Page 1

Kodak ImageLite ESY Scanner Film

Kodak Gen 5

GAI Film

Kodak ImageLite IRF Scanner Film

Kodak Gen 5 GIR Film

Technical Information Instruction Sheet – TI2407

August 2006

Features / Customer Product Specifications

Kodak ImageLite scanner films and Gen 5 films are designed for use with a wide range of today's

electronic dot-generating color scanners, image recorders, imagesetters and contact-screen scanners. All

are cut to "true-fit" scanner sizes to match dimensions specified by scanner manufacturers. These

products can be used in most conventional rapid-access developers, such as Kodak RA 2000 developer

and replenisher. It should be possible to achieve satisfactory results in most other rapid-access type

developers. These films are coated on a dimensionally stable Estar base with antistatic and surface

properties to ensure dependable transport and handling behavior.

ESY/GAI • A high contrast, blue sensitive film for use on electronic-dot generation

(EDG) color or monochrome scanners.

• Optimized for use with raster scanning output devices using an argonion laser (488 nm) as the exposing source.

IRF/GIR • High contrast, infrared sensitive film.

• Recommended for use with scanners and recorders that use a laser

diode, emitting light in the infrared area (780 nm).

• Wide exposure and development latitude.

Safelight Recommendations

Safe handling times at various safelight-to-film plane distances can be easily determined by exposing the

films to a screen tint and using a card to step off various amounts of safelight exposure following image

exposure. An increase in dot size or a change in density indicates excessive safelight exposure. For

information on performing safelight tests, see Kodak’s Publication No. K-4, "How Safe is Your Safelight?"

Kodak ImageLite ESY Scanner Film / Kodak Gen 5 GAI Film

This film can be handled under amber or orange-yellow safelight illumination

produced by the following sources:

Page 2

• Deluxe cool-white fluorescent tubes filtered with dark amber safelight sleeves, such as the No.

M58V19.055W (55 wall) sleeve available from Illumination Technology, Inc.

• EncapSulite KY safelight or equivalent safelight.

• A 15-watt tungsten bulb filtered with Rohm and Haas plexiglas amber 2422 material. This material can

also be used to filter tungsten light that enters the work area through the windows. Note: Plexiglas

amber 2422 material is not recommended for use with fluorescent tubes when Kodak ImageLite

scanner film is used.

Can also be handled under most orange or red safelight illumination sources. Keep the film at least 4 feet

(1.2 metres) from the safelight.

Kodak ImageLite IRF Scanner Films / Kodak Gen 5 GIR Film

Use an EncapSulite T20/ND.75 safelight available from EncapSulite International Ltd. or equivalent. Keep

the film at least 1.2 metres (4 feet) from the safelight. Do not expose the film to safelight illumination for

longer than two minutes.

Storage

Keep unexposed film and processed film in a cool, dry place, preferable at a temperature of 70° F (21° C)

or lower and 50% RH. Process film as soon as possible after exposure.

Exposure

Variations in equipment and in methods of use preclude exact exposure recommendations. Minor

adjustments may have to be made in the light intensity of the exposing source when changing from one

emulsion to another. The film will produce consistent results within a particular emulsion number after

the optimum exposure has been determined by trial. Follow the exposure procedures recommended by

the scanner manufacturer.

Contact Applications Using ESY/GAI Film

Exposing with a variable-voltage point-source 100-watt tungsten-type lamp, operated at 8 volts, at a

distance of 5 feet (1.5 metres) to provide 0.5 footcandles of illumination at the film plane, use a trial

exposure of 7 seconds.

Page 3

Mechanized Processing

Notice: Observe precautionary information on products labels and on the Material Safety Data Sheets.

This film can be processed in equipment with mechanical switches or ultrasonic sensors. More details

are available from your Kodak representative or distributor. The following recommendations provide a

range of acceptable developer times and temperatures. Higher development temperatures require

shorter development times. Generally, times and temperatures near the center of the specified range will

produce optimum results for the product. However, criteria other than the development time may dictate

the acceptable processing speed for any particular processor. Within the range given, a development

time should be selected that will provide sufficient fixing, washing and drying of the product. Use Kodak

RA 2000 developer and replenisher (1:4 dilution) at 85 - 105° F (30 - 40° C) and a development range

of 20 - 45 seconds. Replenishment rates are included in the table below:

Average D-max Area Basic Replenishment Rates

10% 0.12 – 0.15 mL/sq. in. (185 – 235 mL/sq. m)

20% 0.20 mL/sq. in. (310 mL/sq. m)

50% 0.30 mL/sq. in. (465 mL/sq. m)

80% 0.48 mL/sq. in. (745 mL/sq. m)

100% 0.60 mL/sq. in. (930 mL/sq. m)

The starting point recommendation for development is 30 seconds at 95° F (35° C). A 1:2 developer

dilution ratio may be used when intermixing with Kodak Recording 2000 films. Use Kodak 3000 fixer

and replenisher, part A (1:3 dilution). The basic replenisher rate is 0.35 mL/sq. in. (545 mL/sq. m). Part B

(hardener) may be used at dilutions up to 1:40 (using

encountered, or where additional protection from post-process abrasions are required. For batch type

processors where ready-to-use solutions are needed, Kodak RA 2001 developer and replenisher and

Kodak RA 3001 fixer and replenisher are recommended. If utilization rate will provide at least one tank

turnover per week, Kodak RA 2050 developer replenisher can be used with lower replenishment rates.

diluted

fixer) where film drying problems are being

© Kodak, 2006. Kodak and Gen 5 are trademarks of Kodak.

Page 4

Kodak ImageLite ESY Scanner Film

Kodak Gen 5

GAI Film

Kodak ImageLite IRF Scanner Film

Kodak Gen 5 GIR Film

Technical Information Data Sheet – TI2407

August 2006

1. Support

Dimensionally Stable Support

ESY 4 mil (0.004 in., 0.10mm) Estar base

2. Reciprocity

With recommended processing, the reciprocity speed change is negligible (1/3-photographic stop or

less) within exposure range of 1/1000 second to 1 billionth second; there is no change in contrast.

3. Dimensional Stability

Dimensional stability is an all-inclusive term. In photography, it applies to size changes caused by

changes in humidity and in temperature, and by processing and aging. The dimensional properties of the

Estar base may vary slightly in different directions within a sheet; the differences that may exist, however,

are not always aligned with the length and width directions:

Differences in size change between length and width should be within 10 percent of each other.

Thermal Coefficient of Linear Expansion

Unprocessed or Processed 0.001% per ° F (0.0018% per ° C)

Page 5

Humidity Coefficient of Linear Expansion

Unprocessed 0.0017% per % RH

Processed 0.0016% per % RH

Processing Dimensional Change

Dependent on drying conditions

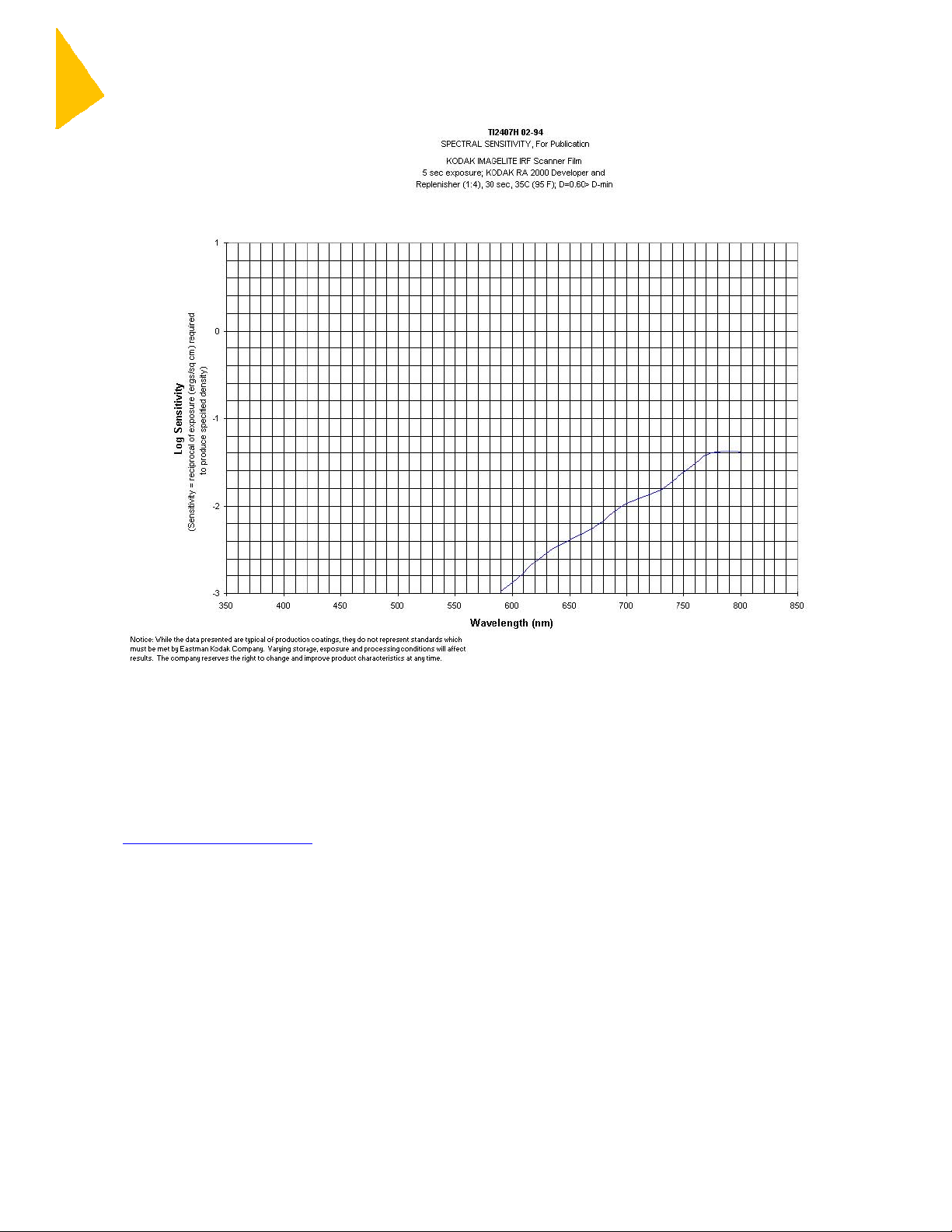

4. Graphs1

How do the graphs on the following pages correspond to the letters below? There are 3 graphs, but only

an A and a B. The titles don’t match, either.

Using Kodak RA 2000 developer and replenisher (1:4)

Characteristic

A. Kodak ImageLite ESY scanner film/Kodak Gen 5 GAI film (3-96)

B. Kodak ImageLite IRF scanner film/ Kodak Gen 5 GIR film (2-94)

Spectral Sensitivity

A. Kodak ImageLite ESY scanner film/ Kodak Gen 5 GAI film (4-96)

B. Kodak ImageLite IRF scanner film/ Kodak Gen 5 GIR film (2-94)

1

NOTICE: While the data presented are typical of production coatings, they do not represent standards

that must be met by Kodak. Varying storage, exposure, and processing conditions will affect results. The

company reserves the right to change and improve product characteristics at any time.

Page 6

Page 7

Page 8

The Kodak products mentioned in this document may not all be available in all regions or countries. If you

have questions or need assistance, contact your local Kodak representative or visit our website:

http://graphics.kodak.com.

The contents of this publication are subject to change without notice.

© Kodak, 2006. Kodak, Estar, Gen 5, and ImageLite are trademarks of Kodak.

Loading...

Loading...