Page 1

Page 2

Page 3

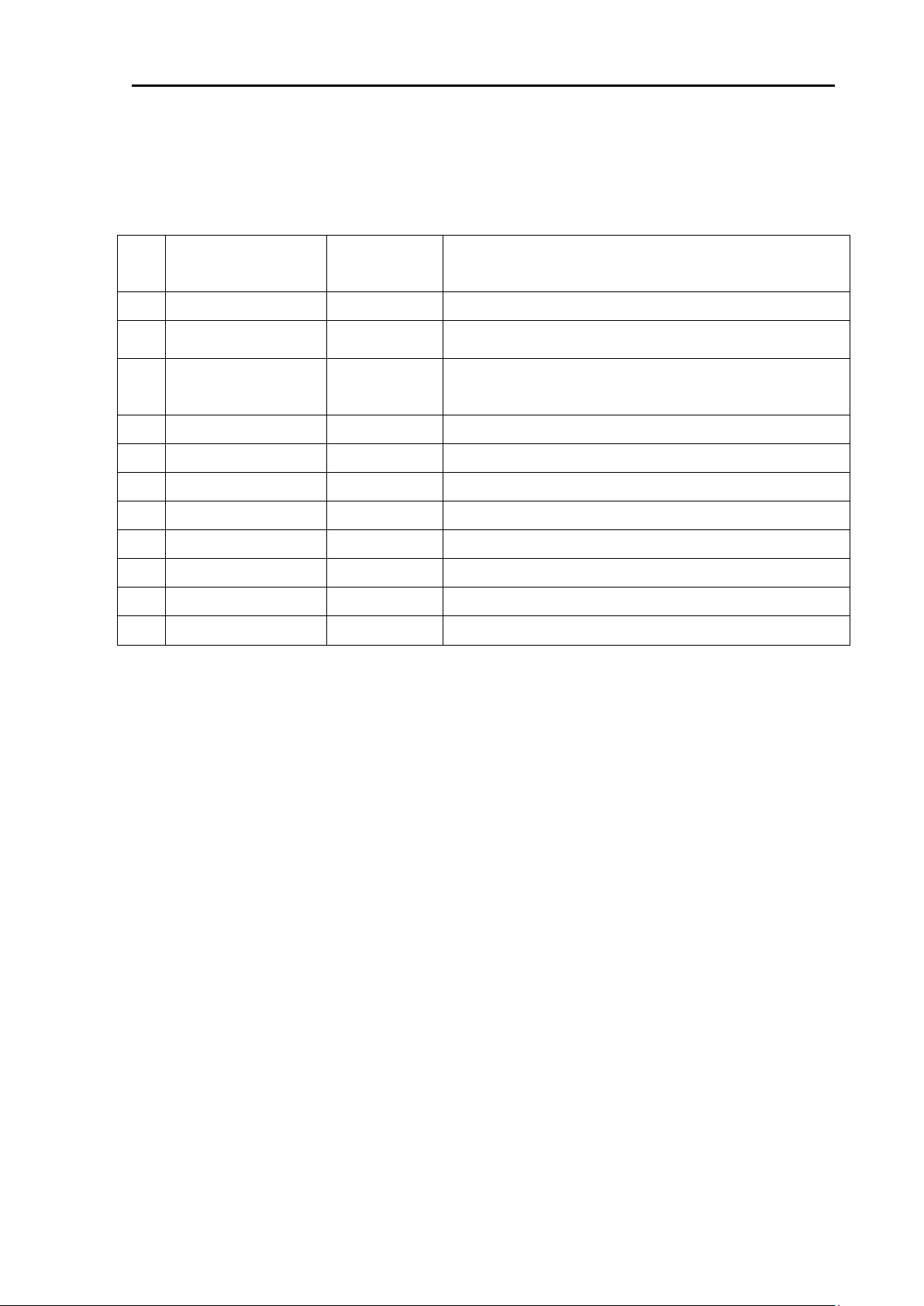

MDC-5200/5500 Series Revision History

No.

Doc. No.-Rev. No.

Date Revised

(Y/M/D)

Revised Content

0

0092655002-00

2016/04/08

First edition

1

0092655002-01

2016/09/07

Content, Chapter 2, Chapter 3, Chapter 4, Chapter 5,

Chapter 7, Cover

2

0092655002-02

2017/10/03

Preface, Chapter 2, Chapter 3, Chapter 4, chapter 5,

Chapter 6, Chapter 7, INTER CONNECTION DIAGRAM,

Cover

3

0092655002-03

2018/04/19

Chapter 3, Chapter 4

4 5 6 7 8 9

10

MDC-5200/5500 Series Installation Manual

Doc No: 0092655002

Document Revision History

Document No. Revised Version Norm

When part of the document needs to be revised, the document has advanced revision number.

The document No. is indicated at the lower right side on the cover and at the left or right side of the

footer region of each page.

© 2016-2018 Koden Electronics Co., Ltd. All rights reserved.

No part of this publication may be reproduced, transmitted, translated in any from by any means

without the written permission of Koden Electronics Co., Ltd. The technical descriptions contained in

this publication are subject to change without notice. Koden assumes no responsibility for any errors,

incidental or consequential damages caused by misinterpretation of the descriptions contained in this

publication.

0092655002-03 i

Page 4

A table of content MDC-5200/5500 Series

A table of content

Document Revision History ...................................................................................................................... i

A table of content ...................................................................................................................................... ii

Preface .................................................................................................................................................... 1

Precaution for operation ................................................................................................................... 1

• Caution about rotating antenna:..................................................................................................... 1

• Caution about health risks caused by radio wave: ........................................................................ 1

• Caution about dangerous internal high voltage in the device: ....................................................... 1

Precautions for maintenance ........................................................................................................... 2

• Caution against residual high voltage: ........................................................................................... 2

• Keep inboard power source “Off”: .................................................................................................. 2

• Caution against the dust: ............................................................................................................... 2

• Measures against static electricity: ................................................................................................ 2

• Prohibited matter: ........................................................................................................................... 2

• Break in procedure of stored radar: ............................................................................................... 2

Chapter 1 Prior to installation ................................................................................... 1-1

1.1 Installation precautions ........................................................................................................... 1-1

1.2 Unpacking of components ....................................................................................................... 1-1

1.3 Appearance verification of each unit and accessories ............................................................ 1-1

1.4 Selection of location for installation ......................................................................................... 1-1

1.4.1 Antenna Scanner unit ........................................................................................................ 1-2

1.4.2 Display unit and Operation unit .......................................................................................... 1-3

1.5 Cable wiring and interconnection ............................................................................................ 1-4

1.5.1 Antenna Scanner unit ........................................................................................................ 1-4

1.5.2 Display unit ........................................................................................................................ 1-4

Chapter 2 System configurations ............................................................................. 2-1

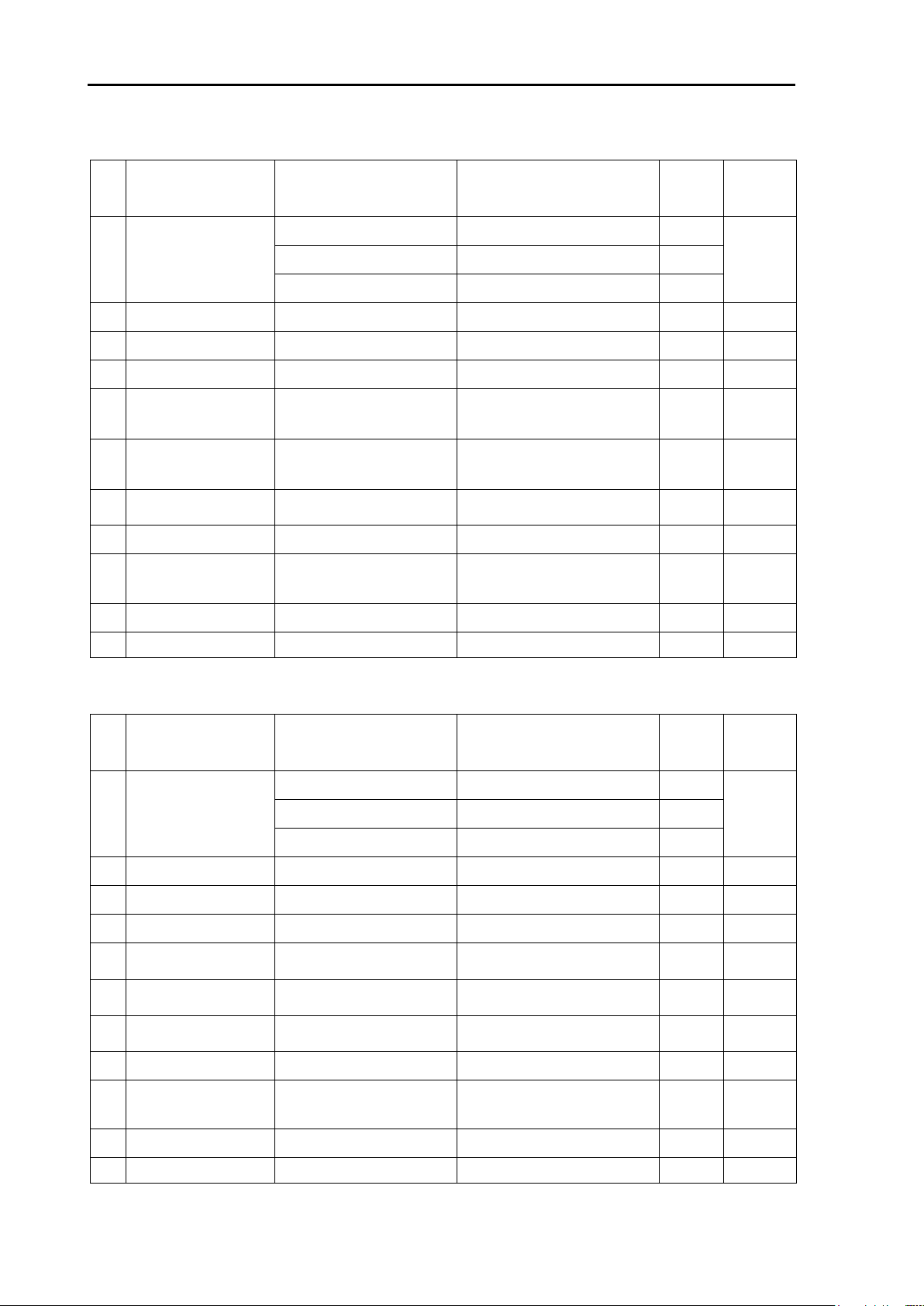

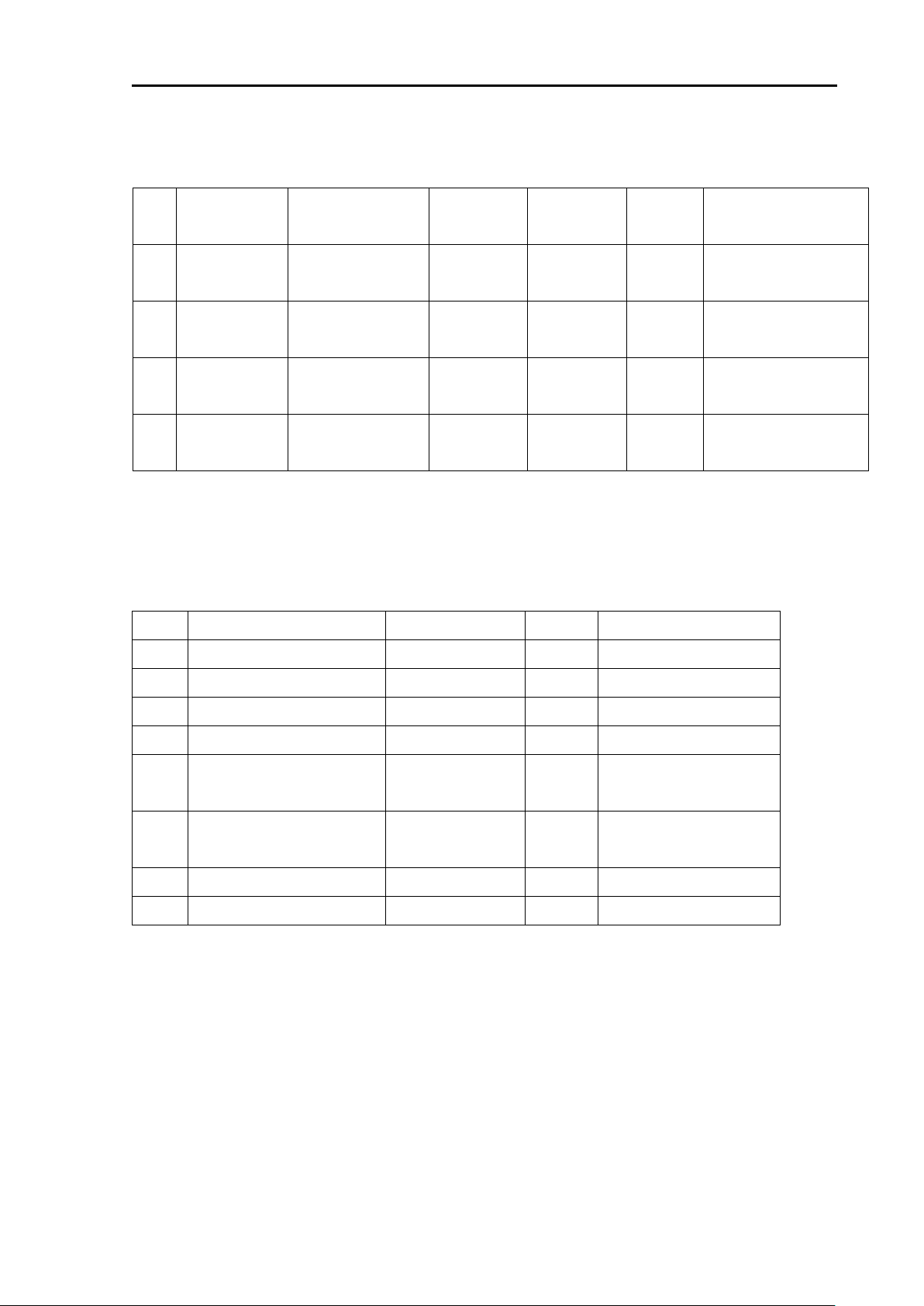

2.1 Standard configuration list ....................................................................................................... 2-1

2.2 Spare parts list ........................................................................................................................ 2-5

2.3 Installation material list ............................................................................................................ 2-5

2.4 Option list ................................................................................................................................ 2-6

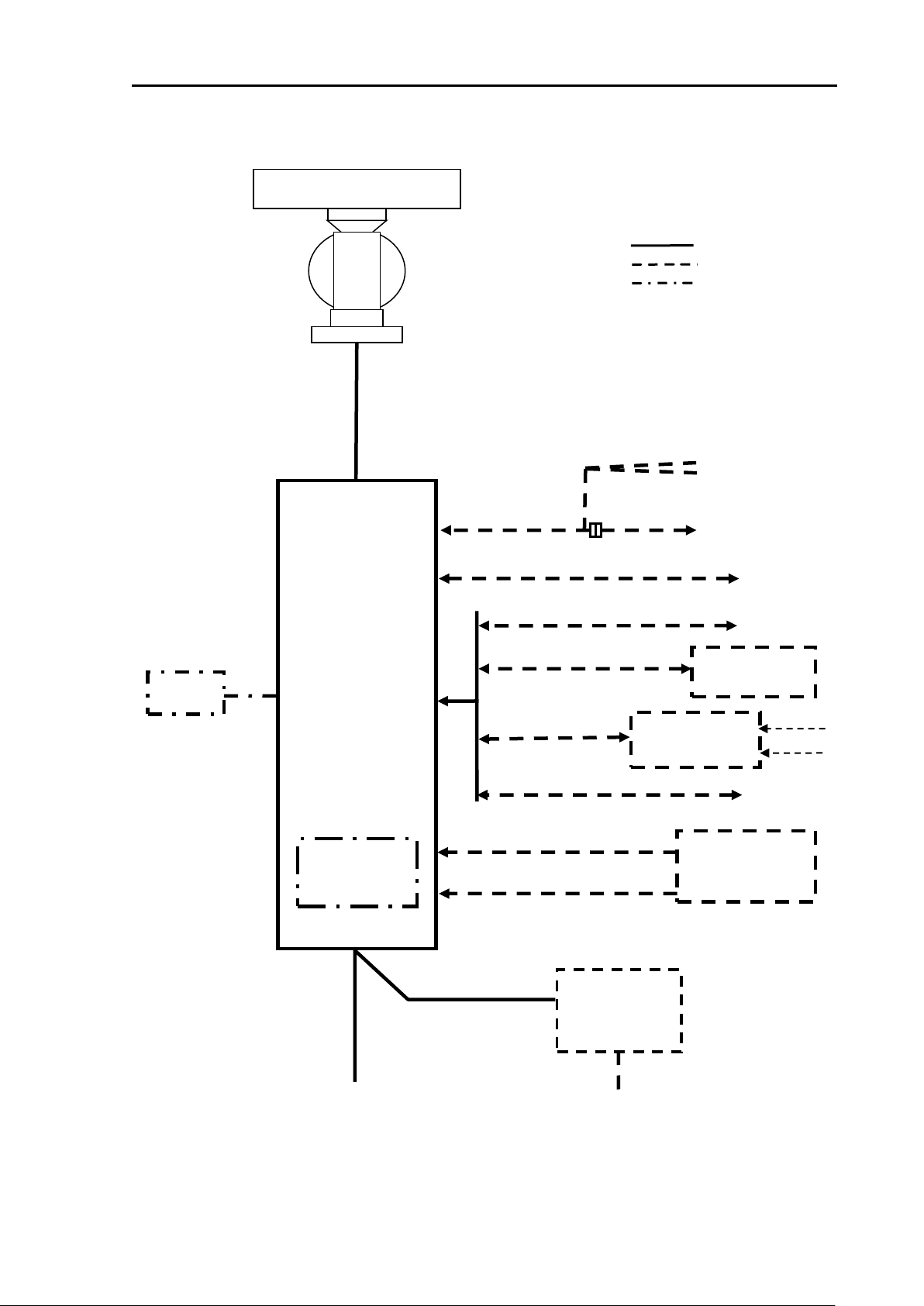

2.5 MDC-5204 series system configuration .................................................................................. 2-7

2.6 MDC-5206/5212/5225 series system configuration ................................................................ 2-8

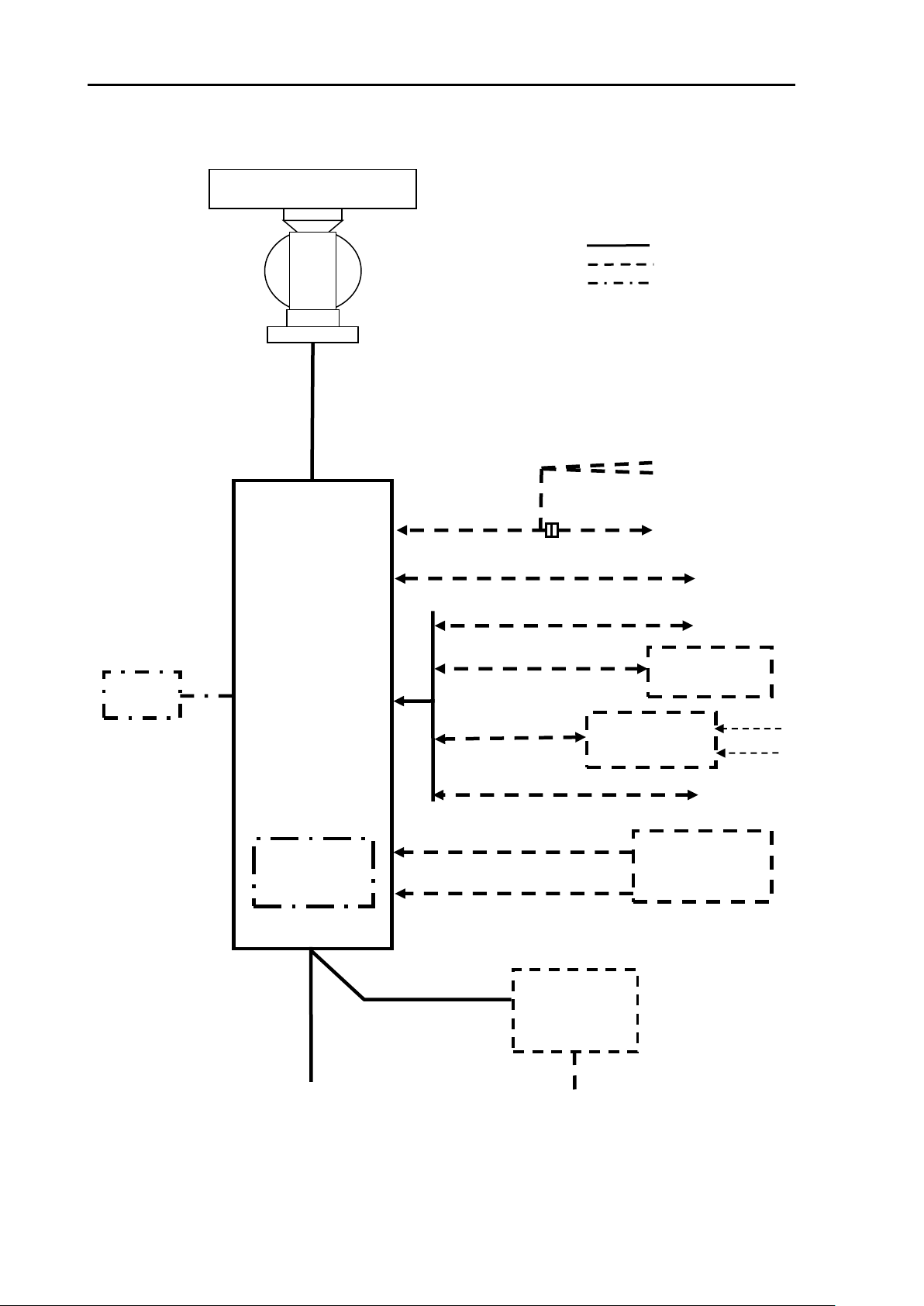

2.7 MDC-5504 series system configuration .................................................................................. 2-9

2.8 MDC-5506/5512/5525 series system configuration .............................................................. 2-10

Chapter 3 Installation method .................................................................................. 3-1

3.1 How to install the Antenna Scanner unit ................................................................................. 3-1

3.1.1 Installation of the Antenna Scanner unit ............................................................................ 3-3

3.1.2 Mounting the Antenna ........................................................................................................ 3-4

ii 0092655002-03

Page 5

MDC-5200/5500 Series A table of content

3.1.3 Installation of the connecting cable 242J159098x-xxM ..................................................... 3-5

3.1.3.1 Scanner unit 4kW (RB806: MDC-5204/5504) ............................................................... 3-5

3.1.4 Installation of the connecting cable CW-845-xxM ............................................................. 3-6

3.1.4.1 Scanner unit 6kW (RB807: MDC-5206/5506) ............................................................... 3-6

3.1.4.2 Scanner unit 12kW (RB808: MDC-5212/5512) ........................................................... 3-11

3.1.4.3 Scanner unit 25kW (RB809: MDC-5225/5525) ........................................................... 3-18

3.2 Interconnection diagram of cable .......................................................................................... 3-23

3.2.1 242J159098 (MDC-5204/5504) ....................................................................................... 3-24

3.2.2 CW-845 (MDC-5206/5212/5225/5506/5512/5525) ......................................................... 3-25

3.3 Installation of the display unit ................................................................................................ 3-26

3.3.1 Installation of MRD-111 (MDC-5200 series) ................................................................... 3-28

3.3.2 Installation of MRD-109/MRO-108 (MDC-5500 series) ................................................... 3-31

3.3.2.1 Table mounting of MRD-109 ....................................................................................... 3-31

3.3.2.2 Table mounting of MRO-108 ....................................................................................... 3-32

3.3.2.3 Flush Mounting of MRD-109 ....................................................................................... 3-34

3.4 Cable connection to a Display unit ....................................................................................... 3-36

3.4.1 Cable connection for MRD-111 (MDC-5200 series) ....................................................... 3-37

3.4.2 Cable connection for MRD-109 (MDC-5500 series) ....................................................... 3-38

3.4.3 KODEN GPS compass connection ................................................................................. 3-39

3.4.4 Connecting a Gyro converter unit or THD ....................................................................... 3-40

3.4.5 Connecting a Position, Speed or other device of NMEA in/out ....................................... 3-41

3.4.6 Connecting an External monitor & external buzzer ......................................................... 3-42

3.4.7 AIS cable connection ....................................................................................................... 3-43

3.4.8 Cable connection for inter-switch .................................................................................... 3-44

3.4.8.1 Cable connection instructions for cross-over, dual and independent connection ....... 3-44

3.4.8.2 Cable connection for slave display used as a monitor ................................................ 3-45

Chapter 4 Setup after installation .............................................................................4-1

4.1 STARTUP menu ..................................................................................................................... 4-2

4.1.1 Tune adjustment (TUNE) ................................................................................................... 4-2

4.1.2 Heading adjustment (HL OFFSET) ................................................................................... 4-3

4.1.3 Transmitting delay time adjustment (TX DELAY) .............................................................. 4-4

4.1.4 Antenna height (ANT HEIGHT) ......................................................................................... 4-4

4.1.5 Antenna cable length (ANT CABLE) ................................................................................. 4-5

4.1.6 Main Bang Suppression (MBS) ......................................................................................... 4-5

4.1.7 Setup SEA curve (STC CURVE) ....................................................................................... 4-6

4.1.8 Function key usage ........................................................................................................... 4-7

4.1.9 RANGE ENABLE ............................................................................................................... 4-8

4.1.10 TIMES ENABLE ............................................................................................................ 4-11

4.1.11 LOGO ............................................................................................................................ 4-12

0092655002-03 iii

Page 6

A table of content MDC-5200/5500 Series

4.1.12 MOTOR HIGH SPEED .................................................................................................. 4-13

4.1.13 MOUSE SPEED ............................................................................................................. 4-13

4.1.14 TX HOUR DISP ............................................................................................................. 4-13

4.2 Setup I/O Interface ................................................................................................................ 4-14

4.2.1 Setup TIME ...................................................................................................................... 4-15

4.2.2 How to use without NMEA input connection .................................................................... 4-16

4.2.3 Set up Heading interfaces ............................................................................................... 4-17

4.2.3.1 Connection of KODEN GPS compass ......................................................................... 4-17

4.2.3.2 Connection of other device .......................................................................................... 4-17

4.2.3.3 How to input the heading value by manual .................................................................. 4-18

4.2.3.4 Compensation of angle of ship’s bearing .................................................................... 4-18

4.2.4 Setting of STW to be used for SEA STAB ....................................................................... 4-19

4.2.4.1 How to input the STW value by manual ...................................................................... 4-19

4.2.5 Setting of COG/SOG to be used for GROUND STAB ..................................................... 4-19

4.2.5.1 How to input the COG value by manual ...................................................................... 4-20

4.2.5.2 How to input the SOG value by manual ...................................................................... 4-20

4.2.6 Setting of SET/DRIFT to be used for CURRENT mode .................................................. 4-20

4.2.6.1 How to input the SET/DRIFT value by manual ............................................................ 4-20

4.2.7 Setting of latitude and longitude (POSITION) .................................................................. 4-21

4.2.7.1 How to input the POSITION value by manual ............................................................. 4-21

4.2.7.2 Compensation of POSITION data ............................................................................... 4-21

4.2.7.3 How to input the compensation of position data by manual ........................................ 4-21

4.2.8 Setting of serial output ..................................................................................................... 4-23

4.2.8.1 Setting of TLL output ................................................................................................... 4-23

4.2.9 Limiting of type of signal to input port .............................................................................. 4-24

4.2.10 Changing the baud rate of I/O port J3, J5 and J6 .......................................................... 4-25

4.2.10.1 Setting all I/O ports automatically .............................................................................. 4-25

4.2.11 Setup KGC (GPS compass) .......................................................................................... 4-26

4.2.12 Serial monitor ................................................................................................................. 4-26

4.3 Setup SECTOR MUTE mode (Cannot use while transmitting) ............................................. 4-27

4.4 Setup PRESET ...................................................................................................................... 4-27

4.4.1 Setup RAIN MIN and MAX mode .................................................................................... 4-27

4.4.1.1 RAIN MIN (MAN and CFAR mode) ............................................................................. 4-27

4.4.1.2 RAIN MAX (MAN and CFAR mode) ............................................................................ 4-28

4.4.2 Setup SEA MIN and MAX mode ...................................................................................... 4-29

4.4.2.1 SEA MIN (MAN and AUTO mode) .............................................................................. 4-29

4.4.2.2 SEA MAX (MAN and AUTO mode) ............................................................................. 4-30

4.4.3 Setup GAIN MIN and MAX mode .................................................................................... 4-31

4.4.3.1 GAIN MIN (MAN and AUTO mode) ............................................................................. 4-31

iv 0092655002-03

Page 7

MDC-5200/5500 Series A table of content

4.4.3.2 GAIN MAX (MAN and AUTO mode) ........................................................................... 4-32

4.4.4 Setup GAIN OFFSET mode ............................................................................................ 4-33

4.4.5 Setup SEA OFFSET mode .............................................................................................. 4-34

4.5 SAVE and LOAD of Setup data / MAP (Cannot be used while transmitting) ....................... 4-34

4.5.1 Internal save of setup data .............................................................................................. 4-34

4.5.2 External save of setup and map data .............................................................................. 4-35

4.5.3 Parameter reset ............................................................................................................... 4-35

4.5.4 MAP, Target Track and Past Position reset .................................................................... 4-35

4.6 TOTAL Hour and TX Hour (Cannot use while transmitting) ................................................. 4-36

4.7 MENU Setup ......................................................................................................................... 4-36

4.8 Version confirmation ............................................................................................................. 4-37

4.9 How to update the system program ...................................................................................... 4-37

4.10 Setup VECTOR on tracked targets ..................................................................................... 4-38

Chapter 5 Troubleshooting and on board repair .......................................................5-1

5.1 Necessary information at the time of repair request ............................................................... 5-1

5.2 Provided self diagnostic facilities ............................................................................................ 5-1

5.2.1 Alarm display and how to cancel ....................................................................................... 5-1

5.2.1.1 Alarm display list ............................................................................................................ 5-2

5.2.1.2 Operation note display .................................................................................................. 5-6

5.3 Malfunction diagnostics ........................................................................................................... 5-7

5.3.1 Malfunction detection step ................................................................................................. 5-7

5.3.2 Malfunction diagnostics flow chart ..................................................................................... 5-8

5.3.2.1 Initial malfunction diagnostics ........................................................................................ 5-8

5.3.2.2 Cannot turn on the power .............................................................................................. 5-9

5.3.2.3 No display .................................................................................................................... 5-10

5.3.2.4 No response from the antenna unit ............................................................................. 5-11

5.3.2.5 Operation unit error (MDC-5500 series only) ........................................................... 5-12

5.3.2.6 No radar echo .............................................................................................................. 5-12

5.3.2.7 Weak sensitivity of the radar echo .............................................................................. 5-13

5.3.2.8 Data such as heading, speed, latitude/longitude cannot be received ......................... 5-14

5.3.2.9 AIS ............................................................................................................................... 5-15

5.3.2.10 Antenna unit failure ................................................................................................... 5-16

5.3.2.10.1 Antenna unit failure (RB806) .................................................................................. 5-16

5.3.2.10.2 Antenna unit failure (RB807, RB808, RB809) ........................................................ 5-22

5.4 On board repair ..................................................................................................................... 5-27

5.4.1 Replacement of fuse ........................................................................................................ 5-29

5.4.2 Replacement of Internal Battery ....................................................................................... 5-30

0092655002-03 v

Page 8

A table of content MDC-5200/5500 Series

Chapter 6 Maintenance............................................................................................ 6-1

6.1 List of parts that have longevity ............................................................................................... 6-1

6.2 Regular service and cleaning up ............................................................................................. 6-2

6.2.1 Monthly inspection ............................................................................................................. 6-2

6.2.2 Annual inspection ............................................................................................................... 6-2

6.3 Method of exchanging the magnetron .................................................................................... 6-4

6.3.1 Magnetron replacement (RB806) ...................................................................................... 6-4

6.3.2 Magnetron replacement (RB807, RB808) ......................................................................... 6-8

6.3.3 Magnetron replacement (RB809) .................................................................................... 6-12

Chapter 7 Input/output data ..................................................................................... 7-1

7.1 Details of the data input format ............................................................................................... 7-1

7.2 Details of TT tracking data output ......................................................................................... 7-11

7.3 Details of the radar data output ............................................................................................. 7-12

7.4 Interface specification ........................................................................................................... 7-15

7.4.1 Serial data input/output specification ............................................................................... 7-15

7.4.2 External buzzer and external monitor signal specification ............................................... 7-16

7.4.2.1 Circuit fot horizontal sync, vertical sync signal output ................................................. 7-16

7.4.2.2 Circuit for R, G, B video signal .................................................................................... 7-16

7.4.2.3 Buzzer output specification .......................................................................................... 7-17

7.4.3 Serial data input/output specification (AIS) ...................................................................... 7-17

7.4.4 Radar input/output signal specification ............................................................................ 7-18

7.4.5 Talker device code of the data output devices ................................................................ 7-19

7.4.6 Priority of talker device code ............................................................................................ 7-19

INTER CONNECTION DIAGRAM (RB806) .......................................................................................... A-1

INTER CONNECTION DIAGRAM (RB807) .......................................................................................... A-2

INTER CONNECTION DIAGRAM (RB808) .......................................................................................... A-3

INTER CONNECTION DIAGRAM (RB809) .......................................................................................... A-4

INTER CONNECTION DIAGRAM (MRD-109/MRO-108) .................................................................... A-5

INTER CONNECTION DIAGRAM (MRD-111) ..................................................................................... A-6

vi 0092655002-03

Page 9

MDC-5200/5500 Series Preface

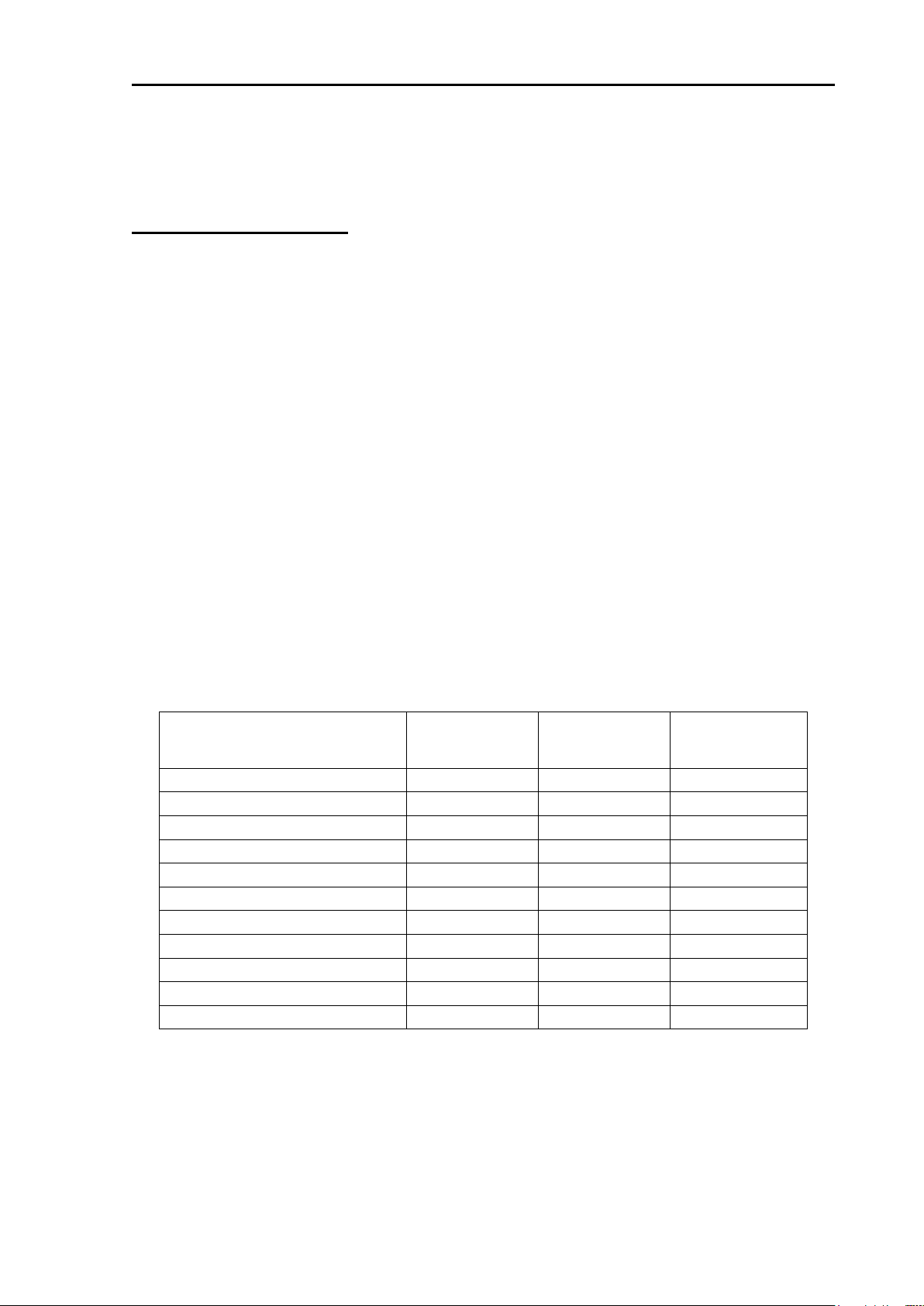

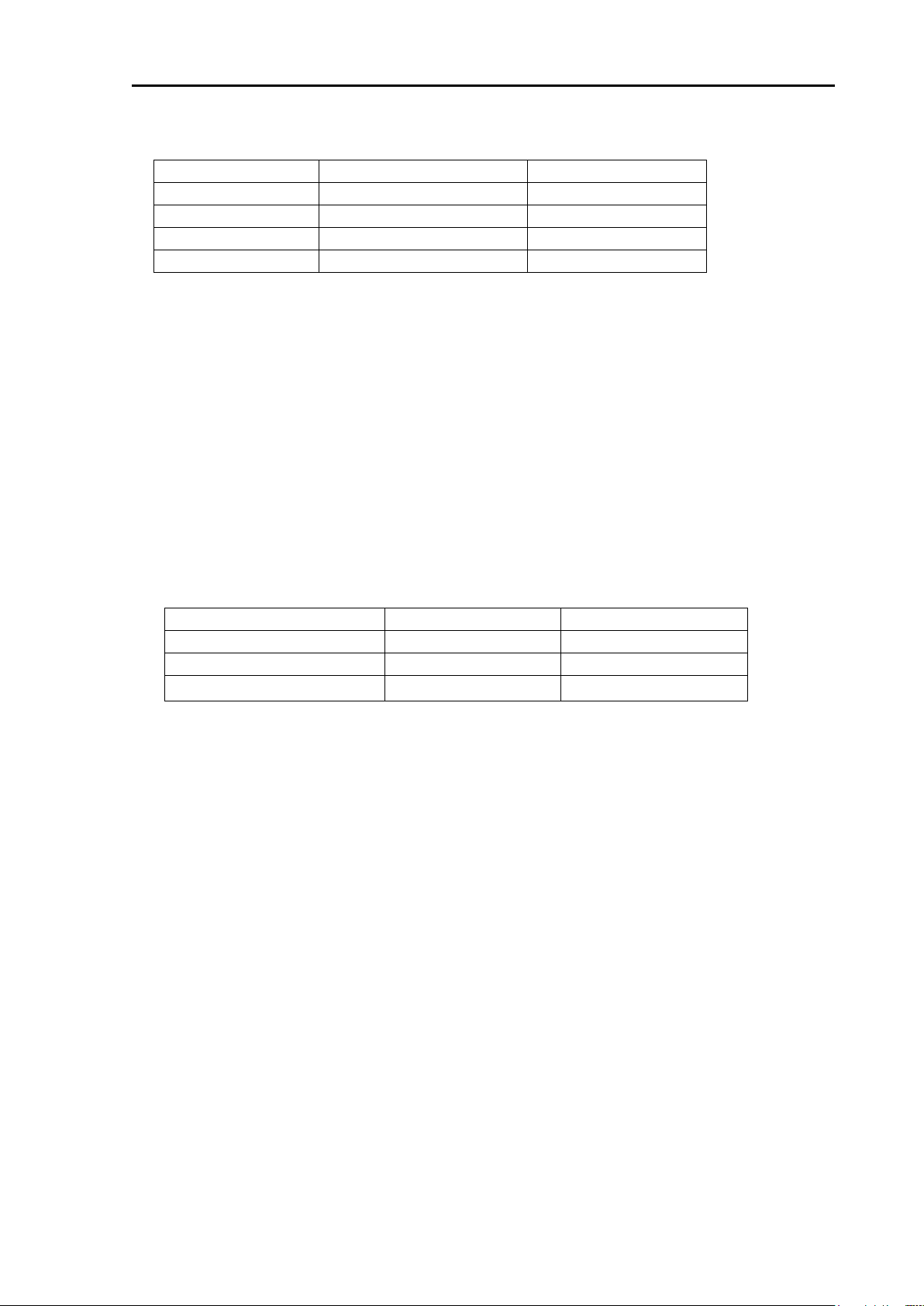

Transmission power / antenna

length

100 W/m2

50W/m2

10 W/m2

4 kW / 3 feet antenna

0.9 m

1.3 m

2.8 m

4 kW / 4 feet antenna

1.0 m

1.4 m

3.1 m

4 kW / 6 feet antenna

1.2 m

1.7 m

3.7 m

6 kW / 4 feet antenna

1.5 m

2.1 m

4.5 m

6 kW / 6 feet antenna

1.7 m

2.4 m

5.4 m

12 kW / 4 feet antenna

2.1 m

2.9 m

6.4 m

12 kW / 6 feet antenna

2.4 m

3.4 m

7.6 m

12 kW / 9 feet antenna

2.9 m

4.1 m

9.0 m

25 kW / 4 feet antenna

2.9 m

4.1 m

9.2 m

25 kW / 6 feet antenna

3.5 m

4.9 m

10.9 m

25 kW / 9 feet antenna

4.1 m

5.8 m

13.0 m

Preface

[Precaution for safety issues]

Precaution for operation

• Caution about rotating antenna:

The radar antenna may start rotating without notice. Please keep away from the antenna for your

safety.

• Caution about health risks caused by radio wave:

Powerful electromagnetic waves are emitted from the antenna during operation. These waves can

cause ill effects on human bodies when exposed to continuous radiation.

International criteria

Though the international regulation states that the electromagnetic waves with a high-frequency

power density of not more than 100 W/m2 do not have an ill effect on human bodies, medical

devices such as a pace makers are sensitive to electromagnetic waves with minute electric power

and their operation may become unstable. In any event, any person with such a device must keep

away from electromagnetic sources.

Specified power density and distance from antennas (according to the

provision as specified in IEC 60945)

• Caution about dangerous internal high voltage in the device:

High voltage that may cause risk of life is present in the Antenna unit and the Display unit of this radar.

This high voltage can remain in the circuit after the switch has been turned off. The high-voltage circuit

has a protective cover with a label “Caution against high voltage” so that no one will accidentally touch

it. Please ensure for your safety that the power switch is turned off and residual voltage in the capacitor

0092655002-03 1

Page 10

Preface MDC-5200/5500 Series

is discharged in a suitable manner when checking the inside of the antenna. Maintenance and

inspection should be conducted by qualified engineers only.

Precautions for maintenance

• Caution against residual high voltage:

Capacitors used in the Display unit and the modulator circuit of the transmission unit may keep high

voltage for several minutes even after turning off power. The maintenance and inspection of this part

should be performed at least 5 minutes after powering off or applying the appropriate measure to

discharge the residual electrical charge.

• Keep inboard power source “Off”:

An electric shock is possible if the power switch is accidentally turned on during the maintenance

operation. In order to prevent such an occurrence, please ensure to disconnect the power breaker of

the onboard power source and the device. Furthermore, it is recommended to post the word-of-caution

tag shown to be in a "working state" near the power switch of the device.

• Caution against the dust:

Dust can temporarily cause distress to the respiratory system. Take care not to inhale dust when

cleaning the interior of the device. It is recommended you wear a safety mask.

• Measures against static electricity:

Static electricity occurring from carpet on the floor of the cabin, clothes made of synthetic fiber etc., may

damage some electronic parts on the printed circuit board. Please work on the printed circuit board only

after taking measures against static electricity.

• Prohibited matter:

Any Display and Scanner unit combination other than specified in the manual is prohibited and will void

manufacturer’s warranty.

• Break in procedure of stored radar:

Following procedure is recommended for “Break In” of the stored radar.

Otherwise the radar sometimes exhibits unstable transmitting operation such as arcing at its initial

operation after long period of storage and make the operation more difficult.

1. Extend preheat time as long as possible (preferably 20 to 30 minutes).

2. Set the pulse width to the shortest one and start the operation.

When the operation in the shortest pulse is stable then go to operation in longer pulse and repeat

the similar step until the operation reaches to the final pulse condition.

2 0092655002-03

Page 11

MDC-5200/5500 Series Chapter 1 Prior to installation

Chapter 1 Prior to installation

1.1 Installation precautions

In order to obtain the maximum performance of radar systems, this radar system should be installed by

qualified engineers in charge of installation and maintenance. Installation procedures include the

following:

(1) Unpacking of components;

(2) Inspection of composition units, spare parts, accessories and installation materials;

(3) Checking of supply voltage and current capacity;

(4) Selection of the location for installation;

(5) Installation of the Antenna-Scanner unit;

(6) Installation of the Display unit;

(7) Attachment of accessories;

(8) Planning and implementation of cable laying and connection;

(9) Coordination after installation.

1.2 Unpacking of components

Unpack components and check that all items correspond with the description of the packing list. When

a discrepancy or damage has been found, please contact the transportation/insurance firm, and follow

procedures for searching for loss items and claim of expense.

1.3 Appearance verification of each unit and accessories

Please check the appearance of each unit carefully, confirm that they are dent and crack free.

Moreover, please also check the interior of each unit and confirm that there is no electric or

mechanical damage.

The illumination panel (back light) of the LCD module is made of glass. If the unit is dropped, damage

may occur. Since the presence of damage might not be found by checking of the appearance, please

confirm in the display after power on.

1.4 Selection of location for installation

In order to obtain the maximum performance of the units, it is necessary to install them in consideration

of matters as described below.

0092655002-03 1-1

Page 12

Chapter 1 Prior to installation MDC-5200/5500 Series

=15m

40m

16°

Antenna

height

Minimum range

Navigation buoy with

corner reflector

When the antenna height

rises, Minimum Range

becomes long.

Minimum

range(m)

Antenna

height(m)

=(

This area is prohibited from

setting up of the structure.

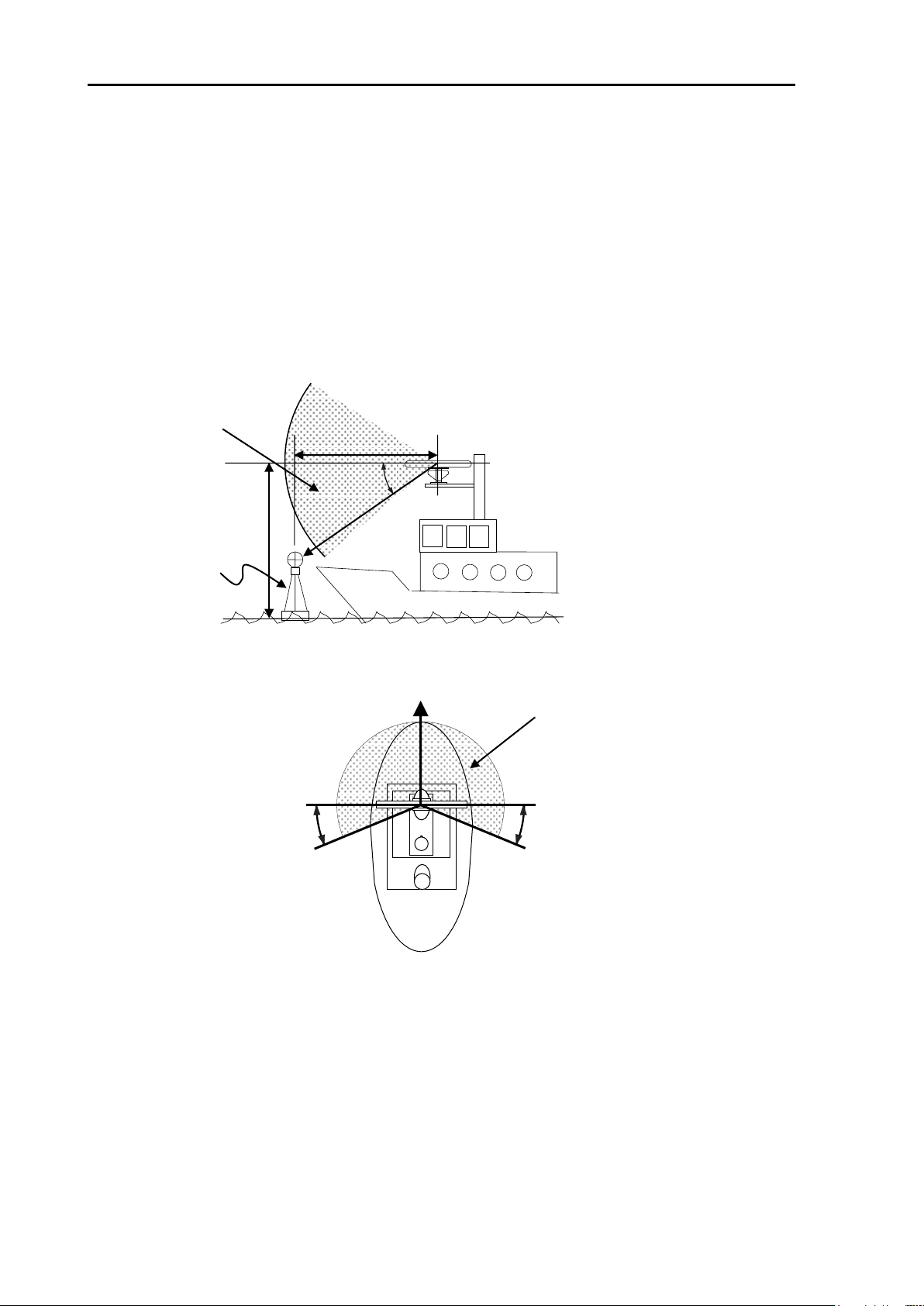

Figure 1.1 Vertical chart of recommended antenna installation position.

BOW

22.5°

22.5°

This area is prohibited from setting

up of the structure.

Figure 1.2 Horizontal chart of recommended antenna installation position.

1.4.1 Antenna Scanner unit

(1) Blind sectors shall be kept to a minimum, and shall not be placed in an arc of the horizon from the

right ahead direction to 22.5° abaft the beam and especially shall avoid the right ahead direction

(relative bearing 000°). The installation of the antenna shall be in such a manner that the

performance of the radar system is not substantially degraded. The antenna shall be mounted

clear of any structure that may cause signal reflections, including other antenna and deck structure

or cargo. In addition, the height of the antenna shall take account of target detection performance

relating to range of first detection and target visibility in sea clutter.

(2) Keep the surface of the Antenna-Scanner unit platform horizontal as much as possible.

(3) The Antenna-Scanner unit should be installed in front of large objects or exhaust stack to prevent a

blind sector or the effects on the antenna by engine exhaust soot.

(4) Keep sufficient maintenance area.

(5) Keep safety distance from magnetic compass.

1-2 0092655002-03

Page 13

MDC-5200/5500 Series Chapter 1 Prior to installation

Scanner unit type

Standard compass

Steering compass

RB806 (4kW)

2.0 m

1.4 m

RB807 (6kW)

1.2 m

0.8 m

RB808 (12kW)

1.4 m

0.9 m

RB809 (25kW)

1.4 m

0.9 m

Display unit type

Standard compass

Steering compass

MRD-111 (MDC-5200 series)

0.7 m

0.5 m

MRD-109 (MDC-5500 series)

1.2 m

1.0 m

MRO-108 (MDC-5500 series)

0.3 m

0.3 m

Table 1.1 Safety distance of compass from the Scanner unit

1.4.2 Display unit and Operation unit

(1) The orientation of the Display unit shall be such that the user is looking ahead, the lookout view is

not obscured and there is minimum ambient light on the display viewing surface.

(2) Choose the best location from humidity, spray, rain, and direct sunlight.

(3) Keep sufficient maintenance area. Especially sufficient space is required near the back panel

where cables are connected.

(4) Keep as far as possible from other radio devices.

(5) Keep safety distance from magnetic compass.

Table 1.2 Safety distance of compass from Display unit and Operation unit

0092655002-03 1-3

Page 14

Chapter 1 Prior to installation MDC-5200/5500 Series

1.5 Cable wiring and interconnection

1.5.1 Antenna Scanner unit

(1) The connecting cable between the Antenna-Scanner unit and the Display unit should run apart

from any other radio antenna cable or power cables of the other devices. Do not lay the radar cable

in parallel to the sea surface together with other cables. These considerations are effective to

prevent random radio interference between systems. When these measures cannot be applied

because of space limitations, use metal pipes for each cable or other suitable ways to shield.

(2) In order to maximize the performance of the radar, the antenna cable and the power cable should

be as short as possible, and should be laid within the nominal length.

(3) Connect the shielded braided wire of the antenna cable to the grounding terminal inside the

Antenna unit

1.5.2 Display unit

(1) Ground the braided wire of a cable firmly with the cable clamp fixing screw to the back panel.

(2) The Display unit housing should be grounded to the ship ground by using the ground terminal of the

back panel.

1-4 0092655002-03

Page 15

MDC-5200/5500 Series Chapter 2 System configurations

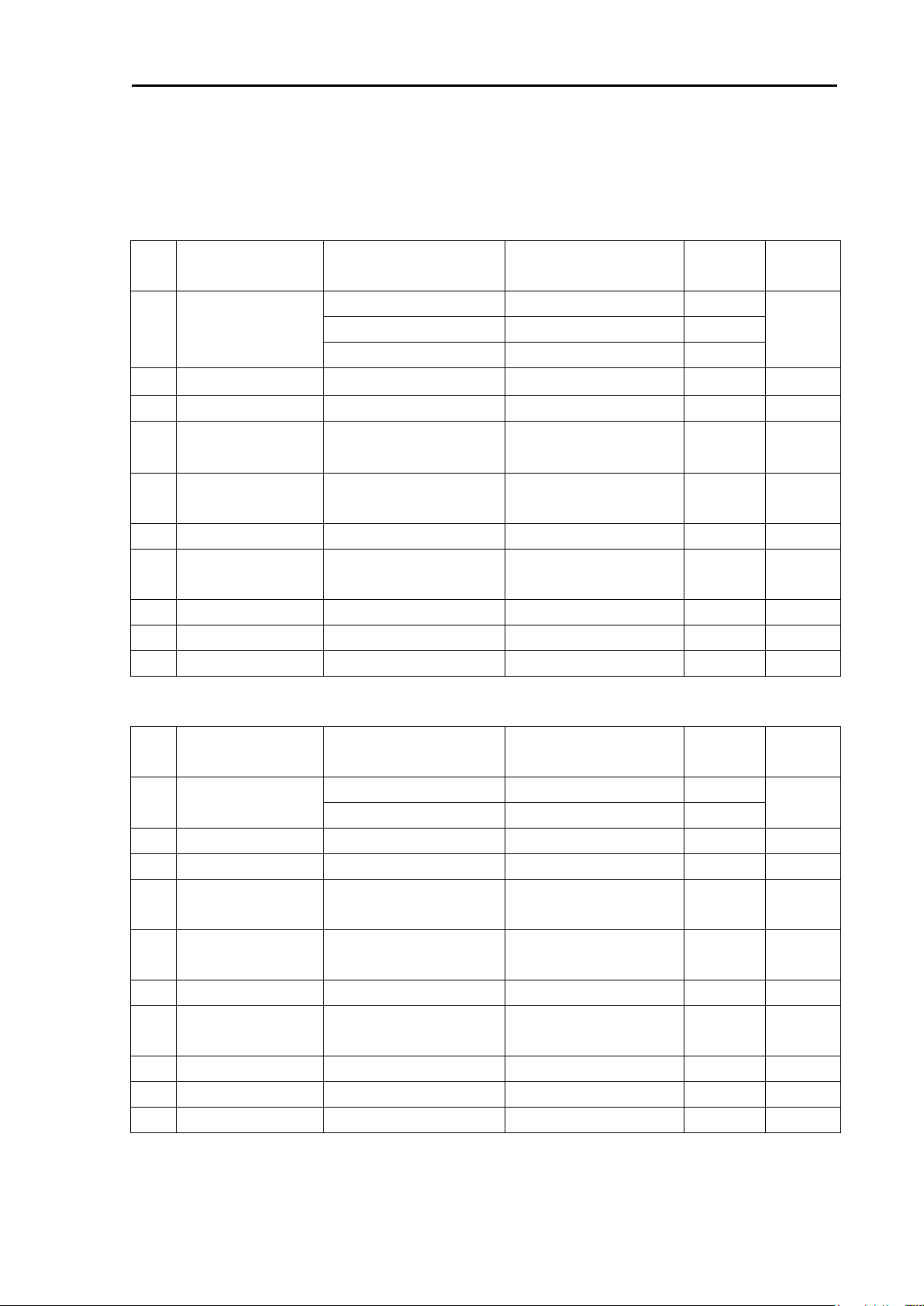

No.

Name

Type

Comment

Weight/

Length

Quantity

1

Antenna

RW701A-03

3 ft

5 kg

1

RW701A-04

4 ft

6 kg

RW701A-06

6 ft

8 kg

2

Scanner unit

RB806

4 kW

16.1 kg

1

3

Display unit

MRD-111

12.1 inch

8.2 kg

1

4

Connecting cable

242J159098B-15M

With connectors on the

both sides

15 m

1

5

Power cable

CW-259-2M

With a connector on the

single side

2 m

1

6

Spare parts

SP-MRD-109_111

See spare parts list

1 set

7

Installation material

M12-BOLT.KIT

See installation material

list

1 set

8

Document

MDC-5200_5500.OM.E

Operation manual

1 9

Document

MDC-5200_5500.IM.E

Installation manual

1 10

Document

MDC-5200_5500.QR.E

Quick reference

1

No.

Name

Type

Comment

Weight/

Length

Quantity

1

Antenna

RW701A-04

4 ft

6 kg

1

RW701A-06

6 ft

8 kg

2

Scanner unit

RB807

6 kW

18.1 kg

1 3 Display unit

MRD-111

12.1 inch

8.2 kg

1

4

Connecting cable

CW-845-15M

With connectors on the

both sides

15 m

1

5

Power cable

CW-259-2M

With a connector on the

single side

2 m

1

6

Spare parts

SP-MRD-109_111

See spare parts list

1 set

7

Installation material

M12-BOLT.KIT

See installation material

list

1 set

8

Document

MDC-5200_5500.OM.E

Operation manual

1 9

Document

MDC-5200_5500.IM.E

Installation manual

1 10

Document

MDC-5200_5500.QR.E

Quick reference

1

1

-

Chapter 2 System configurations

2.1 Standard configuration list

MDC-5204

MDC-5206

0092655002-03 2-1

Page 16

Chapter 2 System configurations MDC-5200/5500 Series

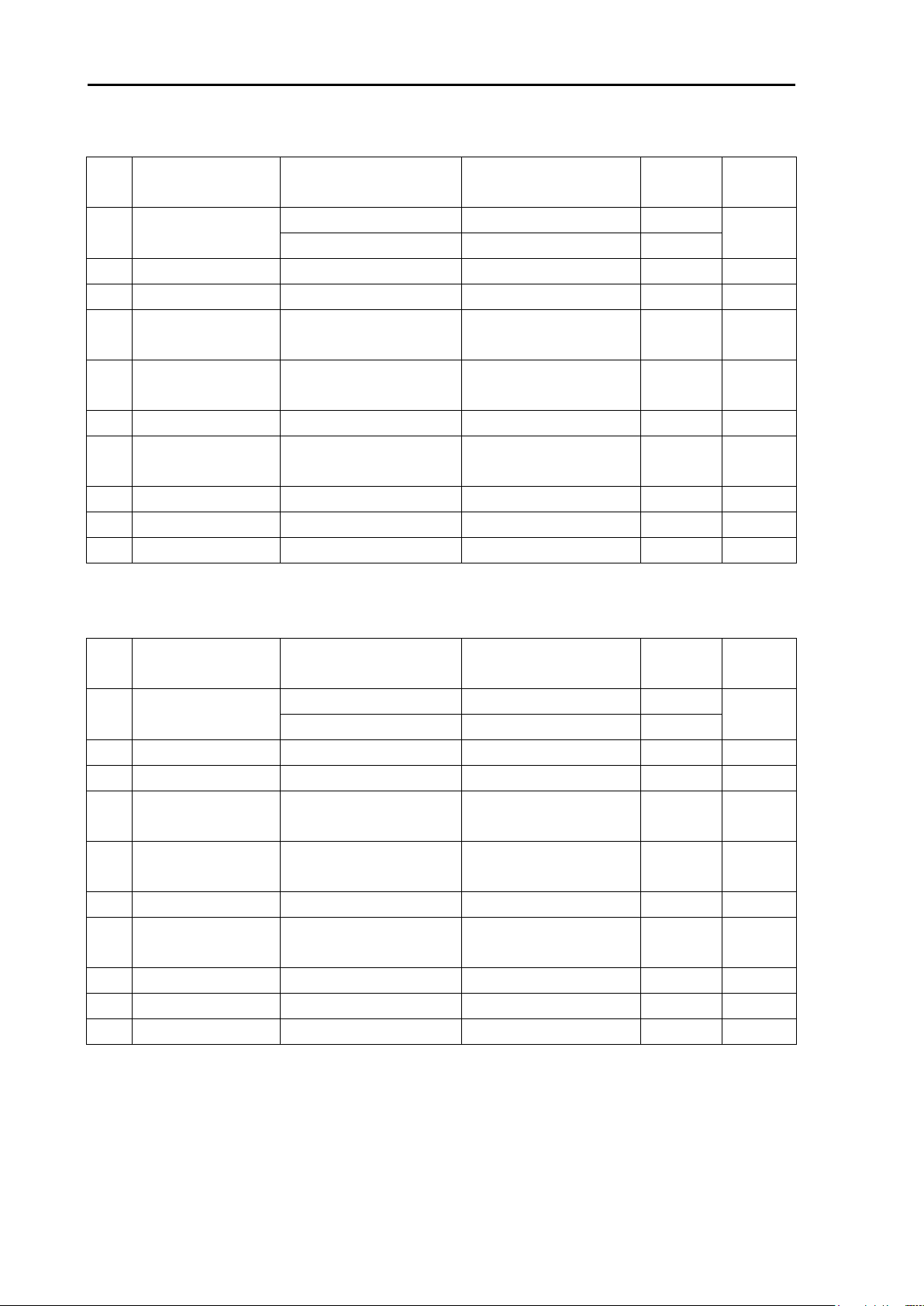

No.

Name

Type

Comment

Weight/

Length

Quantity

1

Antenna

RW701A-04

4 ft

6 kg

1

RW701A-06

6 ft

8 kg

2

Scanner unit

RB808

12 kW

18.0 kg

1 3 Display unit

MRD-111

12.1 inch

8.2 kg

1

4

Connecting cable

CW-845-15M

With connectors on the

both sides

15 m

1

5

Power cable

CW-259-2M

With a connector on the

single side

2 m

1

6

Spare parts

SP-MRD-109_111

See spare parts list

1 set

7

Installation material

M12-BOLT.KIT

See installation material

list

1 set

8

Document

MDC-5200_5500.OM.E

Operation manual

1 9

Document

MDC-5200_5500.IM.E

Installation manual

1 10

Document

MDC-5200_5500.QR.E

Quick reference

1

No.

Name

Type

Comment

Weight/

Length

Quantity

1

Antenna

RW701A-04

4 ft

6 kg

1

RW701A-06

6 ft

8 kg

2

Scanner unit

RB809

25 kW

20.0 kg

1 3 Display unit

MRD-111

12.1 inch

8.2 kg

1

4

Connecting cable

CW-845-15M

With connectors on the

both sides

15 m

1

5

Power cable

CW-259-2M

With a connector on the

single side

2 m

1

6

Spare parts

SP-MRD-109_111

See spare parts list

1 set

7

Installation material

M12-BOLT.KIT

See installation material

list

1 set

8

Document

MDC-5200_5500.OM.E

Operation manual

1 9

Document

MDC-5200_5500.IM.E

Installation manual

1 10

Document

MDC-5200_5500.QR.E

Quick reference

1

MDC-5212

MDC-5225

2-2 0092655002-03

Page 17

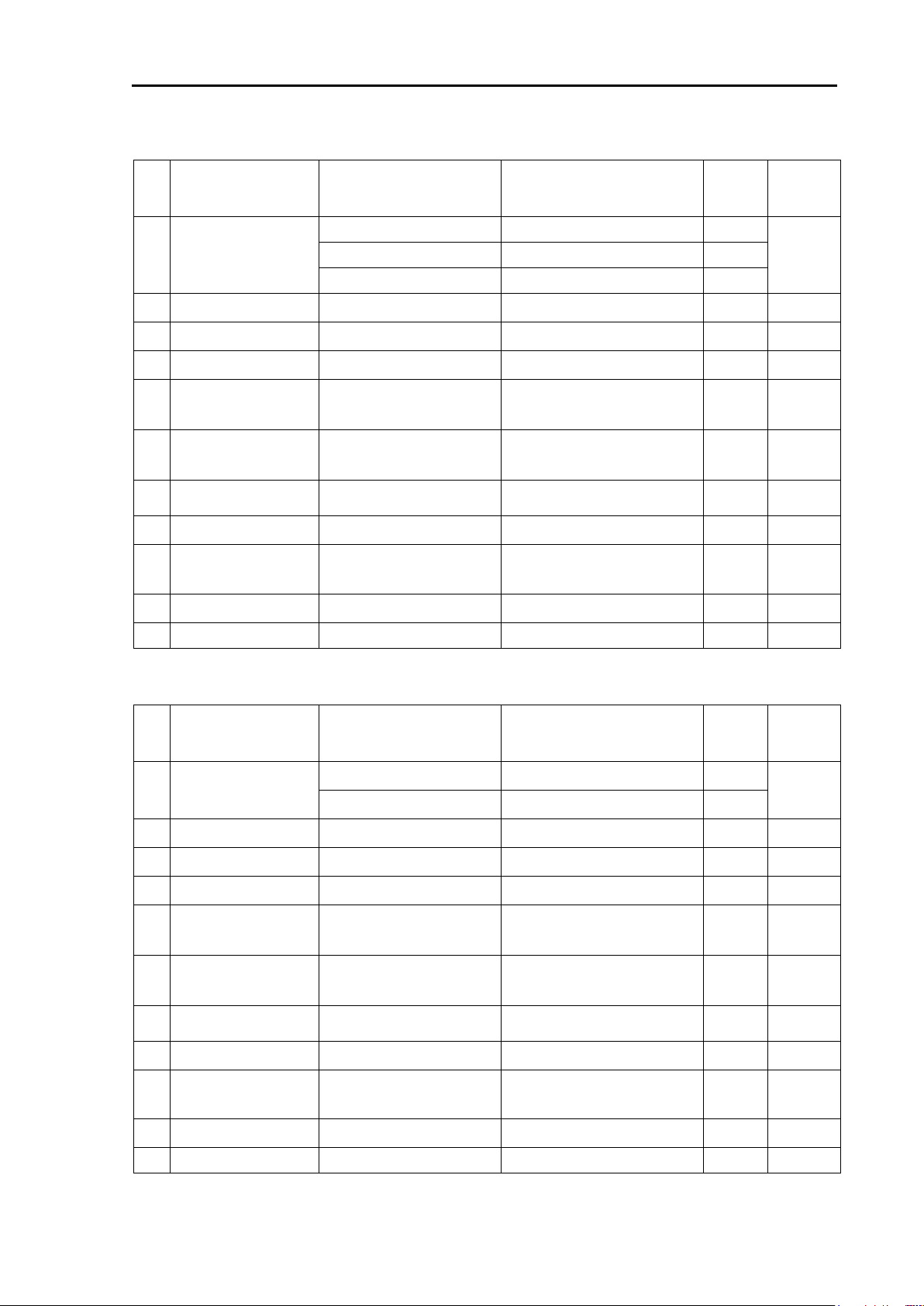

MDC-5200/5500 Series Chapter 2 System configurations

No.

Name

Type

Comment

Weight/

Length

Quantity

1

Antenna

RW701A-03

3 ft

5 kg

1

RW701A-04

4 ft

6 kg

RW701A-06

6 ft

8 kg

2

Scanner unit

RB806

4 kW

16.1 kg

1

3

Dispaly unit

MRD-109

15 inch

12.5 kg

1 4 Operation unit

MRO-108

1.8 kg

1

5

Connecting cable

242J159098B-15M

With connectors on the both

sides

15 m

1

6

Power cable

CW-259-2M

With a connector on the

single side

2 m

1

7

Spare parts

SP-MRD-109_111

See spare parts list

1 set

8

Installation material

M12-BOLT.KIT

See installation material list

1 set

9

Document

MDC-5200_5500.OM.E

Operation manual

1

10

Document

MDC-5200_5500.IM.E

Installation manual

1

11

Document

MDC-5200_5500.QR.E

Quick reference

1

No.

Name

Type

Comment

Weight/

Length

Quantity

1

Antenna

RW701A-04

4 ft

6 kg

1

RW701A-06

6 ft

8 kg

2

Scanner unit

RB807

6 kW

18.1 kg

1 3 Dispaly unit

MRD-109

15 inch

12.5 kg

1 4 Operation unit

MRO-108

1.8 kg

1

5

Connecting cable

CW-845-15M

With connectors on the both

sides

15 m

1

6

Power cable

CW-259-2M

With a connector on the

single side

2 m

1

7

Spare parts

SP-MRD-109_111

See spare parts list

1 set

8

Installation material

M12-BOLT.KIT

See installation material list

1 set

9

Document

MDC-5200_5500.OM.E

Operation manual

1

10

Document

MDC-5200_5500.IM.E

Installation manual

1

11

Document

MDC-5200_5500.QR.E

Quick reference

1

MDC-5504

MDC-5506

0092655002-03 2-3

Page 18

Chapter 2 System configurations MDC-5200/5500 Series

No.

Name

Type

Comment

Weight/

Length

Quantity

1

Antenna

RW701A-04

4 ft

6 kg

1

RW701A-06

6 ft

8 kg

RW701B-09

9 ft

12 kg

2

Scanner unit

RB808

12 kW

18.0 kg

1 3 Dispaly unit

MRD-109

15 inch

12.5 kg

1 4 Operation unit

MRO-108

1.8 kg

1

5

Connecting cable

CW-845-15M

With connectors on the both

sides

15 m

1

6

Power cable

CW-259-2M

With a connector on the

single side

2 m

1

7

Spare parts

SP-MRD-109_111

See spare parts list

1 set

8

Installation material

M12-BOLT.KIT

See installation material list

1 set

9

Document

MDC-5200_5500.OM.E

Operation manual

1

10

Document

MDC-5200_5500.IM.E

Installation manual

1

11

Document

MDC-5200_5500.QR.E

Quick reference

1

No.

Name

Type

Comment

Weight/

Length

Quantity

1

Antenna

RW701A-04

4 ft

6 kg

1

RW701A-06

6 ft

8 kg

RW701B-09

9 ft

12 kg

2

Scanner unit

RB809

25 kW

20.0 kg

1 3 Dispaly unit

MRD-109

15 inch

12.5 kg

1 4 Operation unit

MRO-108

1.8 kg

1

5

Connecting cable

CW-845-15M

With connectors on the both

sides

15 m 1 6

Power cable

CW-259-2M

With a connector on the

single side

2 m

1

7

Spare parts

SP-MRD-109_111

See spare parts list

1 set

8

Installation material

M12-BOLT.KIT

See installation material list

1 set

9

Document

MDC-5200_5500.OM.E

Operation manual

1

10

Document

MDC-5200_5500.IM.E

Installation manual

1

11

Document

MDC-5200_5500.QR.E

Quick reference

1

MDC-5512

MDC-5525

2-4 0092655002-03

Page 19

MDC-5200/5500 Series Chapter 2 System configurations

No.

Name

Specification

Comment

Type

(Dimension)

Quantity

Usage

1

Fuse

F-1065-15A

Normal type

Tubular

(φ6.4 x 30)

1

Main power

2

Fuse

MF51NN250V5A/

N20-250V

Normal type

Tubular

(φ5.2 x 20)

1

Motor power

3

Fuse

FGMB 250V/0.8A

Normal type

Tubular

(φ5.2 x 20)

1

High voltage power

supply

4

Carbon brush

24Z125209B

1set

Antenna motor

(For RB806/RB807)

No.

Name

Specification

Quantity

Usage

1

Hexagon bolt

B12X55U

4

Antenna-Scanner unit

2

Nut

N12U

8

Antenna-Scanner unit

3

Plain washer

2W12U

8

Antenna-Scanner unit

4

Spring washer

SW12U

4

Antenna-Scanner unit

5

Anti electro corrosive

washer

56R7201M2

4

Antenna-Scanner unit

6

Anti electro corrosive

washer

56R7202M2

4

Antenna-Scanner unit

7

Ferrite core

GRFC-13

1

Antenna-Scanner unit

8

Cable band

AB150-W

2

Antenna-Scanner unit

2.2 Spare parts list

SP-MRD-109/111

2.3 Installation material list

M12-BOLT.KIT

0092655002-03 2-5

Page 20

Chapter 2 System configurations MDC-5200/5500 Series

No.

Name

Specification

Comment

Weight

/Dimension

/Quantity

1

Gyro converter

S2N, U/N 9028C

qwerty-electronik

2

Log pulse NMEA

converter

L1N, U/N 9181A

qwerty-electronik

200pulse/NM only

3

Gyro / Log interface

ADPC-101

1.5 kg

4

Rectifier unit

PS-010

5A fuse attached

3.5 kg

VL-PSG001

20A fuse attached

5

AC power cable

VV-2D8-3M

Without connectors on the both

sides

3 m

6

Junction box

JB-35

With CW-376-5M

7

Connecting cable

CW-373-*

*: 5M, 10M or 30M

With 6-pin water resistant

connectors at both ends (cable

for data)

5 m, 10 m

or 30 m

CW-374-5M

With a 6-pin connector and a

6-pin water resistant connector

(cable for data)

5 m

CW-376-5M

With a 6-pin water resistant

connector and one end plain

(cable for data)

5 m

CW-387-5M

With a 8-pin water resistant

connector and one end plain

(cable for AIS)

5 m

CW-561- *

*: 10M or 30M

With 12-pin water resistant

connectors at both ends (cable

for remote display)

10 m or 30 m

CW-576-0.5M

With a 10-pin water resistant

connector and D-Sub connector

(analog RGB)

+Alarm out

0.5 m

CW-560-2M

With 15-pin water resistant

D-Sub connectors at both ends

(Cable for VDR or external

Display unit to connect

CW-576-0.5M)

2 m

CW-401- *

*: 5M or 10M

Operation unit cable

(For MRO-108)

5 m or 10 m

8

Antenna-Scanner unit

- Display unit

connecting cable

242J159098C-20M

With connectors on both sides

(242J159098:For RB806)

20 m

242J159098D-30M

30 m

242J159098*-**M

100 m Max.

CW-845-*

*: 20M, 30M, 40M

50M, 65M, 100M

(CW-845: For RB807/808/809)

20 m, 30 m,

40m, 50 m,

65 m or 100m

CW-845-xxM

100 m Max.

(Designated)

2.4 Option list

2-6 0092655002-03

Page 21

MDC-5200/5500 Series Chapter 2 System configurations

Display unit

MRD-111

Connecting cable

242J159098B-15M (Standard)

242J159098C-20M

242J159098D-30M

242J159098*-**M (**100 m Max.)

Scanner unit

RB806 (4kW)

Power cable

CW-259-2M

Rectifier

PS-010

or

VL-PSG001

Onboard DC power supply

21.6 to 41.6V DC

Onboard AC power supply

100/115V AC

200/230V AC

AC power cable

VV-2D8-3M

External buzzer

GPS Compass

KGC-222

Gyro/log Interface

ADPC-101

AIS

CW-387-5M

CW-576-0.5M

Slave display

MRD-111

MRD-109+MRO-108

CW-373-5M

CW-561-10M

J1

J2

J8

External monitor (XGA)

Analog RGB

CW-560-2M

GYRO

LOG

J3

Gyro NMEA

signal

J5

GPS Plotter

Other

J6

Antenna

RW701A-03

RW701A-04

RW701A-06

CW-376-5M

CW-376-5M

J3

Standard

Option

Owner supplied

J7

POWER

C-MAP

SD CARD

USB Mouse/

Track ball

USB

CW-373-5M

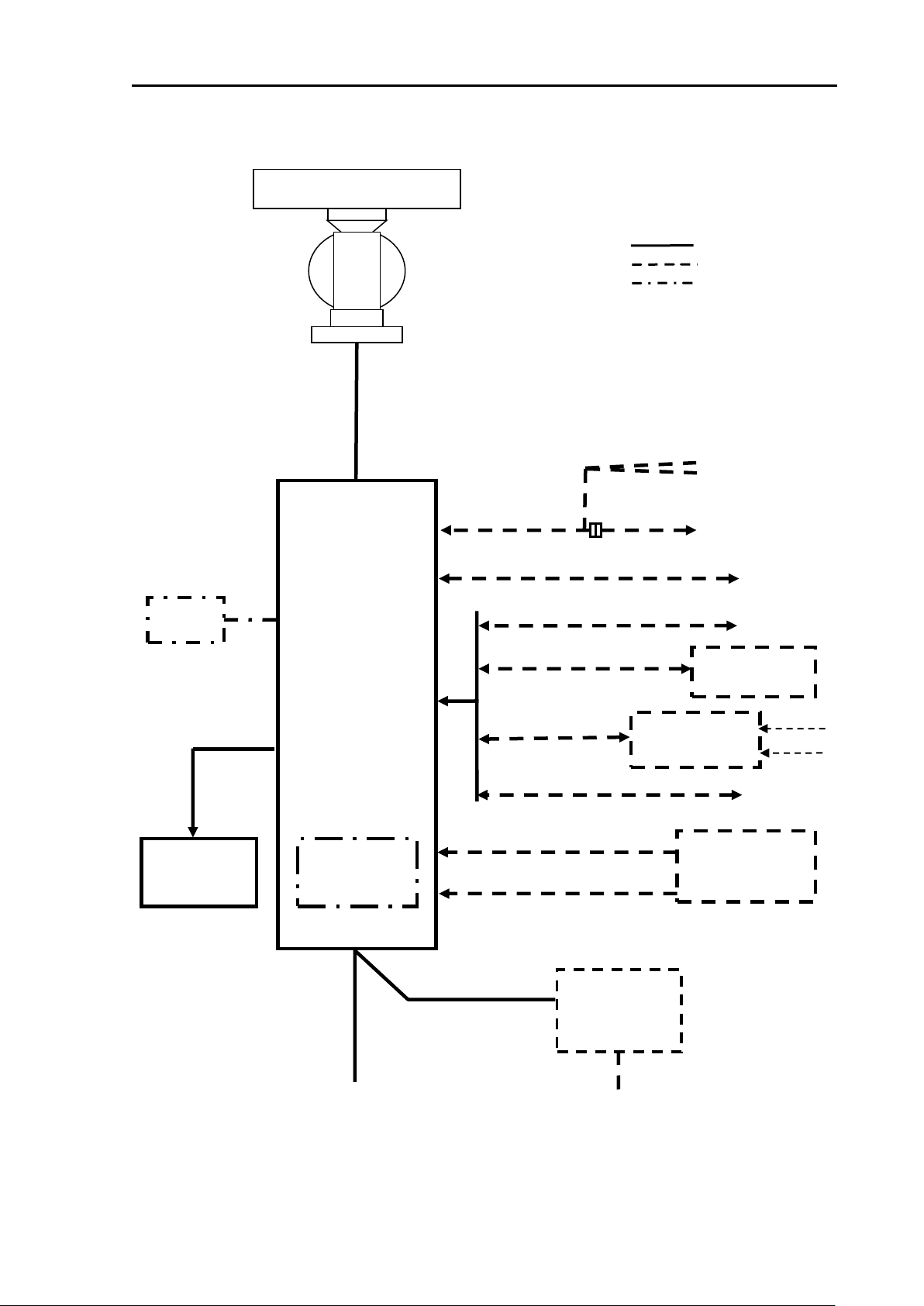

2.5 MDC-5204 series system configuration

0092655002-03 2-7

Page 22

Chapter 2 System configurations MDC-5200/5500 Series

Display unit

MRD-111

Connecting cable

CW-845-15M (Standard)

CW-845-20M/30M/40M/50M/65M/100M

CW-845-**M (**100 m Max.)

Scanner unit

RB807 (6kW)

RB808 (12kW)

RB809 (25kW)

Power cable

CW-259-2M

Rectifier

PS-010

or

VL-PSG001

Onboard DC power supply

21.6 to 41.6V DC

Onboard AC power supply

100/115V AC

200/230V AC

AC power cable

VV-2D8-3M

External buzzer

GPS Compass

KGC-222

Gyro/log Interface

ADPC101

AIS

CW-387-5M

CW-576-0.5M

Slave display

MRD-111

MRD-109+MRO-108

CW-373-5M

CW-561-10M

J1

J2

J8

External monitor (XGA)

Analog RGB

CW-560-2M

GYRO

LOG

J3

Gyro NMEA

signal

J5

GPS Plotter

Other

J6

Antenna

RW701A-04

RW701A-06

CW-376-5M

CW-376-5M

J3

Standard

Option

Owner supplied

J7

POWER

C-MAP

SD CARD

USB Mouse/

Track ball

USB

CW-373-5M

2.6 MDC-5206/5212/5225 series system configuration

2-8 0092655002-03

Page 23

MDC-5200/5500 Series Chapter 2 System configurations

Display unit

MRD-109

Connecting cable

242J159098B-15M (Standard)

242J159098C-20M

242J159098D-30M

242J159098*-**M (**100 m Max.)

Scanner unit

RB806 (4kW)

Power cable

CW-259-2M

Rectifier

PS-010

or

VL-PSG001

Onboard DC power supply

21.6 to 41.6V DC

Onboard AC power supply

100/115V AC

200/230V AC

AC power cable

VV-2D8-3M

External buzzer

GPS Compass

KGC-222

Gyro/log Interface

ADPC101

AIS

CW-387-5M

CW-576-0.5M

Slave display

MRD-111

MRD-109+MRO-108

CW-373-5M

CW-561-10M

J1

J2

J8

External monitor (XGA)

Analog RGB

CW-560-2M

GYRO

LOG

J3

Gyro NMEA

signal

J5

GPS Plotter

Other

J6

Antenna

RW701A-03

RW701A-04

RW701A-06

CW-376-5M

CW-376-5M

J3

Standard

Option

Owner supplied

J7

POWER

C-MAP

SD CARD

USB Mouse/

Track ball

USB

CW-373-5M

Operation unit

MRO-108

J9

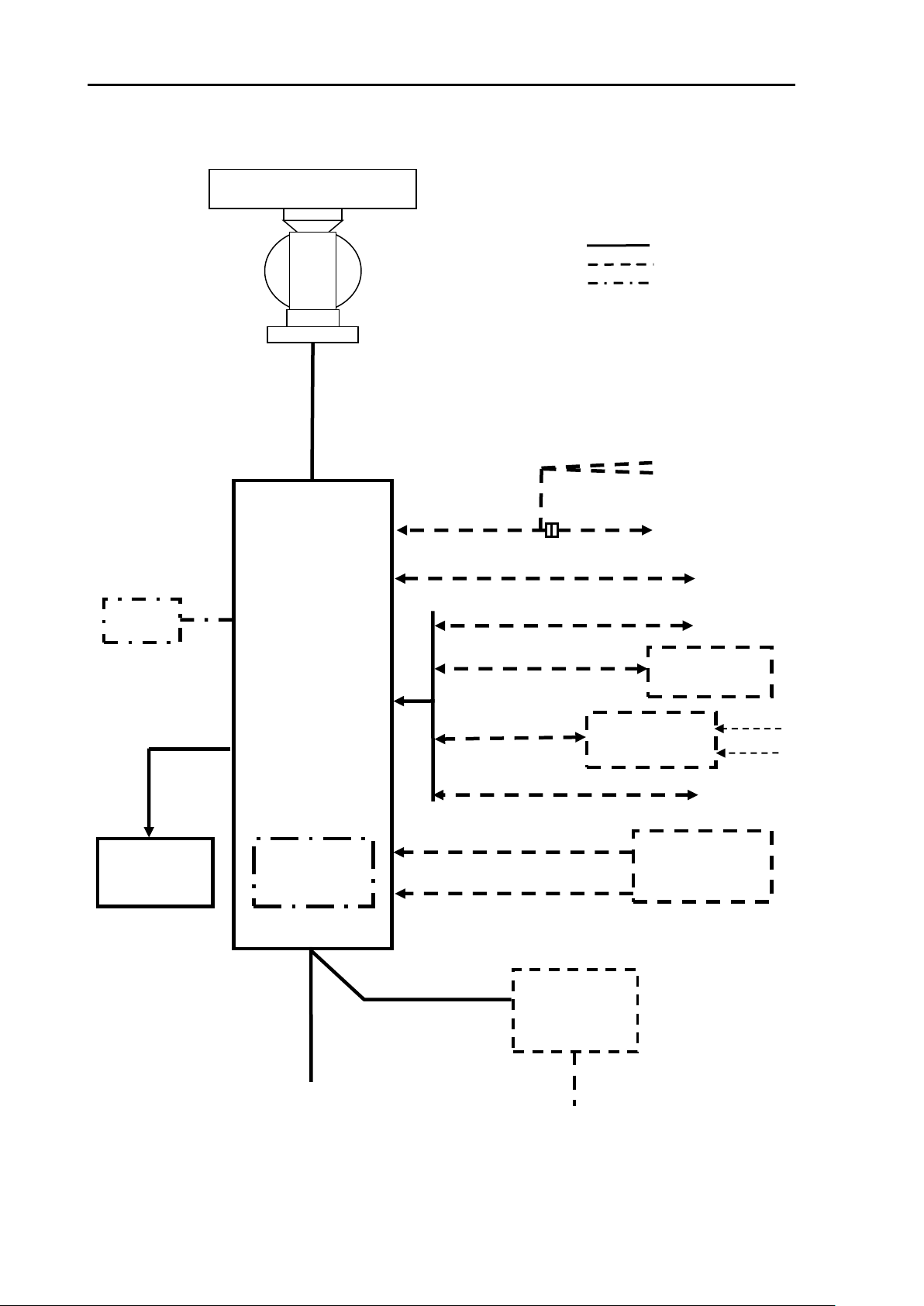

2.7 MDC-5504 series system configuration

0092655002-03 2-9

Page 24

Chapter 2 System configurations MDC-5200/5500 Series

Display unit

MRD-109

Connecting cable

CW-845-15M (Standard)

CW-845-20M/30M/40M/50M/65M/100M

CW-845-**M (**100 m Max.)

Scanner unit

RB807 (6kW)

RB808 (12kW)

RB809 (25kW)

Power cable

CW-259-2M

Rectifier

PS-010

or

VL-PSG001

Onboard DC power supply

21.6 to 41.6V DC

Onboard AC power supply

100/115V AC

200/230V AC

AC power cable

VV-2D8-3M

External buzzer

GPS Compass

KGC-222

Gyro/log Interface

ADPC101

AIS

CW-387-5M

CW-576-0.5M

Slave display

MRD-111

MRD-109+MRO-108

CW-373-5M

CW-561-10M

J1

J2

J8

External monitor (XGA)

Analog RGB

CW-560-2M

GYRO

LOG

J3

Gyro NMEA

signal

J5

GPS Plotter

Other

J6

Antenna

RW701A-04

RW701A-06

RW701B-09

(MDC-5512/5525 only)

CW-376-5M

CW-376-5M

J3

Standard

Option

Owner supplied

J7

POWER

C-MAP

SD CARD

USB Mouse/

Track ball

USB

CW-373-5M

Operation unit

MRO-108

J9

2.8 MDC-5506/5512/5525 series system configuration

2-10 0092655002-03

Page 25

MDC-5200/5500 Series Chapter 3 Installation method

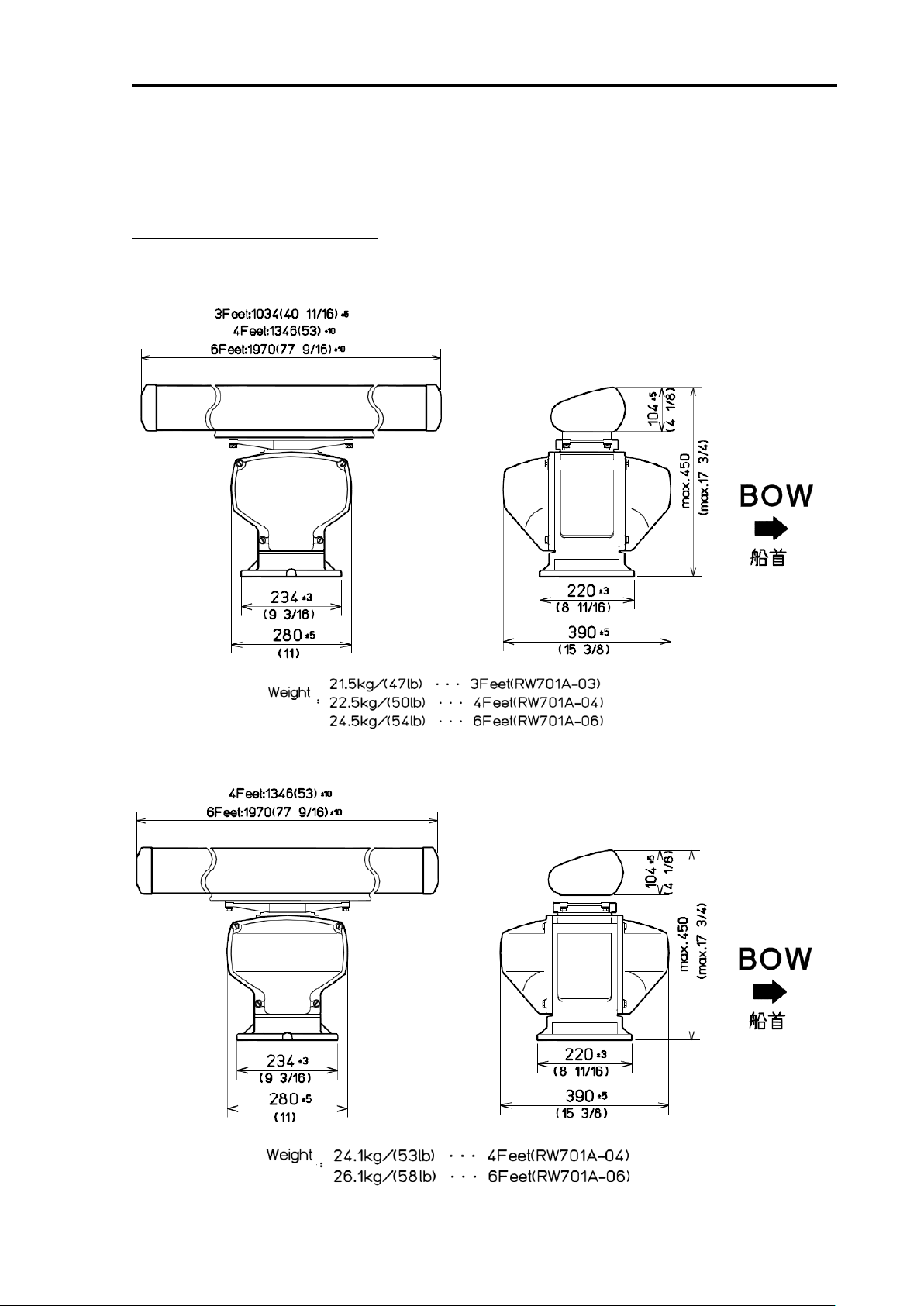

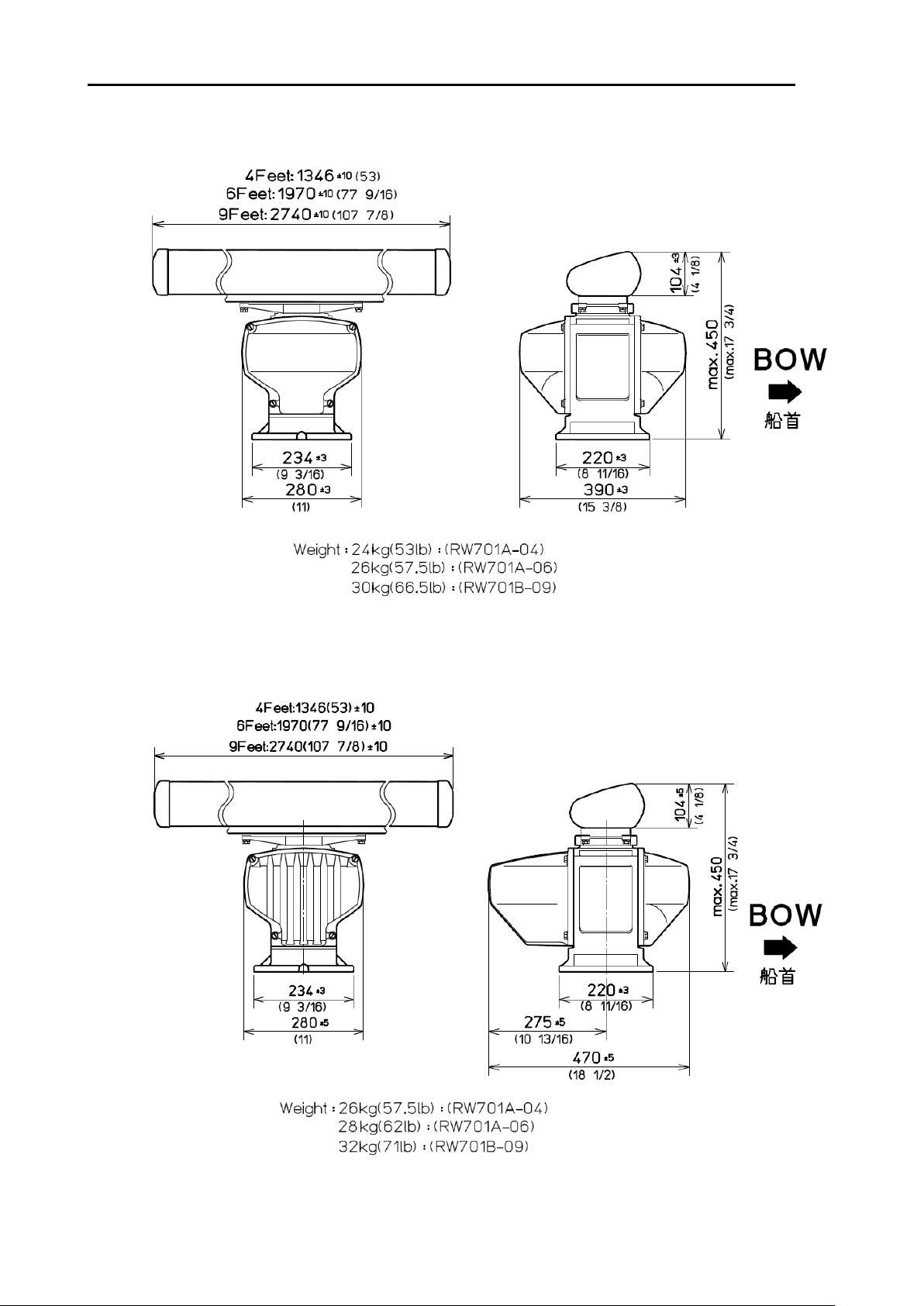

Unit: mm (inch)

Chapter 3 Installation method

3.1 How to install the Antenna Scanner unit

External view and dimensions

RB806

RB807

0092655002-03 3-1

Page 26

Chapter 3 Installation method MDC-5200/5500 Series

Unit: mm (inch)

RB808

RB809

3-2 0092655002-03

Page 27

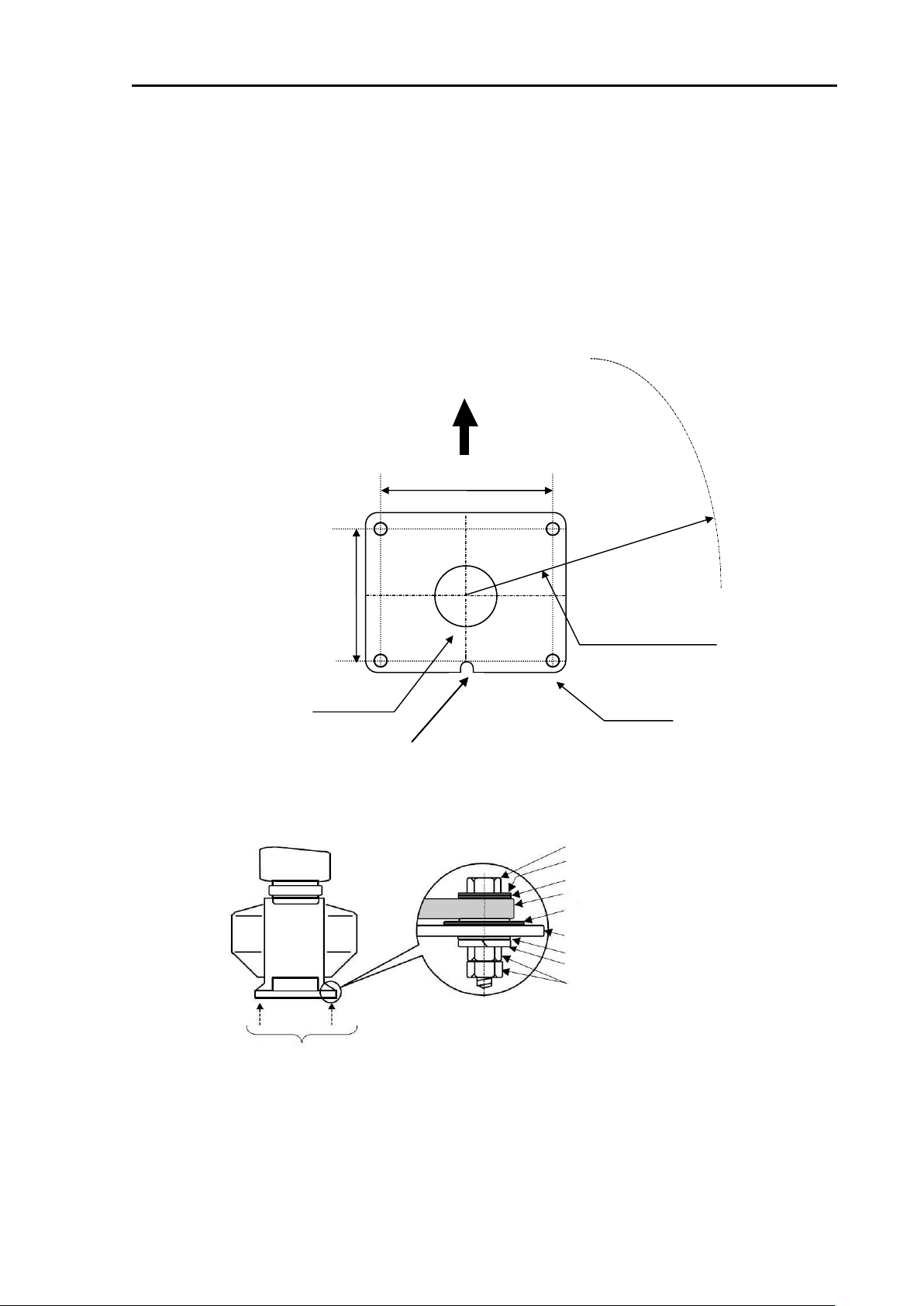

MDC-5200/5500 Series Chapter 3 Installation method

Unit: mm (inch)

100 φ

RA774UA

Figure 3.1 Plain view of mounting hole

199

(7.83)

185

(7.28)

(0.55)

(3.97)

Notch of Scanner

Heading

Antenna rotating radius

R600 (3 ft Antenna unit)

R700 (4 ft Antenna unit)

R1000 (6 ft Antenna unit)

R1400 (9 ft Antenna unit)

14φx 4

Cable opening

Figure 3.2 Assembly of Scanner unit base

Mounted with four bolts

M12 Double nut

Spring washer

Washer

M12 bolt

Platform

Scanner unit base

Washer

Anti-electro corrosive washer

Anti-electro corrosive washer

3.1.1 Installation of the Antenna Scanner unit

The Antenna Scanner unit is equipped to orient the notch of the attachment to stern as shown in Figure

3.1. Installation in this way eases maintenance work. Also refer to the consideration on equipment

shown in 1.4.1.

(1) Four mounting holes 14 mm in diameter are located on the mounting platform with reference to

Figure 3.1.

(2) The Antenna Scanner unit is secured with four 12 mm stainless steel bolts contained in installation

material.

0092655002-03 3-3

Page 28

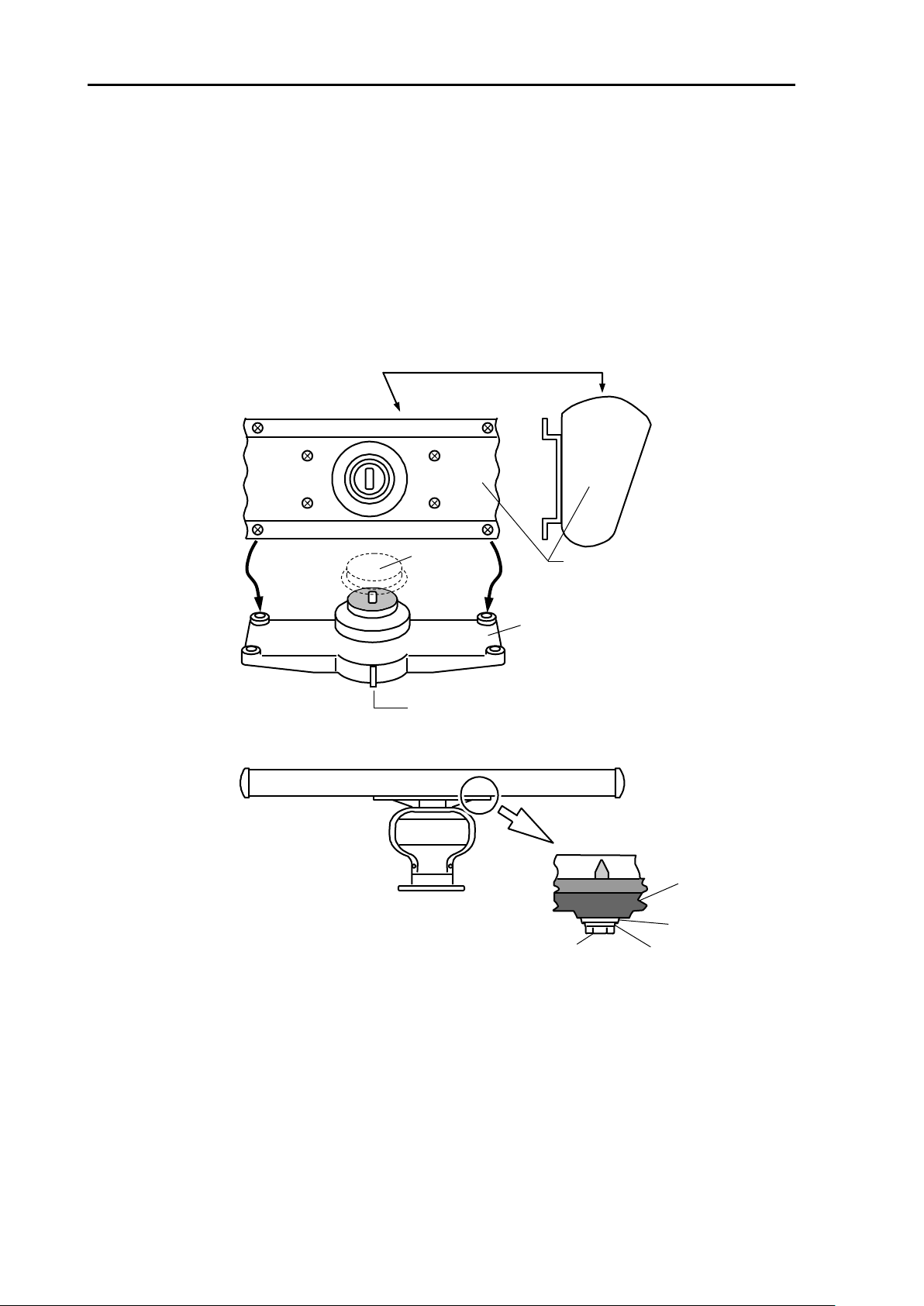

Chapter 3 Installation method MDC-5200/5500 Series

Antenna radiation side (KODEN –mark side)

Antenna

Rotating base

Remove

Protective cap

Projection mark

Figure 3.3 Antenna assembly to the rotating shaft

Rotating base

Flat washer

Spring washer

Installation bolt

3.1.2 Mounting the Antenna

(1) Remove the protective cap on top of the Scanner unit rotational shaft.

(2) Remove four bolts tentatively fixed to the base of the antenna and install the Scanner unit to the

rotating base. Align the direction of antenna radiation side (KODEN –mark side) with the projection

mark on the rotating base.

(3) Fix the aerial with four bolts removed in step 2.

3-4 0092655002-03

Page 29

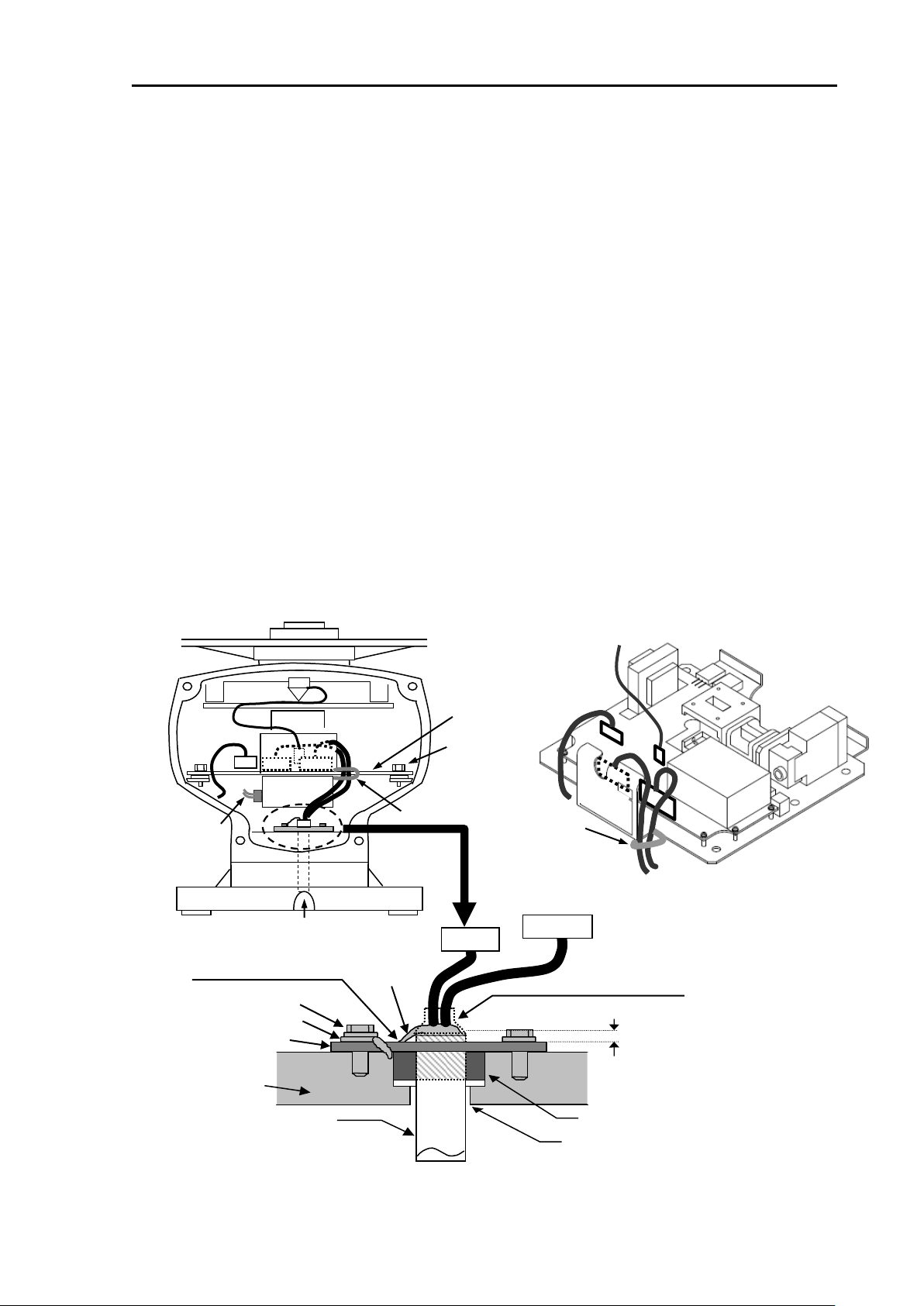

MDC-5200/5500 Series Chapter 3 Installation method

4kW (RB806)

cable clamp

X12

X11

X1

X2

Fixing bolt

TR unit

Magnetron lead wire

cable clamp

X1

X2

X11

X12

magnetron

Cut portion of Scanner unit base

Fixing bolt

Shield braid terminal

Cable holder plate

Scanner unit

Antenna cable

Put the shield braid

under the cable holder plate

as short as possible.

7-pins connector

Shield braid

9-pins connector

Remove the heat contraction tube

Rubber packing

Cable inlet hole

Make the height less than 5mm

TR unit

3.1.3 Installation of the connecting cable 242J159098x-xxM

3.1.3.1 Scanner unit 4kW (RB806: MDC-5204/5504)

(1) Please make sure power supply of the Scanner unit is OFF.

(2) Disassemble the front cover of the Scanner unit from the rear cover by loosening fixing bolts.

(3) Remove the TR unit by disconnecting the connector X1 and X2 after loosening fixing bolts of the

TR unit. Please make sure magnetron does NOT touch metals.

(4) Remove the cable holder plate and the rubber packing by loosening bolts at the bottom of the

Scanner unit box.

(5) Antenna cable shall be taken into the Scanner unit box through the cable inlet hole.

(6) Antenna cable shall be fixed as described in the illustration below, using the cable holder plate and

the rubber packing removed in 4. Shield braid terminal shall be fixed under the cable holder plate

together with lug terminal, after removing the edge portion of heat contraction tube of the antenna

cable.

(7) Mount the TR unit after connecting the X1 and X2 connectors (removed in 3) by fixing bolts.

(8) 7 pin connector shall be connected to X11 of the TR unit, 9 pin connector to X12.

(9) Antenna cable shall be clamped onto the TR unit. Please make sure the antenna cable does NOT

touch magnetron lead wires.

(10) The front and rear covers of the Scanner unit shall be fixed by fixing bolts.

0092655002-03 3-5

Page 30

Chapter 3 Installation method MDC-5200/5500 Series

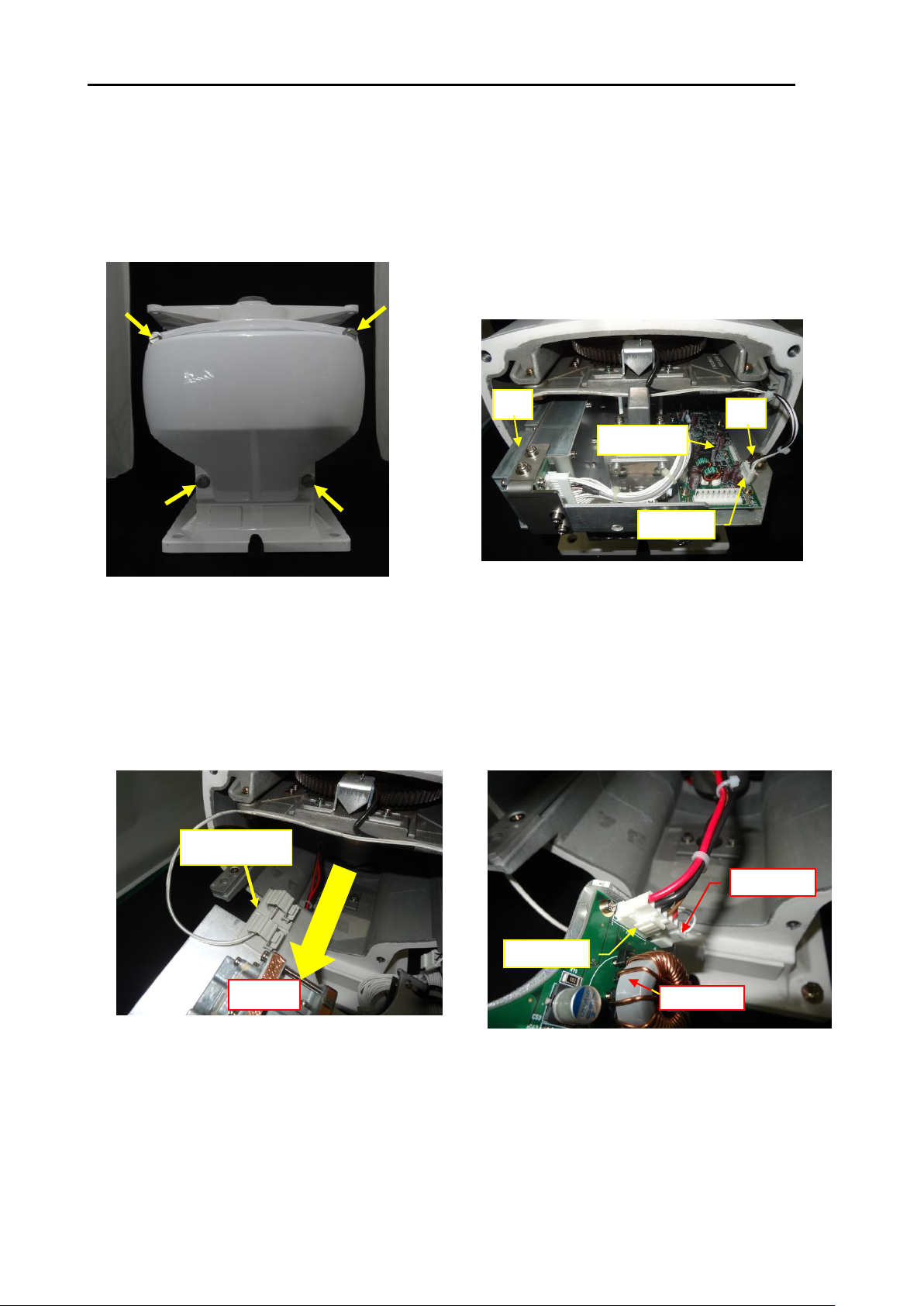

1) Remove back cover by loosening four fixing

bolts.

(Tool: Wrench 13mm)

2) Disconnect connectors P3 from J3

[E61-120X].

Remove the two fixing bolts.

(Tool: Wrench 13mm)

PCB: E61-120X

P3 <- J3

Bolt

Bolt

3) Pull out the TR unit, remove the

cable clamp.

TR unit

Cable clamp

4) Disconnect connector P2 from J2 and

P2 from J5.

P2 <- J2

PCB: E71-110X

P2 <- J5

3.1.4 Installation of the connecting cable CW-845-xxM

3.1.4.1 Scanner unit 6kW (RB807: MDC-5206/5506)

Make sure the radar system is turned off.

3-6 0092655002-03

Page 31

MDC-5200/5500 Series Chapter 3 Installation method

5) This picture is the view of scanner unit housing.

(a) Cable holder plate

(b) Cable clamp-b

(c) Cable clamp-c

(a)

(b)

(c)

6) Remove two fixing bolts.

(Tool: Wrench 8mm)

Remove the cable holding plate and

rubber packing.

Cable holding plate

Fixing bolt (8mm)

Rubber packing

Cable inlet hole

8) Pull in the connecting cable into the

scanner unit through the cable inlet hole

Guide the cable to the cable holding

plate.

7) The connecting cable CW-845-xxM

Blue tapes are wound as a mark on the cable.

Blue tape mark-b

Blue tape mark-a

Blue tape mark-c

Connecting cable

0092655002-03 3-7

Page 32

Chapter 3 Installation method MDC-5200/5500 Series

9) Attach rubber packing to the blue tape

mark-a.

Rubber packing

Blue tape mark-a

10) Attach cable holding plate and fix it with

two bolts.

(Tool: Wrench 8mm)

Cable holding plate

11) Attach the ferrite core from blue tape-b

to 10cm end.

Blue tape mark-b

12) Secure the ferrite core in place by using

provided bands.

Note: The ferrite core and the bands are included

with the installation material.

Ferrite core

Band

Band

3-8 0092655002-03

Page 33

MDC-5200/5500 Series Chapter 3 Installation method

13) The cable placed in the far right under

the motor.

14) Clamp the cable by the cable

clamp-b.

Cable clamp-b

Cable clamp-b

Clamp the blue tape mark by

the cable clamp-c.

Blue tape mark-c

Cable clamp-c

15) This picture is the view of the cable layout.

Clamp the blue tape mark-c by the cable clamp-c.

0092655002-03 3-9

Page 34

Chapter 3 Installation method MDC-5200/5500 Series

18) Insert TR unit in the scanner unit

housing.

TR unit

16) Connect connector P2 to J2 and P4 to J5.

[PCB E71-110X].

P2 -> J2

PCB: E71-110X

P4 -> J5

17) Through the P4 to J5 to clamp A and B.

P4 -> J5

Clamp A

Clamp B

19) Connect connectors P3 to J3 [PCB E61-120X]

Fix the two fixing bolts.

(Tool: Wrench 13mm)

PCB: E61-120X

P3-> J3

Bolt

Bolt

3-10 0092655002-03

Page 35

MDC-5200/5500 Series Chapter 3 Installation method

23) Attach the back cover by tightening four fixing

bolts.

(Tool: Wrench 13mm)

20) Remove the screw-A and the screw-B.

B

Clamping band

A

Connecting cable

Shield braid terminal

Clamping band

21) Clamp the connecting cable by the

clamping band and fix with screw-A.

Fix the shield braid terminal with screw-B.

22) Connect connector P2 to J2 [PCB E61-120x].

Connect the connectors P1 and P3 to J1 and J3

[PCB E71-110X].

P3 -> J3

P2 -> J2

PCB: E61-120X

PCB: E71-110X

P1 -> J1

0092655002-03 3-11

Page 36

Chapter 3 Installation method MDC-5200/5500 Series

4) Disconnect connector P2 from J2

[E61-110X].

1) Remove back cover by loosening four fixing

bolts.

(Tool: Wrench 13mm)

2) Disconnect connectors P3 from J3

[E61-120X].

Remove the two fixing bolts.

(Tool: Wrench 13mm)

PCB: E61-120X

P3 <- J3

Bolt

Bolt

3) Pull out the TR unit.

TR unit

P2 <- J2

PCB: E61-110X

3.1.4.2 Scanner unit 12kW (RB808: MDC-5212/5512)

Make sure the radar system is turned off.

3-12 0092655002-03

Page 37

MDC-5200/5500 Series Chapter 3 Installation method

6) Remove two fixing bolts.

(Tool: Wrench 8mm)

Remove the cable holding plate and

rubber packing.

8) Pull in the connecting cable into the

scanner unit through the cable inlet hole.

Guide the cable to the cable holding plate.

Cable holding plate

Fixing bolt (8mm)

Rubber packing

7) The connecting cable CW-845-xxM

Blue tapes are wound as a mark on the cable.

Blue tape mark-b

Blue tape mark-a

Blue tape mark-c

Connecting cable

Cable inlet hole

5) This picture is the view of the inside of the

scanner unit housing.

(a) Cable holding plate

(b) Cable clamp-b

(c) Cable clamp-c

(d) Cable clamp-d

(a)

(b)

(c)

(d)

0092655002-03 3-13

Page 38

Chapter 3 Installation method MDC-5200/5500 Series

9) Attach rubber packing to the blue tape

Mark-a.

Rubber packing

Blue tape mark-a

10) Attach cable holding plate and fix it

with two bolts.

(Tool: Wrench 8mm)

Cable holding plate

12) Secure the ferrite core in place by using

provided bands.

Note: The ferrite core and the bands are included

with the installation material.

Band

Band

Ferrite core

11) Attach the ferrite core to side of the

blue tape mark-b.

Blue tape mark-b

Ferrite core

3-14 0092655002-03

Page 39

MDC-5200/5500 Series Chapter 3 Installation method

14) Clamp the cable by the cable

clamp-b.

Cable clamp-b

Ferrite core

15) This picture is the view of the cable layout.

Clamp the blue tape mark-c by the cable clamp-c.

Cable clamp-d

Cable clamp-b

Blue tape mark-c

Cable clamp-c

Clamp the blue tape mark by the

cable clamp-c.

13) Tilt the cable with the ferrite core

toward the cable clamp-b.

Cable clamp-b

Ferrite core

0092655002-03 3-15

Page 40

Chapter 3 Installation method MDC-5200/5500 Series

19) Connect connectors P3 to J3 [PCB E61-120X]

Fix the two fixing bolts.

(Tool: Wrench 13mm)

16) Connect connector P2 to J2

[PCB E61-110X].

P2 -> J2

PCB: E61-110X

17) Hook the P2 to J2 to the clamp.

P2 -> J2

Clamp

18) Insert TR unit in the scanner unit

housing.

TR unit

PCB: E61-120X

P3-> J3

Bolt

Bolt

3-16 0092655002-03

Page 41

MDC-5200/5500 Series Chapter 3 Installation method

21) Clamp the connecting cable by the

clamping band and fix with screw-A.

Fix the shield braid terminal with screw-B.

Connecting cable

Shield braid terminal

Clamping band

20) Remove the screw-A and the screw-B.

B

Clamping band

A

22) Connect connector P2 to J2 [PCB E61-120x].

Connect the connectors P1 and P3 to J1 and J3

[PCB E61-110X].

P3 -> J3

P2 -> J2

PCB: E61-120X

PCB: E61-110X

P1 -> J1

23) Attach the back cover by tightening four

fixing bolts.

(Tool: Wrench 13mm)

0092655002-03 3-17

Page 42

Chapter 3 Installation method MDC-5200/5500 Series

4) Disconnect connector P2 from J2

[E62-110X].

3) Pull out the TR unit.

TR unit

2) Disconnect connectors P3 and P4 from J3

and J4 [E61-120X].

Remove the two fixing bolts.

(Tool: Wrench 13mm)

P3 <- J3

PCB: E61-120X

Bolt

Bolt

1) Remove the back cover by loosening four fixing

bolts.

(Tool: Wrench 13mm)

P2 <- J2

PCB: E62-110X

3.1.4.3 Scanner unit 25kW (RB809: MDC-5225/5525)

Make sure the radar system is turned off.

3-18 0092655002-03

Page 43

MDC-5200/5500 Series Chapter 3 Installation method

5) This picture is the view of the inside of the

scanner unit housing.

(a) Cable holding plate

(b) Cable clamp-b

(c) Cable clamp-c

(d) Cable clamp-d

(a)

(b)

(c)

(d)

6) Remove the fixing two bolts.

(Tool: Wrench 8mm)

Remove cable holding plate and

rubber packing.

Cable holding plate

Fixing bolt (8mm)

Rubber packing

8) Pull into the inside of the scanner unit housing

through the cable inlet hole.

Guide the cable to the cable holding plate.

Cable inlet hole

7) The connecting cable CW-845-xxM

Blue tapes are wound as a mark on the cable.

Blue tape mark-b

Blue tape mark-a

Blue tape mark-c

Connecting cable

0092655002-03 3-19

Page 44

Chapter 3 Installation method MDC-5200/5500 Series

9) Attach rubber packing to the blue tape

Mark-a.

Rubber packing

Blue tape mark-a

10) Attach cable holding plate and fix it

with two bolts.

(Tool: Wrench 8mm)

Cable holding plate

12) Secure the ferrite core in place by using

provided bands.

Note: The ferrite core and the bands are included

with the installation material.

Band

Band

Ferrite core

11) Attach the ferrite core to side of the

blue tape mark-b.

Blue tape mark-b

Ferrite core

3-20 0092655002-03

Page 45

MDC-5200/5500 Series Chapter 3 Installation method

14) Clamp the cable by the cable

clamp-b.

Cable clamp-b

Ferrite core

15) This picture is the view of the cable layout.

Clamp the blue tape mark-c by the cable clamp-c.

Cable clamp-d

Cable clamp-b

Blue tape mark-c

Cable clamp-c

Clamp the blue tape mark by the

cable clamp-c.

13) Tilt the cable with the ferrite core

toward the cable clamp-b.

Cable clamp-b

Ferrite core

0092655002-03 3-21

Page 46

Chapter 3 Installation method MDC-5200/5500 Series

16) Connect connector P2 to J2

[PCB 62-110X].

P2 -> J2

PCB: E62-110X

17) Hook the P2 to J2 to the clamp.

P2 -> J2

Clamp

19) Connect connectors P3 and P4 to J3 and J4 [PCB

E61-120X]

Fix the two fixing bolts.

(Tool: Wrench 13mm)

P3 -> J3

PCB: E61-120X

Bolt

Bolt

18) Insert the TR unit in the scanner unit

housing.

TR unit

3-22 0092655002-03

Page 47

MDC-5200/5500 Series Chapter 3 Installation method

23) Attach the back cover by tightening four

fixing bolts.

(Tool: Wrench 13mm)

20) Remove screw-A and screw-B.

A

B

Clamping band

21) Clamp the connecting cable by the

clamping band and fix with screw-A.

Fix the shield braid terminal with screw-B.

Clamping band

Connecting cable

Shield braid terminal

22) Connect connector P2 to J2 [PCB

E61-120x].

Connect connectors P1 and P3 to J1 and J3

[PCB E62-110X].

P2 -> J2

P1 -> J1

P3 -> J3

PCB: E61-120X

PCB: E62-110X

0092655002-03 3-23

Page 48

Chapter 3 Installation method MDC-5200/5500 Series

Antenna-Scanner unit Display unit

P2 PX

Description Cable color No. No. Cable color Description

Ground

GND

Shield

V/TRG

Grey (coax)

9

7

Brown

BP/SHF

V/TRG-RTN

Shield86

Shield

BP/SHF-RTN

DATA-RTN

Shield

4

Description

Cable color

No.

DATA

Red

5

+24V

Blue

1

23Orange (thick)

+12V

--15

Green (thick)

+53V-RTN

16

Blue (thick)

+53V-RTN

13

Yellow (thick)

+53V

14

Shied

V/TRG-RTN

11--

12

Red (thick)

+53V

9

Shield

BP/SHF-RTN

10

Grey (coax)

V/TRG

6

Red

DATA

7

-

8

Brown

BP/SHF

-5Shield

DATA-RTN

2

Blue

+24V

3

Orange (thick)

+12V

+53V-RTN

Green (thick)

6

+53V-RTN

Blue (thick)

7P1+250V

Purple11

Purple

+250V

+53V

Red (thick)

44Yellow

GND

+53V

Yellow (thick)

5--2GND

Yellow

3

Figure 3.4 Interconnection of cable (242J159098x) between Antenna-Scanner unit and Display unit

3.2 Interconnection diagram of cable

3.2.1 242J159098 (MDC-5204/5504)

3-24 0092655002-03

Page 49

MDC-5200/5500 Series Chapter 3 Installation method

Antenna-Scanner unit Display unit

P1 PX

Description Cable color No. No. Cable color Description

Ground

GND

Shield

+53V-RTN

Green (thick)

3

+53V-RTN

Blue (thick)

4

+53V

Red (thick)

1

+53V

Yellow (thick)

2P3Description

Cable color

No.16Blue (thick)

+53V-RTN

GND

Yellow

315Green (thick)

+53V-RTN

--214Shied

V/TRG-RTN

+250V

Purple

113Yellow (thick)

+53V

Description

Cable color

No.12Red (thick)

+53V

10

Grey (coax)

V/TRG

P2

11--

V/TRG

Grey (coax)

99Shield

BP/SHF-RTN

V/TRG-RTN

Shied88

Brown

BP/SHF

BP/SHF

Brown77--

BP/SHF-RTN

Shield66

Red

DATA

DATA

Red55

Shield

DATA-RTN

DATA-RTN

Shield44

Yellow

GND

+24V

Blue11

Purple

+250V

+12V

Orange (thick)

33Orange (thick)

+12V

--22Blue

+24V

3.2.2 CW-845 (MDC-5206/5212/5225/5506/5512/5525)

Figure 3.5 Interconnection of cable (CW-845) between Antenna-Scanner unit and Display unit

0092655002-03 3-25

Page 50

Chapter 3 Installation method MDC-5200/5500 Series

MRD-111 (MDC-5200 series)

MRD-109 (MDC-5500 series)

Unit: mm (inch)

3.3 Installation of the display unit

The Display unit can be mounted tabletop or panel flush mount using following procedures.

Install the display unit so that when user is looking ahead, the lookout view is not obscured.

The orientation of the display unit should be such that the user is looking ahead. The lookout view

should not be obscured and the ambient light should cause minimum degradation on the display.

External view and dimensions

3-26 0092655002-03

Page 51

MDC-5200/5500 Series Chapter 3 Installation method

MRO-108 (MDC-5500 series)

Unit: mm (inch)

0092655002-03 3-27

Page 52

Chapter 3 Installation method MDC-5200/5500 Series

Figure 3.6 Diagram of installation procedure on the table

Unit: mm (inch)

3.3.1 Installation of MRD-111 (MDC-5200 series)

3.3.1.1 Table mounting of MRD-111

(1) Remove two knob bolts from which the Display unit is secured on the mounting bracket.

(2) Remove the Display unit from the mounting bracket and put it on a stable flat place.

(3) Place the mounting bracket in the appropriate setting position and secure it with five 5 mm screws.

(4) Remount the Display unit on the mounting bracket and secure it with knob bolts which were

removed in (1).

3-28 0092655002-03

Page 53

MDC-5200/5500 Series Chapter 3 Installation method

Figure 3.7 Maintenance space necessary for tabletop Display unit

Unit: mm (inch)

Note: In case of mounting the Display unit on the table, some maintenance space is required for cabling,

connector access, fuse replacement, fastening of bolts, etc. as shown in the following figure.

0092655002-03 3-29

Page 54

Chapter 3 Installation method MDC-5200/5500 Series

(4mm screw for 4holes)

(5/8)

16

(12 1/8)

308

(11 13/16)

300

(5/8)

16

(10 25/32)

274

(5/8)16

(12 3/64)

306

(10 35/64)

268

(12 1/8)

308

Unit : mm(inch)

Display unit

M4 screw (four places)

Corner guard cap (four places)

Figure 3.8 The opening and nut-holes for Display unit

(1) Cut an opening and drill 4.0 mm (in the

case of fixed nut) four nut-holes with the

size shown in Figure 3.8, on the side for

attachment of a Display unit on a panel.

(2) Unscrew two knob bolts that hold the

Display unit to the mounting bracket.

(3) Remove the Display unit from the mounting

platform and put it on a level place.

(4) Detach four corner guard caps.

Figure 3.9 Mounting the Display unit into place

3.3.1.2 Flush Mounting for MRD-111

Preparation:

Installation:

(1) Place the Display unit in the precut opening on the panel.

(2) Secure the Display unit with four corners fastened with 4 mm screw as shown in the following figure.

(3) Fit in four corner guard caps.

3-30 0092655002-03

Page 55

MDC-5200/5500 Series Chapter 3 Installation method

Figure 3.10 Diagram of installation procedure

3.3.2 Installation of MRD-109/MRO-108 (MDC-5500 series)

3.3.2.1 Table mounting of MRD-109

(1) Remove four knobs that the Display unit is secured on the mounting bracket.

(2) Remove the Display unit from the mounting bracket and put it on a stable flat place.

(3) Place the mounting bracket in the appropriate position and secure it with five screws.

(4) Remount the Display unit on the mounting bracket and secure it with knob bolts which were

removed in (1).

0092655002-03 3-31

Page 56

Chapter 3 Installation method MDC-5200/5500 Series

Figure 3.11 Maintenance space requirements

Unit: mm (inch)

Note: When mounting the Display unit on the tabletop, some maintenance space is required for cabling,