Page 1

Getting Started

The

Kodak Digital Science

your printer to produce the best possible color response. In simplest

terms, printer calibration adjusts the response of the printer so that a

specific data input value yields a specific color density output. When a

printer is properly calibrated, it generates the correct density for each

given data value. Calibration considers only a single primary color at a

time and measures the density for the primary color.

Density is one color aspect that can be easily and reliably measured, so

calibrating the Kodak Professional 8670 PS printer(8670 printer) is easy

and straightforward.

calibration utility (calibration utility) allows

Operator’s Guide

Printing

Guide

Color Management

Calibration

Network

Interface Guide

The calibration utility lets you select either a visual calibration process or

a more accurate densitometer calibration.

System Requirements

To use the calibration utility, your system must have the following

hardware and software:

Macintosh Systems

Recommended System Configuration

•

a 68040 or PowerPC processor

•

Apple Operating System 7.5 or higher software

CONTENTS

INDEX

SEARCH

HELP

Getting Started

Easy Cal

Setting Preferences

and Using

Calibration Tables

Visual Gray Balance

Visual Linearity

Densitometer

Calibration

Page 2

•

16 MB of RAM

•

color monitor

•

export module for the 8670 printer

•

densitometer if you will be doing the densitometer calibration procedure

Minimum System Configuration

•

68030 processor

•

Apple Operating System 7.1

•

8 MB of RAM

•

standard color or black and white monitor (minimum resolution 640 x

400 pixels

•

export module for the 8670 printer

•

densitometer if you will be doing the densitometer calibration

NOTE: The export module software for Macintosh systems is included on

the software CD that came with your printer. Windows Systems

Recommended System Configuration

•

486 or Pentium processor

•

MS-DOS version 6.22 or later

Operator’s Guide

Printing

Guide

Color Management

Calibration

Network

Interface Guide

Getting Started

Easy Cal

Setting Preferences

and Using

Calibration Tables

Visual Gray Balance

Visual Linearity

Densitometer

Calibration

•

Microsoft Windows for workgroups 3.11 or Windows 95 software

•

16 MB of RAM

CONTENTS

INDEX

SEARCH

HELP

Page 3

•

4 MB of hard disk space

•

color monitor

•

export module for the 8670 printer

•

densitometer if you will be doing the densitometer calibration

Minimum System Configuration

•

386 processor

•

MS-DOS version 5.0 or later

•

Microsoft Windows 3.1, Windows for workgroups 3.11, or Windows 95

software

•

8 MB of RAM

•

4 MB or hard disk space

•

standard color or black and white monitor (standard VGA; minimum

resolution 640 x 480 pixels)

NOTE: The export module software for Windows systems is included on

the software CD that came with your printer.

Installing the Software for the Calibration Utility

The software for the calibration utility and the export module are included

on the CD that came with your printer. Install the CD in the CD-ROM

drive, and use the browser to locate and install the software.

Operator’s Guide

Printing

Guide

Color Management

Calibration

Network

Interface Guide

Getting Started

Easy Cal

Setting Preferences

and Using

Calibration Tables

Visual Gray Balance

Visual Linearity

Densitometer

Calibration

CONTENTS

INDEX

SEARCH

HELP

Page 4

Getting Started with the Calibration Utility

Operator’s Guide

Before you use the calibration utility, you should be thoroughly familiar

with how to operate the printer. If you plan to use the densitometer

calibration, you should be familiar with densitometr y and how to operate

and calibrate your densitometer.

How Often To Calibrate

Calibrate your printer whenever the density or color balance of the prints

do not look correct. You may also want to calibrate your printer after it has

been serviced. Be sure that you calibrate for the correct media installed.

Calibrating your printer means calibrating the printing system—printer

and media.

Calibration Methods

The visual calibration components of the calibration utility include Easy

Cal, Visual Gray Balance, and Visual Linearity. While these methods do

not yield as accurate a result as a densitometer calibration, they can

make significant improvements in the consistency of results.

Easy Cal

Visual Gray Balance calibration. Ref

running an Easy Cal calibration.

—a five-step process to quickly calibrate your printer using the

er to “Easy Cal” for instructions on

Printing

Guide

Color Management

Calibration

Network

Interface Guide

Getting Started

Easy Cal

Setting Preferences

and Using

Calibration Tables

Visual Gray Balance

Visual Linearity

Densitometer

Calibration

CONTENTS

INDEX

SEARCH

HELP

Page 5

Visual Gray Balance

neutral gray. Visual Gray Balance calibration ensures that the correct

percentages of cyan, magenta, and yellow dye are printed over the entire

tonal range to produce a neutral gray. Use the Visual Gray Balance

calibration if the color balance of your prints is not correct. Ref

“Visual Gray Balance” for instructions on running a Visual Gray Balance

calibration.

—calibrates your printer so that it produces a

er to

Operator’s Guide

Printing

Guide

Color Management

Visual Linearity

darkness. Visual Linearity ensures that your printer produces an accurate

representation of the requested density values over the entire tonal

range. Use the Visual Linearity calibration if the color balance is correct,

but the density is too dark or light. Ref

instructions on running a Visual Linearity calibration.

—calibrates your printer for the correct lightness/

er to “Visual Linearity” for

Densitometer Calibration

A densitometer calibration calibrates your printer’s response based on the

densitometer reading for selected patches on a test print. Calibrating your

printer with a densitometer yields the most accurate calibration results for

color balance and density. Ref

instructions on running a Densitometer calibration.

CONTENTS

INDEX

er to “Densitometer Calibration” for

SEARCH

HELP

Calibration

Network

Interface Guide

Getting Started

Easy Cal

Setting Preferences

and Using

Calibration Tables

Visual Gray Balance

Visual Linearity

Densitometer

Calibration

Page 6

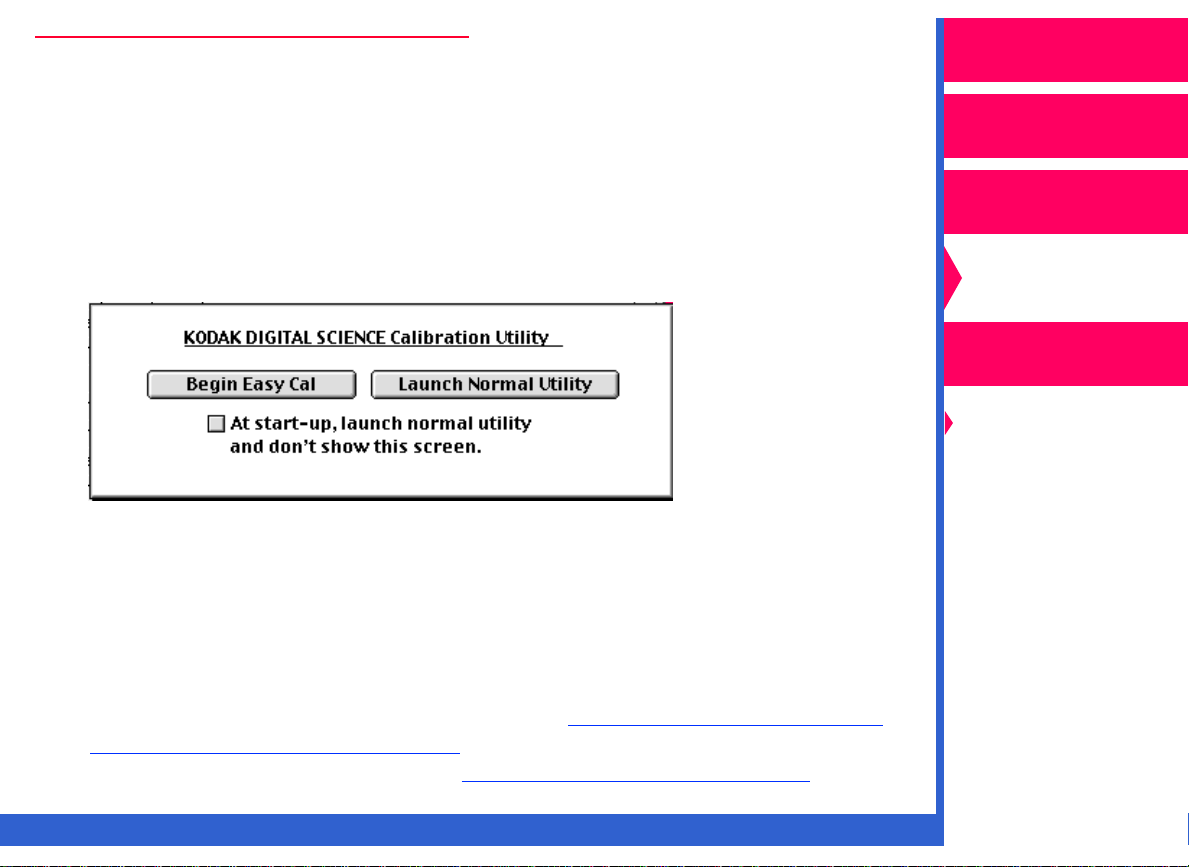

Starting the Calibration Utility

Operator’s Guide

The following steps describe how to start the calibration utility:

NOTE: The illustrations in this chapter show Macintosh system dialog

boxes. The dialog boxes for Windows are similar and have

identical functionality.

1.

Double-click on the icon for the calibration utility.

The calibration utility selection box opens.

2.

Do one of the following:

•

Click on

or

•

Click on

procedures.

Begin Easy Cal

Launch Normal Utility

to launch Easy Cal,

to use the other calibration

Printing

Guide

Color Management

Calibration

Network

Interface Guide

Getting Started

Easy Cal

Setting Preferences

and Using

Calibration Tables

Visual Gray Balance

Visual Linearity

Densitometer

Calibration

For infor mation about the Normal Utility, ref

Utility to Calibrate Your Printer.” For more infor mation on the

calibration utility selection box, ref

CONTENTS

INDEX

er to “Option Descriptions.”

SEARCH

er to “Using the Normal

HELP

Page 7

Using the Normal Utility to Calibrate Your Printer

Operator’s Guide

The Normal Utility allows you to create a new calibration document or

start from a previously-saved calibration document.

When you click on

selection box, the Normal Utility calibration procedure starts up; and the

Printer Calibration Utility window opens.

NOTE: If this is the first time you have run the calibration utility, or there

are no printers on the Select Printer menu, or the Preferences

files have been deleted, you must select and open the export

module.

For infor mation about creating a new calibration table, ref

“Creating a New Calibration Document.” For information about

opening an existing calibration document, ref

Calibration Table as the Star ting Point.”

Launch Normal Utility

in the Calibration Utility

er to

er to “Using an Existing

Printing

Guide

Color Management

Calibration

Network

Interface Guide

Getting Started

Easy Cal

Setting Preferences

and Using

Calibration Tables

Visual Gray Balance

Visual Linearity

Densitometer

Calibration

CONTENTS

INDEX

SEARCH

HELP

Page 8

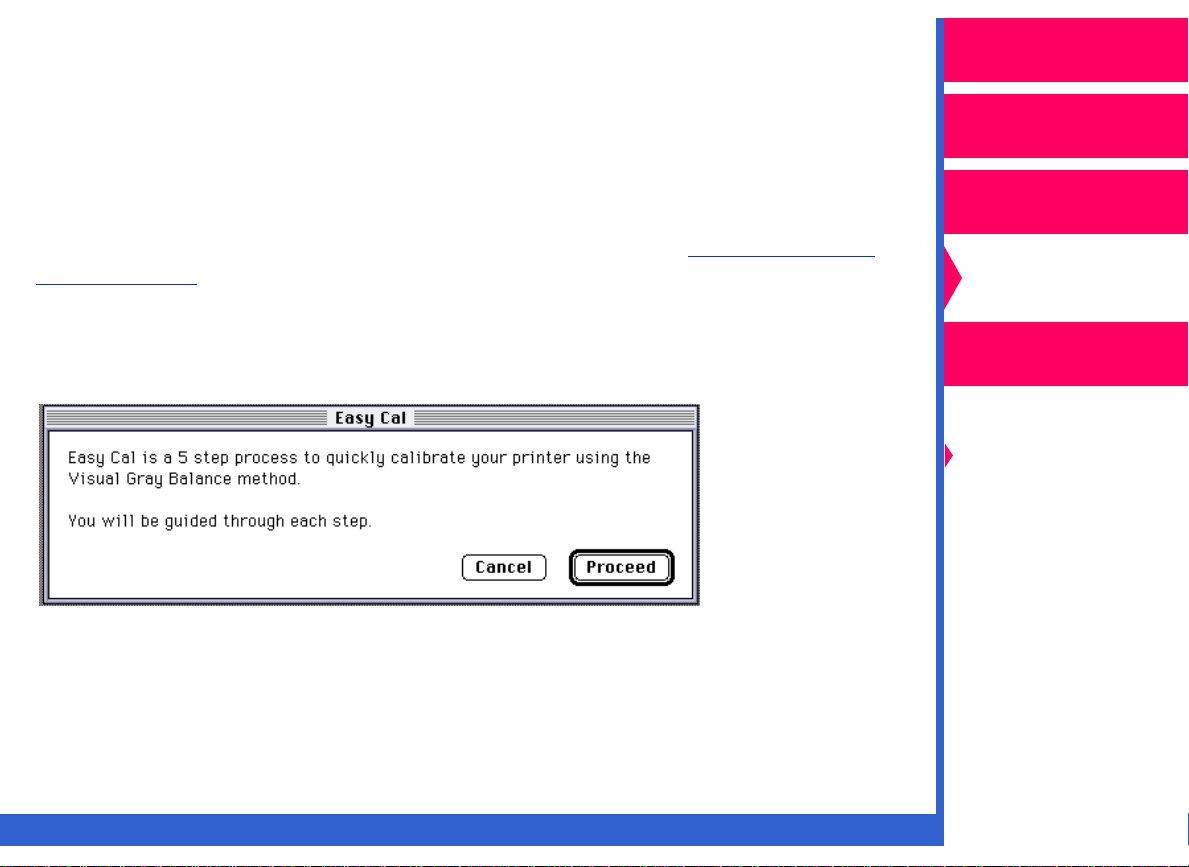

Easy Cal

Operator’s Guide

Easy Cal provides you with the steps to guide you through the process of

calibrating your printer based on a Visual Gray Balance calibration.

NOTE: You cannot use Easy Cal to calibrate a printer with a black-only

ribbon.

For a description of the dialog boxes used in Easy Cal, ref

Descriptions.”

When you click on

dialog box, the Easy Cal calibration procedure starts up.

The Easy Cal dialog box appears.

•

Click on

Proceed

Begin Easy Cal

.

in the Calibration Utility selection

er to “Option

Printing

Guide

Color Management

Calibration

Network

Interface Guide

Getting Started

Easy Cal

Setting Preferences

and Using

Calibration Tables

Visual Gray Balance

Visual Linearity

Densitometer

Calibration

NOTE: Clicking on

CONTENTS

Cancel

INDEX

accesses the Normal Utility.

SEARCH

HELP

Page 9

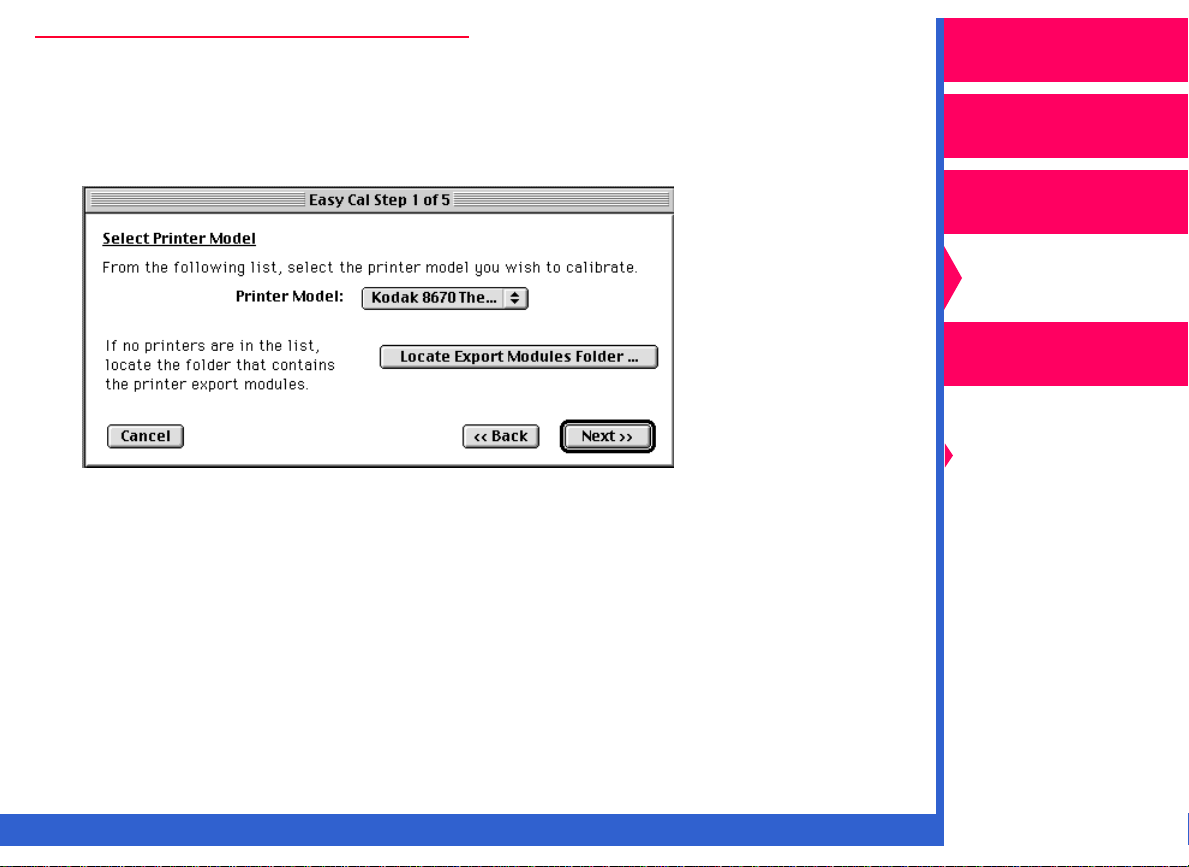

Easy Cal Step 1

Operator’s Guide

The Easy Cal Step1of 5 dialog box appears. This dialog box allows

you to select the printer model you wish to calibrate and locate the

folder containing the expor t module.

1.

Select the printer from the Printer Model drop-down list.

NOTE: If the printer you want to calibrate does not appear on the menu,

you must locate and select the expor t module for that printer.

2.

Click on

3.

In the file selection box that appears, locate and open the folder that

contains the export module:

Locate Export Modules Folder

.

Printing

Guide

Color Management

Calibration

Network

Interface Guide

Getting Started

Easy Cal

Setting Preferences

and Using

Calibration Tables

Visual Gray Balance

Visual Linearity

Densitometer

Calibration

•

On Macintosh systems, use the path System Folder:Applications

Support:Kodak:Plug-ins (Printing).

CONTENTS

INDEX

SEARCH

HELP

Page 10

•

On Windows systems, use the path C:\Windows\Kodak\Plugins

(Printing).

Operator’s Guide

4.

Select the export module, and click on

Easy Cal Step 1 of 5 dialog box.

5.

Click on

Next.

Open

. You are returned to the

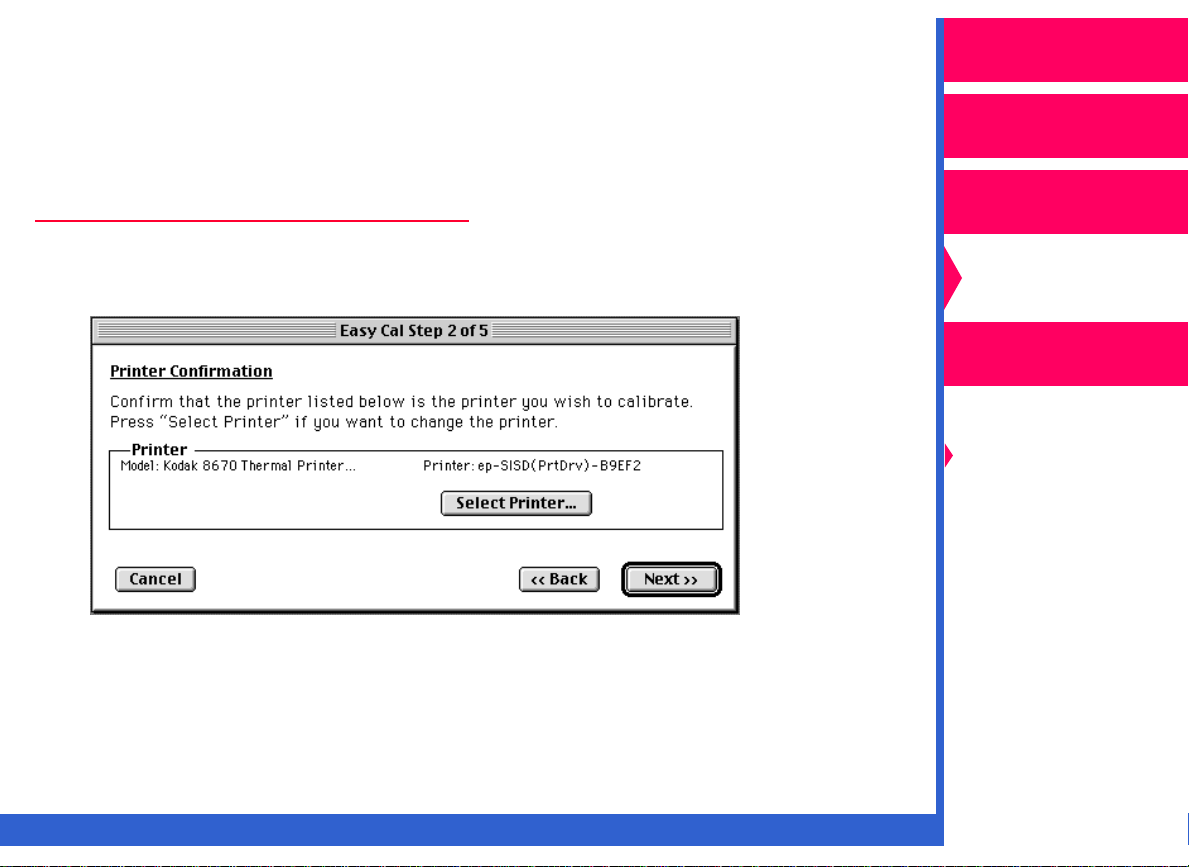

Easy Cal Step 2

The Easy Cal Step 2 of 5 dialog box appears.

1.

If you want to calibrate a different printer than the one that appears in

the Printer box, go to Step 2 in this procedure. If you do not need to

Next

select a new printer, click on

to go to Easy Cal Step 3 of 5.

Printing

Guide

Color Management

Calibration

Network

Interface Guide

Getting Started

Easy Cal

Setting Preferences

and Using

Calibration Tables

Visual Gray Balance

Visual Linearity

Densitometer

Calibration

2.

Click on

CONTENTS

Select Printer

INDEX

.

SEARCH

HELP

Page 11

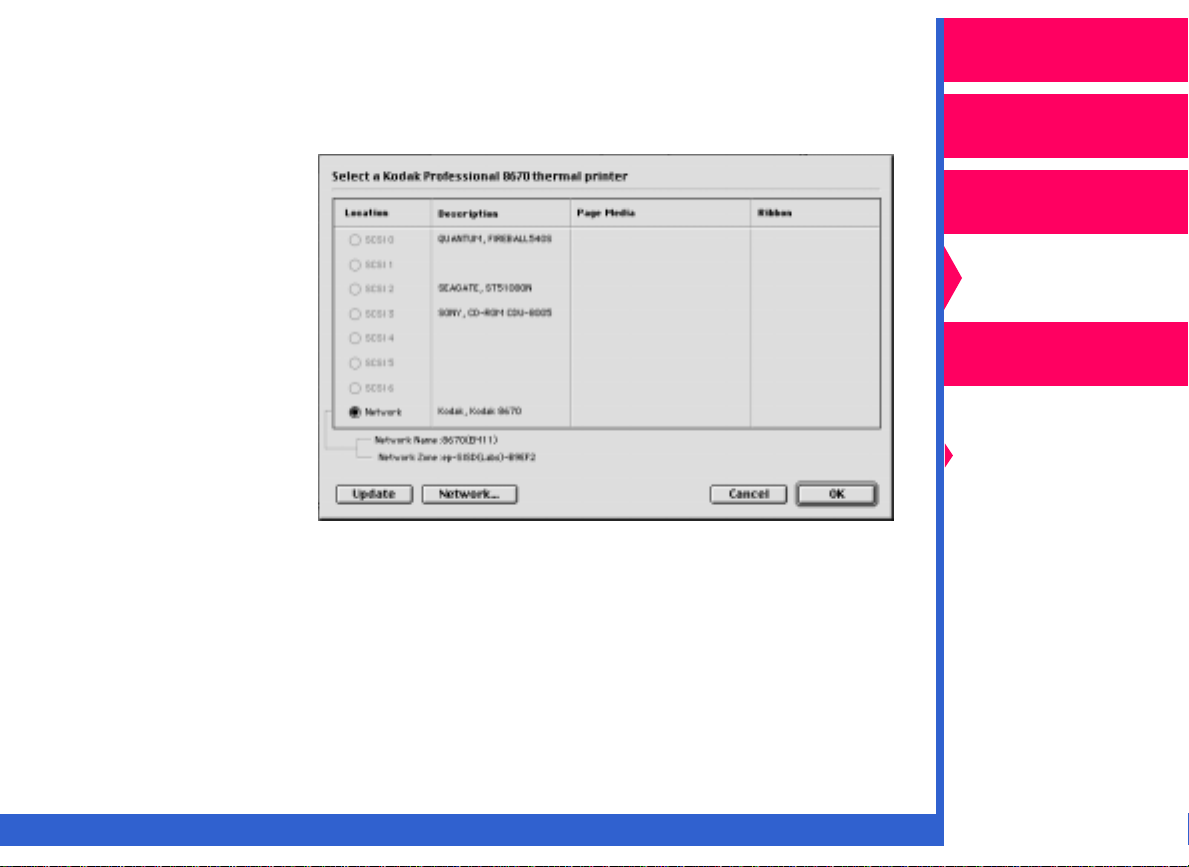

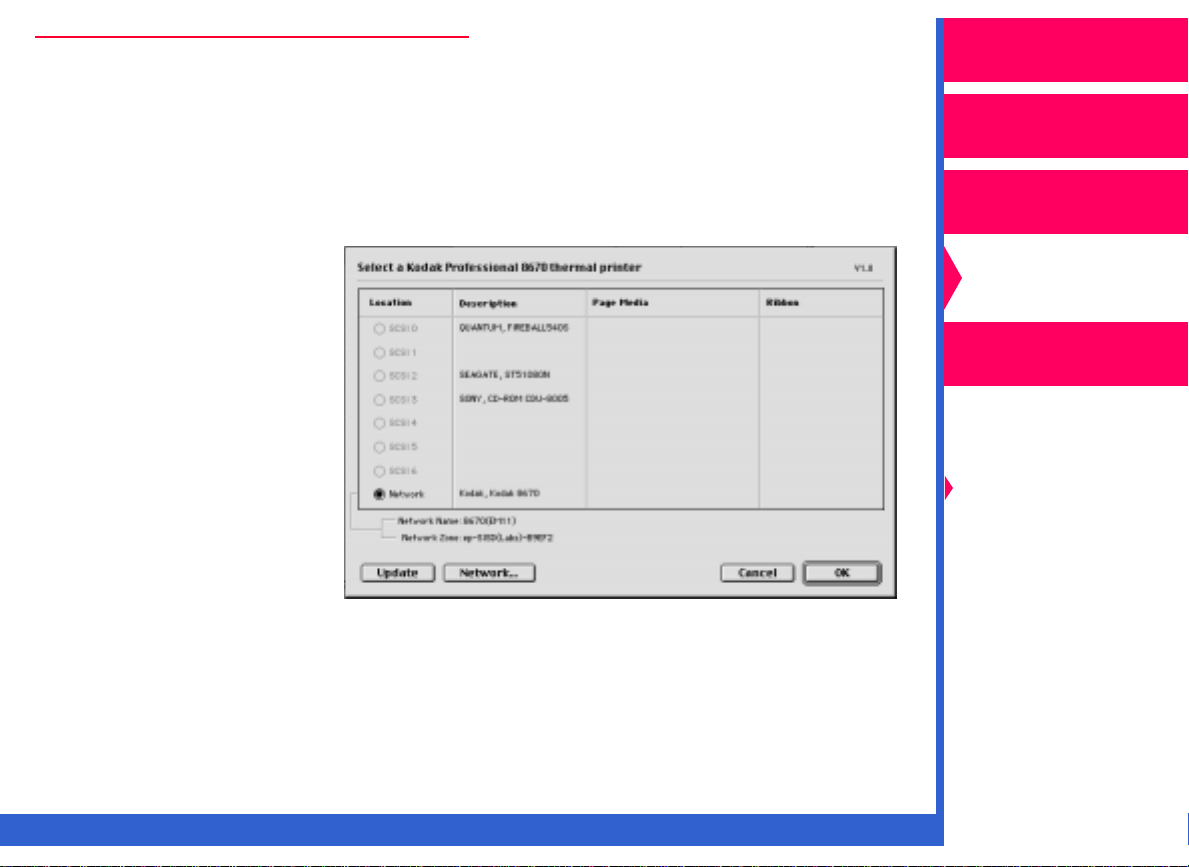

A dialog box appears that allows you to select the printer you wish to

calibrate.

Operator’s Guide

Macintosh systems

If the 8670 printer:

•

has a network

connection, click on

Network

in the

Select a Kodak

Professional 8670

thermal printer

dialog box.

In the selection box

that opens, choose

the correct 8670

OK

printer. Click on

to return to the

Select a Kodak

Professional 8670

thermal printer

dialog box.

•

has a SCSI connection, click on the radio button for the correct 8670

printer.

Printing

Guide

V1.0

Color Management

Calibration

Network

Interface Guide

Getting Started

Easy Cal

Setting Preferences

and Using

Calibration Tables

Visual Gray Balance

Visual Linearity

Densitometer

Calibration

CONTENTS

INDEX

SEARCH

HELP

Page 12

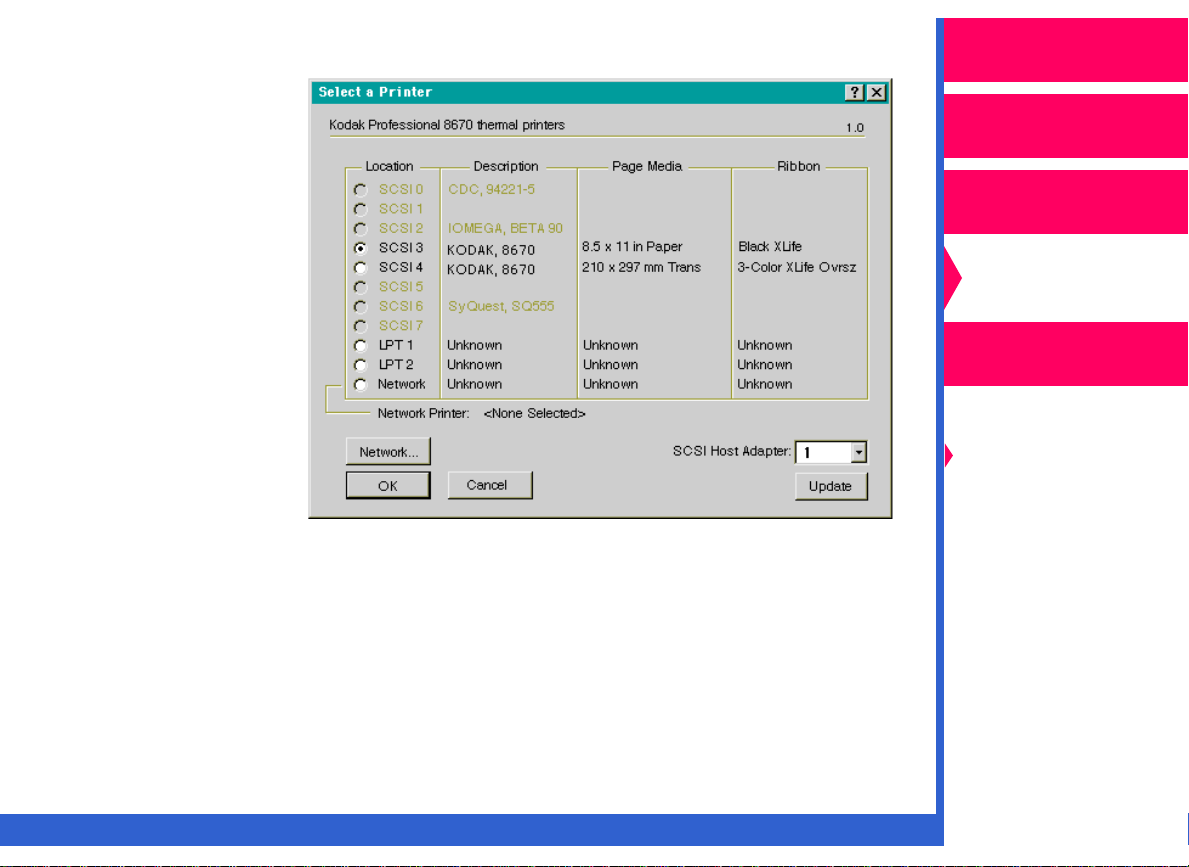

For Windows systems

If the 8670 printer:

•

has a SCSI

connection, click on

the radio button for

the correct 8670

printer.

•

has a network

connection, click on

Network

Browse

correct printer in

the Browse for

Printer dialog box

that opens.

•

has a parallel

connection, click on

the radio button for either LPT1 or LPT2 to select the printer.

Click on

NOTE: If your computer has more than one SCSI host adapter, pull down

.Click on

. Locate the

OK

in the Select a Printer dialog box.

the SCSI Host Adapter list. Select the por t address for the SCSI

host adapter for the selected 8670 printer.

Operator’s Guide

Printing

Guide

Color Management

Calibration

Network

Interface Guide

Getting Started

Easy Cal

Setting Preferences

and Using

Calibration Tables

Visual Gray Balance

Visual Linearity

Densitometer

Calibration

3.

Click on Next in the Easy Cal Step 2 of 5 dialog box.

CONTENTS

INDEX

SEARCH

HELP

Page 13

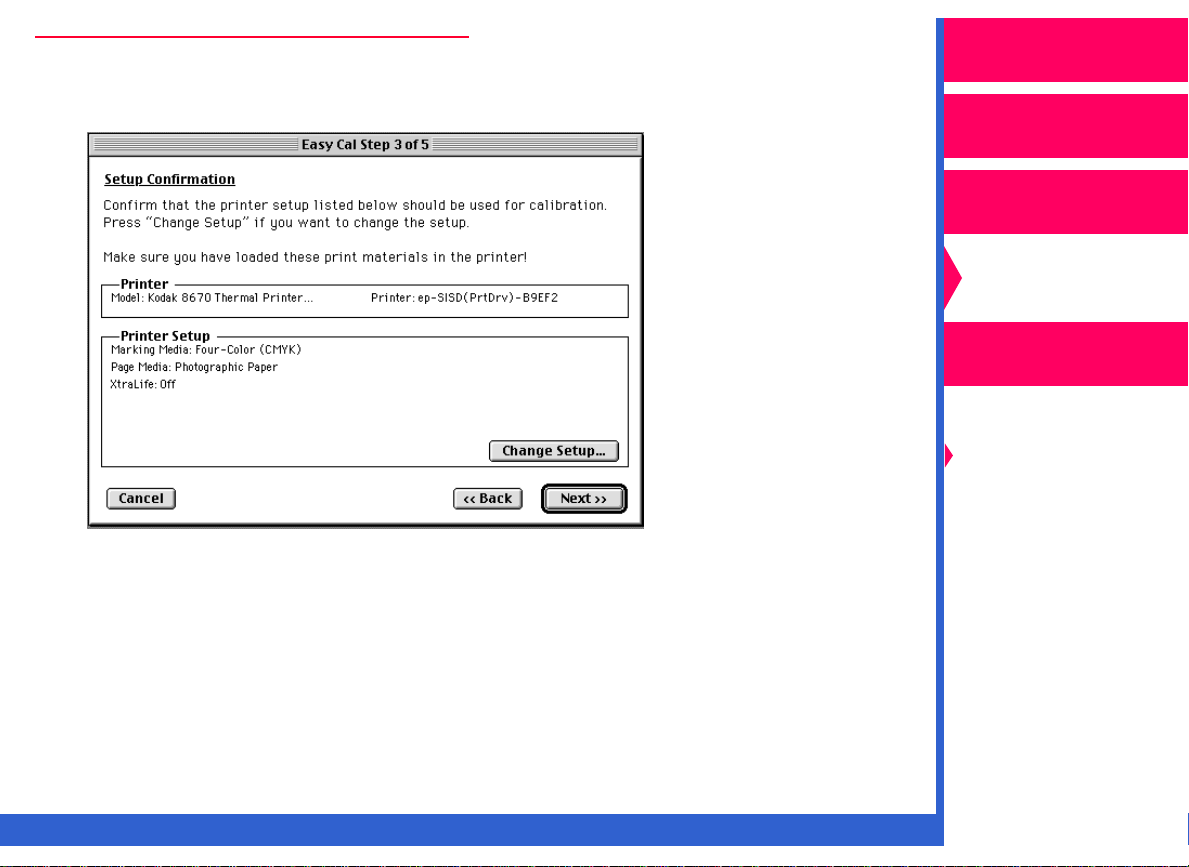

Easy Cal Step 3

Operator’s Guide

The Easy Cal Step 3 of 5 dialog box appears.

1.

Make sure that the ribbon and paper type information is correct.

NOTE: If you do not need to change the setup, click on

2.

Click on

Change Setup

.

Next

Printing

Guide

Color Management

Calibration

Network

Interface Guide

Getting Started

Easy Cal

Setting Preferences

and Using

Calibration Tables

Visual Gray Balance

.

Visual Linearity

Densitometer

Calibration

CONTENTS

INDEX

SEARCH

HELP

Page 14

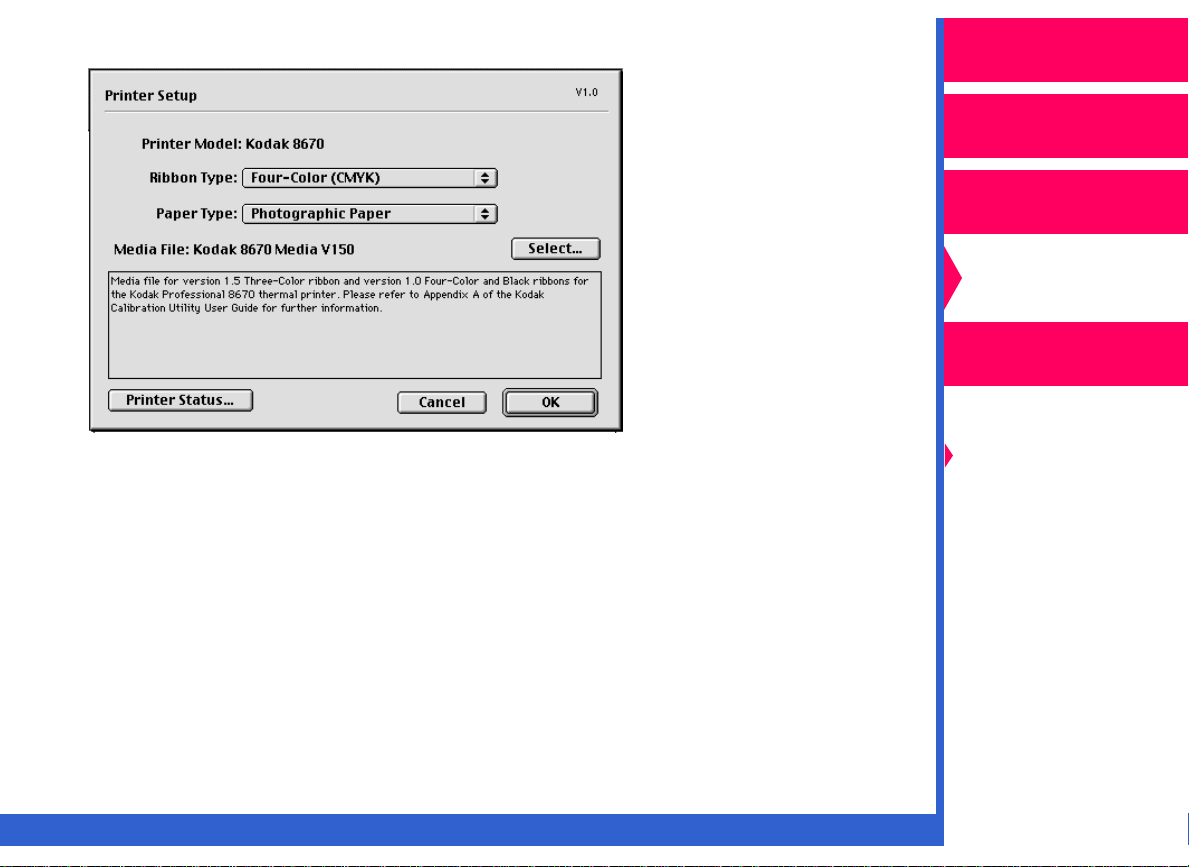

The Printer Setup for Calibration dialog box appears.

NOTE: Your Printer Setup dialog box may be different depending on your

printer export module.

3. Make the necessary changes in the Printer Setup dialog box.

OK

4. Click on

5. Click on

.

Next

in the Easy Cal Step 3 of 5 dialog box.

Operator’s Guide

Printing

Guide

Color Management

Calibration

Network

Interface Guide

Getting Started

Easy Cal

Setting Preferences

and Using

Calibration Tables

Visual Gray Balance

Visual Linearity

Densitometer

Calibration

CONTENTS

INDEX

SEARCH HELP

Page 15

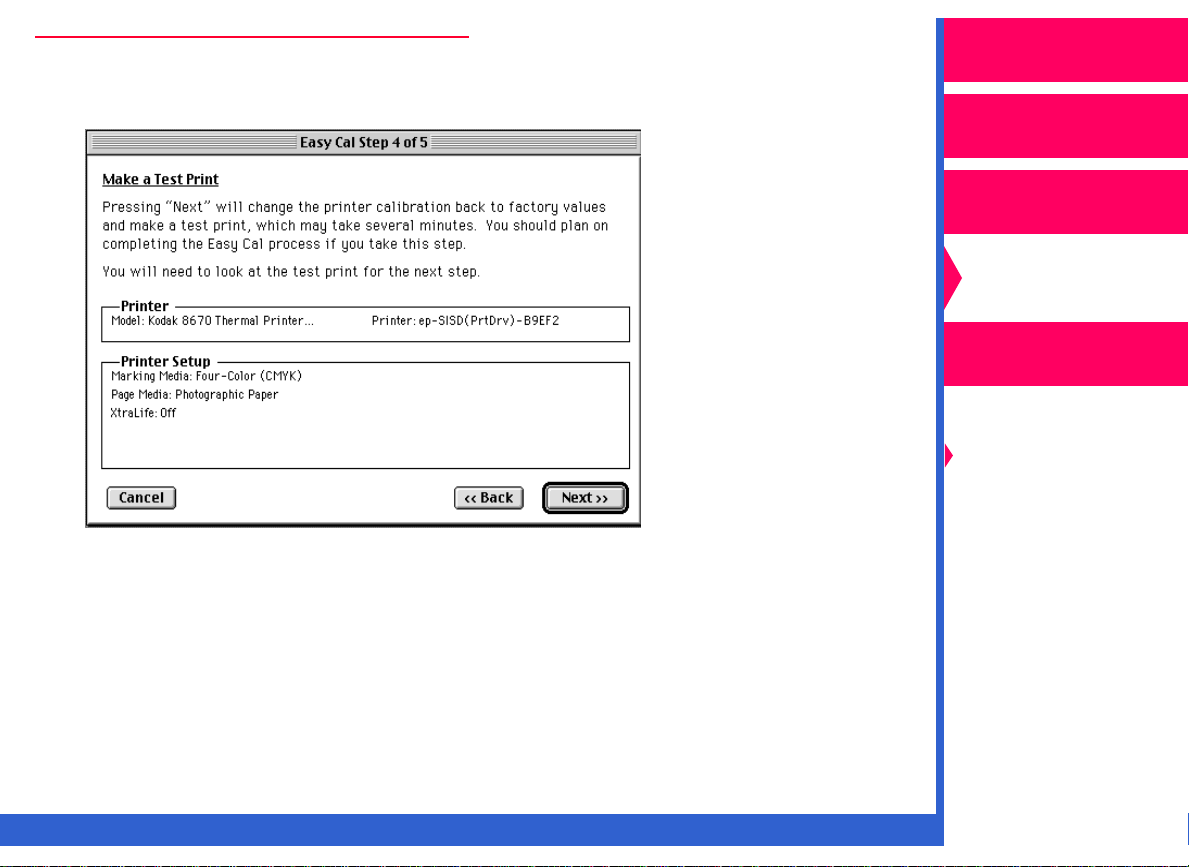

Easy Cal Step 4

Operator’s Guide

The Easy Cal Step 4of 5 dialog box appears.

.

1. Make sure that the Printer and Printer Setup information are correct.

IMPORTANT: Clicking on Next sends the default calibration table to the

printer and overwrites the previous table.

Printing

Guide

Color Management

Calibration

Network

Interface Guide

Getting Started

Easy Cal

Setting Preferences

and Using

Calibration Tables

Visual Gray Balance

Visual Linearity

Densitometer

Calibration

CONTENTS INDEX SEARCH HELP

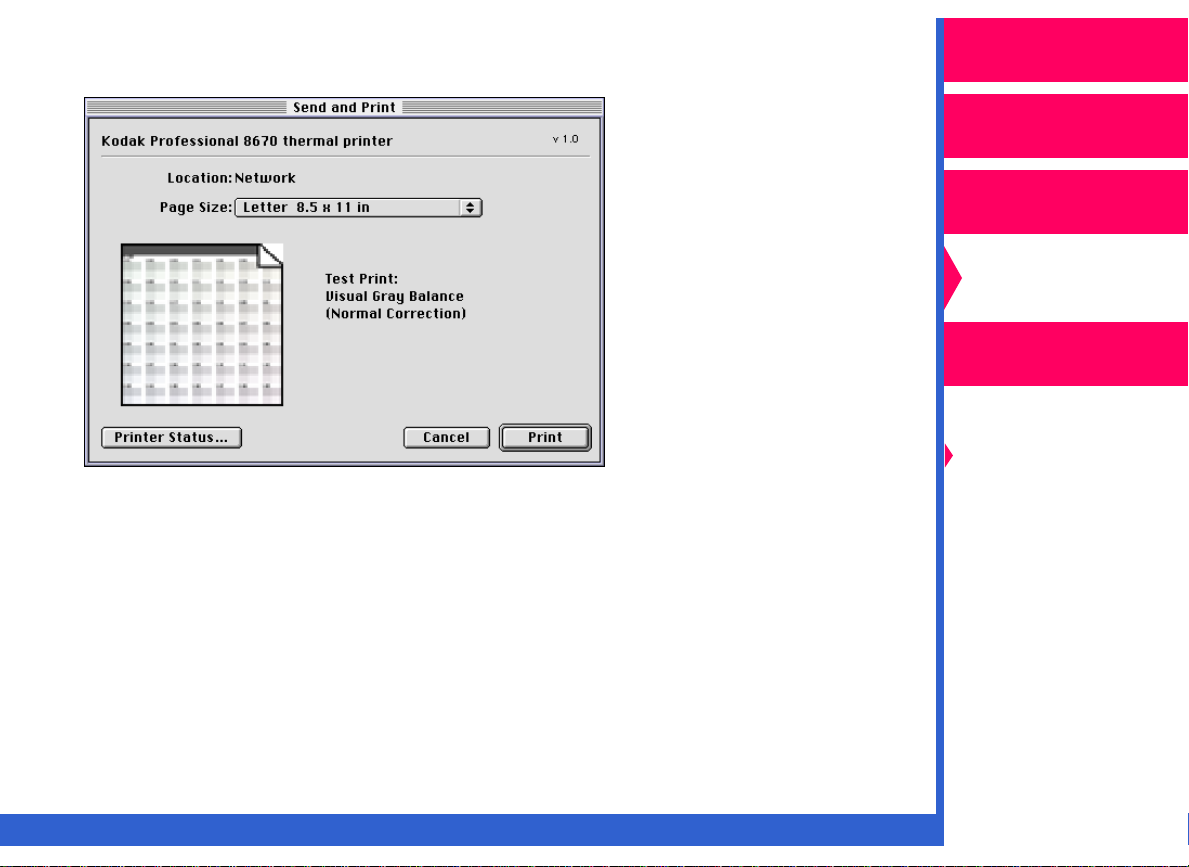

Page 16

2. Click on

table is overwritten. The Send and Print dialog box appears.

NOTE: The Send and Print dialog box may be different depending on

3. Click on

The calibration test print is printed on the specified printer.

Next

. The default table is sent to the printer, and the previous

your printer’s export module.

Print

.

Operator’s Guide

Printing

Guide

Color Management

Calibration

Network

Interface Guide

Getting Started

Easy Cal

Setting Preferences

and Using

Calibration Tables

Visual Gray Balance

Visual Linearity

Densitometer

Calibration

CONTENTS INDEX SEARCH HELP

Page 17

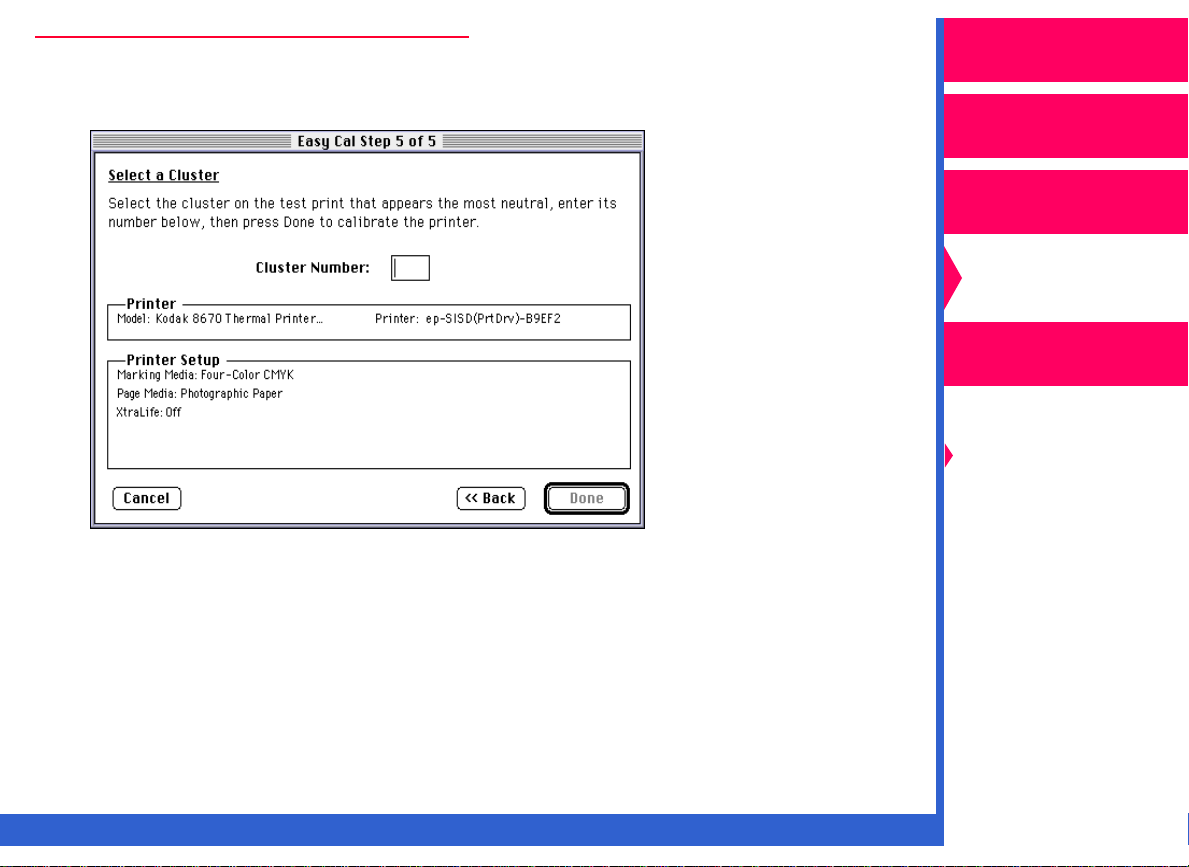

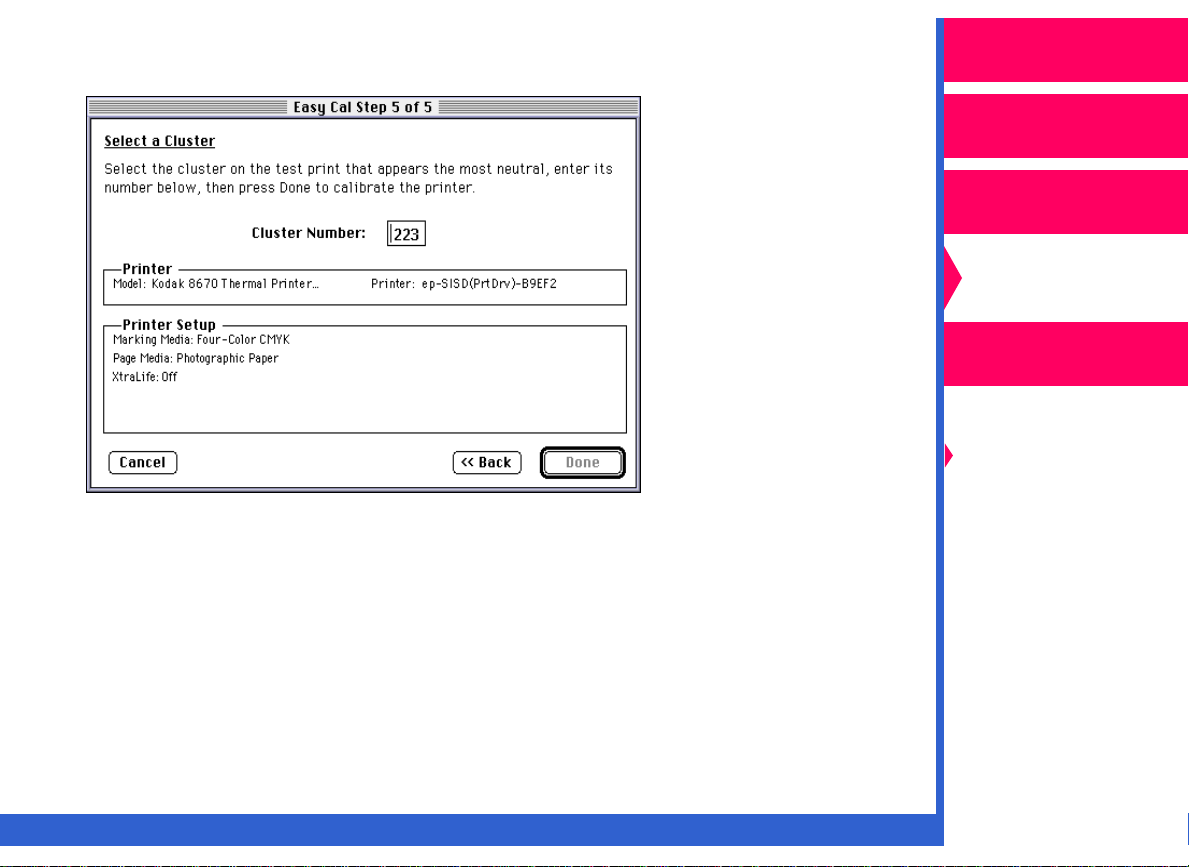

Easy Cal Step 5

Operator’s Guide

The Easy Cal Step 5 of 5 dialog box appears.

1. Use the test print to calibrate your printer in the Easy Cal Step 5 of 5

dialog box. Look at the test print, and decide which grayscale cluster

appears the most neutral gray.

Printing

Guide

Color Management

Calibration

Network

Interface Guide

Getting Started

Easy Cal

Setting Preferences

and Using

Calibration Tables

Visual Gray Balance

Visual Linearity

Densitometer

Calibration

CONTENTS INDEX SEARCH HELP

Page 18

2. Enter the number of the most neutral grayscale cluster in the Cluster

Number text box.

NOTE: If you want to print an updated test print, you can click on

return to the Easy Cal Step 4 of 5 dialog box.

If cluster number 225 on the updated test print is the most neutral

gray, then the calibration is successful. Type 225 in the Cluster

Number text box, and go to Step 3 of this procedure.

Back

to

Operator’s Guide

Printing

Guide

Color Management

Calibration

Network

Interface Guide

Getting Started

Easy Cal

Setting Preferences

and Using

Calibration Tables

Visual Gray Balance

Visual Linearity

Densitometer

Calibration

3. Click on

CONTENTS INDEX SEARCH HELP

Done

.

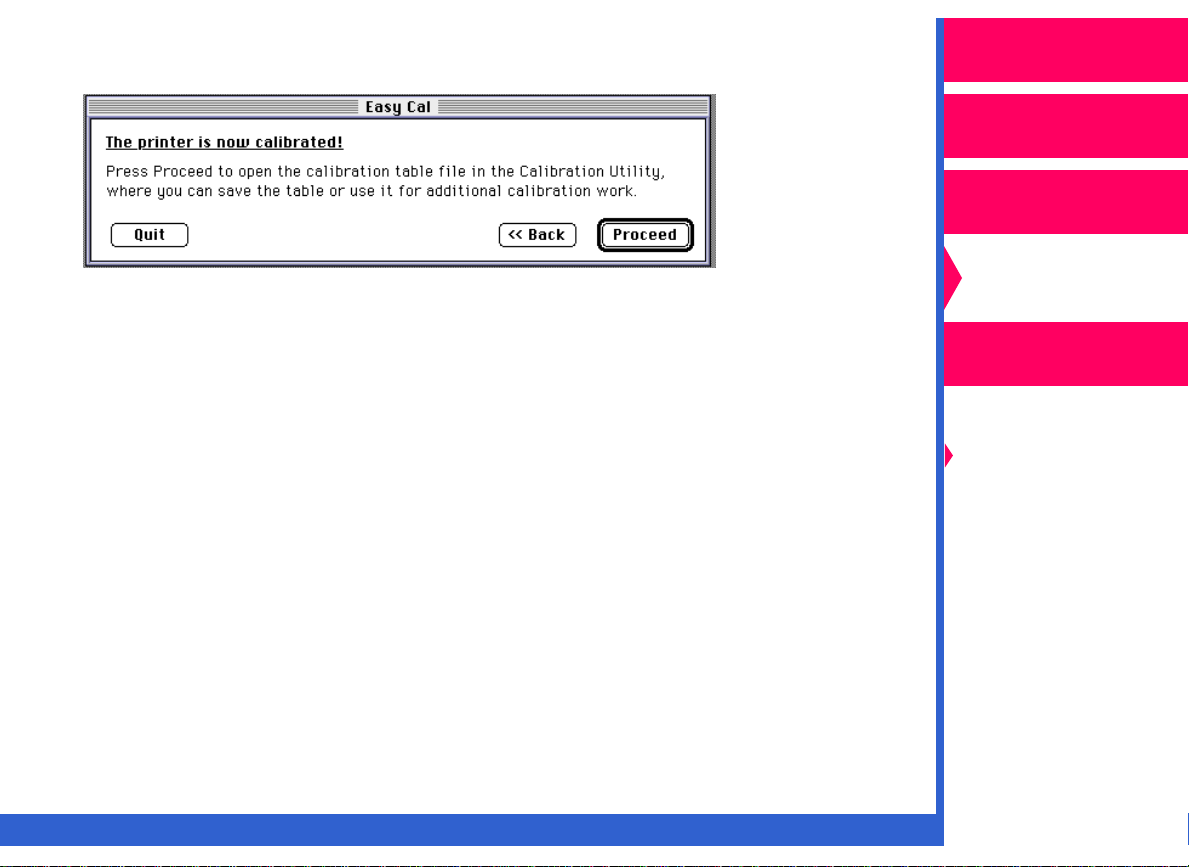

Page 19

The printer calibration begins. When calibration completes, the Easy

Cal dialog box appears.

Quit

4. Click on

.

Operator’s Guide

Printing

Guide

Color Management

Calibration

Network

Interface Guide

Getting Started

Easy Cal

Setting Preferences

and Using

Calibration Tables

Visual Gray Balance

Visual Linearity

Densitometer

Calibration

CONTENTS INDEX SEARCH HELP

Page 20

Setting Preferences and Using Calibration

Operator’s Guide

Tables

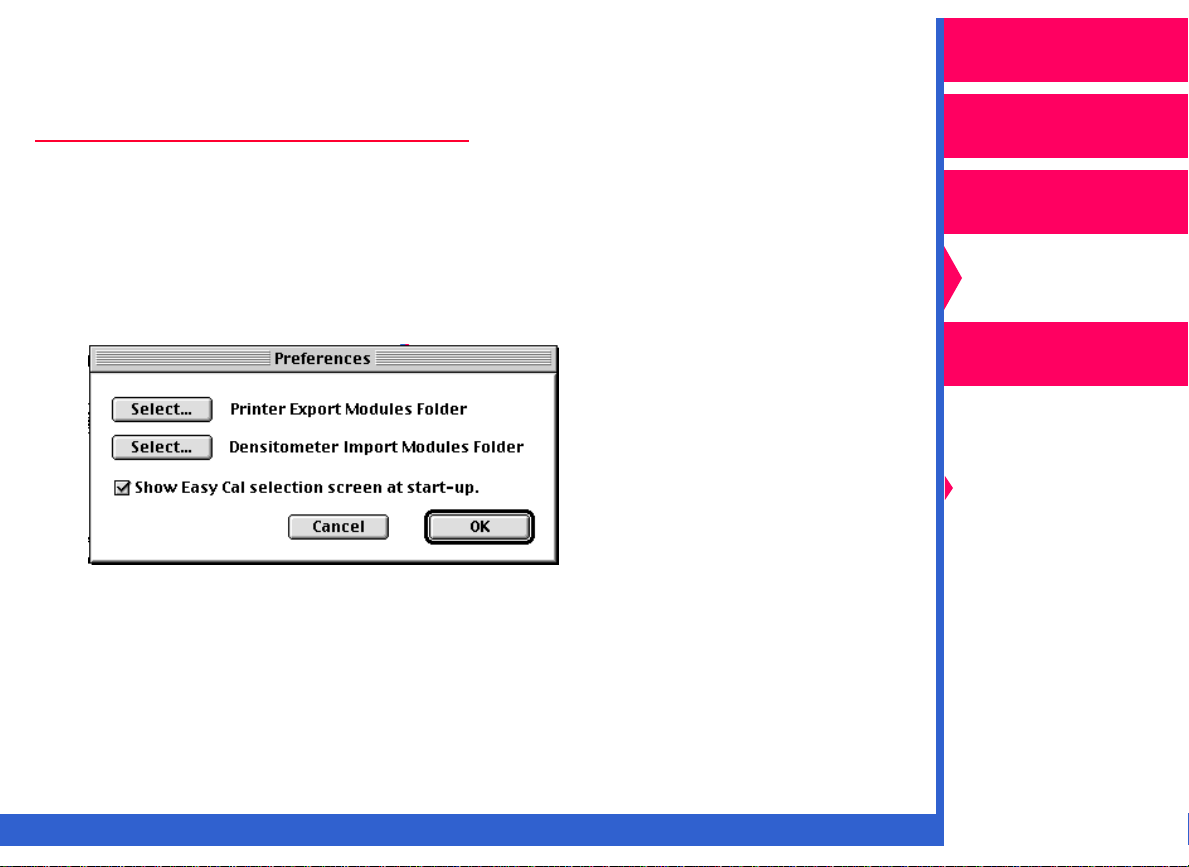

Using the Preferences Dialog Box

You can specify the folders that contain the export and import modules

(used for densitometer settings) in the Preferences dialog box.

1. Pull down the File menu, and select “Preferences”.

The Preferences dialog box appears.

2. Click on

the folders containing the expor t module and the impor t module.

Your selections are saved.

Select

, and use the file selection box that appears to locate

Printing

Guide

Color Management

Calibration

Network

Interface Guide

Getting Started

Easy Cal

Setting Preferences

and Using

Calibration Tables

Visual Gray Balance

Visual Linearity

Densitometer

Calibration

CONTENTS INDEX SEARCH HELP

Page 21

Selecting and Setting Up a Printer

Operator’s Guide

1. Pull down the Printer menu, and highlight “Select Printer”.

2. Select “8670 Thermal Printer”

Macintosh systems

If the 8670 printer:

• has a network

connection, click on

Network

a Kodak Professional

8670 thermal printer

dialog box.

In the selection box

that opens, chose the

correct 8670 printer.

Click on

to the Select a Kodak

Professional 8670

thermal printer dialog

box.

in the Select

OK

to return

Printing

Guide

Color Management

Calibration

Network

Interface Guide

Getting Started

Easy Cal

Setting Preferences

and Using

Calibration Tables

Visual Gray Balance

Visual Linearity

Densitometer

Calibration

• has a SCSI connection, click on the radio button for the correct 8670

printer.

CONTENTS INDEX SEARCH HELP

Page 22

For Windows systems

If the 8670 printer:

• has a SCSI

connection, click

on the radio

button for the

correct 8670

printer. Click on

OK

.

Operator’s Guide

Printing

Guide

Color Management

Calibration

• has a network

connection, click

Network

on

Browse

on

locate the correct

printer in the

Browse for Printer

dialog box that

opens. Click on

Select a Printer dialog box.Click on

• has a parallel connection, click on the radio button for LPT1 or LPT2.

Click on

NOTE: If your host computer has more than one SCSI host adapter

installed, pull down the SCSI Host Adapter list. Select the por t

address for the SCSI host adapter for the selected 8670 printer.

CONTENTS INDEX SEARCH HELP

, and

OK

.Click

OK

.

in the Network Printer dialog box to return to the

OK

again.

Network

Interface Guide

Getting Started

Easy Cal

Setting Preferences

and Using

Calibration Tables

Visual Gray Balance

Visual Linearity

Densitometer

Calibration

Page 23

3. Pull down the Printer menu, and select “Printer Setup”.

The Printer Setup dialog box appears.

NOTE: The configuration of the Printer Setup dialog box may be different

depending on the selected printer.

4. Select the ribbon and paper type for which you are calibrating.

OK

5. Click on

.

Operator’s Guide

Printing

Guide

Color Management

Calibration

Network

Interface Guide

Getting Started

Easy Cal

Setting Preferences

and Using

Calibration Tables

Visual Gray Balance

Visual Linearity

Densitometer

Calibration

CONTENTS INDEX SEARCH HELP

Page 24

Creating a New Calibration Document

Operator’s Guide

The following steps describe how to create a new calibration document to

use as a starting point for your calibration:

New

1. Pull down the File menu, and select

The Calibration Table dialog box appears.

.

Printing

Guide

Color Management

Calibration

Network

Interface Guide

Getting Started

Easy Cal

Setting Preferences

and Using

Calibration Tables

Visual Gray Balance

Visual Linearity

Densitometer

Calibration

NOTE: If the correct paper and ribbon do not appear, click on

Setup

Ref

CONTENTS INDEX SEARCH HELP

to change the paper and ribbon you wish to calibrate for.

er to “Selecting and Setting Up a Printer”.

Change

Page 25

2. Select a starting point for the calibration document:

Operator’s Guide

Read Current Table from Printer

•

the starting point.

NOTE: The “Read Current Table from Printer” starting point is not

available with Windows systems.

Use Printer’s Default Table

•

Copy Table from File

•

calibration table. Click on

appears which allows you to find and open the folder that contains

the calibration table you want to use as the star ting point.

NOTE: For more infor mation on the Calibration Table dialog box, ref

“Option Descr iptions.”

3. Click on OK.

—uses a previously-created and saved

Select File

—uses the printer’s current table as

—uses the printer’s default table.

, and a file selection dialog box

Printing

Guide

Color Management

Calibration

Network

Interface Guide

er to

Getting Started

Easy Cal

Setting Preferences

and Using

Calibration Tables

Visual Gray Balance

Visual Linearity

Densitometer

Calibration

CONTENTS INDEX SEARCH HELP

Page 26

A Calibration Document window appears.

4. Make sure that the information in the Printer Setup Information box is

correct and that you are creating a calibration table for the correct

ribbon and paper.

You can now calibrate your printer by running the Visual Gray

Balance and Visual Linearity calibration procedures.

Operator’s Guide

Printing

Guide

Color Management

Calibration

Network

Interface Guide

Getting Started

Easy Cal

Setting Preferences

and Using

Calibration Tables

Visual Gray Balance

Visual Linearity

Densitometer

Calibration

If you have a densitometer, you can run just the Densitometer

calibration procedure. You do not need to do Visual Gray Balance and

Visual Linearity calibrations.

CONTENTS INDEX SEARCH HELP

Page 27

NOTE: If you are using a black ribbon, you cannot use the Visual Gray

Balance calibration procedure. Go directly to the Visual Linearity

calibration procedure.

Using an Existing Calibration Table as the Starting Point

Follow the steps below only if you have previously created and saved a

calibration table. If the table you select as a starting point does not

contain printer setup information, ref

Printer.”

1. Select “Copy

Table from File” in

the Starting Point

box.

2. Click on

.

File

Select

er to “Selecting and Setting Up a

Operator’s Guide

Printing

Guide

Color Management

Calibration

Network

Interface Guide

Getting Started

Easy Cal

Setting Preferences

and Using

Calibration Tables

Visual Gray Balance

Visual Linearity

Densitometer

Calibration

CONTENTS INDEX SEARCH HELP

Page 28

An open file dialog box

appears.

Operator’s Guide

3. Find and open the folder

that contains the

calibration document you

want to use as the

starting point for your

new document.

NOTE: The data in the document selected as a starting point is specific

to the ribbon and paper selected when the document was

created.

4. Click on

Open.

Printing

Guide

Color Management

Calibration

Network

Interface Guide

Getting Started

Easy Cal

Setting Preferences

and Using

Calibration Tables

Visual Gray Balance

Visual Linearity

Densitometer

Calibration

CONTENTS INDEX SEARCH HELP

Page 29

The file selection dialog box closes. The selected calibration

document appears after the

5. Click on

OK

.

Copy Table from File

radio button.

Operator’s Guide

Printing

Guide

Color Management

Calibration

Network

Interface Guide

Getting Started

Easy Cal

Setting Preferences

and Using

Calibration Tables

Visual Gray Balance

Visual Linearity

Densitometer

Calibration

CONTENTS INDEX SEARCH HELP

Page 30

A Calibration Document window appears.

Opening an Existing Calibration Table

1. Pull down the File menu, and select “Open”.

2. Find and open the folder that contains the calibration table you want

to use in the file selection box that appears.

Operator’s Guide

Printing

Guide

Color Management

Calibration

Network

Interface Guide

Getting Started

Easy Cal

Setting Preferences

and Using

Calibration Tables

Visual Gray Balance

Visual Linearity

Densitometer

Calibration

3. Click on

A Calibration Document window appears.

CONTENTS INDEX SEARCH HELP

Open

.

Page 31

Using the Calibration Document Window

Operator’s Guide

Use the Calibration Document window to set up and run Visual Gray

Balance, Visual Linearity, and Densitometer calibrations.

1. Make sure that the information in the Printer Setup Information box is

correct and that you are creating a calibration table for the ribbon and

paper you want to use.

Printing

Guide

Color Management

Calibration

Network

Interface Guide

Getting Started

Easy Cal

Setting Preferences

and Using

Calibration Tables

Visual Gray Balance

Visual Linearity

Densitometer

Calibration

2. Enter the information for the printer you are calibrating in the Printer

Description text box.

CONTENTS INDEX SEARCH HELP

Page 32

3. Enter the information about the ribbon and paper you are calibrating

for in the Media Description text box.

Operator’s Guide

NOTE: Entries in the Printer Description and Media Descr iption text

boxes are optional and do not appear on the test print.

Calibrating Y our Printer

If you have a densitometer, you can run the Densitometer Calibration

procedure. If you run the Densitometer Calibration procedure, you do not

have to do Visual Gray Balance and Visual Linearity calibrations.

If you do not have a densitometer, you can calibrate your printer by

running the Visual Gray Balance or Visual Linearity Calibration

procedures.

Printing

Guide

Color Management

Calibration

Network

Interface Guide

Getting Started

Easy Cal

Setting Preferences

and Using

Calibration Tables

Visual Gray Balance

Visual Linearity

Densitometer

Calibration

CONTENTS INDEX SEARCH HELP

Page 33

Visual Gray Balance

Operator’s Guide

Visual Gray Balance calibrates your printer so that it produces a neutral

gray. The calibration utility allows you to select from three Visual Gray

Balance calibration prints. Each of these prints presents 49 numbered

grayscale clusters. Each cluster is made up of four boxes of varying

densities. A Visual Gray Balance calibration print looks similar to the

following example:

The clusters on the three prints include a range of colors. Clusters in the

upper left corner have a green hue. Clusters in the lower right corner have

a magenta hue. Three different calibration prints allow you to choose the

degree of color shift.

Printing

Guide

Color Management

Calibration

Network

Interface Guide

Getting Started

Easy Cal

Setting Preferences

and Using

Calibration Tables

Visual Gray Balance

Visual Linearity

Densitometer

Calibration

CONTENTS INDEX SEARCH HELP

Page 34

Fine—offers the least degree of difference between clusters. This print is

useful when it is difficult to choose between clusters on the normal

calibration print.

For example, you printed a normal pr int and find that the most neutrallooking clusters are next to each other, but one still looks slightly green

while the other still looks slightly magenta. You can print a fine calibration

print to get more choices within a smaller range of colors.

Operator’s Guide

Printing

Guide

Color Management

Normal—offers a moderate degree of difference between clusters. The

amount of correction in this print is appropriate for most calibration jobs.

Coarse—offers the greatest degree of difference in clusters. This print is

useful when neutral areas in prints appear very green or very magenta.

CONTENTS INDEX SEARCH HELP

Calibration

Network

Interface Guide

Getting Started

Easy Cal

Setting Preferences

and Using

Calibration Tables

Visual Gray Balance

Visual Linearity

Densitometer

Calibration

Page 35

Running a Visual Gray Balance Calibration

Operator’s Guide

1. Pull down the Calibration menu, and select “Visual Gray Balance” and

then “Setup Visual Gray Balance”.

The Calibration Setup—Visual Gray Balance dialog box appears.

NOTE: For a description of the dialog boxes used in the Visual Gray

Balance Calibration, ref

2. Select the amount of correction. Click on OK.

er to “Option Descriptions.”

Printing

Guide

Color Management

Calibration

Network

Interface Guide

Getting Started

Easy Cal

Setting Preferences

and Using

Calibration Tables

Visual Gray Balance

Visual Linearity

Densitometer

Calibration

CONTENTS INDEX SEARCH HELP

Page 36

You return to the Calibration Document window.

3. Click on

Send & Print

.

Operator’s Guide

Printing

Guide

Color Management

Calibration

Network

Interface Guide

Getting Started

Easy Cal

Setting Preferences

and Using

Calibration Tables

Visual Gray Balance

Visual Linearity

Densitometer

Calibration

CONTENTS INDEX SEARCH HELP

Page 37

The Send and Print dialog box appears.

NOTE: The Send and Print dialog box may be different depending on

your printer’s export module.

4. Click on

You return to the Calibration Document window. The calibration test

print is printed on the specified printer.

5. View the calibration test print, and determine which cluster appears

the most neutral.

Print

.

Operator’s Guide

Printing

Guide

Color Management

Calibration

Network

Interface Guide

Getting Started

Easy Cal

Setting Preferences

and Using

Calibration Tables

Visual Gray Balance

Visual Linearity

Densitometer

Calibration

CONTENTS INDEX SEARCH HELP

Page 38

If the number of the cluster that appears to be the most neutral ends

in 25, the printer is already calibrated. Do a Visual Linear ity

calibration. If the number of the most neutral cluster does not end in

25, recalibrate your printer to the most neutral cluster number.

Input

6. Click on

The Input Test Print Values dialog box appears.

7. Enter the number of the most neutral cluster in the box.

.

Operator’s Guide

Printing

Guide

Color Management

Calibration

Network

Interface Guide

Getting Started

Easy Cal

Setting Preferences

and Using

Calibration Tables

Visual Gray Balance

Visual Linearity

Densitometer

Calibration

CONTENTS INDEX SEARCH HELP

Page 39

NOTE: If you enter a value that ends in 25, the calibration table does not

change.

Operator’s Guide

8. Click on

The calibration table data is updated, and the Calibration Table

window appears.

9. Click on

the neutral in the cluster you selected, and you do not want to look at

another calibration print.

A confirmation box appears.

10. Click on

Recompute the Table

Send

in the Calibration Table window if you are satisfied with

Send

in the confirmation box.

.

Printing

Guide

Color Management

Calibration

Network

Interface Guide

Getting Started

Easy Cal

Setting Preferences

and Using

Calibration Tables

Visual Gray Balance

Visual Linearity

Densitometer

Calibration

CONTENTS INDEX SEARCH HELP

Page 40

The recomputed table is sent to the printer, and the following

message appears.

OK

11. Click on

.

Operator’s Guide

Printing

Guide

Color Management

Calibration

Network

Interface Guide

The calibration table is computed using the specified values, and you

return to the Calibration Document window. You should now perform a

Visual Linearity calibration.

NOTE: You should make another test print to verify your input value

adjustments.

CONTENTS INDEX SEARCH HELP

Getting Started

Easy Cal

Setting Preferences

and Using

Calibration Tables

Visual Gray Balance

Visual Linearity

Densitometer

Calibration

Page 41

Visual Linearity

Operator’s Guide

Visual Linearity calibrates your printer so that it produces the correct

density. Use the

Reference Card (reference card) included with the calibration utility to

select a cluster for each of the six density ranges. Visual Linearity

calibration prints look similar to the following examples.

NOTE: For best results, do a Visual Gray Balance calibration before you

start the Visual Linearity calibration.

Kodak Digital Science

Calibration Utility

Printing

Guide

Color Management

Calibration

Network

Interface Guide

Getting Started

Easy Cal

Setting Preferences

and Using

Calibration Tables

Visual Gray Balance

Visual Linearity

Densitometer

Calibration

CONTENTS INDEX SEARCH HELP

Page 42

Using the Reference Card

Operator’s Guide

Use the reference card which comes with your printer to

perform Visual Linearity calibrations. The following steps

describe how to use the reference card:

1. Lay the reference card with the name at the top on the

first row of the calibration test print.

2. Slide the reference card across each path in the row,

and determine which of the nine patches in the row

most closely matches the darkness on the reference

card.

NOTE: It may not be possible to find a cluster in which all

six gray levels exactly match the reference card. Select the

cluster that is the closest match. Match the darkness on the

reference card and not the color.

3. Repeat Step 2 for each row on the calibration print.

Printing

Guide

Color Management

Calibration

Network

Interface Guide

Getting Started

Easy Cal

Setting Preferences

and Using

Calibration Tables

Visual Gray Balance

Visual Linearity

Densitometer

Calibration

CONTENTS INDEX SEARCH HELP

Page 43

Running a Visual Linearity Calibration

Operator’s Guide

After you have run a Visual Gray Balance calibration, run the Visual

Linearity calibration to recompute the current calibration table using

values from the test print.

1. Pull down the Calibration menu, and select “Visual Linearity”.

You return to the Calibration Document window.

Printing

Guide

Color Management

Calibration

Network

Interface Guide

Getting Started

Easy Cal

Setting Preferences

and Using

Calibration Tables

Visual Gray Balance

Visual Linearity

Densitometer

Calibration

2. Click on

CONTENTS INDEX SEARCH HELP

Send & Print

.

Page 44

The Send and Print dialog box appears.

NOTE: Your Send and Print dialog box may be different depending on

your printer’s export module.

For a description of the dialog boxes used in the Visual Linearity

Calibration, ref

3. Click on

You return to the Calibration Document window. The calibration test

print is printed on the specified printer.

Print

.

er to “Option Descriptions.”

Operator’s Guide

Printing

Guide

Color Management

Calibration

Network

Interface Guide

Getting Started

Easy Cal

Setting Preferences

and Using

Calibration Tables

Visual Gray Balance

Visual Linearity

Densitometer

Calibration

4. Click on Input in the Calibration Document window,

CONTENTS INDEX SEARCH HELP

Page 45

The Input Test Print Values dialog box appears.

One, three, or four density value columns appear in the Input Test

Print Values dialog box depending upon the ribbon that is in the

printer.

5. Use the calibration utility reference card to select a box number.

If all of the Visual Linearity numbers on the test print are box number

5, the printer is already calibrated. If the Visual Linear ity numbers on

the test print are not all box number 5, you must recalibrate the

printer. Go to Step 6.

Operator’s Guide

Printing

Guide

Color Management

Calibration

Network

Interface Guide

Getting Started

Easy Cal

Setting Preferences

and Using

Calibration Tables

Visual Gray Balance

Visual Linearity

Densitometer

Calibration

6. Type in the values you selected from the test print in the text boxes.

Click on

CONTENTS INDEX SEARCH HELP

Recompute the Table

button.

Page 46

The calibration table is computed using the specified values, and the

Calibration window appears.

Send

7. Click on

to send the table to the printer.

Operator’s Guide

Printing

Guide

Color Management

Calibration

Network

Interface Guide

Getting Started

Easy Cal

Setting Preferences

and Using

Calibration Tables

Visual Gray Balance

Visual Linearity

Densitometer

Calibration

CONTENTS INDEX SEARCH HELP

Page 47

Densitometer Calibration

Operator’s Guide

The Densitometer Calibration corrects the printer’s response based on a

densitometer reading for selected patches on a test print. If you have a

densitometer, you do not need to run Visual Gray Balance and Visual

Linearity calibrations. You only need to do a Densitometer Calibration.

With the Densitometer Calibration procedure, you make a test print and

measure the density values for each of the patches on the test print with

the densitometer. You then enter the density results for each of the

patches in the Densitometer Input Test Print Values dialog box.

The printer can print either a 15 or a 38-step test print. Using the 38-step

target yields the best calibration results; however, calibration time is

increased if you use a manual densitometer. The Densitometer

Calibration test prints look similar to the following examples depending on

the media you are calibrating for :

Printing

Guide

Color Management

Calibration

Network

Interface Guide

Getting Started

Easy Cal

Setting Preferences

and Using

Calibration Tables

Visual Gray Balance

Visual Linearity

Densitometer

Calibration

CMY

CONTENTS INDEX SEARCH HELP

K

CMYK

Page 48

Running a Densitometer Calibration

Operator’s Guide

1. Make sure your densitometer is calibrated and set up according to

the manufacturer’s instructions.

2. Pull down the Calibration menu, and select “Densitometer”.

3. Pull down the Calibration menu, and select “Setup Densitometer”.

The Calibration Setup — Densitometer dialog box appears.

NOTE: For a description of the dialog boxes used in the Densitometer

Calibration, ref

4. Select a densitometer status in the Densitometer box.

5. Pull down the Number of Squares menu in the test Print box, and

select the number of squares you want in your test print.

er to “Option Descriptions.”

Printing

Guide

Color Management

Calibration

Network

Interface Guide

Getting Started

Easy Cal

Setting Preferences

and Using

Calibration Tables

Visual Gray Balance

Visual Linearity

Densitometer

Calibration

OK

6. Click on

CONTENTS INDEX SEARCH HELP

.

Page 49

The Calibration Document window appears.

7. Click on

Send & Print

.

Operator’s Guide

Printing

Guide

Color Management

Calibration

Network

Interface Guide

Getting Started

Easy Cal

Setting Preferences

and Using

Calibration Tables

Visual Gray Balance

Visual Linearity

Densitometer

Calibration

CONTENTS INDEX SEARCH HELP

Page 50

The Send and Print dialog box appears.

NOTE: Your Send and Print dialog box may be different depending on

your printer’s export module.

Print

Input

.

.

8. Click on

You return to the Calibration Document window. The specified printer

prints the test print.

9. Click on

Operator’s Guide

Printing

Guide

Color Management

Calibration

Network

Interface Guide

Getting Started

Easy Cal

Setting Preferences

and Using

Calibration Tables

Visual Gray Balance

Visual Linearity

Densitometer

Calibration

CONTENTS INDEX SEARCH HELP

Page 51

The Input Test Print Values dialog box appears.

One, three, or four density value columns appear depending upon the

ribbon that is in the printer.

For manual densitometers only, valid characters in this dialog box

include numbers from 0 to 9 and decimal points. The valid range is 0

to 3.000. Move from cell to cell using the arrow keys. You can copy

and paste any group of contiguous fields in a rectangular pattern.

Operator’s Guide

Printing

Guide

Color Management

Calibration

Network

Interface Guide

Getting Started

Easy Cal

Setting Preferences

and Using

Calibration Tables

Visual Gray Balance

Visual Linearity

Densitometer

Calibration

10. Type the test print values in the text boxes in the Input Test Print

Values dialog box.

CONTENTS INDEX SEARCH HELP

Page 52

NOTE: You can impor t data from a densitometer automatically with an

import module. If your densitometer has an associated import

module, the densitometer readings are imported directly into the

dialog box. If your densitometer does not have an import module,

er to “Using the Kodak Digital Science File Reader.”

ref

11. Click on

The calibration table is computed using the specified values, and the

Calibration Document window appears.

Recompute the Table

.

Operator’s Guide

Printing

Guide

Color Management

Calibration

Network

Interface Guide

Getting Started

Easy Cal

Setting Preferences

and Using

Calibration Tables

Visual Gray Balance

Visual Linearity

Densitometer

Calibration

CONTENTS INDEX SEARCH HELP

Page 53

Option Descriptions

Operator’s Guide

This section describes the calibration utility menus and dialog box

options.

File Menu

This section describes the options on the File pulldown menu.

New—accesses the Calibration Document window so that you can select

options for the current printer setup.

Open—accesses a file open dialog box so you can select an existing

calibration table from which to start.

Close—closes the current calibration document.

Printing

Guide

Color Management

Calibration

Network

Interface Guide

Getting Started

Easy Cal

Setting Preferences

and Using

Calibration Tables

Visual Gray Balance

Visual Linearity

Densitometer

Calibration

CONTENTS INDEX SEARCH HELP

Page 54

Save—saves changes to the current calibration document. When you

name a calibration document, you may want to include characters that

indicate the selected paper types. Saving a document in this way allows

you to select it later to use as a starting point for a new calibration

document.

Save As—accesses a dialog box in which you can specify a new name

and location for the current calibration settings. When you name a

calibration document, you may want to include characters that indicate

the selected paper type. Naming a document in this way allows you to

select it later to use as a starting point for a calibration document.

Revert—returns a calibration document to its original state. All

recomputations are discarded.

Operator’s Guide

Printing

Guide

Color Management

Calibration

Network

Interface Guide

Preferences—accesses a dialog box that allows you to specify the folder

containing the export module and the folder containing the import

modules.

CONTENTS INDEX SEARCH HELP

Getting Started

Easy Cal

Setting Preferences

and Using

Calibration Tables

Visual Gray Balance

Visual Linearity

Densitometer

Calibration

Page 55

Use the following default paths for locating the folder containing the

export module:

Operator’s Guide

• On Macintosh systems—System Folder:Applications

Support:Kodak:Plug-ins (Printing).

• On Windows systems— C:\Windows\Kodak\Plug-ins (Printing)

Use the following default paths for locating the folder containing the

import modules:

• On Macintosh systems— Kodak DS Calibration Utility:Densitometer

Import Modules

• On Windows systems—C:\Kodakcal\Densitom

Quit—exits the Calibration Utility.

Printing

Guide

Color Management

Calibration

Network

Interface Guide

Getting Started

Easy Cal

Setting Preferences

and Using

Calibration Tables

Visual Gray Balance

Visual Linearity

Densitometer

Calibration

CONTENTS INDEX SEARCH HELP

Page 56

Edit Menu

Operator’s Guide

The Edit menu is enabled only when the Calibration Table window is open.

NOTE: The options in the Edit menu are enabled only when you enter

text in the Printer Description and Media Description boxes.

Calibration Menu

The Calibration menu is enabled when the Calibration Table window is

open. You can choose to calibrate based on your input to the Visual Gray

Balance, Visual Linearity, and Densitometer dialog boxes.

Printing

Guide

Color Management

Calibration

Network

Interface Guide

Getting Started

Easy Cal

Setting Preferences

and Using

Calibration Tables

Visual Gray Balance

Visual Linearity

Densitometer

Calibration

CONTENTS INDEX SEARCH HELP

Page 57

Calibration Setup — Visual Gray Balance

This dialog box allows you to specify the degree of correction to apply

with the current calibration table.

Operator’s Guide

Printing

Guide

Color Management

Calibration

Network

Interface Guide

Amount of Correction

Amount of Correction

The

difference between the neutrals in the calibration print:

Fine—the calibration print offers the least degree of difference in neutrals

between the cluster in the upper left corner and the cluster in the lower

right corner. The cluster in the upper left corner is only slightly green and

the cluster in the lower right corner is only slightly magenta.

Select Fine to get the smallest hue range. The hue differences between

clusters will be small so that you can fine-tune by choosing between

similar neutrals.

CONTENTS INDEX SEARCH HELP

buttons allow you to specify what degree of

Getting Started

Easy Cal

Setting Preferences

and Using

Calibration Tables

Visual Gray Balance

Visual Linearity

Densitometer

Calibration

Page 58

Normal—the calibration print offers a moderate degree of difference in

neutrals between the cluster in the upper left corner and the cluster in the

lower right corner. The cluster in the upper left corner is somewhat green

and the cluster in the lower right corner is somewhat magenta.

Select Normal to get a larger hue range than “Fine.” This means that the

hue differences between clusters are slightly larger and that adjacent

clusters are less similar.

Operator’s Guide

Printing

Guide

Color Management

Coarse—the calibration print offers the greatest degree of difference in

neutrals between the cluster in the upper left corner and the cluster in the

lower right corner. The cluster in the upper left corner is distinctly green,

and the cluster in the lower right corner is distinctly magenta.

Select Coarse to get the largest hue range. This means that the hue

differences between clusters are easily discernible and adjacent clusters

are distinctly different.

CONTENTS INDEX SEARCH HELP

Calibration

Network

Interface Guide

Getting Started

Easy Cal

Setting Preferences

and Using

Calibration Tables

Visual Gray Balance

Visual Linearity

Densitometer

Calibration

Page 59

Calibration Setup—Densitometer

NOTE: Make sure that your densitometer is calibrated before you try to

calibrate your printer with the densitometer values.

Operator’s Guide

Printing

Guide

Color Management

Calibration

Network

Interface Guide

Densitometer—This setting allows you to specify what type of density

data (Status A or Status T) your densitometer provides. The Calibration

Utility calculates the table data using the density type that the export

module needs for the current calibration slot.

Test Print — Number of Squares

The Number of Squares menu in the Test Print box allows you to specify

the number of squares (15 or 38) in your test print.

CONTENTS INDEX SEARCH HELP

Getting Started

Easy Cal

Setting Preferences

and Using

Calibration Tables

Visual Gray Balance

Visual Linearity

Densitometer

Calibration

Page 60

Printer Menu

Operator’s Guide

The Printer menu allows you to select a printer or set up the printer from

the menu bar.

Select Printer—a menu with the printer types that you can select from

appears. Selecting a printer type opens a dialog box that allows you to

choose the specific printer you wish to calibrate.

Printer Setup—the Printer Setup for Calibration dialog box appears so

that you can select the ribbon and paper installed in the printer.

Easy-Cal Menu

The Easy-Cal menu allows you to start the Easy Cal calibration procedure

from the menu bar.

Begin—the Easy Cal calibration procedure starts up.

Printing

Guide

Color Management

Calibration

Network

Interface Guide

Getting Started

Easy Cal

Setting Preferences

and Using

Calibration Tables

Visual Gray Balance

Visual Linearity

Densitometer

Calibration

Begin with Previous Settings—the Easy Cal Step 4 dialog box appears.

CONTENTS INDEX SEARCH HELP

Page 61

KODAK DIGITAL SCIENCE Calibration Utility Dialog Box

Operator’s Guide

When you launch the Calibration Utility for the first time, the Calibration

Utility dialog box appears.

You can click on

Launch Normal Utility

or Densitometer calibration procedures.

NOTE: If you want to go directly to the Normal Utility without this dialog

box opening each time you start the Calibration Utility, select “At

start-up launch nor mal utility and don’t show this screen”.

To use Easy Cal from within the Nor mal Utility, pull down the Easy-Cal

menu, and select “Begin” or “Begin with Previous Settings”.

Begin Easy Cal

to go to the Visual Gray Balance, Visual Linearity,

to start up Easy Cal, or you can click on

Printing

Guide

Color Management

Calibration

Network

Interface Guide

Getting Started

Easy Cal

Setting Preferences

and Using

Calibration Tables

Visual Gray Balance

Visual Linearity

Densitometer

Calibration

CONTENTS INDEX SEARCH HELP

Page 62

Calibration Table Dialog Box

Operator’s Guide

Pull down the File menu and select ”New” to access a dialog box that

allows you to create a new calibration table.

Printer Setup

The Printer Setup box lists information about the ribbon and paper type

for which the printer will be calibrated.

Printing

Guide

Color Management

Calibration

Network

Interface Guide

Getting Started

Easy Cal

Setting Preferences

and Using

Calibration Tables

Visual Gray Balance

Visual Linearity

Densitometer

Calibration

CONTENTS INDEX SEARCH HELP

Page 63

Click on Change Setup to change the ribbon and paper settings.

Change Setup—accesses the Printer Setup for Calibration dialog box so

that you can select options that match the paper in the printer you are

calibrating.

Operator’s Guide

Printing

Guide

Color Management

Calibration

Network

Interface Guide

Getting Started

Easy Cal

Setting Preferences

and Using

Calibration Tables

Visual Gray Balance

Visual Linearity

Densitometer

Calibration

CONTENTS INDEX SEARCH HELP

Page 64

Starting Point

The Starting Point box allows you to select the data that will act as a base

for the new calibration table.

Operator’s Guide

Printing

Guide

Color Management

Calibration

Read Current Table From Printer—allows you to retrieve and begin with

the table currently in the printer. After the table is loaded, you can edit it

and recalibrate the printer. This option is not always available as a

starting point.

NOTE: The Read Current Table From Printer is not available if the printer

cannot return this information. For example, many printers with a

parallel connection have this item deselected.

Use Printer’s Default Table—default data in the printer acts as the

starting point for the new calibration document.

Copy Table from File—the calibration table you select with the Select

File button acts as the starting point for the new calibration document.

CONTENTS INDEX SEARCH HELP

Network

Interface Guide

Getting Started

Easy Cal

Setting Preferences

and Using

Calibration Tables

Visual Gray Balance

Visual Linearity

Densitometer

Calibration

Page 65

Select File—opens a file open box so you can choose an existing

calibration document from which to start.

Operator’s Guide

Printing

Guide

Color Management

Calibration

OK

OK

The

window. Refer to Ref

information.

Cancel

The

calibration document.

CONTENTS INDEX SEARCH HELP

button closes the dialog box and opens the Calibration Table

er to “Calibration Document Window” for more

Cancel

button closes the dialog box without creating a new

Network

Interface Guide

Getting Started

Easy Cal

Setting Preferences

and Using

Calibration Tables

Visual Gray Balance

Visual Linearity

Densitometer

Calibration

Page 66

Calibration Document Window

Operator’s Guide

The Calibration Document window allows you to specify information about

the calibration table.

Printer Description

The Printer Description text box allows you to enter information that

describes the printer you are calibrating. The text you enter is used to

describe the specifics of a particular calibration table. This text is not

printed on the test print. An entry is optional.

Printing

Guide

Color Management

Calibration

Network

Interface Guide

Getting Started

Easy Cal

Setting Preferences

and Using

Calibration Tables

Visual Gray Balance

Visual Linearity

Densitometer

Calibration

CONTENTS INDEX SEARCH HELP

Page 67

Media Description

The Media Description text box allows you to enter information that

describes the paper and the ribbon for which the calibration table will be

used. The text you enter is used to help describe the specifics of a

particular calibration table. This text is not printed on the test print. An

entry is optional.

Calibration T ools

Operator’s Guide

Printing

Guide

Color Management

Calibration Tools offers handling options for the calibration table.

Send & Print—sends the current calibration table to the printer. A

calibration print is generated so you can evaluate the results.

Input—accesses the Input Test Print Values dialog box so you can enter

visual gray balance, visual linearity, and densitometer data.

Send—sends the current calibration table to the printer without

generating a calibration print. This button is usually used after you have

created a test print and recomputed the calibration table.

CONTENTS INDEX SEARCH HELP

Calibration

Network

Interface Guide

Getting Started

Easy Cal

Setting Preferences

and Using

Calibration Tables

Visual Gray Balance

Visual Linearity

Densitometer

Calibration

Page 68

Using the Kodak Digital Science File Reader

Operator’s Guide

The calibration utility includes the

that you can import data into the Input Test Print Values screen from a

densitometer. To use the file reader, you need the following software:

• a utility to capture the values from the densitometer. If software is not

provided with your densitometer, you may use a terminal program.

NOTE: The values from the densitometer should have no more than 3

decimal places.

• an application such as Microsoft Excel or SimpleText to save the data

as a text file.

The following steps describe how to use the file reader:

1. Create a document to capture the data from the densitometer. Be

sure to save the document as a text file.

2. Select "Kodak File Reader" from the Import Modules menu.

3. Click on

Import

.

Kodak Digital Science

file reader so

Printing

Guide

Color Management

Calibration

Network

Interface Guide

Getting Started

Easy Cal

Setting Preferences

and Using

Calibration Tables

Visual Gray Balance

Visual Linearity

Densitometer

Calibration

CONTENTS INDEX SEARCH HELP

Page 69

The Kodak Digital Science File Reader dialog box opens.

Operator’s Guide

Printing

Guide

Color Management

Calibration

4. Specify the end-of-field character used in your densitometer file:

“space,” “comma,” “tab,” “CR” (carriage return), “CR-LF” (carriage

return/line feed), “LF” (line feed), and “Semi-colon.”

5. Specify the end-of-record character used in your densitometer file:

“space,” “comma,” “tab,” “CR” (carriage return), “CR-LF” (carriage

return/line feed), “LF” (line feed), and “Semi-colon.”

6. Click on

data from your densitometer. When the file opens, the data will be

imported into the Input Test Print Values window.

7. Complete the Densitometer Calibration procedure. Ref

a Densitometer Calibration”.

CONTENTS INDEX SEARCH HELP

Open

. Locate the document you wish to use to capture the

er to “Running

Network

Interface Guide

Getting Started

Easy Cal

Setting Preferences

and Using

Calibration Tables

Visual Gray Balance

Visual Linearity

Densitometer

Calibration

Loading...

Loading...