Page 1

TECHNICAL DATA /

COLOR NEGATIVE FILM

K OD AK VISION2 HD Color Scan

Film 7299

February 2005 • H-1-7299t

KODAK VISION2 HD Color Scan Film 7299 is a

high-speed color negative motion picture film designed for

use with the KODAK VISION2 HD System. When

transferred to video via telecine and used in conjunction with

image processing available in the KODAK VISION2 HD

Digital Processor, 7299 Film can be automatically

manipulated to reproduce the tone and color characteristics

of other Kodak color negative films. 7299 Film, itself, has

been optimized specifically for scanning applications to

provide superior light capture and image rendition for

transfer to digital data.

When used correctly in the KODAK VISION2 HD

System, 7299 Film can be properly exposed at an exposure

index of either 500 for high-speed applications or 320 for

lower-speed applications. It can also be exposed properly in

either daylight or tungsten shooting conditions without the

use of corrective filters. Image processing used in the

KODAK VISION2 HD Digital Processor will automatically

compensate for these different exposure conditions to

produce properly balanced video images.

BASE

KODAK VISION2 HD Color Scan Film 7299 has an acetate

safety base with rem-jet backing.

DARKROOM RECOMMENDATIONS

Do not use a safelight. Handle unprocessed film in total

darkness.

STORAGE

Store unexposed film at 13°C (55°F) or lower. For extended

storage, store at -18°C (0°F) or lower. Process exposed film

promptly. Store processed film according to the

recommendations in ANSI/PIMA IT9.11-1998: for

medium-term storage (minimum of ten years), store at

10°C(50°F) or lower at a relative humidity of 20 to 30

percent; for extended-term storage (for preservation of

material having permanent value), store at 2°C (35°F) or

lower at a relative humidity of 20 to 30 percent. For active

use, store at 25°C(77°F) or lower, at a relative humidity of

50 +/- 5 percent. This relates to optimized film handling

rather than preservation; static, dust-attraction and

curl-related problems are generally minimized at the higher

relative humidity . After usage, the film should be returned to

the appropriate medium- or long-term storage conditions as

soon as possible.

For more information about medium- and long-term

storage, see ANSI/PIMA IT9.11-1998,

SMPTE RP131-2002, and KODAK Publications No. H-1,

KODAK Motion Picture Film available online at http://

www.kodak.com/US/en/motion/support/h1, and No. H-23,

The Book of Film Care.

EXPOSURE INDEXES

High-Speed Application: Tungsten (3200 K) - 500

Lower-Speed Application: Tungsten (3200 K) - 320

Use these indexes with incident- or reflected-light

exposure meters and cameras marked for ISO or ASA speeds

or exposure indexes. These indexes apply for meter readings

of average subjects made from the camera position or for

readings made from a gray card of 18-percent reflectance

held close to and in front of the subject. For unusually lightor dark-colored subjects, decrease or increase the exposure

indicated by the meter accordingly.

KODAK VISION2 HD Color Scan Film 7299 has been

designed for optimum performance at an exposure index of

both 500 and 320. EI500 can be chosen in low-light

situations where speed is required with no degradation in

image quality, shadow detail, or black level. EI320 can be

chosen if light is sufficient or if improved shadow rendition

is desired. When properly used with the KODAK VISION2

HD Digital Processor, 7299 Film is also capable of being

shot without correction in either tungsten or daylight

sources. It should be noted, however, that the designed color

balance of the film is 3200 K tungsten, and a KODAK

WRATTEN Filter No. 85 can be used to balance daylight

exposures on the camera if desired (though the exposure

index must be adjusted by

2

⁄3 stops accordingly).

COLOR BALANCE

When correctly used in the KODAK VISION2 HD System

with the KODAK VISION2 HD Digital Processor, this film

can be properly exposed in either tungsten (3200 K) or

daylight (5500 K) sources. Natively, however, the film is

balanced for exposure with tungsten illumination (3200 K)

and filtration can be used for other illuminant sources if

desired. For tungsten shooting, you can also expose this film

with lamps that have slightly higher or lower color

temperatures (+/- 150 K) without correction filters, since

final color balancing can be done in telecine transfer. For

other light sources, use the correction filters in the table

below. Separate tables are listed for shooting 7299 Film at a

nominal speed of EI500 and EI320.

©Eastman Kodak Company, 2005

Page 2

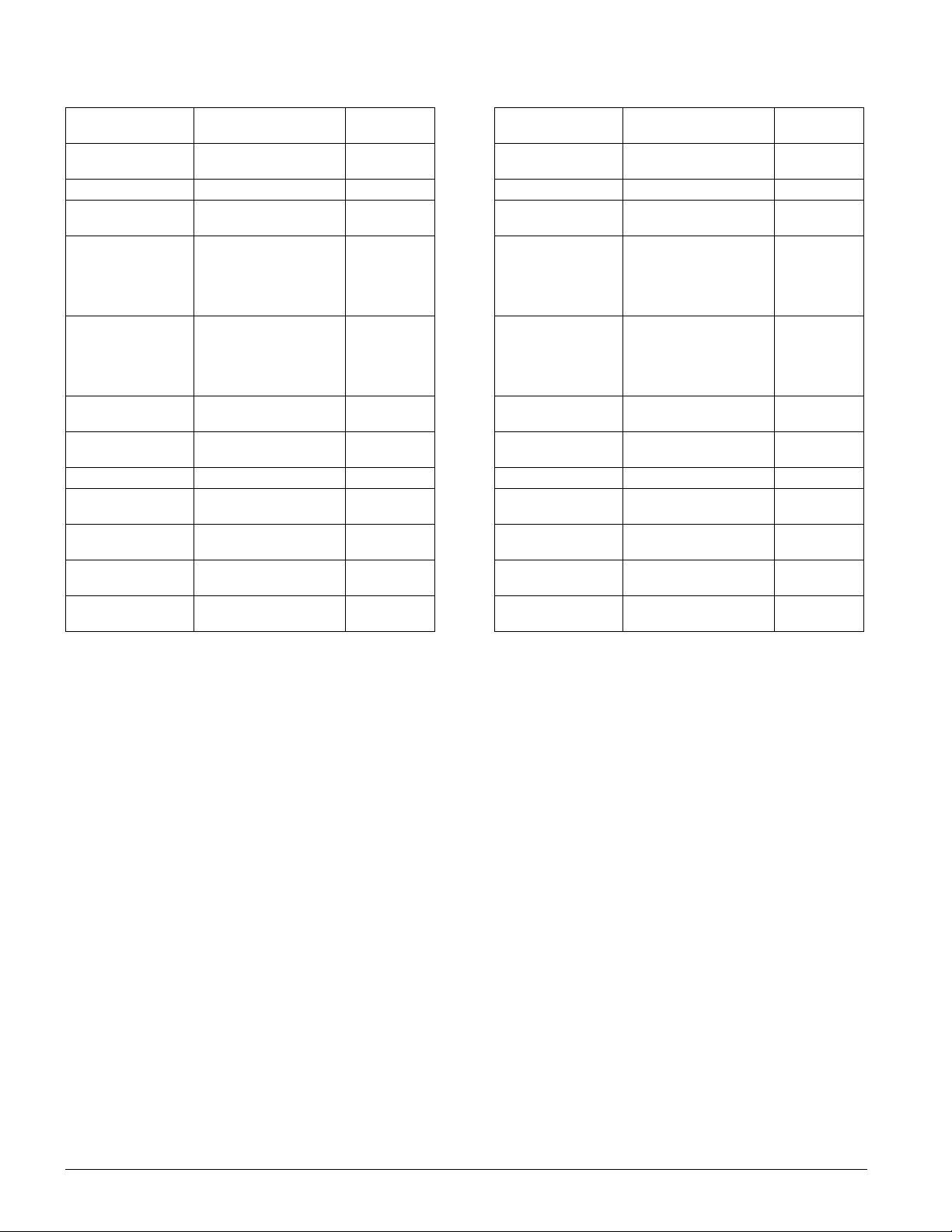

KODAK VISION2 HD Color Scan Film at nominal speed of EI500

KODAK VISION2 HD Color Scan Film at nominal speed of EI320

Light Source

KODAK Filters on

Camera

1

Tungsten (3000 K) WRATTEN Gelatin No.

82B

Exposure

Index

320

Tungsten (3200 K) None 500

T ungsten photoflood

(3400 K)

None 500

Daylight (5500 K)

but using digital

correction in

None 500

KODAK VISION2

HD System

Daylight (5500 K)

without digital

WRATTEN Gelatin No.

85

320

correction in

KODAK VISION2

HD System

White-Flame Arcs WRATTEN Gelatin No.

85B

Yellow-Flame Arcs Color Compensating

20Y

200

320

OPTIMA 32 None 500

VITALITE WRATTEN Gelatin No.

85

Fluorescent, Cool

2

White

Fluorescent, Deluxe

Cool White

2

WRATTEN Gelatin No.

85 + 10M

WRATTEN Gelatin No.

85C + 10R

Metal Halide WRATTEN Gelatin No.

85

1

These are approximate co rr ec tio ns only. Make final corrections during

printing.

2

These are starting-point recommendations for trial exposures. If the kind

of lamp is unknown, a KODAK Color Compensating Filter CC 40R can

be used with an exposure index (EI) of 250.

320

200

320

320

Light Source

KODAK Filters on

Camera

1

Tungsten (3000 K) WRATTEN Gelatin No.

82B

Exposure

Index

200

Tungsten (3200 K) None 320

T ungsten photoflood

(3400 K)

None 320

Daylight (5500 K)

but using digital

correction in

None 320

KODAK VISION2

HD System

Daylight (5500 K)

without digital

WRATTEN Gelatin No.

85

200

correction in

KODAK VISION2

HD System

White-Flame Arcs WRATTEN Gelatin No.

85B

Yellow-Flame Arcs Color Compensating

20Y

125

200

OPTIMA 32 None 320

VITALITE WRATTEN Gelatin No.

85

Fluorescent, Cool

2

White

Fluorescent, Deluxe

Cool White

2

WRATTEN Gelatin No.

85 + 10M

WRATTEN Gelatin No.

85C + 10R

Metal Halide WRATTEN Gelatin No.

85

1

These are approximate corrections only. Make final corrections with

telecine color correction.

2

These are starting-point recommendations for trial exposures. If the kind

of lamp is unknown, a KODAK Color Compensating Filter CC 40R can

be used with an exposure index (EI) of 160.

200

125

200

200

Note: Consult the manufacturer of high-intensity ultraviolet

lamps for safety information on ultraviolet radiation and

ozone generation.

2 KODAK VISION2 HD Color Scan Film 7299 • H-1-7299t

Page 3

EXPOSURE TABLE - TUNGSTEN LIGHT

At 24 frames per second (fps), 170-degree shutter opening:

KODAK VISION2 HD Color Scan Film at nominal speed of EI500

Lens

Aperture

Footcandles

Required

f/1.4 f/2 f/2.8 f/4 f/5.6 f/8 f/11 f/16

5 10 20 40 80 160 320 640

KODAK VISION2 HD Color Scan Film at nominal speed of EI320

Lens

Aperture

Footcandles

Required

Use this table for average subjects that contain a

combination of light, medium, and dark colors. When a

subject includes only pastels, use at least

exposure; dark colors require

f/1.4 f/2 f/2.8 f/4 f/5.6 f/8 f/11 f/16

8 16 32 64 125 250 500 1000

1

1

⁄2 stop more exposure.

⁄2 stop less

RECIPROCITY CHARACTERISTICS

You do not need to make any filter corrections or exposure

adjustments for exposure times from 1/1000 to 1 second. If

your exposure is in the 10 second range, it is recommended

that you increase your exposure by1 stop and use a KODAK

Color Compensating Filter CC 10R.

PROCESSING

Process in Process ECN-2.

Most commercial motion-picture laboratories provide a

processing service for these films. See KODAK Publication

No. H-24.07, Processing KODAK Color Negative Motion

Picture Films, Module 7 available online at http://

www.kodak.com/US/en/motion/support/processing/h247/

h2407.pdf, for more information on the solution formulas

and the procedure for machine processing these films. There

are also pre-packaged kits available for preparing the

processing solutions. For more information on the

EASTMAN ECN-2 Kit Chemicals, check Kodak's Motion

Picture Films for Professional Use price catalog.

FILM-TO-VIDEO TRANSFERS

KODAK VISION2 HD Color Scan Film 7299 is intended

exclusively for telecine transfer using the K ODAK VISION2

HD Digital Processor. With the telecine set to the nominal

starting conditions as recommended for the KODAK

VISION2 HD System, color and tone characteristics can be

automatically set to match the baseline technical starting

point of any other Kodak color negati ve film. Once set to this

starting condition, normal color correction can be applied as

with any other typical motion picture negative film.

For more information on the KODAK VISION2 HD

System, please refer to the KODAK VISION2 HD Digital

Processor User Guide, Part No. 4F2310.

IMAGE STRUCTURE

The modulation-transfer and diffuse rms granularity curves

were generated from samples of 7299 Film exposed with

tungsten light and processed as recommended in Process

ECN-2 chemicals. For more information on image-structure

characteristics, see KODAK Publication No. H-1, KODAK

Motion Picture Film available online at http://

www.kodak.com/US/en/motion/support/h1.

MTF

The "perceived" sharpness of any film depends on various

components of the motion picture production system. The

camera and projector lenses and film printers, among other

factors, all play a role. But the specific sharpness of a film

can be measured and charted in the Modulation Transfer

Curve.

rms Granularity:

Refer to curve.

Read with a microdensitometer, (red, green, blue) using a

48-micrometer aperture.

The "perception" of the graininess of any film is highly

dependent on scene content, complexity, color, and density.

Other factors, such as film age, processing, exposure

conditions, and telecine transfer may also have significant

effects.

IDENTIFICATION

After processing, the product code numbers 7299 (16 mm),

emulsion, roll, and strip number identification, KEYKODE

Numbers, and manufacturer/film identification code (EI) are

visible along the length of the film.

KODAK VISION2 HD Color Scan Film 7299 • H-1-7299t 3

Page 4

CURVES

Sensitometric Curves

Diffuse rms Granularity Cu r ve s

Log Exposure (lux seconds)

3.0

Exposure: 3200 K Tungsten 1/50 sec

Process: ECN-2; Status M

2.0

1.0

B

G

R

0.0

-8 -7 -6 -5 -4 -3 -2 -1 0 1 2 3 4 5 6 7 8 9

-1.8 -1.2

Camera Stops

-0.6

0-2.4-3.0-3.6

The curves describe this film's response to red, green, and

blue light. Sensitometric curves determine the change in

density on the film for a given change in log exposure.

Modulation-Transfer Function Curves

1000

Exposure: Tungsten 3200 K;

Process: ECN-2

1

3.0

Process ECN-2

2.8

2.6

2.4

2.2

2.0

1.8

1.6

1.4

DENSITY

1.2

1.0

0.8

0.6

0.4

0.2

0.0

0.0 1.0 2.0 3.0 4.0 5.0

TI2636C

LOG RELATIVE EXPOSURE

G

B

G

0.10

0.05

0.04

R

0.03

0.02

B

0.01

0.006

R

0.005

0.004

0.003

0.002

0.001

To find the rms Granularity value for a given density, find

the density on the left vertical scale and follow horizontally

to the characteristic curve and then go vertically (up or

down) to the granularity curve. At that point, follow

horizontally to the Granularity Sigma D scale on the right.

Read the number and multiply by 1000 for the rms value.

Note: This curve represents granularity based on modified

measuring techniques.

1

GRANULARITY SIGMA D

100

B

G

10

RESPONSE (%)

1

1 10 100 1000

SPATIAL FREQUENCY (cycles/mm)

R

This graph shows a measure of the visual sharpness of this

film. The x-axis, "Spatial Frequency," refers to the number

of sine waves per millimeter that can be resolved. The y-axis,

"Response," corresponds to film sharpness. The longer and

flatter the line, the more sine waves per millimeter that can

be resolved with a high degree of sharpness—and, the

sharper the film.

1.NOTE: Sensitometric and Diffuse RMS Granularity

curves are produced on different equipment. A slight

variation in curve shape may be noticed.

4 KODAK VISION2 HD Color Scan Film 7299 • H-1-7299t

Page 5

Spectral Sensitivity Curves

Spectral Dye Density Curves

4.0

Effective Exposure: 1/25 sec;

Process ECN-2; Status M; D=0.2>D-min

3.0

*

2.0

LOG SENSITIVITY

1.0

0.0

250 300 350 400 450 500 550 600 650 700 750

*Sensitivity = reciprocal of exposure (erg/cm ) required

TI2636D

Yellow-

Forming

Layer

WAVELENGTH (nm)

to produce specified density

Magenta-

Forming

Layer

Cyan-

Forming

Layer

2

These curves depict the sensitivity of this film to the

spectrum of light. They are useful for determining,

modifying, and optimizing exposure for blue- and

green-screen special-effects work.

1.8

Process: ECN-2; D-mins subtracted

1.6

1.4

1.2

1.0

0.8

0.6

Yellow

0.4

DIFFUSE SPECTRAL DENSITY

0.2

0.0

-0.2

300 350 400 450 500 550 600 650 700 750 800

TI2636E

Midscale Neutral

Magenta

WAVELENGTH (nm)

Cyan

Minimum Density

These curves depict the spectral absorptions of the dyes

formed when the film is processed. They are useful for

adjusting or optimizing any device that scans or prints the

film.

Note: Cyan, Magenta, and Yellow Dye Curves are

peak-normalized.

NOTICE: The sensitometric curves and data in this publication represent product tested

under the conditions of exposure and processing specified. They are representative of

production coatings, and therefore do not apply directly to a particular box or roll of

photographic material. They do not represent standards or specifications that must be met

by Eastman Kodak Company. The company reserves the right to change and improve

product characteristics at any time.

SIZES AVAILABLE

Standard Products Available

Identification No.

16 mm SP457 122 (400) T Winding B 1R-7605 (1R-2994)

16 mm SP458 244 (800) Z Winding B 1R-7605 (1R-2994)

Metres (Feet)

Length in

Core Description Perforations

KODAK VISION2 HD Color Scan Film 7299 • H-1-7299t 5

Page 6

MORE INFORMATION

Outside the United States and Canada, please contact your Kodak representative.

You can also visit our web site at www.kodak.com/go/motion for further information. You may want to bookmark our location

so you can find us easily the next time.

Films Cinematographer’s Field Guide

Image Structure KODAK Motion Picture Film

Specification Numbers Cinematographer’s Field Guide

Storage KODAK Motion Picture Film

LAD LAD—Laboratory Aim Density

Transfer KODAK Telecine Analysis Film User’s Guide

KODAK Publication No. H-2

KODAK Publication No. H-1

KODAK Publication No. H-2

KODAK Publication No. H-1

The Book of Film Care

KODAK Publication No. H-23

KODAK Publication No. H-61

KODAK Publication No. H-822

KODAK Telecine Exposure Calibration Film User’s Guide

KODAK Publication No. H-807

6 KODAK VISION2 HD Color Scan Film 7299 • H-1-7299t

Page 7

KODAK VISION2 HD Color Scan Film 7299

Kodak Locations

FOR DIRECT ORDERING IN THE UNITED STATES

AND CANADA: 1-800-621-FILM

CHICAGO, ILLINOIS

Information: 630-910-4929

DALLAS, TEXAS

Information: 972-346-2979

HOLLYWOOD, CALIFORNIA

6700 Santa Monica Boulevard

Los Angeles, California

90038-1203

Information: 323-464-6131

NEW YORK, NEW YORK

360 West 31st Street

New York, New York

10001-2727

Information: 212-631-3418

LATIN AMERICA REGION

8600 NW 17th Street

Suite 200

Miami, Florida 33126-1006

Phone: 305-507-5146

VERDUN, QUEBEC

Kodak Canada, Inc.

4 Place du Commerce, Suite 100

Ile des Soeurs

Verdun, Quebec

Canada H3E 1J4

Information: 514-761-7001

Fax: 514-768-1563

Orders: 1-800-621-FILM (3456)

Fax Orders: 1-866-211-6311

TORONTO, ONTARIO

Kodak Canada Inc.

3500 Eglinton Avenue West

Toronto, Ontario

Canada M6M 1V3

1-800-621-FILM (3456)

BURNABY, BRITISH COLUMBIA

Kodak Canada, Inc.

4185 Still Creek Drive

Suite C150

Burnaby, British Columbia

Canada V5C 6G9

Tel: 1-800-621-FILM (3456)

EUROPEAN, AFRICAN, AND ME

REGION

Eastman Kodak Company

Kodak Ltd. Kodak House

Hemel Hempstead

Herts, HP1 1JU England

Local: 01442-845-945

Fax: 01442-844-458

Eastman Kodak SA

29-31 Route de l'aeroport

Case postale 271

Le grand Sacconex, 1215

Geneve 15

Information: +41-22-747-2000

Fax: +41-22-747-2200

ASIA PACIFIC REGION

AUSTRALIA

Melbourne: 613-9353-2561

Toll free: 1-800-337-935

CHINA (Peoples Republic)

Beijing: 8610-6561-6561

Shanghai: 8621-6350-0888

Guangzhou: 8620-8319-8888

HONG KONG

Tel: 852-2564-9352

INDIA

91-22-652-6826

INDONESIA

62-21-570-5212

JAPAN

81-3-5644-5348

KOREA

82-2-708-5561

MALAYSIA

60-3-757-2722

NEW ZEALAND

64-9-302-8665

PAKISTAN

92-21-561-0150

PHILIPPINES

632-810-0331

SINGAPORE

65-476-9688

TAIWAN

886-2-2893-8108

THAILAND

66-2-271-3040 Ext. 310

KODAK VISION2 HD Color Scan

Film 7299

KODAK Publication No. H-1-7299t

Kodak, Eastman, Keykode, Vision2, and Wratten are trademarks.

New 2-05

Printed in U.S.A.

Loading...

Loading...