Page 1

Super12 Document Printer

A-61121

Part No. 1H7191

User’s

Guide

Page 2

Using the Super12 Document Printer

The

Kodak Digital Science

specified information on documents as they pass through the transport

system.

The Super12 Document Printer can be an accessory on the following:

Super12 Document Printer prints customer-

Kodak Digital Science

•

Kodak Digital Science

•

Kodak Imagelink

•

Kodak Imagelink

•

NOTE: For the purpose of this User’s Guide, when referring to the

scanner, scanner/microimager or microimager, the term

scanner

“

Some of the features of the

Printer are:

• Prints up to 144 characters per page (12 characters, 12 lines)

• Improved print quality

• A choice of red or black print cartridges

• Auto-purge

• Auto-wiping

• Adjustable print contrast

” will be used.

Document Scanner 9500

Document Scanner/Microimager 990

Scanners 900 and 923

Microimager 70

Kodak Digital Science

Super12 Document

A-61121 May 1999 1

Page 3

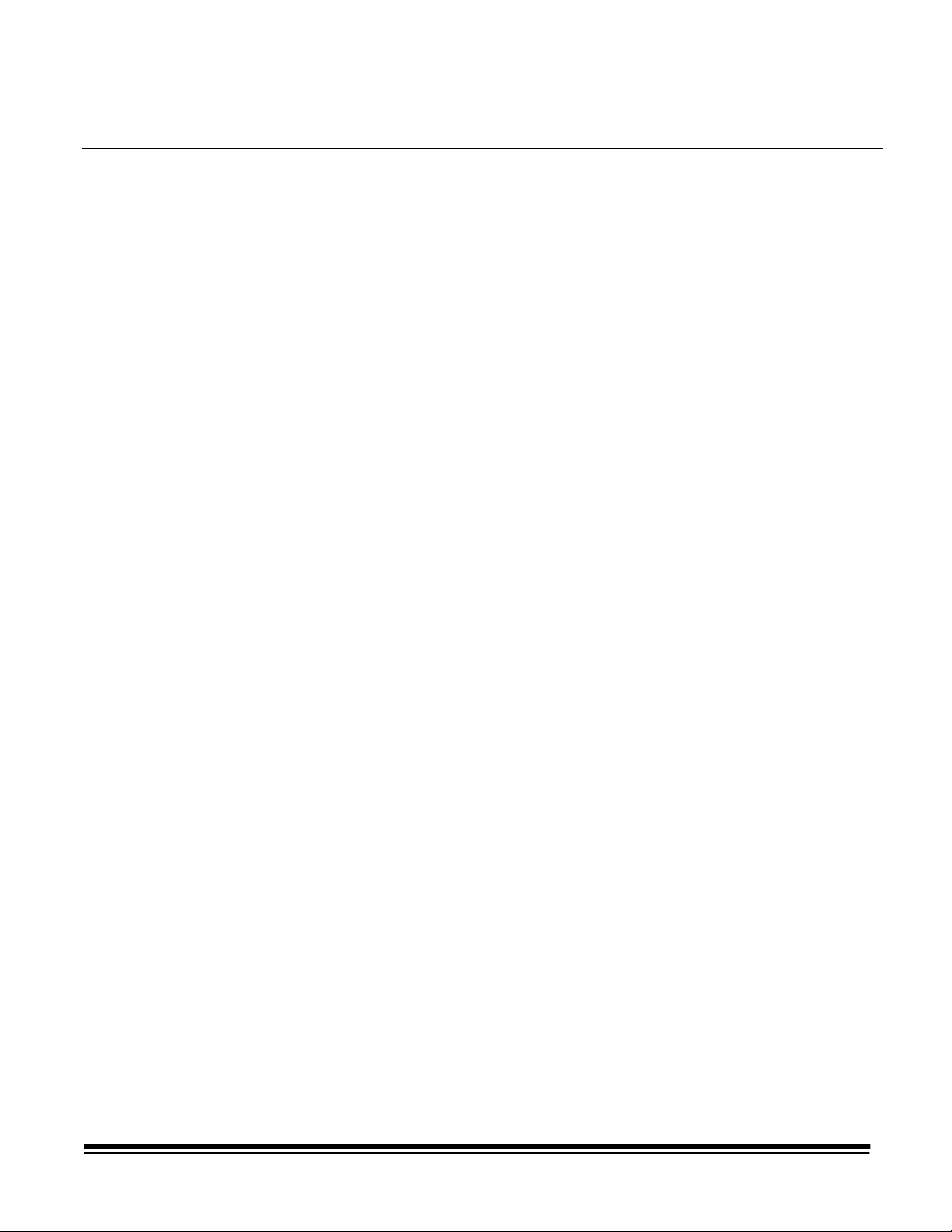

Printed information

The information printed by the Super12 Document Printer is defined

during installation.

The Super12 Document Printer prints up to 12 lines per document.

Each line can be a maximum of 12 characters, consisting of as many as

three of the following items:

• Document image address

• Day of the week

• Date

• Time

• Roll number, if applicable

• Total document count

• Messages 1–9

The same information may be printed on documents of all levels, or

different information may be printed on documents of different levels.

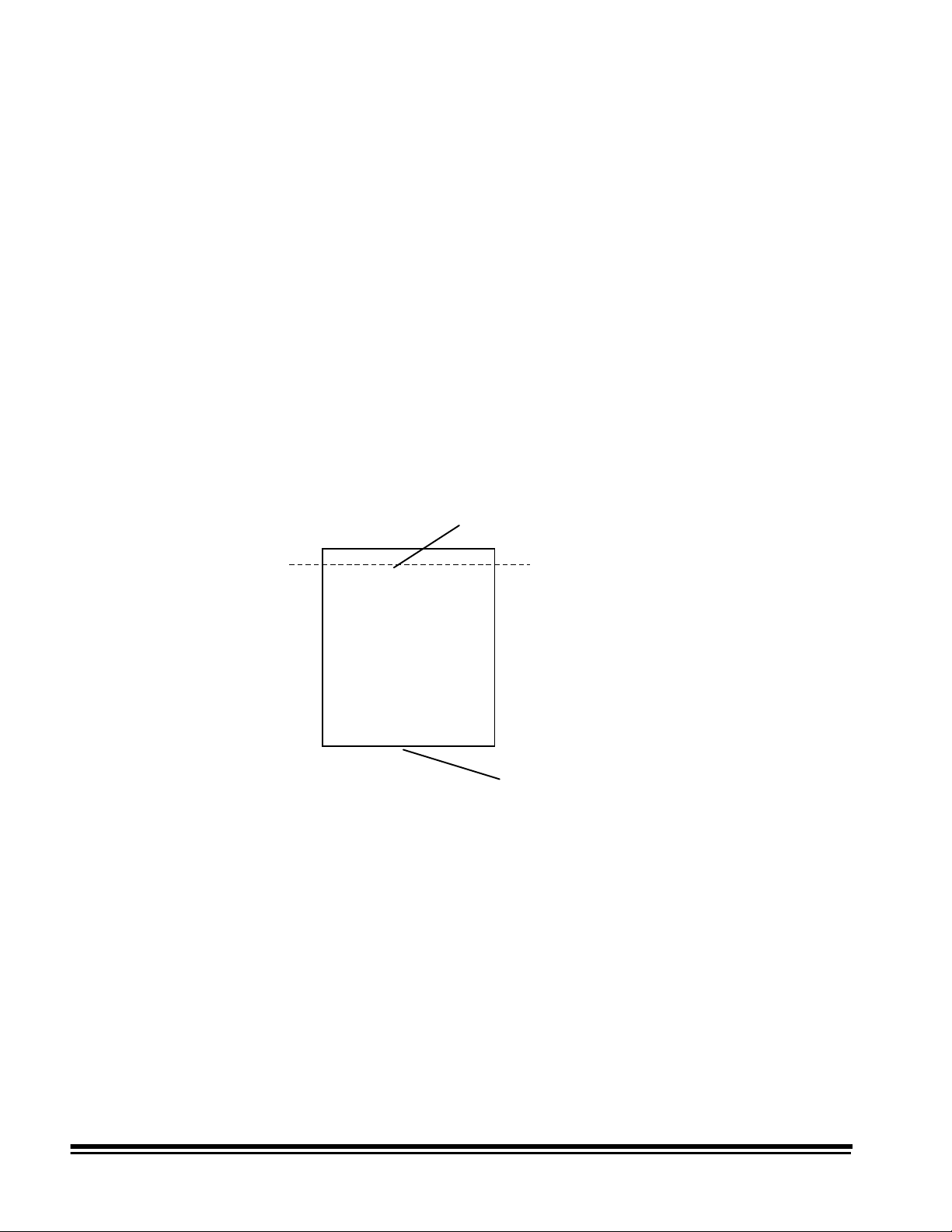

The information printed by the Super12 Document Printer always

appears in rows parallel to the leading edge of the document(s) as

shown:

Document travels

through transport

Orientation — information is printed on each document in Comic

orientation.

Font — only one font is available for the Super12 Document Printer.

IMPORTANT:

The Super12 Document Printer allows you to print only

up to line 15 (relative to the print template, which is used

in conjunction with print position to determine distance

of the printed information from the leading edge of the

document).

2 A-61121 May 1999

Page 4

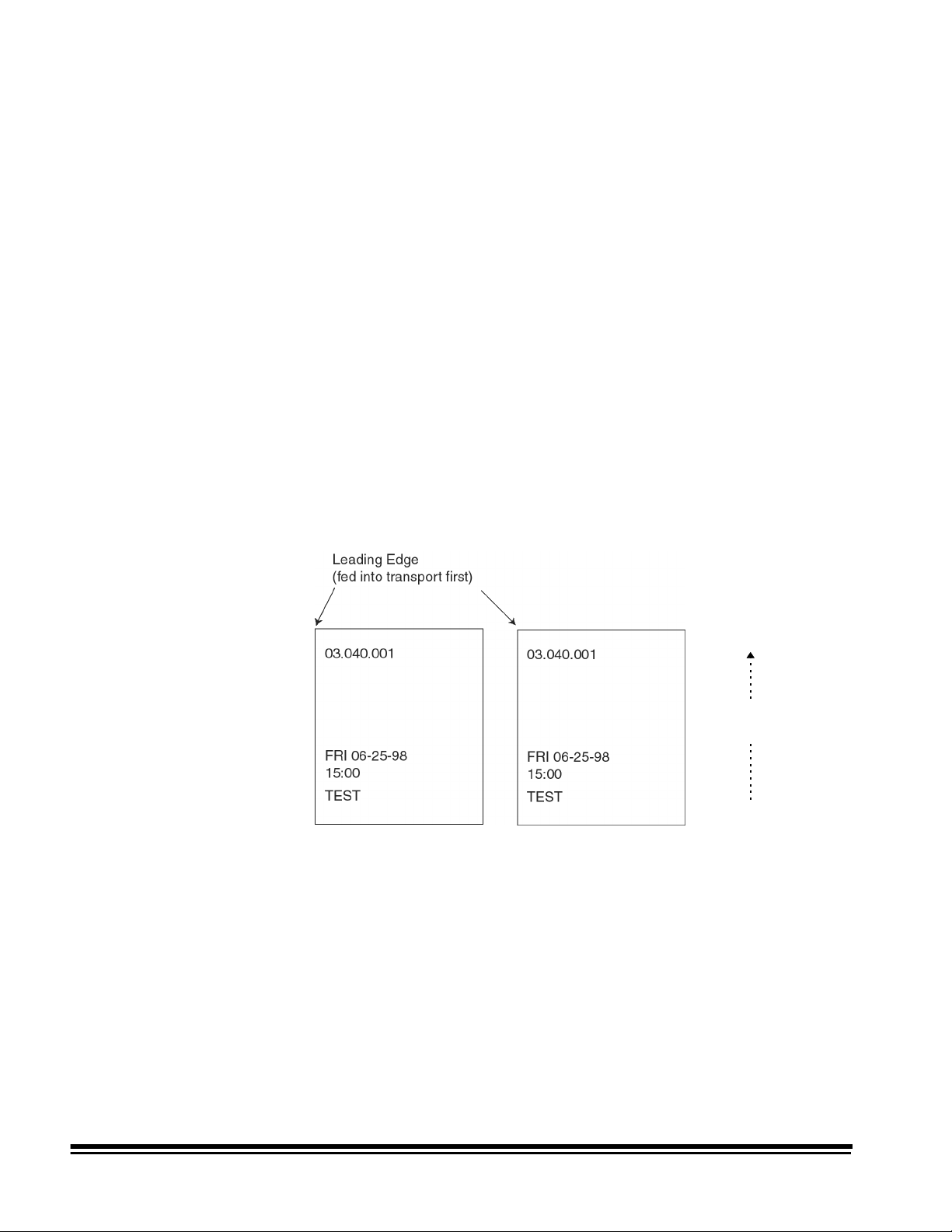

Changing the print location and print position

Super12

Document Printer

The location of the information you want printed on a document is

determined by the print location of the Super12 Document Printer and

the pre-defined print position.

Print Location

The Super12 Document Printer can be placed in one of six available

locations across the transport plate. The orientation of the printer when

in position 1, 2 or 3 is different than when the printer is in position 4, 5

or 6.

Printer bracket

Transport

plate

Plastic strips cover print

locations

NOTE: Before you change print locations, remove the plastic strips

covering the print locations you want to print in. The plastic

strips cover the print locations on both the transport plate and

the belt module (not shown in this illustration). Plastic strips

should be left in place for any unused locations.

A-61121 May 1999 3

Page 5

To remove the plastic strips from a print location:

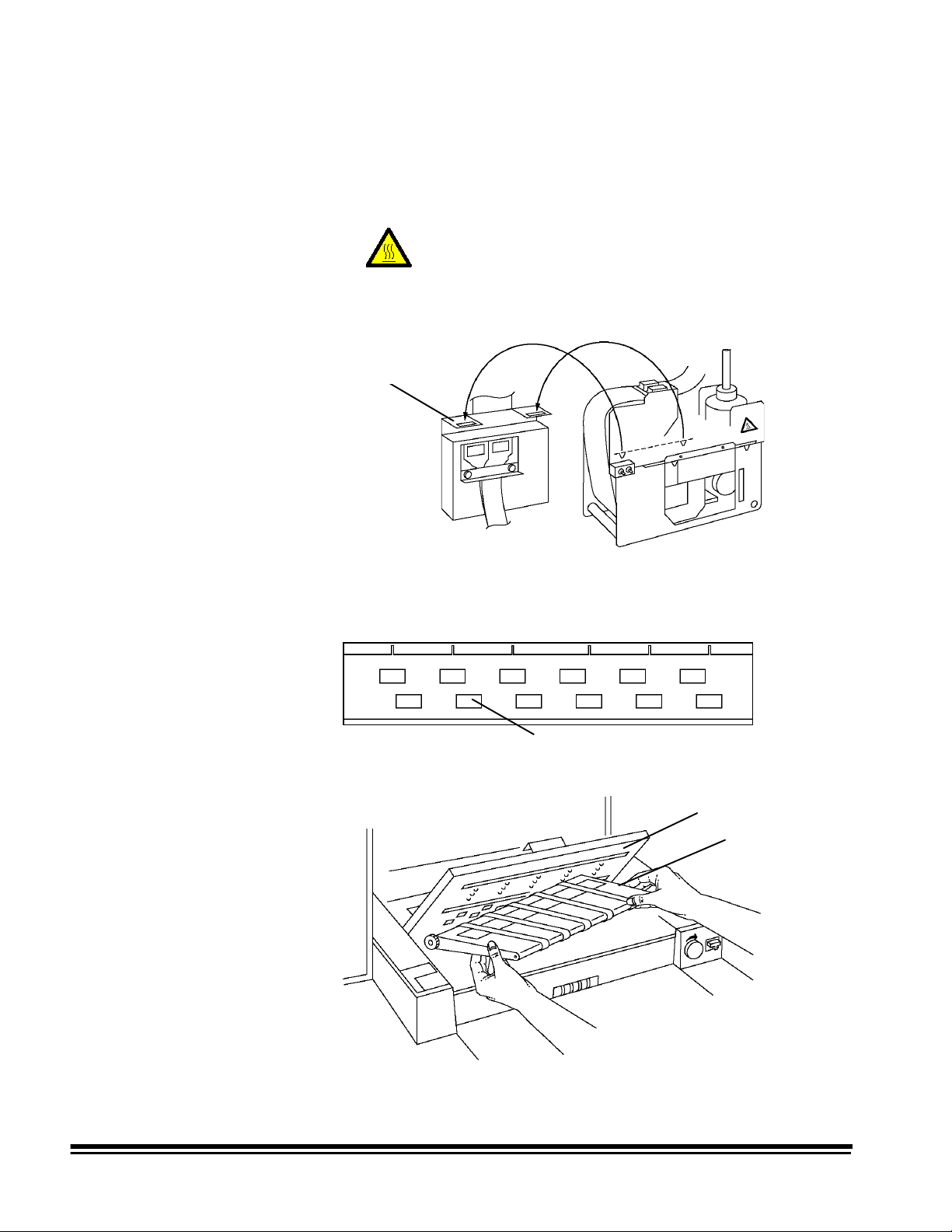

1. Open the front cover of the scanner.

2. Lift the printer f rom the printer bracket and place it on the hanger

bracket to keep it out of the way.

CAUTION: Hot surface, avoid contact.

NOTE:Be sure the flex cable is placed between the two hooks so it

does not get damaged.

Hanger bracket

3. Remove the plastic strips from any print locations (on the transport

plate) that you will be printing in.

Plastic strips

4. Lift the transport plate and remove the belt module.

Transport plate

Belt module

4 A-61121 May 1999

Page 6

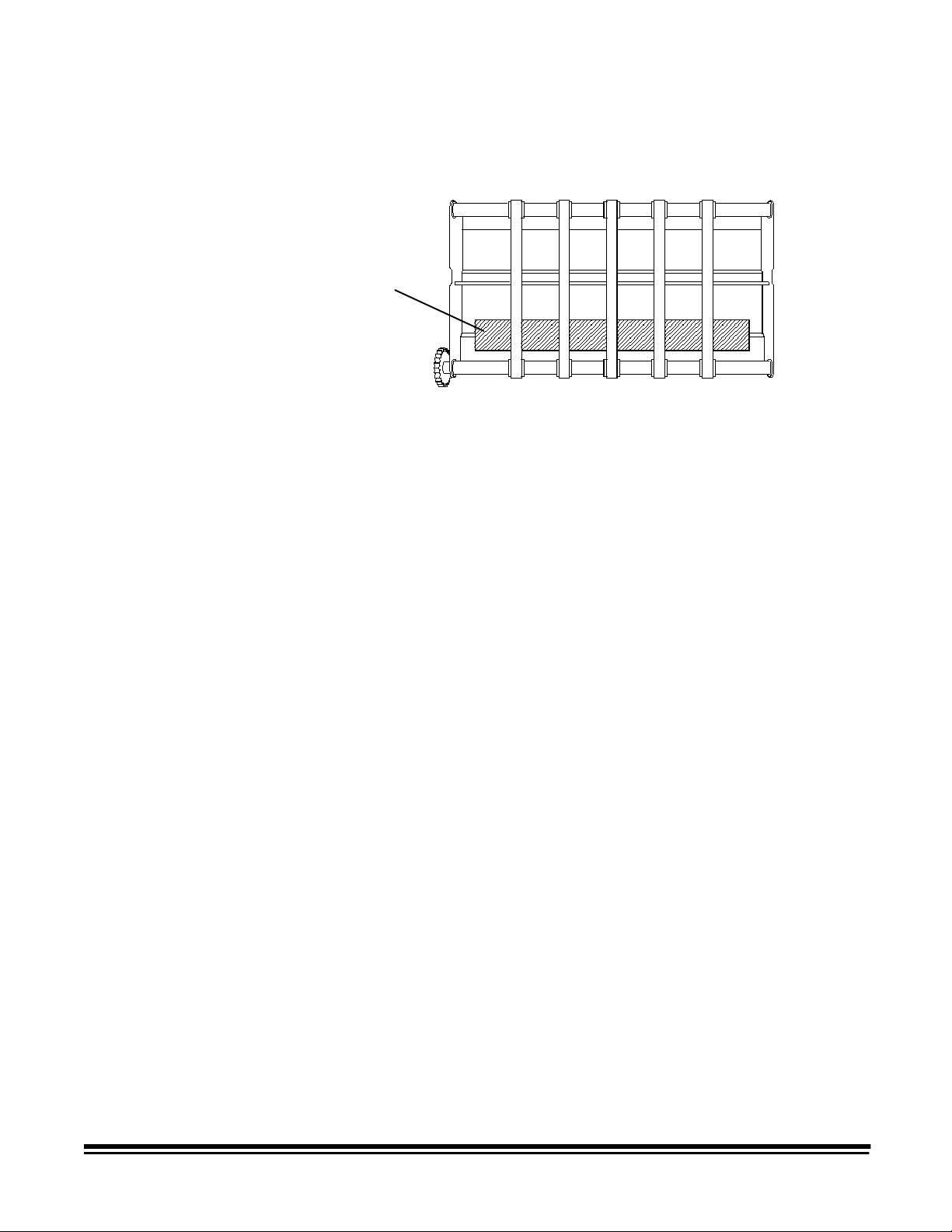

5. Remove the plastic strips from the desired print locations from the

underside of the belt module. The print locations that you remove

the plastic strips from should correspond with the strips you

removed from the transport plate.

Plastic strips

NOTE:Verify that the maintenance tray is in place before

continuing. If the maintenance tray is not in place, see

“Replacing the maintenance tray” for more information.

6. Replace the belt module.

7. Lower the transport plate.

8. Lift the printer from the hanger bracket, rotate it 180° if necessary,

and place it into the desired print location. The printer is firmly in

place if you cannot slide the printer from its location.

NOTE:If you are rotating the Super12 Document Printer, be careful

not to twist or strain the flex cable.

9. When finished, close the front cover.

A-61121 May 1999 5

Page 7

Print Position

The print position specifies how far from the leading edge (fed into the

transport first) of the document the information will be printed. The

default print position is defined at installation.

You can temporarily change the default print position by using function

code F46. The new print position will be used to print information until

function code F02 (Restore Mode) is used to return the starting print

position to its original value (provided mode overrides are not saved), or

until function code F46 is used again to change the print position(s).

NOTES:

• Restore Mode (F02) restores all initial printer settings, except the

print contrast setting and print alignment.

• The print position should be carefully calculated. Make sure to set

the print position close enough to the leading edge of the document

so the printed information is not truncated before reaching the

trailing edge of the document.

Leading edge

(fed into transport first

)

03.040.001

FRI 11-16-97

15:00

TEST

Starting print position

Trailing edge

6 A-61121 May 1999

Page 8

Enabling/disabling the Super12 Document Printer

Make sure the Super12 Document Printer is enabled before feeding

documents.

• The Super12 Document Printer may be enabled/disabled separately

at the mode level using function code F43.

• If you have enabled the Super12 Document Printer, but do not want

to print on the next document fed into the transport, you may omit

printing on the next document only by entering function code F44.

• During normal operation or a print test, the operator interface panel

will beep when the Super12 Printer has reached the capped or print

position. The beep occurs approximately 5 seconds after pressing

Run or Stop.

IMPORTANT:

Whenever Run or Stop is pressed, the Super12

Document Printer moves to a capped or print

position. The capped position covers the print

cartridges to keep them from drying out.

When Run is pressed, the message, E133 Feeder

waiting for printer will be displayed. When the

message clears and the scanner beeps, the printer

has moved into the print position.

When Stop is pressed, wait for the beep to sound

before opening the front door or turning off power,

so the printer has time to move into the capped

position

.

A-61121 May 1999 7

Page 9

Function codes

The information printed by the Super12 Document Printer is defined

during installation.

Individual modes are defined for use with specific applications. If a

Super12 Document Printer has been installed, some or all modes may

allow use of the Super12 Document Printer. In addition, the customerspecified information to be printed is defined for each mode.

The Super12 Document Printer provides easy installation and cleaning

of two print cartridges for 12-character printing. In addition to these

features, the following functions can be used:

• F39 Variable print contrast setting — allows you to increase or

decrease the amount of ink put on the document.

• F45 Print testing capability before use — allows you to test the print

quality of the Super12 Document Printer.

• F48 Auto-purging with no operator intervention — allows you to

initiate an automatic purging of the print heads. This function can be

done when the transport is off.

• F49 Print image alignment — allows you to specify how far to move

the left half of an image up or down on the document so it will align

with the right half of the image.

F39 — Changing the print contrast

• F56 Open jet/connection detection — allows you to determine

whether or not there are nonfunctional ink jets in the Super12

Document Printer. Also checks the print head(s) connection to the

flex cable to assure the print heads(s) are installed properly.

To change the print contrast setting:

1. Enter function code F39.

2. Press Enter. The current contrast setting will be displayed.

3. Press the up (↑) arrow to increment, or press the down (↓) arrow to

decrement the displayed value. Incremental values are: 12, 25, 37,

50, 62, 75, 87 and 100%.

NOTE:High contrast levels may cause ink smear on some types of

documents.

4. Press Enter to save the value.

8 A-61121 May 1999

Page 10

F45 — Verifying print quality

Perform the following procedure to verify the print quality is satisfactory:

1. Enter function code F45 (Print Test) and press Enter.

2. Press 2 (Test Pattern). The transport starts automatically.

3. Feed a blank sheet of paper; a test pattern will be printed.

4. Evaluate the appearance of the test pattern. A complete test

pattern should look similar to the following illustration:

• If the pattern is complete, begin work.

• If the pattern is not legible:

◊ Check to see that the print cartridges are inserted properly.

See the section entitled, “Installing a new print cartridge” for

more information.

◊ Perform function code F48 (Purge function) to help unclog

the print head jet openings.

◊ Repeat the print test.

5. Press 1 and verify your current mode image looks acceptable.

NOTES:

• If you select a blank print template or the No Print Template

option (depending on the specific mode you are printing in), then

the selection of 1, Current Mode Image, may print nothing.

• Print Test Pattern always prints with 100% contrast.

• The Mode Image prints with the specified contrast setting (F39).

A-61121 May 1999 9

Page 11

F49 — Aligning the print image

To align the print image so the left half of the image matches the right

half of the image:

1. Enter function code F49.

2. Press Enter. The current alignment value will be displayed.

3. Press the up (↑) arrow to move the left half of the image closer to

the leading edge of the document (the value will decrease) or press

the down (↓) arrow to move the left half of the image farther away

from the leading edge of the document (the value will increase).

4. Press Enter to save the value.

10 A-61121 May 1999

Page 12

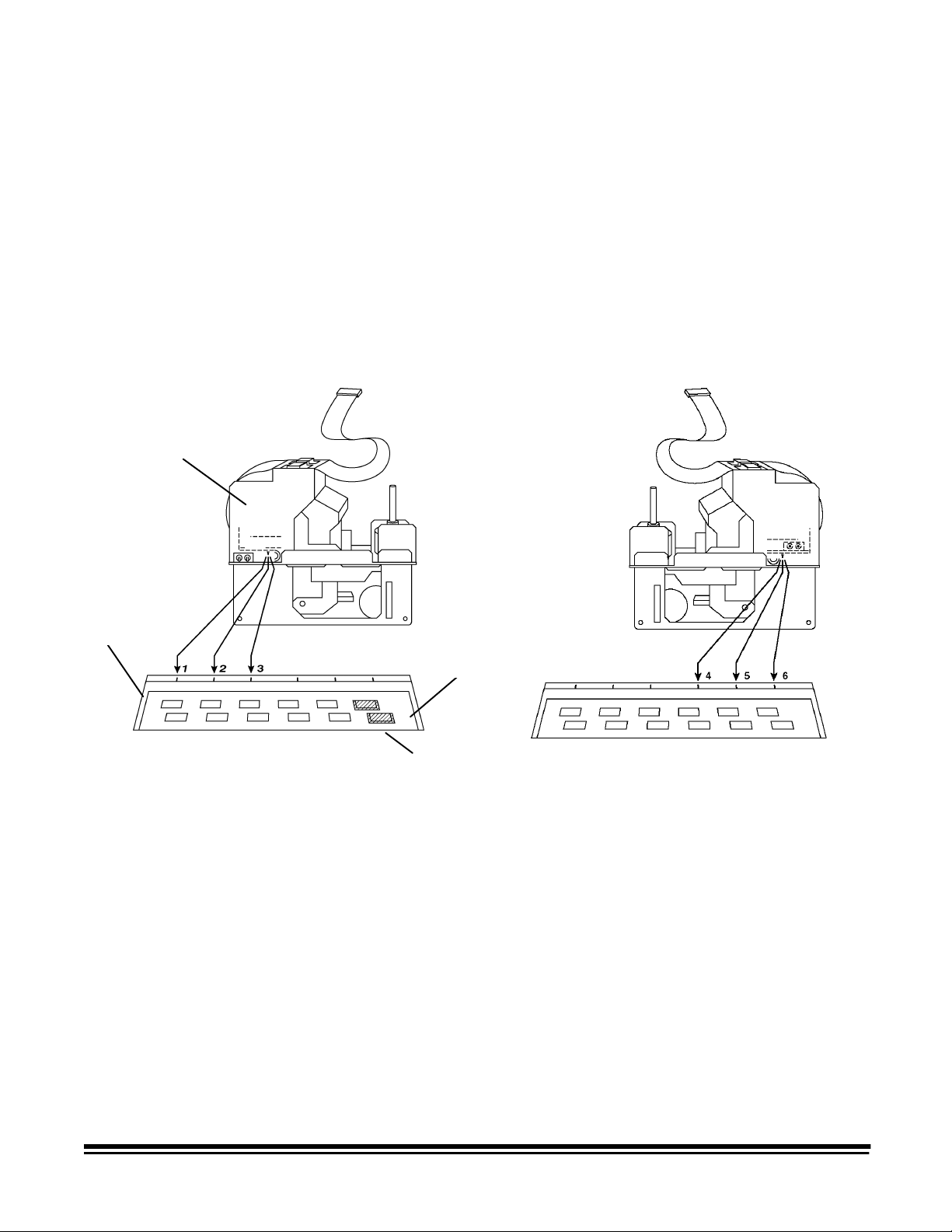

F56 — Checking the print cartridge jet connections

To determine if all ink jets are functioning properly:

1. Enter function code F56.

2. Press Enter. The number of jets out per character, as well as the

total number of jets out, will be displayed.

Print Cartridge Status

000000000000 00

All zeros will be displayed if the ink jets on both cartridges are

operating correctly.

NOTE:If the Super12 Document Printer is in print location 1, 2 or 3,

the left 6 characters are associated with the print cartridge

that is farthest away from the orientation switch, and the right

6 characters are associated with the print cartridge that is

closest to the orientation switch.

If the Super12 Document Printer is in print location 4, 5 or 6,

the left 6 characters are associated with the print cartridge

that is closest to the orientation switch, and the right 6

characters are associated with the print cartridge that is

farthest away from the orientation switch.

Orientation switch

3. Press C to clear the display.

A-61121 May 1999 11

Page 13

Installing a new print cartridge

Before you begin, be sure the scanner is powered-on.

IMPORTANT:

Do not remove or insert print cartridges while the

printer is in the capped position. Use function code

F40, Option 1 - Change Head(s) or damage can be

done to the Super12 Document Printer.

To install a new print cartridge(s):

1. Enter function code F40 and press Enter. The following message

will be displayed:

Print Head Position

1=Change Head(s) 2=Clean Printer

2. Select 1;a

message is no longer displayed, open the front cover of the

scanner.

3. Note the current location of the Super12 Document Printer, then lift

it out of the printer bracket and place it on the feeder top cover. This

will make it easier to insert the print cartridges.

Please Wait

CAUTION: Hot surface, avoid contact.

message will be displayed. When this

Front

cover

12 A-61121 May 1999

Page 14

4. If the print cartridges are already installed, remove the cartridges.

5. Open the new print cartridge package and remove the p rint

cartridge from the package.

6. Remove the protective tape from the bottom of the print cartridge.

NOTE:Do not discard the protective tape if you plan on storing a

partially used print cartridge. You will need to place this tape

over the orifice plate on the print cartridge to keep it from

drying out.

Orifice plate

Protective tape

The small window on the side of the black print cartridge indicates if

the cartridge is empty, full or how much ink is left in the cartridge. If

the window is green, the print cartridge is full; if the window is black,

it is empty.

green

indicates Full

black

indicates Empty

Red print cartridges do not have the Full/Empty indicator, therefore,

you can weigh the print cartridge to estimate how much ink remains.

A full print cartridge weighs approximately 110 grams; an empty

print cartridge weighs approximately 70 grams.

A-61121 May 1999 13

Page 15

7. Slide a new print cartridge in the Super12 Document Printer slots,

then gently push the cartridge forward until you hear and feel it click

into place. Use the illustration below as a guide.

IMPORTANT: If changing both print cartridges, install the one

that is farthest away from the Orientation switch

first.

8. When inserting the second print cartridge, hold it closer to the

orientation switch when sliding it in place

CAUTION: Hot surface, avoid contact.

Orientation

switch

9. After the print cartridges are installed and locked into place, press

the print head continuity button. This checks that the print head is

placed correctly in the printer.

Print head

continuity

button

Flex cable lights

14 A-61121 May 1999

Page 16

If either (or both) print cartridges are not seated correctly, one (or

both) of the yellow lights on the flex cable will flash. If this happens,

repeat Steps 7 through 9 until the print cartridges are installed

correctly.

NOTE:The flashing lights on the flex cable correspond with the print

cartridge(s) that is not positioned correctly.

10. W hen the print cartridges are installed correctly, reinstall the

Super12 Document Printer in the desired print location.

NOTES

• If you are rotating the Super12 Document Printer, be careful not

to twist or strain the flex cable.

• Be sure the plastic strips are removed only from the print

locations you want to print in, from both the transport plate and

belt module. Plastic strips should be left in place for any

unused locations.

11. Close the front cover when the Super12 Document Printer is seated

properly.

12. Perform function code F45 to test the print heads.

A-61121 May 1999 15

Page 17

Maintenance

This section provides:

• Recommended cleaning guidelines.

• A list of catalog numbers and supplies needed to maintain the

Super12 Document Printer.

• Cleaning procedures for the Super12 Document Printer.

• Instructions for changing the maintenance tray.

Cleaning guidelines

Use the following information as a guide when performing routine

maintenance of the Super12 Document Printer.

The Super12 Document Printer maintenance varies with usage levels,

paper types, print contrast and the number of characters printed. The

following guidelines are recommended:

• If you scan/film less than 5,000 documents per day, perform the

maintenance procedures on the Super12 Document Printer once

every two weeks.

• If you scan/film more than 5,000 documents per day, perform the

maintenance procedures on the Super12 Document Printer once a

week.

The imaging guides, transport and sensor areas must also be cleaned

daily to maintain print quality. Ink can accumulate in any one or all of

these areas, reducing overall print quality. Cleaning may be required

more often depending upon environmental conditions or paper types.

Refer to one of the following guides for detailed cleaning procedures:

A# Description

A-61092 User’s Guide for the

Scanner 9500

Kodak Digital Science

Document

A-61096 User’s Guide for the

Scanner/Microimager 990

A-41308 User’s Guide for the

A-61603V Video Tape (PAL format) — Maintenance and Feeder

Adjustment Procedures

A-61604V Video Tape (SECAM format) — Maintenance and

Feeder Adjustment Procedures

Video tapes and technical publications can be ordered through the BIS

Customer Service Center at: 1-888-247-1234.

Rubber gaskets and the maintenance tray should be changed

approximately every six months, this will vary with usage levels.

IMPORTANT:

Do not use any cleaning solutions or solvents when

Kodak Digital Science

Kodak Imagelink

Microimager 70

Document

performing these cleaning procedures.

16 A-61121 May 1999

Page 18

Cleaning materials and supplies

Use the Super12 Maintenance Kit that comes with the Super12

Document Printer.

The Maintenance Kit contains the following:

• Cleaning swabs

• Rubber gaskets

• A maintenance tray

The following supplies are available through your Kodak sales contact.

Supply CAT No.

Super12 Maintenance Kit 165 8483

Black print cartridge (6/package) 822 1376

Red print cartridge (6/package) 145 6532

Cleaning the document printer

To clean the Super12 Document Printer, follow the steps below.

1. Enter function code F40 and press Enter. The following message

will be displayed:

Print Head Position

1=Change Head(s) 2=Clean Printer

2. Select 1;a

Please Wait

message will be displayed. When this

message is no longer displayed, open the front cover of the

scanner.

3. Note the current location of the Super12 Document Printer, then lift

it out of the printer bracket and place it on the feeder top cover.

CAUTION: Hot surface, avoid contact.

4. Remove the print cartridges. If there is any ink build-up on the print

cartridges, clean it with a swab.

5. Place the printer back in the desired print location.

6. Close the front cover.

A-61121 May 1999 17

Page 19

7. Enter function code F40 and press Enter. The following message

will be displayed:

Print Head Position

1=Change Head(s) 2=Clean Printer

8. Select 2;a

Please Wait

message will be displayed. When this

message is no longer displayed, open the front cover of the

scanner.

9. Lift the printer out of the printer bracket and place it on the feeder

top cover.

10. With a supplied swab, wipe off the rubber gaskets and the area

around the gaskets.

NOTE:The rubber gaskets can be removed and cleaned.

Periodically, it may be necessary to replace the rubber

gaskets with a new set. Make sure the gaskets are seated

properly before continuing.

Gaskets

Wipers

11. W ipe off any ink build-up on the rubber wipers.

12. Tilt the Super12 Document Printer, as illustrated, and wipe the flex

cable connectors and splatter guards.

Splatter guards

Flex cable connectors

13. When finished, place the Super12 Document Printer into the

desired print location.

14. Close the front cover.

18 A-61121 May 1999

Page 20

To replace the print cartridges:

15. Enter function code F40 and press Enter. The following message

will be displayed:

Print Head Position

1=Change Head(s) 2=Clean Printer

16. Select 1;a

Please Wait

message will be displayed. When this

message is no longer displayed, open the front cover of the

scanner.

17. Lift the printer out of the printer bracket and place it on the feeder

top cover.

18. Reinsert the print cartridges.

19. Press the print head continuity button to verify both print cartridges

are installed correctly.

Print head

continuity button

20. Replace the Super12 Document Printer to the desired print location.

21. Close the front cover.

A-61121 May 1999 19

Page 21

Cleaning the transport area

To thoroughly clean the transport area, perform the following procedure:

1. Open the front cover.

2. Note the current location of the Super12 Document Printer, then lift

it from the printer bracket, being careful not to strain the flex cable.

3. Place the Super12 Document Printer on the hanger bracket to keep

it out of the way while you are cleaning other areas of the machine.

CAUTION: Hot surface, avoid contact.

NOTE:Be sure the flex cable is placed between the two hooks so it

does not get damaged.

Hanger bracket

The following illustrations show the transport areas which need to be

cleaned and how to clean them:

1. Lift the transport plate.

2. Wipe the transport plate surfaces with a slightly water-dampened,

lint-free cloth to remove any ink deposits. Ensure that the topside of

the print locations are clean.

3. Wipe the bottom of the transport plate thoroughly with a slightly

water-dampened, lint-free cloth. Make certain that the underside of

the print locations are clean.

4. Insert the Super12 Document Printer into the desired position in the

transport plate, being careful not to strain the flex cable.

5. Close the front cover.

20 A-61121 May 1999

Page 22

Replacing the maintenance tray

Periodically the Super12 Document Printer maintenance tray may need

to be replaced.

To access and replace the maintenance tray:

1. Open the front cover of the scanner.

2. Place the printer on the hanger bracket so it is out of the way.

CAUTION: Hot surface, avoid contact.

Hanger bracket

NOTE:Be sure the flex cable is placed between the two hooks so it

does not get damaged.

3. Lift and lock the transport plate into place.

4. Lift and remove the belt module and place it aside.

Transport plate

Belt module

A-61121 May 1999 21

Page 23

5. Lift out the used maintenance tray and dispose of it according to

your local and state regulations.

Maintenance tray

6. Open the package containing the new maintenance tray and

remove it.

7. Insert the new maintenance tray; be sure it is firmly in place. The

alignment blocks on the bottom of the maintenance tray should be

placed around the two angled brackets as shown:

When the maintenance tray is seated correctly, the ink spray from

the Super12 Document Printer should be deposited in the center

area of the foam in the maintenance tray.

6. Re-install the belt module.

7. Unlock and replace the transport plate.

8. Remove the printer from the hanging bracket and place it in the

proper print location.

9. Close the front cover.

22 A-61121 May 1999

Page 24

Storage and handling of print cartridges

If unused print cartridges are going to be stored for a period of time,

replace the protective tape on the orifice plate of the print cartridge.

Orifice plate

Protective tape

NOTE: Dispose empty print cartridges according to your local and state

regulations.

A-61121 May 1999 23

Page 25

Troubleshooting

Problem Solution

This section lists possible problems you may encounter when using the

Kodak Digital Science

Super12 Document Printer.

Printing a partial image or printing

backwards

Experiencing print problems at startup

due to heads drying up

Image is drifting from the desired print

location

Poor print quality If you are experiencing poor print quality, check the

Be sure the Super12 Document Printer is seated correctly

on the printer bracket.

• Press Stop and wait approximately 5 seconds for the

Super12 Document Printer to reach the capped position

before opening any doors, performing any printer

functions or turning off any switches.

• Press F48 (Auto Purge).

• Press F45 (Test Pattern).

See the next section entitled “How print position is effected

by patch reading” for more detailed information.

following:

• Check to be sure the print cartridges are not empty.

If you are using a black print cartridge, check the

Full/Empty indicator to see how much ink remains in the

cartridge. If it is empty, insert a new print cartridge.

If you are using a red print cartridge, weigh the print

cartridge to be sure it has an adequate ink supply; a full

print cartridge weighs approximately 110 grams; an

empty print cartridge weighs approximately 70 grams.

• Use F56 to verify that all jets are functioning properly.

• Clean the wipers and gaskets. See the procedures in

the section entitled, “Maintenance”.

When finished:

• Press F48 (Auto Purge).

• Press F45 (Test Pattern).

24 A-61121 May 1999

Page 26

How print position is effected by patch reading

Patch Reading OFF — Print Position 0.25 inch

Print Position

The ability to print at the designated print position will be effected by

patch reading, and by the amount of printed information which changes

for each document. If you encounter print position drift, it may be

necessary to change your print template using the Mode Setup

Software or change your current print position further down the page.

Following are some examples illustrating print drifting with Patch

Reading turned off and on.

Patch Reading turned off

The following illustration shows the print position when 1 to 3 half or full

print lines have been changed with Patch Reading turned off.

NOTE: A half print line consists of 6 characters; a full print line consists

of 12 characters.

Print position drifting occurs when more than 3 full print lines need to

change.

2 half print lines

changed

2 full print lines

changed

3 half print lines

changed

3 full print lines

changed

Patch Reading turned on

If Patch Reading is turned on, and if the print position exceeds 1 inch,

then the patch window will be forced to 4 inches. Patches must be

within the first 4 inches of the document. Following is a table indicating

print positions and patch window size.

Print Position Patch Window Close

.125 inches 2.5 inches after lead edge

.25 inches 2.5 inches after lead edge

.375 inches 2.5 inches after lead edge

.50 inches 2.5 inches after lead edge

.625 inches 2.5 inches after lead edge

.75 inches 2.5 inches after lead edge

.875 inches 2.5 inches after lead edge

1 inch 4 inches after lead edge

more than 1 inch 4 inches after lead edge

A-61121 May 1999 25

Page 27

If the print position is set at less than 1 inch, the patch window will close

¾

t

at 2.5 inches after the lead edge; the printer can change up to 1 full

print line and be able to print at the designated position. However, if

more than 1 full print line needs to be changed, the image may drift

down the page depending on how much more information needs to be

changed.

Patch Reading ON — Print Position 0.25 inches — Patch Window is 2.5 inches

Print Position

Approximately

¾-inch drift

Approximately

¼-inchdrift

Approximately

1

-inchdrif

1 half print

line changed

1 full print line

changed

2 half print

lines changed

2 full print

lines changed

If your document is longer than 3 inches and the print position is set at

1 inch, the patch window will close at 4 inches after the lead edge; the

printer can change up to a half print line and be able to print at the

designated position. However, if more than a half print line needs to be

changed, the image may drift down the page depending on how much

more information needs to be changed.

Patch Reading ON — Print Position 1 inch — Patch Window is 4 inches

PrintPosition

Approximately

½-inch drift

Approximately

½-inch drift

Approximately

1½-inch drift

3 half print

lines changed

Approximately

1-inch drift

3 full print

lines changed

Approximately

2 ½-inch drift

1 half print

line changed

1 fullprint line

changed

2 halfprint

lines changed

2fullprint

lines changed

3 half print

lineschanged

3fullprint

lines changed

For example, if 2 full print lines need to be changed, the image may

print 1.5 inches further down the page; not at the designated 1 inch.

NOTE: Print drift may occur if you use function codes F39 or F49 while

the transport is running.

26 A-61121 May 1999

Page 28

Error codes

Following is a list of errors codes you may encounter when using the

Super12 Document Printer.

Error: E133 Feeder waiting for printer.

Probable cause: The feeder will not be ready until the printer has

moved to the print position.

Solution: Wait until the printer has moved into the print position.

Error: E206 Check Print Cartridge(s)

Probable cause: This error may be displayed for one of the following

reasons:

• Either no print cartridge(s) is installed or one or both print

cartridge(s) may be installed but not making a good connection.

• The print cartridge may be defective.

• The flex cable may not be working properly.

Solution: Be sure the print cartridges are seated correctly and that they

are making a good connection.

1. Enter function code F56 to determine if more than 10 jets are out on

any one or more characters.

2. Press F40 and select Option 1, Change Heads.

3. Open the front cover of the scanner.

4. Lift the printer out of the printer bracket. One or both of the flex

cables lights will be blinking.

5. Determine which print cartridge is not making a good connection.

The blinking light(s) on the flex cable correspond with the print

cartridge that is not seated correctly.

6. Reinstall the print cartridges.

IMPORTANT:

When installing the print cartridges, be sure you

hear and feel the print cartridge click into place.

7. Press the print head continuity button. If the flex cable lights stop

flashing, a good connection is made.

8. Place the printer back in the desired print location and close the

door.

A-61121 May 1999 27

Page 29

If E206 continues to be displayed or the flex cable lights continue to

flash, enter F45 to do a Print Test. If the print quality is acceptable,

ignore the E206 error or the flashing flex cable lights.

If the print quality is not acceptable, try changing one or both of the print

cartridges, then enter F45 again to do another Print Test.

If the print quality is still not acceptable, the flex cable may not be

working properly. Call service.

Error: E806 Printer System Error

Probable cause: One or both print cartridges may be seated

incorrectly.

Solution: Be sure the print cartridges are seated correctly. If the

problem persists, replace the print cartridges. If E806 continues to be

displayed, call service.

Error: E810 Printer System Error

Probable cause: If you encounter this error and the system is still

working, then the print template is longer than 15 lines.

Solution: Enter Mode Setup Software and redefine the print template. If

you do not have Mode Setup Software, call service.

If you encounter this error and the system is not working, call service.

Error: E813 Printer System Error

Probable cause: This is a motor error; something has stopped the

progress of the motor in the Super12 Document Printer.

Solution: Perform the following steps:

1. Open the front door and clear any items that could block or interfere

with the swing arm.

2. Close the front door. The printer will move into the capped position

and any errors should clear.

If the error persists, call service.

28 A-61121 May 1999

Page 30

A-61121 Part No. 1H7191 3/99

©Eastman Kodak Company, 1999

Printed in U.S.A.

EASTMAN KODAK COMPANY

Document Imaging

Rochester, New York 14650

Kodak, Imagelink, Digital Science and

the ds monogram symbol are

trademarks of Eastman Kodak

Company.

Printed on recycled paper.

DOCUMENT

IMAGING

Loading...

Loading...