Koden KDS-6000BB Installation Manual

KDS-6000BB Revision History

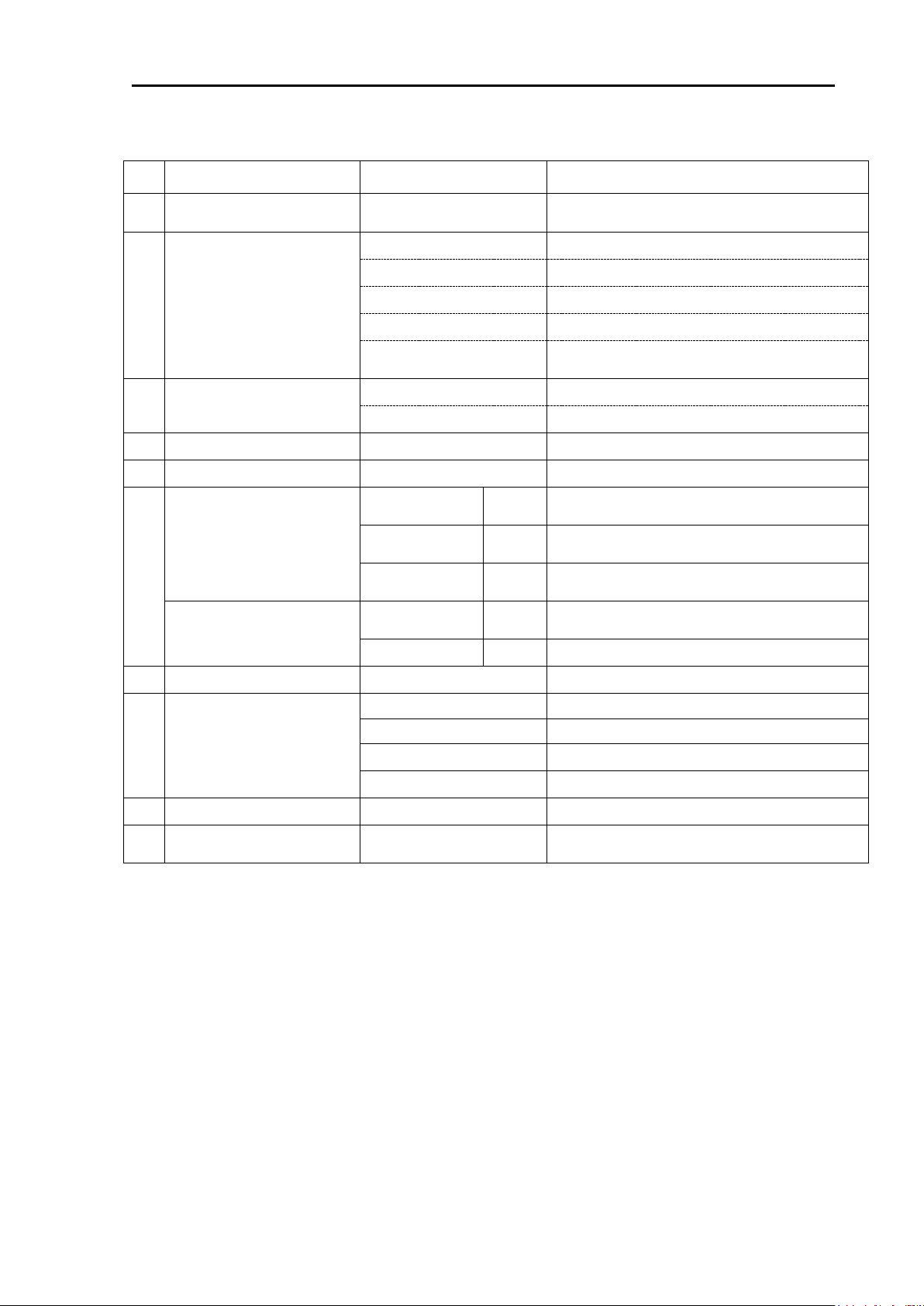

No.

Doc. No-Rev. No.

Revised Date

(Y/M/D)

Revised Content

0

0092660002-00

2014/09/29

First edition

1

0092660002-01

2014/12/05

System Configuration, Configuration of

Equipment, Chapter 1

2

0092660002-02

2015/03/16

System Configuration, Configuration of

Equipment, Chapter 1

3

0092660002-03

2015/07/14

Chapter 1

4

0092660002-04

2015/11/20

System Configuration, Configuration of

Equipment

5

0092660002-05

2016/03/17

Configuration of Equipment, External View,

Chapter 1

6

0092660002-06

2017/11/02

Chapter 3

7

8

9

10

KDS-6000BB Installation Manual

Doc No: 0092660002

Document Revision History

Document No. Revised Version Norm

When part of the document needs to be revised, the document has advanced revision number.

The document No. is indicated at the lower right side on the cover and at the left or right side of the

region of each page.

© 2014-2017 Koden Electronics Co., Ltd. All rights reserved.

No part of this publication may be reproduced, transmitted, translated in any form by any means

without the written permission of Koden Electronics Co., Ltd. The technical descriptions contained in

this publication are subject to change without notice. Koden assumes no responsibility for any errors,

incidentals or consequential damages caused by misinterpretation of the descriptions contained in this

publication.

0092660002-06 i

Important Notice KDS-6000BB

Important Notice

• For copy and transcription of this Installation Manual (hereinafter referred to as this

manual), permission from Koden is needed. Koden prohibits the un-authorized copy and

transcription of this manual.

• If this manual is lost or damaged, consult a dealer of Koden or Koden.

• The specification of the products and the contents in this manual are subject to change

without notice.

• The contents displayed on the menu of product may be different from the expression of this

manual. The fonts and shapes of the keys and menus in the illustration may differ from the

actual ones, and some parts may be omitted.

• Koden is not liable for damages and troubles arisen from misunderstanding of the contents

in this manual.

• Koden is not liable for any damages caused by earthquake, lightning, wind and flood

damage and fire for which Koden is not responsible, and actions by third parties, other

accidents, customer’s unintended error/abuse and the use under other abnormal

conditions.

• Koden is not liable for damages of accompaniment (change/loss of memorized content,

loss of business profit, stop of business) arisen from use or failure of our products.

• If the stored data are changed or lost, irrespective of causes of troubles and damages,

Koden is not liable for them.

• Koden is not liable for any damages arisen from malfunction caused by combination of

software and connected equipment in which Koden is not engaged.

ii 0092660002-06

KDS-6000BB For Your Safe Operation

Symbol

Meaning

Mark for warning

This symbol denotes that there is a risk of death or serious injury when

not dealing with it correctly.

Mark for danger of high voltage

This symbol denotes that there is a risk of death or serious injury caused

by electric shock when not dealing with it correctly.

Mark for caution

This symbol denotes that there is a risk of slight injury or damage of

device when not dealing with it correctly.

Mark for prohibition

This symbol denotes prohibition of the specified conduct. Description of

the prohibition is displayed near the mark.

Be careful of high voltage inside

A high voltage, which may risk your life, is used. This high voltage

remains in the circuit after you have powered off switch. To prevent

touching the high voltage circuit inadvertently, the hard cover is

provided to the high voltage circuit and the high voltage caution label is

affixed. Ensure to power off switch for your safety and discharge the

electricity remaining in the capacity before starting to check. An

engineer authorized by our company should inspect and maintain.

Be sure to power off in the boat

If the power switch is inadvertently powered on during work, you will be

electrified. To prevent such accident from occurring, ensure to power off

in the boat and the power of equipment. Furthermore, it is safer to hang

the caution tag described as [Under Work] near the power switch of

equipment.

Be careful of dust

Inhaling dust may cause A respiratory disease. When cleaning the

inside of equipment, be careful not to inhale dust. Wearing a safety

mask is recommended.

Warning

Warning

Caution

Warning

For Your Safe Operation

Symbol used in this Installation Manual

The following pictograms are used in this manual. The meaning of each symbols shall be well

understood and the maintenance and inspection shall be carried out.

Caution items on equipment

0092660002-06 iii

For Your Safe Operation KDS-6000BB

Caution on location of equipment

Do not install the equipment where it is excessively damp and suffers

from excessive water drops.

Measures against static electricity

The static electricity may be generated from the carpet on the floor in

the cabin or clothes made of synthetic fiber. The static electricity may

destroy the electronic parts on the circuit board. Handle the circuit

board, taking the measure of static electricity free.

Caution at installation of a transducers

Install the transducer at the location where it is not affected by bubble

and noise The bubble and noise seriously degrade the performance of

this unit.

Do not disassemble or modify. It may leads to trouble, fire, smoking or

electric shock. In case of trouble, contact our dealer or our company.

In case of smoke or fire, boat power off and the power of this unit. It may

cause fire, electric shock or damage.

Be cautious of remaining high voltage

A high voltage may remain in the capacitor for several minutes after you

have powered off. Before inspecting inside, wait at least 5 minutes after

powering off or discharge the remaining electricity in an appropriate

manner. Then, start the work.

The information displayed in this unit is not provided directly for your

navigation. For your navigation, be sure to see the specified material.

Use the specified fuse. If un-specified fuse is used, it may cause a fire,

smoke or damage.

Whenever transmitting, be sure to submerge the transducer in water

first. If transmitted without submerging the transducer, it may be

damaged.

Caution

Caution

Caution

Warning

Warning

Caution

Caution

Caution

Cautions on handling

iv 0092660002-06

KDS-6000BB Contents

Contents

Document Revision History ............................................................................................................. i

Important Notices ............................................................................................................................ ii

For Your Safe Operation ................................................................................................................ iii

Contents ......................................................................................................................................... v

System Configuration ................................................................................................................... vii

Configuration of Equipment ......................................................................................................... viii

External View ............................................................................................................................. xiv

Specification ............................................................................................................................ xvii

Chapter 1 Installation .................................................................................................................. 1-1

1.1 Installation precautions .......................................................................................................... 1-1

1.1.1 Unpacking of components .......................................................................................... 1-1

1.1.2 Appearance verification of each unit and accessories ................................................ 1-1

1.1.3 Selection of location for installation ............................................................................. 1-1

1.1.4 Laying and connection of cables ................................................................................. 1-2

1.1.5 Confirmation after installation ..................................................................................... 1-2

1.2 Installation of KDS-6000BB Display unit ................................................................................ 1-3

1.3 Installation of KDC-6000BB Processor unit ........................................................................... 1-3

1.4 Installation of an Operation unit ............................................................................................. 1-4

1.4.1 Desk-top installation of Operation unit ....................................................................... 1-4

1.4.2 Flush-mount installation of Operation unit ................................................................. 1-6

1.4.3 Installation of TD position alarm / Ext. Sync. Box ....................................................... 1-7

1.5 Installation of Hull unit ............................................................................................................ 1-8

1.5.1 Installation location of Hull unit ................................................................................... 1-8

1.5.2 Maintenance space for TD tank ................................................................................. 1-9

1.5.3 Installation conditions for a TD tank ......................................................................... 1-10

1.5.4 Example of installation of the TD tank ..................................................................... 1-11

1.5.5 Assembly of Hull unit ................................ ................................ ............................... 1-13

1.6 Wiring .................................................................................................................................. 1-22

1.6.1 Connection of cables to Processor unit ................................................................... 1-22

1.7 List of input/output sentences .............................................................................................. 1-35

1.7.1 Input sentences ....................................................................................................... 1-35

1.7.2 Output sentences ..................................................................................................... 1-35

Chapter 2 Adjustment ................................................................................................................. 2-1

2.1 Setup of frequency of Transducer unit ................................................................................... 2-1

2.1.1 Setting of frequency ................................................................................................... 2-1

2.2 Setting of gain of Transducer unit .......................................................................................... 2-1

2.3 Setup of TX power ................................................................................................................. 2-2

0092660002-06 v

Contents KDS-6000BB

2.3.1 Display of TX power menu ....................................................................................... 2-2

2.4 Train correct ........................................................................................................................ 2-3

Chapter 3 Maintenance ............................................................................................................... 3-1

3.1 Inspection .............................................................................................................................. 3-1

3.2 Cleaning ................................................................ ................................................................ 3-1

3.2.1 Monitor/Processor units ............................................................................................. 3-1

3.2.2 Hull unit ...................................................................................................................... 3-2

3.3 Fuse replacement .................................................................................................................. 3-2

3.4 Diagnostics of troubles .......................................................................................................... 3-2

3.4.1 Necessary information for requesting repair .............................................................. 3-2

3.4.2 System check ............................................................................................................ 3-3

3.4.3 Setting at factory ........................................................................................................ 3-4

3.4.4 Other maintenance menu .......................................................................................... 3-4

3.4.5 Update of programs ................................................................................................... 3-6

3.5 If you suspect a trouble ....................................................................................................... 3-10

vi 0092660002-06

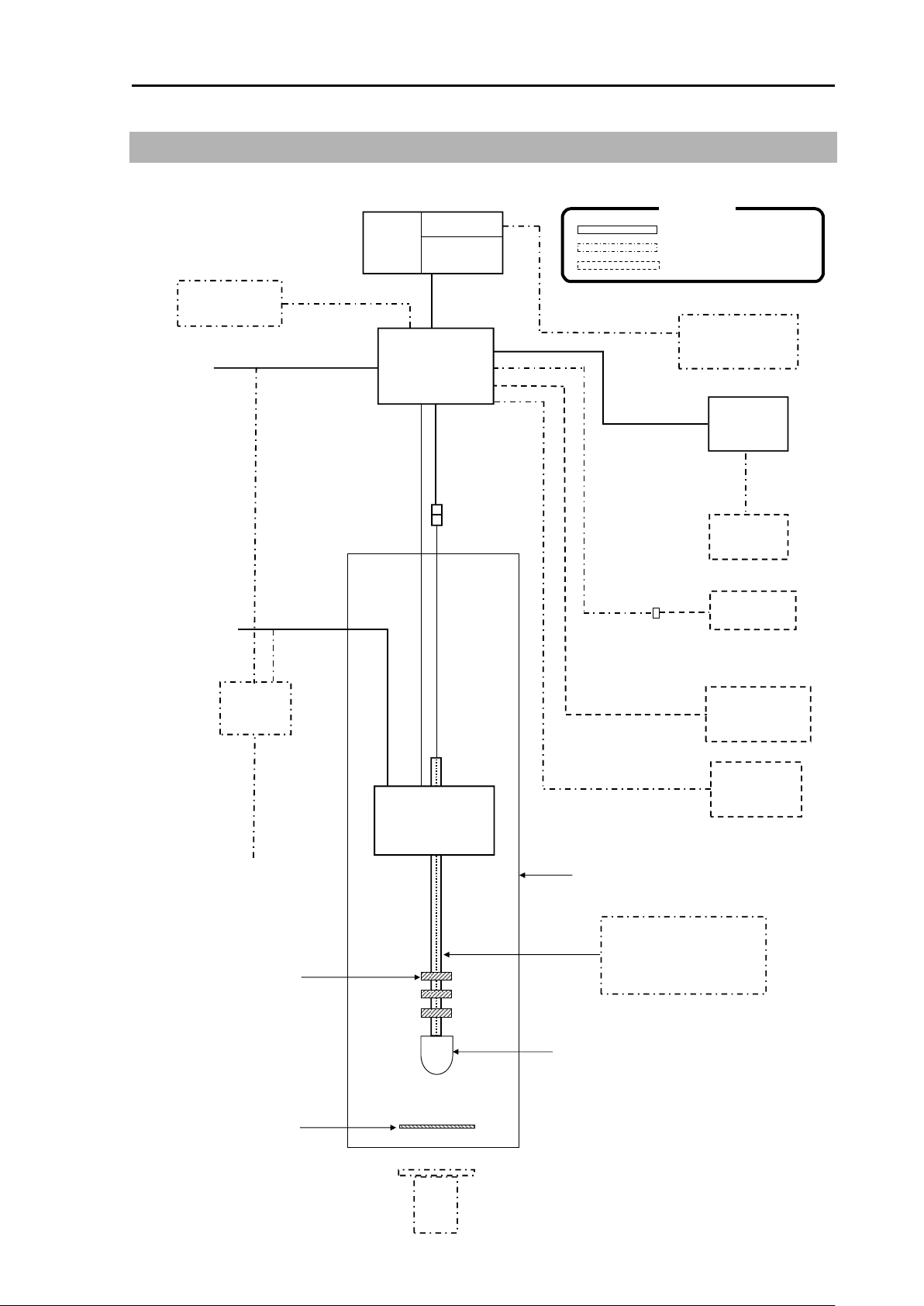

KDS-6000BB System Configuration

Onboard DC

power supply

10.8 to

31.2VDC

J8 (6P)

Remote controller

RCW-14

Display unit

17 inch LCD monitor

is acceptable

Echo sounder

GPS Compass

NMEA Converter

TD shaft

ESR-1504(1411mm)

/ESR-160 32679C-2(1681mm)

/ESR-160 32679C-3(1981mm)

/ESR-160 (40φ-4t-3000mm)

Shaft guide

ESR-1510

ESR-1511

For ESR-1507

Hull unit

DHU-630

TD tank

ESR-1506

/30927C-2

/30927C-3

/ESR-1507

/FRPTD tank set

_G16ELA0010

Gum packing

ESR-1512

Transducer unit

DHU-6302

with 10m cable

Onboard AC

power supply

100/115VAC

200/230VAC

AC power cable

VV-2D8-3M

CW-373-5M

CW-376-5M

POWER (3P)

J6 (8P)

J2 (12P)

J1 (5P)

CW-259-2M

Hull unit

control cable

CW-593-20M

TD position

alarm / Ext.

Sync. Box

JB-36

DOU-620

DOU-620R

(with RCW-14)

CW-576-0.5M

J5 (10P)

External monitor

D-sub15P

Cable for external

monitor

(CW-560-2M is

acceptable)

CW-275-10M

Transducer unit

extension cable

CW-590-15M

18P female

18P male

Processor unit

DPU-610

DPU-610ST

(Sona-ToneTMmodel)

J7 (16P)

15P

Onboard DC

power supply

10.8 to

31.2VDC

Trigger In/Out

CW-413-5M

CW-412-5M

Hull unit

DHU-6301

Power rectifier

PS-010

Operation

unit

External speaker

NP-108

DPU-610ST

(Sona-ToneTMmodel)

Cable for

external speaker

Standard configuration

Option

Owner supply

Legend

System Configuration

Connection Diagram

0092660002-06 vii

Configuration of Equipment KDS-6000BB

No

Name of item

Type

Remark

Weight/

Length

Qty

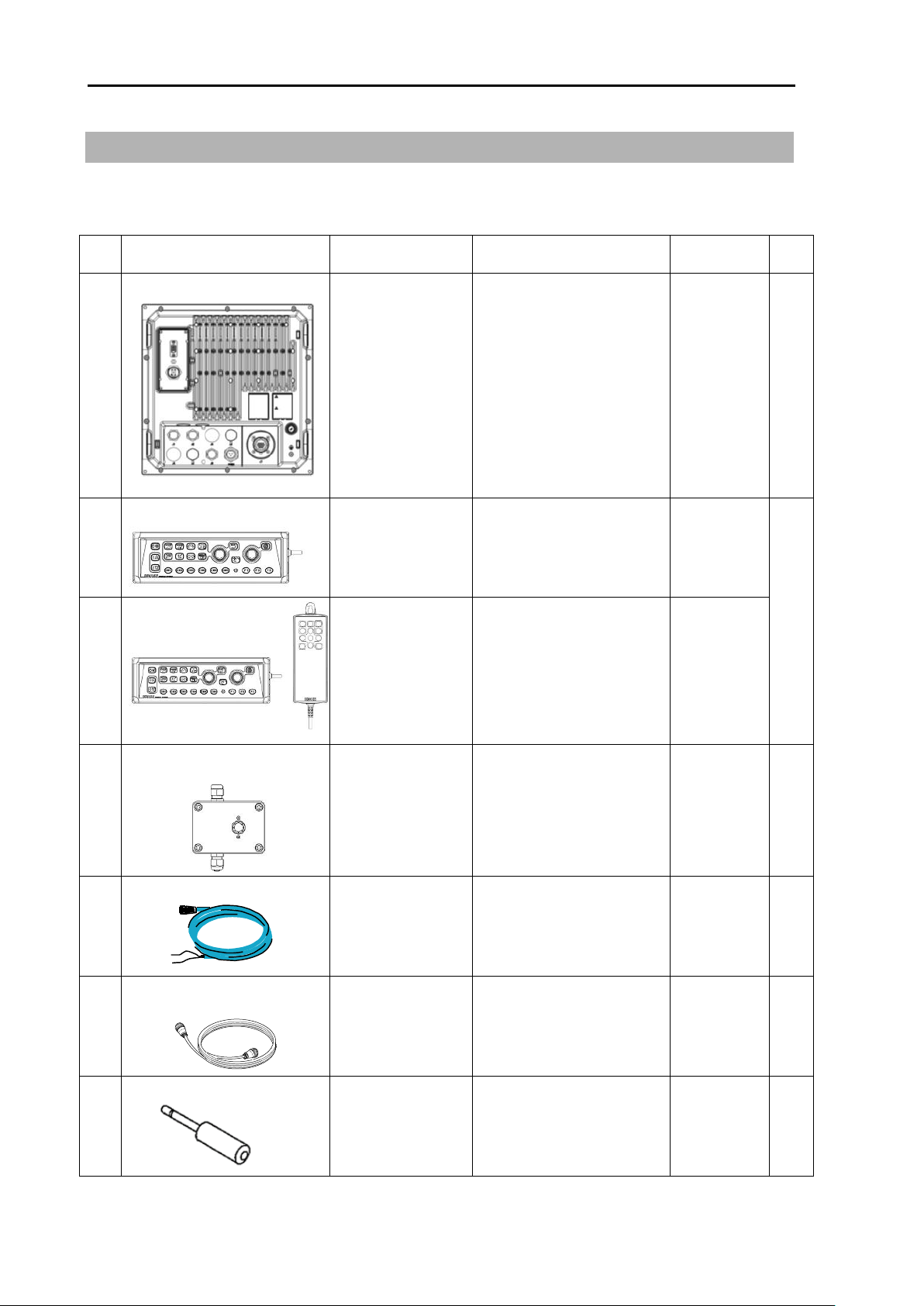

1

Processor unit

DPU-610/

DPU-610ST

(Sona-ToneTM

model)

No display unit

VGA output

5.1kg

1

2-1

Operation unit

DOU-620

With mounting bracket

and 5m cable

1.1kg

1

2-2

Operation unit

DOU-620R

With mounting bracket,

5m cable and Remote

controller (RCW-14 with

5m cable)

DOU-620

1.1kg/

RCW-14

0.31kg

3

TD position alarm / Ext.

Sync. Box

JB-36

With 5m cable

(CW-413-5M/With 5 pin

connector and one end

plain)

5m

1

4

DC power cable

CW-259-2M

With 3 pin connector and

one end plain

2m 1 5

Transducer unit extension

cable

CW-590-15M

With a 18 pin connector

and a 12 pin water

resistant connector

15m 1 6

Audio system plug

MP-105LC-RoHS

For Sona-ToneTM model

1

Configuration of Equipment

Standard Equipment Configuration List

a. DPU-610/610ST (Processor unit), DOU-620/620R (Operation unit)

viii 0092660002-06

KDS-6000BB Configuration of Equipment

No

Name of item

Type

Remark

Weight/Length

Qty

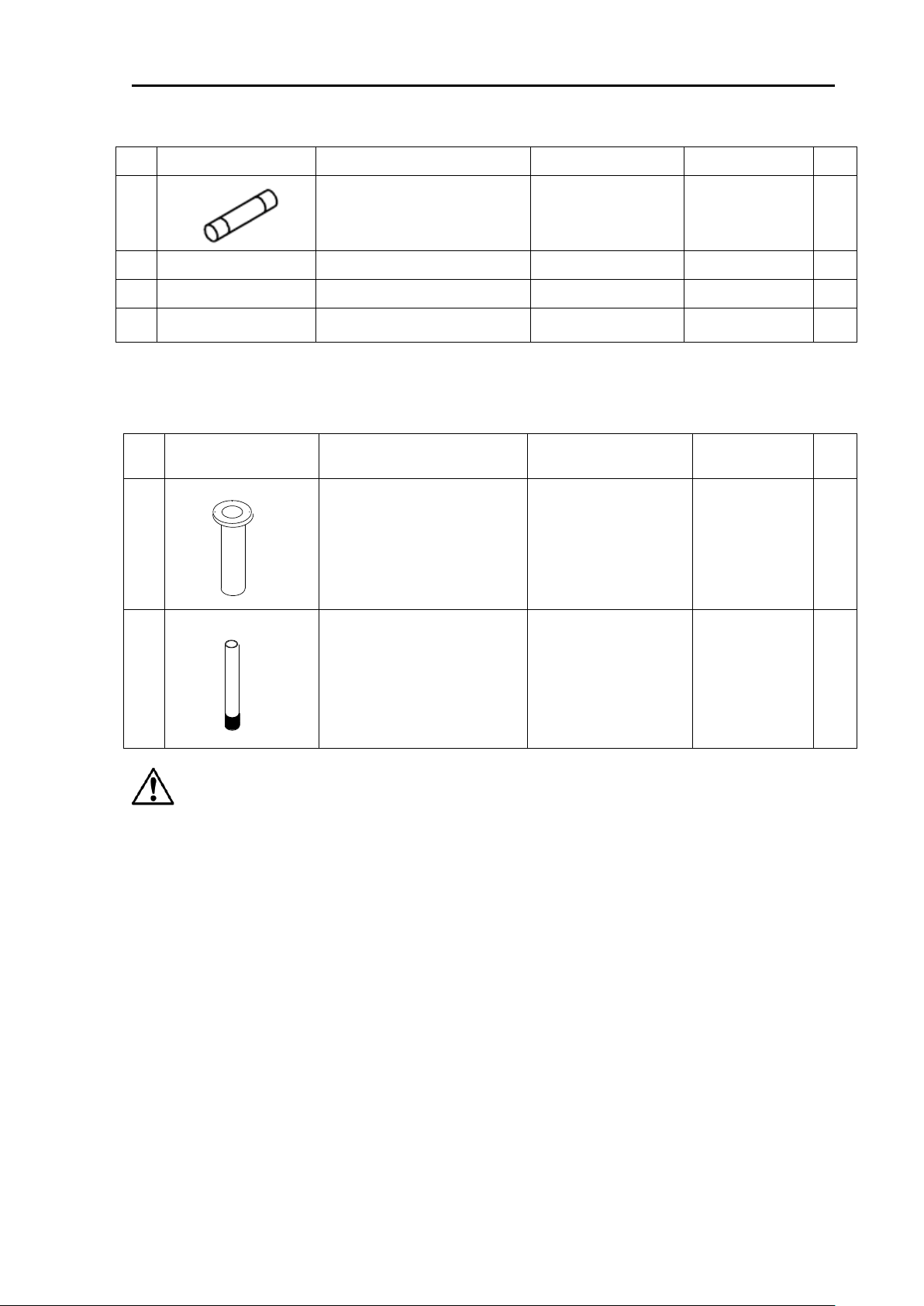

7

Fuse

F-7161-10A/N30C-125V

Cylinder (ø 6.4x30)

Normal fusion type

for main power

3

8

Operation manual

KDS-6000BB.OM.E

English

1

9

Quick Reference

KDS-6000BB.QR.E

English

1

10

Installation manual

KDS-6000BB.IM.E

English

1

No.

Name of item

Type

Remark

Weight/Length

Qty

1

TD tank

ESR-1506 (PVC) 1230mm

30927C-2 (PVC) 1500mm

30927C-3 (PVC) 1800mm

ESR-1507 (FRP) 1500mm

Select according to

equipment.

*Refer to Option list.

9.0kg

11.0kg

13.0kg

12.0kg

1

2

TD shaft

ESR-1504

ESR-160_32679C-2

ESR-160_32679C-3

ESR-160_40φ-4t-3000mm

Select according to

equipment.

*Refer to Option list.

1411mm

1681mm

1981mm

3000mm

1

Caution: TD tank and TD shaft are options.

b. TD tank / TD shaft

0092660002-06 ix

Configuration of Equipment KDS-6000BB

×8

×8

×8

×8

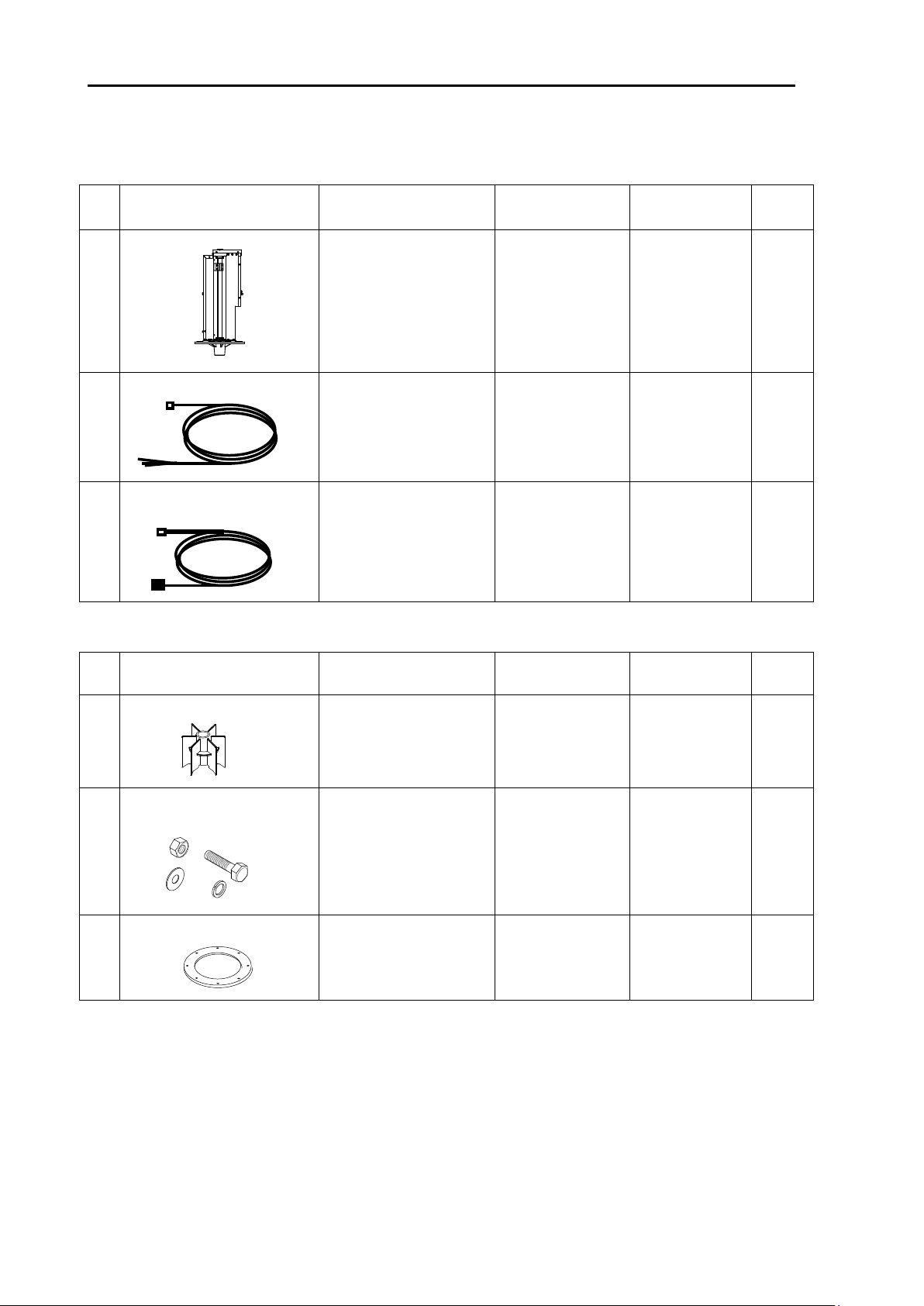

No

Name of item

Type

Remark

Weight/Length

Qty

1

Hull unit

DHU-6301

17.0kg

1

2

DC power cable

CW-275-10M

Cable is built

into the Hull unit

10m

1

3

Hull unit

control cable

CW-593-20M

Cable is built

into the Hull unit

20m

1

d. DHU-6302 (Transducer unit)

Package 2-1

No

Name of item

Type

Remark

Weight/Length

Qty

1

Shaft guide

ESR-1510

3

2

Bolt set

SUS-M16-55-Assy

(M16x55L, 2W16U,

SW16U, N16U)

EACH

8

3

Gum packing for flange

ESR-1512

Gum 1

c. DHU-6301 (Hull unit)

Package 1-1

x 0092660002-06

KDS-6000BB Configuration of Equipment

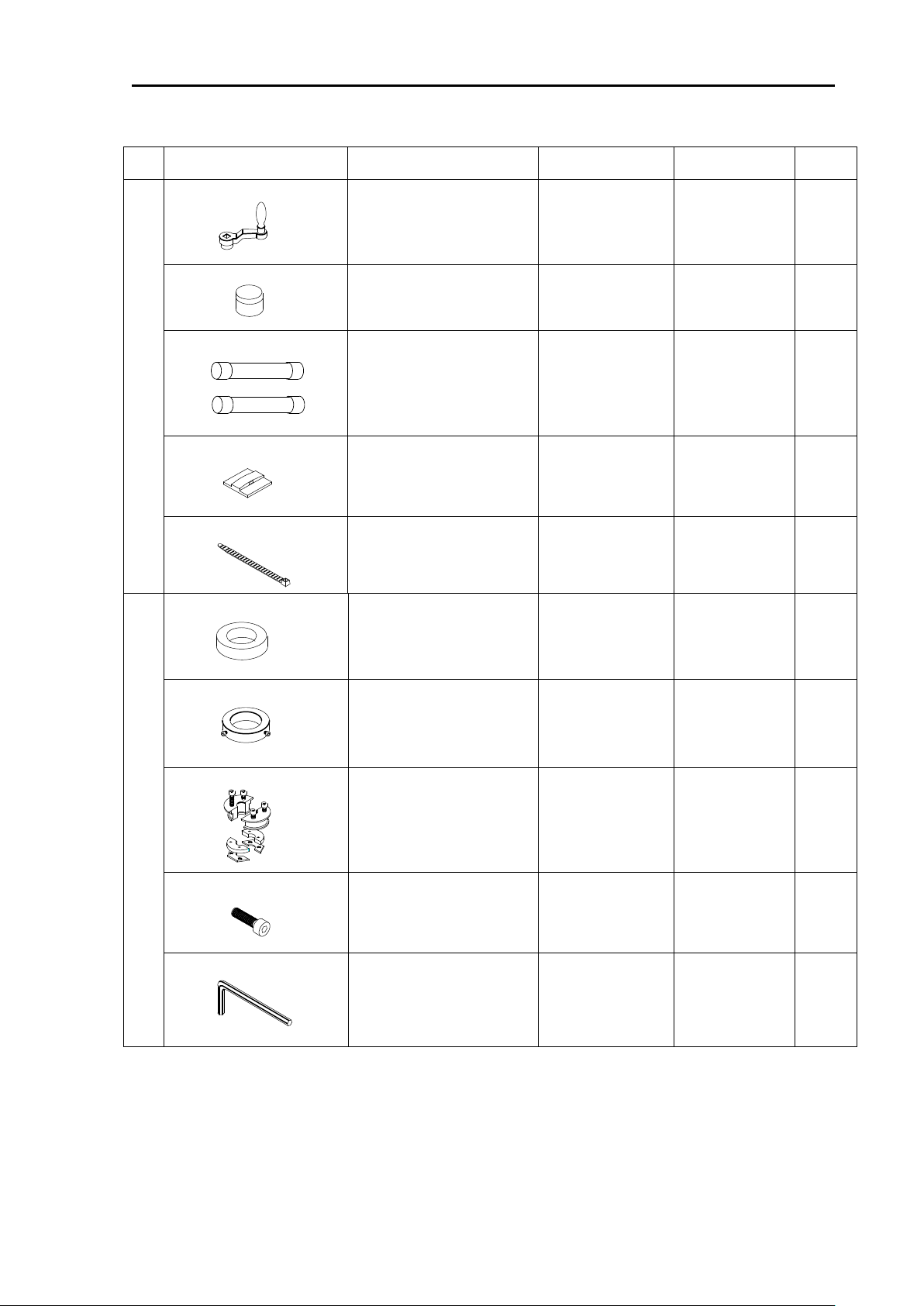

No

Name of item

Type

Remark

Weight/Length

Qty

4

Crank handle

OB-03

1

Grease

100g

1

Fuse

F-7161-4A

F-7161-8A

At input of 12 V

At input of 24 V

EACH

3

ANP base

ANP-1

2

Binding Band

AB-100-1000

2

5

Damper

34924D

1

Fixing collar

32681D

2

Shaft cap

34378D

1

Cap bolt

CB4X10U

4

HEX rod wrench

1.5mm ×1

2.5mm ×1

3.0mm ×1

EACH

1

1 SET

4A

8A

0092660002-06 xi

Configuration of Equipment KDS-6000BB

No

Name of item

Type

Remark

Weight/Length

Qty

1

Transducer unit

DHU-6302

With 10m cable

(With 18 pin

water resistant

connector)

9.0kg

1

2

Bath cork

Bath cork (White) 50g

50g

1

HEX rod wrench

3.0mm ×1

5.0mm ×1

EACH

1

Package 2-2

Caution: Don’t carry the Transducer unit (DHU-6302) by holding its cable. Such

xii 0092660002-06

manner may cause breakage of the equipment.

KDS-6000BB Configuration of Equipment

No

Name of item

Type

Remark

1

Remote controller

RCW-14

With 5m cable, (Assembled the

connection cable into the Operation unit)

2

TD tank

(For *xxxx mm of TD

shaft)

*TD shaft length

ESR-1506

PVC, 1230mm (For 1411mm of TD shaft)

30927C-2

PVC, 1500mm (For 1681mm of TD shaft)

30927C-3

PVC, 1800mm (For 1981mm of TD shaft)

ESR-1507

FRP, 1500mm

FRP TD tank set

(Including Shaft guide)

ESR-1507(1), ESR-1510(2),

ESR-1511(2)

3 Shaft guide

ESR-1510

ESR-1506 / 1507

ESR-1511

ESR-1507 (For FRP TD tank)

4

Power rectifier

PS-010

With 2 pieces of 5A fuse

5

AC power cable

VV-2D8-3M

Both ends plain

6

Connecting cable

CW-372-5M

5m

With 5 pin water resistant connector and

one end plain

CW-373-5M

5m

6 pin water resistant connectors at both

ends

CW-376-5M

5m

With 6 pin water resistant connector and

one end plain

Cable for external monitor

CW-576-0.5M

0.5m

With 10 pin water resistant connector and

D-Sub connector

CW-560-2M

2m

D-Sub 15 pin connectors at both ends

7

Junction box

JB-35

1 input, 3 outputs with CW-376-5M

8

TD shaft

ESR-1504

1411mm

32679C-2

ESR-160_1681mm

32679C-3

ESR-160_1981mm

40φ-4t-3000mm

ESR-160_3000mm

9

Monitor

17inch LCD Monitor

With power cable and signal cable

10

External speaker

NP-108

With 5m cable

(For Sona-ToneTM model)

Option List

0092660002-06 xiii

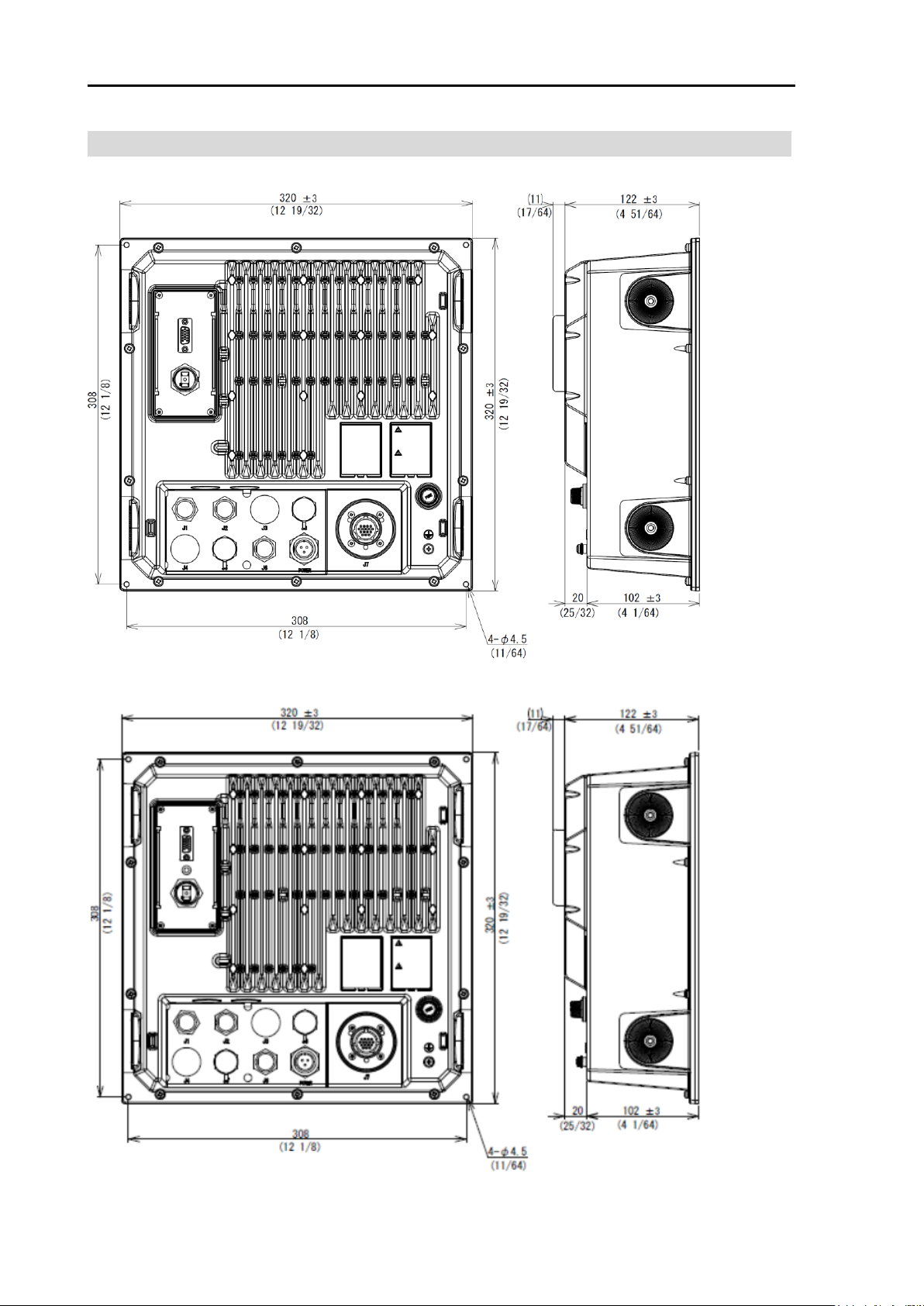

External View KDS-6000BB

Unit: mm (inch)

External View

Processor unit (DPU-610)

Processor unit (DPU-610ST) (Sona-ToneTM model)

Processor unit (DPU-610ST) (Sona-ToneTM model)

xiv 0092660002-06

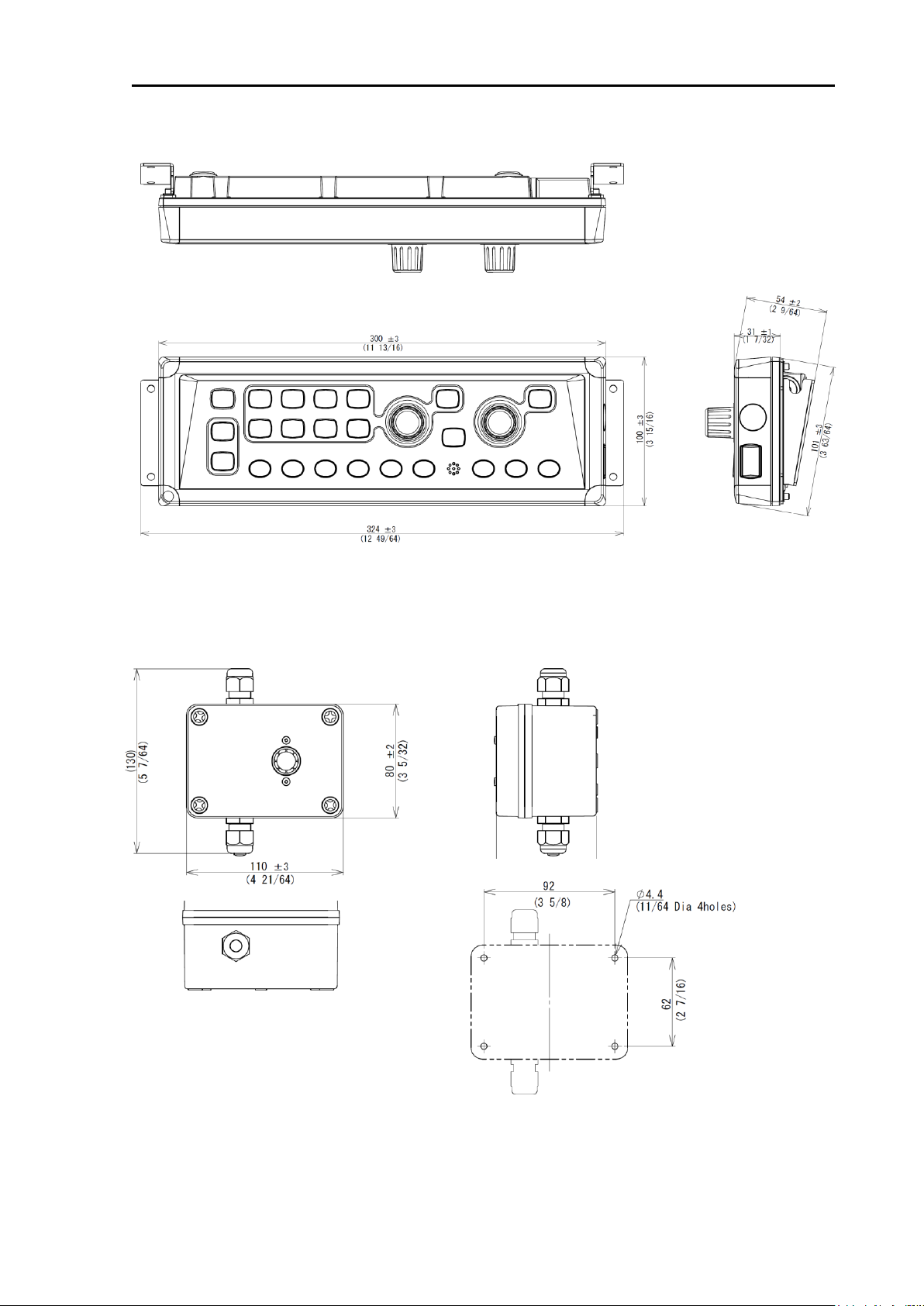

KDS-6000BB External View

Unit: mm (inch)

Installation dimensions

Operation unit (DOU-620)

TD position alarm / Ext. Sync. Box (JB-36)

0092660002-06 xv

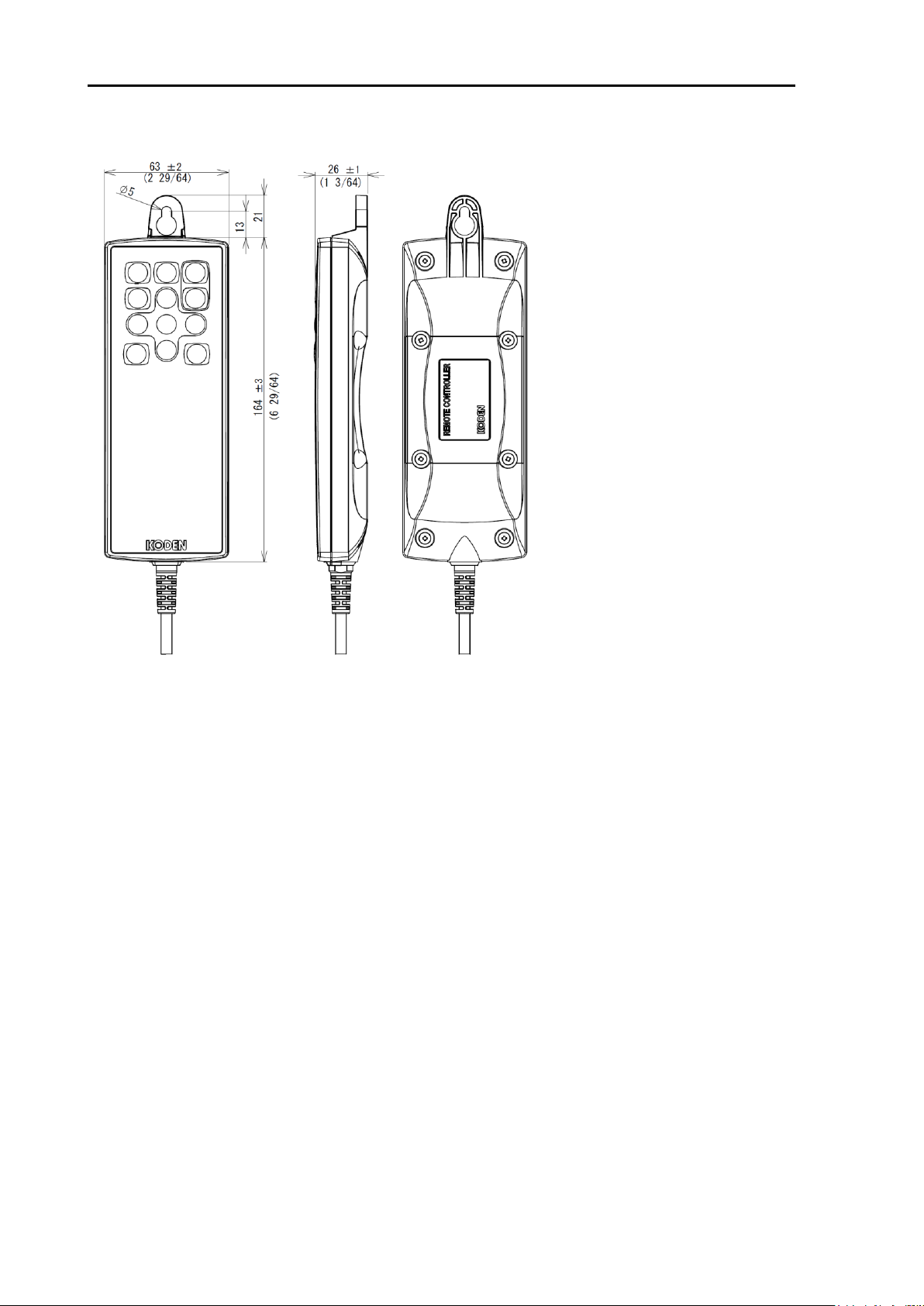

External View KDS-6000BB

Unit: mm (inch)

Remote controller (RCW-14) (Optional)

xvi 0092660002-06

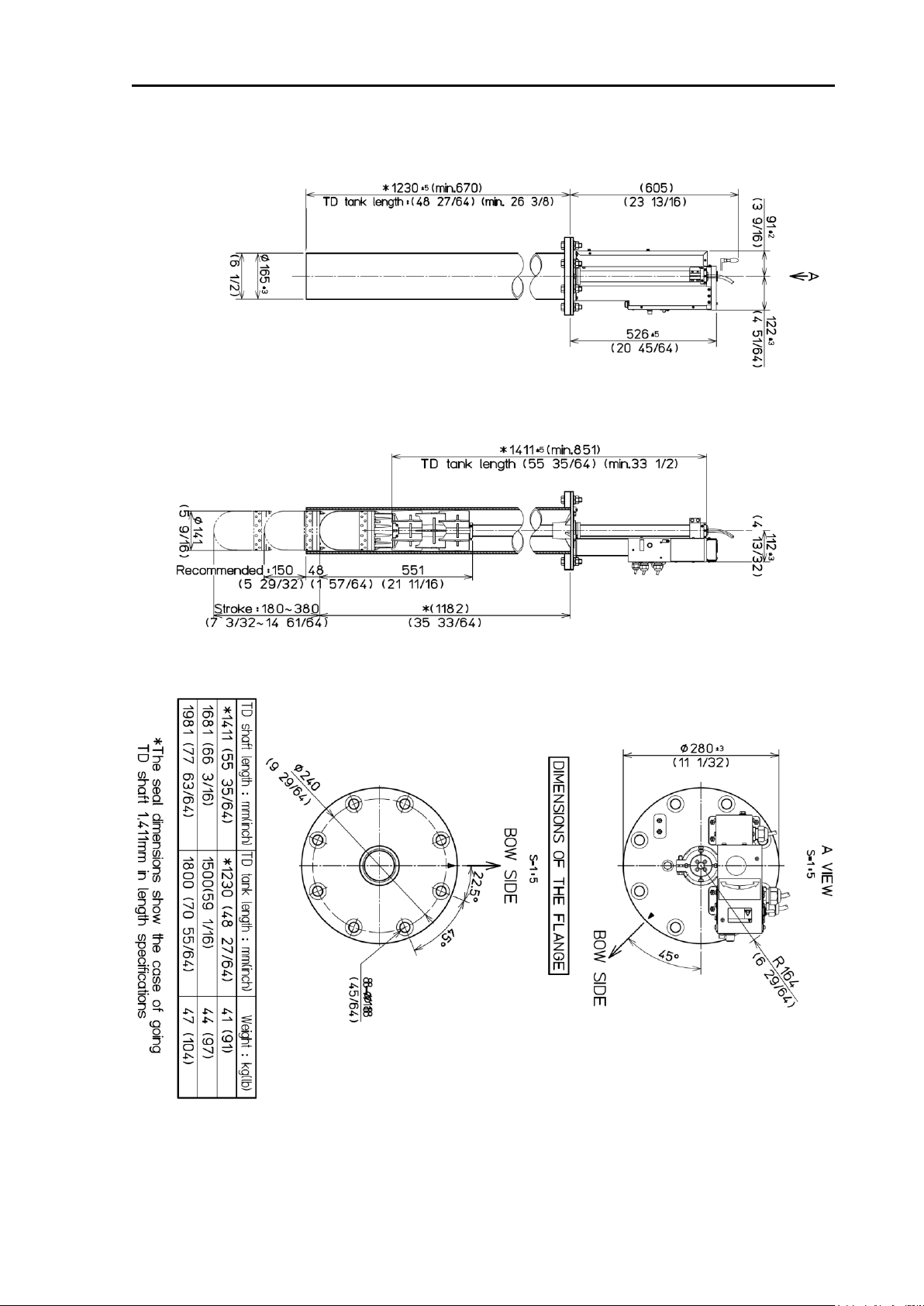

KDS-6000BB External View

Unit: mm (inch)

Hull unit (DHU-630)

0092660002-06 xvii

Specification KDS-6000BB

Sonar mode

Bottom scan mode

Scanning range (m)

Scanning time (sec.) 5º step

Scanning time (sec.) 10º step

Scanning time (sec.) 15º step

Scanning time (sec.) 20º step

Fore, Back, Left, Right

Processor unit

Hull unit

Processor unit

Hull unit

360º Scanning time

(extracts)

Processor unit

Operation unit

Hull unit

DPU-610

DOU-620

DHU-630

Point corner

TD stroke

Basic ranges

Range units

Scanning

sector

angles

Water protection

Bearing center

Presentation modes

Off-center

Target lock

Presentation colors

Reverse, Horizontal, Horizontal + vertical, Marker + horizontal,

Marker + horizontal + vertical

Item

Model

5°step: 5°, 25°, 45°, 85°, 125°, 165°, 205°, 360°

10°step: 10°, 30°, 50°, 90°, 130°, 170°, 210°, 360°

15°step: 15°, 45°, 75°, 105°, 135°, 165°, 225°, 360°

20°step: 20°, 60°, 100°, 140°, 180°, 220°, 260°, 360°

Power supply

8°to 12°

Total1: input / output

10.8 to 31.2 VDC

10.8 to 31.2 VDC

m, ft, fm, l.fm

NMEA0183

DBT、DPT、GGA、GLL、MTW、RMC、TLL、VTG、ZDA

Display resolution

Output power (RMS)

Output frequency

Tilt angle

70 W or less ( 24 VDC)

70 W or less ( 24 VDC)

Output data format and sentences

-15 °C to + 55 °C

16 colors, 8 colors

TVG, Color rejection, Dynamic range, Compass display, Pulse width, Output Power

Control, Noise rejection, A-scope, CM key, Frequency bandwidth, Image correction,

Bearing display, TD auto up, etc.

Input data format and sentences

NMEA0183

GGA、GLL、HDG、HDM、HDT、RMC、VTG、ZDA

Functions

Language

NMEA ports

Operating temperature

Power consumption

Content

1.5 kW

130 to 210 kHz ( 0.1 kHz step)

150 to 380 mm (Recommended value 150 mm)

640 x 480 (VGA)

Any monitor with VGA resolution (Owner supplied)

KDS-6000BB

+5° to -90° (1°step)

ー

10 to 1000 (m), 30 to 3000 (ft), 10 to 600 (fm), 10 to 700 (I.fm)

(8 ranges can be set to users choice)

Display size and type

3°step: 3°, 27°, 45°, 63°, 93°, 117°, 147°, 177°

5°step: 5°, 25°, 45°, 65°, 95°, 115°, 145°, 175°

1°step

English, Japanese, Korean, Traditional Chines, Vietnamese, Spanish, Thai and etc.

Sonar, Off-center, Bottom scan, Echo sounder

Specification

xviii 0092660002-06

KDS-6000BB Chapter 1 Installation

Chapter 1 Installation

1.1 Installation precautions

In order to obtain the maximum performance of the Digital Sonar, this Digital Sonar should be

installed by a qualified engineer in charge of installation and maintenance. Installation

procedures include the following:

(1) Unpacking of components

(2) Inspection of composition units, spare parts, accessories and installation materials.

(3) Checking of supply voltage and current capacity.

(4) Selection of location for installation.

(5) Installation of Display unit, Processor unit, Operation unit and Hull unit.

(6) Attachment of accessories.

(7) Planning and implementation of cable lying and connection.

(8) Coordination after installation.

1.1.1 Unpacking of components

Unpack the components and check that all the items correspond with the description of the

packing list. When a discrepancy or damage has been found, contact the dealer you

purchased of our sales company.

1.1.2 Appearance verification of each unit and accessories

Inspect the appearance of each components and accessories and check that no dents or

damages exist.

If any dents or damages exist and they are believed to be caused by accident during

transportation, contact the transportation and insurance company and consult our sales

company or our dealer nearest to you.

1.1.3 Selection of location for installation

In order to obtain the maximum performance of the unit, it is necessary to install in

consideration of matters described below:

(1) The Processor unit is not waterproof. Do not set it up in the place where water splashes.

(2) Keep enough space for maintenance for the Processor unit and the Hull unit. Especially,

secure enough space at the rear panel where many cables are connected.

(3) The Processor unit, Operation unit and an external monitor shall be set up within the

distance the connection cables are not too stretched.

(4) Keep the equipment as far away from wireless transmitter/receivers as possible.

0092660002-06 1-1

Chapter 1 Installation KDS-6000BB

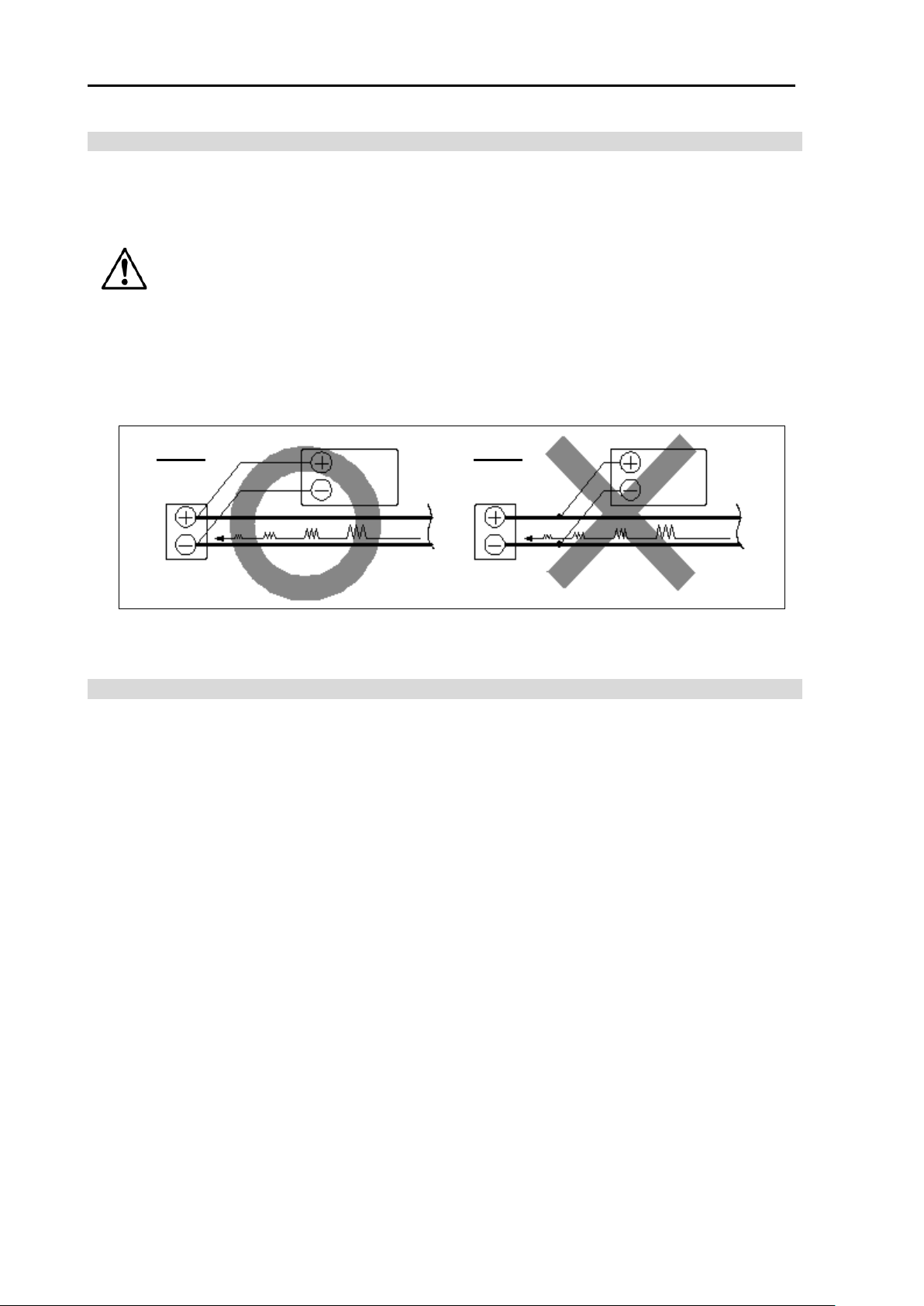

Battery

Good

example

Bad

example

Battery

Display unit, Processor unit or

Display unit, Processor unit

or Hull unit

DPU-610

Noise

Noise

DPU-610

Caution

1.1.4 Laying and connection of cables

(1) Keep the cables related with the Hull unit and the power cable as far away from the cables

of other electronic equipment as possible.

(2) The cabinet of the display unit and the Processor unit shall be securely grounded to the

hull, using the grounding terminal on the rear panel.

All chassis shall be securely grounded as a means of noise

suppression. The – (negative) output is isolated (floating) output.

(3) If you connect the power cable directly to the battery, interference from the other

electronics equipment is expected to be less. (See Fig. 1.1)

Hull unit

or

DHU-630

or

DHU-630

Fig. 1.1 KDS-6000BB Connection of power line

1.1.5 Confirmation after installation

Be sure to confirm the following points before starting. The confirmation is mandatory to

operate the equipment normally:

(1) Is the power voltage in the boat within the appropriate voltage range? Is the current

capacity enough?

(Voltage range: 10.8 VDC to 31.2 VDC measured at the power connector.)

(2) Is the electric current capacity sufficient?

(Power consumption: Processor unit (DPU-610)/70W, Hull unit (DHU-630) /70W)

(3) Is the cabling from the Hull unit correct? Is the wiring shorted?

1-2 0092660002-06

Loading...

Loading...