Page 1

Scanners

Patch Code Information

A-61599

CAT No. 845 9380

A-61599

October 2006

Page 2

Patch Code Information for Kodak Scanners

Patch description

This document provides information that supports the following scanners.

• Kodak Scanners 9XYZ, 5XYZ, 7XYZ, i800/i1800 (with image addressing) Series Scanners and the

Kodak Microimager 70—these scanners are equipped with the Patch Reader. The Patch Reader recognizes

patches with bars that are parallel to the lead edge of the document. All of these scanners may use patches

for image addressing. In addition, the i800/i1800 (with image addressing) Series Scanners may use toggle

patches for Color on the Fly functionality.

• Kodak Scanners i280, 3590C and i600/i1800 (without image addressing) Series Scanners—these

scanners are not equipped with a Patch Reader. These scanners recognize patches with bars that are per-

pendicular to the lead edge of the document. These scanners will only recognize the toggle patch for Color on

the Fly functionality and do not have image addressing.

A patch is a pattern of parallel, alternating black bars and spaces that is printed on a document.

Kodak Scanners which have patch reading capability can recognize patch documents

and automatically assign a document image level, increment the document image address, or perform Color on

the Fly functionality.

The wide bars should be 0.20 inches (5 mm) wide

be 0.08 inches (2.03 mm) wide

(20 mm)

+0.01 inches (0.25 mm). The minimum overall length of the patch bars is 2 inches (50 mm).

+ 0.01 inches (0.25 mm). The maximum width of the patch code is 0.80 inches

NOTE: The patch codes illustrated below are not to spec. Use the patch sheets included in this packet for

specifications.

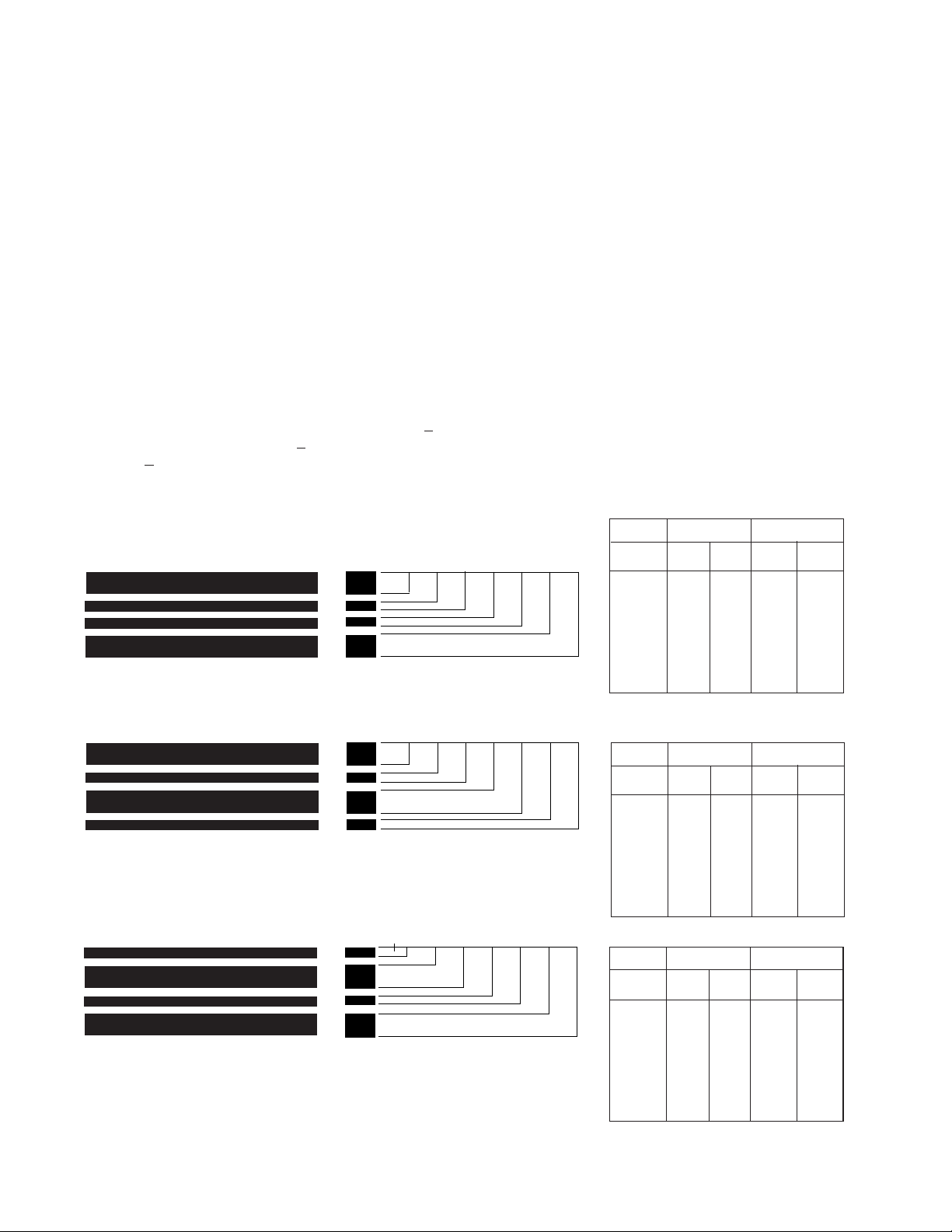

Patch Codes

Patch 2

Patch code specifications

Patch 2

Assigns image level 2 to the

current document.

+ 0.01 inches (0.25 mm). The narrow bars and spaces should

Zone Millimetres

A

B

C

D

E

F

G

A 0.19 0.21 4.83 5.33

B 0.27 0.29 6.86 7.37

C 0.35 0.37 8.89 9.40

D 0.43 0.45 10.92 11.43

E 0.51 0.53 12.95 13.46

F 0.59 0.61 14.99 15.49

G 0.79 0.81 20.07 20.57

Inches

Low

Range

High

Range

Low

Range

High

Range

Patch 3

Assigns image level 3 to the

current document.

Patch T / Transfer Patch

Assigns a predefined image level

to the next document. The

predefined image level is based

upon the transfer patch definition

which is defined for each applica-

Patch 3

A

B

C

D

E

F

Patch T / Transfer Patch

A

B

C

D

E

F

tion. For example, if the transfer

patch definition is image level 2,

then use of a transfer patch

assigns image level 2 to the next

document.

Zone Inches Millimetres

High

High

Low

Range

Low

Range

Low

Range

Range

G

G

A 0.19 0.21 4.83 5.33

B 0.27 0.29 6.86 7.37

C 0.35 0.37 8.89 9.40

D 0.43 0.45 10.92 11.43

E 0.63 0.65 16.00 16.51

F 0.71 0.73 18.03 18.54

G 0.79 0.81 20.07 20.57

Zone Inches Millimetres

Low

Range

Range

A 0.07 0.09 1.78 2.29

B 0.15 0.17 3.81 4.32

C 0.35 0.37 8.89 9.40

D 0.43 0.45 10.92 11.43

E 0.51 0.53 12.95 13.46

F 0.59 0.61 14.99 15.49

G 0.79 0.81 20.07 20.57

High

Range

High

Range

Page 3

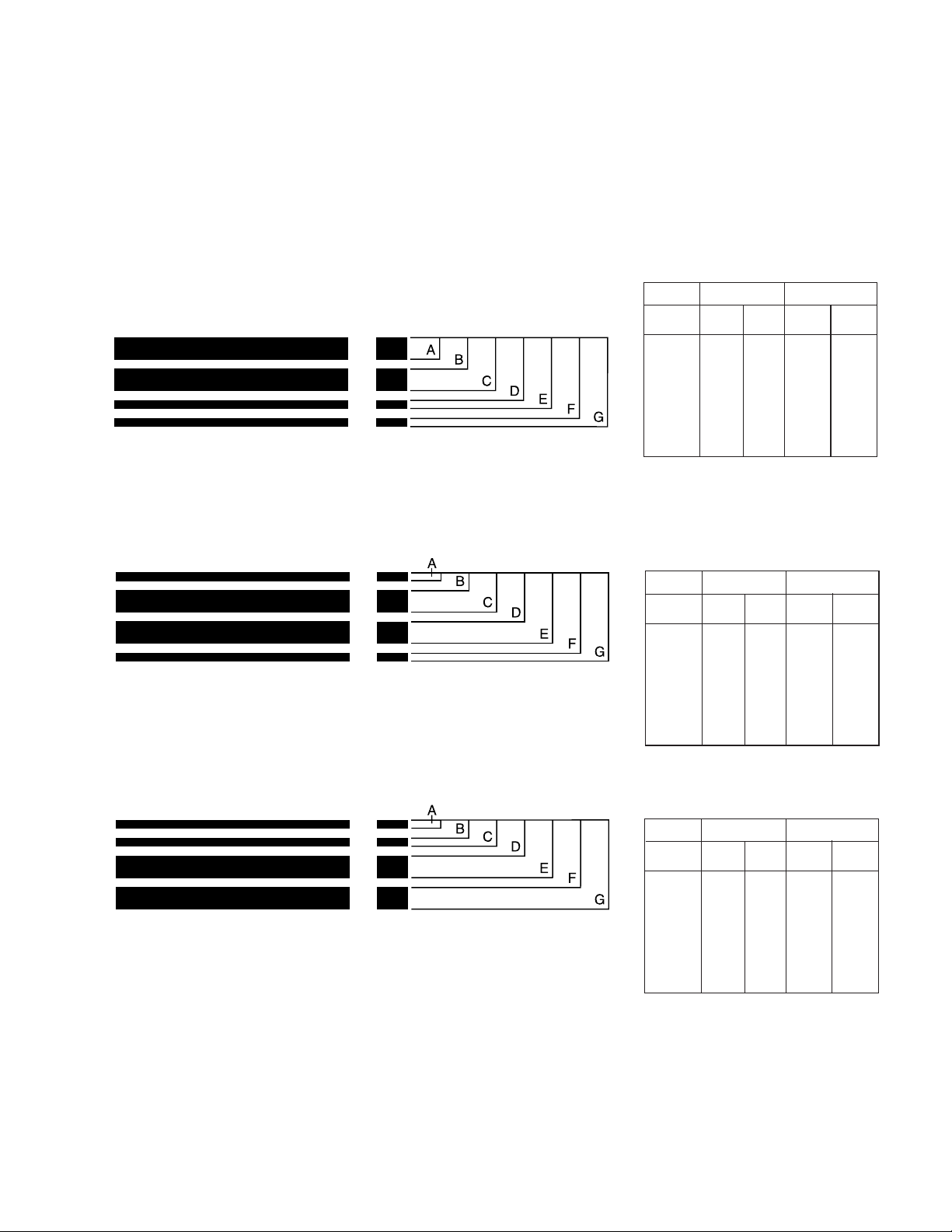

Patch Types 1, 4 and 6 can be used by the host for post-scan image control for the i800/i1800 (with image

addressing) Series Scanners (they are not used for image addressing).

The Toggle Patch may be used to switch back and forth from bi-tonal and color/grayscale scanning for the

i280, 3590C, i600, i800 and i1800 (without image addressing) Series Scanners. This provides Color on the

Fly during capture, with no need for post-scan processing by the host application.

NOTE: The patch codes illustrated below are not to spec. Use the patch sheets included in this packet for

specifications.

Patch Codes

Patch code specifications

Patch 1 Patch 1

Patch 4/Toggle Patch

Patch 4/Toggle Patch

Zone Millimetres

Inches

Low

Range

High

Range

Low

Range

High

Range

A 0.19 0.21 4.83 5.33

B 0.27 0.29 6.86 7.37

C 0.47 0.49 11.94 12.45

D 0.55 0.57 13.97 14.48

E 0.63 0.65 16.00 16.51

F 0.71 0.73 18.03 18.54

G 0.79 0.81 20.07 20.57

Zone Inches Millimetres

High

Low

Range

Range

Low

Range

Range

High

A 0.07 0.09 1.78 2.29

B 0.15 0.17 3.81 4.32

C 0.35 0.37 8.89 9.40

D 0.43 0.45 10.92 11.43

E 0.63 0.65 16.00 16.51

F 0.71 0.73 18.03 18.54

G 0.79 0.81 20.07 20.57

Patch 6

Patch 6

Zone Inches Millimetres

High

Low

Range

Range

Low

Range

Range

High

A 0.07 0.09 1.78 2.29

B 0.15 0.17 3.81 4.32

C 0.23 0.25 5.84 6.35

D 0.31 0.33 7.87 8.38

E 0.51 0.53 12.95 13.46

F 0.59 0.61 14.99 15.49

G 0.79 0.81 20.07 20.57

Page 4

For Kodak Scanners 9XYZ, 5XYZ, 7XYZ, i800/i1800 (with image addressing) Series Scanners

and 70 Microimager:

The minimum overall length of the patch bars is 2 inches (50 mm).

Patch positioning

Horizontal and vertical placement of the patch code

is critical for proper operation. If the patch code is

placed improperly on the document, the patch

sensors may fail to sense the patch.

• Patches should appear with the bars parallel to

the leading edge of the document (fed into the

transport first).

• There must be at least 0.25 inches (6 mm) of

space between the patch code and any other

printed information.

Horizontal placement/positioning

• There are five patch sensor locations for the

scanner models listed above, except for the i1800

Series Scanners which have four patch sensor

locations.

• Horizontal placement of patch codes is affected by

the position of the side guides. Make certain the

side guides are positioned so the patch code will

be transported directly past the window in which

the patch reader is installed.

• Use of a standard 2.5-inch (62.5 mm) patch code

is recommended to ensure the patch code may

still be read even if there is a slight variation in the

positioning of the side guide(s).

Refer to Figure A.

Figure A

Center of Transport

Page 5

Leading Edge of Document

(fed into transport first)

A

Vertical placement/positioning

• Patch codes must appear at least 0.25 inches

(6 mm) from the right, left, and leading edges of

the document.

• Patch codes must appear no more than 3.75

inches (94 mm) from the leading edge of the

document [1.6 inches (40 mm) on the 5XYZ and

7XYZ Scanners].

Refer to Figure B.

BC

3.75 inches (94 mm)

Patch Area

Figure B

A, B, and C = 0.25 inches (6 mm)

Patch Reader Positions

for 9XYZ, 5XYZ, 7XYZ,

i800 Series Scanners

and 70 Microimager

Patch Reader Positions

for i1800 Series Scanners

(with image addressing)

Page 6

For i280, 3590C and i600/i1800 (without

image addressing) Series Scanners

The minimum overall length of the patch bars is

0.75 inches (19 mm).

Patch Positioning

Horizontal and vertical placement of the patch

code is critical for proper operation. If the patch

code is placed improperly on the document, the

scanner may fail to read the patch.

• Patches should appear with the bars perpendicular to the lead edge of the document (fed

into the transport first).

• Any other (non-patch) printed information to the

left or right of the patch could cause false

readings (see “E” on the illustration).

• Patch codes must be at least 0.25 inches (6 mm)

from the left and right edge of the document and

must appear at least 0.5 inches (12.7 mm) from

the lead edge of the document.

• The Patch Reading Area ends 2.0 inches from the

lead edge of the document. At least 0.75 inches of

the patch code must appear within the Patch

Reading Area.

For All Scanners

Printing specifications

A patch code is a parallel pattern of bars (black,

low reflectance) and spaces (clear, high

reflectance).

The ink used to print the black bars must be

carbon-based black or equivalent. The printed

black bars must reflect less than 20% of the light

source.

The bond paper that forms the spaces must be

white or a light pastel color that reflects at least

65% of the light source.

This package contains several pages of cameraready patch codes. These copies adhere to the

specifications provided and may be used by a

printer when creating patch documents.

Two types of camera-ready patch codes are

provided:

• 2.5-inch (62.5 mm) long patch codes which may

be used when preprinting patch code labels or

when printing patch codes directly on application documents.

Reliability requirements

• Print the patch code only on the top page of

multiple-part forms with carbon paper inserts.

Smudged carbon in the patch code area can

cause false readings.

• If patch-coded forms are printed in pads, make

sure the torn edges are not fed into the machine

first (not the leading edge). A ragged leading edge

preceding the patch code may cause the distance

to the first bar to be out of tolerance.

• Avoid photocopying patches. Photocopiers tend

to increase the size of the black bars while

simultaneously reducing the white space, thus

altering the print specifications.

• Print patch codes with carbon-based ink.

NOTES: Ink which is used to print bar codes

typically has a high carbon content.

Soy-based inks are not recommended.

• Avoid printing patches on glossy paper. Glare can

cause the patch to be misread.

• Full-page width and full-page length patch code

documents which may be used to create fullpage patch documents which are used as batch

headers; interleaved among application documents. These full-page patches may be fed into

the transport without regard to orientation.

Page 7

Page 8

A-61599 10/06

Printed in U.S.A.

Eastman Kodak Company

Document Imaging

Rochester, New York 14650

© Kodak,2006. Kodak is a

trademark Kodak.

Loading...

Loading...