Page 1

Document Scanner 9500

and Document

Scanner/Microimager 990

Product

Page 2

Kodak Digital Science Document Scanner 9500

Product description

The Kodak Digital Science Document Scanner 9500 is a high-speed (up to

155 pages-per-minute*), medium- to high-resolution (up to 300 dpi) rotary

scanner designed for high-volume digital capture of business documents.

The Scanner 9500 captures printed characters, handwritten text, and

graphics from documents of various sizes (from 2.5 in [64 mm] to 30 in

[762 mm] long and from 2.5 in [64 mm] to 12 in [305 mm] wide) and

thicknesses (standard documents up to 0.014 inches [0.36 mm]; even

thicker documents may be scanned using the gap release feature).

Customers may choose the Scanner 9500S (simplex) which captures a

page image from single-sided pages or the Scanner 9500D (duplex) which

captures front and back page images from two-sided pages in a single

pass.

Page images are transmitted to a host computer along with an image

header which contains a variety of information, allowing for easy indexing,

database storage and retrieval.

__________

* Standard-sized documents fed in landscape orientation; continuous transport using the Semi-

Automatic Feeder.

Page 3

Features and benefits

The Document Scanner 9500 offers the following features and benefits:

• Freestanding floor console unit.

• Control Panel which provides an easy-to-use operator interface

with: equipment operation keys, standard function keys,

programmable function keys, numeric keypad, status indicators,

and an 80-character LCD Status Display which reflects the current

setup and displays operator messages.

• Gap Adjustment Knob and Gap Release Lever which allows for

adjusting varying document thicknesses.

• Documents are loaded and unloaded from the front and returned

to the exit hopper in their original sequence.

• Adaptive Threshold Processor which provides uniform image

quality of scanned documents regardless of their color, paper

texture, print color or density.

• Access doors allow easy access to the document transport system

without removing the feeder, transport plates, etc. or moving the

Scanner away from the wall.

• Easy daily calibration is performed by feeding a white sheet of

paper.

• Easy daily, weekly, monthly and annual maintenance routines

which require an average of only ten minutes per day.

• Computer-based diagnostics and modular design enable quick and

easy problem diagnosis and repair, reducing downtime.

• Selectable scan resolution from 300–70 dpi.

• Image compression (GIII 1-dimensional; GIII 2-dimensional; GIV).

• Image processing capabilities (such as cropping, image

enhancement filters, noise filter, screening/dithering, thresholding,

etc.).

• Resettable document counter.

• Automatically generates image addresses (from a customer-

defined base address).

• Eighteen programmable modes provide customization for specific

applications.

Page 4

Optional accessories

All accessories have been designed to operate at paper transport speed.

Using these accessories will not reduce overall processing speed.

The following accessories are available to customize scanner applications:

• Advanced Document Controller — detects document overlap

and skew.

• Bar Code Reader — provides a hands-off method of entering data

by automatically reading and decoding information encoded in bar

code form. Decoded bar code information is included in the image

header.

• Check Feeder — provides continuous feeding of check-sized

documents.

• Check Stacker — provides continuous stacking of check-sized

documents.

• Document Printer Controller — allows use of the document printers

(one or two DP1 printers, and one DP12 printer).

• Document Printer 1 — allows customer-specified information to

be printed on documents (single line, vertical orientation—38

characters maximum) as they pass through the transport system.

This information is used for document identification and tracking.

• Document Printer 12 — allows customer-specified information to

be printed on documents (multiple lines, horizontal orientation—

144 characters maximum) as they pass through the transport

system. This information is used for document identification and

tracking.

• Endorser — automatically imprints endorsements on the rear side

of documents (with a variety of die stamp styles) as they pass

through the transport system.

• Footswitch — provides a hands-off method of performing

document level changes or commonly used functions while

documents are being fed into the transport system.

• Imaging Station Lamps — provides color form drop-out capability

for more efficient document storage.

• Patch Reader — controls document level changes by

automatically sensing a predefined patch code and changing the

document level accordingly.

Page 5

Kodak Digital Science Document Scanner/Microimager 990

Product description

The Kodak Digital Science Document Scanner/Microimager 990 is a highperformance (up to 120 pages-per-minute*) rotary document scanner and

microfilmer designed for medium- to high-volume digital capture of

business documents. The Scanner/Microimager 990 captures printed

characters, handwritten text, and graphics from documents of various sizes

(from 2.5 in [64 mm] to 30 in [762 mm] long and from 2.5 in [64 mm] to 12

in [305 mm] wide) and thicknesses (standard documents up to 0.014

inches [0.36 mm]; even thicker documents may be scanned/filmed using

the gap release feature).

The Scanner/Microimager 990S captures front and back page images from

two-sided documents on film while simultaneously scanning the front side.

The Scanner/Microimager 990D captures front and back page images from

two-sided documents on film while simultaneously scanning the front and

back sides.

Scanned page images are transmitted to a host computer along with an

Image Header which contains a variety of information, allowing for easy

Page 6

Features and benefits

The Document Scanner 990 offers the following features and benefits:

• Control Panel which provides an easy-to-use operator interface

with: equipment operation keys, standard function keys,

programmable function keys, numeric keypad, status indicators,

and a LCD Status Display which reflects the current setup and

displays operator messages.

• Gap Adjustment Knob and Gap Release Lever which allows for

adjusting varying document thicknesses.

• Documents are loaded and unloaded from the front and returned

to the exit hopper in their original sequence.

• Access doors allow easy access to the document transport system

without removing the feeder, transport plates, etc. or moving the

Scanner away from the wall.

• Easy daily calibration is performed by feeding a white sheet of

paper.

• Easy daily, weekly, monthly and annual maintenance routines

which require an average of only ten minutes per day.

• Computer-based diagnostics and modular design enable quick and

easy problem diagnosis and repair, reducing downtime.

• Selectable scan resolution from 200–67 dpi.

• Image compression (GIII 1-dimensional; GIII 2-dimensional; GIV).

• Image processing capabilities (such as cropping, image

enhancement filters, noise filter, screening/dithering, thresholding,

etc.).

• Resettable document counter.

• Image addresses automatically generated (from a customer-

defined base address).

• Eighteen programmable modes provide customization for specific

applications.

• Event confirmation tones/lights.

• Programmable in five languages.

• Standard SCSI-2 interface.

Page 7

Optional accessories

document level changes or commonly used functions while

All accessories have been designed to operate at paper transport speed.

Using these accessories will not reduce overall processing speed.

The following accessories are available to customize scanner/microimager

applications:

• Adaptive Threshold Processor — provides uniform image quality

of scanned documents regardless of their color, paper texture,

print color or density.

• Advanced Document Controller — detects document overlap

and skew.

• Bar Code Reader — provides a hands-off method of entering data

by automatically reading and decoding information encoded in bar

code form. Decoded bar code information is included in the image

header.

• Check Feeder — provides continuous feeding of check-sized

documents.

• Check Stacker — provides continuous stacking of check-sized

documents.

• Document Printer Controller — allows use of the document

printers (one or two DP1 printers, and one DP12 printer).

• Document Printer 1 — allows customer-specified information to

• Document Printer 12 — allows customer-specified information to

• Endorser — automatically imprints endorsements on the rear side

• Film Writing Module — allows information to be written on the

• Footswitch — provides a hands-off method of performing

be printed on documents (single line, vertical orientation—38

characters maximum) as they pass through the transport system.

This information is used for document identification and tracking.

be printed on documents (multiple lines, horizontal orientation—

144 characters maximum) as they pass through the transport

system. This information is used for document identification and

tracking.

of documents (with a variety of die stamp styles) as they pass

through the transport system.

film next to each document image for document identification and

tracking.

Page 8

• Patch Reader — controls document level changes by

automatically sensing a predefined patch code and changing the

document level accordingly.

• Scanner/Microimager 990S-990D Upgrade Module — allows for

an upgrade from a Scanner 990S to a Scanner 990D.

• Semi-Automatic Feeder — allows for manual feeding (one

document at a time) or automatic feeding of mixed size documents

(a group/batch of documents at a time).

• Smart Cassettes 100 and 215 — features foolproof duo mode,

easy threading and graphic display of film remaining.

• Workstation Side Console

Page 9

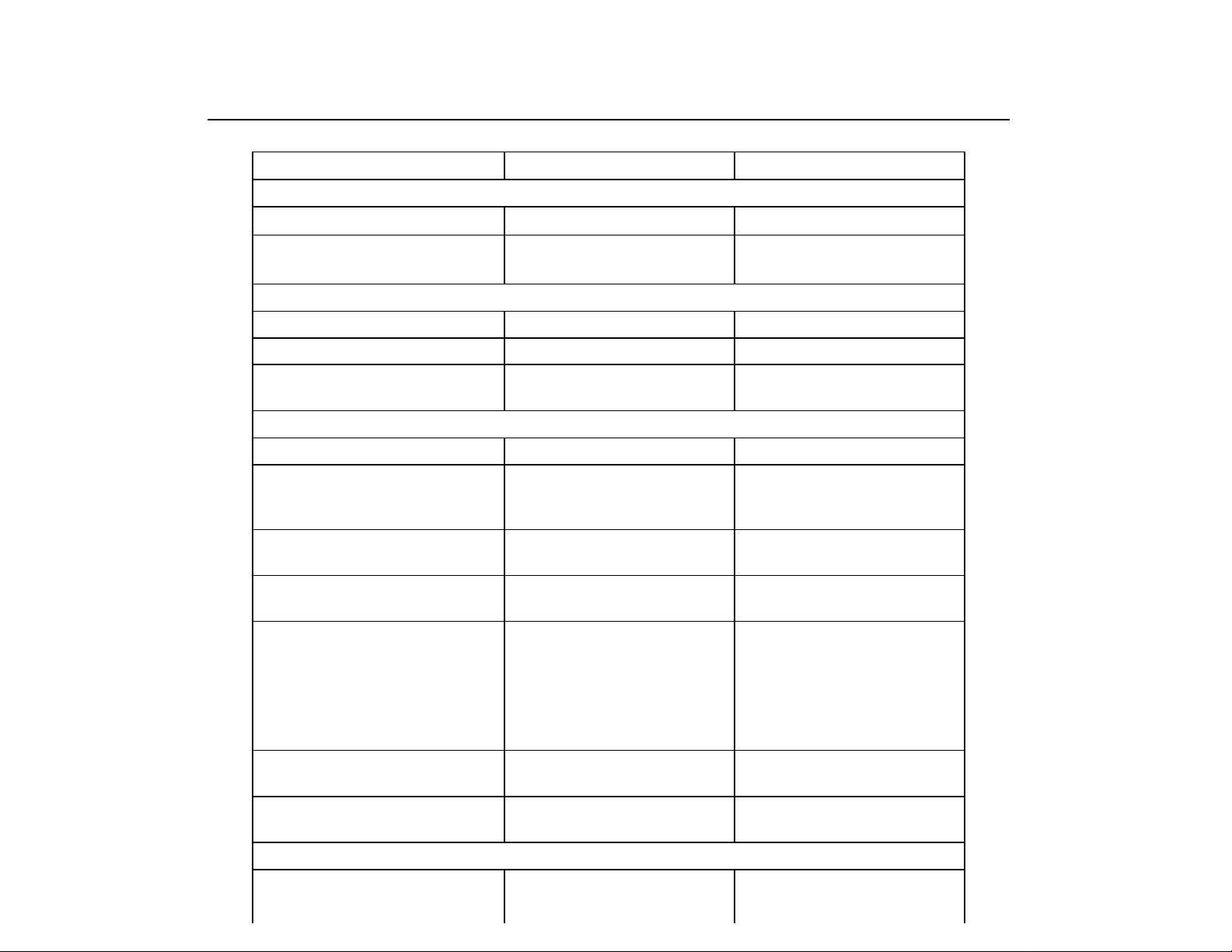

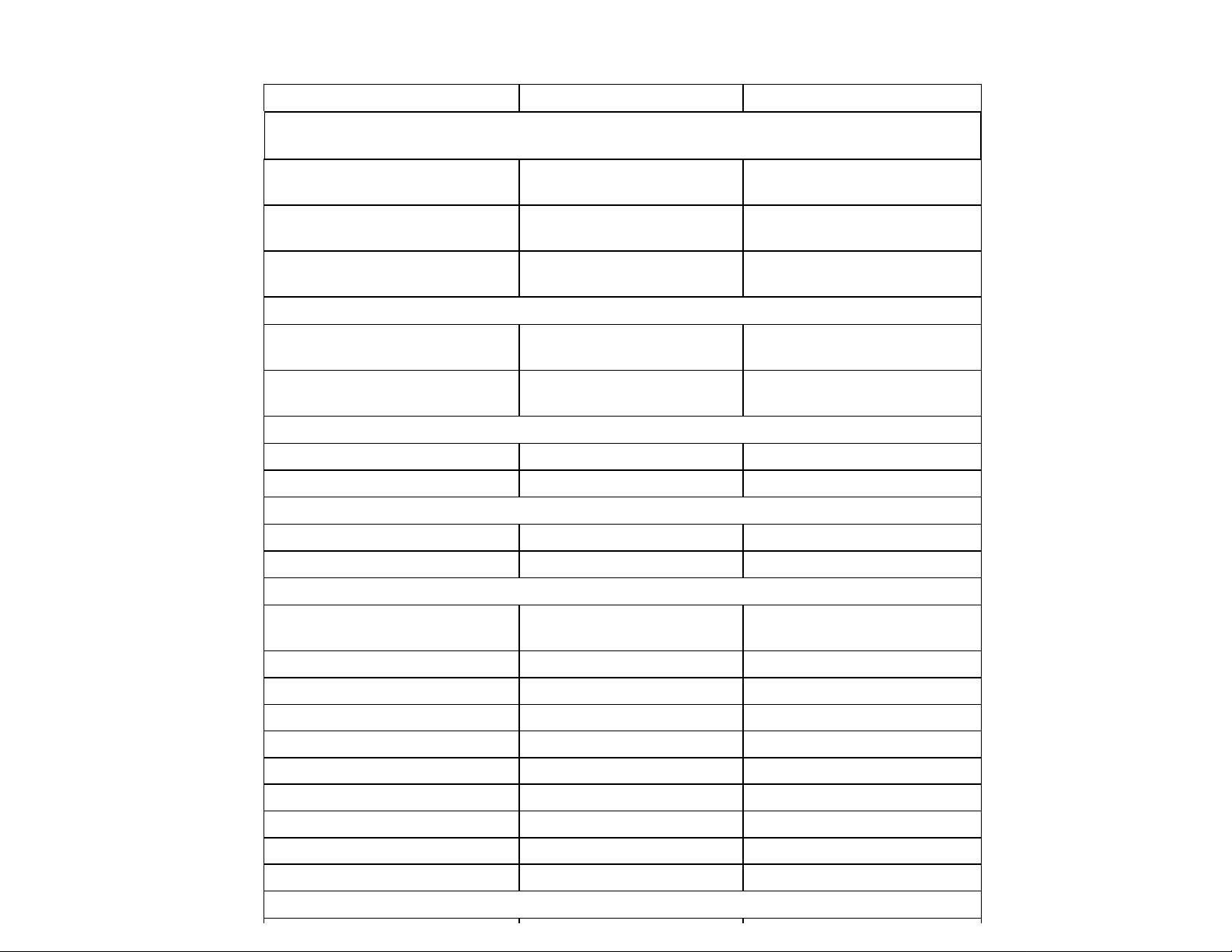

Product Comparison Matrix

Feature Scanner 9500 Scanner/Microimager 990

Speed*

² 200 dpi

> 200 dpi

² 300 dpi

Scanning capabilities

Scanning modes simplex and duplex simplex and duplex

Resolution 300–70 dpi 200–67 dpi

Buffer size 4 megabytes (simplex)

Microfilming capabilities

Film modes n/a simplex, duplex and duo

Reduction ratios n/a 24X (simplex)

Number of

film cassettes

Film cassette types n/a Smart Cassette 100

Film types n/a HQ Microfilm 1461

120 pages per minute 90 pages per minute

80 pages per minute n/a

4 megabytes (simplex)

8 megabytes (duplex)

n/a minimum of 1

8 megabytes (duplex)

40X (simplex, duplex, duo)

50X (simplex, duplex, duo)

maximum of 2

Smart Cassette 215

(Estar Base)

16 mm x 30.5 m (100 ft)

HQ Microfilm 3461

(Estar Base)

16 mm x 65.5 m (215 ft)

Programmable

application modes

Programmable

control panel keys (P-keys)

Image Address

Maximum length 15 characters

(12 alphanumeric;

18 18

10 10

15 characters

(12 alphanumeric;

Page 10

Feature Scanner 9500 Scanner/Microimager 990

Original document

specifications

Document width 2.5 – 12 inches

64 – 305 mm

Document length 2.5 – 30 inches*

64 – 508 mm

Document thickness 0.0015 – 0.014 inches

0.0381 – 0.36 mm

2.5 – 12 inches

64 – 305 mm

2.5 – 30 inches*

64 – 508 mm

0.0015 – 0.014 inches

0.0381 – 0.36 mm

Maximum feed height

Semi-automatic feeder 1.5 inches

approx. 350 sheets

Check feeder 1.5 inches

approx. 350 sheets

1.5 inches

approx. 350 sheets

1.5 inches

approx. 350 sheets

Maximum stack height

Std exit hopper 2 inches 2 inches

Check stacker** approx. 465 sheets approx. 465 sheets

Feeder/Stacker options

Check feeder Y Y*

Check stacker Y Y

Optional capabilities

Bar Code reading for data

Y Y

input

Document printing

38 character (DP1) Y Y

144 character (DP12) Y Y

Endorsing n/a Y

Film Writing n/a Y

Footswitch Y Y

Patch reading Y Y

End-fed Y Y

Skew/Length monitoring Y Y

Image Headers

Page 11

Contents

Feature Scanner 9500 Scanner/Microimager 990

Document number

Y Y

(sequential id)

Image size Y Y

Document level Y Y

Mode Y Y

Line length Y Y

Page length Y Y

Image Address Y Y

Compression type Y Y

Date Y Y

Time Y Y

Roll number n/a Y

Resolution Y Y

Bit order Y Y

Skew Y Y

Polarity Y Y

Header flags Y Y

Optional information Y Y

Electronic image

retrieval methods

Header only

Image only

Header and Image

Header only

Image only

Header and Image

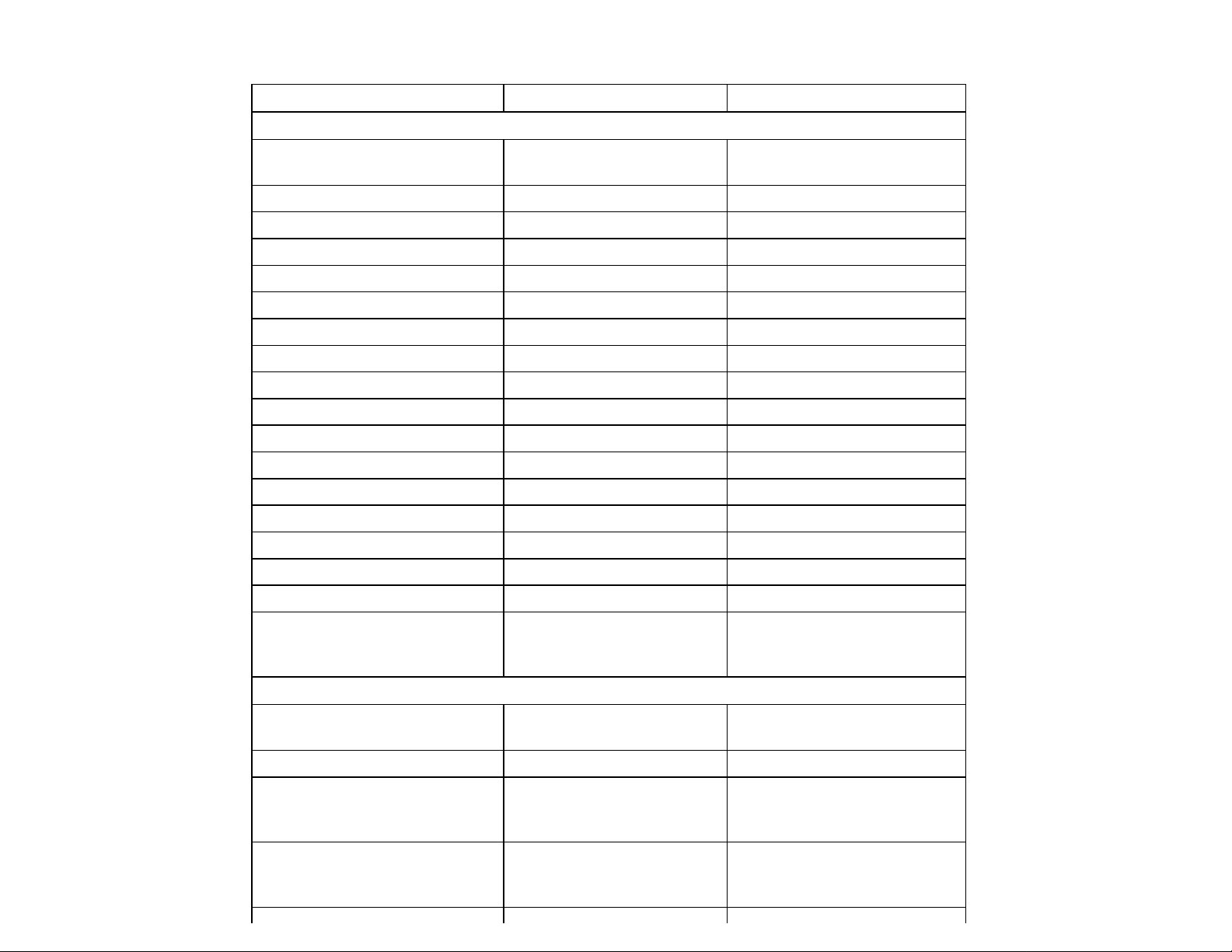

Image Processing Capabilities

Bit order* lsb/left to msb/right

msb/left to lsb/right

lsb/left to msb/right

msb/left to lsb/right

Cropping Y Y

Compression G III 1-dimensional

G III 2-dimensional

G IV

Image enhancement

filters

Screen removal

Text

Fine line

G III 1-dimensional

G III 2-dimensional

G IV

Screen removal

Text

Fine line

Page 12

Feature Scanner 9500 Scanner/Microimager 990

Image Processing Capabilities (continued)

Screening 3-level

4-level Bayer dither

16-level

16-level Bayer dither

32 -level

64-level

64-level Bayer dither

Thresholding Adaptive

Fixed

Adaptive Threshold

Processing (standard)

3-level

4-level Bayer dither

16-level

16-level Bayer dither

32 -level

64-level

64-level Bayer dither

Adaptive

Fixed

Adaptive Threshold

Processing (accessory)

Integration Software

Device Driver and Toolkit Windows Version 4.1

Sun Solaris, Version 1.1

IBM OS/2 and ImagePlus

Windows NT, Version 1.0

Capture Subsystem Sun Solaris, Version 2.3

Windows NT, Version 3.1

Windows Version 4.1

Sun Solaris, Version 1.1

IBM OS/2 and ImagePlus

Windows NT, Version 1.0

Sun Solaris, Version 2.3

Windows NT, Version 3.1

Equipment Dimensions

Height 48 inches / 122 cm 48 inches / 122 cm

Width 29 inches / 74 cm 29 inches / 74 cm

Depth 51 inches / 130 cm 51 inches / 130 cm

Weight 630 pounds / 227 kg 750 pounds / 340 kg

Interface SCSI-2 SCSI-2

Ports RS232:

COIN1–Service/Diag

COIN2–Bar code

RS232:

COIN1–Service/Diag

COIN2–Bar code

Page 13

Application Samples and Solutions

The Scanner 9500 and Scanner/Microimager 990 are designed to improve

the efficiency of general business document applications, such as record

keeping and customer service.

The Scanner 9500 and Scanner/Microimager 990 serve not only the crucial

function of document capture, providing extremely high productivity along

with exceptional image quality, but also fulfill specific application

requirements.

Transportation: Freight and waybill processing

Requirement Solution

Equipment capable of handling highvolume applications.

Equipment capable of capturing only a

portion of a document.

Equipment that can reduce or eliminate

the need for manual data entry of

information used in tracking and billing

shipments.

Sample Equipment Configuration

To implement the freight and waybill processing sample described, these

equipment and accessory components and supplies should be included in

the Equipment Sale and Supply order:

• Scanner 9500

• Check Feeder

• Check Stacker

The Scanner 9500 is capable of processing an average

of over 91,000 page images per 8-hour day using the

Check Feeder for smaller-sized documents.

The built-in image processing capabilities can be used to

reduce or crop the size of the scan window.

The Bar Code Reader can reduce or eliminate the need

for manual data entry by processing information encoded

in Code 3 of 9, Interleaved 2 of 5, or Codabar format.

The bar codes may be preprinted on forms or printed on

labels which are affixed to the documents prior to

scanning.

• Bar Code Reader

Page 14

Insurance: Claims processing

Requirement Solution

Equipment that can handle high-volume

applications.

Equipment that can output both electronic

data images to fulfill customer service

requirements and the need to handle

documents twice.

Equipment that can accommodate a

variety of document sizes, shapes,

textures, and conditions.

Equipment that can produce document

images which are suitable for customer

service.

Equipment that can assist in reducing

storage space requirements.

Equipment that can provide automatic

indexing.

The Scanner/Microimager 9500 can process 30,000

standard-sized page images per 8-hour day.

The Scanner/Microimager 990 can capture page images

and output them in electronic and film formats in a single

pass. There are no filmed data images to fulfill recordkeeping requirements.

The Semi-Automatic Feeder and transport system can

handle a broad range of document sizes, shapes,

textures, and conditions; there is no need to separate the

claim forms from the receipts, or to be unduly concerned

about the condition of the documents.

The built-in image processing capabilities and automatic

exposure control optimizes the appearance of the

electronic document images, making them easy to read.

The built-in compression algorithms can be utilized to

reduce the amount of storage space required for

electronic document images.

One of five built-in indexing schemes may be used in

conjunction with a Patch Reader to make document level

changes resulting in automatic generation of a unique

image address for each document.

The image address can be printed on the original

document, using the Document Printer 1. This printed

Image Address will also appear on the electronic image

and can be used to reference the original paper, if

needed.

Sample Equipment Configuration

To implement the claims processing sample described, these equipment

and accessory components and supplies should be included in the

Equipment Sale and Supply order:

• Scanner 9500 • Semi-Automatic Feeder

• Document Printer Controller • Document Printer 1

• Document Printer 1 Ink Cartridge • Patch Reader

Page 15

Pharmaceutical / Medical: Research records and patient file processing

Requirement Solution

Equipment that can handle high-volume

applications.

Equipment that can output both electronic

and film data images to fulfill customer

service and record-keeping requirements.

Equipment that can accommodate a

variety of document sizes, shapes,

textures, and conditions.

Equipment that can produce document

images which are suitable for customer

service.

Equipment that can assist in reducing

storage space requirements.

The Scanner/Microimager 990 can process an average

of 22,000 standard-sized page images per 8-hour day.

The Scanner/Microimager 990 can capture page images

and output them in electronic and film formats in a single

pass. There is no need to handle documents twice.

The Semi-Automatic Feeder and transport system are

designed to handle a broad range of document sizes,

shapes, textures, and conditions; there is no need to

separate the patient forms from the billing receipts.

The built-in image processing and automatic exposure

control capabilities can optimize the appearance of

electronic and filmed document images making them

easy to read.

The built-in compression algorithms can be utilized to

reduce the amount of storage space required for

electronic document images.

In addition, a drop-out color element can be used to

capture information from a pre-printed form, such as the

HCFA form, without capturing the pre-printed information

(printed using a drop-out color ink) by hiding the preprinted information from the Scanner/Microimager 990.

The selection of a reduction ratio as high as 50X and a

duplex or duo film mode maximizes the number of

documents placed on each roll of film reducing the

amount of storage space.

Sample Equipment Configuration

To implement the research records and patient file processing sample

described, these key equipment and accessory components and supplies

should be included in the Equipment Sale and Supply order:

• Scanner/Microimager 990

• Semi-Automatic Feeder

• Drop-Out Color Element

• HQ Microfilm 3461

Page 16

Government: Land records processing

Requirement Solution

Equipment that can output both electronic

and filmed data images to fulfill customer

service and record-keeping requirements.

Equipment that can produce document

images which are suitable for customer

service.

Equipment that can provide consistent

indexing and cross-referencing

capabilities across all media types

(original, electronic, and film).

Sample Equipment Configuration

The Scanner/Microimager 990 can capture page images

and output them in electronic and film formats in a single

pass. There is no need to handle documents twice.

The built-in image processing and automatic exposure

control capabilities can optimize the appearance of the

electronic and filmed document images making them

easy to read.

One of five built-in indexing schemes may be used in

conjunction with a Patch Reader to make document level

changes resulting in automatic generation of a unique

image address for each document.

The image address can be printed on the original

document, using the Document Printer 1, as well as

written on film next to the filmed document image using

the Film Writing Module.

The roll number corresponding to the roll of film on which

the filmed document image is stored can also be

included in the scanned document.

To implement the land records processing sample described, these

equipment and accessory components and supplies should be included in

the Equipment Sale and Supply order:

• Scanner/Microimager 990

• Semi-Automatic Feeder

• Document Printer Controller

• Document Printer 1

• Document Printer 1 Ink Cartridge

• Film Writing Module

• HQ Microfilm 1461

• Smart Cassette 100

Page 17

Equipment, Software, Parts, Tools and Supplies

New equipment

An Equipment Sale and Supply Order (ES&S) must be completed using the

information contained in this section.

Mainframe Catalog Number

Scanner 9500S 187-9287

Scanner 9500D 165-2866

Scanner/Microimager 990S 194-6227

Scanner/Microimager 990D 816-6621

Catalog

Accessory

Advanced Document Controller 820-6880 x x x x

Bar Code Reader 822-0790

Document Printer Controller 816-8684 x x x x

Document Printer 1 140-3021 x x x x

Document Printer 12 833-4872 x x x x

Document Scanning Array

(DSA)

Endorser 800-7106 x x

Number

849-8198 x x std std

9500

S D

990

S D

Film Writing Module 192-7912 x x

Footswitch 124-8707 x x x x

Patch Reader 833-9749 x x

DSA Patch Reader 864-6556 x x

Check Feeder 177-5030 x x x

Check Stacker (Scanner) 801-4318 x x x x

Self-Centering Feed Tray 124-2130 x x x std

Semi-Automatic Feeder 129-9163 x x x std

Imaging Interface Kit 151-3126 x x x

Workstation Side Console 844-2915 x x x x

Adaptive Threshold Processor

(simplex)

890-5739 std x

Page 18

Scanner 9500

The following will assist you in determining which accessories to order

when patch reading or bar code reading is required.

Desired Functionality Required Accessories Catalog #

Patch Patch Reader 833-9749

Bar Code Bar Code Reader 822-0790

Scanner 990

Patch

Bar Code

The following will assist you in determining which accessories to order

when patch reading or bar code reading is required.

Scanner/Microimager 990S (simplex)

Desired Functionality Required Accessories Catalog #

Patch DSA Patch Reader 864-6556

Bar Code Bar Code Reader 822-0790

Patch

Bar Code

Scanner/Microimager 990D (duplex)

Desired Functionality Required Accessories Catalog #

Patch DSA Patch Reader

Bar Code Bar Code Reader

Patch Reader

Bar Code Reader

DSA Patch Reader

Bar Code Reader

Imaging Interface Kit

Imaging Interface Kit

833-9749

822-0790

864-6556

822-0790

864-6556

151-3126

822-0790

151-3126

Patch

Bar Code

DSA Patch Reader

Bar Code Reader

864-6556

822-0790

Page 19

Upgrade equipment

386/486 AT

861-2046

From To Required Accessory Catalog #

The following tables will assist you in determining which accessories to

order when patch reading or bar code reading is being added/upgraded.

If your current mainframe does not have any accessories functionality

(i.e. patch reading or bar code reading).

9500S 9500D 9000S to 9000D Upgrade

Module

Scanner/Microimager 990S (simplex)

Current Functionality Additional Functionality Required Accessory Catalog #

Patch reading Bar code reading Bar Code Reader 822-0790

Bar code reading Patch reading DSA Patch Reader 864-6556

Scanner/Microimager 990D (duplex)

Current Functionality Additional Functionality Required Accessory Catalog #

Patch reading Bar code reading Bar Code Reader 822-0790

Software

Software available to assist in the integration of the Scanner 9500 and

Scanner/Microimager 990. The software listed below is enabling software.

Kodak has other software solutions available, for more information call your

local Kodak representative.

The desired software must be included on the ES&S.

NOTE: Integration software is licensed through BIS VAR/System

Integrators.

TC

Mode Setup Software

Software Catalog #

Mode Setup Software 183-1072

Device Drivers/Toolkits

Operating System Catalog #

Sun SCSA, SunOS 4.1.2 894-6543

Microsoft DOS 816-4261

Page 20

Parts and tools

This section lists the parts and tools which are needed to properly maintain

your system, as described in the appropriate User’s Guide.

NOTE: Field Engineers/Specialists are not authorized to order these

items; they should be ordered by the customer.

Part/Tool Order Number

Upper Imaging Guide 964365

Lower Imaging Guide 942000

Scanner 923 Air Filter (used on 9500) 942890

Scanner/Microimager 990 Air Filter 321984

Exposure System Fluorescent Lamps

(4 required)

Document Scanning Array White Element 912583

Cassette Storage Carton 984059

Film Take-up Spool 870564

Document Printer Blotter Set 984370

Document Printer 12 Priming Syringe TL 4547

Bar Code Reader Standard Test

Document Set

Staticide Wipes (box of 24 wipes) 1C8102

Round Cleaning Brush, natural bristle TL 2253

Flat Cleaning Brush, natural bristle TL 2156

United States and Canada:

Parts and tools are available through Parts Services at Eastman Kodak

Company:

• Call Parts Services at 1 (800) 431-7278; or

• Send a facsimile order to (716) 724-3051.

964683

TL-4528

Asia Pacific Region; Europe, Africa, Middle East; and Latin America

Region:

Parts and tools are available through Parts and tools are available through

Eastman Kodak Company’s Parts Services.

Page 21

Supplies

Following is a listing of supplies which are required when using the

Scanner/ Microimager 990, Document Printer 1, Document Printer 12,

Endorser, or color drop-out capability.

Start-up supplies may also be included on the ES&S order. Ask your local

Kodak sales representative who/where to contact when replenishing

supplies.

NOTE: Field Engineers/Specialists are not authorized to order these

items; they should be ordered by the customer.

Film supplies

Accessory supplies

Supply Catalog #

Smart Cassette 100 153-7166

Smart Cassette 215 835-7584

HQ Microfilm 1461(Estar Base)

16mm x 30.5 m (100 ft) 822-3232

HQ Microfilm 3461(Estar Base) 845-1502

16mm x 65.5 m (215 ft)

Document Printer 1

Supply Catalog #

Ink Cartridge—Black 822-3893

Document Printer 12

Supply Catalog #

Ink Cartridge Care Kit 111-7811

Ink Cartridge—Black 172-5175

Ink Cartridge—Magenta 170-6274

Ink Cartridge Replenisher Black (pkg of 4) 186-3406

Ink Cartridge Replenisher Magenta (pkg of 4) 182-8904

Page 22

Endorser

It is recommended that at least one die drum, one die set, and two ink

rollers be included on the ES&S order.

Supply Catalog #

Die Drum 822-6896

Die Drum—Payee 835-7683

Die Drum—International 831-6770

Die Set 157-6172

Die Set—Payee 822-7456

Die Set—Special 804-7532

Ink Roller—Red 149-1984

Ink Roller—Purple 149-1018

Ink Roller—Green 104-0492

Ink Roller—Black 142-0272

Document Scanning Array Lamps (990)

Supply Catalog #

Red Drop-Out Color Element 806-0824

Green Drop-Out Color Element 817-8626

Blue Drop-Out Color Element 813-7903

Imaging Station Lamps (9500)

Supply Catalog #

Red Imaging Drop-Out Color Element (set of 2) 175-9893

Green Imaging Drop-Out Color Element (set of 2) 104-9675

Blue Imaging Drop-Out Color Element (set of 2) 160-0410

Page 23

Publications

Available publications

The following publications are available for the Scanner Products.

Code # Description

A-61091 Kodak Digital Science Document Scanner 9500 and 990

Scanner/Microimager Integrator’s Guide

A-61092 Kodak Digital Science Document Scanner 9500 User’s Guide

A-61093 Kodak Digital Science Document Scanner 9500 and 990

Scanner/Microimager Product Information

A-61094 Kodak Digital Science Document Scanner 9500 and 990

Scanner/Microimager Installation Planning Guide

A-61095 Kodak Digital Science Document Scanner 9500 and 990

Scanner/Microimager User’s Reference

A-61096 Kodak Digital Science Document Scanner 990

Scanner/Microimager User’s Guide

A-61097 Kodak Digital Science Document Scanner 9500 and 990

Scanner/Microimager Installation Questionnaire Instructions

(Mode Setup Instructions)

A-61098 Kodak Digital Science Document Scanner 9500 and 990

Scanner/Microimager Installation Accessories Guide

A-61099 Bar Code Made Easy

A-61599 Patch Code Information

A-61004 OS/2 Device Driver Installation and Integration Guide

(IBM ImagePlus only)

A-61030 Device Driver/Toolkit Sun Solaris Systems Product Guide

A-61160 Device Driver/Toolkit Windows Product Guide

(Windows/95/NT)

A-61025 Sun Solaris Capture Subsystem Operator’s Manual

A-61026 Sun Solaris Capture Subsystem Administrator’s Guide

A-61027 Sun Solaris Capture Subsystem Integrator’s Guide

A-61052 Windows NT User’s and Administrator’s Guide

A-61051 Windows NT Integrator’s Guide

Page 24

United States and Canada:

Publications may be included on the ES&S and/or ordered through

Advertising Distribution in Rochester, New York. Provide the quantity,

publication name and number, name and phone number of caller, purchase

order number, billing address, and ship-to address.

• Send written requests to:

Eastman Kodak Company

BIS Order Desk

901 Elmgrove Road

Rochester, New York 14653-6204

Place telephone requests toll-free between 8:00 a.m. and 8:00 p.m.

(EST) Monday through Friday: 1 (800) 828-5921.

Facsimile requests should be sent to: 1 (800) 535-4622.

Asia Pacific Region; Europe, Africa, Middle East; and Latin America

Region:

Scanner 9500/990 publications are available through local channels.

Please contact your local Kodak representative for details.

Page 25

Performance and Standards

Following are the maximum machine throughput in pages per hours at

base resolutions (200 and 300 dpi) for the Scanner 9500 and

Scanner/Microimager 990.

Base Resolution 200 dpi Base Resolution 300 dpi

9500 9500 990 990 9500 9500 990 990

Document Size

5.8" x 8.3" (A5)

148 mm x 210 mm

8.3" x 11.7" (A4)

210 mm x 297 mm

8.5" x 11" (Letter)

216 mm x 279 mm

8.5" x 14" (Legal)

216 mm x 356 mm

11" x 14"

279 mm x 356 mm

11" x 17"

279 mm x 432 mm

11.7" x 16.5" (A3)

297 mm x 420 mm

Agency approvals

Portrait Landscape Portrait Landscape Portrait Landscape Portrait Landscape

9,700 13,600 6,970 9,530 6,400 8,975 n/a n/a

7,000 9,700 5,100 6,970 4,620 6,400 n/a n/a

7,400 9,500 5,400 6,820 4,880 6,270 n/a n/a

5,500 n/a 4,320 n/a 3,630 n/a n/a n/a

5,500 n/a 4,320 n/a 3,630 n/a n/a n/a

4,500 n/a 3,600 n/a 2,970 n/a n/a n/a

5,000 n/a 3,705 n/a 3,300 n/a n/a n/a

Following are the agency approvals for the Scanner 9500 and

Scanner/Microimager 990.

UL1950 US safety

CSA 950 Canadian safety

EN60 950/09.87 European safety (GS Mark for TUV)

DOC Canadian EMI

VCCI/EN55022 Japanese EMI

EN55022/EEC499(82) European EMI

EN55022 Australian EMI (New Zealand)

Page 26

Technical Information

Further information regarding any of the topics presented here is provided

in Installation Planning and System Maintenance Guide (A-61000).

Installation

Acoustical emissions

Cabling requirements

Electrical and operating requirements

This equipment and accessories are installed by a Kodak Field Engineer

and takes approximately 4 hours.

Scanner 990 —Acoustical emissions shall be less than or equal to 67 dB

during operation and less than or equal to 62 dB while idle.

Scanner 9500 —Acoustical emissions shall be less than or equal to 76 dB

during operation and less than or equal to 67 dB while idle.

The customer/system integrator must provide the SCSI cable used to

connect the equipment and host computer. It is not included with the

Scanner 9500 or Scanner/Microimager 990.

This equipment is manufactured to operate within one of the following sets

of power constraints or configured to do so by your Kodak Field Engineer:

Voltage Hz/Cycles Amps 9500 Amps 990

90 -110 V ac 50/60 Hz

1 phase

104 -127 V ac 60 Hz

1 phase

198 - 254 V ac 50 Hz

1 phase

15 amps

@ 100 V ac

12 amps

@ 120 V ac

6 amps

@ 220-240 V ac

15 amps

@ 100 V ac

12 amps

@ 120 V ac

10 amps

@ 220-240 V

ac

A separate, dedicated power line with one duplex receptacle is required for

each Scanner.

Two outlets are required:

• One individual dedicated branch AC circuit employing one

standard 3-prong, grounded duplex outlets. These outlets are

designated for the machine and service diagnostic equipment.

The outlets should meet the following standards:

Page 27

Voltage requirements

• Impedance between neutral and ground wires: less than 2 ohms

• Neutral to ground voltage: less than 1 volt AC maximum

• Voltage drop across circuit breaker: less than 0.1 volts

• Impluse voltage spikes transients: less than 50% of nominal line

voltage

• Surge voltage: less than 5’1 of nominal line voltage

AC power quality and conditioning

Environmental requirements

Dimensions and weight

In some locations, even though recommended wiring practices have been

followed, the power reaching the scanner may exhibit unstable power

quality characteristics. System errors and intermittent data loss could

result.

Power conditioning equipment may be required to overcome the power

quality problems. Kodak can make arrangements for an on-site power

analysis in an area with exceptionally unstable power.

Consult with your electrical contractor or utility company to ensure that onsite wiring complies with the specifications and that wall outlets and comply

with codes

This equipment can operate in a typical office environment under the

following conditions:

Scanner Temperature Relative

Humidity

9500/990 59° to 86° F

15° to 30° C

This equipment has the following dimensions and weight, with all optional

accessories included:

15 to 76% 5200 Btu

Heat

Dissipation

Scanner Height Width Depth Weight

9500 48 in.

122 cm

990 48 in.

122 cm

NOTE: With the Workstation Side Console, the width is 60 in (152 cm).

29 in.

74 cm

29 in.

74 cm

51 in.

130 cm

51 in.

130 cm

630 lbs

227 kg

785 lbs

356 kg

Page 28

New Equipment Warranty United States and Canada

Kodak warrants this equipment to function properly for three months from date of initial installation, when installed

within one year from date of shipment. This warranty covers the purchaser of this equipment as well as anyone else

who owns it during the warranty period.

Warranty repair coverage

If this equipment does not function properly during the warranty period, Kodak’s Technical Assistance Center (TAC)

will provide telephone assistance to Customer’s designated liaison. When determined necessary by Kodak, a

Kodak Field Engineer will perform on-site service to adjust and/or replace parts required to maintain the equipment

in an operating condition which is consistent with Kodak’s specifications.

Days and hours of coverage

Warranty coverage is available Monday through Friday during Kodak’s normal working hours (usually 8:00 a.m. to

5:00 p.m.), excluding holidays celebrated locally. On-site service performed after normal working hours will be billed

at prevailing overtime rates.

How to obtain service

Call 1 (800) 822-1414. In order for Kodak to provide assistance, the designated liaison must provide Customer’s

access code.

Customer responsibilities

1. Designate a knowledgeable System Administrator and one or two trained alternates who will be the only source

of liaison with Kodak Service Personnel. Liaison names must be provided to Kodak

2. Provide initial problem-solving assistance to site users.

3. Perform appropriate problem analysis and corrective actions by following troubleshooting instructions and

remedial actions as prescribed by Kodak.

4. Perform Customer maintenance and error recovery procedures.

5. Provide immediate access to equipment when service is required.

6. Notify Kodak if equipment is to be physically moved to a different location. Customer is responsible for all costs

associated with relocation.

Limitations

Standard warranty service is limited to the contiguous United States, Hawaii, and certain areas of Alaska.

This warranty does not cover: circumstances beyond Kodak’s control (such as Customer overriding, bypassing or

defeating interlock switches on equipment or devices sold by Kodak); problems due to failure of Customer to

conform to Kodak’s site specifications; service or parts to correct problems resulting from the use of attachments,

accessories or alterations not marketed by Kodak; relocation or service required as the result of relocation;

unauthorized modifications or service; misuse; abuse; failure to follow Kodak’s operating instructions; or supply

items (such as glass and lamps).

Kodak makes no other warranties, express, implied, or of merchantability or fitness for a particular purpose

for this equipment.

Repair or replacement without charge are Kodak’s only obligations under this warranty. KODAK WILL NOT BE

RESPONSIBLE FOR ANY CONSEQUENTIAL OR INCIDENTAL DAMAGES RESULTING FROM THE SALE, USE,

OR IMPROPER FUNCTIONING OF THIS EQUIPMENT, REGARDLESS OF THE CAUSE. Such damages for

Page 29

New Equipment Warranty Europe, Africa, Middle East

Kodak makes no other warranties, express, implied, or of merchantability or fitness for a particular purpose for this

Providing Revenue for the Equipment was realized in the country of final placement, Kodak will warrant the

equipment in terms of manufacturing defects and fitness for use within advertised performance and functionality

parameters for a minimum period of Three months, providing the equipment is installed within 1 year of purchase

and has not benefited from any previous warranties. The warranty is extended to any person(s) owning the

equipment within the three month period.

Warranty repair

Should the need arise to call Kodak Service during the warranty period, Kodak will provide support via their Local

Customer Equipment Service Division, either remotely, on-site, or a combination of both, as deemed appropriate by

Kodak Technical Personnel. Repair of the system will be to correct manufacturing defects and to maintain

performance of the equipment in line with advertised specification and functionality.

Days and hours of coverage

Warranty support is available Monday to Friday 8.30 a.m. to 5.00 p.m., excluding local holidays. Support may be

available outside of these hours at local discretion and at local overtime billing rates.

How to obtain service

Contact your local Kodak representative to obtain the telephone number which may be used to contact your local

Customer Equipment Services Division.

Customer/end user responsibilities

1. Have a minimum of two trained personnel nominated as the primary point of contact for Kodak Support.

2. Provide initial problem-solving assistance to users and assist Kodak Support in initial problem quantification and

analysis.

3. Perform all customer maintenance and error recovery procedures.

4. As problems are identified that require on-site visits, to ensure the equipment is readily available to the support

personnel.

5. Equipment movement and relocation will be chargeable at the current local per-call rate.

Limitations

Standard warranty coverage is available within Europe, Africa, and Middle Eastern Region PROVIDING sale

revenue is realized within the country of final placement. Equipment placed outside of the country where sale

revenue was realized will be offered standard warranty coverage providing the final placement is within one of the

following countries: Austria, Belgium, Denmark, Finland, Germany, Greece, Holland, Hungary, Ireland, Italy,

Norway, Portugal, Spain, Sweden, Switzerland, United Kingdom. Equipment purchased outside of the above

countries and placed in any country other than the one where the original purchase was made will be offered support

and the current local rate (available from the local Kodak organization), providing support resource for the product

exists.

This warranty does not cover circumstances beyond the control of Kodak, including but not limited to; problems

associated with the failure to comply with Kodak Site Specifications; problems arising from the use of non-Kodak

attachments or accessories; relocation or resultant service; unauthorized modifications or service; misuse; abuse;

failure to follow Kodak’s operating and use instructions; or any components deemed by Kodak to be consumable

items (glass, lamps, etc.).

Page 30

New Equipment Warranty Asia Pacific Region and Latin America Region

The terms and conditions of the new equipment warranty will be provided by the Kodak company in the country in

which the sale is finalized, or by a Kodak-appointed distributor in those countries where Kodak does not have direct

sales representation.

Page 31

Service Agreement Terms United States and Canada

Service agreement availability

Standard agreement service is available within the contiguous United States, Hawaii and certain areas of Alaska.

Service agreements purchased at the time of equipment sale become effective the day after warranty expiration.

Service agreements may be purchased at a later date, provided the equipment is in proper operating condition.

Kodak agrees to perform the following service for a time period of one year, unless otherwise specified.

Service agreement coverage

During the term of this agreement, Kodak’s Technical Assistance Center (TAC) will provide telephone assistance to

Customer’s designated liaison. When determined necessary by Kodak, a Kodak Field Engineer will perform on-site

service to adjust and/or replace parts required to maintain the equipment in an operating condition which is

consistent with Kodak’s specifications.

When periodic maintenance (PM) is included in the agreement, Kodak will perform the specified number of calls to

clean, test, and maintain the equipment in proper working order. When possible, PMs will be performed at the same

time as repair service.

How to obtain service

Call 1 (800) 822-1414. In order for Kodak to provide assistance, Customer’s access code (Customer Identification

Number) must be provided to Kodak.

Days and hours of coverage

Unless premier (extended hours) coverage is purchased, this agreement covers service during Kodak’s normal

working hours (usually 8:00 a.m. to 5:00 p.m. local time) Monday through Friday, excluding Kodak holidays.

On-site service will be available outside Kodak’s normal working hours at prevailing overtime rates.

Limitations

This agreement does not cover: circumstances beyond Kodak’s control; problems due to failure of Customer to

conform to Kodak’s site specifications; rebuilding or reconditioning of equipment; service or parts required to correct

problems resulting from the use of attachments, accessories or alterations not marketed by Kodak; relocation of

equipment or service required as the result of relocation; unauthorized modifications or service; misuse; abuse;

supply items; or failure to follow Kodak’s operating instructions.

The services outlined in these terms are Kodak’s only obligation under this agreement. KODAK WILL NOT BE

RESPONSIBLE FOR ANY CONSEQUENTIAL OR INCIDENTAL DAMAGES RESULTING FROM THE SALE, USE,

OR IMPROPER FUNCTIONING OF THIS EQUIPMENT, REGARDLESS OF THE CAUSE. Such damages for which

Kodak will not be responsible, include, but are not limited to, loss of revenue or profit, loss of data, downtime costs,

loss of use of the equipment, cost of any substitute equipment, facilities or services or claims of your customers for

such damages.

This limitation of liability will not apply to claims for injury to persons or damage to property causes by the sole

negligence or fault of Kodak or by persons under its direction or control.

On-site response time

Page 32

When the Plus-2 (guaranteed 2-hour response) is purchased, Kodak will provide on-site service within two hours. If

the 2-hour response time is not met, credit will be provided as follows:

At completion of the agreement, and upon written request, Kodak will credit Customer one percent of applicable

agreement price time the number of calls for which response time was not met. Such credit will not exceed the

premium paid for guaranteed response on the machine to which the credits apply.

Customer responsibilities

1. Designate a knowledgeable System Administrator and one or two trained alternates who will be the only source

of liaison with Kodak Service Personnel. Liaison names must be provided to Kodak.

2. Provide initial problem-solving assistance to site users.

3. Perform appropriate problem analysis and corrective actions by following troubleshooting instructions and

remedial actions as prescribed by Kodak.

4. Perform customer maintenance and error recovery procedures.

5. Provide immediate access to equipment when service is required.

6. Notify Kodak if equipment is to be physically moved to a different location. Customer is responsible for all costs

associated with relocation.

NOTE: Failure to meet these responsibilities may result in additional charges at the prevailing per-call rates.

Renewal

Kodak will provide for renewal, at the prices and terms then in effect, as long as a service agreement is available.

Cancellation

Service agreements may be canceled by either Customer or Kodak upon 30 days’ written notice. Kodak will issue a

prorated credit for any remaining prepaid agreement coverage. Customer will be charged for any service provided

when equipment is not covered by a service agreement.

Billing and terms of payment

Billing is in advance and prices will vary dependent upon billing arrangements (annual, quarterly or monthly).

Payment terms are net 30 except for renewals, which are due by the renewal date.

Assignment

Customer shall not assign its rights under this agreement without the prior written consent of Kodak. Such consent

will not be unreasonably withheld.

Page 33

Service Agreement Terms Europe, Africa, Middle East

Service agreement availability

Standard Service Agreements are available across the European, African and Middle Eastern region where a

support resource currently exists or there are plans to establish the appropriate support infrastructure if a mutual

agreement is reached between the customer and the local Kodak organization, based upon a business case

analysis. Service Agreements may be purchased at any time during the useful life of a product; however, an

inspection may be necessary if the sale of the S/A does not occur immediately following warranty or a previous S/A

expiration.

Service agreement coverage

During the term of the Service Agreement, Kodak will provide support via their Customer Equipment Service

Division, either remotely, on-site or a combination of both, as deemed appropriate by Kodak Technical personnel.

Repair of the system will be to maintain performance of the equipment in line with advertised specification and

functionality.

Days and hours of coverage

Service Agreement support is available Monday to Friday 8.30 a.m. to 5.00 p.m., excluding local holidays. Support

may be available outside of these hours at local discretion and at a premium to the standard contract.

Limitations

This Service Agreement does not cover circumstances beyond the control of Kodak, including but not limited to;

problems associated with the failure to comply with Kodak Site Specifications; problems arising from the use of nonKodak attachments or accessories; relocation or resultant service; unauthorized modifications or service; misuse;

abuse; failure to follow Kodak’s operating and use instructions; or any components deemed by Kodak to be

consumable items (glass, lamps, etc.).

The services outlined in this document are Kodak’s only obligation under the terms of any agreement. Kodak will not

be responsible for any consequential or incidental loss or damage resulting from the sale, use, or improper function

of this equipment, regardless of the cause. Such damages may include but are not limited to, loss of revenue, loss

of use of equipment, cost of any substitute equipment, facilities, services, or claims by your customers for such

damages.

Response times

Kodak’s objective is to provide on-site service within the following timeframes: Specific country detail will be

supplied locally and may vary from the guidelines presented below.

Distance From Within Outside

Support Resource Contract Hours Contract Hours

0-50 Km 4 hours Best Effort

50-100 Km 8 hours Best Effort

Over 100 Km 16 hours Best Effort

Enhanced hours of coverage, guaranteed response times, and improved response times may be available within

individual countries or specific geographic locations at the discretion of local Service management.

Page 34

Customer responsibilities

1. Have a minimum of Two trained personnel nominated as the primary point of contact for Kodak Support.

2. Provide initial problem solving assistance to users and assist Kodak Support in initial problem quantification and

analysis.

3. Perform all customer maintenance and error recovery procedures.

4. As problems are identified that require on-site visits, to ensure the equipment is readily available to the support

personnel.

5. Equipment movement and relocation will be chargeable at the current local per-call rate.

Failure to meet these responsibilities and any resultant service calls may be charged at the prevailing local per-call

rate.

Renewal

Generally these will be available annually, providing Service Agreement support continues to be available.

Cancellation

Terms will be country specific.

Billing of terms and payment

Terms will be country specific.

This document is prepared for guidance only and is general in nature. Country specific arrangements for support

including, but not limited to Service Agreement cost, Warranty duration, per-call cost, availability of support and

hours of coverage must be confirmed with the local Customer Equipment Service Division.

Page 35

Service Agreement Terms Asia Pacific Region and Latin America Region

The service agreement terms will be provided by the Kodak company in the country in which the sale is finalized.

Page 36

EASTMAN KODAK COMPANY

Business Imaging Systems

Rochester, New York 14650

Loading...

Loading...