Page 1

Operator's Manual A-62032

Part No. 3C4923

KODAK

IMAGELINK

TM

Printer 7

BUSINESS IMAGING SYSTEMS

Page 2

The

Kodak Imagelink

Paper Supply, CAT No. 859 1943, the

and the

with the following standards and bear therefore a CE mark:

following the provisions of the applicable directives:

Kodak Imagelink

Printer 7, CAT No. 887 9405, with the

Kodak Imagelink

Printer 7 Sorter Interface, CAT No. 199 7964, are in conformance

EN 55022 Class B/1987

EN 50082-1/1992

EN 60555-2/1987

EN 60950/1993

89/336/EEC and amendments

73/23/EEC and amendments.

Printer 7 Sorter, CAT No. 864 6754,

Kodak Imagelink

Printer 7

LE PRESENT APPAREIL NUMERIQUE N’EMET

PAS DE BRUITS READIOELECTRIQUES

DEPASSANT LES LIMITES APPLICABLES AUX

APPAREILS NUMERIQUES DE LE CLASSE A

PRESCRITES DANS LE REGLEMENT SUR LE

BROUILLAGE RADIOELECTRIQUE EDICTE

PAR LE MINISTERE DES COMMUNICATIONS

DU CANADA.

This equipment complies with the requirement in part 15 of FCC Rules for a class A

computing device. Operation of this equipment in a residential area may cause unacceptable

interference to radio and TV reception requiring the operator to take whatever steps may be

necessary to correct the interference.

(Canada only)

This digital apparatus does not exceed the Class A limits for radio noise emissions from

digital apparatus as set out in the interface - causing equipment standard entitled “Digital

Apparatus,” ICES - 003 of the Department of Communications.

THIS DIGITAL APPARATUS DOES NOT

EXCEED THE CLASS A LIMITS FOR RADIO

NOISE EMISSIONS FROM DIGITAL

APPARATUS AS SET OUT IN THE RADIO

INTERFERENCE REGULATIONS OF

THE CANADIAN DEPARTMENT OF

COMMUNICATIONS.

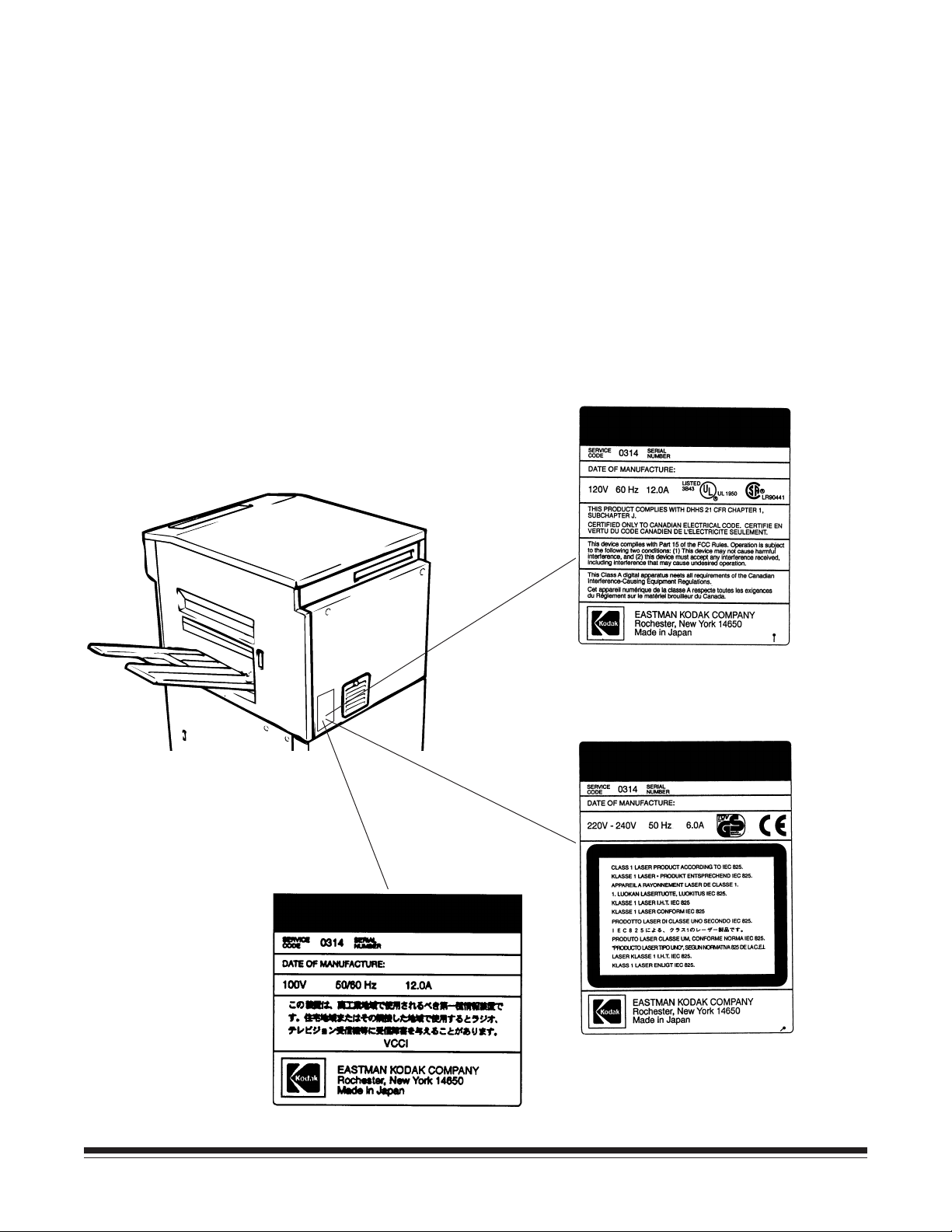

WARNING: The use of controls or adjustments or the performance of procedures other than

those specified in this publication may result in hazardous radiation exposure. This product

complies with 21 CFR, Chapter 1, Subchapter J, as indicated on the label located on the rear

cover of the printer.

A-62032 November 1996 i

Page 3

Warning and safety information

Locate the printer in a well-ventilated room.

A negligible amount of ozone is generated during

normal operation of this printer. An unpleasant

odor may, however, be created in poorly ventilated

rooms during extensive printer operations. For a

comfortable, healthy, and safe operating

environment, it is recommended that the room be

well-ventilated.

A dedicated electrical socket-outlet shall be

installed near the printer and shall be easily

accessible.

KODAK

IMAGELINKTM Printer 7

KODAK

IMAGELINKTM Printer 7

KODAK

IMAGELINKTM Printer 7

ii November 1996 A-62032

Page 4

Section 1 Overview

Introduction

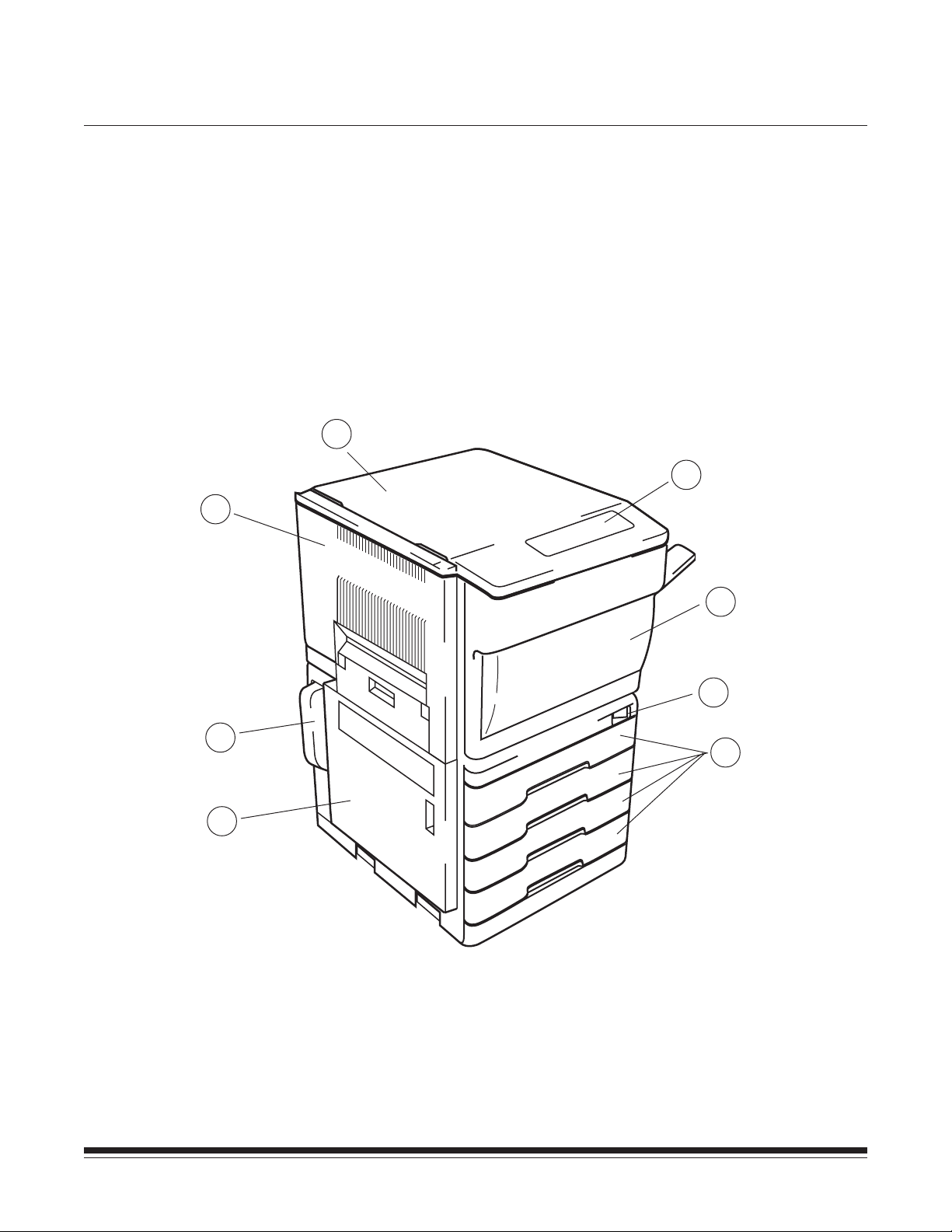

Location/Description of parts—Front

3

We are pleased that you have purchased the

Printer 7. We feel confident that you will find your new laser printer

more than adequate to meet your printing needs.

In order to make the best use of the printer, we recommend that

you read the information in this manual carefully and follow the

instructions contained herein. This manual, along with the

appropriate

Node manuals, provides information on operating the printer,

setting up the printer, operator maintenance, and instructions on

how to clear a jam.

4

Kodak Imagelink

Digital Workstation and Network

Kodak Imagelink

5

6

2

1

1. Paper Supply Cabinet Door

2. Toner Collection Bottle

3. Printer Left Cover

4. Printer Top Cover

5. Operation Panel (See page 2-1 for detailed

drawing.)

7

8

6. Printer Front Cover

7. Power ON/OFF Switch

8. Paper Cassette (Universal Cassette)

A-62032 November 1996 1-1

Page 5

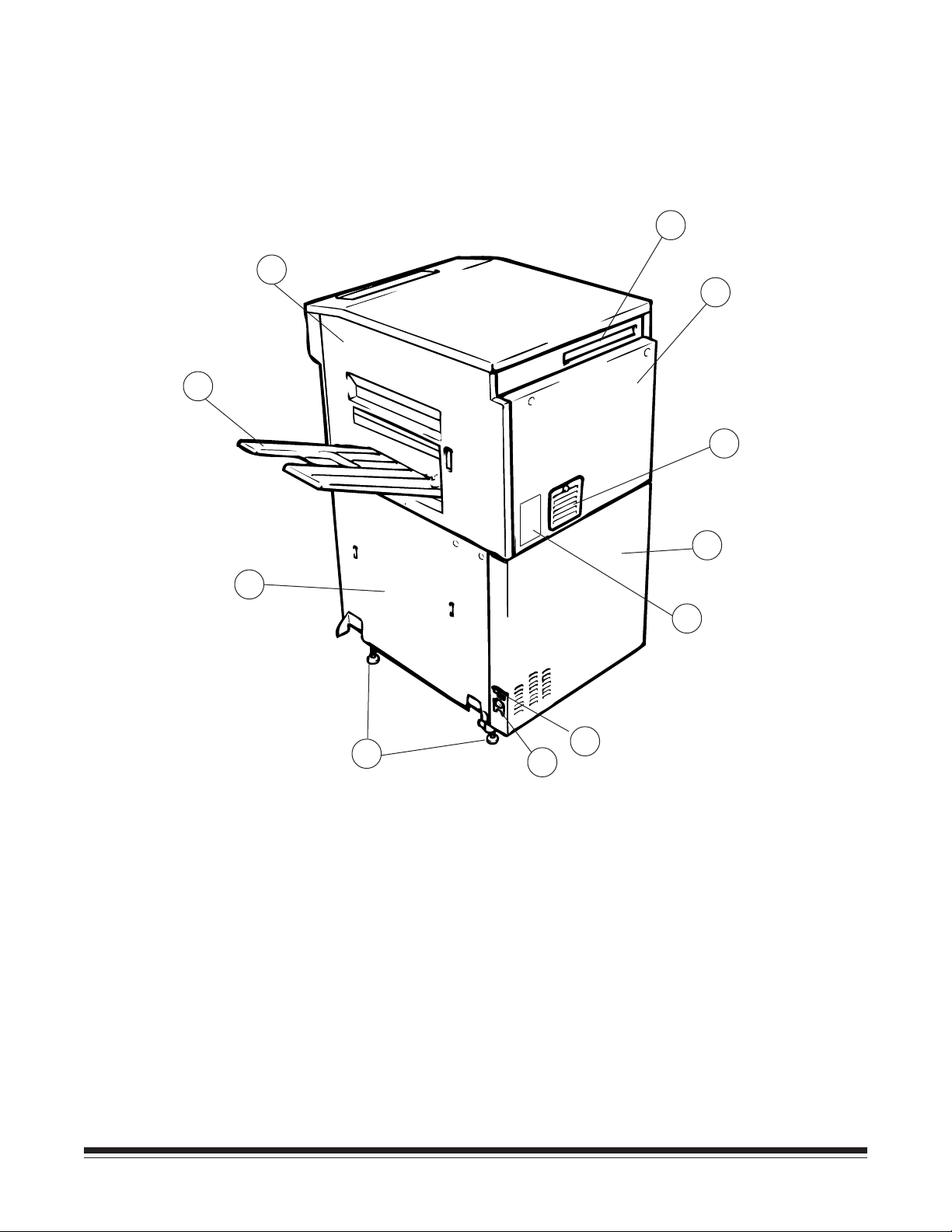

Location/Description of parts—Back

11

10

12

13

14

15

9

19

9. Paper Supply Cabinet Right Cover

10. Paper Exit Tray

11. Printer Right Cover

12. Printer Cable Interface Socket

13. Printer Rear Cover

14. Image Transfer/Paper Separator Ozone

Filter Cover

16

17

18

15. Paper Supply Cabinet Rear Cover

16. Dataplate

17. Circuit Breaker

18. Power Cord Socket

19. Adjustable Feet

1-2 November 1996 A-62032

Page 6

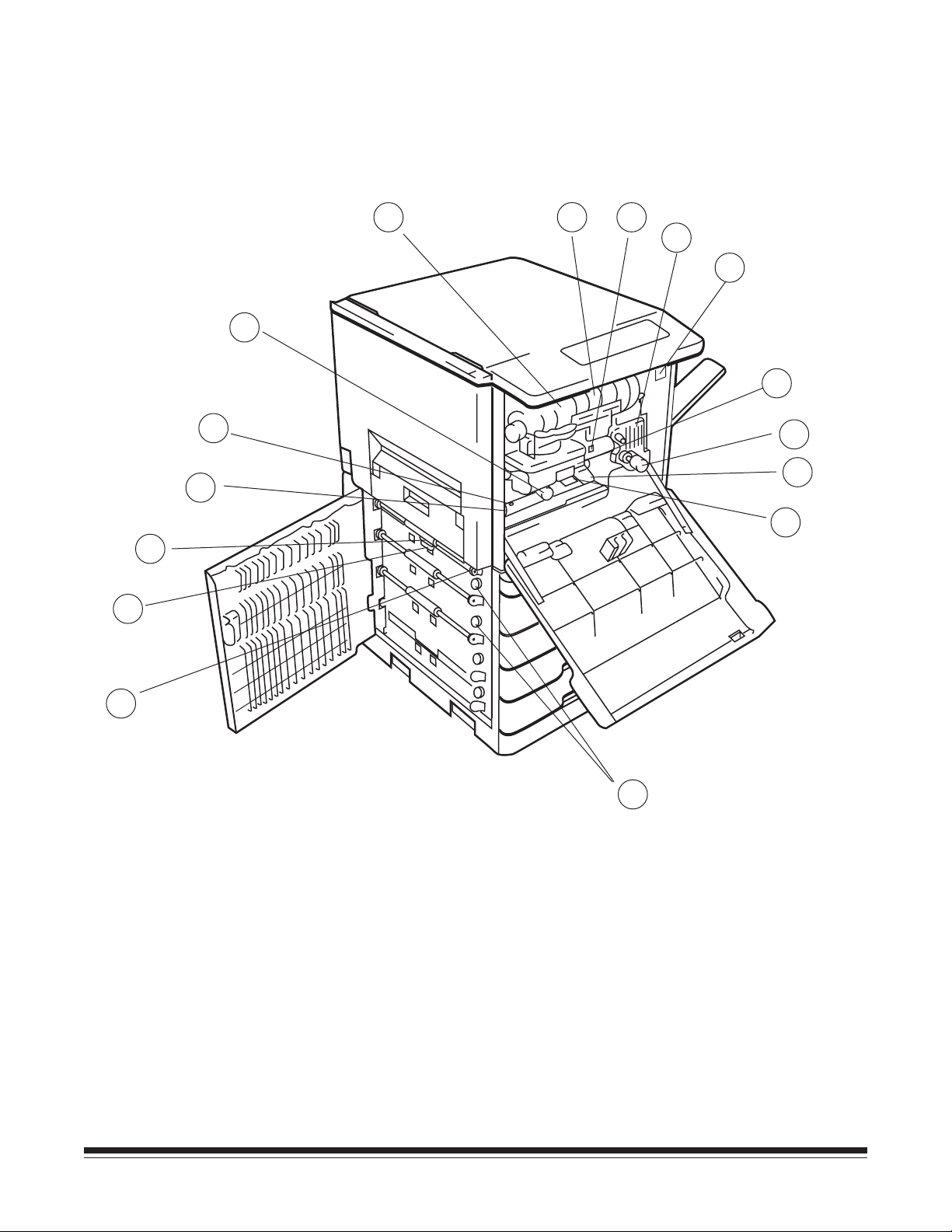

Location/Description of parts—Inside

21

22

23

24

25

26

27

28

29

30

31

32

33

34

20

20. Vertical Transport Roller Knob (M6)

21. Separator Roller

22. Feed Roller

23. Transport Roller Knob (M5)

24. Transport Section Release Plate (M4)

25. Synchronizing Roller Knob (M3)

26. Toner Bottle Holder

27. Toner Bottle

35

28. Drum Charge Ozone Filter

29. Fusing Unit

30. Mechanical Print Counter

31. Electrophotographic (EP) Unit

32. Fusing Roller Knob (M1)

33. Release Lever (M2)

34. Image Transfer/Paper Separator Charger

35. Paper Take-Up Section Release Knob

A-62032 November 1996 1-3

Page 7

Section 2 Operation

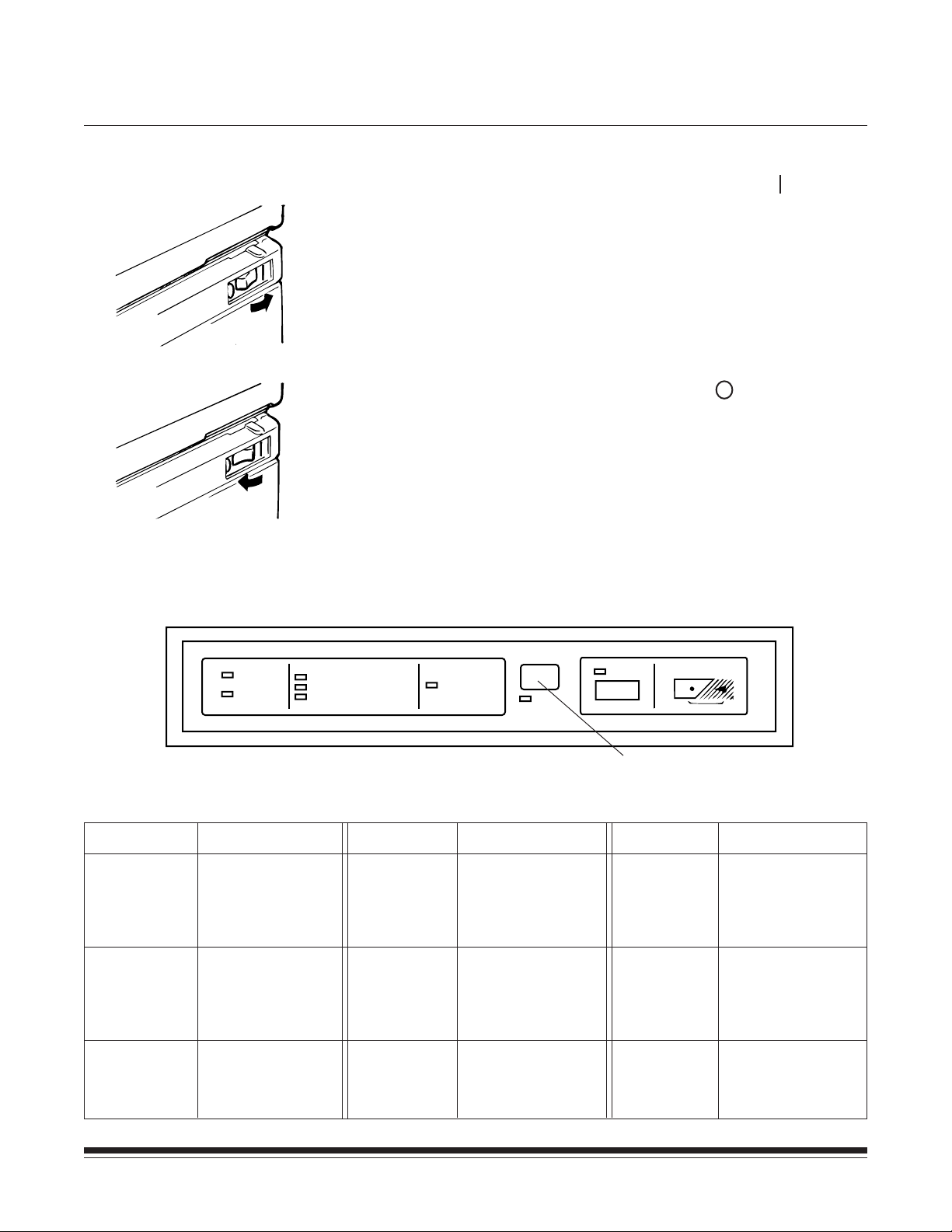

Turning the printer on and off

Operation panel

Check that the power cord has been connected to the printer and

outlet; turn the power ON/OFF switch to its right side ( side) to

turn the power on.

Turn the power ON/OFF switch to its left side ( side) to turn the

power off.

The operation panel contains the Printer Status and Error Code

displays, and the Test controls.

Printer Status

Ready

Busy

Paper Jam

READY

BUSY

PAPER JAM

TONER EMPTY

USED TONER BOTTLE FULL

Indicates

Printer able

to accept

new print

commands

Currently printing,

unable to accept

new print

commands

Clear paper jam

PAPER EMPTY

SELECTED

TRAY

Printer Status

Toner Empty

Used Toner

Bottle Full

Paper Empty

Selected

Tray

CHECK

Error Code Display

(2 characters appear,

see Appendix C)

Indicates

Replace with a

new Toner Bottle

Replace with a

new Used Toner

Collection Bottle

Paper cassette you

are using is empty,

refill paper.

TEST

CANCEL

Test Control

Test

Cancel

Functions

Press to start Test

Print function only

when the Ready

indicator is lit.

Press to cancel

Test Print

function.

A-62032 November 1996 2-1

Page 8

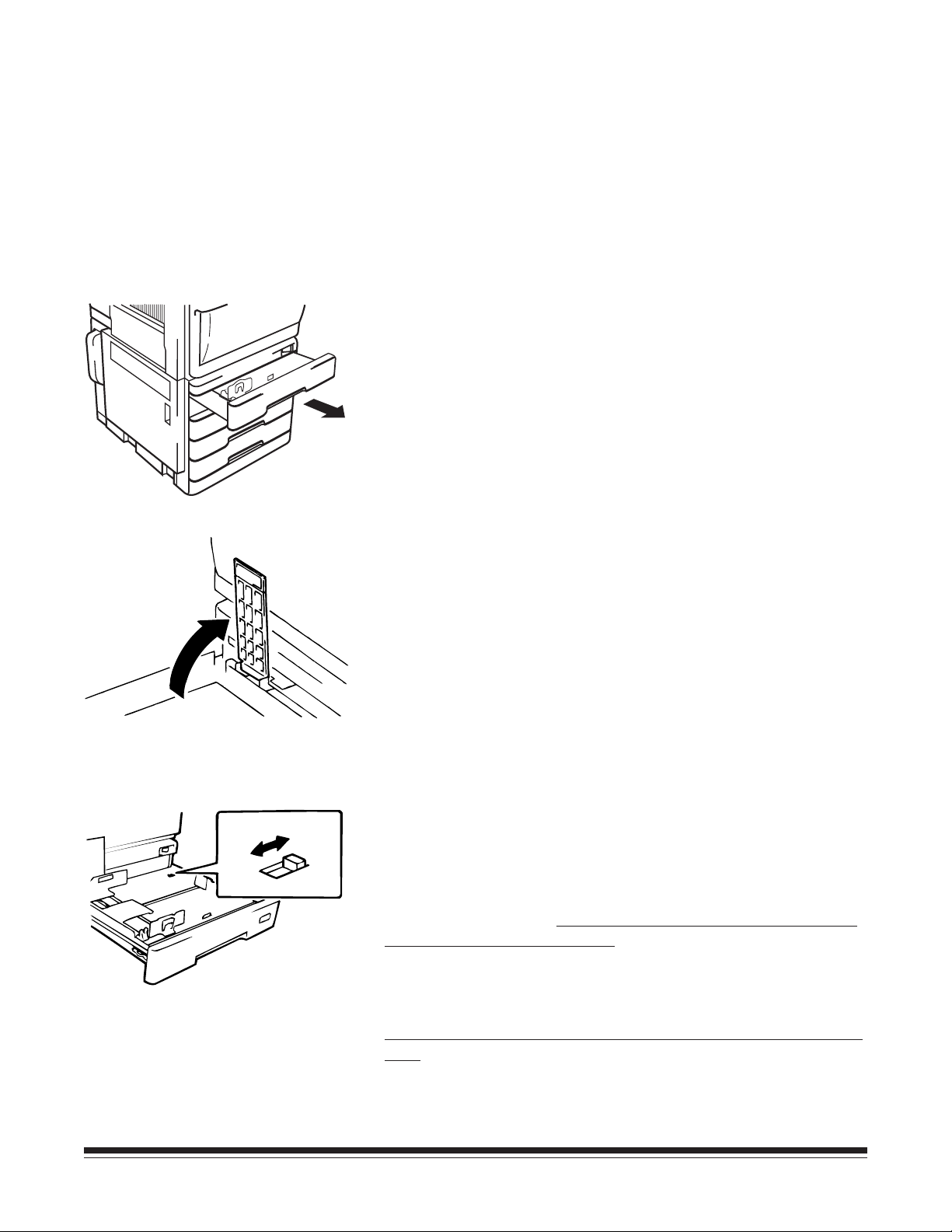

Loading paper

This laser printer supplies paper to the printer by feeding paper into

the unit automatically from one of four universal cassettes.

Universal cassette

The universal cassette can be used to feed the following paper

sizes: A3T, B4T, A4T/Y, A5T, B5T/Y, B6T, LedgerT, LegalT,

LetterT/Y, ExecutiveT/Y, InvoiceT, 7 x 8 1⁄2". (T means lengthwise

feeding and Y means crosswise feeding.) See Appendix A for more

information on paper sizes. 350 sheets of paper can be loaded in

each of the 4 universal cassettes.

NOTE: B5Y and B6T feed from upper 3 cassettes only.

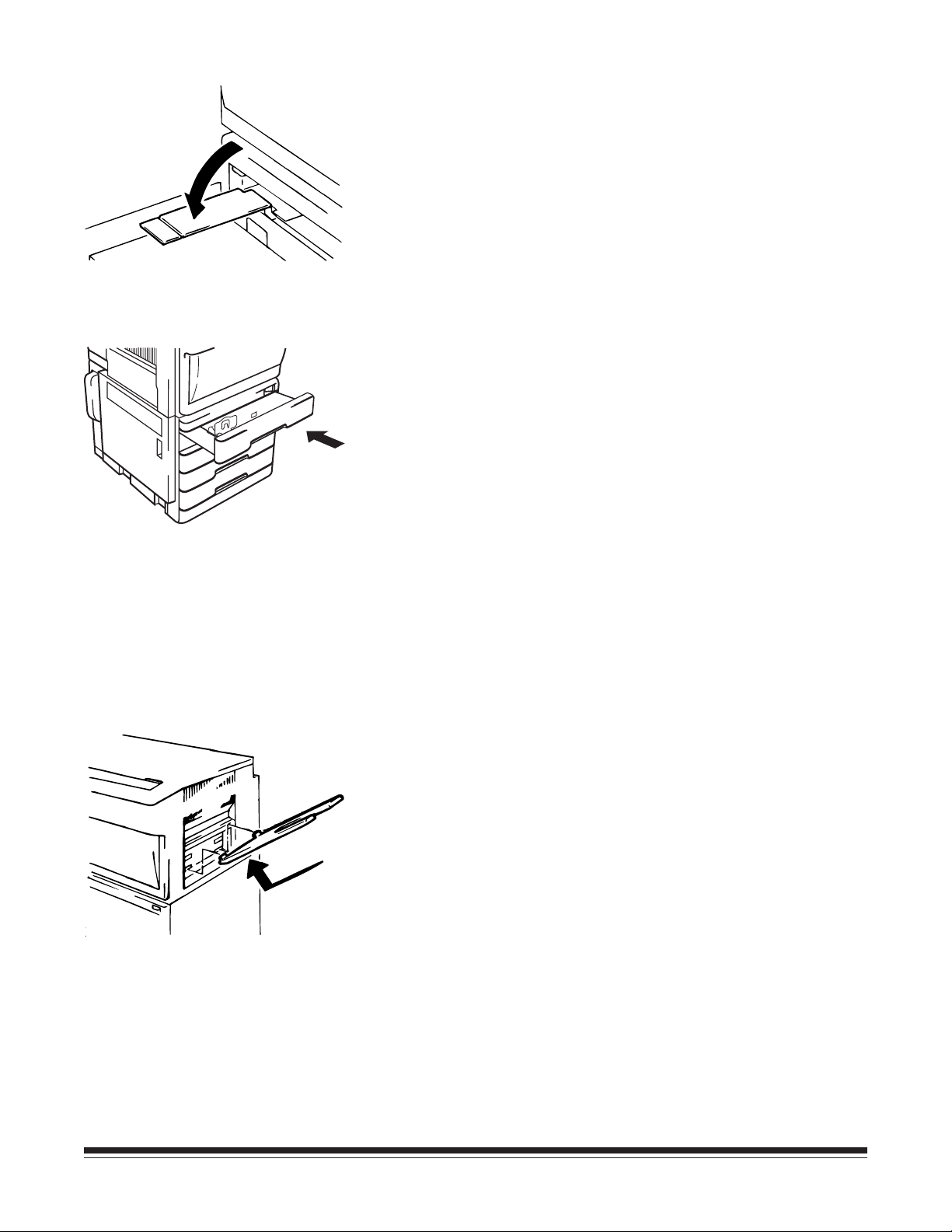

1. Pull the universal cassette out as far as it will go from the

cabinet.

Inch

Metric

USA only

Swing up the lift-up plate release lever to lower the paper lift-up

plate in the cassette.

2. Change the switch position located on the rear right side in

the cassette, depending on the paper size to be used.

Switch to “Metric” when paper size is A3T, B4T, A4T/Y,

B5T/Y, A5T, or B6T.*

All trays must be set to “Metric” if the

previous paper sizes are used.

Switch to “Inch” when paper size is 11 x 17" (LedgerT),

8-1/2 x 14" (LegalT), 8-1/2 x 11" (LetterT/Y), 7-1/4 x 10-1/2"

(ExecutiveT/Y), 5-1/2 x 8-1/2" (InvoiceT), or 7 x 8 1/2".*

All trays must be set to “Inch” if the previous paper sizes are

used.

*All trays must have the same size paper to use the Digital Workstation or

Network Node AUTO feature.

2-2 November 1996 A-62032

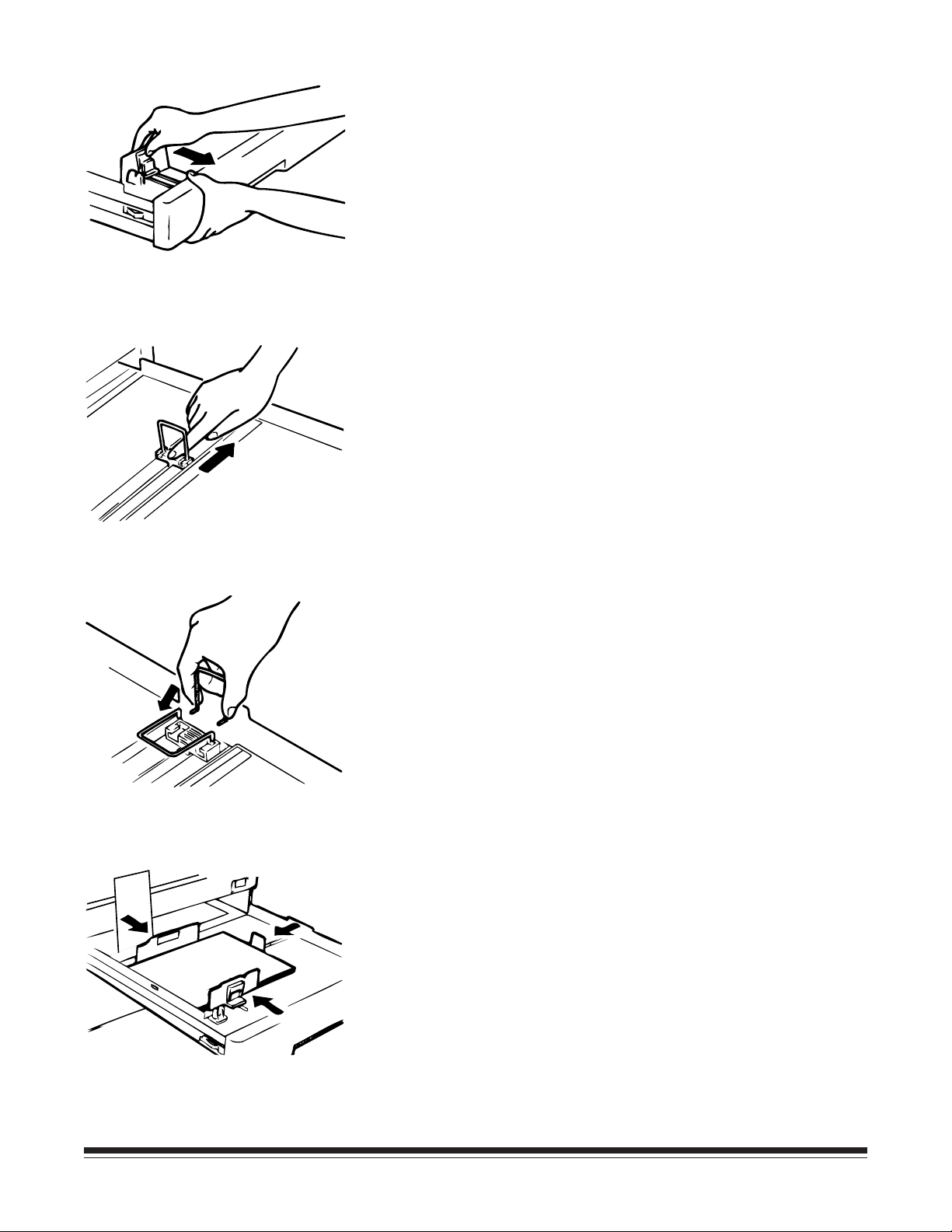

Page 9

3. While holding the cassette, depress and spread the front paper

guide wider than the paper size to be used.

4. Slide the green resin plate of the right paper guide toward the

right side wider than the paper size to be used.

NOTE: Be sure to slide the resin plate and not to hold the lever

part, as that may bend it.

5. When you load the ledgerT size paper, slide the right paper

guide all the way to the right side and remove the lever by

depressing it from the both sides. And insert the edges of the

lever in the position shown in the illustration.

6. Align the stack of paper and set the paper in the cassette with

the sealed surface down. While holding the cassette, slide

and fit the front and right paper guides to the paper edges.

NOTE: Be sure to slide the resin plate to move the right paper

guide. Check that the top level of the paper does not

exceed the line marked on the rear paper guide.

A-62032 November 1996 2-3

Page 10

USA only

Swing the lift-up plate release lever back into position to lift up the

paper lift plate.

7. Push the universal cassette back into position.

Installing the paper exit tray

To attach the paper exit tray, insert the two hooks of the paper exit

tray into the lower holes of the paper exit section.

2-4 November 1996 A-62032

Page 11

Clearing paper jams

When a paper jam occurs, remove the paper jammed in each

section according to the following procedures.

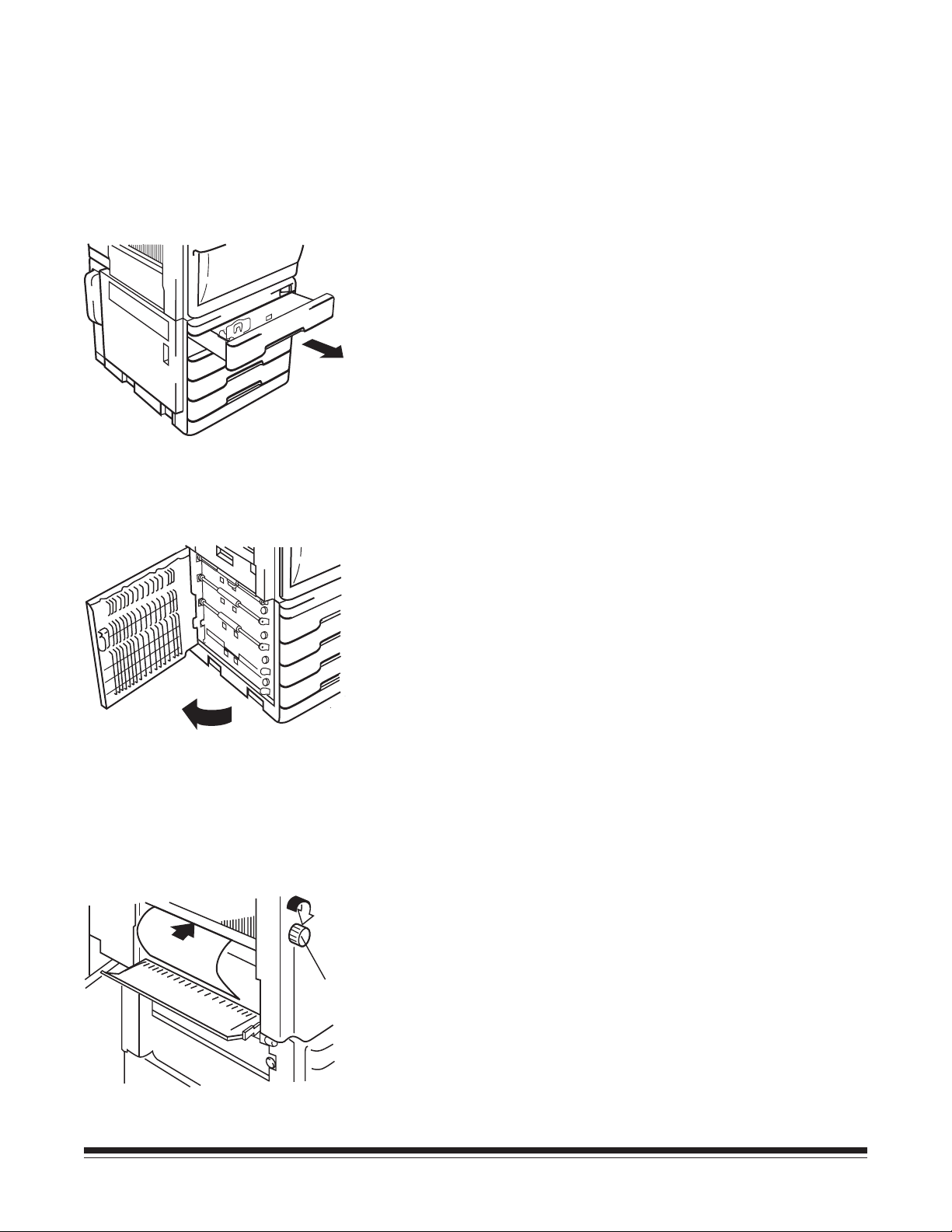

Inside the paper supply cabinet (J1 error)

1. Pull the paper cassettes out from the printer and check if the

paper in each cassette is stored correctly. If the paper is not

stored correctly, remove the jammed piece of paper. Push the

paper cassettes back into position.

2. Open the paper supply cabinet door (C2) and remove any

paper. Close the paper supply cabinet door.

3. If the leading edge of jammed paper has been fed into the

printer, open the front cover, send the paper into the printer

by rotating the transport roller knob (M5), and remove the

paper. (Refer to the “Jam Removal Diagram” label inside the

M5

A-62032 November 1996 2-5

printer front cover.) Close the front cover.

Page 12

Inside the printer (J2 or J3 error)

M2

1. Open the front cover and release lever M2 to unlock the

vacuum unit.

M5

M4

2. Open the transport section release plate (M4). Remove the

paper by rotating the transport roller knob (M5) or the

synchronizing roller knob (M3) in the direction of the arrow.

M3

3. When the leading edge of jammed paper has reached into the

fusing unit, remove the paper toward the inside of the printer

while depressing and rotating the roller knob (M1) in the

direction of the arrow.

NOTE: Rotate the roller knob (M1) only in the direction of the

arrow and do not remove the paper by pulling it into the

paper exit direction.

M1

2-6 November 1996 A-62032

Page 13

Inside the sorter and sorter interface unit (J4 or J6 error)

Lock Release Lever

1. Press the lock release lever of the 20-bin sorter to open the

sorter.

“Removing Jammed

Paper” diagram

2. Open the transport guide plates (upper and lower) of the

sorter to check if the paper is jammed inside the option. If the

paper has jammed, remove the paper. Close the transport

guide plates. (Refer to “Removing Jammed Paper” diagram

label as shown in illustration.)

NOTE: Open the lower transport guide plate for the 20-bin

sorter to check if the paper jammed inside. (Refer to

“Removing Jammed Paper” diagram label as shown in

illustration.)

A-62032 November 1996 2-7

Page 14

3. Open the upper cover of the sorter interface unit and check to

be sure there is no jammed paper. If there is paper, remove it

and close the upper cover again.

4. Close the 20-bin sorter.

2-8 November 1996 A-62032

Page 15

Changing a toner bottle

A toner bottle will print approximately 6,000 pages of A4 size

paper when the black-to-white ratio on the prints is 12%. When

the cartridge is out of toner, the toner empty indicator will light on

the operation panel. Replace the toner bottle by following the steps

below.

NOTE: Do not replace the toner bottle except when the toner

empty indicator appears.

1. Open the front cover.

1

2

Toner Bottle

Holder Lever

2. Pull the toner bottle holder lever to swing the toner bottle out

of the printer (1). Remove the toner bottle from the toner

holder (2).

3. Turning the toner seal right side up, insert the new toner

bottle into the holder so that the protrusions of the bottle fit in

the cutouts of the holder.

NOTE: Do not peel off the toner seal yet.

A-62032 November 1996 2-9

Page 16

4. Check that the triangle marks on the toner bottle and the toner

bottle holder face each other as in the illustration. Holding

the toner bottle with your left hand, gently pull the toner seal

out of the toner bottle.

5. Swing the toner bottle holder back into position.

6. Close the front cover.

2-10 November 1996 A-62032

Page 17

Changing the toner collection bottle

The used toner full indicator will appear on the operation panel

approximately every 100,000 prints when the black-to-white ratio

on the prints is 12%. When this indicator appears, follow the steps

below to replace the toner collection bottle.

1. Take out the toner collection bottle and cover the mouth with

the cap attached on the bottle.

2. Insert the new toner collection bottle into the printer.

A-62032 November 1996 2-11

Page 18

Appendix A Specifications

General specifications

Type.....................Console-type dry electrophotographic printer

Resolution ............ 400 DPI

Print method ........Laser diode, polygon mirror system

-3

Laser ....................Maximum power: 1.1 x 10

(W)

Wavelength: 785 +10, -15 nm

Dimensions .......... Width : 36" (860 mm) x depth : 27" (684 mm) x

height : 40" (1,006 mm)

Weight ................. 253 lb (115 kg)

Print speed ...........– First print

A4Y: 8 seconds or less

A3T: 8.3 seconds or less

– Multi print of same image

A4Y: 30 prints per minute

A3T: 18 prints per minute

Warmup time .......Within 3 minutes

Power supply .......120 V 60 Hz, 100 V 50/60 Hz,

220-240 V 50 Hz

Power

consumption (W)

Area Mode Printer

100/120 V warmup

standby

printing

220-240V warmup

standby

printing

alone

1220

270

1040

1440

270

1040

with

options

1240

290

1080

1460

290

1080

Acoustic noise......Printer alone

53 dB (A) or less (operation)

40 dB (A) or less (idle)

With options

58 dB (A) or less (operation)

40 dB (A) or less (idle)

Environment.........Temperature: 10–35°C (50–95°F)

Humidity: 15–85% RH

NOTE: Best performance will be obtained within the temperature

range of 15–25°C at a humidity range of 15–70% RH. Some

reduction of performance can be expected around 30°C

with RH above 70%.

Monthly prints......75,000 prints on average (150,000 prints

maximum)

Machine life ......... 4,800,000 prints or 5 years (whichever

occurs first)

A-62032 November 1996 A-1

Page 19

Option .................20-Bin Sorter with Sorter Interface Unit

Top Bin of sorter: 100-sheet capacity

Bins 2–20: 50-sheet capacity each

Paper feeding ....... Four Universal Cassettes each holding 350 sheets

Paper types .......... Standard paper: 60-90g/m

2

(16–24 lb)

Paper sizes

Paper Cassette

Size A B

A3 297 mm

(11.7 in.)

A4* 210 mm

(8.27 in.)

A5 148 mm

(5.83 in.)

JIS B4 257 mm

(10.12 in.)

JIS B5*

†

182 mm

(7.17 in.)

†

B6

129 mm

(5.08 in.)

Ledger 11.0 in.

(279.4 mm)

Legal 8.5 in.

(215.9 mm)

Letter* 8.5 in.

(215.9 mm)

420 mm

(16.5 in.)

297 mm

(11.7 in.)

210 mm

(8.27 in.)

364 mm

(14.3 in.)

257 mm

(10.12 in.)

182 mm

(7.17 in.)

17.0 in.

(431.8 mm)

14.0 in.

(355.6 mm)

11.0 in.

(279.4 mm)

Invoice 5.5 in.

(139.7 mm)

Executive* 7.25 in.

(184.2 mm)

7.0 x 8.5 in. 7.0 in.

(177.8 mm)

*These papers can be fed in either direction (i.e.,

dimensions are interchangeable for these sizes).

†

Feeds from upper 3 cassettes only.

A

NOTE:

• Dimension A cannot be greater than 11.7 in.

(297 mm).

B

Feed

Direction

• Dimension B

greater.

Smaller sizes may cause paper jams.

must

Paper output ........ Face up output system

8.5 in.

(215.9 mm)

10.5 in.

(266.7 mm)

8.5 in.

(215.9 mm)

be 8.25 in. (209.6 mm)

or

A-2 November 1996 A-62032

Page 20

Appendix B Installation considerations

Space requirements

The figures and illustrations below show the minimum space

required for the installation of your printer.

— Installed without sorter option

100 (4) 860 (34) 100 (4)

Unit: mm (inch)

1006 (39 5/8)

Top

684 (27) 100 (4)

A-62032 November 1996 B-1

Page 21

Installed with sorter option

Unit: mm (inch)

100 (4)

540 (21 1/4)

1093 (43)

100 (4)

553 (21 3/4)

1006 (39 5/8)

500 (19 3/4)

684 (27)

B-2 November 1996 A-62032

Page 22

Installation environment

Select the proper environment for using the printer to obtain the

optimum service from your printer. It should NOT be placed in a

location:

— which is exposed to direct sunlight.

— which is in the direct air stream of a cooler, heater, or

ventilator.

— where the temperature and the humidity are extremely high or

low. The room temperature should be 10–35°C (50–95°F) and

humidity should be 15–85% RH.

— which does not have a stable, level floor.

— which could easily get wet.

— which has poor ventilation and where ammonia gas might be

generated.

— which is far from a power supply.

NOTE: Please contact your service representative when you need to

move the printer to another place.

Power source

Before connecting the power cord of the printer to the outlet, check

the following items:

— Only connect to a dedicated electrical socket-outlet.

— Use the printer in a place which is near an electrical outlet

and where there is little voltage fluctuation. (The power

supply voltage should be specified voltage ±10% for imaging

and +10% or -15% for feeding. The power supply frequency

should be specified ±1 Hz.)

— Do not plug the power cord into a multi-socket extension

cord.

— At frequent intervals, check to see that the power plug is not

abnormally hot, that there are not any cracks or scrapes on

the cord, and that the power plug is fully inserted into the

socket.

— Be sure to use an outlet made for a 3-pin plug.

A-62032 November 1996 B-3

Page 23

Ordering information for the Printer 7 and accessories

CAT

No.

Kodak Imagelink

Kodak Imagelink

Kodak Imagelink

Kodak Imagelink

100 V, 50/60 Hz 128 5733

Kodak Imagelink

Kodak Imagelink

220-240 V, 50 Hz 859 1943

Kodak Imagelink

Kodak Imagelink

Kodak Imagelink

for Extension, Multiplexor or Printer 7 170 5268

Kodak Imagelink

for Extension, Multiplexor or Printer 7 143 3929

Kodak Imagelink

Printer 7 / 100 V, 50/60 Hz 104 8131

Printer 7 / 120 V, 60 Hz 159 9646

Printer 7 / 220-240 V, 50 Hz 887 9405

Printer 7 Paper Supply /

Printer 7 Paper Supply / 120 V, 60 Hz 852 6428

Printer 7 Paper Supply /

Printer 7 Sorter 864 6754

Printer 7 Sorter Interface 199 7964

Printer Cable, 10-foot /

Printer Cable, 20-foot /

Printer 5/7 Interface Board 173 0316

Ordering information for consumables for the Printer 7

Handling of consumables

CAT No.

Kodak Imagelink

Kodak Imagelink

Consumables such as paper and toner could affect the printer

condition. Before using any consumable, please carefully read the

label.

For paper and toner

— Do not keep paper and toner where they will be exposed to

direct sunlight, or in a place which is close to any kind of

heating device.

— To prevent absorption of moisture, paper which has been

removed from its wrapper but not loaded in the cassette

should be stored in a sealed plastic bag in a cool, dark place.

Printer 7 Toner 877 2220

Printer 7 Toner Collection Bottle 899 6670

— Never use the toner used for any other model of printer.

B-4 November 1996 A-62032

Page 24

Appendix C Printer 7 error, maintenance, and

caution codes

Error Codes

Code Explanation Action Needed

A0 No used toner collecting bottle. Seat the toner bottle properly; install one if

necessary.

A1 No EP unit. Seat the EP unit properly; install a new one if

necessary*; or call service. See page 1-3.

A2 No fuser. Seat the fuser correctly; install a new one if

necessary*; or call service. See page 1-3.

A3 Unacceptable paper at the sorter interface. Use paper specified for this printer. See page A-1.

E0 Unacceptable paper at the sorter. Use paper specified for this printer. See page A-1.

E1 The front cover is open. Close the front cover. See page 1-1.

E2 Cabinet door cover open Close the cabinet door. See page 1-1.

E3 The sorter bin cover is open. Close the sorter bin cover.

E4 The sorter interface cover is open. Close the sorter interface cover.

E5 The sorter bins are full of print paper. Empty all the sorter bins.

E6 Fuser web is empty. Install a new fuser unit* or call service.

E8 The sorter has been improperly installed in

the printer.

E9 Manual paper inserted. Remove the paper causing the jam.

J1 A paper jam has occurred between the

cassette and the synchronizing roller.

J2 A paper jam has occurred at the EP unit. Clear the jam. Open the front cover and clear the

J3 A paper jam has occurred between the

synchronizing roller and the fusing unit.

J4 A paper jam has occurred at the sorter. Clear the jam. Open sorter cover and clear the

J6 A paper jam has occurred at the sorter

interface.

20 The drum-charge erase lamp has

malfunctioned.

Correctly set the sorter to the printer.

Clear the jam. Open the front cover and cabinet

door and clear jam in stack. See page 2-5.

jam at the EP unit. See page 2-6.

Clear the jam. Open the front cover and clear the

jam. See page 2-6.

jam. See page 2-7.

Clear the jam. Open the sorter cover and sorter

interface cover and clear the jam. See page 2-7.

Turn the printer off and then on again. If the

problem persists, call for service.

* These maintenance procedures are to be performed by Kodak authorized and fully trained persons only. These

errors (for the EP unit and fuser unit) normally appear every 150,000 prints. At this time, an Image Quality Kit needs

to be installed. This kit includes: a new EP unit, a fuser unit, a transfer/separator corona, and feed rollers. Customers

with a Shared Maintenance Agreement will install the Image Quality Kit. Other customers should call Service

immediately.

A-62032 November 1996 C-1

Page 25

Error Codes (continued)

Code Explanation Action Needed

21 The drum-charge corona has malfunctioned. Turn the printer off and then on again. If the

problem persists, call for service.

22 The thermistor has malfunctioned. Turn the printer off and then on again. If the

problem persists, call for service.

23 An excessively high temperature has been

detected.

24 A heater lamp has malfunctioned. Turn the printer off and then on again. If the

25 The main drive motor has malfunctioned. Turn the printer off and then on again. If the

26 The transfer corona or separator has

malfunctioned.

27 The polygon drive motor has malfunctioned. Turn the printer off and then on again. If the

28 The S-SCAN-out has malfunctioned. Turn the printer off and then on again. If the

38 Command overflow. Call for service.

44 There is an error in the external

communications system.

46 The TSCR communications malfunctioned. Turn the printer off and then on again. If the

47 The sorter communications malfunctioned. Turn the printer off and then on again. If the

48 The sorter interface unit communications

malfunctioned.

Turn the printer off and then on again. If the

problem persists, call for service.

problem persists, call for service.

problem persists, call for service.

Turn the printer off and then on again. If the

problem persists, call for service.

problem persists, call for service.

problem persists, call for service.

Turn the printer off and then on again. If the

problem persists, call for service.

problem persists, call for service.

problem persists, call for service.

Turn the printer off and then on again. If the

problem persists, call for service.

49 Developing bias error. Turn the printer off and then on again. If the

problem persists, call for service.

50 PC drum drive malfunctioned Turn the printer off and then on again. If the

problem persists, call for service.

51 The develop roller drive malfunctioned. Turn the printer off and then on again. If the

problem persists, call for service.

52 The develop sleeve malfunctioned. Turn the printer off and then on again. If the

problem persists, call for service.

53 The toner supply motor malfunctioned. Turn the printer off and then on again. If the

problem persists, call for service.

54 Elevator tray 1 malfunctioned. Open paper cassette #1. Check paper position,

and close paper cassette. If the problem persists,

call for service.

C-2 November 1996 A-62032

Page 26

Error Codes (continued)

Code Explanation Action Needed

55 Elevator tray 2 malfunctioned. Open paper cassette #2. Check paper position,

and close paper cassette. If the problem persists,

call for service.

56 Elevator tray 3 malfunctioned. Open paper cassette #3. Check paper position,

and close paper cassette. If the problem persists,

call for service.

57 Elevator tray 4 malfunctioned. Open paper cassette #4. Check paper position,

and close paper cassette. If the problem persists,

call for service.

58 The ozone fan malfunctioned. Turn the printer off and then on again. If the

problem persists, call for service.

59 The power supply fan malfunctioned. Turn the printer off and then on again. If the

problem persists, call for service.

80 There is a problem with the sorter. Turn the printer off and then on again. If the

problem persists, call for service.

Preventive Maintenance Codes

Code Explanation Action Needed

P0 EP unit needs replacement. Install a new EP unit*, or call for service.

P2 The toner collection bottle is full. Replace with a new collection bottle. See

page 2-11.

Caution Codes

Code Explanation Action Needed

C0 The toner collection bottle is near full. The

printer will shut down approximately 500

Replace the toner collection bottle with a new

one. See page 2-11.

prints after this error is posted.

C1 The toner bottle is almost empty. Replace the toner bottle with a new one.

See page 2-9.

C2 The fuser web is almost used up. The printer

Replace with a new fuser unit* or call for service.

will shut down approximately 500 prints

after this error is posted.

* These maintenance procedures are to be performed by Kodak authorized and fully trained persons only.

These errors (for the EP unit and fuser unit) normally appear every 150,000 prints. At this time, an Image

Quality Kit needs to be installed. This kit includes: a new EP unit, a fuser unit, a transfer/separator corona,

and feed rollers. Customers with a Shared Maintenance Agreement will install the Image Quality Kit. Other

customers should call Service immediately.

A-62032 November 1996 C-3

Page 27

Appendix D Maintenance

Before conducting any maintenance procedures, follow these

precautions:

—Before beginning the maintenance procedures, be sure to turn

OFF the power ON/OFF switch and unplug the printer’s

power cord.

— Do not put any equipment that produces a magnetic field near

the printer.

— Do not attempt to remove the units other than those described

in the manual.

Use the mechanical print counter to check the number of prints

made to determine when certain maintenance procedures should

be performed.

Mechanical

Print Counter

Every 75,000 prints

Cleaning the image transfer/paper separator charger wires

The image transfer/paper separator charger wires should be cleaned

every 75,000 prints. Follow the steps described below to clean the

unit. Before cleaning the wire, be sure to turn OFF the power ON/

OFF switch and unplug the power cord.

1. Open the front cover. Release the lock of the vacuum unit

release lever (M2) and lower the vacuum unit. Push down on

the front edge of the image transfer/paper separator charger

and pull the charger out of the printer.

A-62032 November 1996 D-1

Page 28

2. Remove the (4) paper guides by lifting them straight up. Clean

the outside of housing with a soft cloth.

3. Carefully clean the wires using the cleaning pen contained in

the accessories for the machine as in the illustration.

4. Reinstall the four paper guides. Insert the image transfer/paper

separator charger onto the guides of the suction unit until the

charger is locked by the front edge of the guides. Lift up the

vacuum unit release lever (M2) and lock it into the EP unit.

Close the front cover.

NOTE: Be sure the charger is installed correctly. If the vacuum

unit will not lock into place or if there are printing

problems, reinstall the charger.

D-2 November 1996 A-62032

Page 29

Cleaning the printer

External cleaning

Internal cleaning

The printer should be cleaned on a regular basis to prevent

potential malfunctions. Before cleaning the printer, be sure to turn

off the power ON/OFF switch and unplug the power cord from the

outlet.

1. Wipe the cover and external parts of the printer with a dry,

soft cloth. If the cover is extremely dirty, use a cloth that has

been dampened slightly in a neutral cleaning solution.

1. Release the lock of the unit release lever (M2) and lower the

vacuum unit.

2. Wipe the belt of the vacuum unit with a dry and soft cloth.

A-62032 November 1996 D-3

Page 30

New equipment warranty—

Kodak Imagelink

Printer 7

Kodak warrants this equipment to function properly for three

months from date of shipment. However, certain requirements

may dictate a different warranty period. This warranty covers

the purchaser of this equipment as well as anyone else who

owns it during the warranty period.

Warranty repair coverage

Days and hours of coverage

How to obtain service

Limitations

If this equipment does not function properly during the

warranty period, Kodak will provide on-site repair service

during Kodak’s normal working hours. Such repair service will

include any adjustments and/or replacement of parts necessary

to maintain the equipment in an operating condition which is

consistent with Kodak’s specifications.

Warranty coverage is available Monday through Friday

during Kodak’s normal working hours (usually 8:00 a.m. to

5:00 p.m.), excluding holidays celebrated locally.

Any on-site service performed after normal working hours will

be billed at prevailing overtime rates.

In the U.S. call (800) 356-3253; or call your local Kodak

Service Office.

Standard warranty service is limited to the contiguous United

States, Hawaii, and certain areas of Alaska.

This warranty does not cover: circumstances beyond Kodak’s

control (such as Customer overriding, bypassing or defeating

interlock switches on equipment or devices sold by Kodak);

problems due to failure of Customer to conform to Kodak’s site

specifications; service or parts to correct problems resulting

from the use of attachments, accessories or alterations not

marketed by Kodak; relocation of equipment or service

required as the result of relocation; unauthorized modifications

or service; misuse; abuse; failure to follow Kodak’s operating

instructions; or supply items (such as glass and projection

lamps).

A-62032 November 1996

KODAK MAKES NO OTHER WARRANTIES, EXPRESS,

IMPLIED, OR OF MERCHANTABILITY OR FITNESS FOR A

PARTICULAR PURPOSE FOR THIS EQUIPMENT.

Repair or replacement without charge are Kodak’s only

obligations under this warranty. KODAK WILL NOT BE

RESPONSIBLE FOR ANY CONSEQUENTIAL OR INCIDENTAL

DAMAGES RESULTING FROM THE SALE, USE, OR

IMPROPER FUNCTIONING OF THIS EQUIPMENT,

REGARDLESS OF THE CAUSE. Such damages for which Kodak

will not be responsible, include, but are not limited to, loss of

revenue or profit, downtime costs, loss of use of the

equipment, cost of any substitute equipment, facilities or

services or claims of your customers for such damages.

Page 31

This limitation of liability will not apply to claims for injury to

persons or damage to property caused by the sole negligence

or fault of Kodak or by persons under its direction or control.

The

Kodak Imagelink

of 4.8 million print actuations or 5 years, whichever

occurs first. Kodak reserves the right to discontinue

service agreements or increase the service agreement

price when the life expectancy of the printer is reached.

Printer 7 has a rated machine life

A-62032 November 1996

Page 32

Index

A

Acoustic noise, A-1

Adjustable feet, 1-2

B

C

Cassettes (see also paper or

universal cassettes)

Caution codes, C-3

Circuit breaker, 1-2

Consumables

handling, B-4

ordering of, B-4

Mechanical print counter, 1-3,

D-1

“Metric” paper position switch,

2-2

N

O

Ordering information

accessories, B-4

consumables, B-4

Printer 7, B-4

Operation panel, 1-1, 2-1

Overview, 1-1–1-3

D

Dataplate, 1-2

E

Electrophotographic unit (see

EP unit)

Environment, A-1, B-3

EP unit, (See electrophoto-

graphic (EP unit), 1-3

Error codes, C-1–C-2

F

Feed roller, 1-3

Fusing roller knob (M1), 1-3

Fusing unit, 1-3

G

H

I

“Inch” paper position switch,

2-2

Installation

considerations, B-1

environment, B-2

Image transfer/paper separator

charger, 1-3

Image transfer/paper separator

ozone filter cover, 1-2

M

Machine life, A-1, Warranty

Maintenance, D-1–D-3

P

Paper,

clearing jams, 2-5–2-8

feeding, A-2

loading, 2-2

sizes, A-2

types, A-2

Paper cassette 1-1, 2-2–2-4

Paper exit tray, 1-2

installing, 2-4

Paper supply cabinet door, 1-1

Paper supply cabinet rear

cover, 1-2

Paper supply cabinet right

cover, 1-2

Paper take-up section release

knob, 1-3

Power

consumption, A-1

source, B-3

supplies, A-1

Power cord socket, 1-2

Power ON/OFF switch, 1-1,

2-1

Preventive maintenance codes,

C-3

Printer

installation

considerations, B-1

location/description of

parts, 1-1–1-3

overview, 1-1

print method, A-1

speed, A-1

A-62032 November 1996 Index-1

Page 33

status, 2-1

test print function, 2-1

turning on and off, 2-1

Printer cable interface socket,

1-2

Printer front cover, 1-1

Printer left cover, 1-1

Printer rear cover, 1-2

Printer right cover, 1-2

Printer top cover, 1-1

T

Test control, 2-1

Toner bottle, 1-3

changing, 2-9, 2-10

Toner bottle holder, 1-3

Toner collection bottle, 1-1

changing, 2-11

Transport roller knob (M5), 1-3

Transport section release plate

(M4), 1-3

Q

R

Release lever (M2), 1-3

S

Safety information, ii

Separator roller, 1-3

Sorter, 2-7, A-2, B-2

Sorter interface unit, 2-7, B-2

Space requirements, B-1, B-2

Specifications, A-1

Synchronizing roller knob

(M3), 1-3

U

Universal cassette (see paper

cassette)

V

Vertical transport roller knob

M6, 1-3

W

warnings, i, ii

warranty, IBC

Index-2 November 1996 A-62032

Page 34

A-62032 Part No. 3C4923 11/96©Eastman Kodak Company, 1996 Printed in U.S.A.

Business Imaging Systems

EASTMAN KODAK COMPANY

Rochester, New York 14650

Kodak and Imagelink are trademarks of

Eastman Kodak Company.

Printed on recycled paper.

Loading...

Loading...