................... 9

1.7 Workplace ............................................................................................................................ 10

1.8 Authorized operators ............................................................................................................. 10

1.9 Personal protective equipment ................................................................................................ 11

1.10 Safety measures at the work site ............................................................................................. 11

1.11 Protective devices ................................................................................................................. 12

1.12 Leaving the tractor ................................................................................................................ 13

1.13 Safety tool attachments ......................................................................................................... 13

2

TRANSPORT ...................................................................................................................... 14

2.1 Tractor size / machine dimensions ........................................................................................... 14

2.2 Technical data ...................................................................................................................... 15

3

OPERATION ...................................................................................................................... 16

3.1 Commissioning...................................................................................................................... 16

3.2 Starting ............................................................................................................................... 16

3.3 Switching gears in general ...................................................................................................... 17

3.4 Gear switching - steering shaft ................................................................................................ 17

3.5 Shifting – fixed shaft .............................................................................................................. 19

3.6 Shifting – forward/ reverse gear on the shaft ............................................................................ 20

3.7 Clutch .................................................................................................................................. 20

3.8 Power take-off ...................................................................................................................... 21

3.9 Differential gears ................................................................................................................... 22

3.10 Engine ................................................................................................................................. 23

3.11 Gas pedal ............................................................................................................................. 23

3.12 Shaft adjustment ................................................................................................................... 24

3.13 Steering shaft - optionally / for Type 4M standard ...................................................................... 24

3.14 Parking brake / brake - optional .............................................................................................. 26

3.15 Device connection ................................................................................................................. 27

4

MALFUNCTIONS ................................................................................................................ 29

4.1 Malfunctions and their remedy ................................................................................................ 29

5

MAINTENANCE.................................................................................................................. 31

5.1 Maintenance plan .................................................................................................................. 31

5.2 Engine ................................................................................................................................. 32

5.3 Gear box .............................................................................................................................. 32

5.4 Driving wheels ...................................................................................................................... 33

5.5 Steering shaft ....................................................................................................................... 33

5.6 General ................................................................................................................................ 33

5.7 33

5.7 Tool attachments .................................................................................................................. 34

5.8 Safe-keeping and storage ....................................................................................................... 34

6

APPENDIX ......................................................................................................................... 35

6.1 Lubricants / adhesives ........................................................................................................... 35

6.2 Accessories .......................................................................................................................... 35

EU DECLARATION OF CONFORMITY ................................................................................................ 36

Page 5

Version 01-2009

S500K

P

ROPER USAGE

Proper usage

The -2-wheel tractors (Type 4H 500 / 4K 500 / 4M 500) as well as the original at-

tachment equipment approved by the manufacturer are exclusively constructed for the usual usage and work in agriculture and forestry, such as grass and field mowing. This can also include

snow removal, winter work and sweeping.

The 2-wheel tractor is depending on the shaft position designed for the following work:

Front attachment: For mowing, rotation ploughing, chaffing, soil drilling, cleaning, snow

blowing, snow removal, transport.

only with steering shaft

Hedge construction: Rotary tilling, ploughing, grubbing, one axled trailer (brakes required).

• The conditions set down in the offer and in the "proper usage" are decisive. Every usage ex-

tending beyond this is not proper usage. The manufacturer assumes no liability for damages

resulting from this; the risk is borne solely by the user.

• This work is only allowed in appropriate scope of the engine size, wheel size and relation-

ship of the surroundings.

• The -2-wheel tractor (Type 4H 500 / 4K 500 / 4M 500) may only be used, main-

tained and repaired by persons who are familiar with this and have been instructed about

the hazards.

• The 2-wheel tractor may not be used on strongly sloping territory. For these special

usages there are tool attachments, twin wheels, iron hanging wheels, track widening, etc.

• Unauthorized changes to the construction of the 2-wheel tractor are prohibited for

reasons of safety!

• The relevant accident prevention directives as well as the other general safety, occupational

health, and traffic rules must be complied with.

Important!

The operating and maintenance conditions prescribed in this operator manual for the

2-wheel tractor are the conditions for the proper usage and must be strictly complied

with.

Warning!

Should the machine be used for a purpose other then the intended purpose listed above or

driven at powers greater than allowed, hazardous situations for persons can result or material damages occur.

Information!

Improper and prohibited use of the machine are not recognized by the manufacturer. Improper attachment of auxiliary devices and parts, which have not been obtained from

exclude any liability for damages resulting from this.

G

ENERAL SAFETY NOTES

Page 6

Version 01-2009

S500K

1 General safety notes

1.1 Possible hazards during interaction with the 2-wheel tractor

In the case of improper usage or misuse hazards threaten for

• the life and limb of the operator,

• of the

2-wheel tractor and other property of the operator,

• the efficient work of the -2 -wheel tractor

All persons involved with the commissioning, operation, and maintenance of the -2-wheel

tractor must:

• be accordingly qualified

• observe and follow this operator manual precisely!

It is a matter of your safety!

1.2 Safety notes and hints

The following symbols are used in this operator manual:

Warning!

Points out important safety hints in this operator manual.

When you see this symbol, be aware of possible risks of injury. Read the following note carefully and inform the other operators.

Caution!

Indicates a possibly dangerous situation.

Nonobservance of this note could lead to light injuries.

Information!

Indicates safety tips and other useful information.

Wear protective

glasses

Wear protective

gloves

Wear safety shoes

Wear hearing prote

c-

tion

Before repair, mainte-

nance and cleaning

work, turn off the engine

and remove the spark

plug connector!

Before commissioning,

read and observe the

operator manual and

safety notes!

Page 7

Version 01-2009

G

ENERAL SAFETY NOTES

S500K

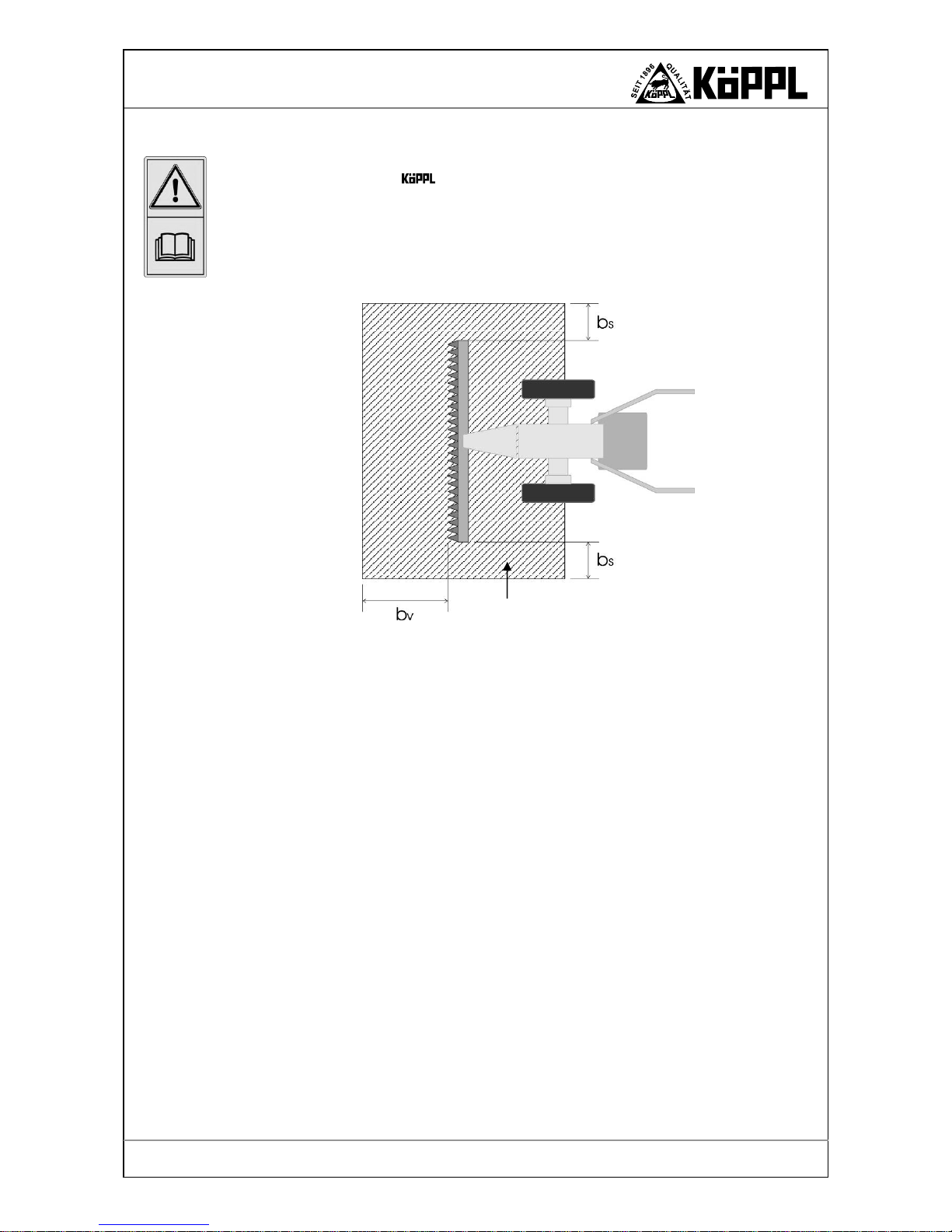

1.3 Hazards due to accessories

Tool attachments, mowing devices and other utilized auxiliary devices may not deactivate the

protective equipment of the

-

2-wheel tractor.

Standing in the hazard zone during work is prohibited.

This zone begins in the middle of the wheel axle, reaches laterally and forwards - depending on

attachment - to various distances:

with

- Mowing beam b

s

= 1 m bv = 2 m

- Snow removal sign bs = 0.5 m bv = 2 m

- AZM-S b

s

= 2 m bv = 5 m

- AZM-A bs = 25 m bv = 25 m

- Sweeping machine bs = 2 m bv = 5 m

- Snow blower bs = 25 m bv = 25 m

- Rotary tiller bs = 2 m bv = 5 m

Also observe the operator manuals of the respective implements!

Hazard zone

Page 8

Version 01-2009

S500K

G

ENERAL SAFETY NOTES

1.4 Emissions

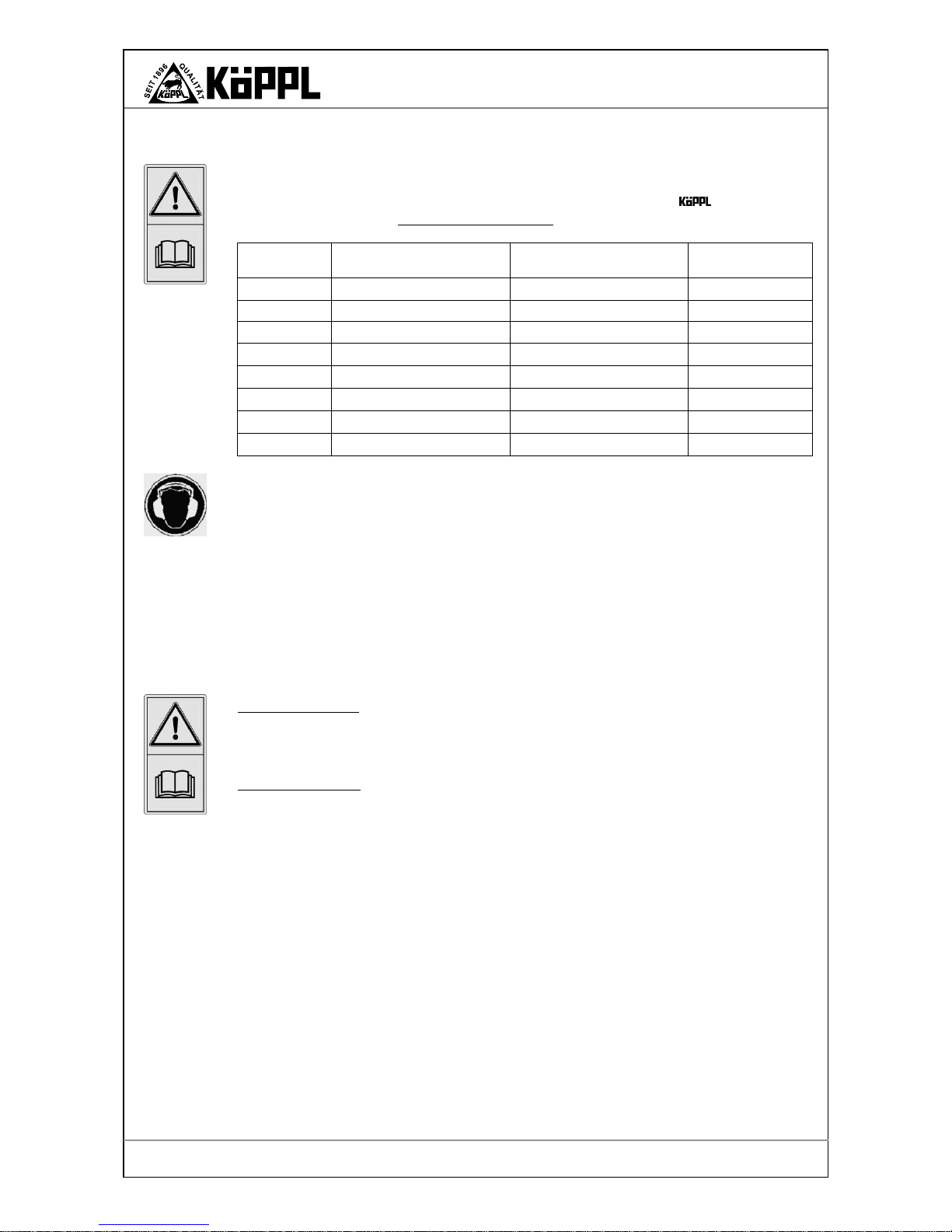

1. Noise information (Sound power level EN ISO 3744, noise pressure level EN ISO 11201)

The A-rated sound power and A-rated Emission-noise pressure level of the

-2-wheel tractor

is at the ear of the operator without auxiliary devices

Design

Sound power level

[dB (A)]/[ rpm]

Noise pressure level

[dB (A)]/[ rpm]

Vibrations

[m/s²]

506 97.3 84.0 2.5

510 98.8 84.7 3.6

512 98.1 86.5 3.7

505H 102.7 93.4 3.9

508H 104.2 92.5 4.2

512H 103.5 90.1 4.6

Depending on the attachment, an increased noise pressure level from up to 4.5 dB(A) can be expected - wear hearing protection!

• The measurement is made on the lawn outdoors; Based on EN ISO 3744 (sound power lev-

el) and EN ISO 11201 (noise pressure level).

• The measurement device used, Norsonic Type 116, conforms to the standard DIN IEC 651

- class 1, DIN IEC 804 - class 1, DIN 45657 - class 1.

• Engine speed = highest engine operating speed

• Radius of the half-shaped measurement surface = 4 m.

2. Vibrations - measurements taken in accordance with EN 1033

Measurement device

• Measurement device - CASTEL, GA-2003

• Vibration pickup - MONITRAN LTD, MTN / P100T-10, S/N 203988

Operating conditions

• Fuel filled approx. 50%.

• Steering shaft set to the body size of the operator.

• Machine broken in and warmed up.

• Measured on the steering shaft in accordance with EN 12733.

• Engine speed = highest engine operation speed

Page 9

Version 01-2009

G

ENERAL SAFETY NOTES

S500K

1.5 Hazard sources

The -2-wheel tractor may be used on commercial and well as private plots.

• Before every start-up, check the machine for traffic and operational safety!

• In addition to the information in this operator manual, observe the general safety and acci-

dent prevention directives!

• During usage of the

-2-wheel tractor on public traffic routes (streets) the directives of

the street traffic ordinance apply in its most recent version. (For this also see 1.6)

• Before beginning work, you must be familiar with all equipment and actuating elements

and their functions. Make certain that all protective devices are properly installed!

• The user is responsible to third parties in the work area!

• Standing in the work and hazard zones of the -2-wheel tractor is prohibited!

• Before starting to drive, check the surrounding area - children! Ensure sufficient visibility!

• Do not let engine run in closed rooms!

• The driver's clothing should be close-fitting. Avoid wearing loose clothing. Wear firm

shoes!

• Caution is recommended when working with fuel - increased risk of fire! Never refuel in

the vicinity of open flames, ignitable sparks and hot engine parts. Do not smoke when fueling!

• Before fueling, switch off the engine and pull out the ignition key (if present). Do not refuel

in closed rooms. Do not spill fuel! Use suitable filling aids.

• To avoid risk of fire, keep the main engine clean!

• Before maintenance and cleaning work, turn off the engine and remove the spark plug

connector!

• When coupling and decoupling tool attachments to or from the main engine, particu-

lar caution is necessary!

• Make certain that all protective devices are properly installed!

1.6 Lighting devices on single-axle tractors

Here one must differentiate whether the one axled tractor

• is guided by a pedestrian on the shafts,

• is driven from a seat cart (single-track trailer) or

• driven from a trailer.

One axled tractors, which are guided by a pedestrian on the shafts, require during darkness - or

when the weather requires – at least one simple lamp with white light, which should be attached

to the left side or carried along manually, so that the light is well visible to oncoming and passing traffic (§ 50 Para. 2 of the Road traffic act and § 17 Para. 5 of the Road traffic act).

One axled tractors which are driven from a seat cart or a trailer

• must be equipped up to a width of 1000 mm with one headlight,

• beyond a width of 1000 mm with two headlights

, which when pulling a one axled trailer can be fastened to this (§ 50 Para. 2 of the Road traffic

act).

If the one axled tractor is driven from a single-track seat cart, then a triangular reflector and a

taillight must be attached (§ 53 Para. 6 of the Road traffic act), blinking lights (travel direction

indicator) are not required for a seat cart. (§ 54 Para. 5 No. 5 of the Road traffic act).

For one axled tensile or work machines, which are operated by a walk-behind person, no operating permit or driver's license is required.

During transport of a one axled tractor with trailer on public streets, which is used for lof purposes, the operating permit is sufficient up to a design-related maximum speed of 20 km/h. It

Page 10

Version 01-2009

S500K

G

ENERAL SAFETY NOTES

must be guided along. The name and domicile of the holder must be indicated by a sign on the

trailer. A class L driver's license is sufficient. A permit is required for design-related speeds over

20 km/h..

1.7 Workplace

The operator position on the

-2-wheel tractor is found on both steering shafts (operator

field) in front of the -2-wheel tractor

1.8 Authorized operators

Only authorized persons may work with the -2-wheel tractor.

The minimum age for operators is 16 years.

The operator is responsible to third parties in the work area.

The responsibilities for the various activities on the

-2-wheel tractor must be clearly de-

termined and maintained. Unclear competencies are a safety risk.

The operating company must

• make the operator manual available to the operator

• and make certain that the operator has read and understood it.

Operator position

Travel direction

Figure 1. Operator position.

Page 11

Version 01-2009

G

ENERAL SAFETY NOTES

S500K

1.9 Personal protective equipment

For the operation

Wear firm shoes!

Wear close-fitting clothing

For longer work times, suitable hearing protection should be worn.

For the cleaning

Firm protective gloves (leather) for protection against sharp objects

(auxiliary devices).

For sharpening the mowing blade

Wear protective glasses

1.10 Safety measures at the work site

• When starting the engine, the traction drive and gear box must be decoupled.

• Travel, steering, braking as tilt behavior are influenced by tool attachments. There-

fore ensure sufficient steering and braking capability and adapt the work speed to the

environmental conditions!

• When driving on hills, in valleys or across slopes, avoid sudden curves.

• Driving downhill in neutral gear is prohibited! The machine can roll away due to its

own weight!

• When the engine is running, wearers of pace makers may not touch the current-

carrying parts of the ignition system.

• Before starting to drive, check brakes and brake effectiveness.

• Remove larger objects from the work area (e. g. boards, cables, rocks, etc.).

• Keep hands and feet away from moving parts during operation.

• Ensure sufficient lighting in the work area.

• Work cross-wise along the slope, never up or down it!

• Be particularly careful when changing the travel direction on the slope.

• Never decouple and switch gears on inclines.

• Never leave the operator position during the work.

• Never make changes or repairs to load-carrying and safety-related parts (frames, ax-

les, etc.)

• In case of damages, stop the machine immediately. Pull out spark plug connectors on

the main engine and have damages repaired!

• Should the machine be used for cutting fruits, which are considered food, such places

which come into contact with the food may not be lubricated with machine oil or

grease or protected against rust.

• Should risk of slipping exist in sloping territories, then the

- 2-wheel tractor

should be held by an assistant with a rod or rope. The assistant must stand above the

vehicle at a sufficient distance from the work tools.

Loading...

Loading...