Koehler K24394, K24308, K24304, K24398 Instruction Manual

K243XX

Programmable Muffle Furnace

Operation and Instruction Manual

REV A

Koehler Instrument Company, Inc.

1595 Sycamore Avenue • Bohemia, New York 11716-1796 • USA

Toll Free: 1-800-878-9070 (US only) • Tel: +1 631 589 3800 • Fax: +1 631 589 3815

http://www.koehlerinstrument.com • e-mail: info@koehlerinstrument.com

Petroleum Testing & Analysis Instrumentation • Custom Design & Manufacturing

Operation and Instruction Manual

K243XX Ashing Furnace

Table of Contents

1 Introduction ...................................................................................................................3

1.1 Koehler’s Commitment to Our Customers.............................................................................................3

1.2 Recommended Resources and Publi cations.........................................................................................3

1.3 Instrument Specifications.......................................................................................................................3

2 Safety Information and Warnings ................................................................................4

3 Getting Started...............................................................................................................4

3.1 Unpacking ..............................................................................................................................................4

3.2 Setup......................................................................................................................................................4

4 Temperature Controller.................................................................................................5

4.1 Description of Controller.........................................................................................................................5

4.2 Controller Features.................................................................................................................................8

4.3 Entering Information............................................................................................................................... 9

4.4 Setting/Changing Parts of the Controller .............................................................................................11

4.5 Extra Functions ....................................................................................................................................12

4.6 Saving Programs..................................................................................................................................13

4.7 Calling Programs..................................................................................................................................13

4.8 Program Start.......................................................................................................................................14

4.9 Program Change during Execution......................................................................................................14

4.10 Brief Program Interruption.................................................................................................................15

4.11 Terminating a Program.....................................................................................................................15

4.12 Segment Skip Key ............................................................................................................................15

4.13 Info Menu..........................................................................................................................................15

4.14 Configuration/ Customer-Specified Settings.....................................................................................16

4.15 Configuration Options in Configuration Level 1................................................................................16

(Password = “0”).........................................................................................................................................16

4.16 Configuration Options in Configuration Level 2................................................................................17

(Password = “2”).........................................................................................................................................17

4.17 Auto Tune..........................................................................................................................................17

5 Operation .....................................................................................................................18

5.1 General Notes ......................................................................................................................................18

5.2 Regulating the air supply......................................................................................................................18

5.3 Maintenance and fault clearance.........................................................................................................18

6 Service Trouble Shooting...........................................................................................19

6.1 Replacing the heating plates or heating coil ........................................................................................19

6.2 Repairing the lining (only furnaces with brick insulation) .....................................................................19

6.3 Controller Troubleshooting...................................................................................................................20

7 Electrical Trouble Shooting........................................................................................22

8 Service..........................................................................................................................23

9 Storage.........................................................................................................................23

10 Warranty......................................................................................................................23

K243XX-Manual -1-

Operation and Instruction Manual

K243XX Ashing Furnace

12 Returned Goods Policy...............................................................................................23

Notes..................................................................................................................................24

K243XX-Manual -2-

Operation and Instruction Manual

K243XX Ashing Furnace

1 Introduction

The Koehler K243XX Muffle Furnace is the

latest design for performing Ashing of petroleum

products according to the ASTM test methods

listed in Section 1.2.

This manual provides important information

regarding safety, technical reference, installation

requirements, operating condition specifications,

user facility resource requirements, and operating

instructions for the Koehler Muffle Furnace. This

manual should also be used in conjunction with

applicable published laboratory procedures.

Information on these procedures is given in

section 1.2.

1.1 Koehler’s Commitment to Our

Customers

Providing quality testing instrumentation and

technical support services for research and testing

laboratories has been our specialty for more than

50 years. At Koehler, the primary focus of our

business is providing you with the full support of

your laboratory testing needs. Our products are

backed by our staff of technically knowledgeable,

trained specialists who are experienced in both

petroleum products testing and instrument service

to better understand your requirements and

provide you with the best solutions. You can

depend on Koehler for a full range of accurate and

reliable instrumentation as well as support for your

laboratory testing programs. Please do not

hesitate to contact us at any time with your

inquiries about equipment, tests, or technical

support.

Toll Free: 1-800-878-9070 (US only)

Tel: +1 631 589 3800

Fax: +1 631 589 3815

Email: info@koehlerinstrument.com

http://www.koehlerinstrument.com

1.2 Recommended Resources and

Publications

1. American Society for Testing and Materials

(ASTM)

100 Barr Harbor Drive

West Conshohocken, Pennsylvania 194282959, USA

Tel: +1 610 832 9500

Fax: +1 610 832 9555

http://www.astm.org

email: service@astm.org

ASTM Publication:

ASTM D482: Standard Test Method for

Ash from Petroleum Products

ASTM D874: Standard Test Method for

Sulfated Ash from Lubricating Oils and

Additives

ASTM D3174: Standard Test Method for

Ash in the Analysis Sample of Coal and

Coke from Coal

ASTM D4422: Standard Test Method for

Ash Analysis in Petroleum Coke

ASTM D5184: Standard Test Methods for

Determination of Aluminum and Silicon in

Fuel Oils by Ashing, Fusion, Inductively

Coupled Plasma Atomic Emission

Spectrometry, and Atomic Absorption

Spectrometry

1.3 Instrument Specifications

Models:

K24305, K24306,

K24307, K24308,

K24395, K24396,

K24397, K24398

Electrical

Requirements:

208V, 50/60Hz single

phase

240V, 50/60Hz single

phase

Temperature Range:

Temperature Control

Stability:

Open Volume:

Ambient to 1100°C

±3°C

0.07cu. ft. model: 3L

0.16cu. ft. model: 5L

0.33cu. ft. model: 9L

0.47cu. ft. model: 15L

Power:

0.07cu. ft. model: 1.2KW

0.16cu. ft. model: 2.4KW

0.33cu. ft. model: 3.0KW

0.47cu. ft. model: 3.6KW

K243XX-Manual -3-

Operation and Instruction Manual

K243XX Ashing Furnace

2 Safety Information and Warnings

Safety Considerations. The use of this

equipment may involve hazardous materials and

operations. This manual does not purport to

address all of the safety problems associated with

the use of this equipment. It is the responsibility of

any user of this equipment to investigate,

research, and establish appropriate safety and

health practices and determine the applicability of

regulatory limitations prior to use.

Equipment Modifications and Replacement

Parts. Any modification or alteration of this

equipment from that of factory specifications is not

recommended voids the manufacturer warranty,

product safety, performance specifications, and/or

certifications whether specified or implied, and

may result in personal injury and/or property loss.

Replacement parts must be O.E.M. exact

replacement equipment.

Unit Design. This equipment is specifically

designed for use in accordance with the applicable

standard test methods listed in section 1.2 of this

manual. The use of this equipment in accordance

with any other test procedures, or for any other

purpose, is not recommended and may be

extremely hazardous.

Chemical Reagents Information. Chemicals and

reagents used in performing the test may exhibit

potential hazards. Any user must be familiarized

with the possible dangers before use. We also

recommend consulting the Material Data and

Safety Sheet (MSDS) on each chemical reagent

for additional information. MSDS information can

be easily located on the internet at

http://siri.uvm.edu or http://www.sigma-

aldrich.com.

Disposal. Upon delivery the furnace does not

contain any material which is to be classified as

hazardous waste. However, process residues

may collect in the insulation during operation.

These may be dangerous to health and/or

dangerous to the environment.

Therefore we recommend proceeding as follows:

Remove electrical components and dispose of

as electrical waste.

Remove insulation and dispose of as special/

hazardous waste (wear a protective mask P2,

protective gloves and a protective suit).

Dispose of the housing as scrap metal

3 Getting Started

assume that the user is aware of the contents of

this document, which lists the warranty conditions

and important precautions.

3.1 Unpacking

accessories in a secure location. Ensure that all

parts listed on the packing list are present. Inspect

the unit and all accessories for damage. If any

damage is found, keep all packing materials and

immediately report the damage to the carrier. We

will assist you with your claim, if requested. When

submitting a claim for shipping damage, request

that the carrier inspect the shipping container and

equipment. Do not return goods to Koehler without

written authorization.

The instructions for preparing the equipment

Carefully unpack and place the instrument and

3.2 Setup

3.2.1 Installation Site

Place the furnace on a non-flammable support

(stone, metal or similar). Keep a safe distance

from flammable components, 0.5 meter from the

furnace sides and 1meter from the top. The

minimum distance between the furnace sides and

non-flammable materials can be reduced to 0.2

meters.

Ventilation. Provide sufficient room ventilation to

carry off exhaust heat and gases which develop

during the process. Non-observance can result in

a fire risk and danger to health.

K243XX-Manual -4-

Operation and Instruction Manual

K243XX Ashing Furnace

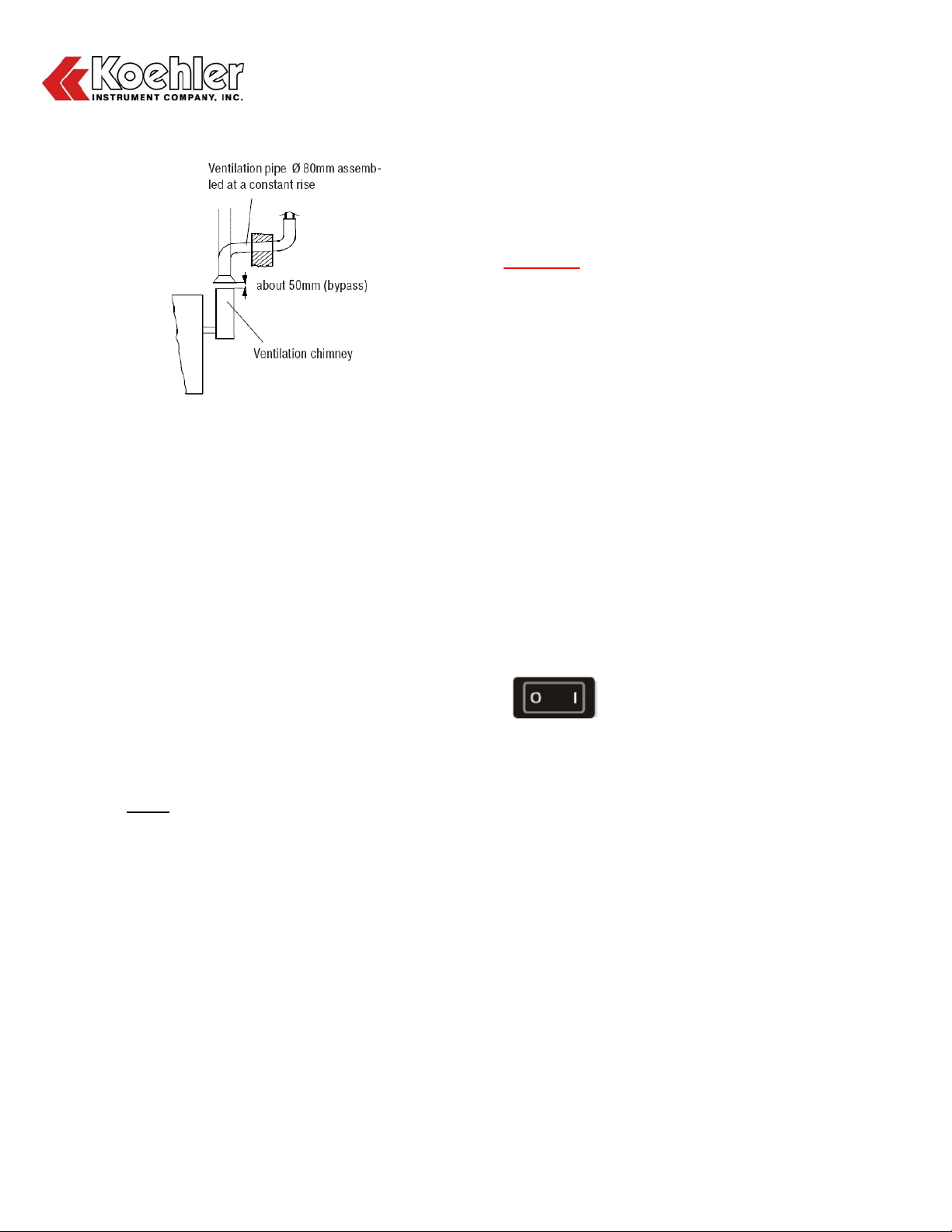

3.2.2 Assembling the Ventilation Pipe

In all cases, we recommend connecting the

furnace to an exhaust ductwork, leading the

arising gasses out of the facility

A standard ventilation pipe of metal with

NW80 – NW 210 can be used. It must be laid

at a constant slope and fastened to the wall or

ceiling.

Caution: The exhaust gases can only be

carried off if the room is ventilated by a

corresponding fresh air opening.

3.2.3 Electrical Connection

Plug the main plug in a corresponding

receptacle which is protected sufficiently

depending on the rated power of the furnace.

If the furnace is ordered / delivered without a

plug, a qualified electrician must connect the

furnace.

NOTE

: Using extension cables and/or junction

boxes may lead to a reduced furnace output

due to the voltage drop in the lines. The

power is also reduced if the connection line to

the junction box is very long, and the furnace

will not reach its nominal temperature. Please

have the connection checked by an

electrician. The voltage may not drop below

the rated load by more than 10%.

WARNING

: For safety, disconnect the power

when performing any maintenance and/or

cleaning.

3.2.4 Initial Heating Procedure

To dry out the brick lining and to create an

oxide protection layer on the resistance wire,

an initial heat run must be performed prior to

testing. This may cause an unpleasant smell.

Provide sufficient ventilation.

Heat the empty furnace up to 1050ºC over the

course of 6 hours. Maintain this temperature

for one hour, then let the furnace cool down

on its own.

The furnace is now ready to operate.

4 Temperature Controller

4.1 Description of Controller

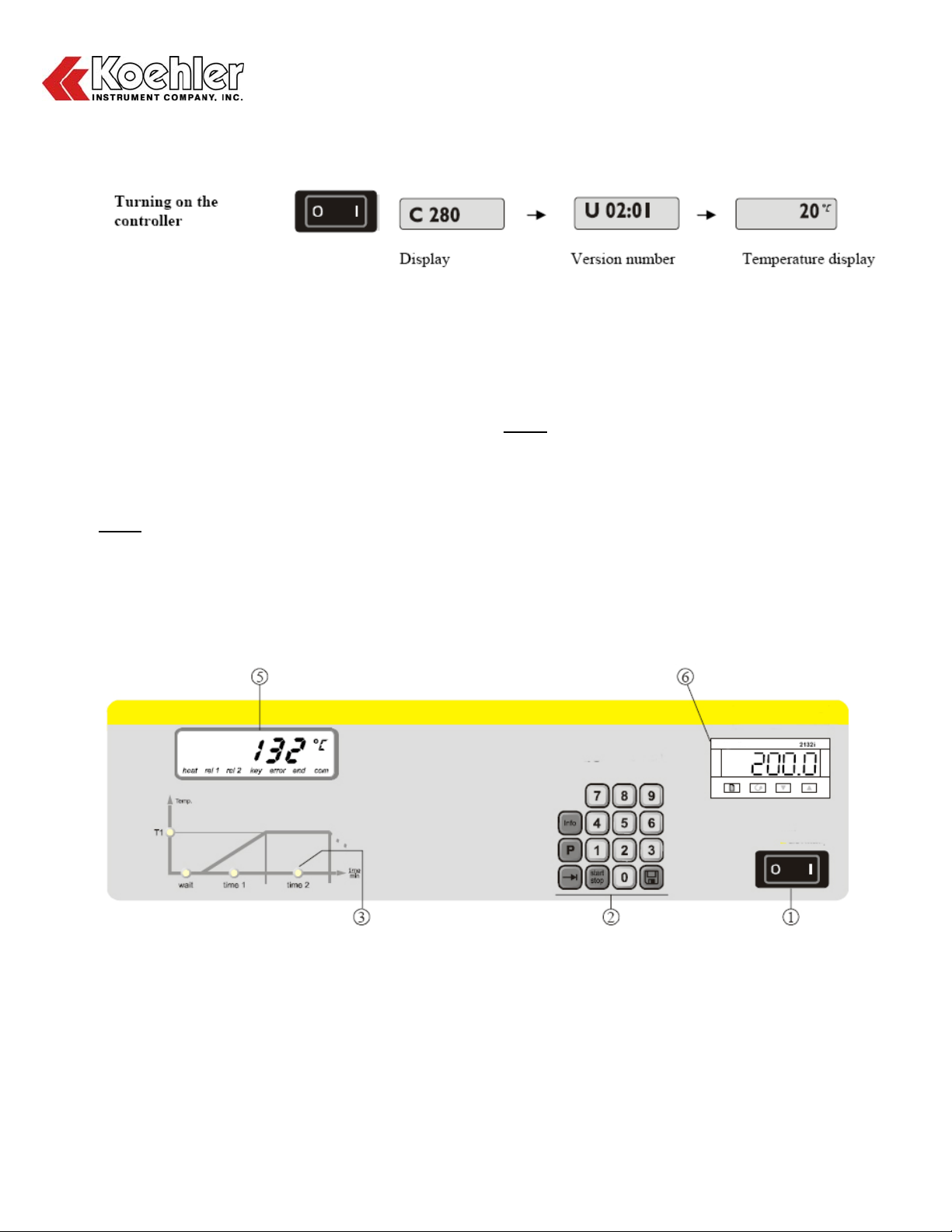

4.1.1 Power Switch/ Control Current Switch

The power switch / control current

switch is located below or next to the keyboard

block. Stop running a heating program before

turning off the furnace with the power switch.

K243XX-Manual -5-

4.1.2 Turning on the Controller/Furnace

Operation and Instruction Manual

K243XX Ashing Furnace

Switch the power switch to the “I” or ON position.

The controller first displays the controller type and

version number and then the temperature display.

Once the temperature is displayed, the controller

is ready to operate.

All necessary settings for proper function of the

furnace have been preconfigured at the factory.

The controllers for the heating program must be

configured on a process- or user- specific basis.

NOTE: Some functions depend on the version

number of the controller. Turn the controller off

4.1.4 Control Panel

and then on again to briefly display the version

number of the controller

4.1.3 Turning off the Controller/Furnace

Turn the main switch to position “O”

NOTE

: End all heating programs before turning

the furnace off at the main switch, otherwise the

controller will generate a fault message when it is

turned back on. See faults/fault messages in the

troubleshooting section.

K243XX-Manual -6-

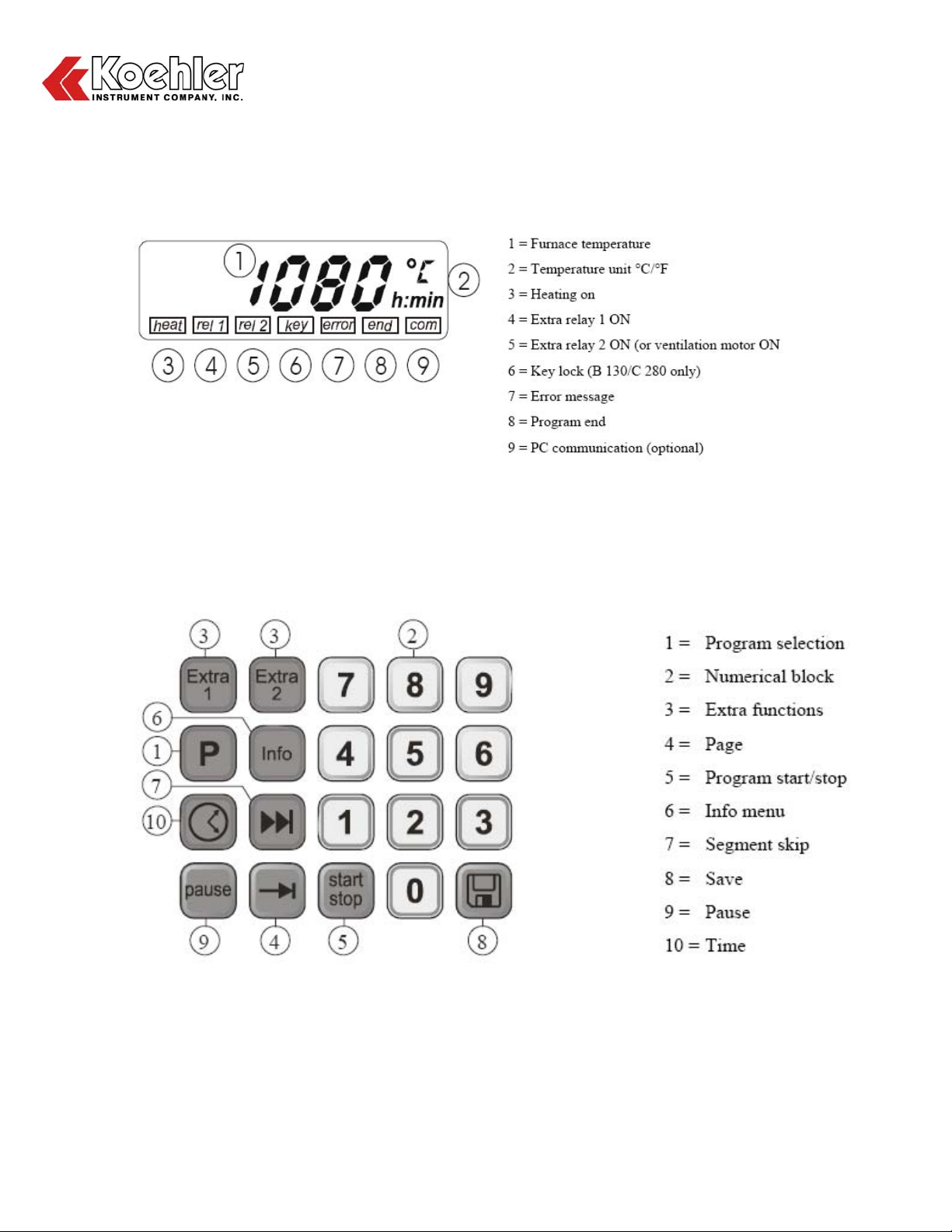

4.1.5 Display Panel

Operation and Instruction Manual

K243XX Ashing Furnace

4.1.6 Keypad

K243XX-Manual -7-

Loading...

Loading...