Koden Electronics RB717A, RB718A User Manual

CHAPTER 6. MAINTENANCE AND INSPECTION

A qualified engineer should carry out most of maintenance work on this radar. If your radar set has

any problem, contact your local dealer for repair.

Very High Voltage is present inside the radar set. Do

not attempt to open the display rear cover or disassemble internal module. When you open the radome, make sure to turn off the main power supply

at switch board.

Even if the radar is switched OFF, the radar set is

still powered with very small amount of current.

The following table shows the maintenance by user. Please check each item periodically.

Tab. 6-1 Maintenance

Inspection Interval Inspection Item Method of Inspection and Maintenance

3-6 months Rust and looseness in

scanner unit

Display screen of LCD

display

6-12 months Grease application to

antenna drive gear

Check for contact of

connectors

Antenna motor

brush(RA52/53/54)

Articles of consumption

The radar uses the life-limited parts as listed below that require periodic replacement.

(1) Magnetron

This part is used in the scanner unit. If distant echo images have become weak, the

magnetron probably may have degraded. In such a case, you need to replace this item.

Consult your local service agent for replacement.

Practical life to replacement: 3000hour(typ.) (500hour guaranteed by the magnetron

manufacturer)

(2) LCD back-light

This part used in the display unit. If the display screen is extremely dark and its illumination cannot be corrected by adjusting the screen brightness, the LCD backlighting lamp

may be faulty or may have burnt out. In such a case, you need to replace it. Consult your

local agent for replacement.

Period of the replacement: 15000 hours (typ.) (1000 hours at 0°C)

!

WARNING

Check if the scanner’s fitting bolts are corroded.

Clean the filter plate and LCD screen surfaces with a soft

and wet cloth. Avoid organic solvent.

Apply an even coating of grease* to the entire surface of

the antenna drive gear with a spatula or brush.

Check whether connectors are properly connected. If not,

redo connection or make good contact by using a contact

restoring chemical agent or by polishing or replace with a

new one if necessary.

Check the length of brushes. If the length is less than

6mm, replace both brushes with new one.

81

A

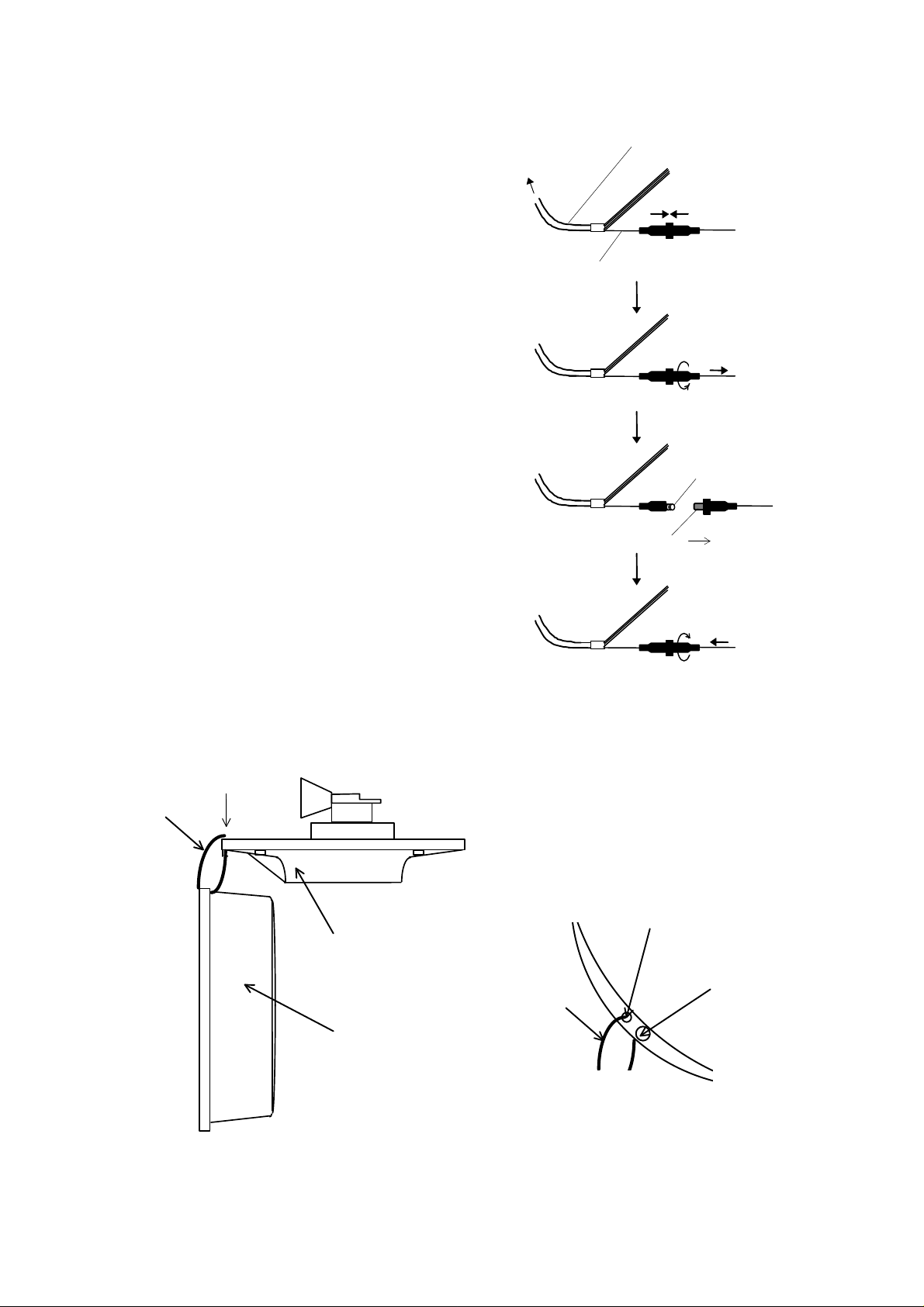

(3) Fuse

The fuse is in-line type, built in

to the power supply cable. If the fuse

appears to be blown, check the fuse. If

To display unit

Power supply cable

Push

blown, replace it following the

procedure shown in Fig.6-2.

Wire(White)

Turn counterclockwise

and pull

Spring

Fuse

Push and turn clockwise

Replace new fuse

Fig. 6-2 Method for replacing fuse

Note: Before maintenance of scanner, you can hang a radome (upper) using cord through hole as fol-

lows.

Cord

A: Top view

Radome(bottom)

Hole

Cord

Fixing screw

Radome(Upper)

Fig. 6-3 Method for replacing fuse

82

CHAPTER 7. TROUBLESHOOTING

This chapter explains how to identify trouble locations when the radar is found faulty and how to

request repair.

If there is any trouble, press and hold the POWER key for 3 seconds to power off. Then turn on the

equipment again and wait 10 sec at least.

If you find the radar is faulty, check it by the following procedure described below. If you find as

a result of inspection that the fault cannot be repaired on board, contact your distributor for repair.

For faster service, please let us know about followings when you request repair:

(1) Ship’s name, place of anchorage, allowable repair period or time

(2) Radar type (This radar is RA53 or RA54.)

(3) Manufacturing number (indicated on the back of the display unit)

(4) Fault symptoms and inspection results

There are high voltage circuits inside of this radar.

Do not attempt to open the rear cover of display unit

or disassemble internal parts. When you open the

radome for installation, power must be off.

Even if power switch is OFF, this radar is still supplied with power inside.

This chapter explains how to identify trouble locations when the radar is found faulty and how to

request repair.

7.1 Fault Diagnosis by Self-check

The radar incorporates a failure diagnostic function (called "self-check") to diagnose faults by the

equipment itself.

Refer to "5.5.4.4 Fault Diagnosis by Self Check (SYSTEM CHECK)" and check whether there is

any fault in your radar.

!

WARNING

83

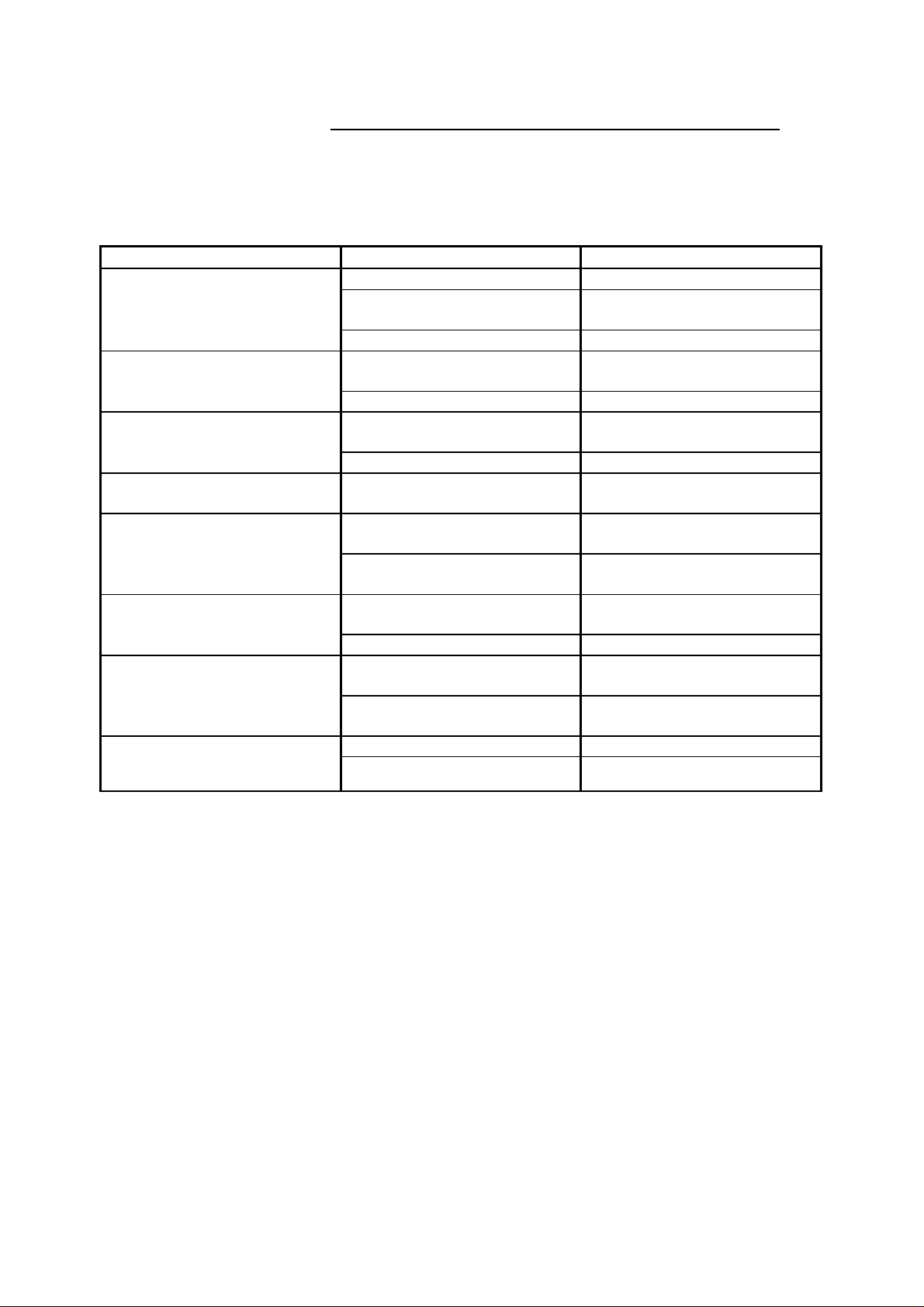

7.2 Inspecting Each Part

When you have finished self-check, inspect each part of the radar according to Tab.7-1.

Tab. 7-1 Troubleshooting

Symptom Cause Corrective action

(1) Radar cannot be powered on. Power cable is disconnected. Connect power cable correctly.

Power supply voltage is outside

of specified value

Use Specified power supply.

(See Section 3.2)

Fuse in power cable is blown. Replace fuse. (See Chapter 6)

(2) Nothing is displayed although radar is powered on.

Brightness is improperly adjusted.

Use BRIL key to adjust. (See

Section 5.3.)

LCD is faulty. Contact your dealer.

(3) Screen is dark. Brightness is improperly ad-

justed.

Use BRIL key to adjust. (See

Section 5.3.

Backlight is faulty. Contact your dealer.

(4) Video does not appear although characters are displayed.

(5) Echo image on screen differs

from actual image.

Timing adjustment is incorrectly

(6) Echo images are blurred. GAIN, STC, or FTC is improp-

Interconnecting cable is out of

place.

Connect interconnecting cable

correctly.

Ship’s heading is incorrectly set. Set ship’s heading correctly.

(See Section 5.5.4.5.4)

Set timing adjustment correctly.

set.

(See Section 5.5.4.5.4)

Adjust. (See Section 5.3.6 to

erly set.

5.3.8.)

Magnetron has degraded. Contact your dealer.

(7) Too much noise. Radar is not tuned correctly Adjust TUNE. (See Section

5.5.3.4)

Radar set is not grounded to

earth.

Connect grounding wire. (See

Section 3.4 to 3.6.)

(8) No response to key pressing. Panel keys are not in contact. Contact your dealer.

Power supply circuit is faulty. Contact your dealer.

84

Loading...

Loading...