Page 1

Page 2

Declaration of Conformity

(As required by Article 6.3 of Directive 1999/5/EC-RTTE Directive)

Declares under his sole responsibility that the produced Marine Radar System manufactured

by

Koden Electronics Co., Ltd.

5278 Uenohara

Uenohara-Shi,

Yamanashi-Ken

409-0112

Japan

Telephone +81 554 20 5865 Telefax +81 554 20 5880

Intended for Worldwide use as a Marine Radar for use aboard non-SOLAS vessels and

identified by the type number MDC-1841BB / MDC-1840BB to which this declaration

refers has been tested to the essential radio test suites required by the notified body and is in

conformity with the standards

EN 6094

EN 6225

ITU-R R

5 : 2002 ( Clauses 9,10 & 12 )

2 : 2004 ( Clauses 4.8, 4.33, 5.8, 5.33 and Annex D )

ecommendation RM.1177

and complies with the essential requirements of Directive 1999/5/EC

Conformity procedure under Annex IV of 1999/5/EC (Technical Construction file) has been

undertaken by

QinetiQ: Cody Technology Park, Ively Road, Farnborough, Hampshire, GU14 0LX,

United Kingdom

The Technical Construction File is held by Mr Heinz Hoghoff at

Koden Elektronik GmbH,

Am Gewerbepark 15,

D-64823 Gross-Umstadt / Hessen

Germany

Telephone +49 6078 2056 Telefax +49 6078 73824

Notified Body : QinetiQ

Kenichi Chiwaki, QA Manager.

Statement Number: QQ-RTTE-12/05-01

Koden Electronics Co., Ltd.

: QQ-RTTE-14/05-01

04 Jul. 2005

Page 3

Declaration of Conformity

(As required by Article 6.3 of Directive 1999/5/EC-RTTE Directive)

Declares under his sole responsibility that the produced Marine Radar System manufactured

by

Koden Electronics Co., Ltd.

5278 Uenohara

Uenohara-Shi,

Yamanashi-Ken

409-0112

Japan

Telephone +81 554 20 5865 Telefax +81 554 20 5880

Intended for Worldwide use as a Marine Radar for use aboard non-SOLAS vessels and

identified by the type number MDC-1860BB / MDC-1810BB / MDC-1820BB to which

this declaration refers has been tested to the essential radio test suites required by the notified

body and is in conformity with the standards

EN 6094

EN 6225

ITU-R R

5 : 2002 ( Clauses 9,10 & 12 )

2 : 2004 ( Clauses 4.8, 4.33, 5.8, 5.33 and Annex D )

ecommendation RM.1177

and complies with the essential requirements of Directive 1999/5/EC

Conformity procedure under Annex IV of 1999/5/EC (Technical Construction file) has been

undertaken by

QinetiQ: Cody Technology Park, Ively Road, Farnborough, Hampshire, GU14 0LX,

United Kingdom

The Technical Construction File is held by Mr Heinz Hoghoff at

Koden Elektronik GmbH,

Am Gewerbepark 15,

D-64823 Gross-Umstadt / Hessen

Germany

Telephone +49 6078 2056 Telefax +49 6078 73824

Notified Body : QinetiQ

Kenichi Chiwaki, QA Manager.

Statement Number: QQ-RTTE-18/05-01

Koden Electronics Co., Ltd.

: QQ-RTTE-19/05-01

12 Oct. 2005

: QQ-RTTE-20/05-01

Page 4

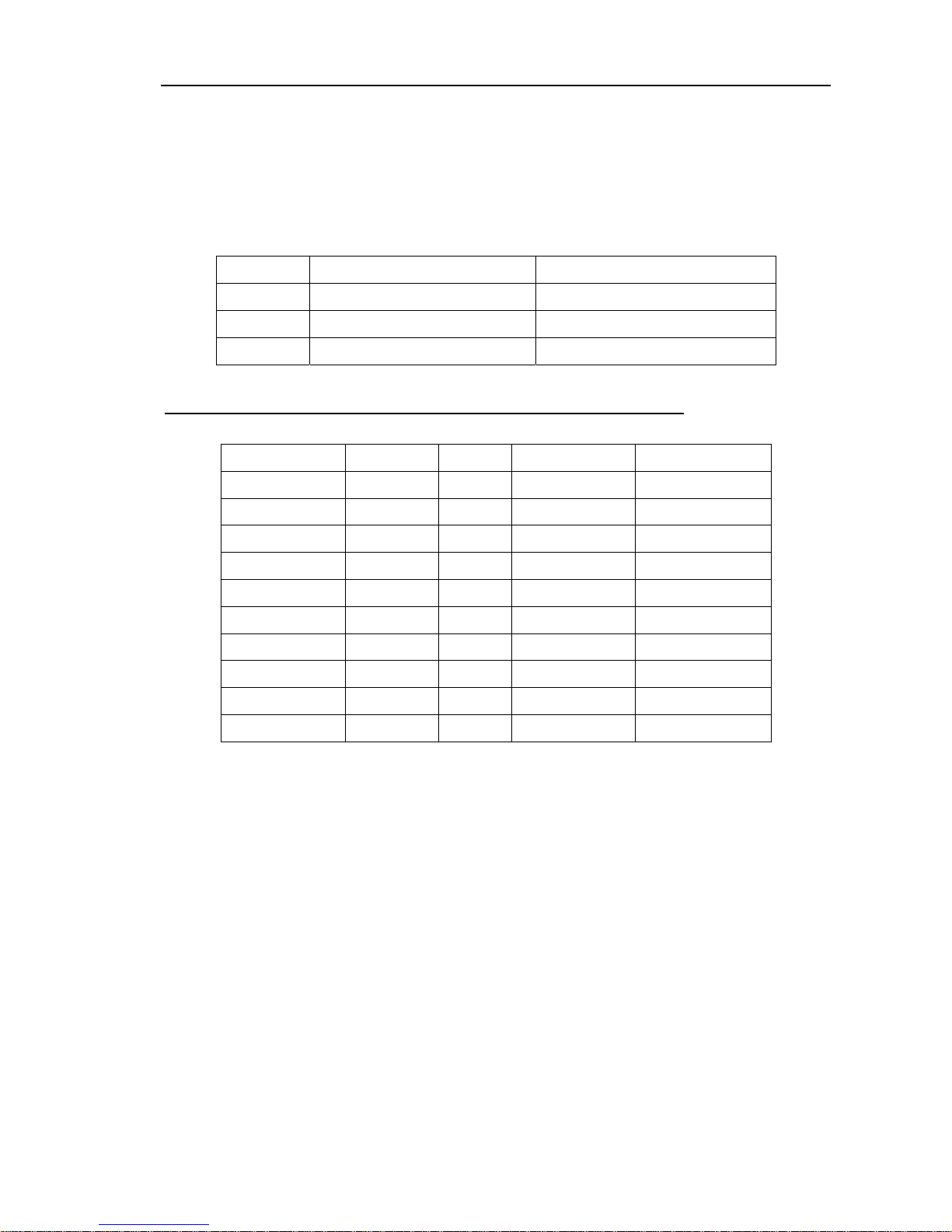

AMENDMENT HISTORY

MDC-1860BB/1810BB/1820BB Series OPERATION MANUAL

Doc No: 0093142122

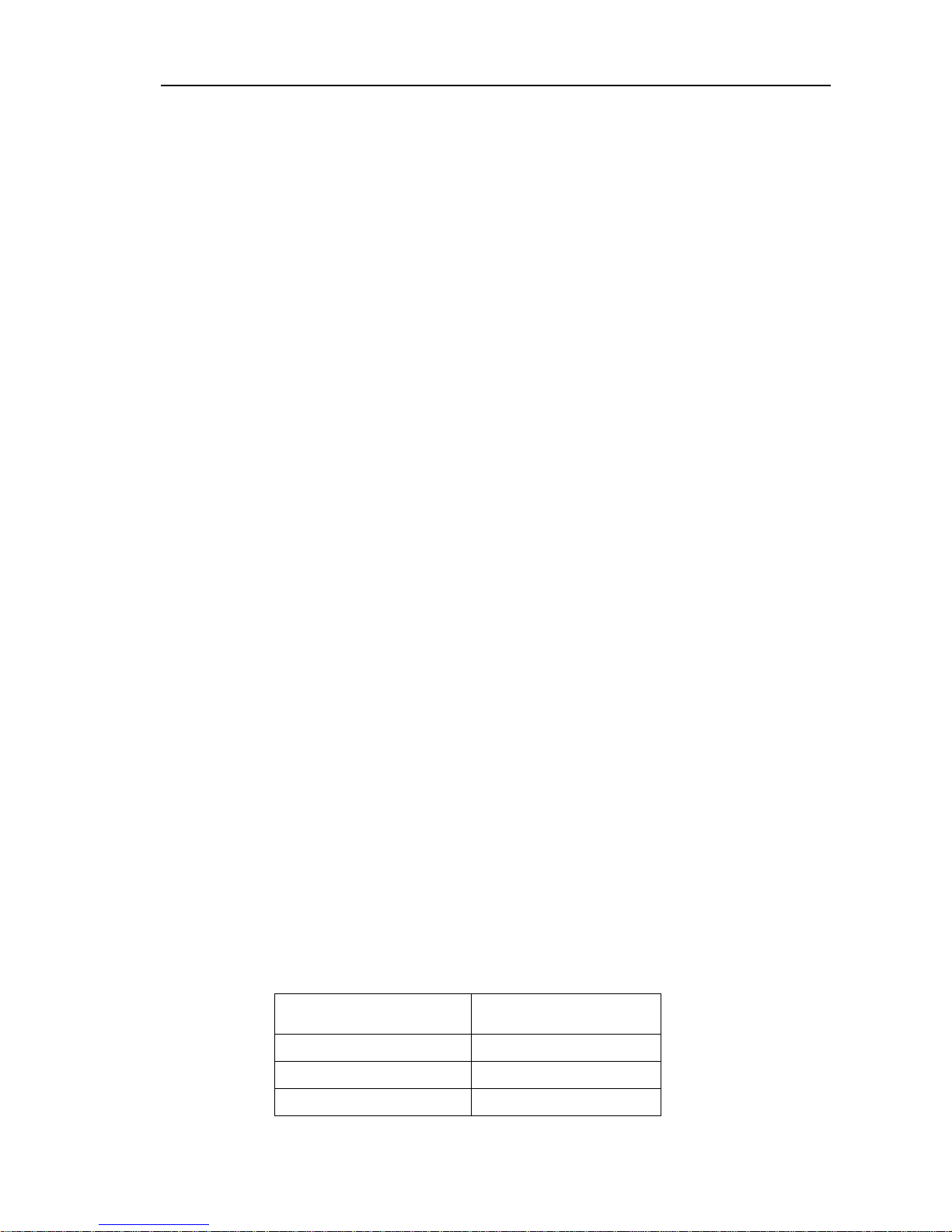

No. Do cument No & Rev No. Date (D/M/Y) Amendments

0 93142122-00 10/12/03 First issue

1 93142122-01

14/01/04

Chapter 3, para 3.6: Entered the

compass safe distance for Display and

Operation unit.

Chapter 5, para 5.2: Deleted “MAP” from

the key switch, which was mistakenly

printed.

2 93142122-02

25/02/04

Preface: Added “Operation of AIS.”

Chapter 1, 2, 4: Amended the power

cable type name. Chapter 3: Added AIS

spec. Chapter 6: Added the descriptions

for AIS display, operation, etc. Chapter 4:

Reedited 4.6.4 by adding 4.6.4.1 and

4.6.4.2 for Display installation methods.

Reedited Para. 4.7.3 to add more details

for GAIN/STC settings. Chapter 10:

Added the AIS sentence.

3 93142122-03 01/04/04 Chapter 2, 4: Added Ferrite Core.

4 93142122-04

02/06/04

Chapter 3,4,10: Added Auto tune

adjustment,

NMEA formatter.

5 93142122-05

09/09/04

Chapter 6.4.1.7 SERIAL

Chapter10.4.5 PIN NO

6 93142122-06 22/02/05 Chapter 1/Chapter 6.9 Add ed

7 0093142122-07/08 (10/04/06)(10/07/06) Declaration/Chapter 3

8 0093142122-09/10 (14/12/06)( 25/07/08) Cover/Chapter 5

9 0093142122-11 20/08/08 Chapter 4,Declaration

10

Amendment policy

When any change is applied in the document, only the document number of the relevant sheet(s) and

cover sheet are modified and the rest of the sheets are not changed. The document number is shown in

the footer area, right or left bottom of each sheet.

○

c

2003 2004 2005 2006 2007 2008 Koden Electronics Co.,Ltd. All rights reserved.

No part of this publication may be reproduced, transmitted, translated in any form by any means without

the written permission of Koden Electronics Co., Ltd. The technical descriptions contained in this

publication are subject to change without notice. Koden assumes no responsibility for any errors,

Page 5

MDC-1840BB/1841BB/1860BB/1810BB/1820BB Series Preface

Operation Manual

93142122-07 (1)

Preface

Safety Notices

OPERATOR SAFETY

Watch for the rotating antenna:

The radar antenna will start to rotate without notice. For your safety, keep away from

the area in the vicinity of the radar antenna.

Be aware of RF Radiation Hazard:

The active radar antenna radiates powerful RF energy. Continuous exposure to RF

energy may cause harmful effects to the human body. It also causes Cardiac

Pacemaker to malfunction. A person who uses a Cardiac Pacemaker should under no

circumstances be exposed to RF radiation.

Most countries accept that RF power density levels below 100 W/m2 cause no

significant RF hazard.

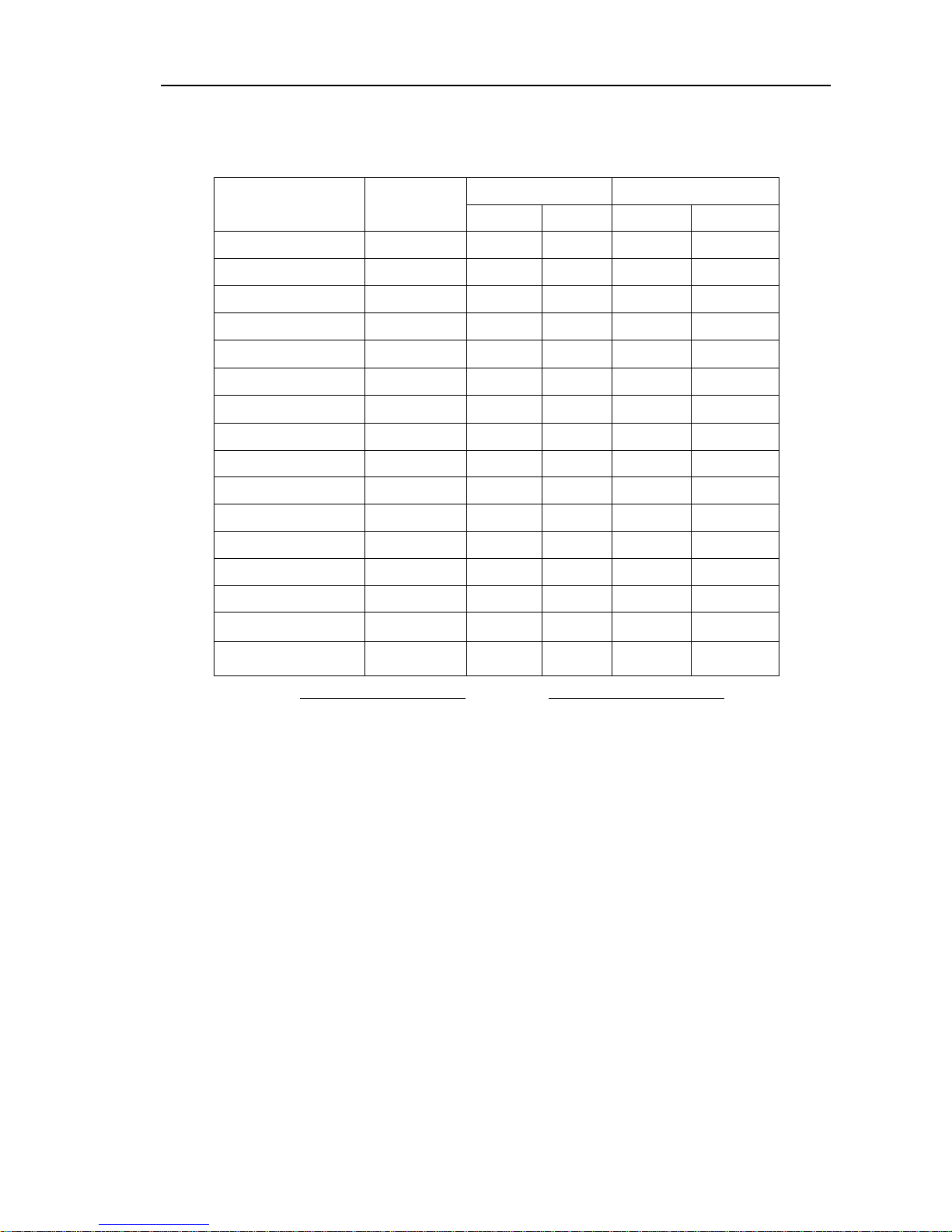

Distance vs. specified RF Power Density Level

Power / antenna length 100 W/m2 10 W/m2

4 KW / 2 ft Aerial 0.80 m 2.54 m

4KW / 3 ft Aerial 0.90 m 2.85 m

4KW / 4 ft Aerial 1.01 m 3.20 m

6 KW / 4 ft Aerial 1.09 m 3.46 m

6 KW / 6 ft Aerial 1.30 m 4.10 m

12 KW / 4 ft Aerial 1.55 m 4.89 m

12 KW / 6 ft Aerial 1.84 m 5.81 m

25 KW / 4 ft Aerial 2.45 m 7.73 m

25 KW / 6 ft Aerial 2.82 m 8.91 m

Dangerous HIGH voltage inside:

Life threatening high voltage is present in the antenna and display units. This high

voltage may be present even after the power switch has been turned off. The high

voltage circuits are provided with protection covers and warning labels to avoid

unintentional contact with these sections. For safety reasons, switch the power off

Page 6

Preface MDC-1840BB/1841BB/1860BB/1810BB/1820BB Series

Operation Manual

(2) 93142122-07

before accessing the internal circuitry and discharge any residual voltages in

capacitors by an appropriate method. Only qualified personnel should attempt these

maintenance procedures.

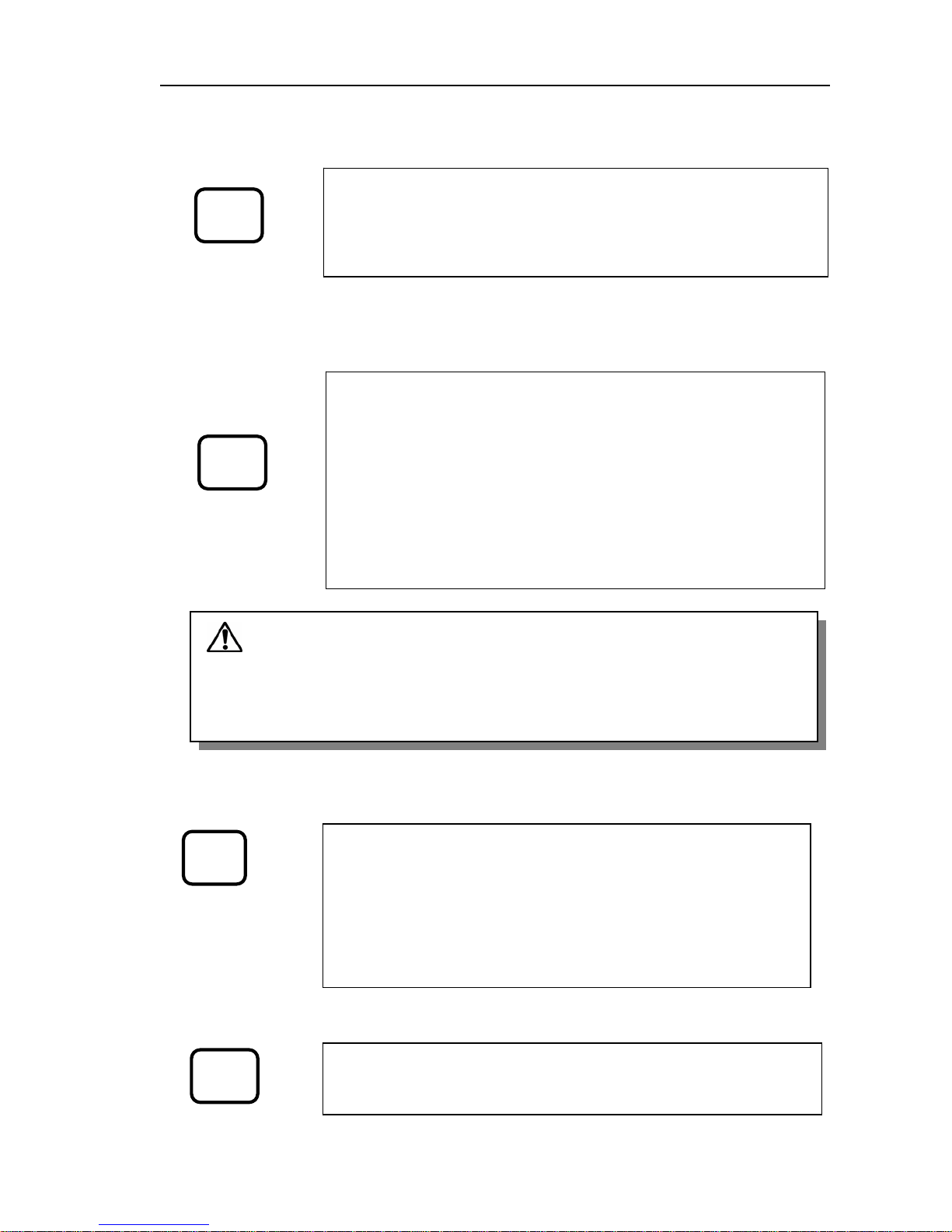

MAINTENANCE SAFETY

Beware of residual high voltages:

High voltages may remain in the capacitors and the anode cap on the Cathode Ray

Tube several minutes after you have turned the power switch off. Wait at least five

minutes or discharge them to ground before starting your inspection.

Make sure the main power supply is OFF:

To prevent an electrical injury due to erroneous power switching, make sure that the

main power supply and the system power switch are both OFF. Also attach a safety

label showing that service is in progress.

Avoid inhaling dust:

The dust could be a temporary health hazard. When cleaning inside of the equipment,

avoid inhaling the dust.

Avoid static electricity:

Take care not to damage the ESDs (Electrostatic Sensitive Devices) due to static

electricity from carpet and cloths.

Page 7

MDC-1840BB/1841BB/1860BB/1810BB/1820BB Series Preface

Operation Manual

93142122-07 (3)

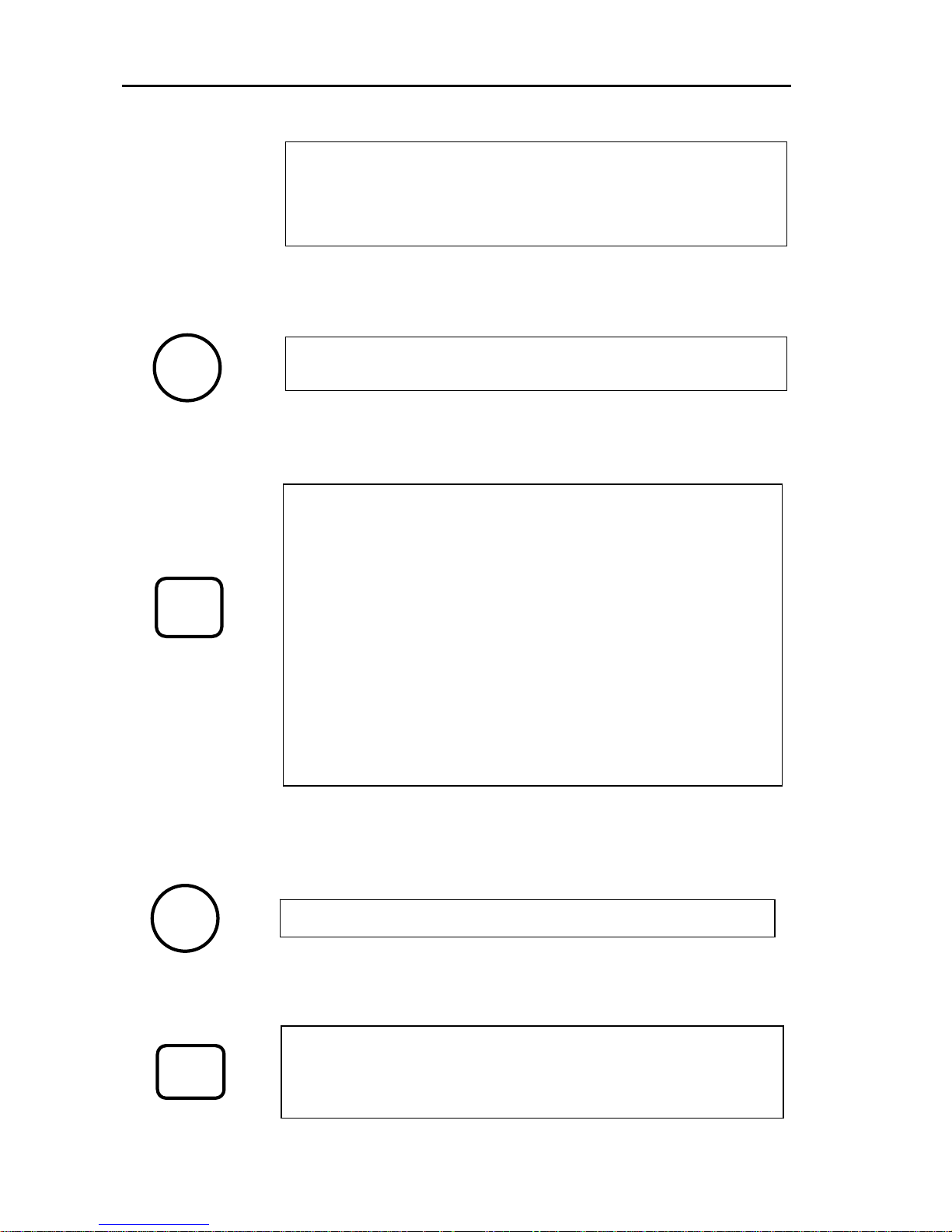

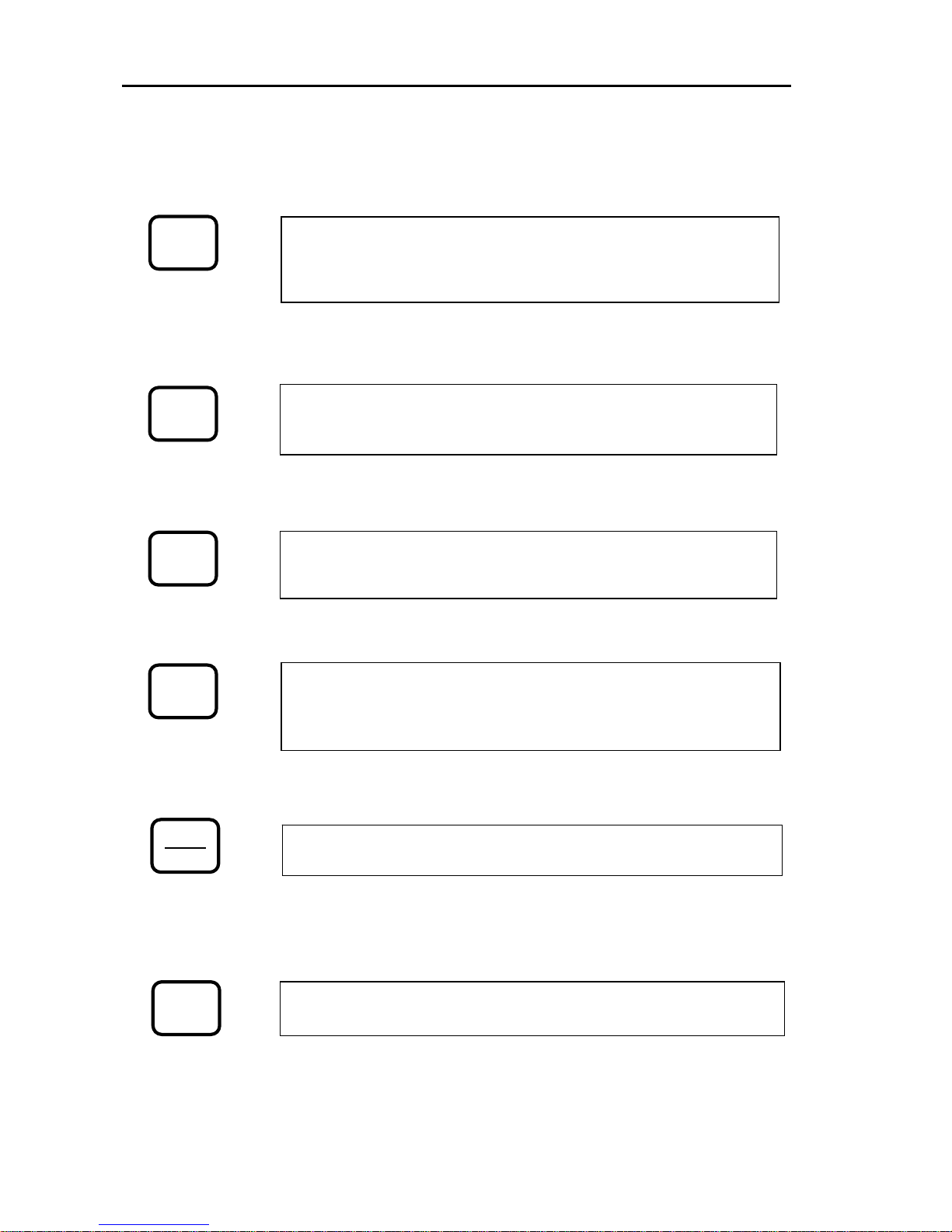

Various symbols used in this manual

The following symbols are used in this manual. Y ou are requested to be fully aware of the meaning

of each symbol before carrying out inspection and maintenance on this radar system

Warning mark

Alarm mark

Caution mark

Warning High Voltage mark

Prohibition mark

To handle the equipment ignoring this sign may lead to fatal

damage or injury to human body.

Warning

To handle the equipment ignoring this sign may lead to injury to

human body or damage to the equipment.

Alarm

To handle the equipment ignoring this sign may lead to electrical

shock to human body.

This sign indicates that a specified action is prohibited. The

prohibited action will be shown in the vicinity of the mark.

To handle the equipment ignoring this sign may lead to a

malfunction of the equipment.

Caution

Page 8

Preface MDC-1840BB/1841BB/1860BB/1810BB/1820BB Series

Operation Manual

(4) 93142122-07

HOW TO USE THIS MANUAL

Scope of this manual

This manual provides necessary information for installation, operation and

maintenance of MDC-1800BB series radar systems.

Organization of this manual

This manual is divided into chapters for quick and easy finding of the information you

require. The titles and contents of each chapter are as follows:

Chapter 1: General Descriptions

- Outline of the equipment

- Equipment category

- EMC compliance statement

- System configuration

- Software type name used

Chapter 2: Equipment Supplied

- Standard equipment list

- Spare parts list

- Installation material list

- Optional items

Chapter 3: Technical Specifications

- Antenna specification

- Display specification

- ATA Specification

- Serial data and sentence used

- Power supply

- Compass Safe Distance

- Environmental specification

- Mechanical specification

Page 9

MDC-1840BB/1841BB/1860BB/1810BB/1820BB Series Preface

Operation Manual

93142122-07 (5)

Chapter 4: Installation

- Installation considerations

- Unpacking each component of the system

- Inspection of each component unit and accessories

- Setting the units

- Cable routing and connections

- Installation procedure

- Setting up after installation

- Setting up option

Chapter 5: Basic Operation

- Introduction

- Control panel layout

- Operating controls

- Getting started

- Basic radar operations

Chapter 6: Using The Menu

- RADAR MENU

- DISP MENU

- ADJUST MENU

- SYSTEM MENU

- MAINTENANCE MENU

- Operation of EPA

- Operation of ATA

- Operation of AIS

Chapter 7: Graphic Displays

- Entering Graphic Mode

- Selecting the Graphic Display/DISPLAY ITEM SELECT MENU

- Registering or modifying the NAVLINE data / NAVLINE DATA INPUT

MENU

Page 10

Preface MDC-1840BB/1841BB/1860BB/1810BB/1820BB Series

Operation Manual

(6) 93142122-07

Chapter 8: Trouble Shooting And On Board Servicing

- Information required for service

- Self diagnosis functions provided

- Trouble shooting

- On board servicing

Chapter 9: Maintenance

- Periodic inspection and cleaning

Chapter 10: Technical References

- Serial input data sentence detail

- Tracking data output sentence detail

- Radar output sentence detail

- Interface requirements

Page 11

MDC-1840BB/1841BB/1860BB/1810BB/1820BB Series Chapter 1

Operation Manual General Descriptions

93142122-07 Contents

Chapter 1

General Descriptions

Contents

Page No.

1.1 Outline of the equipment.........................................................1-1

1.2 Equipment category.................................................................1-1

1.3 EMC compliance statement.....................................................1-1

1.4 System configuration...............................................................1-2

1.5 Software type name used........................................................ 1-3

Page 12

MDC-1840BB/1841BB/1860BB/1810BB/1820BB Series Chapter 1

Operation Manual General Descriptions

93142122-07 1-1

Chapter 1 General Descriptions

1.1 Outline of the equipment

The MDC-1800BB series of radar is designed and manufactured to meet the IEC

technical standards, shown below.

z IEC 60945 4th Edition 2002, General

z IEC 60872-2 and 3: EPA and ATA

z IEC 61162-1 and 2: Digital Interface

z IEC/PAS 60936-5: AIS (display on Radar)

The equipment is composed of two units, the antenna and the processor . The antenna

unit comprises a 3ft, 4 ft or 6 ft aerial, which is mounted on the transceiver unit of

either 4kW(For MDC-1840BB/1841BB), 6kW(For MDC-1860BB), 12 kW (For

MDC-1810BB), or 25 kW (For MDC-1820BB) type. The 4 foot and 6 foot aerials are

encapsulated in a water-sealed, durable plastic case. The transceiver unit is

contained in a waterproof aluminum case.

1.2 Equipment category

The MDC-1800BB series of radar is composed of the component units in the following

categories, specified in the IEC 60945 4th edition, Para 4.4.

Antenna Unit

(Type RB715A, RW701A-03/04/06 + RB716A/RB717A/RB718A/719A):

Exposed to the weather (formerly Class X)

Display Unit (Type MRM-100):

Protected from the weather (formerly Class B)

Operation Unit (Type MRO-100):

Protected from the weather (formerly Class B)

1.3 EMC compliance statement

This series of equipment has been tested and verified by the QinetiQ UK, according to

the IEC 60945 4th Edition, in terms of Electro Magnetic Compatibility and atmospheric

durability against the maritime environment.

Page 13

Chapter MDC-1840BB/1841BB/1860BB/1810BB/1820BB Series

General Descriptions Operation Manual

1-2 93142122-07

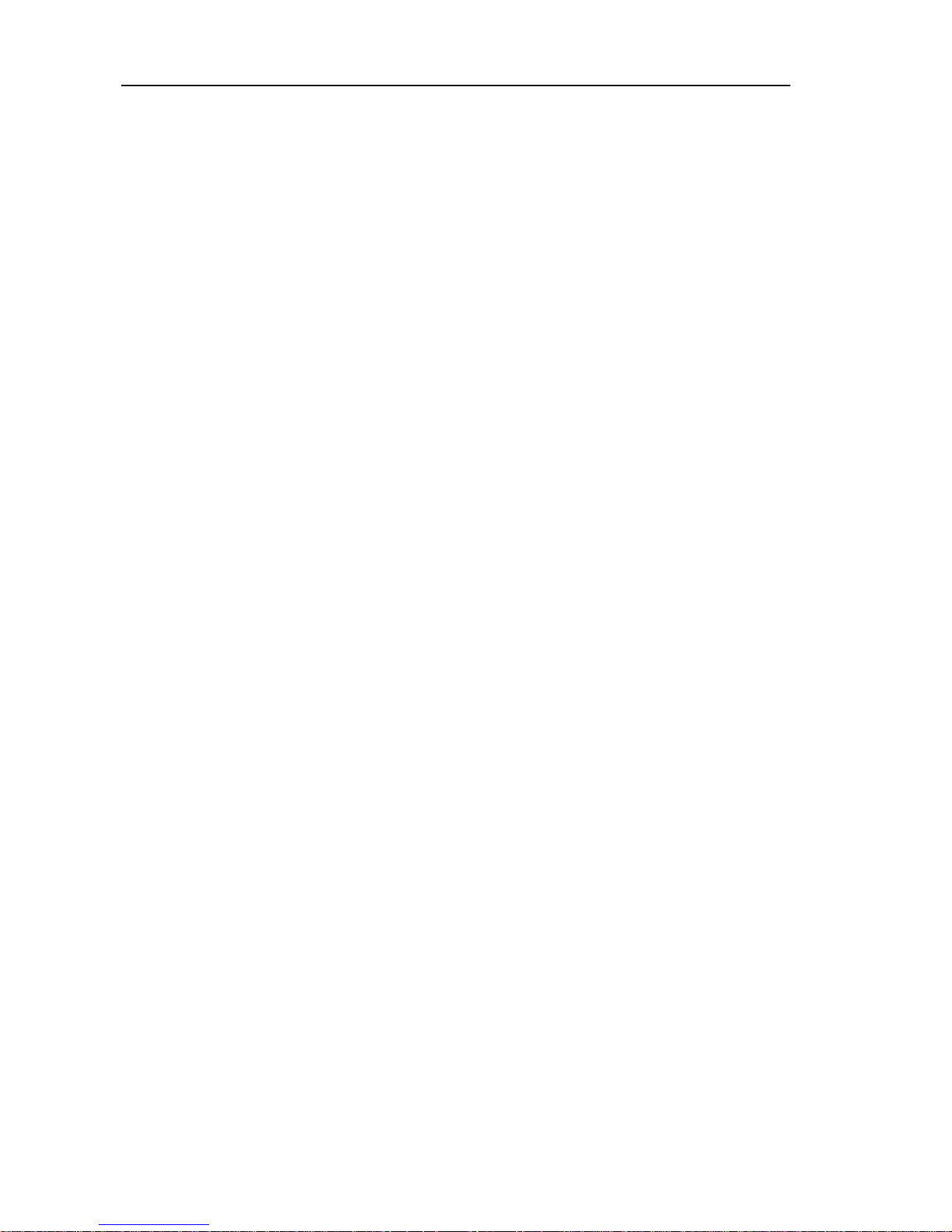

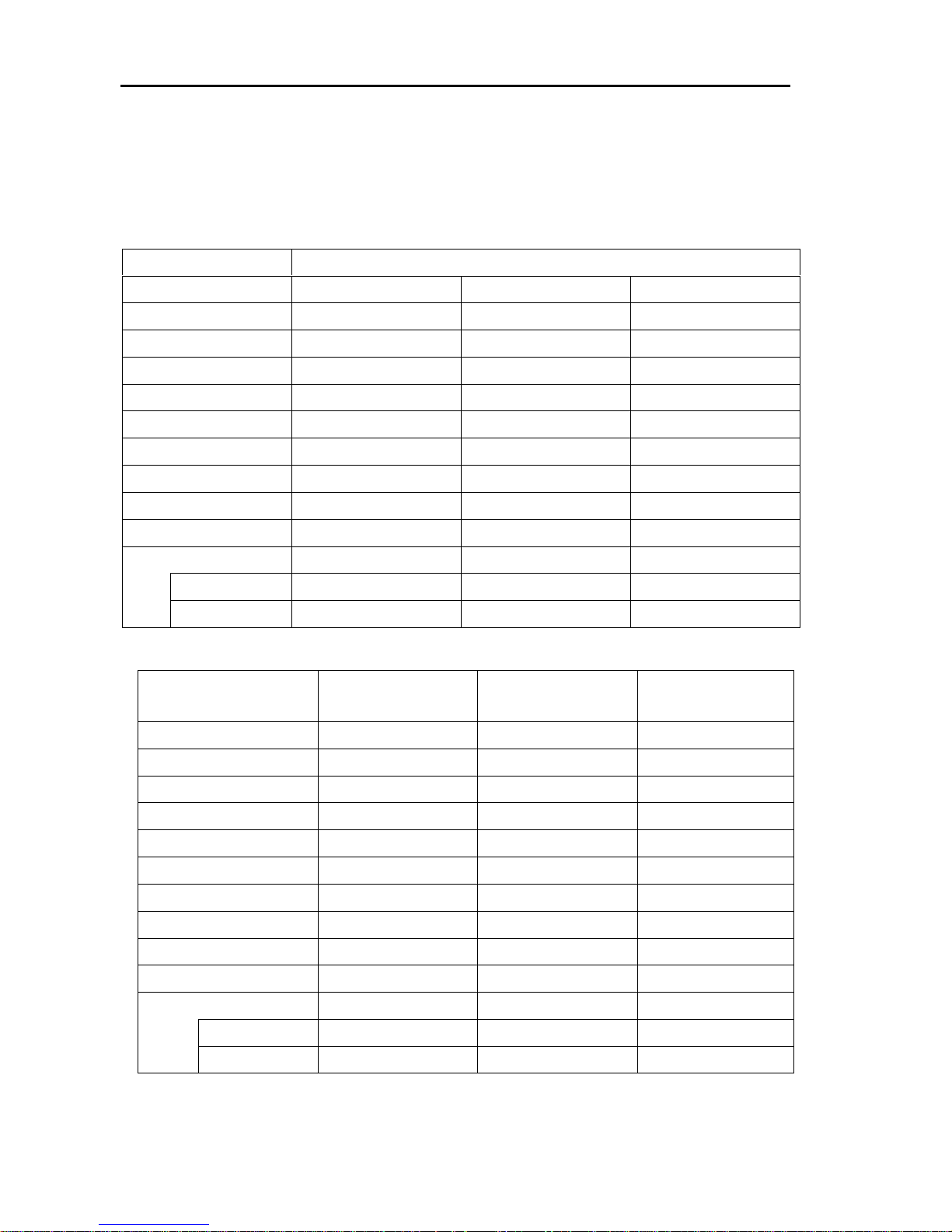

1.4 System configuration

The MDC-1840BB, MDC-1841BB, MDC-1860BB, MDC-1810BB and MDC-1820BB

radar sets are configured as follows:

Refer to Figure 1 for the system configuration of this series.

MDC-1840BB

Component Unit Sub-unit Type name

Antenna Unit Not assigned

Aerial, 3-foot RW701A-03

Aerial, 4-foot RW701A-04

Transceiver RB716A (4kW)

Processor Unit MRM-100

Operation Unit MRO-100

MDC-1841BB

Component Unit Sub-unit Type name

Antenna Unit RB715A (4kW)

Processor Unit MRM-100

Operation Unit MRO-100

MDC-1860BB

Component Unit Sub-unit Type name

Antenna Unit Not assigned

Aerial, 4-foot RW701A-04

Aerial, 6-foot RW701A-06

Transceiver RB717A (6 kW)

Processor Unit MRM-100

Operation Unit MRO-100

Page 14

MDC-1840BB/1841BB/1860BB/1810BB/1820BB Series Chapter 1

Operation Manual General Descriptions

93142122-07 1-3

MDC-1810BB

Component Unit Sub-unit Type name

Antenna Unit Not assigned

Aerial, 4-foot RW701A-04

Aerial, 6-foot RW701A-06

Transceiver RB718A (12 kW)

Processor Unit MRM-100

Operation Unit MRO-100

MDC-1820BB

Component Unit Sub-unit Type name

Antenna Unit Not assigned

Aerial, 4-foot RW701A-04

Aerial, 6-foot RW701A-06

Transceiver RB719A (25 kW)

Processor Unit MRM-100

Operation Unit MRO-100

1.5 Software type name used

The MDC-1800BB series of radar uses the following type of software:

NOTE: The asterisk (*) shows revision code, varied from A to Z.

Software Type Application

KM-D56 * Radar logic board

KM-D62 * Gyro/Log Interface (Option: KSA-08A)

KM-D07 * ATA (Option: MRE-300)

KM-D63 * AIS Interface (Option: AIS-100)

Page 15

Chapter MDC-1840BB/1841BB/1860BB/1810BB/1820BB Series

General Descriptions Operation Manual

1-4 93142122-07

Serial Data IN/OUT

DC mains

10.8 – 41.6 VDC

(RB715A/716A/717A/718A)

21.6 – 41.6 VDC

(RB719A)

AC mains

100/115/200/230 VAC

This section is built into the Display unit

Data 1 (TX/RX)

Data 2 (TX/RX)

Data 3 (TX/RX)

PROCESSOR UNIT

Type MRM-100

ANTENNA UNIT

AERIAL Type

RW701A-03 (3ft), RW701A-04 (4ft) or RW701A-06 (6ft)

TRANSCEIVER Unit

Type RB716A(4kW), RB717A (6kW), RB718A (12 kW) or RB719A (25 kW)

Gyro/Log Interface

Type KSA-08A

(Option)

Bearing Signal

LOG Signal

Gyro Power Supply

(11-40 VDC)

Figure 1.1 System configuration of

MDC-1840BB/1841BB/1860BB/1810BB/1820BB series of radar

Connecting Cable

Type 242J159098B

Length: 15 m

DC Power cable

Type CW-256

Length: 3 m

AC/DC Rectifier

Type PS-010

AC Power Cable

Type: VV2D8

Length: 3 m

AIS Interface

Type AIS-100

(Option)

A TA Type MRE-300

(Option)

OPERATION UNIT

Type MRO-100

Display UNIT

(User supply)

CW-560 (Option)

Length: 2 m

Connecting Cable

Type 242J158055B

Length: 15 m

ANTENNA UNIT

ANTENNA Unit

T

yp

e RB715A(4kW

)

Page 16

MDC-1840BB/1841BB/1860BB/1810BB/1820BB Series Chapter 2

Operation Manual Equipment Supplied

93142122-07 Contents

Chapter 2

Equipment Supplied

Contents

Page No.

2.1 Standard equipment list...........................................................2-1

2.2 Spare parts list.......................................................................... 2-2

2.3 Installation material list............................................................ 2-2

2.4 Optional items .......................................................................... 2-3

Page 17

MDC-1840BB/1841BB/1860BB/1810BB/1820BB Series Chapter 2

Operation Manual Equipment Supplied

93142122-07 2-1

Chapter 2 Equipment Supplied

2.1 Standard equipment list

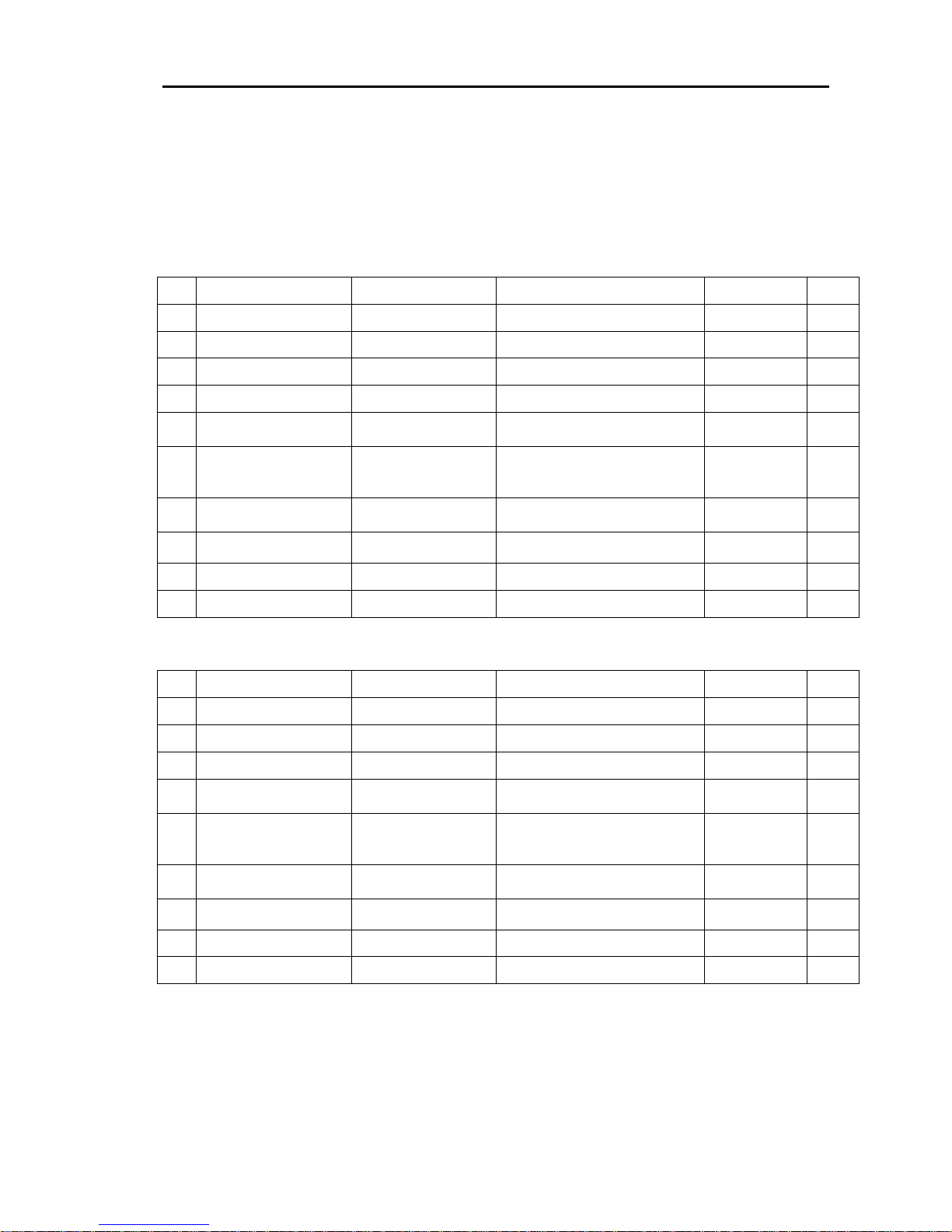

MDC-1840BB

No. Item name T y pe name Remark

Weight/length

Q’ty

1 Aerial RW701A-03/04 3ft / 4 ft 5 kg / 6 kg 1

2 Transceiver u nit RB716A 4 kW 16 kg 1

3 Processor unit MRM-100 5.5 kg 1

4 Operation unit MRO-100 2 kg 1

5 Connecting cable 242J159098B-15M

With connectors attached on

both ends

15 m 1

6 Power cable CW-256-2M

Cable with 5-pin connector on

one end and fly leads on the

other end

2 m 1

7 Display cable CW-560-2M

Cable with D-SUB connector

on both ends

2 m 1

8 S pare parts SP-100 See spare parts list Not specifie d 1 set

9 Installation materials M12-BOLT.KIT See installation material list Not specified 1 set

10 Documents

MDC-1800BSER.OME

Operation manual Not specified 1

MDC-1841BB

No. Item name T y pe name Remark

Weight/length

Q’ty

1 Antenna RB715A 4 kW, 2 ft ( Radome ) 10 kg 1

2 Processor unit MRM-100 5.5 kg 1

3 Operation unit MRO-100 2 kg 1

4 Connecting cable 242J158055B-15M

With connectors attached on

both ends

15 m 1

5 Power cable CW-256-2M

Cable with 5-pin connector on

one end and fly leads on the

other end

2 m 1

6 Display cable CW-560-2M

Cable with D-SUB connector

on both ends

2 m 1

7 S pare parts SP-100 See spare parts list Not specifie d 1 set

8 Installation materials M10-BOLT.KIT See installation material list Not specified 1 set

9 Documents

MDC-1800BSER.OME

Operation manual Not specified 1

Page 18

Chapter 2 MDC-1840BB/1841BB/1860BB/1810BB/1820BB Series

Equipment Supplied Operation Manual

2-2 93142122-07

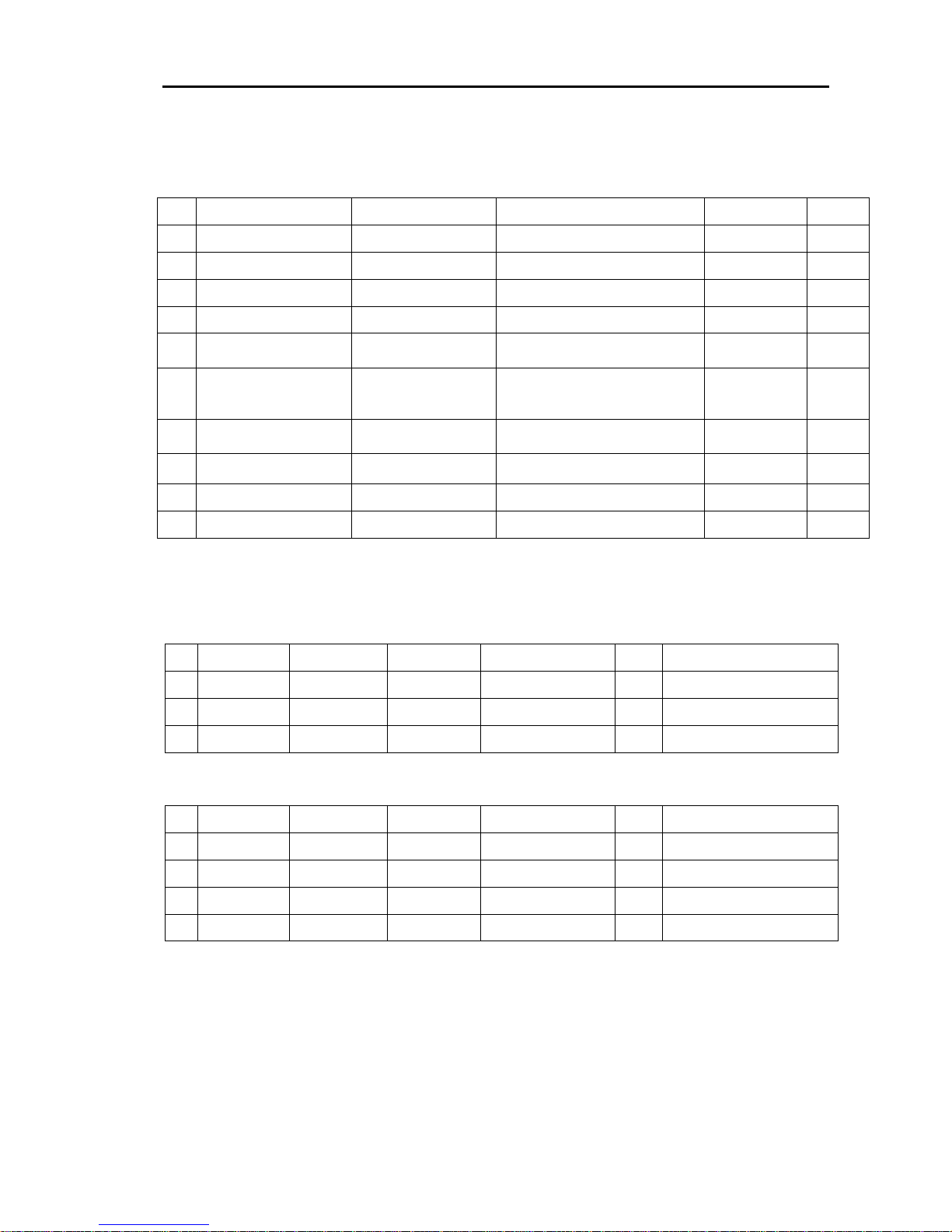

MDC-1860BB

No. Item name T y pe name Remark

Weight/length

Q’ty

1 Aerial RW701A-04/06 4 ft / 6 ft 6 kg / 8 kg 1

2 Transceiver u nit RB717A 6 kW 17 kg 1

3 Processor unit MRM-100 5.5 kg 1

4 Operation unit MRO-100 2 kg 1

5 Connecting cable 242J159098B-15M

With connectors attached on

both ends

15 m 1

6 Power cable CW-256-2M

Cable with 5-pin connector on

one end and fly leads on the

other end

2 m 1

7 Display cable CW-560-2M

Cable with D-SUB connector

on both ends

2 m 1

8 S pare parts SP-100 See spare parts list Not specifie d 1 set

9 Installation materials M12-BOLT.KIT See installation material list Not specified 1 set

10 Documents

MDC-1800BSER.OME

Operation manual Not specified 1

MDC-1810BB

No. Item name T y pe name Remark

Weight/length

Q’ty

1 Aerial RW701A-04/06 4 ft / 6 ft 6 kg / 8 kg 1

2 Transceiver unit RB718A 12 kW 17 kg 1

3 Processor unit MRM-100 5.5 kg 1

4 Operation unit MRO-100 2 kg 1

5 Connecting cable 242J159098B-15M

With connectors attached on

both ends

15 m 1

6 Power cable CW-256-2M

Cable with 5-pin connector on

one end and fly leads on the

other end

2 m 1

7 Display cable CW-560-2M

Cable with D-SUB connector

on both ends

2 m 1

8 S pare parts SP-100 See spare parts list Not specifie d 1 set

9 Installation materials M12-BOLT.KIT See installation material list Not specified 1 set

10 Documents

MDC-1800BSER.OME

Operation manual Not specified 1

Page 19

MDC-1840BB/1841BB/1860BB/1810BB/1820BB Series Chapter 2

Operation Manual Equipment Supplied

93142122-07 2-3

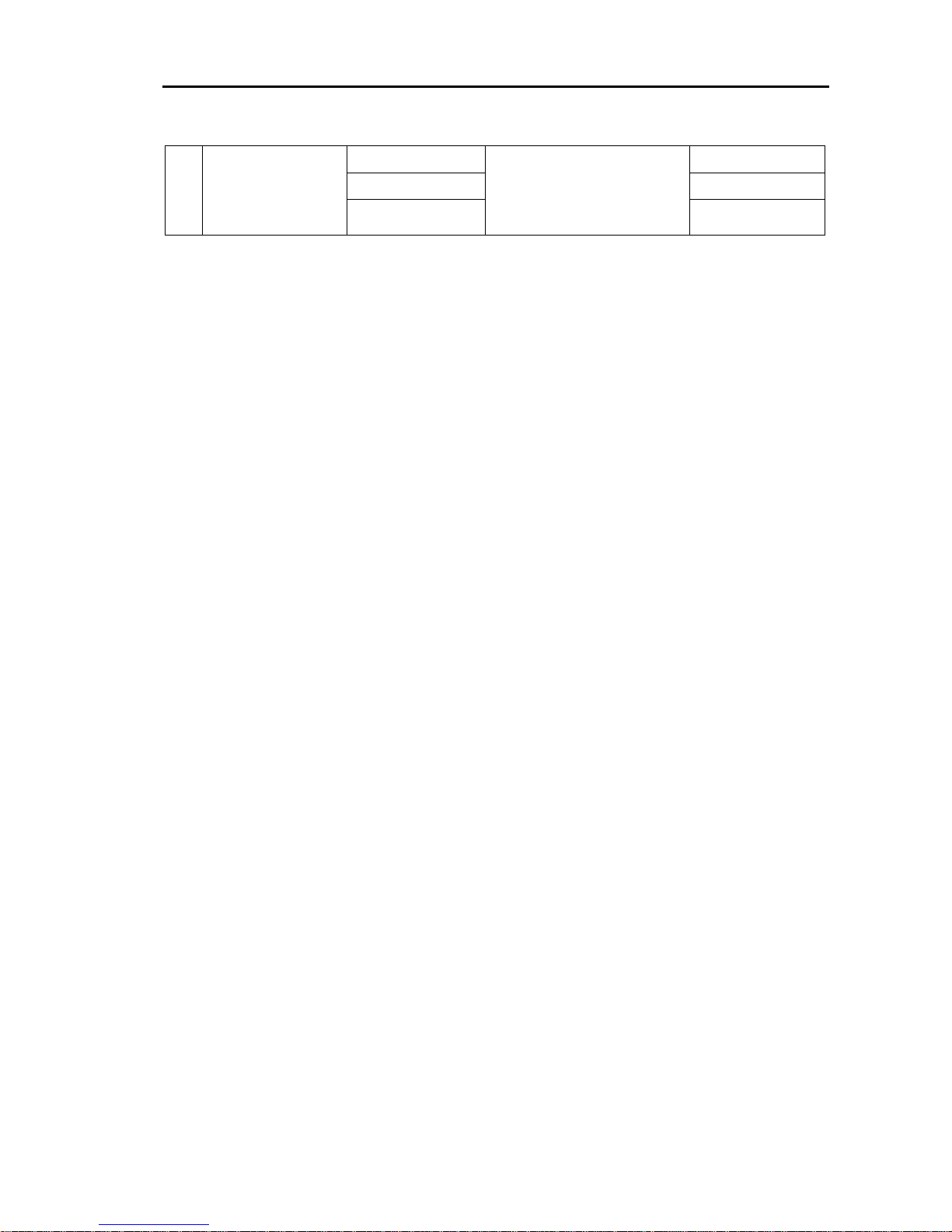

MDC-1820BB

No. Item name T y pe name Remark

Weight/length

Q’ty

1 Aerial RW701A-04/06 4 ft / 6 ft 6 kg / 8 kg 1

2 Transceiver unit RB719A 25 kW 21 kg 1

3 Processor unit MRM-100 5.5 kg 1

4 Operation unit MRO-100 2 kg 1

5 Connecting cable 242J159098B

With connectors attached on

both ends

15 m 1

6 Power cable CW-256-2M

Cable with 5-pin connector on

one end and fly leads on the

other end

2 m 1

7 Display cable CW-560-2M

Cable with D-SUB connector

on both ends

2 m 1

8 S pare parts SP-100 See spare parts list Not specified 1 set

9 Installation materials M12-BOLT.KIT See installation material list Not specified 1 set

10 Documents

MDC-1800BSER.OME

Operation manual Not specified 1

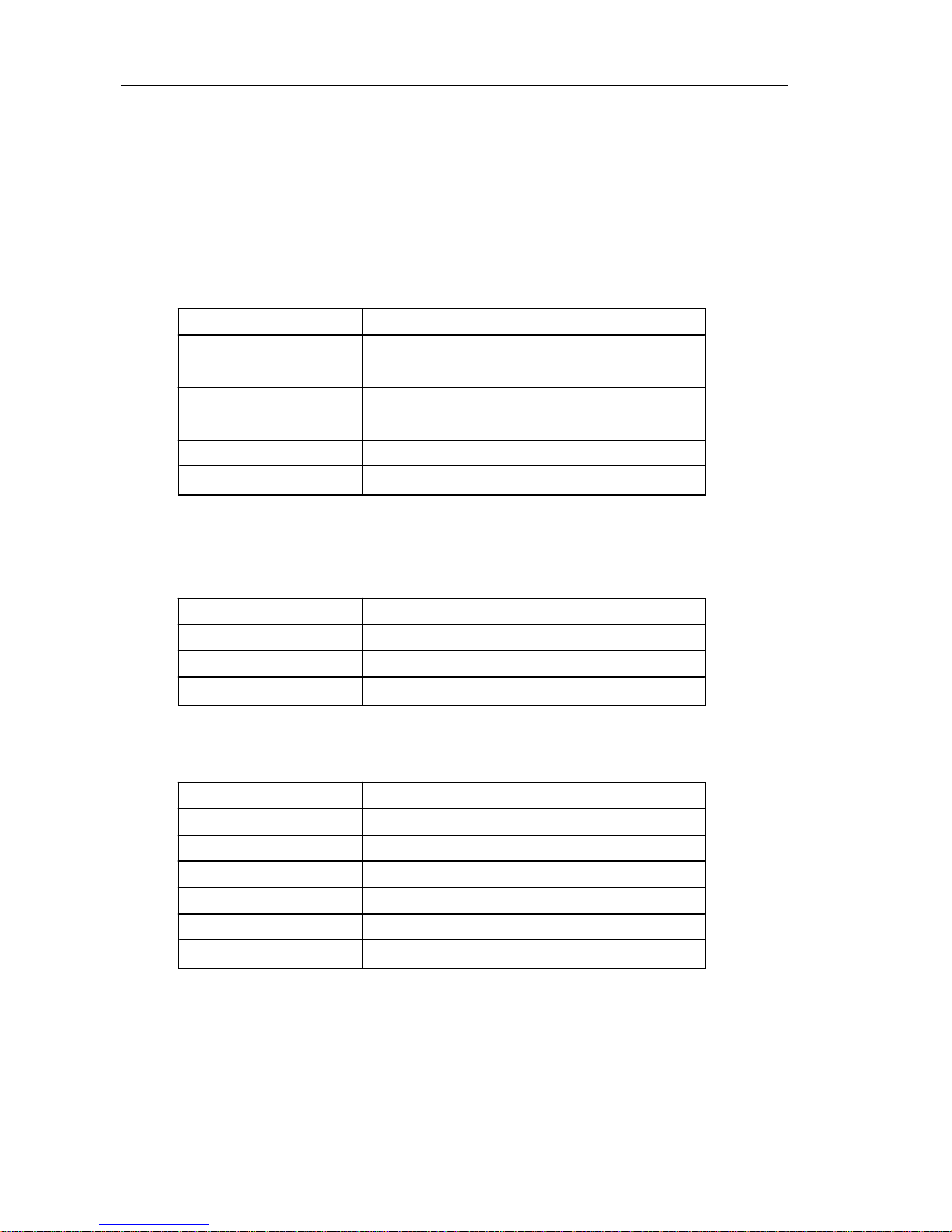

2.2 Spare parts list

MDC-1841BB (Common use)

No Description Rating Remark

Shape (Dimensions)

Q’ty Use

1

Fuse 15A Normal blow

Tubular (

φ

6.3 x 32)

2 Main power supply

2

Fuse 5A Normal blow

Tubular (

φ

5 x 25)

2 Motor power supply

3

Fuse 0.3A Normal blow

Tubular (

φ

5 x 25)

2 High voltage power supply

MDC-1840BB/1860BB/1810BB/1820BB (Common use)

No Description Rating Remark

Shape (Dimensions)

Q’ty Use

1

Fuse 15A Normal blow

Tubular (

φ

6.3 x 32)

2 Main power supply

2

Fuse 5A Normal blow

Tubular (

φ

5 x 25)

2 Motor power supply

3

Fuse 0.3A Normal blow

Tubular (

φ

5 x 25)

2 High voltage power supply

4

Motor brush 24Z125209B Not specified Not specified 1 set Antenna motor

Page 20

Chapter 2 MDC-1840BB/1841BB/1860BB/1810BB/1820BB Series

Equipment Supplied Operation Manual

2-4 93142122-07

2.3 Installation material list

MDC-1841BB

No Description Rating Q’ty Use

1 Hexagonal bolt B10X25U 4 Antenna unit

2 Plain washer 2W10U 8 Antenna unit

3 Spring washer SW10U 4 Antenna unit

4 Ferrite core E04RA400270150 1 Processor unit

MDC-1840BB/1860BB/1810BB/1820BB (Common use)

No Description Rating Q’ty Use

1 Hexagonal bolt B12X55U 4 Antenna unit

2 Nut N12U 8 Antenna unit

3 Plain washer 2W12U 8 Antenna unit

4 Spring washer SW12U 4 Antenna unit

5 Ferrite core E04RA400270150 1 Processor unit

2.4 Optional items

MDC-1840BB/1841BB/1860BB/1810BB/1820BB (Common use)

No. Description Rating Remark Weight/length/Q’ty

1 Gyro/Log Interface KSA-08A

Built into the display unit

Not specified

2 ATA MRE-300 Built into the display unit Not specified

3 AIS Interface AIS-100 Built into the display unit Not specified

CW-387-5M

One end with 8-pin connector

and flying leads on the other

end

for AIS (5 m)

CW-376-5M

One end with a 6-pin

connector and flying leads on

the other end

for GPS etc.

(5 m)

CW-388-5M

One end with 10-pin

connector and flying leads on

the other end

for Gyro/Log

(5 m)

4

Navigator

connecting cable

CW-561-10M

With 12-pin connector on

both ends

for REMOTE

(10 m)

5 Display cable CW-560-2M

With 15-pin connectors on

both ends

for Display

Monitor (2 m)

6 Rectifier PS-010 With two 5 A fuses 3.5 kg

7 AC power cable VV-2D8-3M Flying leads on both ends 3 m

242J158055C-20M 20 m

242J158055D-30M 30 m

8

Connecting cable in

extra length for

RB715A

242J158055E-XM

(See NOTE)

Connectors attached on both

ends

100 m max

Page 21

MDC-1840BB/1841BB/1860BB/1810BB/1820BB Series Chapter 2

Operation Manual Equipment Supplied

93142122-07 2-5

242J159098C-20M 20 m

242J159098D-30M 30 m

9

Connecting cable in

extra length for

RB716A/RB717A/

RB718A/RB719A

242J159098E-XM

(See NOTE)

Connectors attached on both

ends

100 m max

NOTE: The length of the cable is specified by the customer within 100 meters

Page 22

MDC-1840BB/1841BB/1860BB/1810BB/1820BB Series Chapter 3

Operation Manual Technical Specification

93142122-07 Contents

Chapter 3

Technical Specification

Contents

Page No.

3.1 Antenna specification .............................................................. 3-1

3.2 Display specification................................................................ 3-1

3.3 ATA specification (Option)....................................................... 3-2

3.4 AIS specification (Option)........................................................ 3-2

3.5 Serial data and sentence used................................................3-2

3.6 Power Supply............................................................................ 3-3

3.7 Compass Safe Distance...........................................................3-3

3.8 Environmental specification.................................................... 3-3

3.9 Mechanical specification ......................................................... 3-4

Page 23

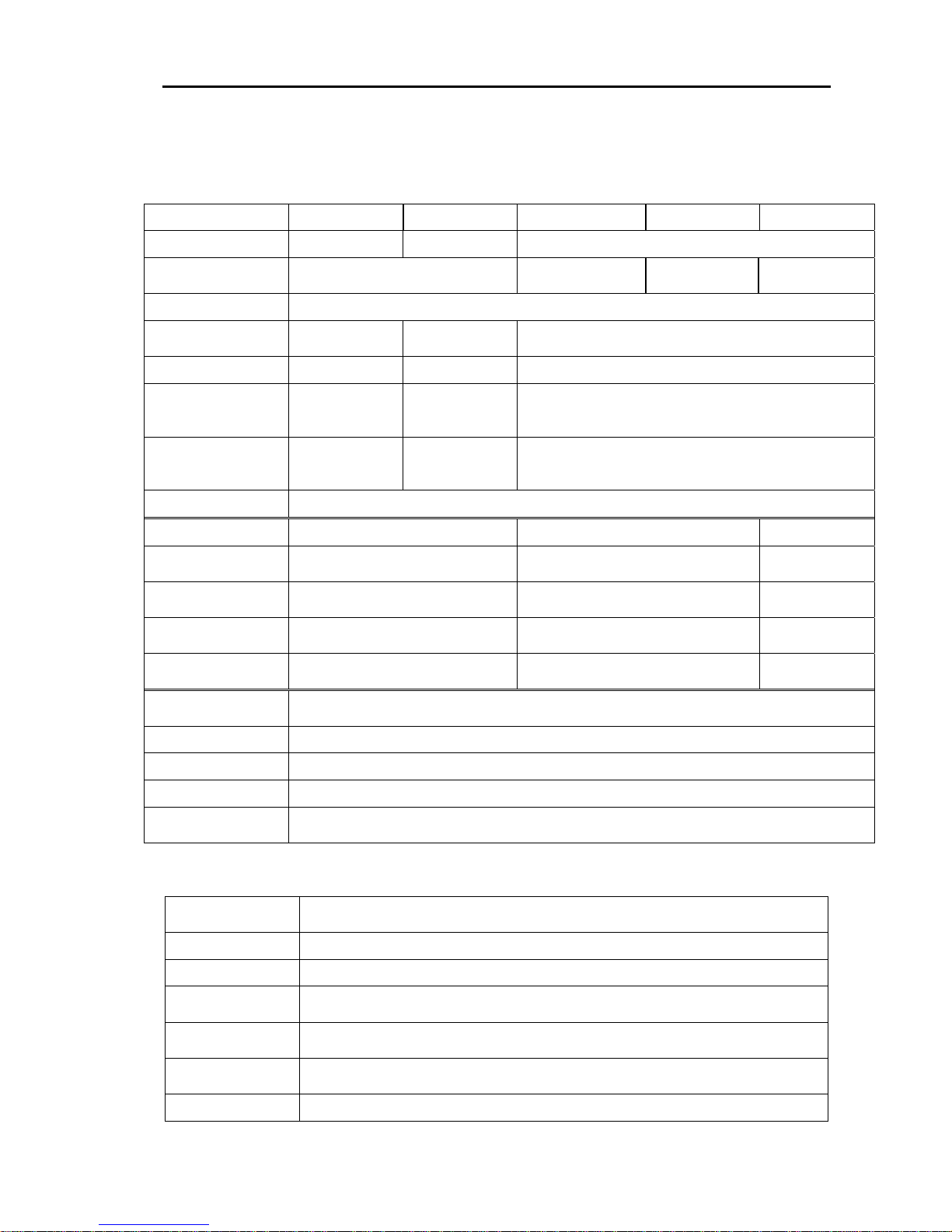

MDC-1840BB/1841BB/1860BB/1810BB/1820BB Series Chapter 3

Operation Manual Technical Specifications

0093142122-08 3-1

Chapter 3 Technical Specifications

3.1 Antenna specification

Model name

MDC-1840BB MDC-1841BB MDC-1860BB MDC-1810BB MDC-1820BB

Aerial length

3 feet / 4 feet 2 feet 4 feet / 6 feet

Peak power

output

4kW 6kW 12kW 25kW

Frequency

9410 +/- 30 MHz

Beam width

Horizontal

2.5

o

/ 1.8o 3.9o 1.8o / 1.2

Vertical

22

o

25o 22o

Side lobes

Within +/- 10

o

Better than

–23dB

Better than

–20dB

Better than –23dB

Outside +/- 10o

Better than

–30 dB

Better than

–20dB

Better than –30 dB

Rotation

24/48 r.p.m.

Transmission pulse

4 kW 6 kW/12 kW 25 kW

width S (Short

pulse)

0.08 μs / 2000 Hz 0.08 μs / 4000 Hz 0.08μs/2000Hz

M1 (Medium 1

pulse)

0.25 μs / 1500 Hz 0.25 μs / 2000 Hz 0.3μs/1300Hz

M2 (Medium 2

pulse)

0.8 μs / 600 Hz 0.5 μs / 1000 Hz 0.6μs/800Hz

L (Long pulse)

0.8 μs / 600 Hz 1.0 μs / 500 Hz

1.2 μs / 500Hz,

450Hz(96NM)

IF center

frequency

60 MHz

IF bandwidth

15 MHz (S, M1) / 3 MHz (M2, L)

Noise figure

Better than 6 dB

Operation in wind

100 knots as relative

Water proofing

grade

IPX6 (IEC60529)

3.2 Processor specification

Effective

diameter

269 mm (at 18 inch LCD monitor)

Resolution

1280 x 1024 pixels

Video level

8 levels

Presentation

mode

Head-up, north-up, course-up and true motion

Range scale

(NM)

1/8 1/4 1/2 3/4 1.5 3 6 12 24 48 (4 kW) 64 (6 kW) 72 (12 kW) 96 (25 kW)

Rings interval

(NM)

1/16 1/8 1/4 1/2 1 2 4 8 (4 kW) 16 (6 kW) 12 (12 kW) 16 (25 kW)

Off-centering

Sweep origin can be moved to any point within 2/3 of the screen radius.

Page 24

Chapter 3 MDC-1840BB/1841BB/1860BB/1810BB/1820BB Series

Technical Specifications Operation Manual

3-2 0093142122-08

Trail display

interval

Every scan, 15 sec, 30 sec, 1 min, 3 min, 6 min, 12 min and OFF

Alarm Entry alarm [alarm range (Minimu m 0.5 NM), depth and bearing can be

varied]

EPA

Up to 10 targets can be plotted, 5 points for one target each

ATA (Option) Display of acquire/track data of up to 10 targets and Guard Zone are

available. Display of guard zone is also available (any alarm range, width

and bearing can be set).

Data available

for EPA and ATA

Speed, course, CPA, TCPA, distance, bearing and age (time elapsed

since the first plot, applicable to EPA only).

Minimum

detectable range

20 meters at 1/8 nm range

Range

resolution

20 meters at 1/8 nm range

Range data

accuracy

70 meters or 1% of the range scale selected, whichever is the greater.

Bearing data

accuracy

+/-1

o

maximum

Navigation data

display

Data of own ship’s position (latitude/longitude)

3.3 ATA specification (Option)

Acquisition Manual

Tracking Automatic

Number of targets tracked Up to 10 targets

Numerical data output Distance, bearing, speed, CPA and TCPA

Alarm Collision alarm and lost alarm

On screen display

Symbols (acquired target, tracked target, target with

data display and lost target), target number and

vectors.

Display mode Relative and True

Tracking distance range Up to 40.0 nm

ATA data output

To be taken via the DATA 1 connector on the display

rear panel.

Signal level: RS422

Data format: IEC1162-1

Page 25

MDC-1840BB/1841BB/1860BB/1810BB/1820BB Series Chapter 3

Operation Manual Technical Specifications

0093142122-08 3-3

3.4 AIS specification (O ption)

Number of targets displayed Up to 64 activated targets and sleeping targets in total

Numerical data indication MMSI, CPA, TCPA, CSE/COG, STW/SOG

On screen display

Symbols, target number and vectors.

Indication limit range 1.0 to 20.0 nm

AIS data input

To be taken via the AIS connector on the display rear panel.

Signal level: RS422

Data format: IEC61162-2

Formatter: ALR, VDO, VDM

3.5 Serial data and sentence used

Serial data: IEC 61162-1 or NMEA 0183 ver 2.30

Sentence: BWC, GGA, GLC, GLL, HDT, RMB, RTE, VBW, VDR, VHW, VTG, WPL

3.6 Power Supply

Mains Input Voltage: 24 VDC / 32 VDC

Input Voltage Tolerance: 10.8 VDC – 41.6 VDC

(for MDC-1840BB/1841BB/1860BB/1810BB)

21.6 VDC – 41.6 VDC (for MDC-1820BB)

Input Power: 170 W nominal at 24 VDC

Transient Protection:

To the requirements of IEC 60945 4th Edition.

Reversed polarity protection: Protected by the Main Fuse.

AC Operation

Rectifier Unit Type PS-010 is required.

Input voltage range: 115/230 VAC

Input voltage tolerance: +/- 10%

Input voltage frequency range: 47 to 63 Hz

Input Power: 220 W

3.7 Compass Safe Distance

Component Unit Type Name Standard Steering

Antenna

RB715A 1.4 m 0.95 m

RB716A/RW701A-03 1.4 m 0.95 m

RB716A/RW701A-04 1.4 m 0.95 m

RB717A/RW701A-04 1.4 m 0.95 m

RB717A/RW701A-06 1.4 m 0.95 m

Page 26

Chapter 3 MDC-1840BB/1841BB/1860BB/1810BB/1820BB Series

Technical Specifications Operation Manual

3-4 0093142122-08

Antenna

RB718A/RW701A-04 1.4 m 0.95 m

RB718A/RW701A-06 1.4 m 0.95 m

RB719A/RW701A-04 1.4 m 0.95 m

RB719A/RW701A-06 1.4 m 0.95 m

Processor Unit MRM-100 1.6 m 1.15 m

Operation Unit MRO-100 0.60 m 0.40 m

3.8 Environmental specification

To the requirements of IEC 60945 4th Edition. The measure environmental

specifications are as follows:

(1) Temperature and humidity

Operating temperature Storage temperature Humidity

Antenna -25oC - +55oC +70oC 93%+/-3% at +40oC

Processor -15oC - +55oC +55oC 93%+/-3% at +40oC

(2) Vibration

2-5Hz up to 13.2 Hz: Amplitude +/-1mm +/-10% (Maximum acceleration 7m/s2 at

13.2Hz)

13.2 Hz up to 100Hz: Maximum acceleration 7 m/s2 constant

3.9 Mechanical specification

Dimensions: W (Width) x Depth x Height, Unit in mm

Weight: Unit in kg

Antenna:

RB715A: 636 x 636 x 255, 10kg

RB716A: 280 x 390 x 450, 21 kg (for 3ft system), 22 kg (for 4ft system)

RB717A/718A: 280 x 390 x 450, 23 kg (for 4ft system), 25 kg (for 6ft system)

RB719A: 280 x 470 x 450, 27 kg (for 4ft system), 29 kg (for 6ft system)

Aerial Swing circle: 1034 for 3 ft, 1346 for 4 ft, 1970 for 6 ft

Processor unit (MRM-100):

320 x 122 x 320, 5.5 kg

Operation unit (MRO-100):

354 x 130 x 49, 2 kg

Page 27

MDC-1840BB/1841BB/1860BB/1810BB/1820BB Series Chapter 3

Operation Manual Technical Specifications

0093142122-08 3-5

Unit in mm

(

inch

)

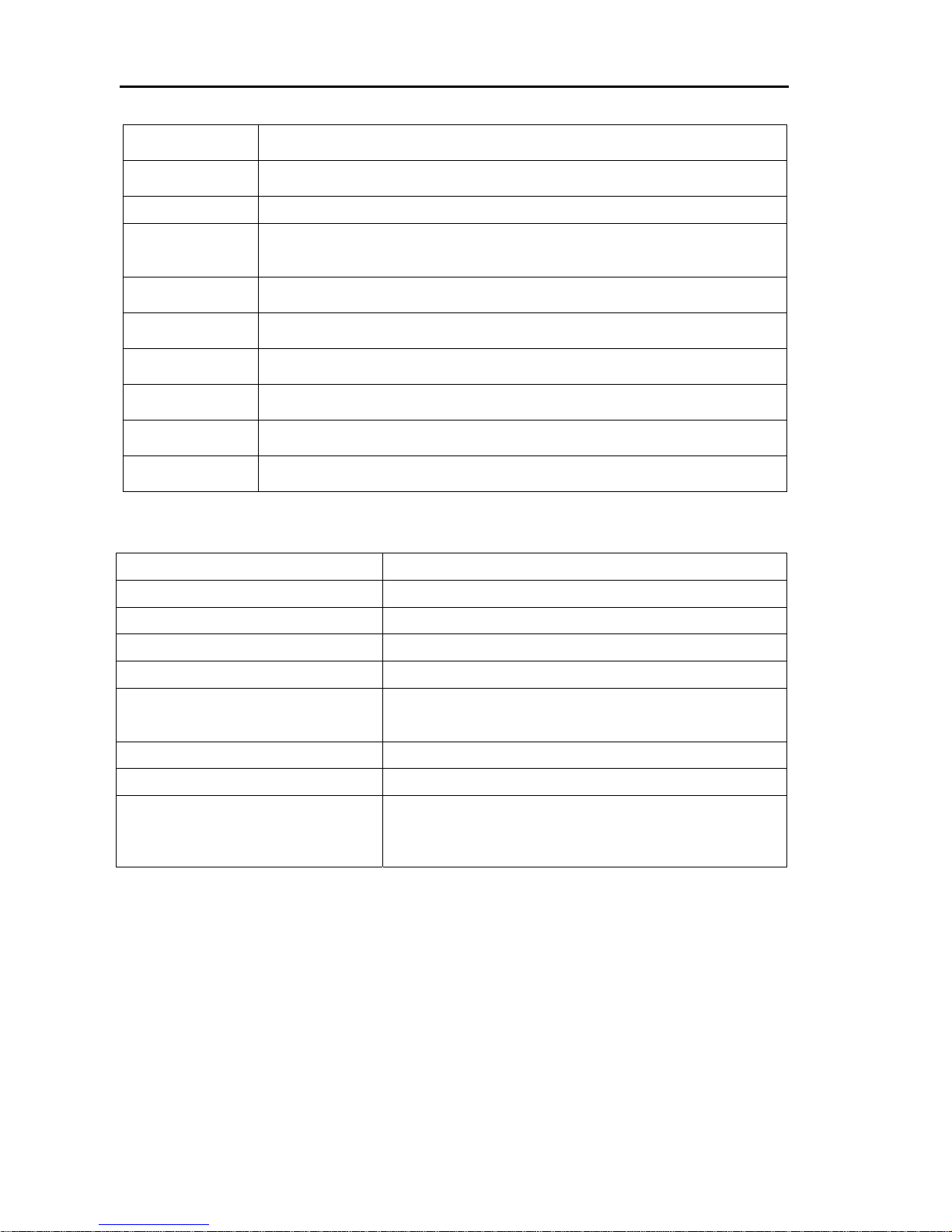

Figure 3.1 External dimensions of the Antenna unit, RB715A

Page 28

Chapter 3 MDC-1840BB/1841BB/1860BB/1810BB/1820BB Series

Technical Specifications Operation Manual

3-6 0093142122-08

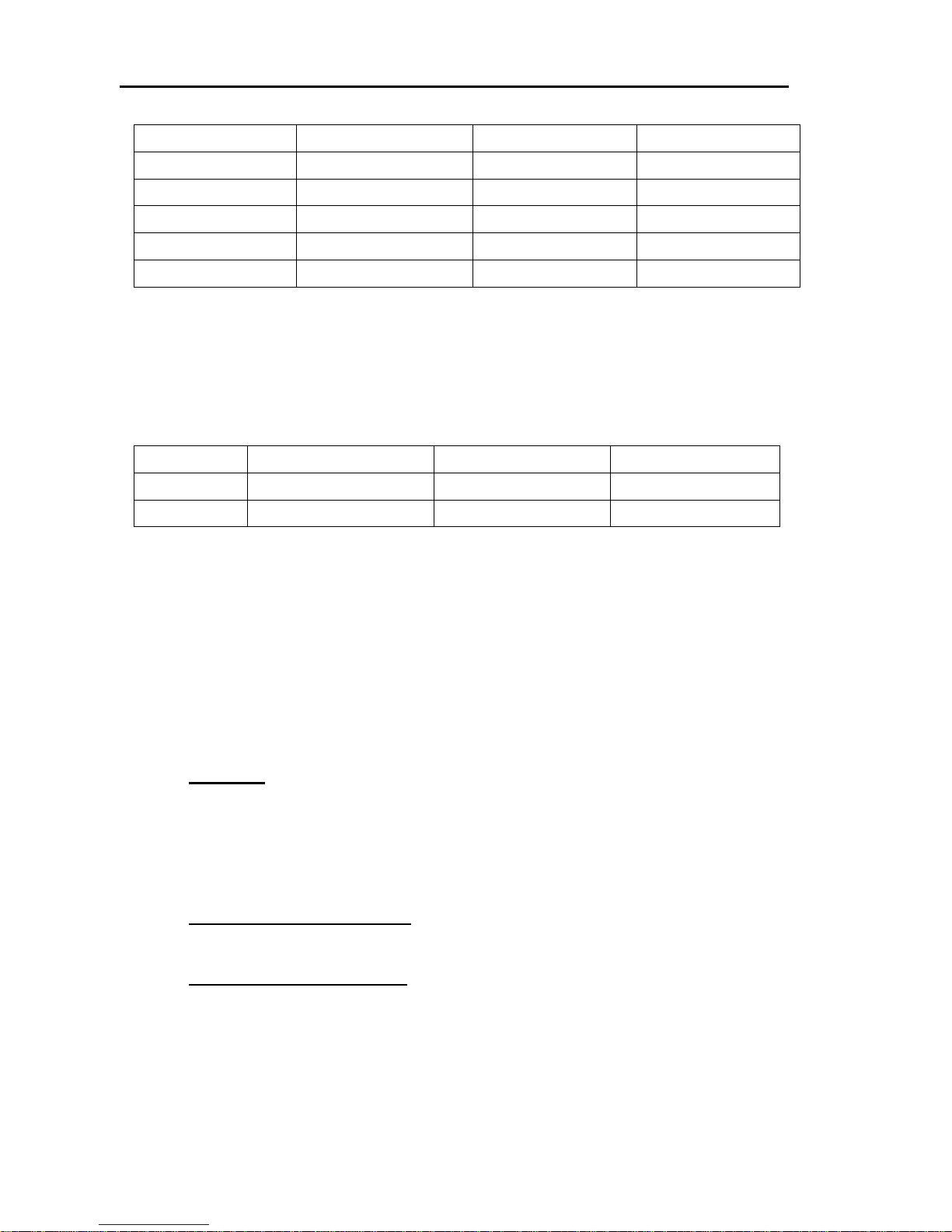

Figure 3.2 External dimensions of the Antenna unit, RB716A

Page 29

MDC-1840BB/1841BB/1860BB/1810BB/1820BB Series Chapter 3

Operation Manual Technical Specifications

0093142122-08 3-7

[Antenna unit]

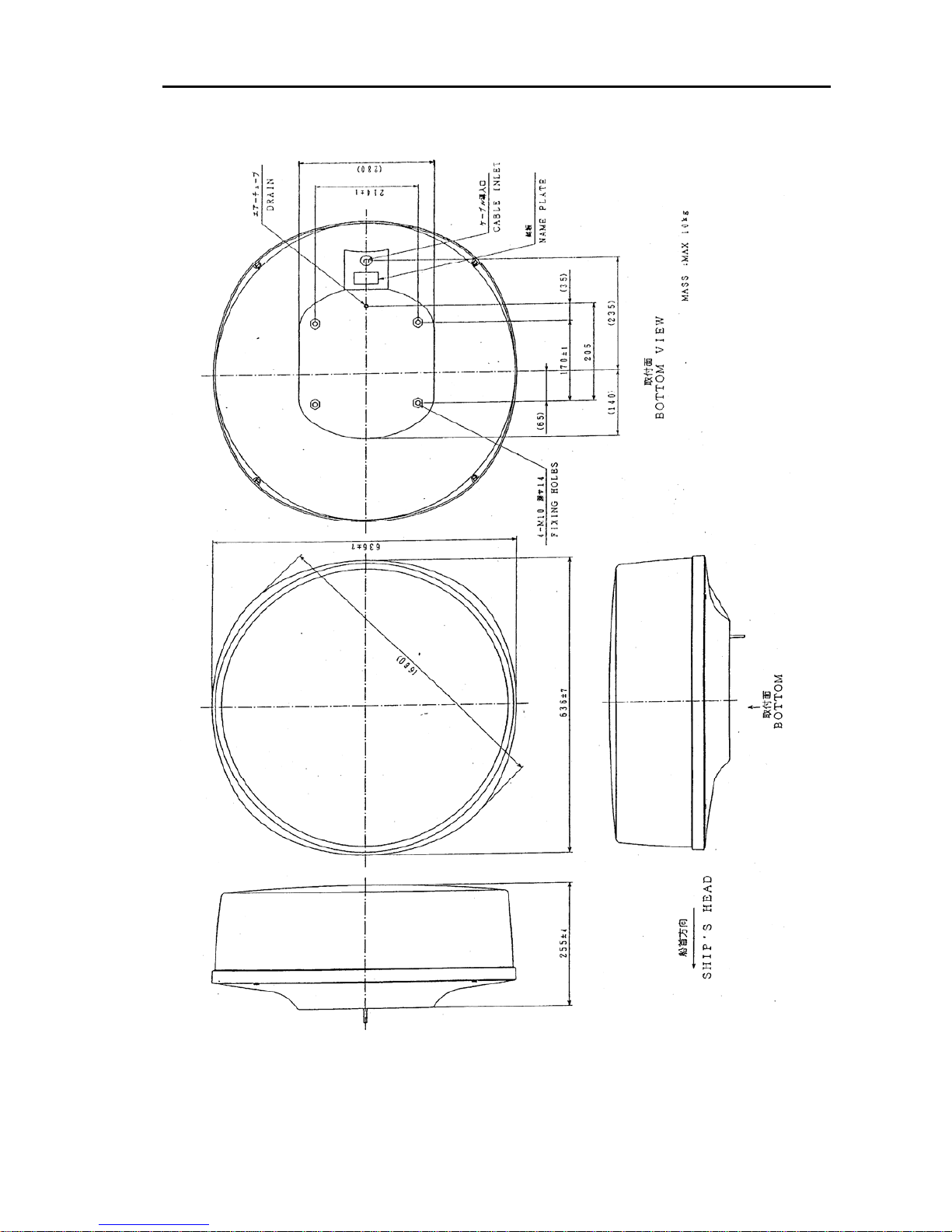

Figure 3.3 External dimensions of the Antenna unit, RB717A / RB718A

Page 30

Chapter 3 MDC-1840BB/1841BB/1860BB/1810BB/1820BB Series

Technical Specifications Operation Manual

3-8 0093142122-08

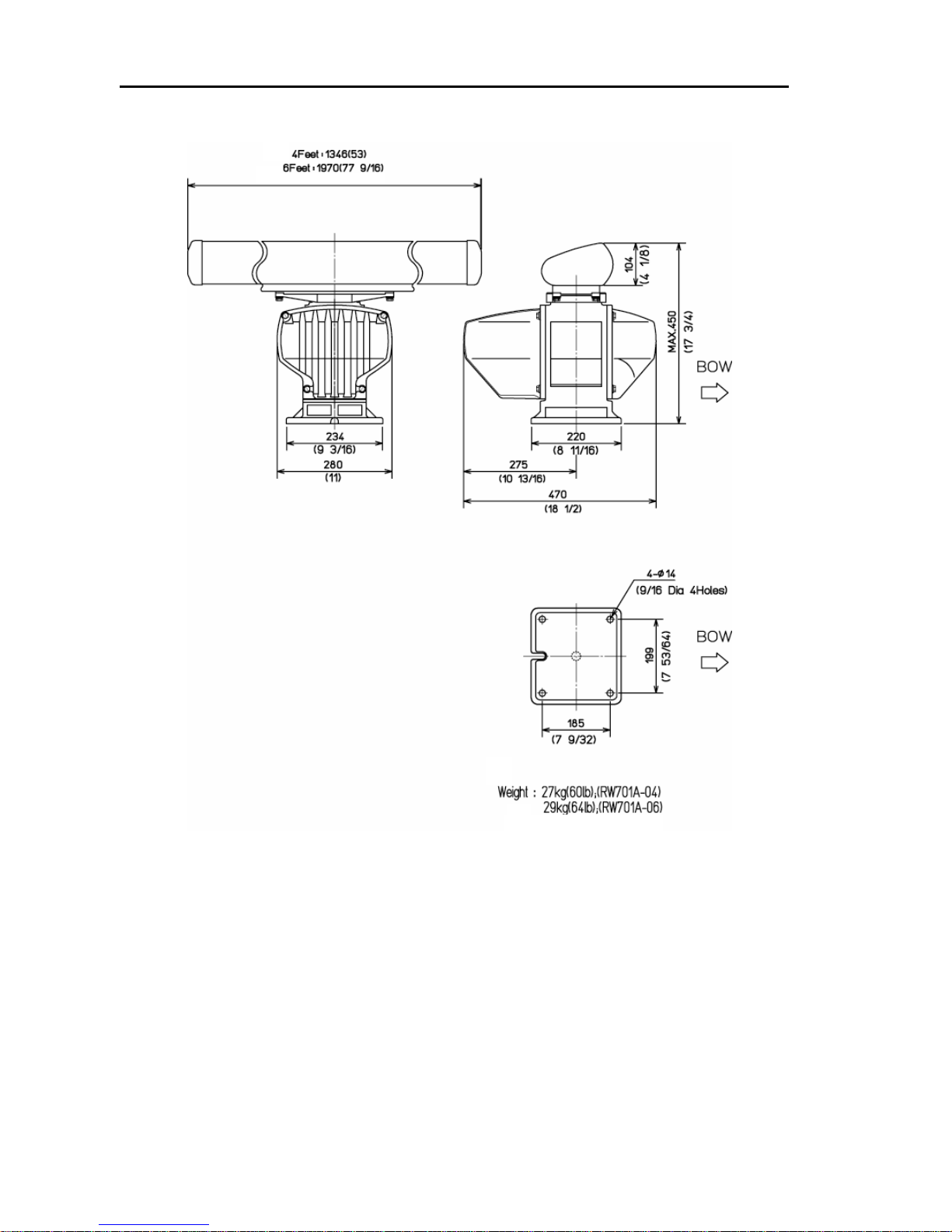

Figure 3.4 External dimensions of the Antenna unit, RB719A

Page 31

MDC-1840BB/1841BB/1860BB/1810BB/1820BB Series Chapter 3

Operation Manual Technical Specifications

0093142122-08 3-9

Figure 3.5 External dimensions of the Processor unit, MRM-100

[Processor unit]

Figure 3.6 External dimensions of Operation Unit, MRO-100

[Operation unit]

Page 32

MDC-1840BB/1841BB/1860BB/1810BB/1820BB Series Chapter 4

Operation Manual Installation

93142122-07 Contents

Chapter 4

Installation

Contents

Page No.

4.1 Installation considerations ......................................................4-1

4.2 Unpacking each component of the system............................4-1

4.3 Inspection of each component unit and accessories...........4-1

4.4 Setting the units .......................................................................4-1

4.4.1 Antenna Unit........................................................................................4-1

4.4.2 Processor Unit and Operation Unit......................................................4-2

4.5 Cable routing and connections............................................... 4-2

4.5.1 Antenna...............................................................................................4-2

4.5.2 Processor Unit.....................................................................................4-3

4.6 Installation procedure ..............................................................4-3

4.6.1 Installing the Transceiver Unit..............................................................4-3

4.6.2 Fitting the Aerial...................................................................................4-4

4.6.3 Connecting the cable...........................................................................4-5

4.6.4 Installing the Processor Unit................................................................4-6

4.6.5 Installing the Operation Unit ................................................................4-8

4.6.5.1 Table mounting..........................................................................4-8

4.6.5.2 Flush mounting.......................................................................4-10

4.6.6 Connecting the cable to the Display unit...........................................4-12

4.6.7 Link setting for the gyroco mpass.......................................................4-13

4.6.8 Ferrite core assembling for Power cable .............................................4-14

4.7 Setting up after installation ................................................... 4-15

4.7.1 Auto tune adjustment.........................................................................4-15

4.7.2 Transmission timing...........................................................................4-16

4.7.3 Ship’s heading setup.........................................................................4-17

4.7.4 Resetting Manual GAIN/STC (Height)/Manual STC..........................4-17

4.7.4.1 Manual GAIN setting...............................................................4-17

4.7.4.2 STC (Height) setting...............................................................4-18

4.7.4.3 Manual STC setting................................................................4-19

Page 33

Chapter 4 MDC-1840BB/1841BB/1860BB/1810BB/1820BB Series

Installation Operation Manual

Contents 93142122-07

Page No

4.8 Setting up option....................................................................4-21

4.8.1 AIS Interface (Option) ....................................................................... 4-21

4.8.2 Remote Display operation................................................................. 4-21

4.8.2.1 Connecting the Remote Display............................................. 4-21

4.8.2.2 Required set up...................................................................... 4-21

4.8.2.3 Possible operation on Remote Display................................... 4-21

APPENDIX 1....................................................................................4-24

Installation of the ATA module, MRE-300........................................................... 4-24

Installation of the AIS module, AIS-100.............................................................. 4-24

Installation of the Gyro Interface module, KSA-08A........................................... 4-25

APPENDIX 2....................................................................................4-28

Optional cables pinouts and cable color-coding designation ............................. 4-28

APPENDIX 3....................................................................................4-29

Recommended TFT Display .............................................................................. 4-29

Page 34

MDC-1840BB/1841BB/1860BB/1810BB/1820BB Series Chapter 4

Operation Manual Installation

0093142122-11 4-1

Chapter 4 Installation

4.1 Installation considerations

General

Qualified service personnel should perform the installation of the MDC-1800BB series.

The installation comprises the following operations.

(1) Unpacking each component of the system.

(2) Inspection of the exterior of each component unit and accessory.

(3) Checking the ship’s mains voltage and current capacity.

(4) Determining the site of installation

(5) Installing the Antenna Unit.

(6) Installing the Display Unit

(7) Installing the accessory items

(8) Planning the cable routing and connections

(9) Commissioning

4.2 Unpacking each component of the system

Unpack your package and check if all of the items stated in the packing list are

contained in the package. If not, report this to the insurance agent for tracing missing

goods or refund.

4.3 Inspection of each component unit and accessories

Carefully check the exterior of each component unit for dents, damage, etc. Also

check the inside of component units for electrical and mechanical damage. The

Cathode Ray Tube is a fragile item, which is easily broken if the display unit is

accidentally dropped.

4.4 Setting the units

To achieve best operational performance, the following factors must be considered.

4.4.1 Antenna Unit

(1) The radar antenna should be mounted on the center line of your ship where no

large obstacles interfere with the path of the radar beam.

(2) Location should be as high as possible, however, keep in mind that nearby objects

may be overlooked if mounted too high. Also note that the higher the antenna, the

higher the level of sea clutter.

(3) The mounting surface should be as flat as possible and approximately parallel

with the vessel’s water line.

Page 35

Chapter 4 MDC-1840BB/1841BB/1860BB/1810BB/1820BB Series

Installation Operation Manual

4-2 0093142122-11

(4) The antenna unit should be positioned forward of large structure and exhaust

stacks, to avoid causing blind sectors on the radar screen as well as

contamination from engine exhaust on the radar antenna aperture.

(5) Provide sufficient servicing space.

4.4.2 Processor Unit, Operation Unit and Display

Processor Unit:

(1) Select a position safe and free of dampness, water spray, rain and direct sunlight.

(2) Provide enough space for servicing.

Operation Unit:

(1) Select a position near the display for easy access and operation. Also consider the

length of the connecting cable that is 2 m.

Display (User purchased item):

(1) Position the display unit as far as possible away from other radio equipment.

(2) Keep a safe distance from the magnetic compass: standard: x.xx m, steering: x.xx

m.

(3) Select a location that provides good observation to radar screen and outside

environment.

(4) Locate the display so that it provides easy viewing from all likely operator’s

positions.

(5) Select a position safe and free of dampness, water spray, rain and direct sunlight.

(6) Provide enough space for servicing. Consider access to the rear panel for

connecting various cables.

(7) Position the display unit as far as possible away from other radio equipment.

4.5 Cable routing and connections

4.5.1 Antenna

(1) The cable connecting the antenna and display should be run separately away from

other cables such as, radio antenna feeders, power cables, etc. Under no

circumstances should it be in parallel arrangement with other cables. These

precautions are essential to avoid radio interference to/from other equipment

installed on the ship. If this is not possible, either cable set should be screened

with metal conduit or another form of shielding.

(2) Cable should be run as short as possible but be kept within the standard length to

achieve best radar performance.

(3) The copper braids of the cable must be grounded via a grounding stud in the

transceiver unit.

Page 36

MDC-1840BB/1841BB/1860BB/1810BB/1820BB Series Chapter 4

Operation Manual Installation

0093142122-11 4-3

4.5.2 Processor Unit

(1) The processor unit must be grounded to the hull via a grounding stud at the rear of

the processor unit.

4.6 Installation procedure

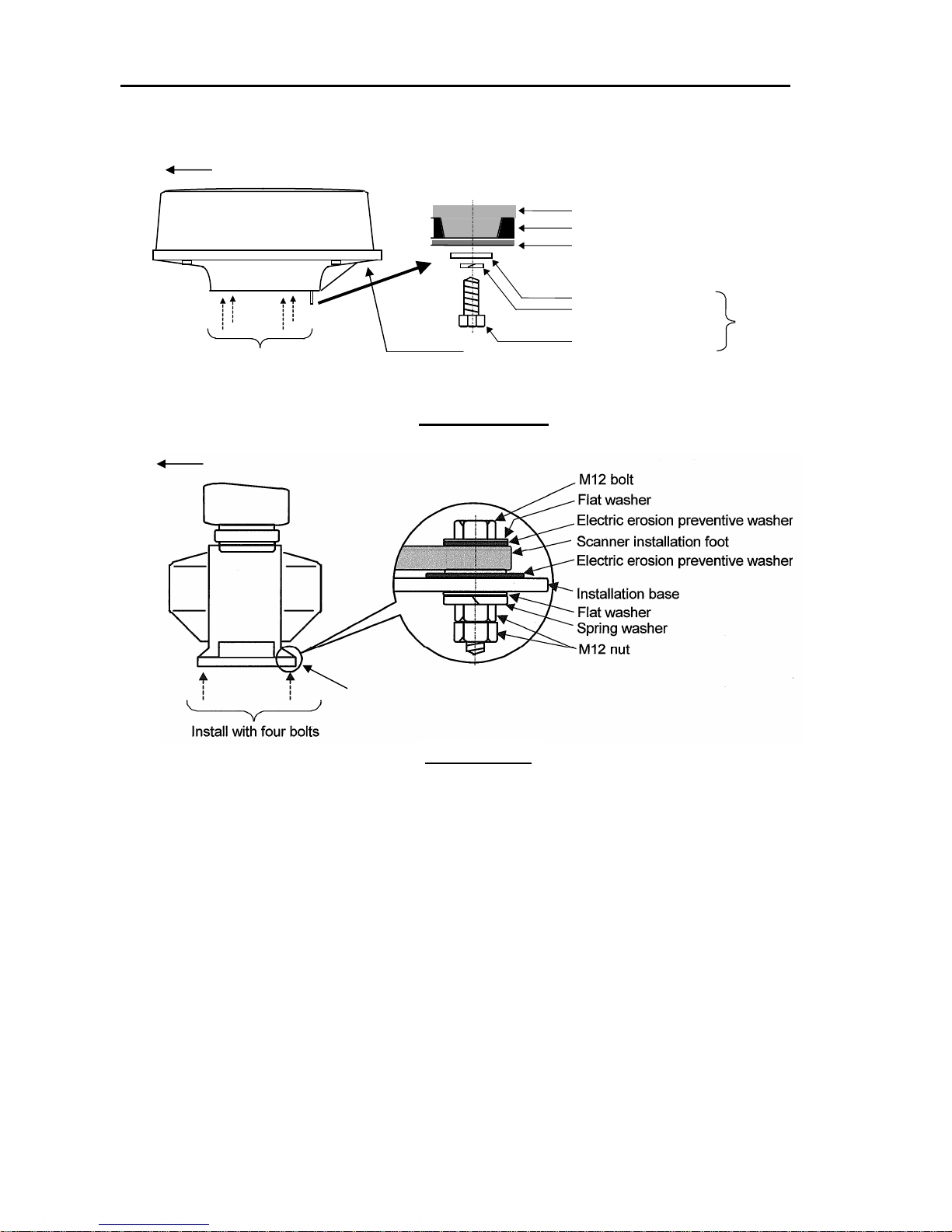

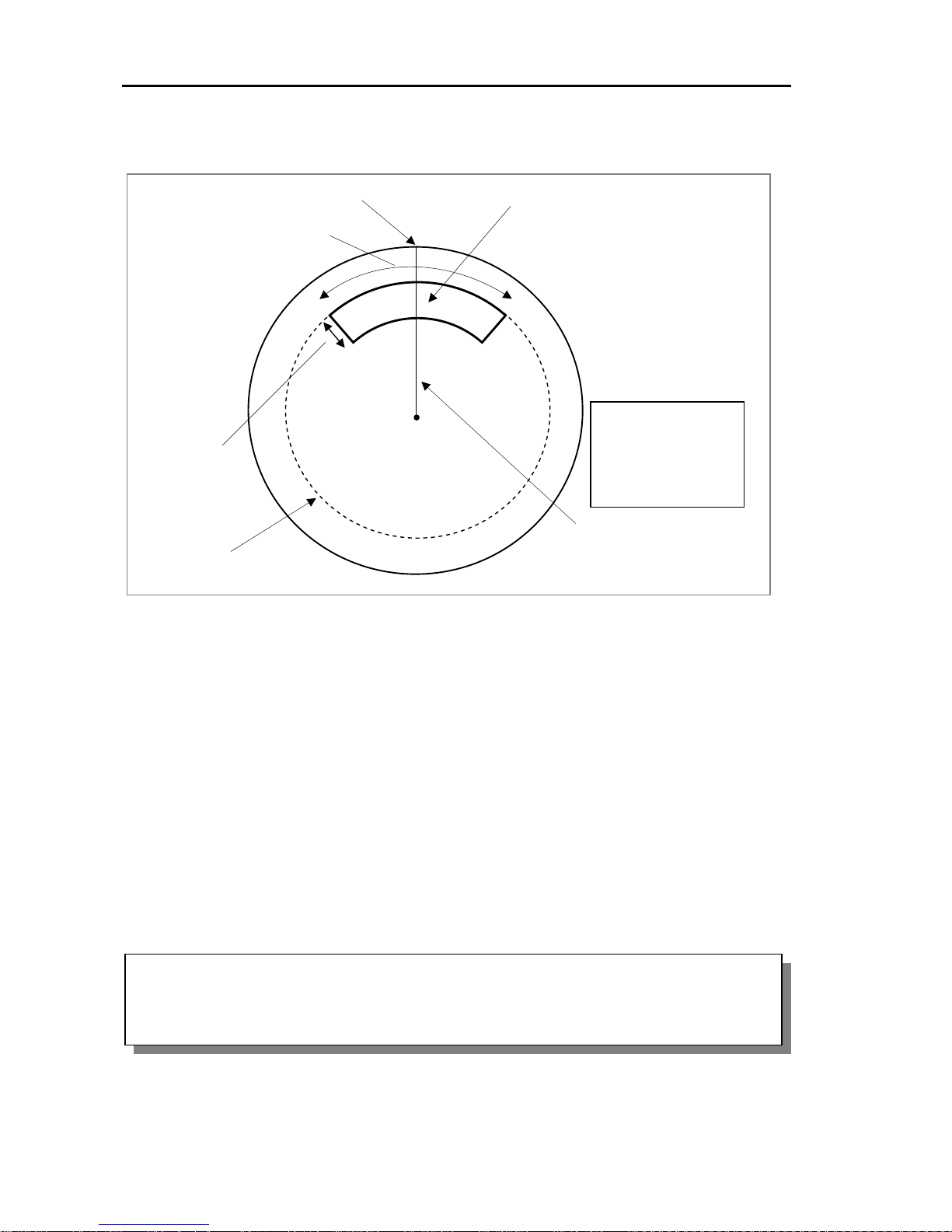

4.6.1 Installing the Transceiver Unit

When mounting the unit, position the transceiver unit as shown, so that a notched part

of the transceiver base is directed towards the aft. This arrangement simplifies cable

fitting and servicing. Also take note of the precautions detailed in paragraph 4.4.1

when you attempt to install the antenna unit.

(1) Drill four fixing holes of 14 mm (12 mm for Radome) diameter on the fitting

surface of a radar platform, as shown in Figure 4.1.

(2) Fit the transceiver unit on the position and fix it using the 12 mm (10 mm for

Radome) stainless bolts prepared as installation materials.

Figure 4.1 Plan view of fixing holes

(0.55)

4-φ14

Center

214

170

4-φ12

Unit:mm (inch)

65

(8.43)

(2.56

)

(0.47)

(6.69)

199

(7.83)

Forward

185

(

7.28 in.

)

Rotation Radius

R550 (3 ft antenna)

R700 (4 ft antenna)

Radome scanner

Open scanner

35

(1.38)

φ15(0.59)

(For Air Tube)

φ100(39.7)

(For Cable Inlet)

Page 37

Chapter 4 MDC-1840BB/1841BB/1860BB/1810BB/1820BB Series

Installation Operation Manual

4-4 0093142122-11

Figure 4.2 Details of the base fixing

Fix four screws

Mount base

Washer

Spring washer

M10 Hexagonal bolt

Radome(bottom)

Chassis

Included

Radome scanner

Ship’s heading

Cable inlet

Cable recess provided here

Ship’s heading

Open scanner

Page 38

MDC-1840BB/1841BB/1860BB/1810BB/1820BB Series Chapter 4

Operation Manual Installation

0093142122-11 4-5

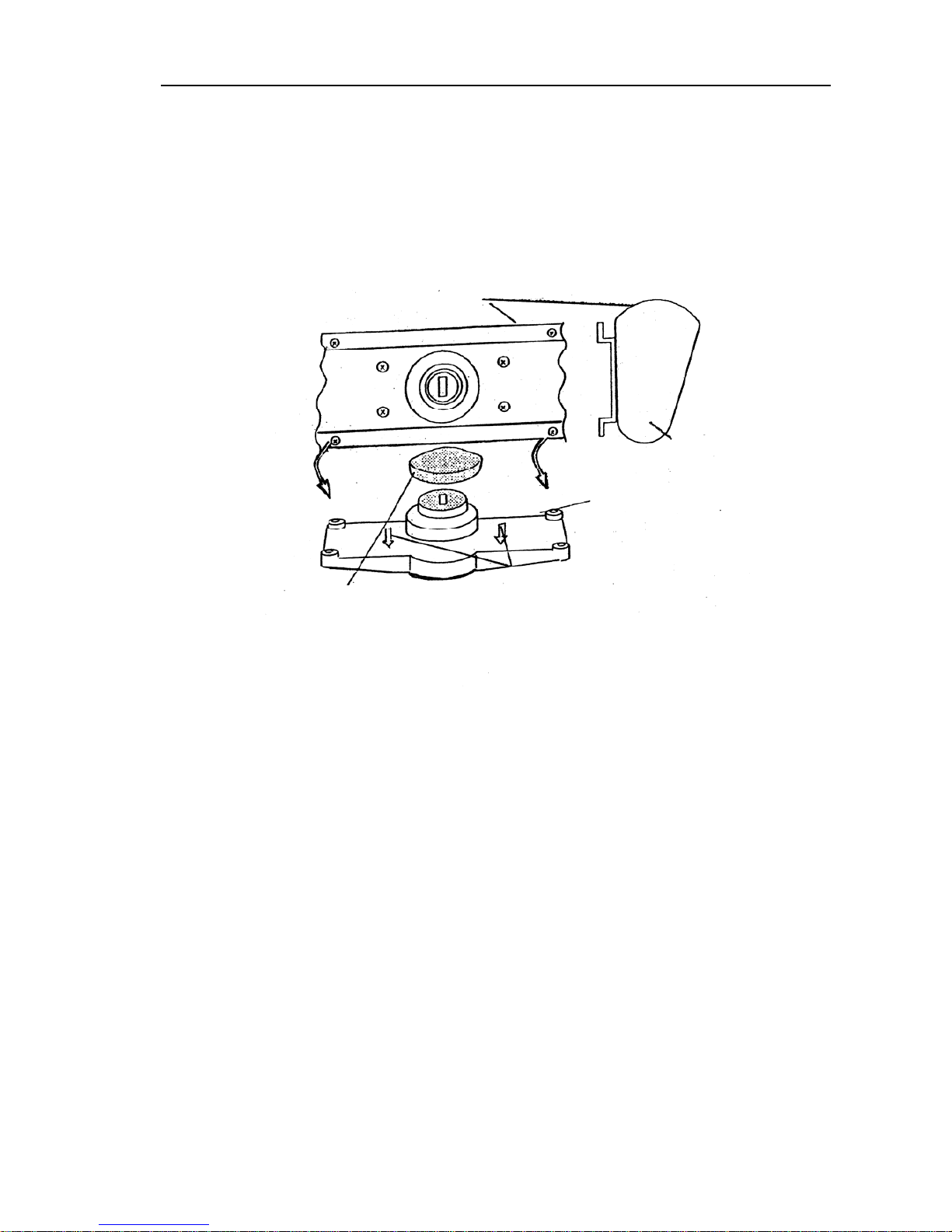

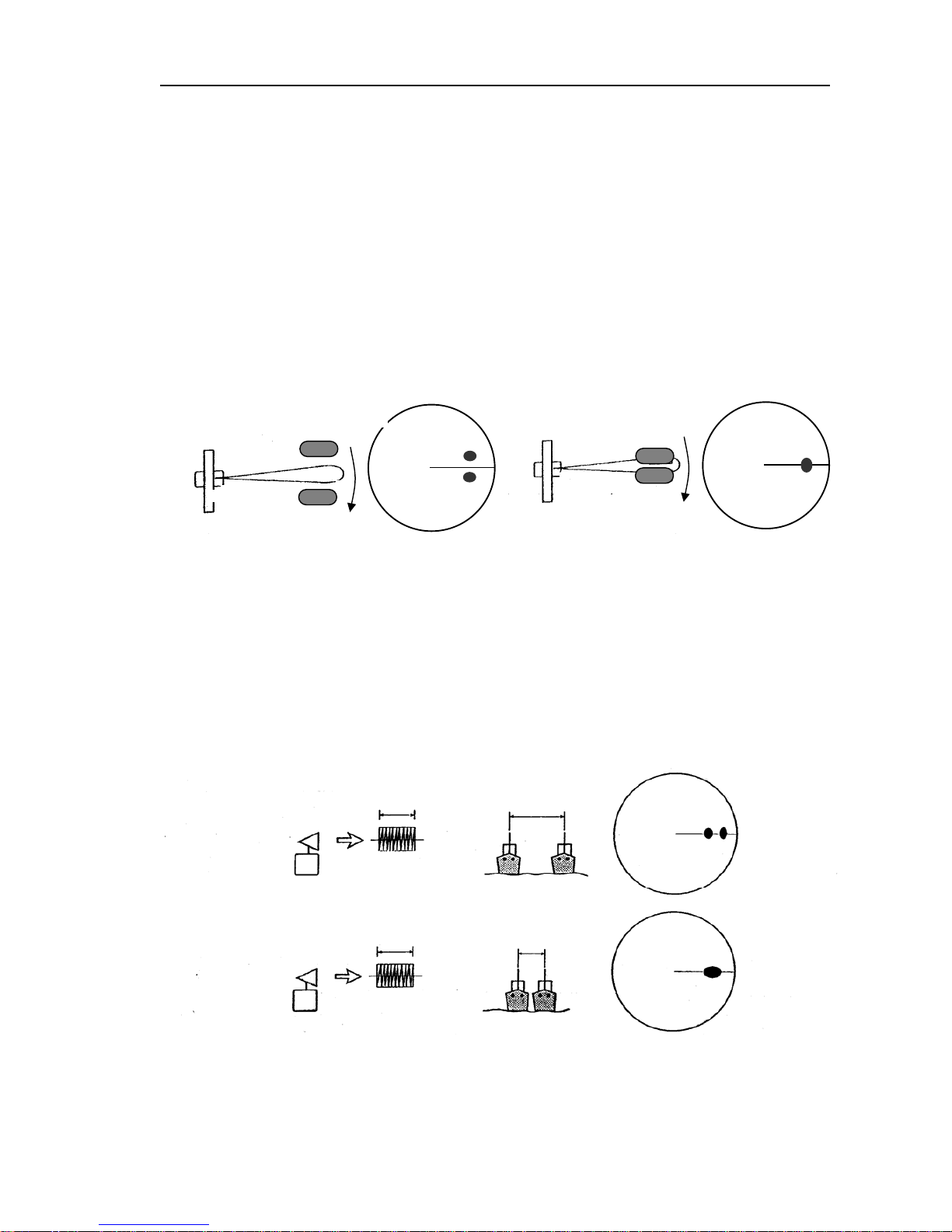

4.6.2 Fitting the Aerial

(1) Remove the protection cap on the outlet of the rotating base.

(2) Fit the aerial on to the rotating base. Orient the aerial front face (the company logo

printed on it) to the direction to which two arrow-marks on the rotating base point.

(3) Fix the aerial with four bolts attached to the aerial base.

Figure 4.3 Fitting the aerial onto the rotating base

Aperture

Aerial

Rotating base

Arrow Mark

Protection cap

Rotating base

Spring

Fixing Bolt

Page 39

Chapter 4 MDC-1840BB/1841BB/1860BB/1810BB/1820BB Series

Installation Operation Manual

4-6 0093142122-11

4.6.3 Connecting the cable

4.6.3.1 Connecting the cable for the Radome type scanner

1) Be sure that the power is off.

2) Remove the upper part of the radome from the scanner unit. Lift it vertically to

avoid bumping it against the antenna. (There are four fixing screws.)

3) Remove the tape securing the antenna.

4) Remove the shield cover located on the backside. (There are four screws.)

5) Remove the cable clamping plate and rubber ring, pass the cable through the

opening, replace the rubber ring, and clamp the cable to the scanner unit with screws

on the fixing plate. Attach the 7-pin connector to X11 and 9-pin connector to X12 of

the printed circuit board.

6) Replace the aluminum cover. Lay the cable shield into the channel machined into

the aluminum housing. Be careful that the cable will not get caught up between the

main unit and cover.

Replace the upper part of the radome being careful not to bump it against the antenna.

Make sure that the cover is positioned in the correct direction as shown in Figure4.4.

The upper and lower parts of the radome each have four alignment markings

indicating screw positions.

Connect the cable to the plug labeled "SCANNER" on the rear panel of the display

unit. Be sure to secure the rubber boot around the cable connector rim.

Ship's

heading

Logo seal on

side wall

Fix four screws

Cable inlet

Figure 4.4 Fitting cover

Page 40

MDC-1840BB/1841BB/1860BB/1810BB/1820BB Series Chapter 4

Operation Manual Installation

0093142122-11 4-7

Fix connector on

PCB(X11, X12)

Stern side

Shield cover

Cable shield

Radome (bottom)

Fixing plate

Rubber ring

Interconnecting cable

X12 (Connect here

)

Radome (bottom)

PCB

Inner shield

X11 (Connect here

)

Figure 4.5 Connecting the cable to the antenna

Page 41

Chapter 4 MDC-1840BB/1841BB/1860BB/1810BB/1820BB Series

Installation Operation Manual

4-8 0093142122-11

4.6.3.2 Connecting the cable for the Open type scanner

(1) Remove the front and rear covers by loosening fixing bolts (4 bolts each).

(2) Remove the TR(transceiver) unit by removing two fixing bolts. Make sure the

magnetron fitted on the transceiver does not attract any magnetizing material.

(3) Remove the rubber sealing, washer, and retainer plate from the antenna cable.

(4) Feed the cable through the access hole through to the inside of the antenna unit.

(5) Slide the rubber sealing, washer and retainer plate onto the cable.

(6) Fix the cable retainer plate over the dressed braid using three fixing bolts.

(7) Fix the antenna cable with the cable clamp.

(8) Connect the antenna cable to the Modulator PCB. (Refer to the interconnection

diagram for detail)

Figure 4.6 Connecting the cable to the antenna

TR unit fixing bolts

Remove these connectors

Fixing bolt

Fixing plate

Interconnection cable

Clump

5 mm maximum

Fixing bolt

Cable shield terminal

Washer

Fixing plate

Scanner unit

Connecting cable

Rubber water sealing

Cable inlet

Lay the braid under the fixing

plate as short as possible.

Peel off residual heat-shrink tube here

Page 42

MDC-1840BB/1841BB/1860BB/1810BB/1820BB Series Chapter 4

Operation Manual Installation

0093142122-11 4-9

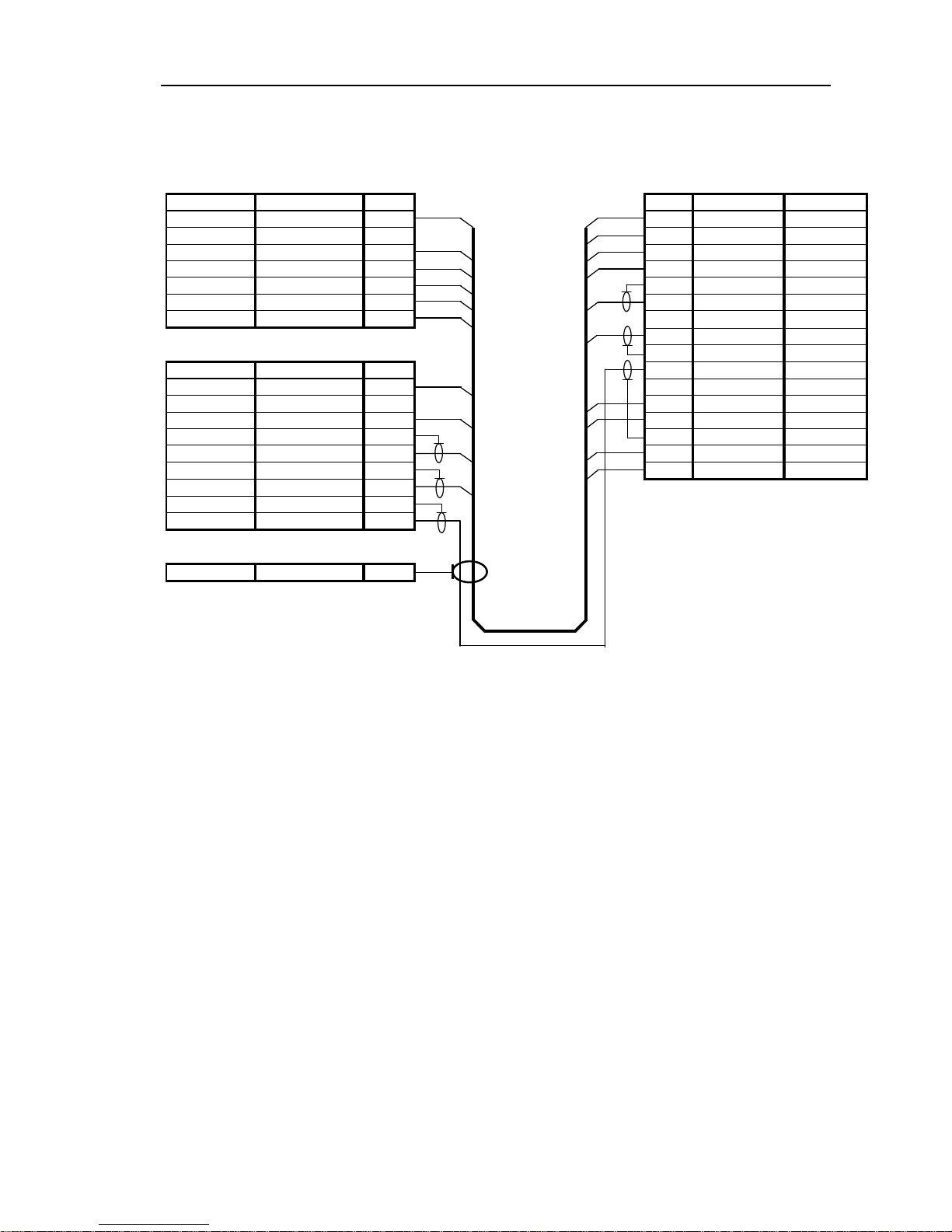

Figure 4.7 Interconnections between Antenna Unit and Display Unit

ANTENNA UNIT PROCESSOR UNIT

P1 PX

Description Color No. No. Color Description

+250V Violet 1 1 Violet +250V

NC NA 2 2 Blue +24V

GND Yellow 3 3 Orange(Larger) +12V

+40V Red(Larger) 4 4 Yellow GND

+40V Yellow (Larger) 5 5 Braid DATA-RTN

+40V-RTN Green (Larger) 6 6 Red (Coax) DATA

+40V-RTN Blue (Larger) 7 7 - -

8 Brown (Coax) BP/SHF

P2

9 Braid BP/SHF-RTN

Description Color No. 10 Gray (Coax) V/TRIG

+24V Blue 1 11 NC NA 2 12 Red(Larger) +40V

+12V Orange (Larger) 3 13 Yellow(Larger) +40V

DATA-RTN Braid 4 14 Braid V/TRIG-RTN

DATA Red (Coax) 5 15 Green(Larger) +40V-RTN

BP/SHF-R Braid 6 16 Blue(Larger) +40V-RTN

BP/SHF Brown (Coax) 7

V/TRIG-RTN Braid 8

V/TRIG Gray (Coax) 9

Grounding Lug

GND Braid 1

Page 43

Chapter 4 MDC-1840BB/1841BB/1860BB/1810BB/1820BB Series

Installation Operation Manual

4-10 0093142122-11

4.6.4 Installing the Processor Unit

The Processor Unit can be installed on tabletop or bulkhead. Use the following

procedure for installation.

(1) Determine the location observing the precaution given in Para 4.4.2.

(2) Place the Processor Unit onto the position where the unit is installed and fix it

using the truss tapping screws prepared in the installation material kit. (4 positions)

Figure 4.8 Installing the Processor Unit

Use M4 (4 mm) tapping screw with 25

mm length or more for good security.

(4 positions)

Page 44

MDC-1840BB/1841BB/1860BB/1810BB/1820BB Series Chapter 4

Operation Manual Installation

0093142122-11 4-11

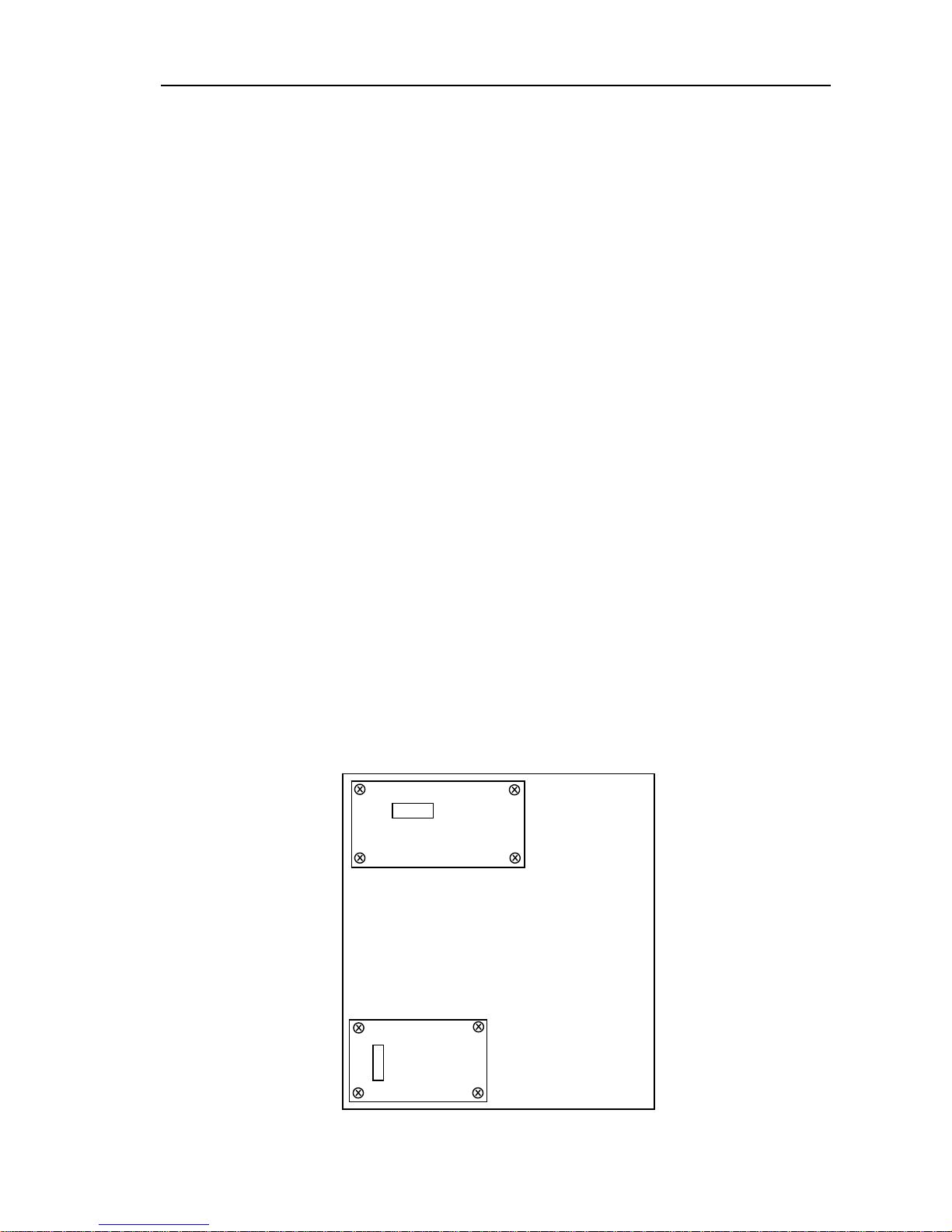

4.6.5 Installing the Operation unit

The Operation Unit can be installed in table mount or flush mount mode.

4.6.5.1 Table mounting

(1) Remove the screw cover (4 positions) at the corner of the operation unit. To do so,

insert a thin, flat screwdriver into a gap between the cover and the operation unit.

Apply gentle pressure to gradually pry the cover off the unit. The screw cover

comes off easily by sliding it upward.

(2) Remove the mounting bracket from the operation unit by loosening the M5 screw

(4 positions).

(3) Determine the place to install the bracket and mark the point of screw. (4 positions)

(4) Put the bracket in place and fix with M5 (5 mm) tapping screw. (4 positions)

Refer to Figure 4.10 and Figure 4.11 for detail.

Figure 4.9 Service space required for the Processor Unit

Page 45

Chapter 4 MDC-1840BB/1841BB/1860BB/1810BB/1820BB Series

Installation Operation Manual

4-12 0093142122-11

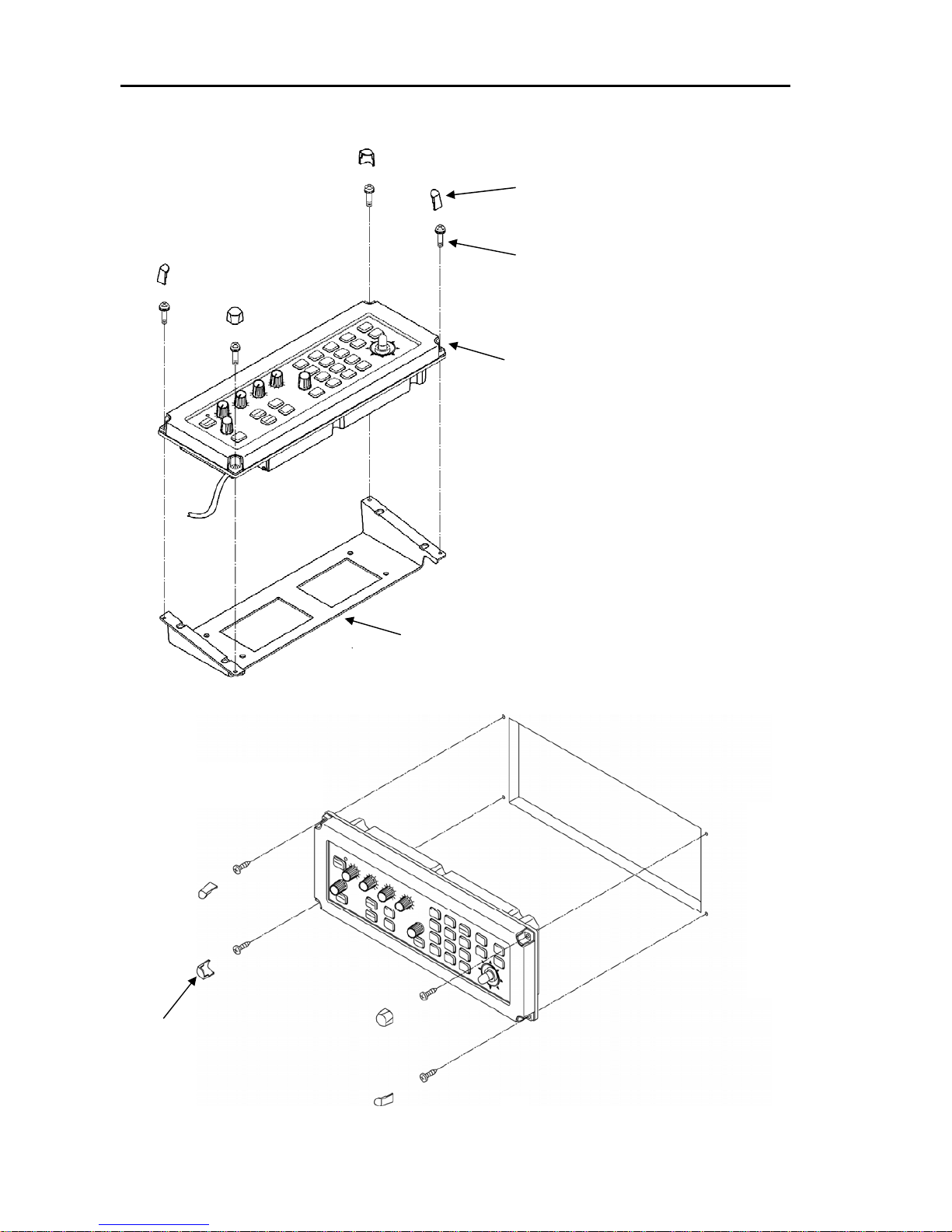

Screw cover (4 positions)

Operation unit

M5 (5 mm) tapping screw (4 positions)

Mounting bracket

M5 (5 mm) Screw (4 positions)

Figure 4.10 Mounting the Control unit

Figure 4.11 Service space required for the Operation unit

Page 46

MDC-1840BB/1841BB/1860BB/1810BB/1820BB Series Chapter 4

Operation Manual Installation

0093142122-11 4-13

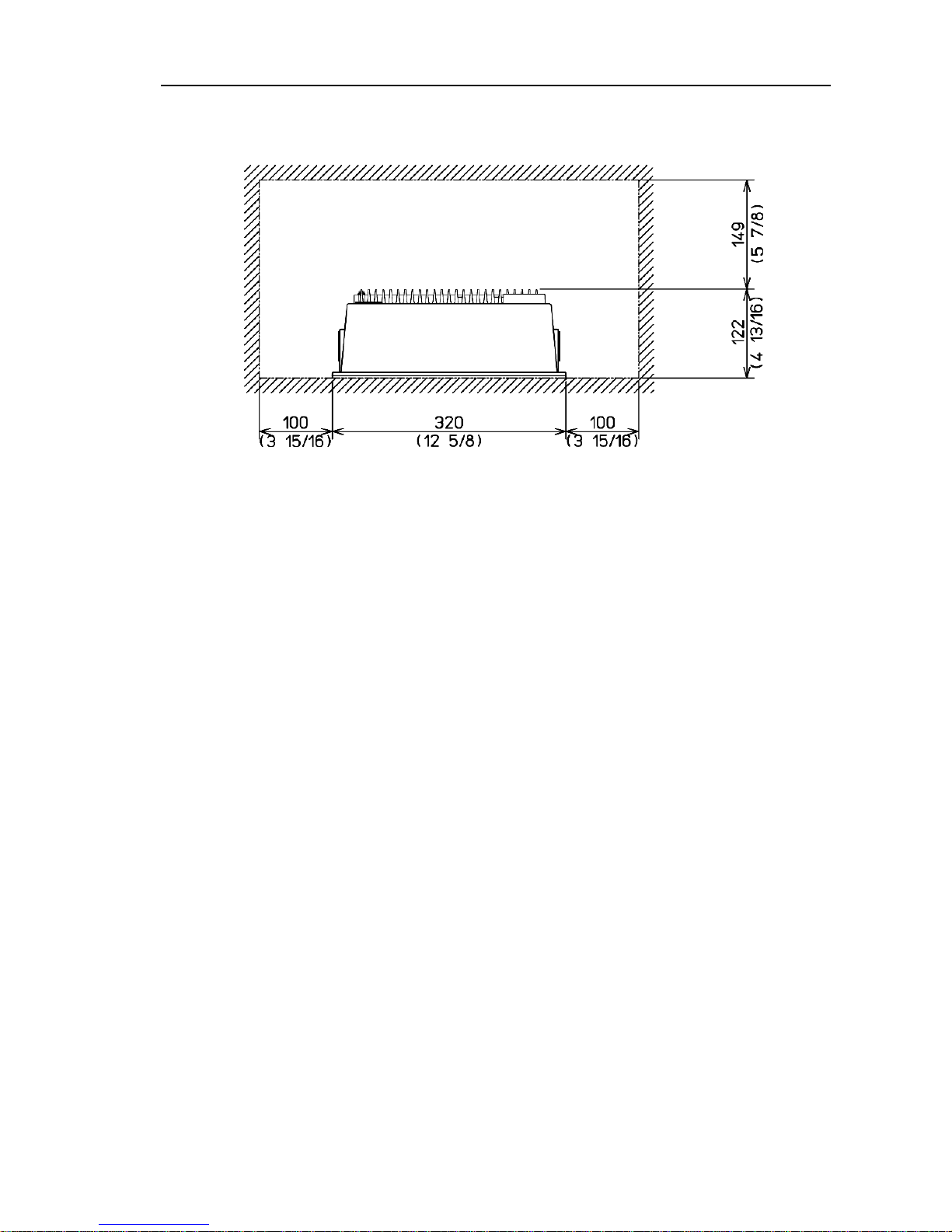

4.6.5.2 Flush mounting

Preparation:

(1) Cut aperture in surface to the dimensions shown below

(2) Mark the fixing points with a sharp-edged tool.

Installation:

(1) Remove the mounting bracket from the Control Box.

(2) Remove a screw cover, which is fitted on each corner of the Control Box front

face.

(3) Put the Control Box and connecting cable into the aperture and connect the cable

to the Processor unit at the specified receptacle. (Refer to Figure 4.15)

(4) Fasten the Control Box to the panel using a 4 mm tapping-screw. (4 positions)

(5) Refit the screw covers removed in step (2).

Figure 4.12 Dimensions of the Operation unit mounting aperture

Page 47

Chapter 4 MDC-1840BB/1841BB/1860BB/1810BB/1820BB Series

Installation Operation Manual

4-14 0093142122-11

Figure 4.13 Removing the Operation

Unit from the Mounting Bracket

Mounting bracket

Operation Unit

Screw covers (4 pcs)

M4 screws (4 pcs)

Figure 4.14 Installing the Operation Unit onto the console panel

M4 Tapping-screws (4 pcs)

Screw covers (4 pcs)

Page 48

MDC-1840BB/1841BB/1860BB/1810BB/1820BB Series Chapter 4

Operation Manual Installation

0093142122-11 4-15

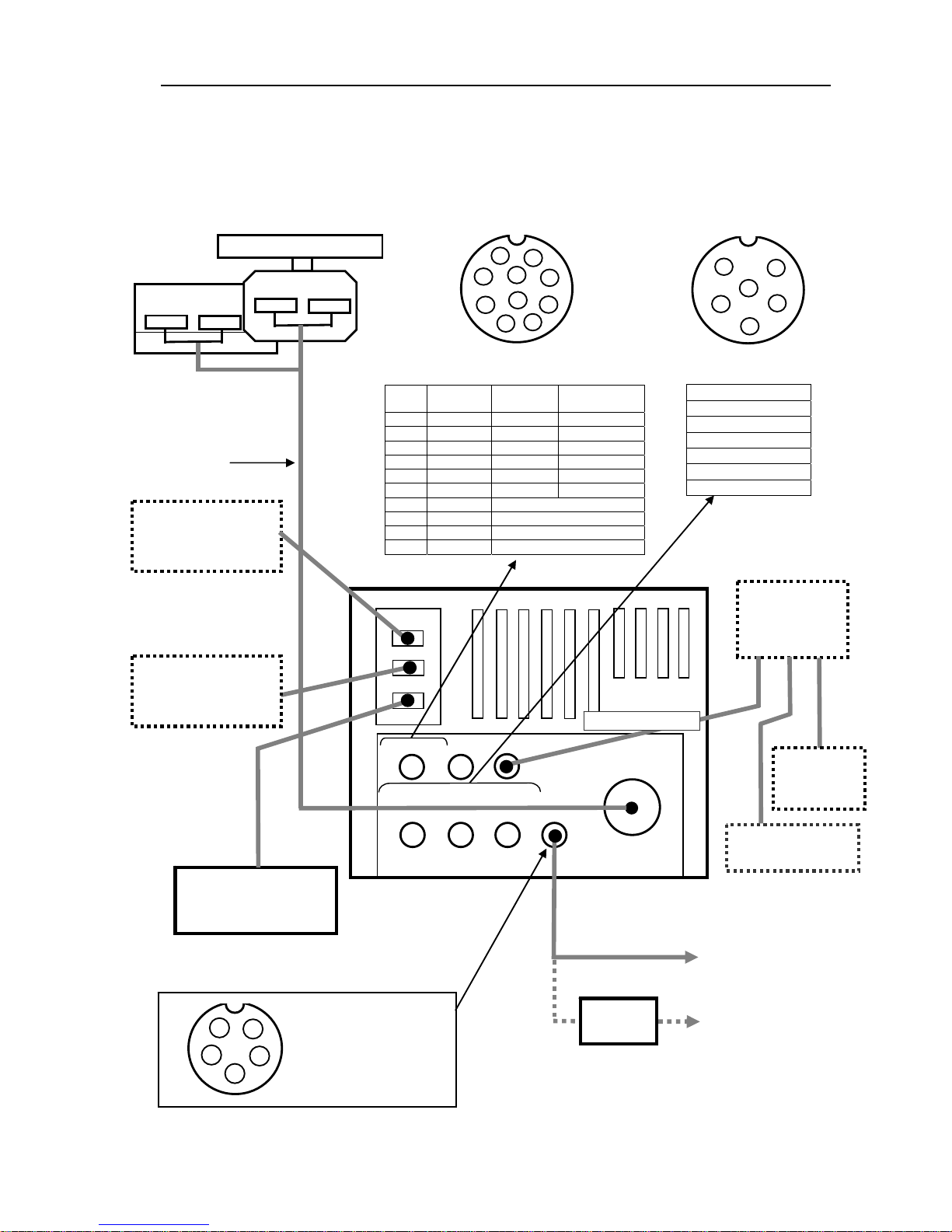

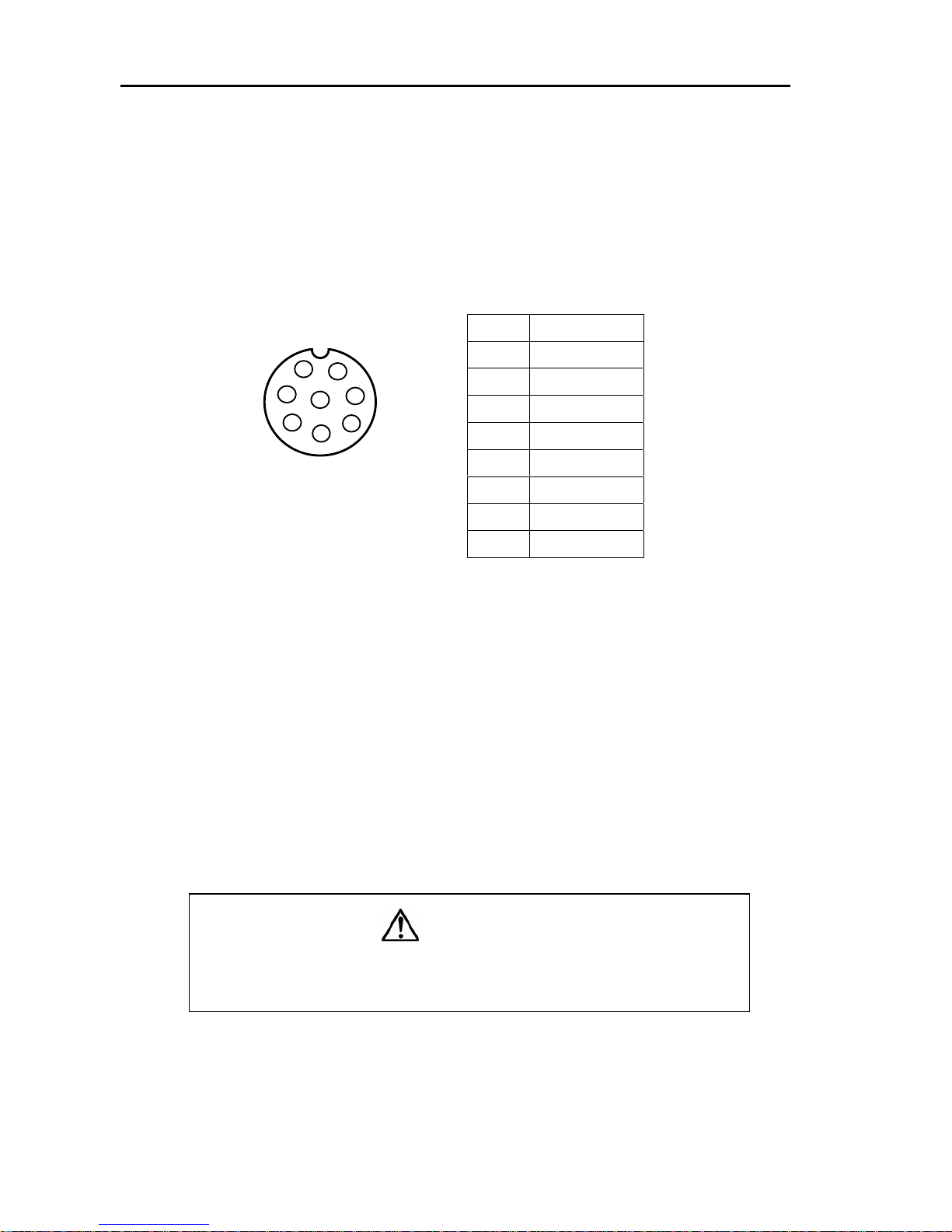

4.6.6 Connecting the cable to the Processor Unit

Connect the antenna cable, power cable and the data cable to the designated sockets

as shown in Figure 4.15.

Processor unit

Power supply for

Gyro/Log Interface

(11-40 VDC)

DC Main Supply

(21.6 – 41.6 VDC)

AC/DC Rectifier

PS-010

Pin assignment on Power Supply Connector

(Top view)

GYRO / LOG

No.1: Main DC (-)

No.2: Main DC (+)

No.3: Gyro I/FDC (+)

No.4: Gyro I/FDC (-)

No.5: Shield

1

2

3

1

2

3

4

5

6

Pin assignment on

Data Connector (Top view)

DATA 1,2 &3

No.1: Shield

No.2: OUT-A

N0.3: OUT-B

No.4: IN-A

No.5: IN-B

No.6: GND

Data connector pin assignment

Gyro/Log Connections

Pin

No.

NAME SYNC STEP

1 S1 X X

2 S2 X X

3 S3 X X

4 R1 X NC

5 R2 X NC

6 COM NC X

7 GND Frame ground

8 LOG 1 Mechanical contact signal

9 LOG 2 Mechanical contact signal

10 N.C.

Connecting cable

Type

242J159098B

L=15 m

Power cable

CW-256, L=2 m

AC cable

VV-2D8, L=3 m

(Option)

4

5

1

2

3

4

5

6

Pin assignment on

Data Connector (Top view)

7

8

9

10

SCANNER

DATA 1

DATA 2

DATA 3

Figure 4.15 Cable connections on the Display Unit

AIS*

REMOTE*

* See 4.8.1, 4.8.2

DISPLAY unit

(User supplied)

Processor

unit

(MRM-100)

Operation unit

(

MRO-100

)

DISPLAY

unit

Operation unit

(MRO-100)

Display cable

Type CW-560,

L=2 m

CW-561, L=10 m

VDR

Type

242J158055B

L=15 m

Page 49

Chapter 4 MDC-1840BB/1841BB/1860BB/1810BB/1820BB Series

Installation Operation Manual

4-16 0093142122-11

4.6.7 Link setting for the gyrocompass

When the Gyro signal voltage is lower than 50V, change the link positions for J721 to

J7125 from “2-3” to “1-2” on the Main Logic PCB (E47-700*) as shown below.

4.6.8 Ferrite core assembling for Power cable

Loop the power cable around the ferrite core three turns at position of 40 cm from the

connector as shown in figure 4.17.

1

2

3

1

2

3

Change setting from “2-3” to “1-2”,

applicable for J721 to J725

Main Logic PCB (E47-700*)

Main cabinet chassis

KSA-08A PCB module

(E47-510*)

Link pins for J721 to J725 for the

gyrocompass voltage setting

Figure 4.16 Locations of the gyrocompass links on the Main Logic PCB

Page 50

MDC-1840BB/1841BB/1860BB/1810BB/1820BB Series Chapter 4

Operation Manual Installation

0093142122-11 4-17

Figure 4.17 Ferrite core assembling for Power cable

Ferrite core

Connector

Page 51

Chapter 4 MDC-1840BB/1841BB/1860BB/1810BB/1820BB Series

Installation Operation Manual

4-18 0093142122-11

4.7 Setting up after installation

A few set ups are required after installation. Before carrying out the setting up

procedures, check the following items in order to make sure the equipment operates

in normal manner:

(1) Check that the ship’s power supply is properly rated to operate the radar system.

(2) No person is present near the platform or on the mast where the radar antenna is

to be operated. Put a warning tag on the display unit that reads, “RADAR

ADJUSTMENT IN PROCESS. DO NOT TOUCH ANY CONTROLS”.

4.7.1 Auto tune adjustment

Menu Item: ADJUST/ PRESET/ AUTO TUNE

It is necessary to adjust the AUTO TUNE for the best radar performance when

installed the radar, or replaced the magnetron.

NOTE: When operating the radar, the following error message happen to be

indicated on the screen in case of the first power on the radar after installation, or

leave the radar switched off for a long period;

"MAGNETRON HEATER CURRENT ABNORMAL", or "MAGNETRON

CURRENT ABNORMAL". If the message is indicated on the screen, please

ageing the magnetron first as follows.

1. Keep the radar OFF more than 20 minutes to wait the magnetron completely

cold.

2. Power ON the radar. Keep the radar to stand by state for an hour.

3. Transmit the radar at 0.25NM range scale for another one hour. Do not change

the range scale during the hour.

4. If above error message is indicated on the screen during this 0.25NM range

operation, start again from item #1.

If the error message is indicated on the screen and stop the transmission even

finish the ageing with above procedure, some problem may happen on the radar.

Please contact to our local dealer.

NOTE: The following setup menus are protected from ordinary key operations. To

use this function, first turn off the radar set. Second, press and hold the MODE key

and turn the radar on. When the standby condition is established, turn the radar on

to enter the following menu functions.

Page 52

MDC-1840BB/1841BB/1860BB/1810BB/1820BB Series Chapter 4

Operation Manual Installation

0093142122-11 4-19

Please perform the following adjustment with entering the maintenance mode by

press MODE key and power on ;

1. Set the range scale to 12NM and above to watch a land or a mountain on the

screen with pressing the range[+] key.

2. Select the TUNE item from the DISP/ ECHO menu, then set it to AUTO.

3. Enter the adjustment state with selecting the AUTO TUNE from the ADJUST/

PRESET menu.

4. Change the value with control the joystick to get the maximum echo visibility on the

screen.

5. Press ENT key to fix the adjustment.

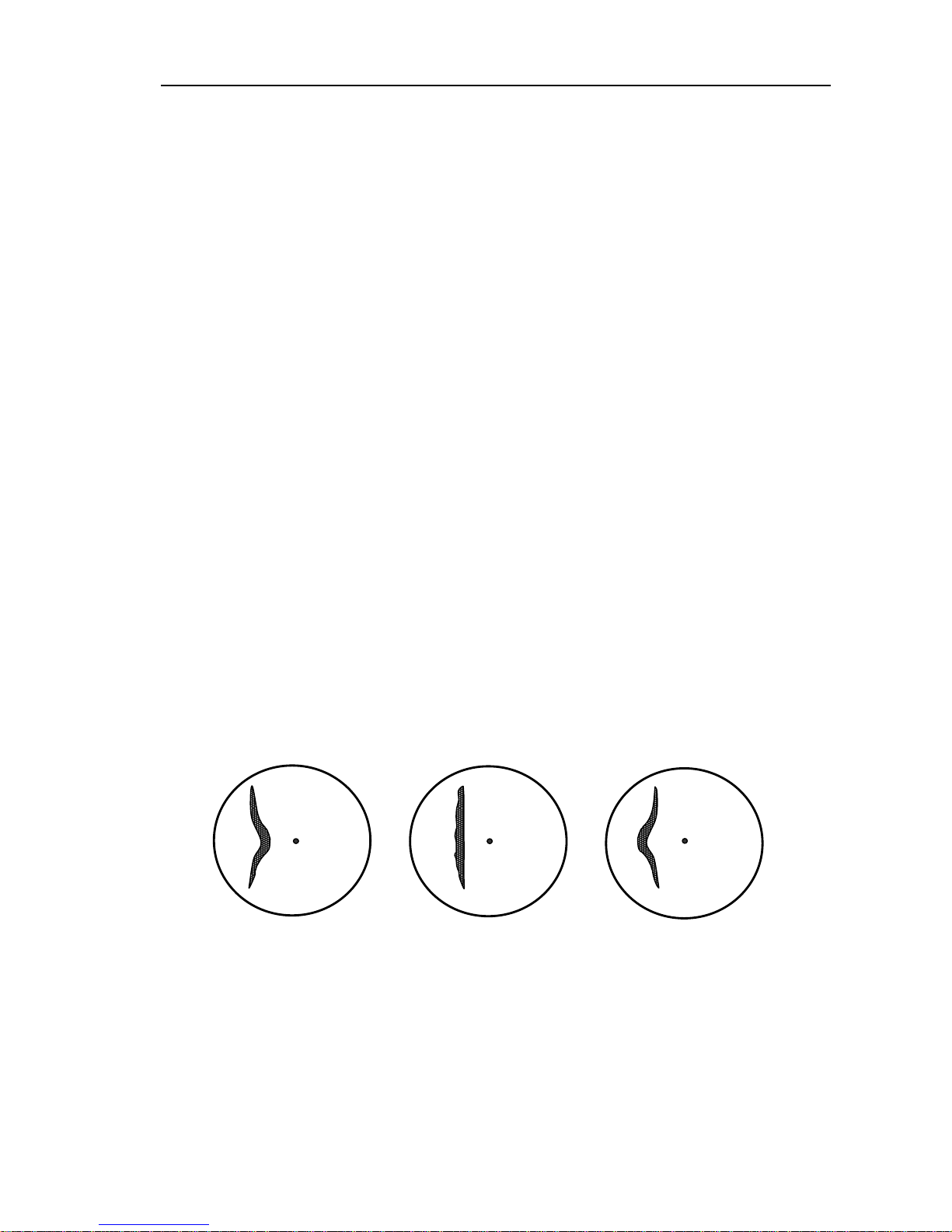

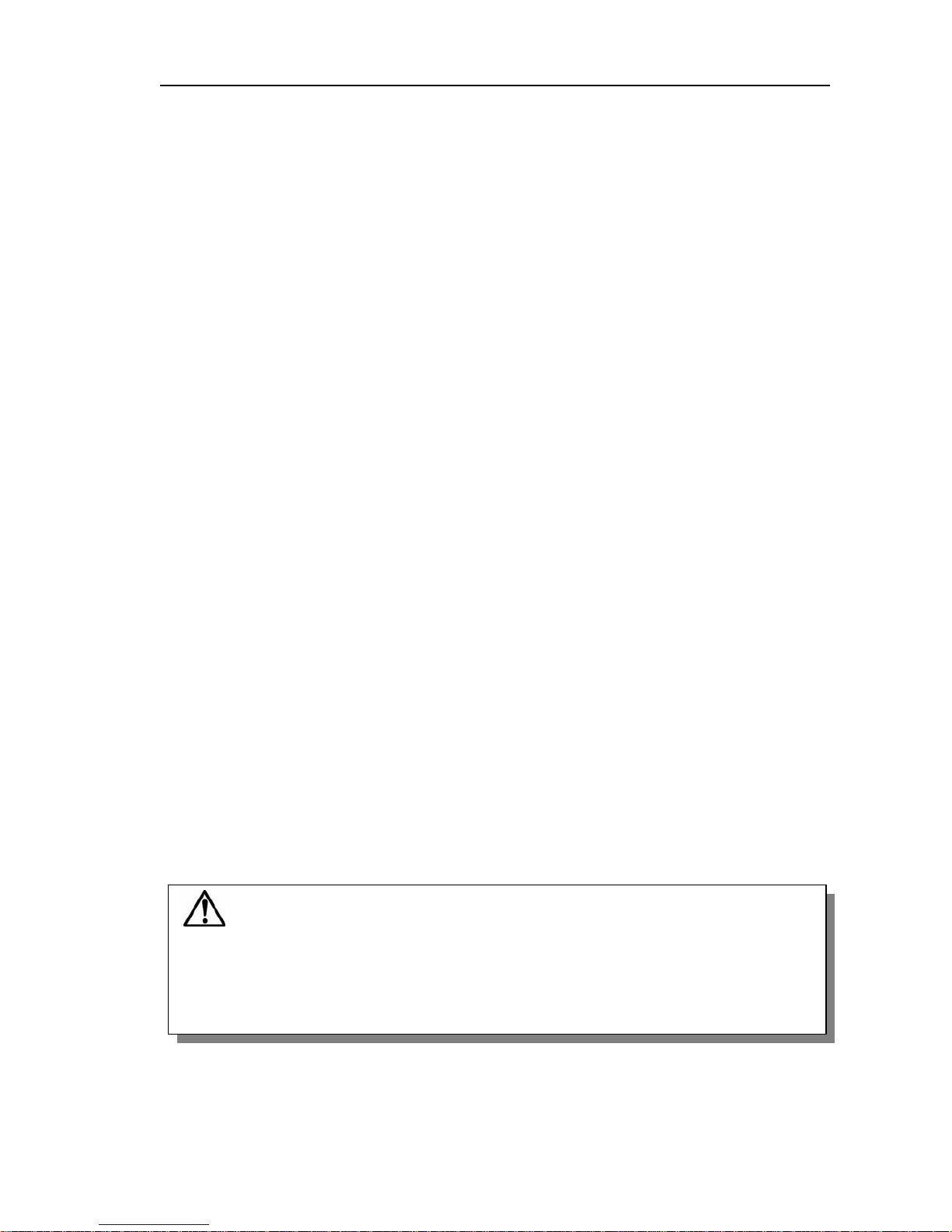

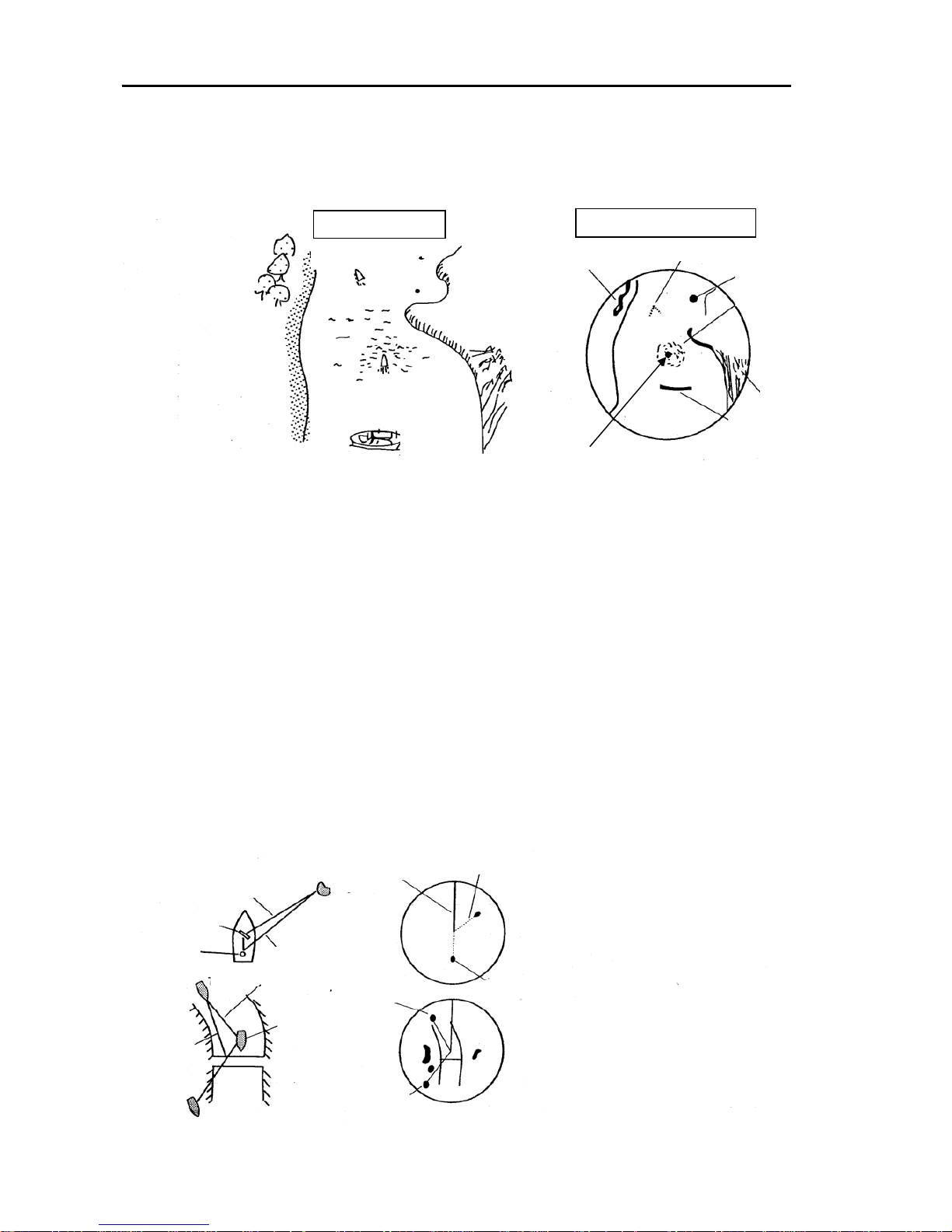

4.7.2 Transmission timing

SYSTEM MENU: SYSTEM SETUP/DELAY

Adjusts the transmission delay time in order to match the timing of radar transmission

and the start of the radar sweep. In practice, refer to the following figures that illustrate

the result of the setting, whether it is properly adjusted or not. To effectively perform

this setting, find an appropriate nearby object that is straight across from your radar.

Carry out the following procedure to set up the proper transmission delay time.

(1) Highlight the DELAY item and press the ENT key to set up the selection-ready

status.

(2) Press the Joystick towards the up or down until a straight video line is shown on

the screen.

(3) Press the ENT key to fix the settings.

Delay time too short

Delay time appropriate

Delay time too much

Figure 4.18 Echo presentation depending on the transmission delay timing

Page 53

Chapter 4 MDC-1840BB/1841BB/1860BB/1810BB/1820BB Series

Installation Operation Manual

4-20 0093142122-11

4.7.3 Ship’s heading set up

SYSTEM MENU: SYSTEM SETUP/HDG

Adjusts the bearing of the radar picture shown on the screen. First, take an optical

bearing of a stationary target located within a viewable range using a standard

magnetic compass on the ship. Then measure the target bearing on the radar. If the

deviation is found more than +/- 1 degree on the screen, carry out the following

procedure for correction.

(1) Move the Joystick up or down to highlight the HDG sign and press the ENT key.

(2) Press the Joystick up or down to change the bearing, in order to set the radar echo

bearing to coincide with the compass bearing.

(4) Press the ENT key to fix the bearing.

4.7.4 Resetting Manual GAIN/STC(Height)/Manual STC

Gain and Sea settings have been properly set at the factory, however, when a need is

arisen to change these settings use the following procedures. Resetting must be

carried out in the following order.

1. Manual GAIN setting

2. STC (Height) setting

3. Manual STC setting

When completed, be sure to record respective setting values in the

GAIN/SEA/HEIGHT sheet prepared in this paragraph.

4.7.4.1 Manual GAIN setting

(1) Press and hold the MODE key and turn the power on. When a beep is heard,

release the key.

(2) Transmit the radar when STBY is displayed on the screen.

(3) Set the RAIN and SEA control to 0, GAIN to 8 and BRILL to 10 (Max),

respectively.

(4) Confirm the following settings. If not set so.

IR level: IR2

SEA, GAIN, RAIN: MANUAL

(5) Set the range scale to maximum. (MDC-1840/41BB: 48 NM,

MDC-1860BB: 64 NM, MDC-1810BB: 72 NM, MDC-1820BB: 96 NM)

(5) Select the GAIN MANUAL menu per ADJUST>PRESET>GAIN MANUAL and

display the GAIN MANUAL index entry window.

(6) Move the Joystick up or down until a desired noise level (density of the noise

speckle) is obtained and press the ENT key to fix the setting.

(7) Record the new GAIN setting value in the GAIN/SEA/HEIGHT Setting Record

Page 54

MDC-1840BB/1841BB/1860BB/1810BB/1820BB Series Chapter 4

Operation Manual Installation

0093142122-11 4-21

sheet (GAIN/SEA/HEIGHT sheet, hereafter).

(8) Repeat the above procedure for all range scales, if required.

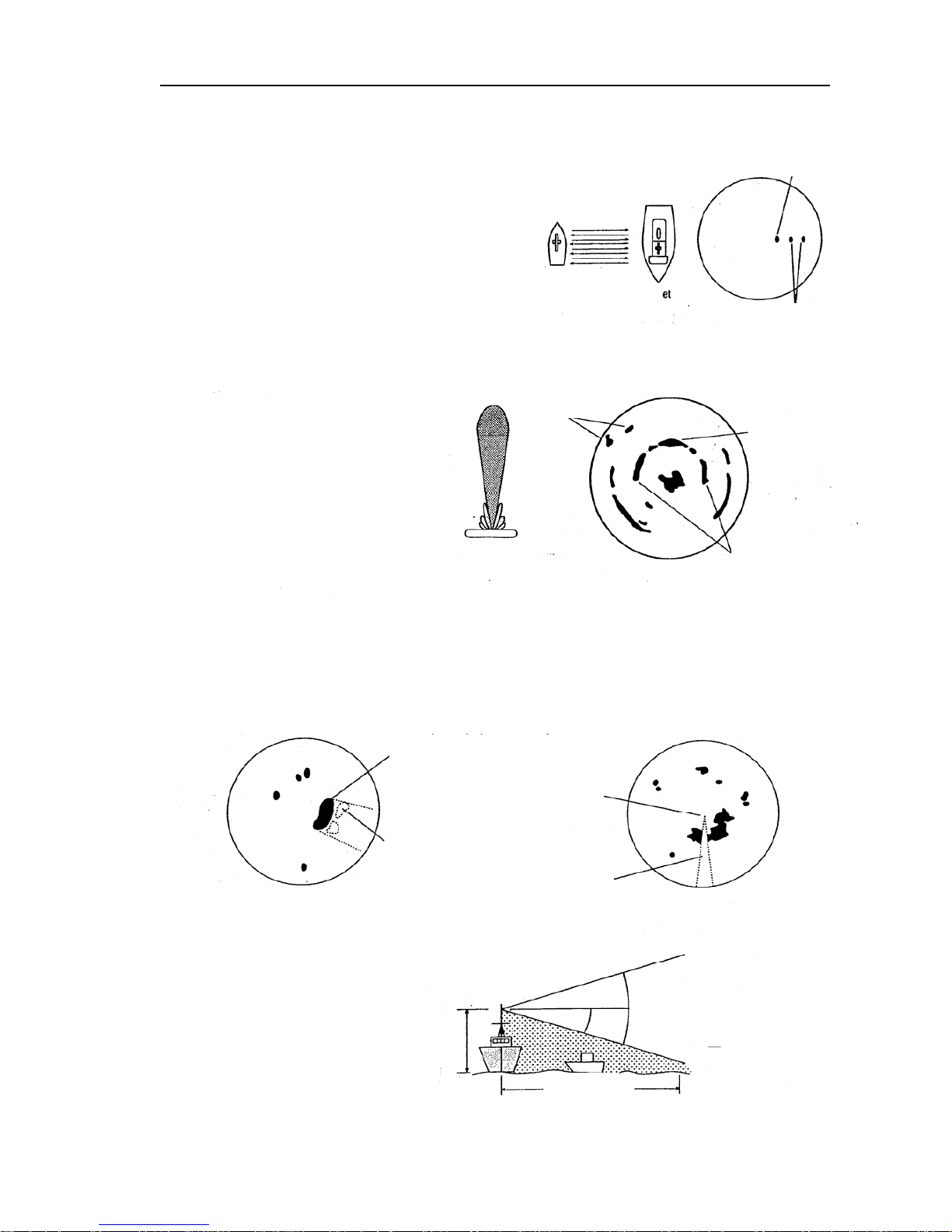

4.7.4.2 STC (Height) setting

The STC characteristic is more less subject to vary depending on the height of the

antenna from the sea surface. Resetting the STC may be needed according to the

circumstances of the respective vessels. To achieve the best result, this setting should

be carried out off shore. Use the following procedure to do.

(1) Set SEA, GAIN and RAIN control to manual mode.

(2) Set GAIN to 8, SEA to 0 and RAIN to 0, respectively. Make sure that the sea

clutter speckle is appropriately shown on the screen. If the speckle is too much

or too short on the display, adjust the GAIN control as appropriate.

(3) Select an appropriate range scale to permit the clutter speckle is shown within

the screen.

(4) Adjust the SEA control to reduce the sea clutter until some residual clutter

speckle is shown.

(5) Turn the SEA control either clockwise or counterclockwise to see the effect of the

STC. If the effect is uniform in both long and short ranges, the STC Height

selection is considered appropriate. In such a case when the short range sea

return is suppressed earlier that that of the long range or vice versa, use the

following procedure to correct.

(6) Go SYSTEM>SYSTEM SETUP>HEIGHT and display the HEIGHT index entry

window.

(7) Adjust the SEA control to see the tendency of the control. If the short-range

clutter return is suppressed in advance to the long range one, reduce the

HEIGHT value by pressing the Joystick downwards, and vice versa.

(8) Adjust the SEA control to confirm the effect. If the result is not satisfactory, repeat

the above procedure.

(9) Press the ENT key to fix the setting.

(10) The HEIGHT index is irrelevant to the range. If this setting cannot be performed

offshore, the HEIGHT index should be selected with reference to the actual

antenna height from the sea surface. Use the following criteria as reference.

Antenna height

Recommended

HEIGHT index

3 m 8

5 m 5

10 m 2

Page 55

Chapter 4 MDC-1840BB/1841BB/1860BB/1810BB/1820BB Series

Installation Operation Manual

4-22 0093142122-11

4.7.4.3 Manual STC setting

This setting allows the maximum STC range to be effective up to 6 NM. Use the

following procedure to set up.

(1) Set radar controls as follows:

Range scale: 12 NM, RAIN/SEA: 0, GAIN: 8, BRILL: 10 (Max)

(2) Activate VRM 1 per: DISP>MARK>VRM 1>ON and press the ENT key.

(3) Set VRM 1 to 6.0 NM.

(4) Turn off IR 2 per: DISP>ECHO>IR>OFF and press the ENT key .

(5) Set SEA, GAIN and RAIN to MANUAL mode.

(6) Set SEA to 10 notch (Maximum).

(7) Go ADJUST>PRESET>SEA MANUAL and display the numeral entry window.

(8) Press the Joystick up or down to allow the background noise speckle is reduced

to about 6 NM. Press the ENT key to fix the setting. Record the value.

(9) Repeat the above procedure to the rest of the range scales using the same

value.

(10) Change range scale from one to the other with the SEA control set to maximum.

If the STC effect is not uniform on some ranges, reset the setting repeating the

above procedure.

(11) Reset IR2 to be activated.

Page 56

MDC-1840BB/1841BB/1860BB/1810BB/1820BB Series Chapter 4

Operation Manual Installation

0093142122-11 4-23

GAIN/SEA/HEIGHT Setting Record sheet

GAIN setting SEA Range scale

Pulse

length

Initial New Initial New

96NM(72or64NM) LP

48NM LP

24NM LP

12NM LP

12NM M2

6NM M2

6NM M1

3NM M2

3NM M1

1.5NM M1

1.5NM SP

0.75NM M1

0.75NM SP

0.5NM SP

0.25NM SP

0.125NM SP

STC HEIGHT : Initial setting: New setting:

Page 57

Chapter 4 MDC-1840BB/1841BB/1860BB/1810BB/1820BB Series

Installation Operation Manual

4-24 0093142122-11

4.8 Setting up option

4.8.1 AIS Interface(Option)

DISP MENU: NAV/AIS

Activate AIS function from DISP/NAV/AIS menu.

Automatic Identification System(AIS) will automatically display ships symbol and data

around your ship. The range of the data display ships can be set from RADAR/AIS

menu.

4.8.2 Remote Display operation

The Processor Unit type MRM-100 can be used as a remote display. To use the

display in this configuration, use the following procedure.

4.8.2.1 Connecting the Remote Display

Connect the Master display (MRM-100) and a Remote display (MRM-100) with the

connecting cable CW-561 (10m) as shown in Figure 4.15.

4.8.2.2 Required set up

Set the RADAR STATUS SELECT MENU setting to INDEPENDENCE/SLAVE, the

display unit will operate with the radar signal supplied from the external radar unit.

Please read "6.9 Operating the Interswitch" on this manual, too.

4.8.2.3 Possible operation on Remote Display

The remote display is configured to be slave to the master display in terms of

transmission control, transmit and standby. Except this function, the remote display

has all controls that the master does, such as, gain, STC, FTC, range scale change,

Pin No. NAME

1 Shield

2 IN-B

3 IN-A

4 OUT-B

5 OUT-A

6 GND

7 AIS ALARM+

8 AIS ALARM-

1

2

3

4

5

6

7

8

Pin assignment on

Data Connector (Top view)

CAUTION:

Do not connect the Antenna unit to the remote display. If do so,

the remote display may malfunction.

Figure 4.19 AIS connector

Page 58

MDC-1840BB/1841BB/1860BB/1810BB/1820BB Series Chapter 4

Operation Manual Installation

0093142122-11 4-25

off-centering, changing mode of operation, VRM, EBL, fixed rings, etc.

In the following circumstances, the display presentation becomes abnormal but is not

fault.

(1) When the transmission is turned off, the slave screen is displayed with plural

coaxial video caused by non-updated video data.

(2) When the master display is set to short range and the remote display to long

range, the remote screen will be shown with coaxial radar picture caused by

higher transmission rate video being supplied from the master display.

(1) On the contrary, when the master display is set to long range and remote display

to short range, the remote display screen will be shown with stretched video

towards range. In a particular case, the radar video display will be shown

halfway due to slower transmission rate.

NOTE: To utilize the nav data, true bearing mode, true motion mode and EPA/ATA

functions in remote display, relevant sensor units such as, gyro compass, speed log

and GPS receiver must be connected.

GYRO / LOG

SCANNER

DATA 1

DATA 2

DATA

AIS

REMOT

GYRO/LOG

SCANNER

DATA 1

DATA 2

DATA

AIS

REMOTE

Master Display

Remote

External Display

Connecting cable

CW-561-10M

(

10m)

Figure 4.20 Remote display connection

Page 59

Chapter 4 MDC-1840BB/1841BB/1860BB/1810BB/1820BB Series

Installation Operation Manual

4-26 0093142122-11

Pin No. NAME

1 VIDEO OUT

2 TRIG OUT

3 GND

4 AZIP OUT

5 SHF OUT

6 GND

7 VIDEO IN

8 TRIG IN

9 GND

10 AZIP IN

11 SHF IN

12 +12Vdc(Not used)

1

2

3

4

5

6

7

8

9

12

10

11

Pin assignment on

REMOTEConnector

(Top view)

Figure 4.21 Remote connector

Page 60

MDC-1840BB/1841BB/1860BB/1810BB/1820BB Series Chapter 4

Operation Manual Installation

0093142122-11 4-27

APPENDIX 1

Installation of the ATA module, MRE-300

The ATA module MRE-300 is installed inside the display unit. Use the following the

instructions for installation.

(1) Locate the position of the four fixing studs on the Main Logic PCB (E47-700*)

prepared for the ATA module. (Refer to the figure below)

(2) Put the ATA module (MRE-300) on the studs and press the module gently

downwards in order that the connector installed on the module properly plugs into

the receptacle J705 on the Main Logic PCB.

(3) Fix the module using the four 3 mm fixing screws, prepared in the ATA module kit.

Installation of the AIS module, AIS-100

The AIS module (AIS-100) is installed inside the display unit. Use the following

instructions for installation.

(1) Locate the position of the four fixing studs on the Main Logic PCB (E47-700*)

prepared for the AIS module. (Refer to the figure below)

(2) Put the AIS module (AIS-100) on the studs and press the module gently

downwards in order that the connector installed on the module properly plugs into

the receptacle J716 on the Main Logic PCB.

(3) Fix the module using the four 3 mm fixing screws, prepared in the AIS-100 kit.

Main Logic PCB

E47-700A

J705 J705

J716

MRE-300

AIS-100

Page 61

Chapter 4 MDC-1840BB/1841BB/1860BB/1810BB/1820BB Series

Installation Operation Manual

4-28 0093142122-11

AIS connector pinouts and cable color coding designaltion:

Cable type name Port name Pin number Signal name Color code

CW-387-5M AIS 1 Shield Braid

2 IN-B Red dot/Orange

3 IN-A Black dot/Orange

4 OUT-B Red dot/White

5 OUT-A Black dot/White

6 GND Black dot/Grey

7 AIS ALARM+ Red dot/Pink

8 AIS ALARM- Black dot/Pink

About AIS malfunction alarm

If the AIS transponder gets failed in operation, the AIS ABNORMAL status is supplied

from the transponder to the display causing the error message to appear on the

screen.

NOTE: In case no alarm signal lines are available in the AIS transponder, link the AIS

ALARM+ (Red dot/Pink wire) and AIS ALARM- (Black dot/Pink) signal lines at the

cable end at the transponder side. This processing is necessary to prevent the AIS

alarm message from being shown mistakenly on the display.

Installation of the Gyro Interface module, KSA-08A

The Gyro Interface module (KSA-08A) is installed inside the processor unit. Use the

following instructions for installation.

(1) Dismount the Main Logic PCB E47-700* disconnecting cables connected to

the PCB.

(2) Unscrew the four 3 mm fixing screws on the corner of the Power PCB E47-600*.

The four screws will be used for fixing the Gyro Interface chassis.

(3) Locate the position of the four fixing studs at the corner on the Power PCB

prepared for the KSA-08A module. (Refer to the figure A.2)

(4) Put and fix the KSA-08A module chassis with E47-510A PCB on the studs

using the four 3 mm fixing screws and connect cables to connector J708 on

the backside of the Main Logic PCB. (Refer to the figure A.2)

(5) Fix the Main Logic PCB E47-700* at the position again.

Figure A.1 Position of the ATA and AIS modules to be installed

Page 62

MDC-1840BB/1841BB/1860BB/1810BB/1820BB Series Chapter 4

Operation Manual Installation

0093142122-11 4-29

(6) Reconnect the cables to the connectors J707 and J718 on the topside of the

Main Logic PCB. (Refer to the figure A.2)

(3) Reconnect all cables to the Main Logic PCB.

Cable connecting list

No. KSA-08A (E47-510A) Main Logic PCB (E47-700*)

1 J512 J708

2 J515 J707

3 J517/518 J718

GYRO connector pinouts and cable color coding designaltion:

Cable type name Port name Pin No. Signal name Color code

CW-388-5M GYRO 1 S1 Red dot/Orange

2 S2 Black dot/Orange

3 S3 Red dot/Grey

4 R1 Red dot/White

5 R2 Black dot/White

6 COM Red dot/Yellow

7 GND Shield

8 LOG1 Red dot/Pink

9 LOG2 Black dot/Pink

10 NC

Page 63

Chapter 4 MDC-1840BB/1841BB/1860BB/1810BB/1820BB Series

Installation Operation Manual

4-30 0093142122-11

Figure A.2 Fitting ATA, AIS and Gyro Interface modules into Main Logic PCB

ATA MRE-300 PCB module

(E35-703*)

Main Logic PCB (E47-700B)

AIS-100 PCB module (E47-720*)

Main cabinet chassis

KSA-08A PCB module

(E47-510*)

J515

J517/J518

J512

J718

J708

J707

Page 64

MDC-1840BB/1841BB/1860BB/1810BB/1820BB Series Chapter 4

Operation Manual Installation

0093142122-11 4-31

APPENDIX 2

Optional cables pinouts and cable color-coding designation

DATA connector pinouts and cable color coding designaltion:

Cable type name Port name Pin No. Signal name Color code

CW-376-5M DATA 1 Shield Shield, Blue

2 OUT-A White

3 OUT-B Red

4 IN-A Orange

5 IN-B Black

6 GND Green

REMOTE connector pinouts and cable color coding designaltion:

Cable type name Port name Pin No. Signal name Color code

CW-561-10M REMOTE 1 VIDEO OUT Coax. Black 1D(*)/White

2 TRIG OUT Coax. Black 2D(*)/White

3 GND Coax. Shield

4 AZIP OUT White

5 AHF OUT Yellow