Page 1

Document Scanner 9500

A-61092

Part No. 1E8133

User’s

Guide

Page 2

Safety Information for Installation Instructions for the

Document Scanner 9500

Science

IMPORTANT: Equipment shall be installed by qualified

personnel.

WARNING: Dangerous voltage. Disconnect the main

power before installation.

Kodak Digital

CAUTION: Hot surface, avoid contact

ATTENTION: Eviter le contact, pieces brulantes

VORSICHT: Heisse oberflaeche, beruehrung vermeiden

Page 3

Safety Information for User/Installation Instructions for the

Automatic Document Feeder

Digital Science

IMPORTANT: Equipment shall be installed by qualified

personnel.

WARNING: Dangerous voltage. Disconnect the main

power before installation.

Kodak

CAUTION: Moving parts, avoid contact

ATTENTION: Eviter le contact, pieces en mouvement

VORSICHT: Bewegliche teile, beruehrung vermeiden

Page 4

1 Introduction

The

Kodak Digital Science

medium- to high-resolution rotar y scanner designed for high-volume

digital capture of business documents. The Document Scanner 9500

captures printed characters, handwritten t ext, and graphics from

documents of various sizes.

NOTE: Illustrations in this User’s Guide are shown using the semi-

automatic feeder.

Document Scanner 9500 is a high-speed,

Scanner features

The Document Scanner 9500 has the following features:

• Scans up to 144 pages per minute (standard sized documents fed

in landscape orientation; continuous transport using the semiautomatic feeder).

• High-speed scanning and image resolution.

◊ Scanner 9500 scans 160 landscape (A4 size) or 120 port r ait

(8 ½ x 11-inch) documents per minute at 200 dpi or 107

landscape (A4 size) or 80 portrait (8 ½ x 11-inch) documents per

minute at 300 dpi.

• Handles documents of up to 2.5 to 20 in. (64 to 508 mm) long,

2.5 to 12 in. (64 to 305 mm) wide, and 0.014 in. (0.36 mm) thick.

The gap release feature allows thicker documents to be scanned.

NOTE: Documents longer than 20 inches can be scanned, but might

require special handling.

• Easy-to-reach control panel keys, identified by gr aphic symbols.

• A high-speed document transport system.

• A two-line, 80-character display for status information and operator

messages.

• Full programmability of 18 application modes, with override

capability.

• Linked modes allow the image address to be carried over from one

mode to another.

• Programmable keys to perform commonly-used functions.

• A transport-on function that allows 27 of the function codes to be

executed while the transport is running.

• Audible tones for selected funct ions, such as footswitch, patch

reading, etc.

• English or other language message display.

• A large, built-in workshelf.

• An adaptable, modular design for easy addition of accessories.

A-61092 September 1999 1-1

Page 5

Scanner options

The following options are available for use with your scanner:

• A choice of feeders (e.g., an optional check feeder, semi-automatic

document feeder or automat ic docum ent feeder)

• A choice of exit hoppers (e.g., an optional check stacker)

• A Footswitch for document level control

• An Endorser for stamping information on documents

• A 600 dpi, 12-character ink-jet printer which supports black and

magenta ink colors

• A Patch Reader for automatic document level control

• End-fed patch capability

• A Bar Code Reader for decoding encoded information

• A skew/length monitor

• A multi-feed detection device

• A workstation console, left or r ight position

1-2 A-61092 September 1999

Page 6

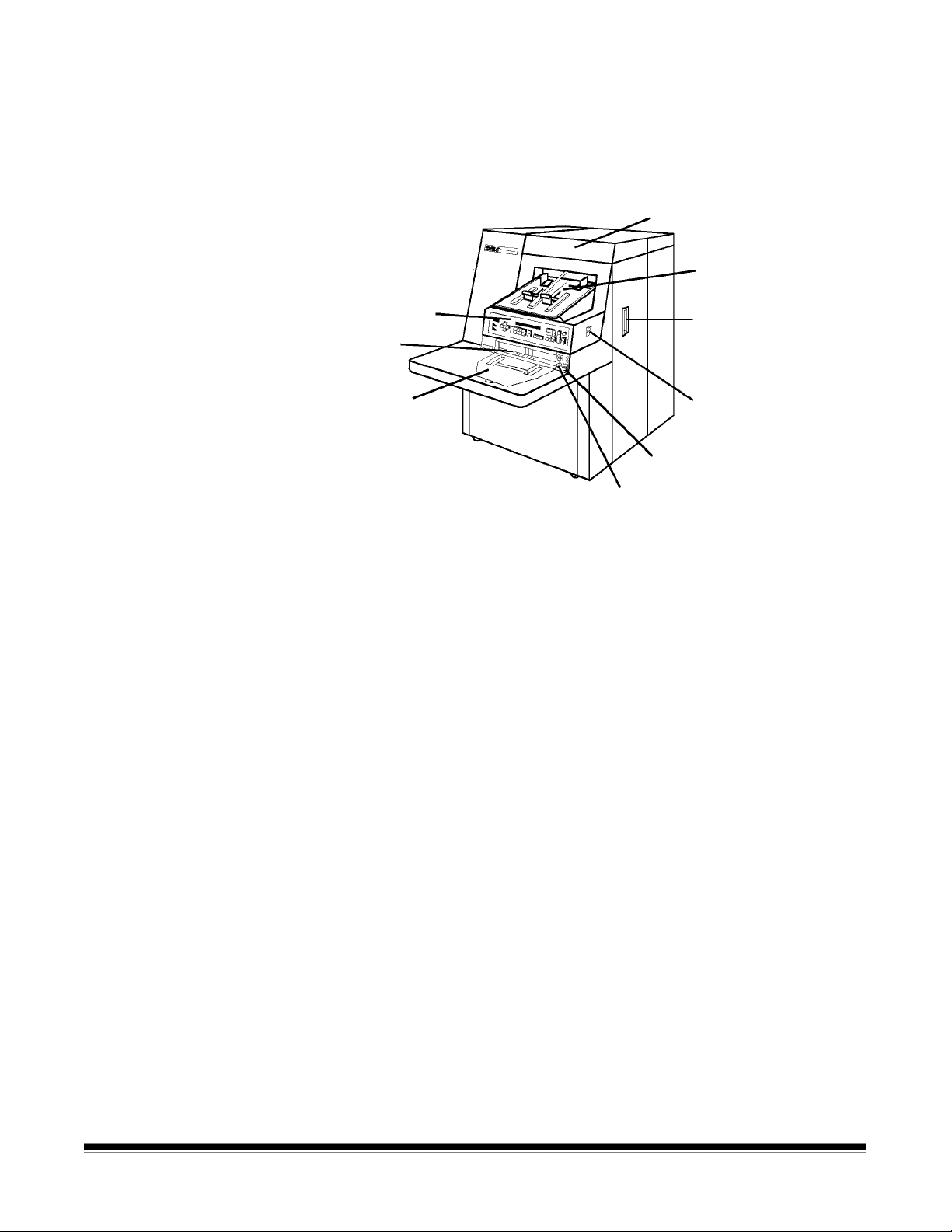

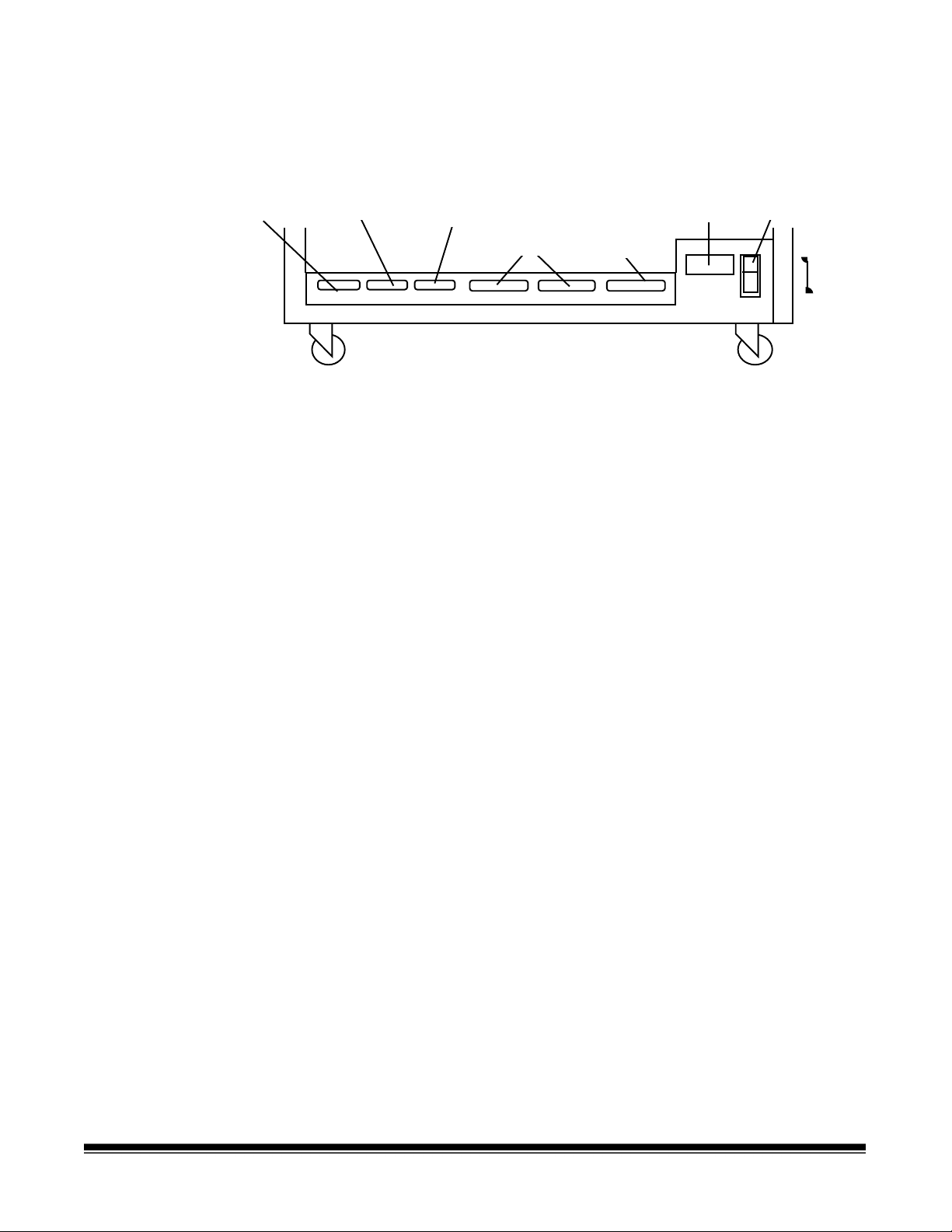

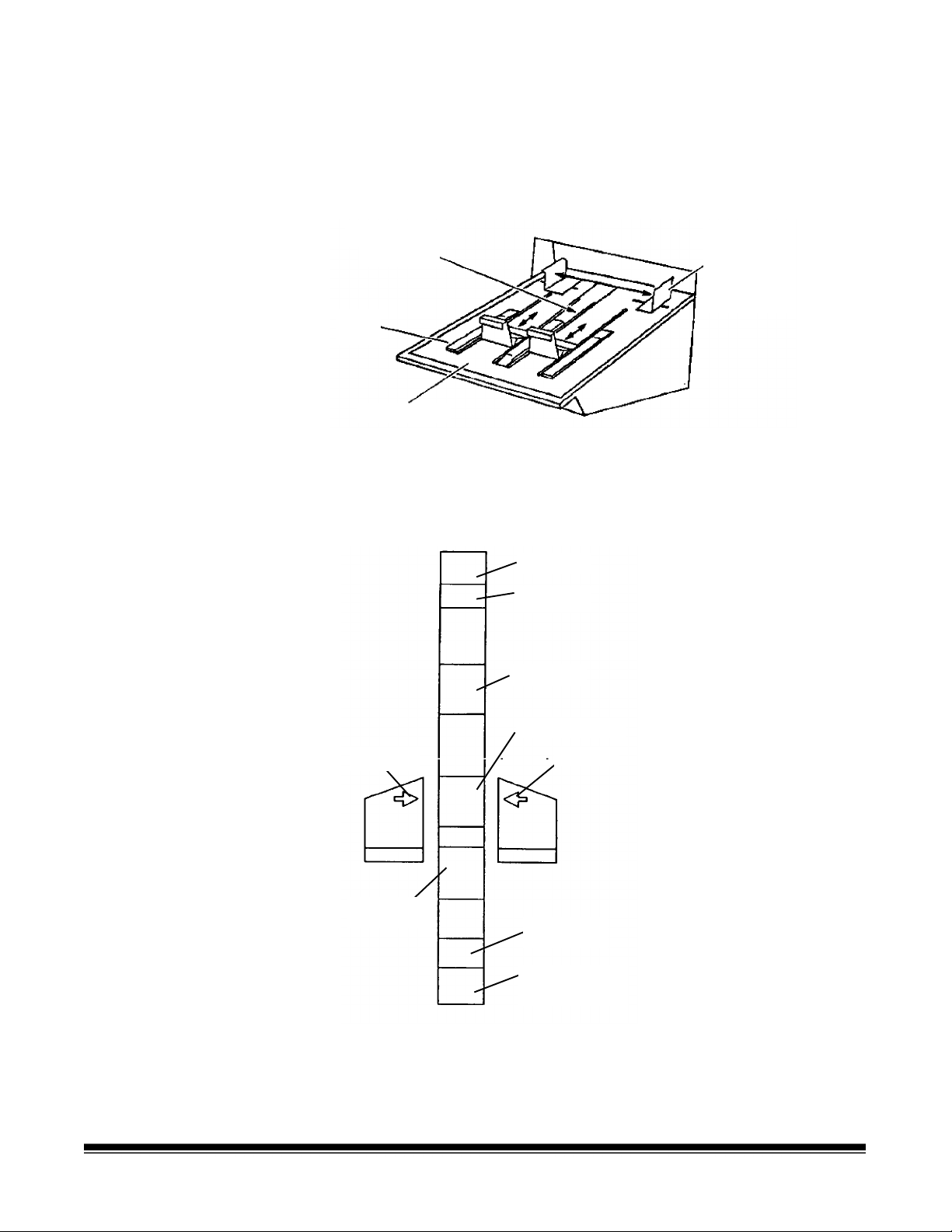

Scanner components

The following illustrations and descriptions will help you locate and

become familiar with scanner components.

Top cover

Exit hopper

Control panel

Right-side access door

Feed and

separator

rollers

Feed tray

Gap adjustment knob

(semi-automatic feeder only)

Side panel switch

Gap release lever

Control panel — contains the status display, indicators, and operating

keys used to control the scanner.

Feed and separator rollers (semi-automatic feeder only) — provides

smooth document feeding of various sizes and textures.

Feed tray — holds documents prior to feeding.

Top cover — provides access behind the transport area

.

Exit hopper — collects documents after they have been scanned.

Right-side access door — provides access to the transport system

components.

Side panel switch — allows you to turn the transport system on and

off.

Gap release lever — allows you to open the feed gap to allow thicker

documents to be fed into the transpor t .

Gap adjustment knob (semi-automatic feeder only) — allows you to

manually adjust the space between the feed and separator rollers f or

documents of varying thicknesses.

A-61092 September 1999 1-3

Page 7

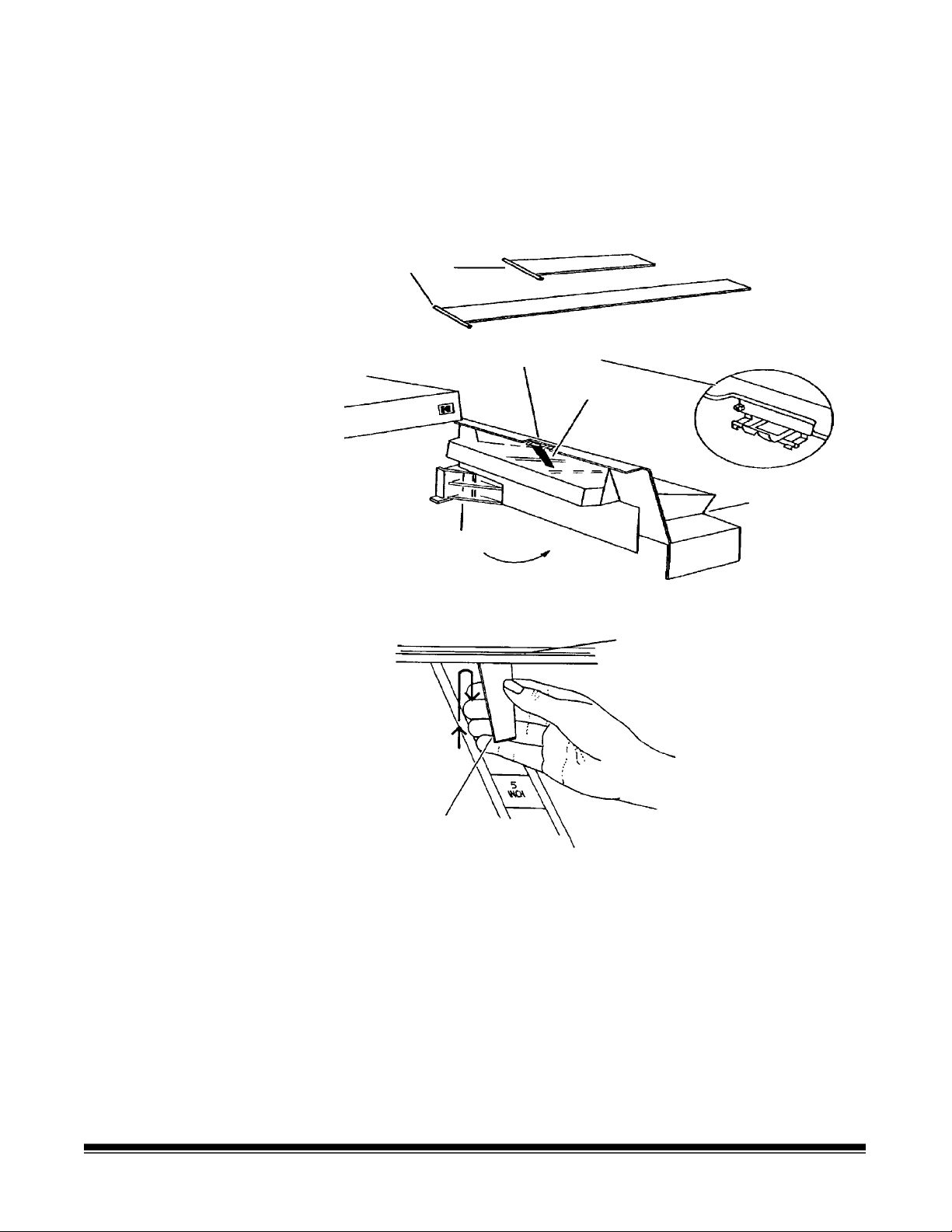

Rear view

J32

Computer

interface 1

(COIN 1)

Computer

interface 2

(COIN 2)

J30 J31 J45

Computer

interface 3

(COIN 3)

SCSI ports

Not Used

J33 J46

Power

cord

Main power switch

ON

OFF

Computer interface 1 (COIN1) — service/diagnostic inter face.

Configures the scanner and runs diag nostics.

Computer interface 2 (COIN2) — bar code interf ace. Transfers

commands between the scanner and external devices/subsystems.

Computer interface 3 (COIN3) — SCSI diagnostic port interface.

System debugging and monitoring SCSI - host computer

communications.

SCSI ports — SCSI interface connection for the scanner.

Power cord — plugs into an appropriat e power outlet .

Main power switch — turns main power to the scanner on and off.

1-4 A-61092 September 1999

Page 8

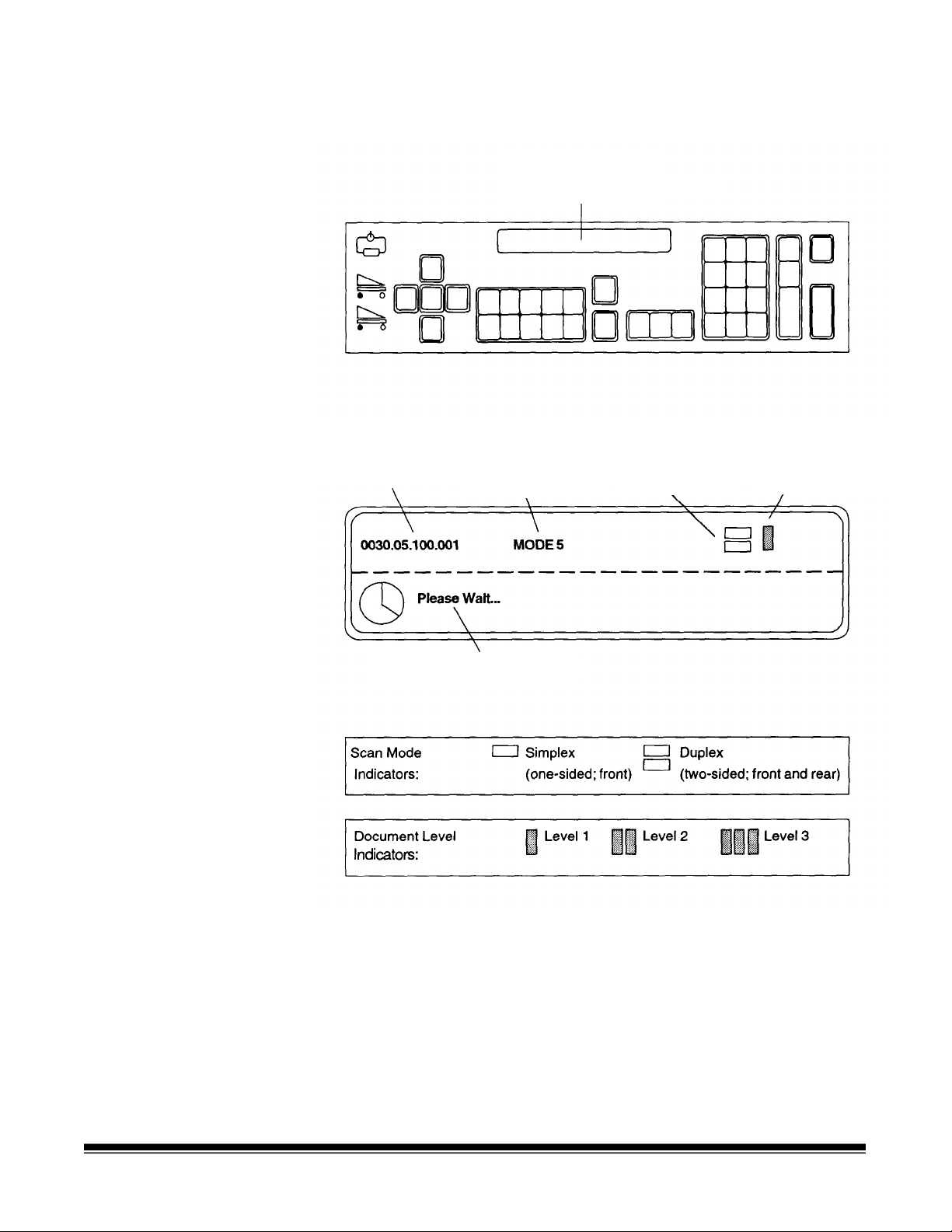

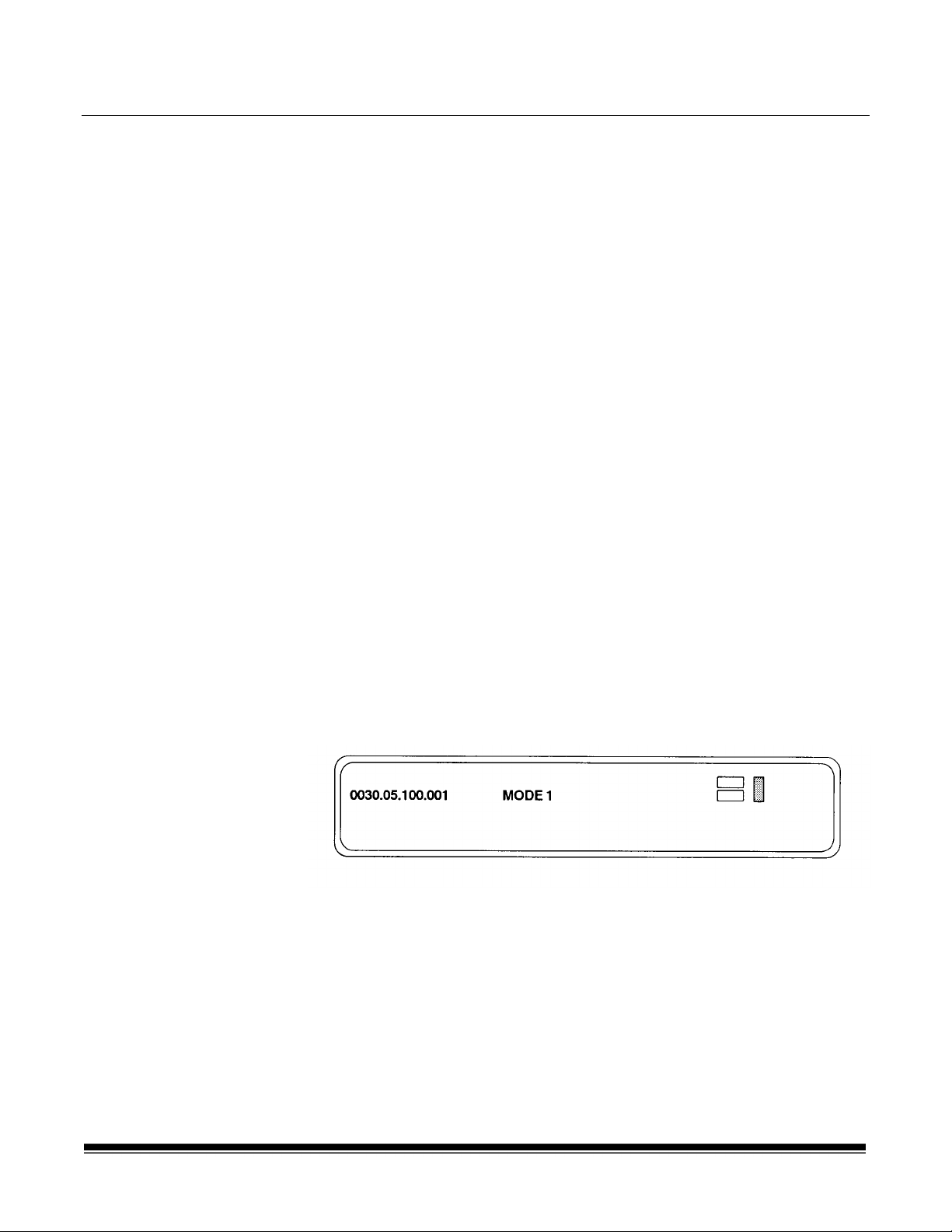

Status display — indicates the image address, scan mode, document

level and operator messages.

Two-line status display

Image address

Mode name/number

Operator message

Scan mode

indicator

Document level

indicator

A-61092 September 1999 1-5

Page 9

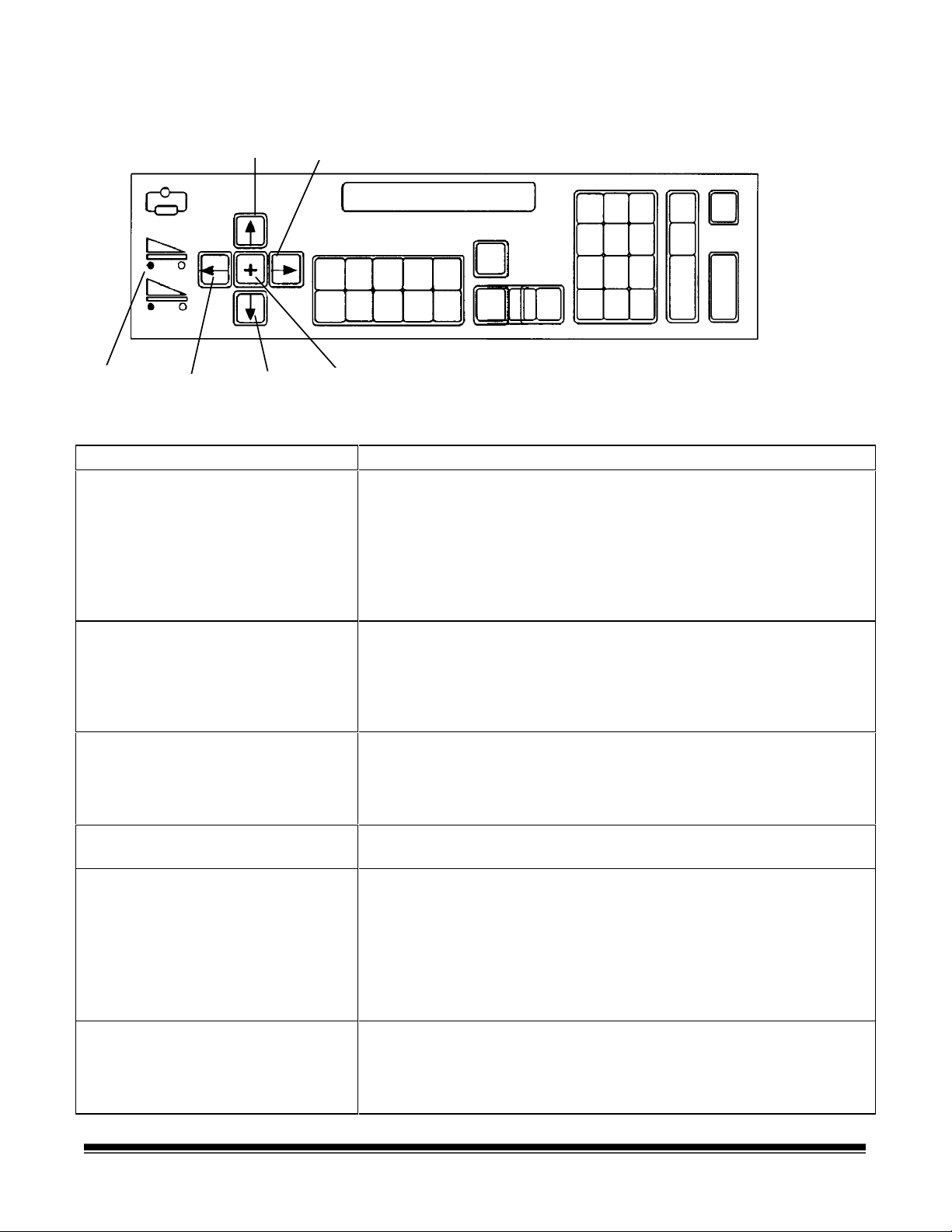

Operating keys and indicators

Scanner

buffer

indicators

Left arrow

Up arrow

Down arrow

Right arrow

Plus key

Key/Indicator Function

Scanner buffer indicators Indicates the amount of image buffer space available.

A full image buffer is represented by a single light in t he display;

an empty image buffer is repr esented by all lights in the display.

• The upper indicator represents the image buffer for f r ont side

images.

• The lower indicator represents the image buffer for rear side

images.

Left arrow (←)

The Left arrow allows you to:

• Decrement values at a slower rate.

• Backspace, delete the last keystroke, or clear messages in

the status display.

• Enter an alphanumeric character in t he im age address.

Down arrow (↓)

The Down arrow allows you to:

• Decrement values at a faster r ate.

• Decrease a data value when used with certain functions.

• Enter an alpha character in the image addr ess fixed field.

Plus key (+) Inputs a value for the image address. When pressed, it allows a

field to remain unchanged.

Right arrow (→)

The Right arrow allows you to:

• Increment values at a slower rate.

• Display additional messages in the status display. A blinking

cursor over the arrow in the display indicates there are

additional messages. Press the Right ar row key to display

these messages.

• Enter an alphanumeric character in the image address.

Up arrow (↑)

The Up arrow allows you to:

• Increment values at a faster rate.

• Increase a data value when used with certain functions.

• Enter an alpha character in the image addr ess fixed field.

1-6 A-61092 September 1999

Page 10

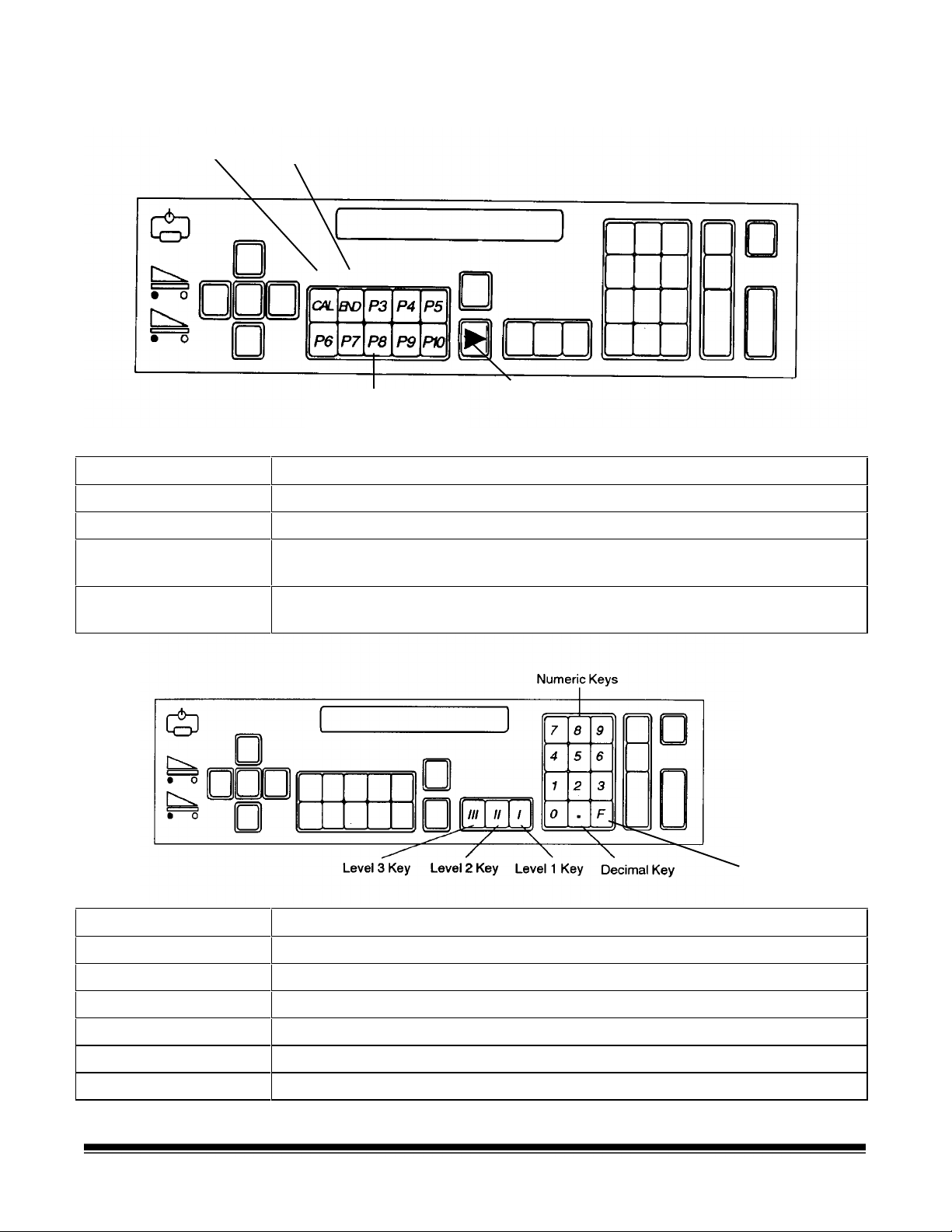

Operating keys and indicators

Calibration key

End

Programmable keys

Jog key

(P keys)

Keys/Indicators Function

CAL Starts the calibration process.

END Informs the host comput er when a batch or job has ended.

Programmable keys

(P keys)

Perform specific functions. The P keys have default values; any or all of the

defaults may be overridden/reprogramm ed at installation.

Jog Momentarily turns on (jogs) the transport system t o help clear document

jams.

F Key

Keys/Indicators Function

Numeric keys (0-9) Enter numeric data such as an image address or function code.

F key Selects one of the available functions, when used with the numeric keys.

Decimal key Inserts a field separator in an image address.

Level 1 key Identifies the next document fed into the scanner as a Level 1 document.

Level 2 key Identifies the next document fed into the scanner as a Level 2 document.

Level 3 key Identifies the next document fed into the scanner as a Level 3 document.

A-61092 September 1999 1-7

Page 11

Operating keys and indicators

Key/Indicator Function

Clear/Cancel The C ke y allows you to:

• Cancel a function without changing the preset values.

• Clear the status display after executing specified function codes.

• Clear an operator message fr om the status display.

Run Turns on the feeder and transport system.

NEXT Allows you to enter the next document image address.

Stop Allows you to stop the feeder and transport system. Docum ents st ill in the transport

system will be scanned and placed in the exit hopper before the transport system

stops.

Enter Enters data for a function code or an image address chang e.

Confirmation tone/alarm

The confirmation tone/alar m is located under the control panel and

sounds when one of the following conditions occur:

• Run is pressed (one long tone).

• Stop or End is pressed (many short tones f ollowed by a long tone) .

• Feeder clutch engages/disengag es ( one short tone).

• Incorrect key is pressed (three shor t t ones).

• Document skew is greater than what is setup in the skew

parameter, or when a document is shorter or longer than the

specified length parameters (one shor t tone).

• A bar code is detected (if the accessory is enabled and the

confirmation tone is enabled).

• A patch code is detected (if the accessory is enabled and the

confirmation tone is enabled).

• The Footswitch is detected (if the accessory is enabled and the

confirmation tone is enabled — one short tone).

1-8 A-61092 September 1999

Page 12

2 Getting Started

The following steps are necessary to prepare the scanner for operation.

Procedures on how to perform these steps are described in t his

chapter.

1. Turn on the main power switch.

2. Turn on the side panel switch.

3. Select the language display.

4. Calibrate the scanner.

5. Adjust the feed and separator roller gap.

6. Adjust the feed shelf posit ion.

7. Adjust the feed shelf side guides.

8. Adjust the exit hopper side guides and end stop.

9. Change the deflector (if required).

10. Prepare documents for scanning.

Turning on the scanner

Selecting the language display

Follow the steps below to turn on the power to the scanner.

1. Turn on the main power switch (located at the rear of the scanner).

NOTE: It is not necessary to turn off the main power switch during

normal daily operations.

2. Turn on the side panel switch.

Wait until the status display indicators are lit and an operating display

appears before you continue.

The scanner may have been configured at installation to allow use of a

second language in the status display. The language used (French,

German, Italian, Spanish, or other) is defined during installation. If

available, the alternate language display may be accessed using

function code F19.

A-61092 September 1999 2-1

Page 13

Calibrating the scanner

Calibration sets the intensity of the lamps, which contribute to the

overall quality of the scanned document image.

The scanner should be calibrated:

• at least once a day when the scanner is turned on using the side

panel switch — prior to scanning documents

• any time the scanner is turned on using the main power switch

• if image quality is poor

• after changing lamps

• after cleaning the scanner or imaging guides

Calibrate the scanner using a calibration targ et (sheet of paper) that is:

• Blank

• Clean

• Matte finish (not glossy)

• White or the same color as the background color of the documents

to be scanned. If you are scanning a variety of color ed docum ents,

use a white calibration target.

• Wider than t he docum ents you are going to scan (i.e., to scan 8.5 x

11 inch (215.9 x 279.4 mm) documents, the calibration target should

be wider than 8.5 inches (215.9 mm). The recommended width for

the calibration target is 12 inches (300 mm).

To calibrate the scanner:

1. Verify the main power and side panel switches are on. A normal

operating status display should appear.

2. Press CAL or enter function code F37 to start the calibration

sequence.

3. Insert the calibration target int o t he feeder.

When calibration is successful, the status display returns to a normal

operating display.

2-2 A-61092 September 1999

Page 14

Unsuccessful calibration

If calibration is not successful, a message appears in the status display.

You may need to:

• Verify you are using a clean, blank sheet of paper as a calibration

target.

• Verify there is not a document already in the document path. (Refer

to the section entitled, “Clearing the document path” in Chapter 7.)

• Clean the imaging guides. (Refer to the section entit led “Cleaning

the imaging guides” in Chapter 5.)

• Calibrate the scanner again. If calibration fails again, change t he

lamps. (Refer to the section entit led, “Replacing the exposure

lamps” in Chapter 5.)

If you have done all of the above and calibration still fails, contact your

service representative.

Preparing documents for scanning

Before you begin processing documents, m ake certain that the

documents may be fed through the scanner easily.

• Remove any staples, rubber bands, loose mending tape, or paper

clips from the documents to be processed.

• Straighten wrinkled edges and tape any torn documents.

• Trim ragged edges.

When using t he semi-automatic feeder, make certain all documents are

of similar size, texture, thick ness and weight , and the leading edges of

all documents are aligned.

A-61092 September 1999 2-3

Page 15

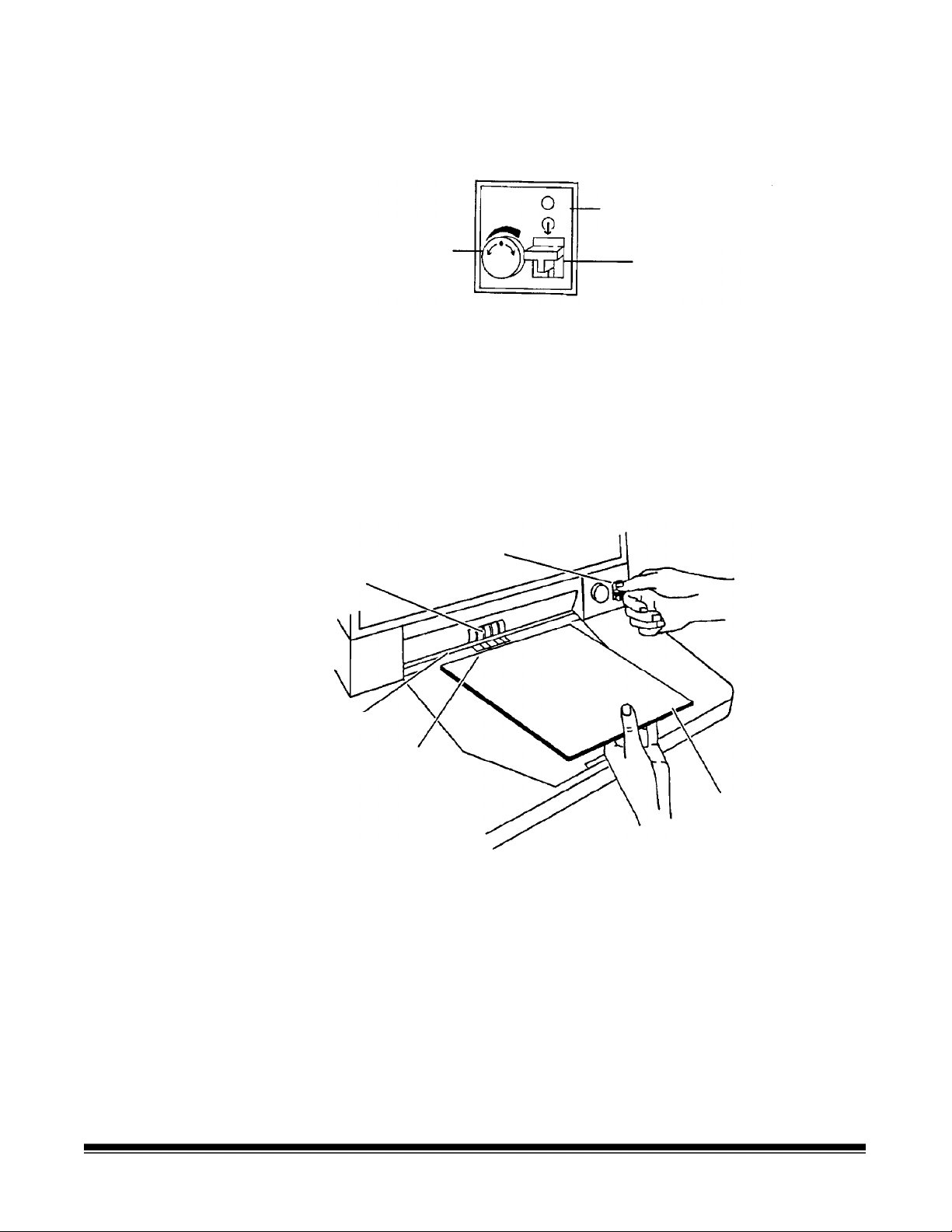

Adjusting the feed

d

and separator roller

(semi-automatic

gap

feeder only)

IMPORTANT:

The gap adjustment k nob on t he control panel increases or decreases

the space between the feed and separator rollers. The gap must be

adjusted properly for smooth t r anspor tat ion of documents without

document overlap.

When documents of different thicknesses are fed in a group, adjust the

gap using the thinnest document in t he group.

The feed and separator roller gap m ay have to be adjust ed to

compensate for:

• Very thin documents (onion skin, tracing paper, etc.).

• Very thick documents (card stock, punch cards, cover stock).

Before adjusting the feed and separator roller gap, be

sure the feed and separator rollers are clean. Cleaning

the feed and separator rollers will frequently resolve

document feeding problems.

The adjustment procedure should only be done when

feeding and separating problems continue after the fee

and separator rollers have been cleaned. For

procedures on cleaning rollers, see Chapter 5,

Maintenance.

• Some coated documents (photographic paper, plastic-coated

paper).

If the gap is not adjust ed pr operly:

• More than one document at a time may be drawn into the transport

system at the same time; not all of the documents will be scanned.

• Documents may be drawn into the transport too quickly; documents

may overlap or be spaced too closely (causing an error display).

• Documents may become skewed during transport; jamming may

occur.

NOTE: Prior to performing the adjustment procedure, t he scanner

must be calibrated and enabled.

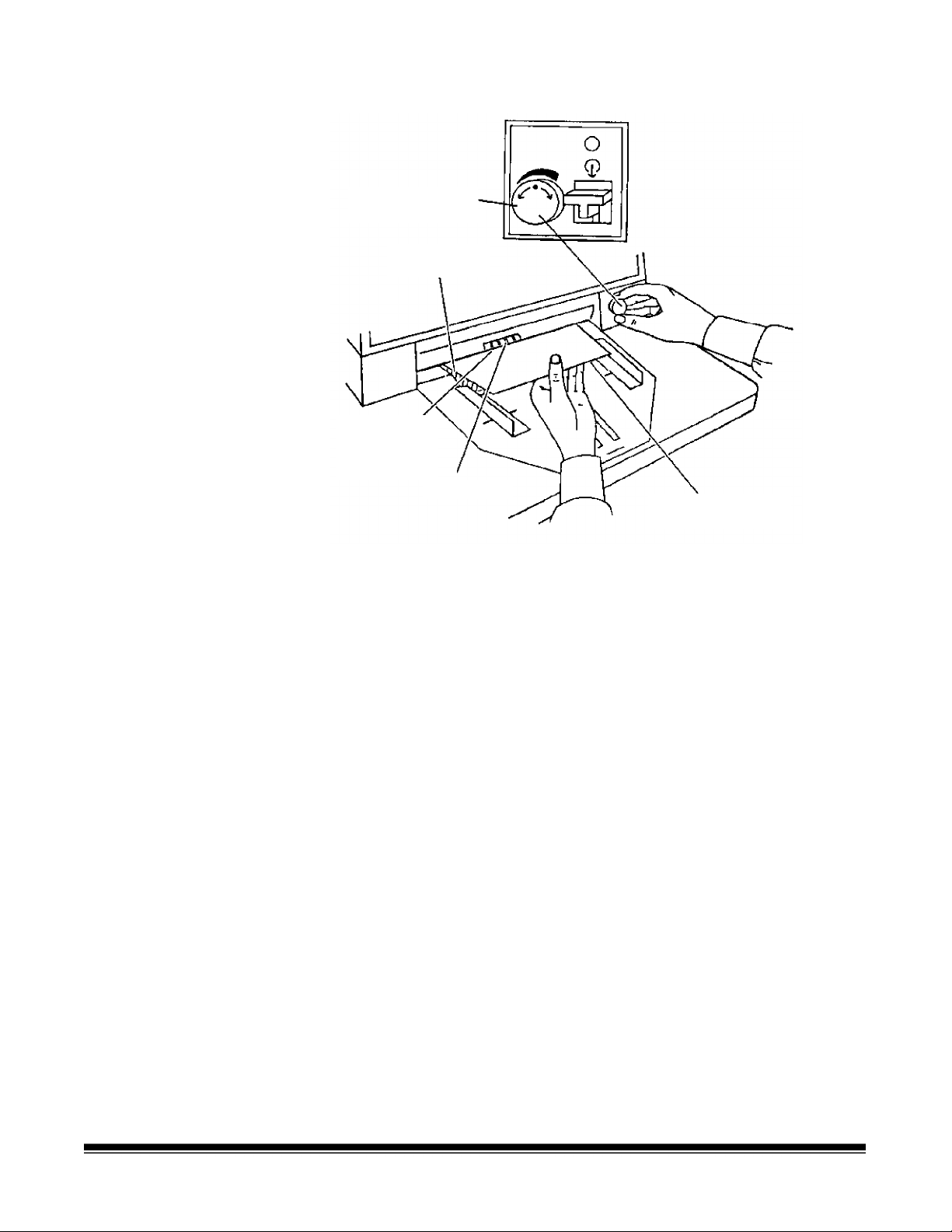

To adjust the feed and separator roller gap:

1. Turn on the side panel switch.

2. Enter function code F04 and enable Counting Only.

3. Press Enter.

4. Press Run.

IMPORTANT:

Do not make a gap adjustment while documents are

in the feeder or transport system; doing so will

produce an inaccurate adjustment.

5. Turn the gap adjustment knob clockwise three com plet e turns, or

until it stops, to open the gap between the feed and separat or

rollers.

2-4 A-61092 September 1999

Page 16

6. Turn the gap adjustment knob counterclockwise 2 1/2 turns.

Gap adjustment knob

Separated

document

Gap

(between feed

and separator

rollers)

Feed rollers

Trailing edge of top

document

7. Select two documents of the same size, texture and thickness,

similar to the types of documents you will be processing.

8. Place one document on top of the other. Hold the documents firmly

by their trailing edges. I nser t them into the gap approximately 1/8 in.

(3 mm).

If the documents separate, repeat the following steps until the

documents do not separate:

• Turn the gap adjustment knob clockwise 1/2 tur n.

• Insert the documents again.

If the documents do not separate, proceed with Step 9.

9. Rotate the gap adjustment knob counterclockwise 1 or 2 clicks.

10. Hold the trailing edges of the documents firm ly. Insert them into the

gap.

• If the bottom document is not separating from the top document ,

remove the documents and repeat Steps 9 and 10 until the

bottom document separates from the top document by

approximately 1 in. (25.4 mm).

• If the bottom document is separat ing from the top document,

proceed with Step 11.

A-61092 September 1999 2-5

Page 17

11. When you have adjusted the gap so the bottom document

g

separates consistently from the top document , rotate the gap

adjustment knob counterclockwise another 1 or 2 clicks to complete

the adjustment.

12. Feed a stack of 50 to 100 documents twice through the transport

system. Verify the final count reflects the total number of docum ents

fed and that the counter shows the same amount each time the

documents are counted.

If the count is not the same, the gap is not adjusted cor r ectly.

Rotate the gap adjustment knob counterclockwise another 1 or 2

clicks and repeat Step 12. Repeat until corrected.

13. Press Stop.

14. Enter function code F04 and disable Counting Only.

15. Press Enter.

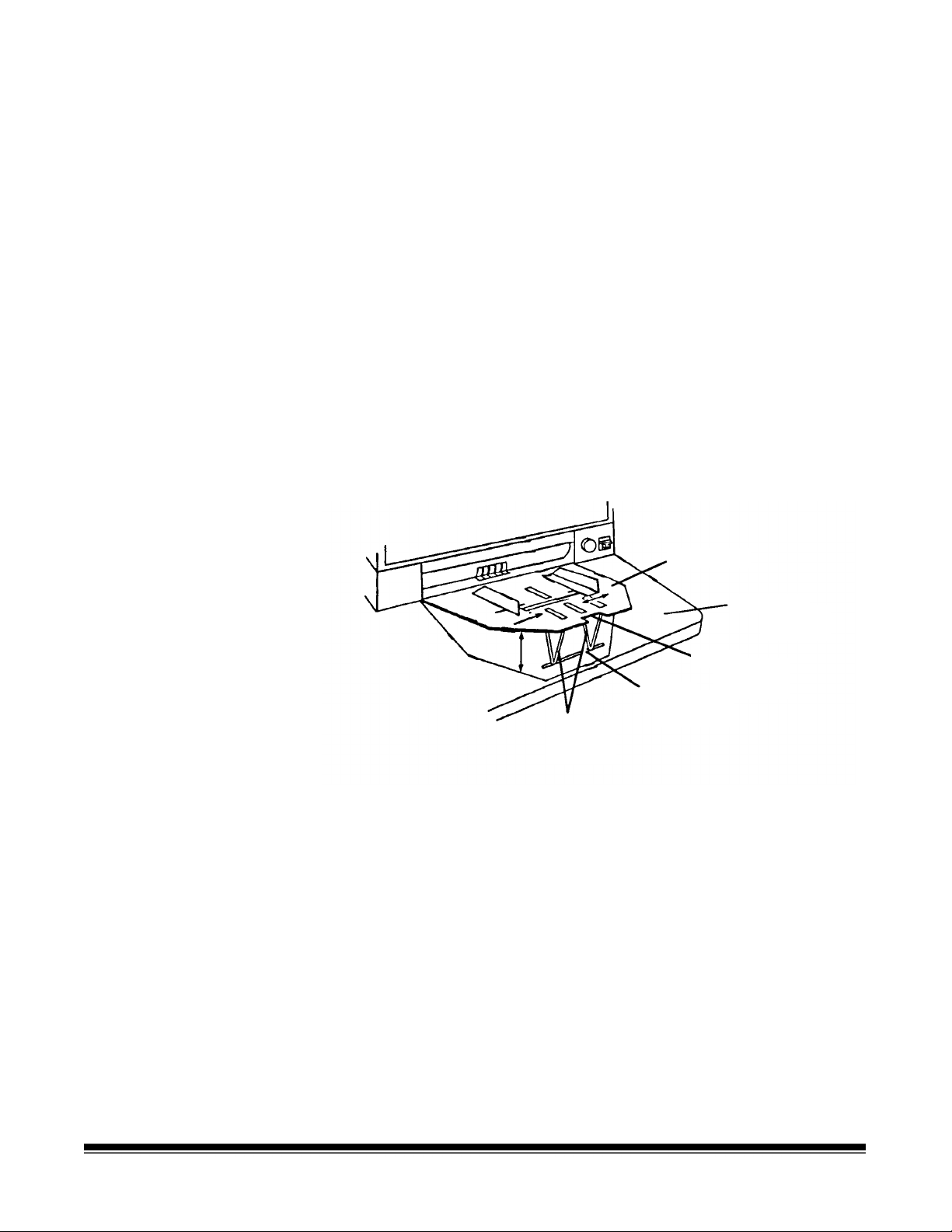

Adjusting the feed

shelf position

automatic feeder only)

(semi-

Before you begin feeding documents into the scanner, adjust the

position of the feed shelf .

Feed shelf

Work shelf

Notch

Groove

Height

adjustment

le

s

To automatically feed multiple documents, the feed shelf should be in

the raised position (as shown above).

To raise the feed shelf:

1. Grasp the notch and lift the feed shelf.

2. Swing the height adjustment leg s out and insert them into the

groove on the work shelf.

To hand-feed documents (one at a time), the feed shelf should be in the

down position (not shown).

To lower the feed shelf:

1. Grasp the notch and lift the feed shelf until the height adjust m ent

legs are no longer resting in the groove on the work shelf.

2. Tuck the height adjustment legs in and lower the feed shelf into

position.

2-6 A-61092 September 1999

Page 18

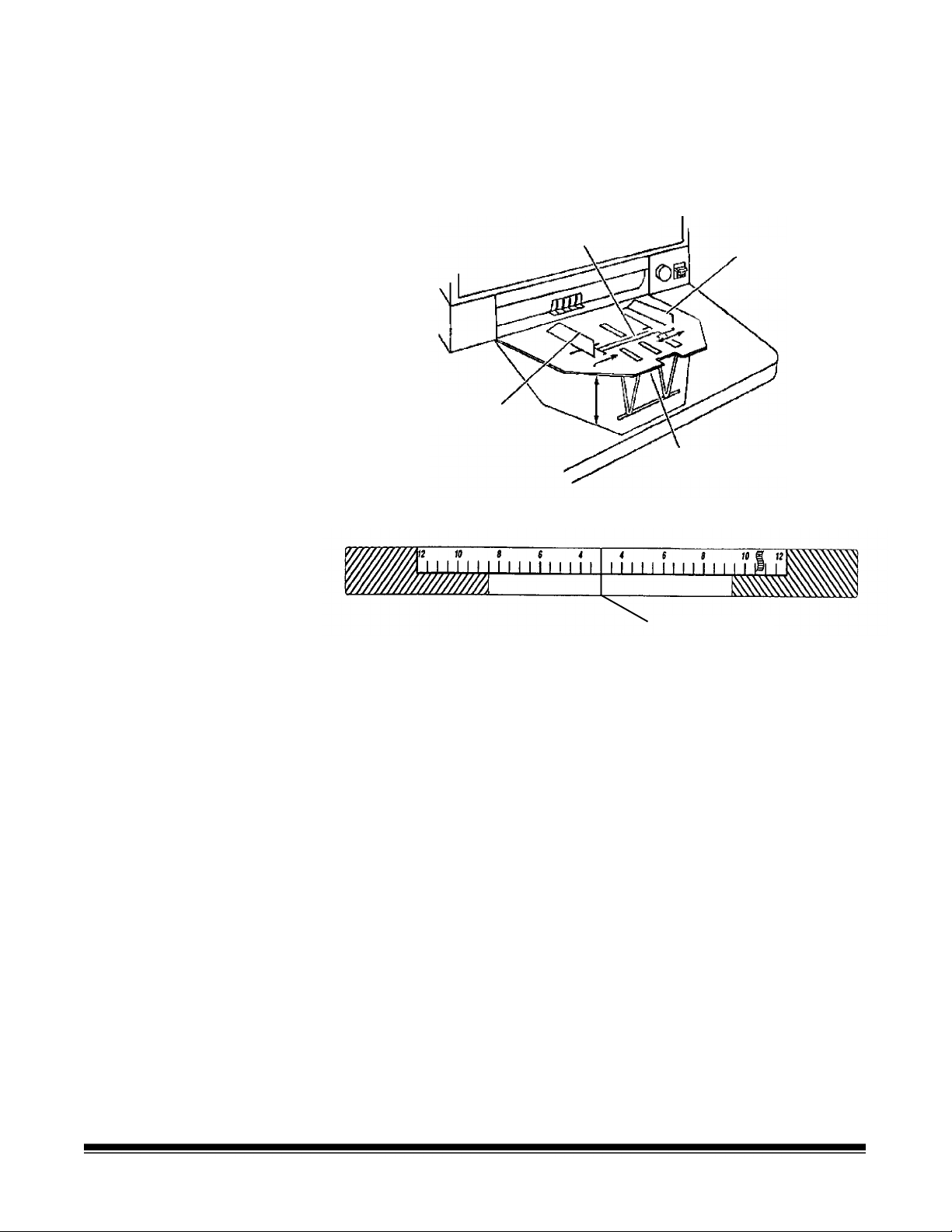

Adjusting the feed

shelf side guides

(semi-automatic feeder

only)

Before you begin processing documents, adj ust the side guides on the

feed shelf to accommodate the documents being processed.

1. Slide apart the side guides on the feed shelf unt il t he feed shelf

label is visible.

Feed shelf label

Side guide

Side guide

Feed shelf

Feed Shelf Label

Center line

2. Center the documents across the feed shelf label. Adjust the feeder

side guides dependent upon the width of the document. Leave

approximately 1/16 in. (2 mm) clearance on each side of the

documents so they feed properly.

NOTE: If the documents are larger than the area shown on the

feed shelf label and do not fit between the side guides,

rotate and reposition the documents within the side guides.

A-61092 September 1999 2-7

Page 19

Adjusting the exit

g

)

8 ½-inch (A5)

Checks

hopper side guides

and end stop

The exit hopper side guides and end stop must be adjust ed so

documents are stacked properly after processing.

1. Adjust the side guides on the exit hopper to mat c h the adjustment

of the side guides on the feed shelf.

Side

Exit hopper

label

End

stop

Exit hopper

guides

(arrows

depict correct

placement of

side

uides

2. Adjust the end stop of the exit hopper by deter m ining the longest

document to be processed. Slide the end stop until t he ar r ows point

to where the length of the longest document is shown on the exit

hopper label.

11-inch (A4)

IBM cards

5-inch

ArrowArrow

14-inch (B3)

17-inch with

adapter (A3)

2-8 A-61092 September 1999

Page 20

Changing the

Short document deflector

Long document deflector

Lip of exit hopper

deflector

The scanner comes with two deflectors (stored in the pocket located

inside the right-side access door), desig ned to help stack the

documents as they exit the transport system and enter the exit hopper.

Use the short deflector for documents less than 5 in. (13 cm) and the

long deflector for docum ents longer than 5 in. (13 cm) as well as for

mixed sizes.

Attachment pin

Holding clip

Deflector

Front cover

(does not have to

be open to attach

deflectors)

(Swings to right)

1. Grasp the deflector near t he at tachment pin (as shown).

(black side must be down)

Deflector

2. Guide the deflector into the exit hopper, just below the lip of the

hopper, to insert the attachment pin in the holding clip.

3. Pull the deflector toward you until it clicks into place.

A-61092 September 1999 2-9

Page 21

3 Operating the Scanner

Overview

This chapter provides instructions for selecting modes, using temporary

operating values and feeding documents using either the semiautomatic feeder or the aut om atic feeder.

The scanning process consists of the following steps:

1. Prepare the scanner for operation (r efer to Chapter 2,

Started

2. The scanner is enabled by the host system.

3. Select a mode for the application. Typically the host computer

performs this step, but it may also be performed by the operator.

4. Select temporary operating values (if r equired).

5. Press the Run key.

6. Feed documents into the transport (refer to

using the semi-automatic

• The scanner assigns a sequential ID number ( for digital image

• The document is scanned.

• The document image header is created.

• The host computer initiates tr ansfer of the document image

for more information.)

Feeding Documents

(or

automatic) feeder

storage), the document im age level and image address.

header and document image to the host system for storage on

magnetic or optical disk media.

later in this chapter).

Getting

• Documents are deposited in the exit hopper, face down, in the

order in which they were fed into the transport.

7. Press the Stop key.

8. Press P2 or enter function code F38 to indicat e end- of-job.

9. Turn off the side panel switch.

NOTE: If the scanner will not be used for 8 hours or more, tur n off

the main power switch.

A-61092 September 1999 3-1

Page 22

Selecting a mode

The scanner offers 18 modes that m ay be programmed for a particular

application or group of applications.

The modes are programmed at the time of installation and stored f or

easy access and use.

Typically, the mode is selected via the host system, using a scannerunique command. However, you may manually select a mode.

To select a mode, do the following:

1. Enter function code F01 (Select Mode) by pressing the F key and

the numeric keys 0 and 1.

2. Press Enter.

3. Enter the desired mode number (modes r ange from 1 to 18).

4. Press Enter.

You can also check with your system administ r at or to see if one or

more of the P keys has been preprogrammed to perform specific

functions.

Temporary operating values

Each of the 18 modes programm ed at the time of installation contain

definitions that affect t he output of the scanner. Each mode is

programmed to confor m to the output requirements of a particular

application or group of applications.

There may be instances, however, when a particular application

requires some variation of an existing mode. In such instances, mode

definitions may be changed using available function codes. See

Chapter 4,

available function codes.

NOTE: Changes to mode definitions remain in effect until another mode

Example:

If mode 15 contains definitions t hat allow you to use the

Imagelink

from the leading edge of the document the endorsement is printed) is

programmed to be 0.5.

Function Codes,

is selected or the side panel switch is turned off. The original

mode definition is only affected by these changes if the mode

overrides are saved (the mode override option may be select ed

at installation and if selected, a plus sign (+) appear s in t he first

line of the status display).

Endorser, the starting print position (which defines how far

for a listing and descriptions of the

Kodak

If there is a special application that r equires the endorsement be printed

1 inch from the leading edge of the document, you may use function

code F59 to temporarily change the starting pr int position.

3-2 A-61092 September 1999

Page 23

Feeding documents

using the semiautomatic feeder

Following are document feeding instruct ions using the semi-automatic

feeder. After the scanner has been prepared for operat ion, the desired

mode and any temporary operating values have been defined, you are

ready to feed documents into the transport.

1. Verify the side panel switch is on and that any adjustments have

been made (feeder side guides, exit hopper side guides, etc.).

2. Press Run.

3. Select a stack of documents that is no m or e than 0.75 in. (19 mm)

thick.

4. Fan the stack of documents so the leading edge of the top

document engages the feed and separat or r oller s as shown:

Top

document

Fanned

documents

5. Place the stack of fanned documents into the feeder so the leading

edge of the top document contacts t he feed and separator rollers.

The documents are drawn into the transport, with the t op docum ent

being fed first. The documents are deposited in the exit hopper

face down, in the order in which they were fed into the transport .

6. Repeat Steps 3 through 5 until all of the application documents

have been fed into the transport.

7. Press Stop after all documents have been deposited in the exit

hopper.

A-61092 September 1999 3-3

Page 24

Feeding thick

)

documents

The gap release lever is used to feed thick documents such as card

stock or cover stock. The lever is located on the front panel of the

scanner, next to the gap adjustment knob.

(Graphic depicts movement

of separator rollers when

lever is used

(Graphic depicts gap

adjustment)

Gap

release

lever

1. Press down and hold the gap release lever. This opens the gap

between the feed and separator rollers, allowing thick docum ents t o

pass between them. You will be able to see the gap open as the

lever is pushed down.

2. Insert the thick docum ent past t he rollers until it is taken into the

transport system.

NOTE: If more than one t hick docum ent is to be scanned, feed

them into the transport one at a time.

Gap release

lever

Feed roller

(hold down)

Gap

Separator

roller

Thick

document

3. After the thick document(s) have been scanned, release the gap

release lever; it will return to its orig inal position. The feed and

separator rollers will return to t heir pr eviously adjusted positions.

3-4 A-61092 September 1999

Page 25

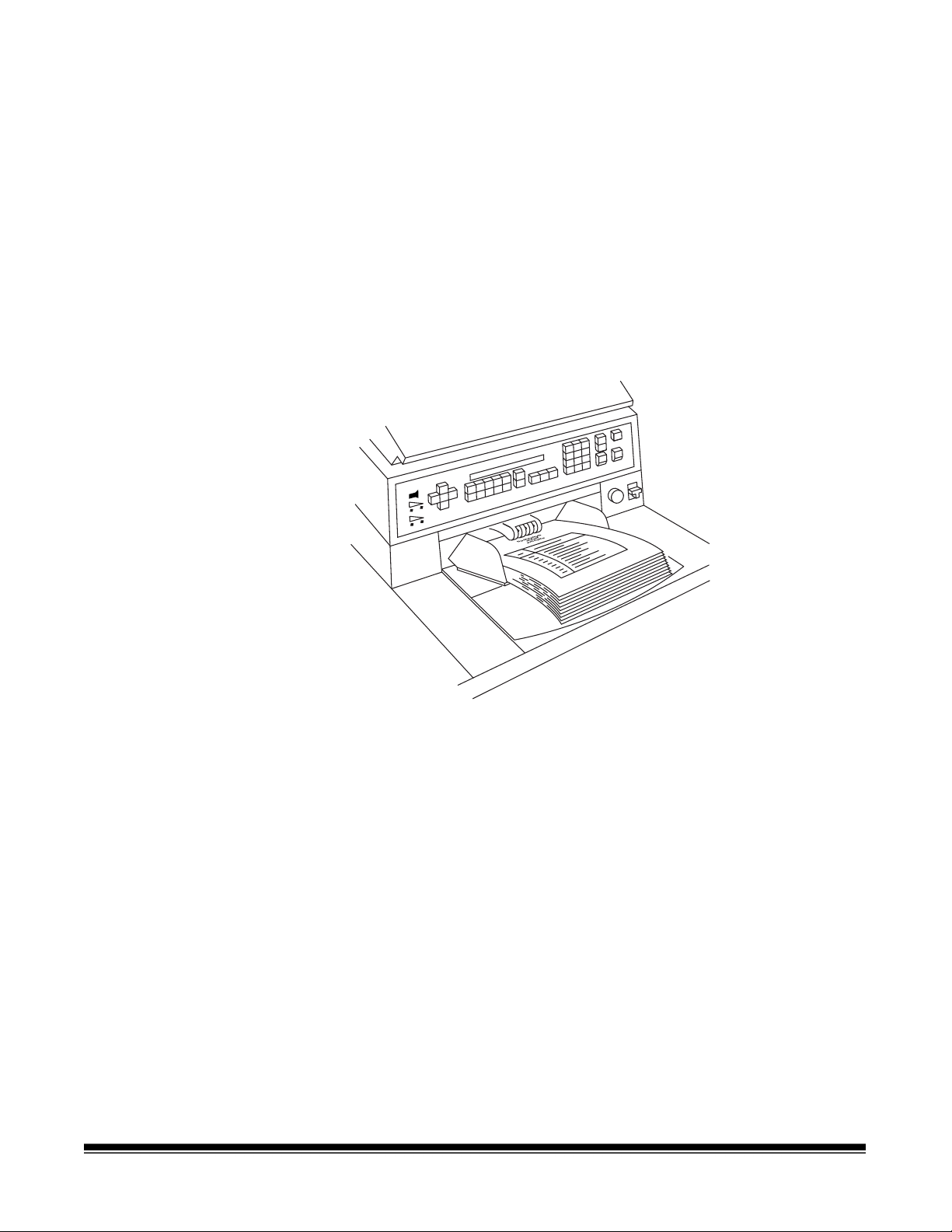

Feeding documents using the automatic feeder

Following are document feeding instruct ions using the automatic

feeder. After the scanner has been prepared for operat ion, the desired

mode and any temporary operating values have been defined, you are

ready to feed documents into the transport.

1. Verify that the power is on and that any adjustments have been

made (feeder side guides, exit hopper side guides, etc.).

2. Select a stack of documents that is no more than 1.5 in. (38 mm)

thick. Hold the stack with the front sides f acing up and the top of the

documents facing toward the scanner. Tap the top edge of the stack

against a flat surface so the documents are in an even bundle.

3. Fan the stack of documents so the leading edge of the t op

document sticks out the farthest.

4. Lift the feeder module up and slide the leading edge of t he

document underneath the feeder module. To help prevent multiple

feeds, place the stack of documents under t he f eeder m odule and

pull the stack back slightly (about ¼-inch) from the separator roller.

5. Press Run.

NOTE: Be sure the documents are center-fed so each document

covers the 3 ½-inch required width.

6. As you scan documents, set the image level, as r equir ed, and

periodically remove documents from the exit hopper.

7. Repeat Steps 2 through 4 until all of t he applicat ion documents

have been fed into the transport.

8. Press Stop after all documents have been deposited in the exit

hopper.

A-61092 September 1999 3-5

Page 26

4 Function Codes

Using function codes

There are a variety of functions available which may be used to

temporarily change operating param et ers, and to obtain system

and accessory status information.

These functions are listed in the Function Code Sum m ar y later in t his

chapter. Following are the procedures for using function codes:

1. Press the F key.

2. Press the numeric keys which correspond to the desired function

code.

3. Press Enter.

If the function is used to enable or disable an operation (turn an option

on or off):

1. Press 1 to turn the option On, or 0 to turn the option Off.

2. Press Enter.

If the function requires numeric input:

1. Press the numeric key(s) requir ed.

2. Press Enter.

If the function is used to incr ement or decrement a measurement or

setting:

• Press the arrow keys to increment or decrem ent as follows:

− Press the Up arrow to increment the measurement by

1 inch (25 mm) or one value, or

− Press the Down arrow to decrement t he m easur ement by

1 inch (25 mm) or one value, or

− Press the Right arrow to increment the measurement by

1/8-inch (3 mm) or one value, or

− Press the Left arrow to decrement the measurement by

1/8-inch (3 mm) or one value.

• Press Enter.

To cancel a function (befor e pr essing Enter ) or clear the status display

after executing a funct ion code:

• Press C (Clear/Cancel).

A-61092 September 1999 4-1

Page 27

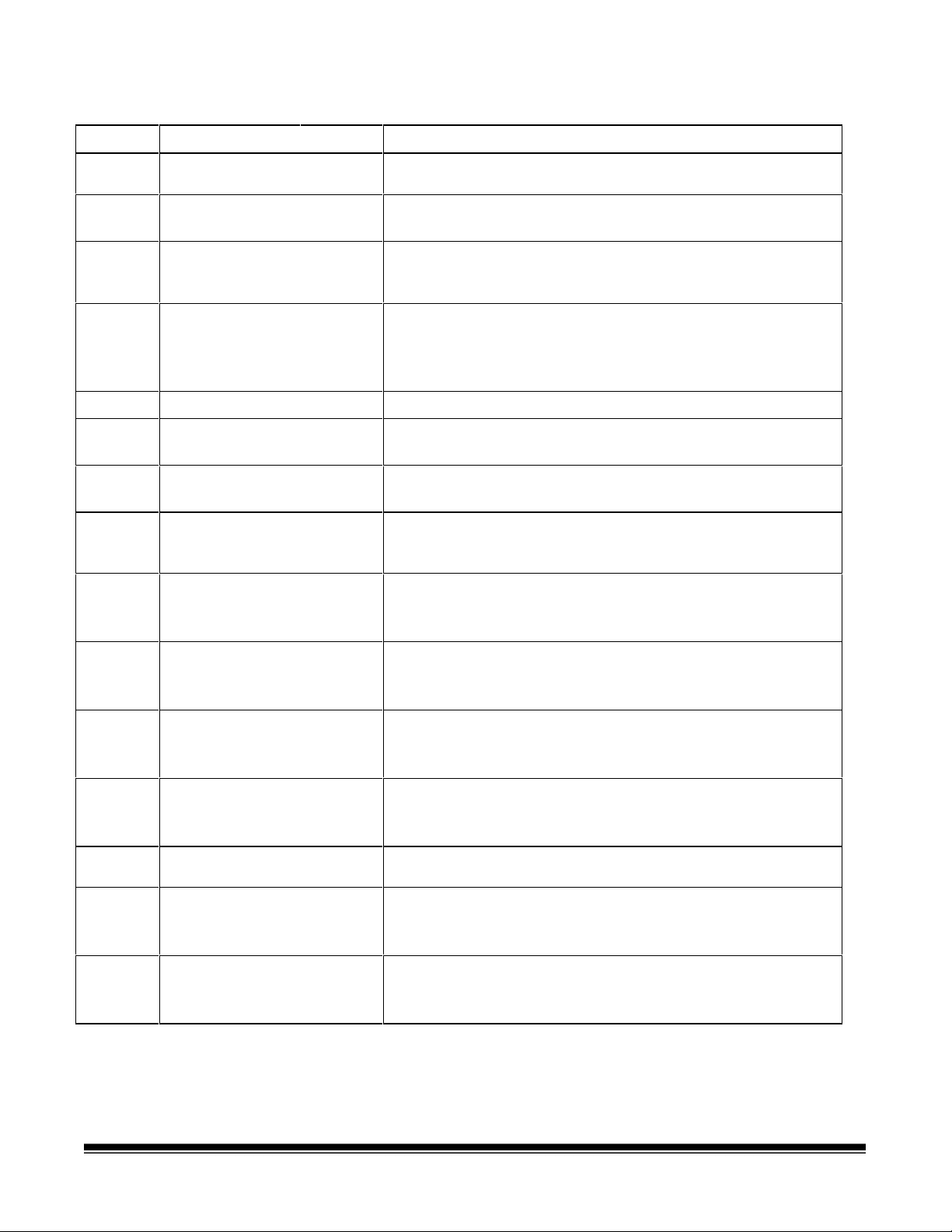

Function code summary

Following is a summary of the functions and their cor r esponding

function code:

Status

Accessory Status*...............................................................F05

Date and Time Display* ‡ ...................................................F23

Elapsed Time* ....................................................................F17

Counters

Level 0 Count*....................................................................F10

Level 1 Count*....................................................................F11

Level 2 Count*....................................................................F12

Level 3 Count*....................................................................F13

Total Document Count*.......................................................F09

Reset Level Counts.............................................................F14

Setup

Action/Confirmation Tone ‡.................................................F93

Alarm Tone ‡......................................................................F16

Alarm Volume.....................................................................F15

Change Date ‡....................................................................F22

Change Time ‡...................................................................F21

Display Contrast..................................................................F18

Display Language...............................................................F19

Measurement System.........................................................F20

Operator ID.........................................................................F34

Scanner Calibration............................................................F37

Mode

Select Mode........................................................................F01

Select Linked Mode ............................................................F91

Counting Only..................................................................... F04

Restore Mode .....................................................................F02

Index/Image Address

Last Image Address*...........................................................F08

Level 0*...............................................................................F07

Level 1*...............................................................................F94

Level 2*...............................................................................F95

Level 3*...............................................................................F96

Fixed Field..........................................................................F92

Next Image Address ...........................................................F97

* May be executed while transport is running.

‡ Available when using advanced capabilities.

4-2 A-61092 September 1999

Page 28

Operation

Run..................................................................................... F99

Terminate Batch*................................................................F06

Stop* ...................................................................................F98

Scanning

Scanner Calibration............................................................F37

Latched Scanning Flag*......................................................F73

Momentary Scanning Flag*.................................................F74

Scanner End-of-Job............................................................F38

Endorser

Endorser On/Off..................................................................F57

Endorser Mode...................................................................F58

Endorser Print Position .......................................................F59

Footswitch

Footswitch Confirmation Tone ‡..........................................F75

Bar Code‡

Bar Code Reading On/Off...................................................F60

Partial Bar Code Reading On/Off........................................F66

Bar Code Reading Confirmation Tone................................F63

Bar Code/Patch Reading Confirmation Tone......................F62

Bar Code Test.....................................................................F65

Omit Bar Code Reading on Next Document*......................F64

Document Controller

Length Checking On/Off.....................................................F70

Omit Length Checking on Next Document Only*................F71

Skew Detection...................................................................F72

Document Printers

All Document Printers On/Off..............................................F40

Primary Document Printer 1 On/Off ....................................F41

Secondary Document Printer 1 On/Off ‡.............................F42

Document Printer 12 On/Off ...............................................F43

Omit Printing on Next Document.........................................F44

Print Position.......................................................................F46

Print Test............................................................................F45

Printer Character Shift ........................................................F39

Printer Open Jet Test..........................................................F56

Purge Frequency................................................................F49

Purge Print Head*...............................................................F48

* May be executed while transport is running.

‡ Available when using advanced capabilities.

A-61092 September 1999 4-3

Page 29

Super12 Document Printer

Print Contrast......................................................................F39

Print Head Position.............................................................F40

Print Test............................................................................F45

Automatic Purge Print Head ...............................................F48

Align Print Image*............................................................... F49

Print Cartridge Status .........................................................F56

NOTE: Function codes F43 and F44 work the same on a

Super12 Document Printer.

Patch Reader

Patch Reader 1 On/Off ....................................................... F50

Patch Reader 2 On/Off ‡ .................................................... F51

End Fed Patch Reading On/Off ‡ .......................................F52

Patch Reading Confirmation Tone ‡...................................F53

Omit Patch Reading on Next Document*............................F54

* May be executed while transport is running.

‡ Available when using advanced capabilities.

4-4 A-61092 September 1999

Page 30

Function code listing

Following is a listing of the function codes and descr ipt ions.

Code Function Code Name Description

F01 Select Mode Allows you to select one of the predefined application

modes. Enter a value from 1 to 18 and press Ent er .

F02 Restore Mode Allows you to restore the current application mode to its

default status, provided mode overrides are not saved.

F04 Counting Only

Allows you to count the number of documents entering

the scanner without scanning. Enter 1 to t ur n Count ing

Only on, or 0 to turn Counting Only off and press Enter.

F05 Accessory Status Displays the current status of each accessor y installed.

Press the Down arrow to view the status of the next

accessory, or press the Up arrow to view the status of the

previous accessory.

F06 Terminate Batch Allows you to prematurely end a batch.

F07 Level 0 Allows you to define the next document scanned as a

Level 0 document.

F08 Last Image Address Allows you to display the image address of the last

document scanned.

F09 Total Document Count

Allows you to display the total number of documents that

entered the feeder (Level 3, Level 2, Level 1 or Level 0).

Press 0 to reset the counter and then press Ent er .

F10 Level 0 Count Allows you to display the total number of documents that

have entered the feeder as Level 0 documents. Press 0 to

reset the counter and then press Ent er .

F11 Level 1 Count Allows you to display the total number of documents that

have entered the feeder as Level 1 documents. Press 0 to

reset the counter and then press Ent er .

F12 Level 2 Count Allows you to display the total number of documents that

have entered the feeder as Level 2 documents. Press 0 to

reset the counter and then press Ent er .

F13 Level 3 Count Allows you to display the total number of documents that

have entered the feeder as Level 3 documents. Press 0 to

reset the counter and then press Ent er .

F14 Reset Level Counts

Allows you to reset all the level counters (Level 0, Level 1,

Level 2, and Level 3) to 0.

F15 Alarm Volume Allows you to adjust the volume of the alarm. Pr ess the

Up arrow to increase the volume or press the Down

arrow to decrease the volume, then press Enter.

F16 Alarm Tone Allows you to adjust the pitch of the alarm t one. Pr ess the

Up arrow to increase the pitch or press the Down arrow

to decrease the pitch, then press Ent er.

A-61092 September 1999 4-5

Page 31

Code Function Code Name Description

F17 Elapsed Time Allows you to display the number of hours the motor,

transport and main power have been running, in addition

to the non-resettable document count. Press the Right

arrow to view the meters.

Meter A — displays motor-on hours

Meter B — displays transport-on hours

Meter C — displays main power-on hours

Meter D — displays document count

F18 Display Contrast Allows you to adjust the contrast of the status display.

Press the Up arrow to increase the contrast or press t he

Down arrow to decrease the contrast, then press Enter.

F19 Display Language Allows you to choose your preferred language. Press the

arrow key to toggle between two available options.

F20 Measurement System Allows you to choose your preferred measurement

system. Press the arrow key to togg le bet ween two

available options.

F21 Change Time Allows you to change the time. Enter the new time in the

format illustrated and pr ess Ent er .

F22 Change Date Allows you to change the date. Enter the new date in the

format illustrated and pr ess Ent er .

F23 Time and Date Display Allows you to view the current time and date.

F34 Operator ID Number Allows you to display the current operator ID number

and/or change to a new operator ID number. Enter a new

operator ID up to 3 digits and press Ent er .

F37 Scanner Calibration Allows you to initiate the calibration process requir ed

before scanning documents. T o do this, feed a calibration

target into the scanner.

F38 Scanner End-of-Job Allows you to signal the host computer that t he last

document of the job has been f ed int o the transport.

F39 Printer Character Shif t

(for Document Print er 12)

Allows you to select which set of ink jets will be used to

print each character. Enter 1 to select the left set of ink

jets, enter 2 to select the cent er set of ink jets, or enter 3

to select the right set of ink jets, then press Ente r.

F39 Print Contrast

(for Super12 Document

Printer)

Allows you to increase or decrease the amount of ink put

on the document. Press the Up arrow for more ink and

press the Down arrow for less ink. Incremental values

are: 12, 25, 37, 50, 62, 75, 87 and 100%.

4-6 A-61092 September 1999

Page 32

Code Function Code Name Description

F40 All Document Printers

On/Off

(for Document Print er s 1

Allows you to turn all Document Printers (primary DP1,

secondary DP1 and DP12) on or off. Enter 1 to turn on or

0 to turn off, then pr ess Ente r .

and 12)

F40 Print Head Position

(for Super12 Document

Printer)

Allows you to change the print heads or clean the printer.

This function can only be performed when the tr ansport is

off. Enter 1 to Change Heads or 2 to Clean Printer, then

press Enter.

F41 Primary DP1 On/Off Allows you to turn the primar y Document Printer 1 on or

off. Enter 1 to turn on or 0 to turn off, then press Enter.

NOTE: If the Super12 Document Printer is inst alled, a

message indicating “Unassigned Function” will be

displayed.

F42 Secondary DP1 On/Off Allows you to turn the secondary Document Printer 1 on

or off. Enter 1 to turn on or 0 to turn off, then press Enter .

NOTE: If the Super12 Document Printer is installed, a

message indicating “Unassigned Function” will be

displayed.

F43 Document Printer 12/

Super12 On/Off

Allows you to turn the Document Printer 12 or Super 12

Document Printer on or of f. Enter 1 to turn on or 0 to turn

off, then press Enter.

F44 Omit Printing on the Next

Document Only

Allows you to specify no information be printed on the

next document scanned. Printing will resume on

subsequent documents. Enter 1 to omit printing on the

next document, or enter 0 to print on t he next docum ent

then press Enter.

NOTE: If you enter F44 and then F45, the Omit Printing

Status on Next Document will be cleared.

F45 Print Test (for Document

Printers 1 and 12)

Allows you to test the position and print quality of all

Document Printers installed. Enter t he number of the print

test you want to perform.

1=Print IA test 3=Shift test

2=Prime test 4=Standard test

This function can be done when the transport is off.

F45 Print Test

(for Super12 Document

Printer)

Allows you to test the position and print quality of the

Super12 Document Printer. Enter the number of the print

test you want to perform.

1=Mode Image — will print the current image for the level

and mode you are in.

2=Test Pattern — will print a preloaded test image.

This function can be done when the transport is off.

NOTE: If you enter F44 and then F45, the Omit Printing

Status on Next Document will be cleared.

A-61092 September 1999 4-7

Page 33

Code Function Code Name Description

F46 Print Position Allows you to specify how far from t he leading edge of the

document printed informat ion will appear. Press the Up

arrow to increment the starting print position by 1 inch

(25 mm), press the Down arrow to decrement the starting

print position by 1 inch (25 mm). Press the Right arrow to

increment the starting print position by 0.125-inch (3 mm),

or press the Left arrow to decrement the st ar ting print

position by 0.125-inch (3 mm), then press Enter.

F48 Purge Print Pattern

Allows you to initiate an immediate priming ink spurt.

(for Document Print er s 1

and 12)

F48 Print Purge Head

(for Super12 Document

Printer)

F49 Purge Frequency

(for Document Print er 1

and 12)

Allows you to initiate an automatic purging of the print

heads.

This function can be done when the transport is off.

Allows you to specify how often, in terms of the num ber of

documents fed into the transpor t, a priming ink spurt is

initiated. Enter the number of documents, up to 50,000

and press Enter.

F49 Align Print Image

(for Super12 Document

Printer)

Allows you to specify how far to move the left half of an

image up or down (in increments of one line) on t he

document so it will align with the right half of the image.

F50 Patch Reader 1 On/Off Allows you to turn the pr im ary Patch Reader on or off.

Enter 1 to turn on or 0 to turn off, then press Enter.

F51 Patch Reader 2 On/Off Allows you to turn the secondar y Patch Reader on or off.

Enter 1 to turn on or 0 to turn off, then press Enter.

F52 End Fed Patch Reading

On/Off

Turn End Fed Patch Reading on if you expect the patch t o

be located in the vertical (vs. horizontal) position on the

document. Enter 1 to turn on or 0 to turn off, then press

Enter.

F53 Patch Reading

Confirmation Tone On/Off

Allows you to turn the confirmation tone on or off which

informs you when the Patch Reader has successfully read

a patch document. Enter 1 to turn on or 0 to turn off, then

press Enter.

F56 Printer Open Jet Test

(for Document Print er s 1

and 12)

Allows you to determine whether or not there are

nonfunctional ink jets in the Super 12 Document Printer

ink cartridge. Press C to return to a norm al oper ating

display.

F56 Printer Cartridge St atus

(for Super12 Document

Printer)

Allows you to determine whether or not there are

nonfunctional ink jets in the Super 12 Docum ent Printer.

Also checks the print head(s) connection to t he flex cable

to assure the print heads(s) are installed properly. Press

C to return to a normal oper at ing display.

F57 Endorser On/Off

Allows you to turn the Endorser on or off. Enter 1 to turn

on or 0 to turn off, t hen pr ess Ent er.

4-8 A-61092 September 1999

Page 34

Code Function Code Name Description

F58 Endorser Mode Allows you to display the current Endorser mode and/or

change the Endorser mode. To chang e to Endorser

mode, press any arrow key to toggle between the two

available options and then press Enter.

F59 Endorser Print Position Allows you to specify how far from the leading edge of the

document the endorsement will appear. Press the Up

arrow to increment the starting print position by 1 inch

(25 mm), press the Down arrow to decrement the starting

print position by 1 inch (25 mm). Press the Right arrow to

increment the starting print position by 0.125-inch (3 mm),

or press the Left arrow to decrement the st ar ting print

position by 0.125-inch (3 mm), then press Enter.

F60 Bar Code Reading 1

On/Off

F62 Bar Code/Patch Reading

Confirmation Tone

Allows you to turn bar code reading on or off . Enter 1 to

turn on or 0 to turn off and then press Enter.

Allows you to turn the bar code/patch reading

confirmation tone on or of f. Enter 1 to turn on or 0 to turn

off and then press Ente r.

F63 Bar Code Reader

Confirmation Tone

Allows you to turn the confirmation tone on or off which

informs you when the Bar Code Reader has successfully

read a bar code document. Enter 1 to turn on or 0 to turn

off and then press Ente r.

F64 Omit Bar Code Reading on

the Next Document Only

Allows you to omit bar code reading on the next document

scanned. Bar Code Reading will resume on subsequent

documents. Enter 1 to turn on or 0 to turn off, then press

Enter.

F65 Bar Code Test

Allows you to perform a test to verify the operat ion of the

Bar Code Reader. Enter the number of the bar code test

you want to perform: 1=Evaluate; 2=Display; 3=%Kodak;

or 4=%Norm, then press Enter.

F66 Partial Bar Code Reading

On/Off

Allows you to turn partial bar code reading on or off. Enter

1 if you want the scanner to read bar codes with a start

character (and

n

characters beyond the start character

that can be read) even if no end character is encountered.

Enter 0 to turn off par tial bar code reading off, then press

Enter.

F70 Length Checking On/Off Allows you to turn length checking on or off which

monitors the length of t he document(s) scanned using

predefined maximum allowable lengths. Enter 1 to turn on

or 0 to turn off and then press Enter.

F71 Omit Length Checking on

the Next Document Only

Allows you to omit length checking on the next document

scanned. Length monitoring will resume on subseq uent

documents. Enter 1 to turn on or 0 to turn off, then pr ess

Enter.

A-61092 September 1999 4-9

Page 35

Code Function Code Name Description

F72 Skew Detection Allows you to turn skew detection on or off which monitors

the amount of skew using predefined skew angle(s).

Enter 1 to turn on or 0 to turn off, then press Enter.

F73 Latched Scanning Flag Allows you to set a flag in the image headers which alerts

the host system that this document, and those which

follow, are of special interest . The flag will remain

activated for every document until it is turned off. Enter 1

to turn on or 0 to turn off, then press Enter.

F74 Momentary Scanning Flag Allows you to set a flag in the image header which alerts

the host system that this document is of special interest.

This flag is set only for t hat one document. Enter 1 to turn

the momentary scanning flag on, then press Enter.

F75 Footswitch Confirmation

Tone

Allows you to turn the confirmation tone on or off which

informs you when the Footswitch is pressed and/or

released. Enter 1 to turn on or 0 to turn off, then press

Enter.

F91 Select Linked Mode Allows you to switch from one application mode to

another, keeping the last im age address. Enter the

number of the application mode you wish to select, then

press Enter.

F92 Fixed Field Allows you to enter a new fixed field value containing

alphanumeric characters.

NOTE: If the fixed field width for t he mode you are using

is 0, and E104 error will be displayed. To correct

this, change to a mode that has a fixed field or

modify the mode you are using so the fixed f ield

is not 0.

F93 Action/Confirmation Tone Allows you to hear the pitch of the alarm tone.

F94 Level 1 Allows you to assign Level 1 to the next document fed into

the transport.

F95 Level 2 Allows you to assign Level 2 to the next document fed into

the transport.

F96 Level 3 Allows you to assign Level 3 to the next document fed into

the transport.

F97 Next Image Address Allows you to input the next image address. Enter the

next image address, then press Enter.

F98 Stop Allows you to stop the transport.

F99 Run Allows you to turn on the tr anspor t .

4-10 A-61092 September 1999

Page 36

5 Maintenance

Cleaning tasks

Cleaning materials

To keep your scanner in good operating condition, the following tasks

should be performed:

• Cleaning the imaging g uides (daily)

• Cleaning the feed and separator roller ( sem i- automatic feeder)

(daily)

• Cleaning the feeder module and separator r oller ( aut omatic feeder)

(daily)

• Cleaning the paper path (daily)

• Vacuuming inside the scanner (daily)

• Cleaning the exposure lamp housings (weekly)

• Cleaning the cabinet (weekly)

• Cleaning the air filter (monthly)

For additional maintenance and feeder adjust m ent information, see

Kodak publication A-61604. This publication is part of the Maintenance

and Feeder Adjustment procedure video; Catalog Number 828 5306.

Materials needed to perform maintenance procedur es ar e:

• A mild cleaning agent

• A quality lens cleaner

• A soft, clean, lint-free cloth

• A soft-bristled cleaning brush

• A vacuum cleaner

• Staticide Wipes

• Roller Cleaning Pads

• Paper Path Cleaner

IMPORTANT:

Replacement parts

A-61092 September 1999 5-1

Consumable parts that can be replaced by the customer include:

• Air filter

• Exposure lamps

• Imaging guides

• Automatic Document Feeder Module

• Automatic Document Feeder Separator Roller

Instructions on how to replace these parts are included later in this

chapter.

Do not use any unauthorized commercial cleaning

solvent in any of the cleaning procedures.

Page 37

Daily maintenance procedures

Maintenance procedures that should be performed daily include

cleaning the imaging guides, the feed and separator rollers, the paper

path and vacuuming inside the scanner.

Cleaning the imaging guides

To clean the imag ing guides, follow the steps below:

IMPORTANT:

1. Open the right-side access door.

NOTE: The illustr ation below shows the rear view of the scanner.

Upper lamp

housing assembly

Upper imaging guide

Lower image guide

Do not use any abrasive materials when cleaning the

imaging guides. This includes abrasive cleansers,

commercial solvents, paper towels, or coarse clot hs.

Lower lamp housing

assembly

Upper imaging guide

Lower imaging guide

2. Locate and grasp the end of the upper im aging guide. Carefully

slide the imaging guide out of its track.

3. Locate and grasp the end of t he lower imaging guide. Caref ully

slide the imaging guide out of its track.

Right-side access door

5-2 A-61092 September 1999

Page 38

4. Remove dust from the imaging guides, using a soft bristle brush.

5. Remove fingerprints or smudges fr om t he imaging guides, wiping

both sides of each imaging guide with a clean, soft, lint-free cloth

slightly moistened with water or lens cleaner. Then, lightly wipe

both sides of each imaging g uide with a dry cloth or an antistatic

wipe.

IMPORTANT:

Do not use cleaning pads on the imaging guides. Do

not use any abrasive materials when cleaning the

guides. This includes abrasive cleansers, commercial

solvents, paper towels, or course cloths.

6. Remove the upper lamp housing assembly.

7. Remove dust from the upper lamp housing assem bly, using a soft

bristle brush.

8. Reinstall the upper lamp housing assembly.

Repeat Steps 6 thr ough 8 for the lower lamp housing assembly.

IMPORTANT:

Use care when handling the imaging guides. Hold

the imaging guides by the green handles only.

9. Grasp and hold the lower imaging guide by the g r een handle and

carefully slide it back into place. Make sure the grooves fully

engage the track.

10. Grasp and hold the upper imaging guide by the green handle and

carefully slide it back into place. Make sure the grooves fully

engage the track.

NOTE: The imaging guides ar e not interchangeable. They can

only be inserted one way.

11. Close the right-side access door.

A-61092 September 1999 5-3

Page 39

Cleaning the feed and

separator rollers (semiautomatic feeder)

Clean the feed and separator rollers at least twice a day to prevent ink,

toner, and dust from collecting on the rollers and preventing docum ents

from separating.

1. Grasp the front cover and swing it open to the right.

Roller cover

Release lever

Feed roller

Separator roller

2. Push the roller cover release lever toward the back of t he m achine.

3. Grasp and rotate the roller cover toward the back of the machine,

exposing the feed and separator rollers.

Roller assembly

Feed roller

Separator roller

4. Hold the feed and separator rollers and scrub them with a roller

cleaning pad until all residue is removed from t he roller ribs. Clean

the five small normal for c e r oller s ( below the feed roller — not

shown in this illustration) in the same manner.

5. Wipe the feed and separator rollers and the five normal f or c e r oller s

with a clean, dry, lint-free cloth to dry the rollers.

6. Rotate the roller assembly back into posit ion.

7. Close the front cover.

5-4 A-61092 September 1999

Page 40

Cleaning the feeder

module and separator

roller (automatic feeder)

Clean the feeder module and separator r oller daily to pr event ink, toner,

and dust from collecting on t he r ollers and preventing documents from

separating.

Cleaning the feeder module and separator roller:

1. O pen the front cover.

2. Push the roller cover release lever toward the back of t he m achine.

3. Grasp and rotate the roller cover toward the back of the machine,

exposing the feeder module and separator roller.

Roller cover

release lever

Roller cover

Feeder

module

4. Remove the feeder module by pushing it t o the right and lifting it out

of its position.

5. Clean both rollers of the f eeder module.

6. Replace the feeder module, by aligning the pins and fitting it into

position.

A-61092 September 1999 5-5

Page 41

Cleaning the separator roller:

1. O pen the front cover.

2. Push the roller cover release lever toward the back of t he m achine.

3. Grasp and rotate the roller cover toward the back of the machine,

exposing the feeder module and separator roller.

Roller cover

release lever

Roller cover

Feeder module

4. Lift and remove the separator roller cover plate.

5. Lift the separator roller out of the grooved brackets.

Separator roller

Grooved brackets

6. Clean the separator roller. Inspect the roller any areas where the

white foam is showing through the roller cover. If the roller shows

signs of wear, obtain and replace the separator roller.

7. Replace the separator roller by aligning t he pins in t he grooved

brackets.

8. Reinsert the separator roller cover plate.

9. Close the feeder cover.

10. Close the front door.

5-6 A-61092 September 1999

Page 42

Cleaning the paper path

NOTE: Before doing the following procedur e, clean the machine

thoroughly and use the roller cleaning pads to clean the f eed,

separator and normal force rollers — star t with a clean

machine.

Use the Paper Path Cleaner to clean the paper path rollers . Per iodically

feed a cleaning sheet with the gum side up thr ough the machine in both

the portrait and landscape orientation.

The paper path should be cleaned twice a day. Before you clean the

paper path, be sure the feed and separator rollers and imaging guides

have been cleaned.

1. To ensure complete coverage of the transport and norm al force

rollers, feed the cleaning sheet in t he center, and to the left and

right of the f eeder docum ent guides.

2. Repeat the procedure until no furt her r esidue is picked up by the

cleaning sheet.

3. Using a clean Paper Path Cleaner sheet, repeat Step 1 to verify that

the rollers are clean.

4. Turn the gum side down, and repeat Steps 1 through 3.

NOTE: When t he gum side is down, it may be necessary to hold

down the gap release lever to allow the Paper Path Cleaner

sheet to feed past the separator roller.

Vacuuming inside the scanner

Regular use of Paper Path Cleaner sheets m ay result in fewer major

cleanings with the roller cleaning pads.

NOTE: If t her e ar e feeder errors after cleaning the feed and separator

rollers, refer to the sect ion ent it led “Adjusting the feed and

separator roller gap”, in Chapter 2.

The sensors located under the horizontal plate in the f eeder/horizontal

transport area and in the upper section of the lower roller housing

assembly, the exposure lamp housings, and the air filter should be

vacuumed or wiped down thoroughly with a clean, dry, soft, lint-free

cloth at least once a week.

Refer to the instructions and illust r ations provided in the Chapter 7,

Troubleshooting,

to assist in accessing the sensor locations.

A-61092 September 1999 5-7

Page 43

Cleaning the feeder/ horizontal transport area

The sensors in the feeder/horizontal tr anspor t area are located under

the horizontal plate, behind the feed/separator r oller s , near the reflector

strips.

1. Open the front cover.

2. Raise the horizontal plate.

3. Vacuum the area underneath the horizontal plate.

4. Remove the lower belt module.

5. Vacuum under the module and wipe with a clean, damp cloth.

6. Replace the lower belt module.

7. Lower the horizontal plate back into place.

8. Close the front cover.

Cleaning the lower roller housing assembly area

To clean the lower roller housing assem bly area, follow the steps

below:

1. Open the top cover.

2. Open the right-side access door.

3. Remove the imaging guides ( not shown in illustra t ion) .

IMPORTANT:

Use care when handling the imaging guides. Hold

the imaging guides by the green handles only.

Vertical baffle handle

Baffle plate

Lower roller

housing assembly

Lower roller

housing

assembly

Screen

4. Grasp the vertical baffle handle, push it in and tur n it

counterclockwise until the baffle plate unlat ches. Pull the baffle

plate down until it stops, this unlocks the lower roller housing

assembly.

5-8 A-61092 September 1999

Page 44

5. Slide the lower roller housing assembly out of its housing and

vacuum inside the housing.

IMPORTANT:

Do not slide the lower roller housing assembly back

into place without first rem oving the imaging guides.

Failure to remove them first can cause m isalignm ent

and/or damage to the machine.

6. Slide the lower roller housing assembly back into its or iginal

position.

7. Replace the imaging guides.

8. Vacuum the screen located at the base of the t r ansport system.

9. Raise the baffle plate and push it into its original position. Turn the

vertical baffle handle and latch it into place.

10. Close the right-side access door and top cover.

A-61092 September 1999 5-9

Page 45

Weekly maintenance procedures

Maintenance procedures that should be performed weekly include

cleaning the exposure lamp housings and cleaning the cabinet.

Cleaning the exposure lamp housings

The upper and lower lamp housings should be cleaned.

1. Open the right-side access door.

2. Remove the upper and lower imaging guides (between the upper

and lower exposure lamp housings — not shown in this illustration).

IMPORTANT:

Use care when handling the imaging guides. Hold

the imaging guides by the green handles only.

Upper lamp housing

Area to

vacuum

Lower lamp housing

2. Remove the lower lamp housing.

Cleaning the cabinet

3. Vacuum the housing.

4. Replace the lower lamp housing.

5. Remove the upper lamp housing.

6. Vacuum the housing.

7. Replace the upper lamp housing.

8. Replace the upper and lower imaging guides.

9. Close the right-side access door.

Clean the exterior of the scanner, the feed shelf, and the hopper ar ea

with a soft cloth. Remove any fingerprints, stains, or stubborn dirt with a

cloth dampened with water or a mild cleaning agent.

5-10 A-61092 September 1999

Page 46

Monthly maintenance procedures

Maintenance procedures that should be performed mont hly include

cleaning the air filter.

Cleaning the air filter

The air filter should be checked and cleaned at least once a month,

and changed as needed.

1. Remove the air filter cover by pressing in on the top of the cover to

release the catch.

Air filter cover

Catch

Air filter

2. Examine t he filter for dust accumulat ion. I f dust has accumulated,

lightly vacuum the outside of the air filter and the air filter cover.

3. Replace t he air filter cover by first inserting the bottom edge and

then pushing the top edge in place.

A-61092 September 1999 5-11

Page 47

Replacement procedures

Replacement procedures should be performed on an as-needed basis.

Components that need periodic replacement include the air filter,

exposure lamps and the imaging guides.

Replacing the air filter

The air filter should be replaced at least once a year, more often if

needed.

IMPORTANT:

Never operate the scanner without an air f ilter installed.

The imaging apparatus will quickly become

contaminated with dust and dirt, im pairing im age qualit y.

1. Remove the air filter cover by pressing in on the top of the cover to

release the catch.

Air filter cover

Catch

Air filter

2. Carefully remove the old air f ilt er. Note the orientation of the filter

as it is removed from the machine.

3. Orient a new air filter the same as the old air filter, and insert it into

the space left open by the old air filter.

4. Replace the air filter cover by first inserting the bottom edge and

then pushing the top edge in place.

5-12 A-61092 September 1999

Page 48

Replacing the exposure lamps

The exposure system consists of four long - life fluorescent lamps.

There are two lamp housings; one upper and one lower. Each lamp

housing contains two lamps.

Change the lamps at least every 500 hours, when image quality

appears to be degrading (and standard maintenance procedures do not

improve the image quality), or when requested to do so by an operator

message. Always replace both lamps in a housing at the same time, or

exposures may appear inconsistent. Always use the recommended

lamps, or image quality may be unacceptable.

1. Turn the side panel switch off.

2. Open the right side access door.

3. Remove the imaging guides. (Refer to the section entitled,

“Replacing the imaging guides”.)

4. Grasp the tab at the end of the upper lam p housing and slide the

housing out of the track.

Tab

Upper lamp housing

WARNING:

Make sure the lamps are cool before attempting

to remove them from the lamp housing.

A-61092 September 1999 5-13

Page 49

5. Carefully grasp the end of the lamp that is nearest the tab and lift it

out of the lamp housing sock et . Free the other end of the lamp and

lift it out of the lamp housing. Remove the second lamp in the same

manner.

6. Dispose of or recycle the used lamps.

7. Install each lamp using the following sequence of steps:

• Face the clear, horizontal line of the new lamp toward the slot in

the bottom of the lamp housing.

• Insert one end of the lamp into t he socket at the tab end of the

lamp housing. Insert the opposite end of the lamp into the other

socket.

WARNING: The exposure lamps are fragil e. Never apply

pressure to the center of the lamp; press down

only on the ends of the lamp.

• Gently push down on each end of the lamp. Do not forc e t he

lamp into place. The lamp should fit securely into the housing

and click into place.

NOTE: Improperly installed lamps (i.e., not securely seated in

the lamp housing) will result in repeated low lam p

warnings.

8. Place the upper lamp housing in the track and slide it back into

place. Repeat Steps 4 through 8 to replace the lamps in the lower

lamp housing.

9. Reinstall the imaging guides.

10. Close the right-side access door.

11. Turn the side panel switch on.

5-14 A-61092 September 1999

Page 50

Replacing the imaging guides

To replace the imaging guides, follow the steps below:

1. Open the right-side access door.

2. Locate and grasp the end of the upper im aging guide. Carefully

slide the imaging guide out of its track.

IMPORTANT:

Use care when handling the imaging guides. Hold

the imaging guides by the green handles only.

3. Locate and grasp the end of the lower imaging guide. Carefully

slide the imaging guide out of its track.

4. Grasp and hold the new lower imaging guide by the green handle

and carefully slide it into place. Make sure t he grooves fully engage

the track.

5. Grasp and hold the new upper imaging guide by the green handle

and carefully slide it into place. Make sure t he grooves fully engage

the track.

NOTE: The imaging guides ar e not interchangeable. They can

only be inserted one way.

6. Close t he right-side access door.

A-61092 September 1999 5-15

Page 51

Replacing the feeder module and separator roller

To replace the feeder module and separator roller, follow the steps

below:

Replacing the feeder module:

1. O pen the front cover.

2. Push the roller cover release lever toward the back of t he m achine.

3. Grasp and rotate the roller cover toward the back of the machine,

exposing the feeder module and separator roller.

Roller cover

release lever

Roller cover

Feeder

module

4. Remove the feeder module by pushing it t o the right and lifting it out

of its position.

5. Reinsert a new feeder module, by aligning the pins and fitting it into

position.

5-16 A-61092 September 1999

Page 52

Replacing the separator roller:

1. O pen the front cover.

2. Push the roller cover release lever toward the back of t he m achine.

3. Grasp and rotate the roller cover toward the back of the machine,

exposing the feeder module and separator roller.

Roller cover

release lever

Roller cover

Feeder module

4. Lift and remove the separator roller cover plate.

5. Lift the separator roller out of the grooved brackets.

Separator roller

Grooved brackets

6. Reinsert a new separator roller by aligning the pins in the grooved

brackets.

7. Reinsert the separator roller cover plate.

8. Close the feeder cover.

9. Close the front door.

A-61092 September 1999 5-17

Page 53

Ordering replacement parts

The following consumable parts can be ordered by calling:

1-800-431-7278.

• Imaging guides

− Upper: Part No. 964365

− Lower: Part No. 942000

• White exposure lamp: Par t No. 964683

• Automatic Document Feeder Module (for autom at ic feeder):

CAT No. 123 6066

• Automatic Document Feeder Separator Roller (for automatic

feeder): CAT No. 161 4908

• Air filter: Part No. 942890

Ordering cleaning materials

The following cleaning materials can be order ed:

• Paper Path Cleaner: Part No. 4C9073 ( pack of 50)

• Roller Cleaning Pads: Part No. 4C9069 (pack of 24)

• Staticide Wipes: Part No. 1C8102 (pack of 24)

5-18 A-61092 September 1999

Page 54

6 Operator Messages

This chapter outlines the actions that should be taken by the user and

system administrator when an operator message appear s in the status

display.

If a message appears in the stat us display that is within the ranges

E000-E299 or E500-E599, you should take the action indicated in the

table(s) in this chapter.

IMPORTANT:

Never power down the machine without f ir st contacting

your system administrator.

If a message appears in the stat us display that is within the ranges

E300-E499 or E600-E999, contact your system administrator.

The following action(s) should be taken:

• Determine whether or not the error can be addressed from the host

system.

• If the error cannot be addr essed from the host system, attem pt to

clear the error by taking the action indicat ed in t he table( s) in this

chapter.

• If the prescribed action(s) does not clear the error, initiate a