Page 1

TECHNICAL DATA /

BLACK-AND-WHITE FILM

K OD AK PR OFESSIONAL PLUS-X

125 Film / 125PX

February 2002 • F-4018

—NOTICE—

To reflect our enduring com m i t m ent to black-and-white

photography, bla ck-and-white film production will take place in

an even more advanced film-coating facility. New technology

applied to these superior, time-tested emulsions will result in

slightly different processing times for the film family. But the

same great films—those you've known and trusted for years—

will still deliver the same breathtaking results.

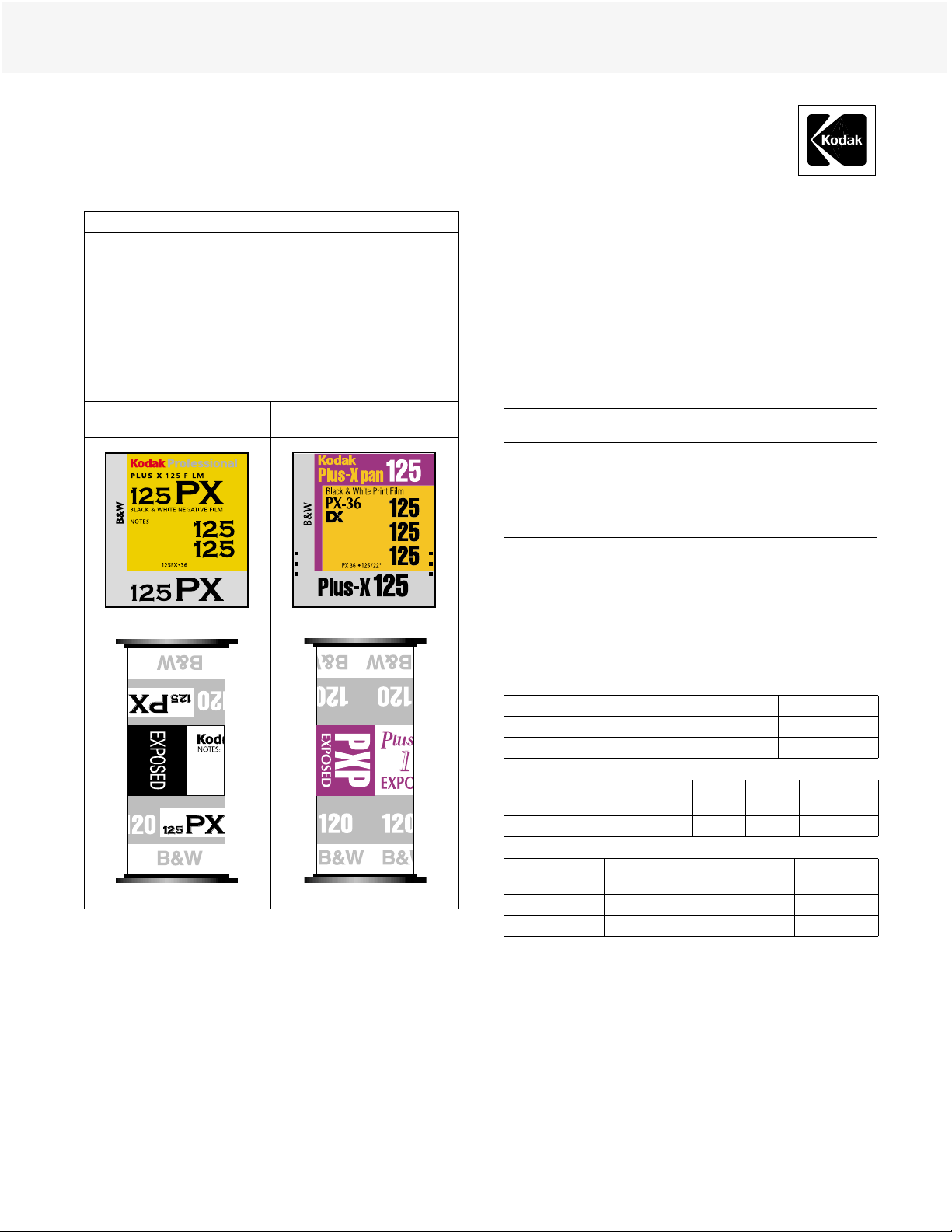

Use the packaging examples below to dete rmine which film

you have, then refer to the corresponding publication for

development times.

New packaging, refer to this

publication (F-4018)

Former packagin g , refer to

Kodak publication F-8:

KODAK PROFESSIONAL PLUS-X 125 Film is a

medium-speed, continuous-tone panchromatic film that is a

good choic e for general-purpose outdoor or st udio

photography. It features extremely fine grain and excellent

sharpness.

KODAK PROFESSIONAL PLUS-X Film is available in

135 size and 35 mm long rolls on a 5-mil gray acetate base,

and in 120 and 220 size on a 3.6-mil acetate base. The 120

and 220 sizes have a retouching surface on the emulsion side.

FEATURES BENEFITS

• Extremely fine grain • Excellent for producing

high-quality images

• Wide exposure latitude • Rich tonality maintained

with overexposure and

underexposure

• Very high sharp ness • Excellent for applica tions

that require a high

degree of enlargemen t

• High resolving power • Good rendition of de ta il

SIZES AVAILABLE

Sizes and CAT numbers may dif fer from country to country.

The numbers below apply to products sold in the United

Sates. Different sizes are av ailable by special order . See your

dealer who supplies KODAK PROFESSIONAL Products.

Roll Base Letter Code CAT No.

135-24 5-mil gray acetate PX 141 0570

135-36 5-mil gray acetate PX 867 7593

Roll

mm x ft

35 x 100 5-mil gray acetate 402 PX 802 4804

Roll Base

120 pro-pack 3.6-mil gray acetate PX 858 5614

220 pro-pack 3.6-mil gray acetate PX 859 2149

Base

Spec

Code

Letter

Code

Letter

Code

CAT No.

CAT No.

©Eastman Kodak Company, 2002

Page 2

STORAGE AND HANDLING

Load and unload your camera in subdued light.

High temperatures or high humidity may produce

unwanted quality changes. Store unexposed film at 24

°F) or lower in the original sealed package. Always store

(75

°C

film (exposed or unexposed) in a cool, dry place. For best

results, process film as soon as possible after exposure.

Protect processed film from strong light, and store it in a

cool dry place. For more information, see KODAK

Publication No. E-3 0, Storage and Care of KODAK Films

and Papers—Before and After Processing.

EXPOSURE

Daylight

Use the exposures in the table below for average front-lit

subjects from 2 hours after sunr ise to 2 hours befor e sunset.

Lighting Conditions Shutter Speed

(second)

Bright/Hazy Sun on Ligh t

Sand or Snow

Bright or Hazy Sun, Distin ct

Shadows

Weak, Hazy Sun (Soft

Shadows)

1/250 f/16

1/250 f/11

1/250 f/8

Cloudy Bright (No Shadows) 1/250 f/5.6

Heavy Overcast, Open

†

Shade

*

Use f/5.6 for backlighted close-up subjects.

†

Subject shaded from sun but lighted by a large area of clear sky.

1/250 f/4

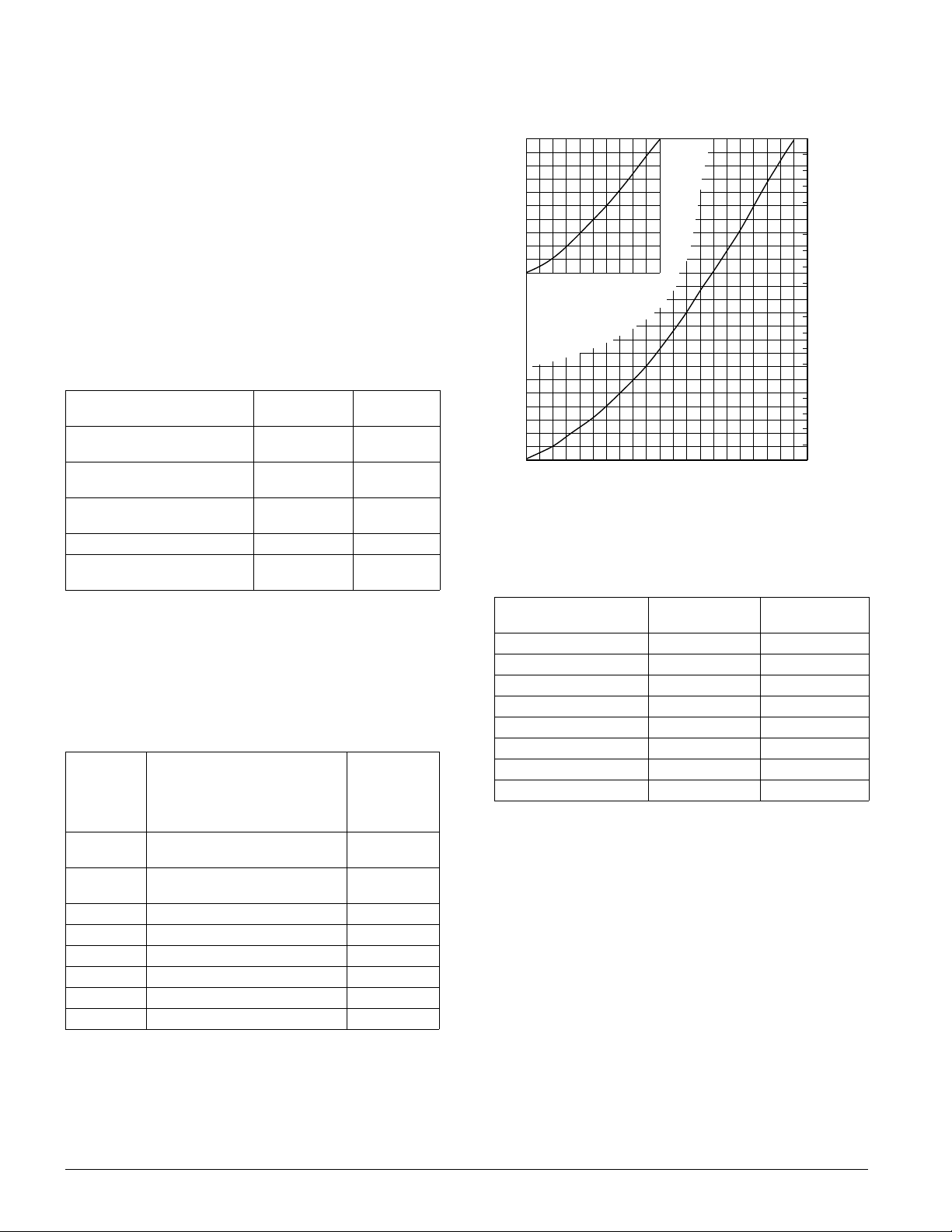

Exposure and Development Adjustments for

Long and Short Exposures

At the exposure times in the table below , compensate for the

reciprocity characteristics of this film by increasing exposure

and adjusting the development as shown.

If Indicated

Exposure

Time Is

(Seconds)

Use This

Lens-

Aperture

Adjustment

OR

1/100,000 +1 stop Change

1/10,000 +1/2 stop Change

1/1,000 None None +10%

1/100 None None None

1/10 None None None

1 +1 stop 2 -10%

10 +2 stops 50 -20%

100 +3 stops 1200 -30%

This

Adjusted

Exposure

Time

(Seconds)

Aperture

Aperture

Lens

Opening

*

AND Use

This

Development

Adjustment

+20%

+15%

50

50

40

40

30

30

20

20

10

10

CALCULATED EXPOSURE

ADJUSTED EXPOSURE TIME (Seconds)

ADJUSTED EXPOSURE TIME (Seconds)

TIME (Seconds)

CALCULATED EXPOSURE

TIME (Seconds)

CALCULATED EXPOSURE TIME (Seconds)

CALCULATED EXPOSURE TIME (Seconds)

10987654321

10987654321

20

19

20

18

19

17

18

16

17

15

16

14

15

13

14

12

13

11

12

10

11

9

10

8

9

7

8

6

7

5

6

4

5

3

4

2

3

1

2

1

100908070605040302010

100908070605040302010

F002_0062GC

Filter Corrections

Multiply the normal exposure time by the filter factor.

KODAK WRATTEN

Gelatin Filter

No. 8 (yellow) 2 1.5

No. 11 (yello wis h gree n) 4 4

No. 15 (deep yellow) 2.5 1 . 5

No. 25 (red) 6 4

No. 29 (red) 6 4

No. 47 (blue) 6 12

No. 58 (green) 8 8

Polarizing Filter 2.5 2.5

Daylight Filter

Factor

T ungsten Filter

Factor

(Minutes)

(Seconds)

1,200

(Minutes)

(Seconds)

1,200

1,100

1,100

1,000

1,000

900

900

800

800

700

700

600

600

500

500

400

ADJUSTED EXPOSURE TIME

400

ADJUSTED EXPOSURE TIME

300

300

200

200

100

100

It may be difficult to use the table to estimate the adjusted

times for calculated exposure times between 1 and

100 seconds. The graph that follows will help you find the

adjusted times for calculated exposure times between those

given in the table.

2 KODAK PROFESSIONAL PLUS-X 125 Film / 125PX • F-4018

Page 3

DARKROOM RECOMMENDATIONS

Handle unprocessed film in total darkness.

Using a safelight will affect your results. If absolutely

necessary, after development is half complete, you can use a

safelight equipped with a KODAK 3 Safelight Filter (dark

green) with a 15-watt bulb for a few seconds. Keep the

safelight at least 4 feet (1.2 metres) from the film. Run tests to

determine that safelight use gives acceptable results for your

application.

For information on safelight testing, see KODAK

Publication No. K-4, How Safe Is Your Safelight?

PROCESSING

These starting-point recommendations are intended to

produce negatives with a contrast appropriate for printing

with a diffusion enlarger. To print negativ es with a condenser

enlarger , you may need to adjust the co ntrast by reducing your

development time. Tank development times shorter than

5 minutes may produce unsatisfactory uniformity.

135, 120, and 220 Rolls

MANUAL PROCESSING

Small-Tank Processing (8- or 16-ounce tank)

With small single- or double-reel tanks, drop the loaded film

reel into the developer and attach the top to the tank. Firmly

tap the tank on the top of the work surface to dislod ge any air

bubbles. Provide initial agitation of 5 to 7 inversion cycles in

5 seconds; i.e., extend your arm and vigorously twist your

wrist 180 degrees.

Then repeat this agitation procedure at 30-second

intervals for the rest of the development time.

Large-Tank Processing (1/2- to 3 1/2-gallon

tank)—Rolls and Sheets

Agitate continuously for the first 15 to 30 seconds by raising

and lowering the basket, rack, or spindle 1/2-inch. Do not

agitate the basket, rack, or spindle for the remainder of the

first minute. Then agitate once per minute by lifting the

basket, rack, or spindle out of the developer, tilting it

approximately 30 degrees, draining it for 5 to 10 seconds,

and reimmersing it. Alternate the direction of tilting the

basket, rack, or spindle.

KODAK

Developer or

Developer and

Replenisher

T-MAX 6

65°F

(18°C)

3

⁄

4

T-MAX RS 5 4

HC-110 (B) 4 31⁄

D-76 61⁄

2

D-76 (1:1) 10 81⁄

1

135: 5

⁄

2

XTOL

135: 6

120: 7

XTOL (1:1) — 81⁄

1

⁄

MICRODOL-X 9

MICRODOL-X

(1:3)

*

With agitation at 30-sec ond intervals. Development times shorter than 5 minutes may prod uce unsatisfactory results.

†

With manual agitation at 1-minute intervals. Development times shorter than 5 minutes ma y produce unsatisfactory results .

4

NR 13 11

Small Tank

68°F

(20°C)

53⁄

1

51⁄

120: 6

87

⁄

4

4

2

2

2

4

70°F

(21°C)

51⁄

43

32

54

73⁄

1

135: 5

⁄

2

120: 51⁄

71⁄

1

3

4

4

2

⁄

4

⁄

4

Development Time (Minutes)

*

135: 41⁄

2

72°F

(22°C)

43⁄

4

1

⁄

2

3

⁄

4

1

⁄

2

71⁄

4

120: 5

75°F

(24°C)

41⁄

4

35

21⁄

2

47

611

135: 4

2

120: 41⁄

Large Tank

65°F

(18°C)

68°F

(20°C)

(21°C)

—————

1

⁄

2

43⁄

4

41⁄

2

33⁄

4

1

⁄

4

61⁄

4

1

⁄

4

93⁄

4

135: 71⁄

4

135: 61⁄

4

4

120: 73⁄

4

120: 63⁄

4

135: 53⁄

120: 61⁄

70°F

41⁄

2

31⁄

2

53⁄

4

83⁄

4

†

4

4

(22°C)

135: 51⁄

120: 51⁄

7 6 — — — — —

131⁄

1

⁄

4

4

63⁄

103⁄

4

53⁄

4

101⁄

2

4

91⁄

4

NR 143⁄

98

4

72°F

75°F

(24°C)

4

2

1

⁄

2

23⁄

4

41⁄

2

3

⁄

4

135: 41⁄

120: 43⁄

61⁄

2

4

43

31⁄

4

51⁄

4

86

71⁄

2

12 101⁄

2

4

NR = Not Recommended.

Note: Use only KODAK HC-110 Developer (Dilution B) to process long rolls of PLUS-X Pan Film on spiral reels. Develop for 6

minutes at 68

°F (20°C) or 4 1/4 minutes at 75°F (24°C).

KODAK PROFESSIONAL PLUS-X 125 Film / 125PX • F-4018 3

Page 4

Rotary-Tube Processing

Follow the agitation recommendations for your processor.

The times given below are starting-point recommendations.

Make tests to determine if results at this rating are acceptable

for your needs.

135 and 120 Rolls

KODAK

Developer or

Developer and

Replenisher

T-MAX 6

T-MAX RS 5 41⁄

XTOL 63⁄

XTOL (1:1) — 8

HC-110 (B) 4 31⁄

D-76 61⁄

Development Time (Minutes)

65°F

(18°C)

68°F

(20°C)

3

⁄

4

53⁄

4

53⁄

2

51⁄

70°F

(21°C)

4

51⁄

4

43

4

51⁄

1

⁄

4

71⁄

2

32

2

54

72°F

(22°C)

4

43⁄

1

⁄

4

43⁄

2

76

3

⁄

1

⁄

75°F

(24°C)

4

41⁄

4

2

3

4

4

4

21⁄

2

2

4

PUSH PROCESSING

Push processing allows you to expose the film at higher

film-speed numbers for conditions such as low-level light,

stop action, or existing light. However, there will be a loss

of shadow detail and an increase in graininess.

Because of the film's exposure latitude, you can

underexpose by one stop at EI 250 and use normal

processing times. Prints will show a slight loss in shadow

detail.

You can underexpose by two stops at EI 500 if you

increase development time by push processing. Prints will

show an increase in contrast and graininess with further loss

of shadow detail. However, results should be acceptable fo r

many applications. Expose a test roll to determine the film

speed that gives the best results for your application.

You can underexpose the film by three stops (EI 1000)

when you use 3-stop push processing in KODAK XTOL

Developer. Prints will show an increase in contrast and

graininess, and an additional loss of shadow detail.

However, results should be acceptable for some

applications. Expose some test rolls to determine the film

speed that gives the best results for your application.

4 KODAK PROFESSIONAL PLUS-X 125 Film / 125PX • F-4018

Page 5

Small Tank

KODAK

Developer or

Developer and

Replenisher

65°F

(18°C)

68°F

(20°C)

135 FIlm 120 Film

70°F

(21°C)

Development Time (Minutes)

72°F

(22°C)

(24°C)

EI 500 (2-Stop Push Process)

T-MAX NR NR NR NR 6

T-MAX RS — 71⁄

D-76 9 7

XTOL 93⁄

4

XTOL (1:1) — 121⁄

81⁄

4

61⁄

2

3

⁄

4

4

71⁄

4

111⁄

76

2

65NR7

1

⁄

2

—5

4

—8

EI 1000 (3-Stop Push Process)

XTOL 111⁄

XTOL (1:1) — 14

KODAK

Developer or

Developer and

Replenisher

65°F

(18°C)

2

10 9 — 7 111⁄

3

⁄

4

131⁄

2

—101⁄

Development Time (Minutes)

135 Film 120 Film

68°F

(20°C)

70°F

(21°C)

72°F

(22°C)

(24°C)

EI 500 (2-Stop Push Process)

T-MAX RS NR NR NR NR 5

XTOL 103⁄

4

91⁄

4

81⁄

2

—6

EI 1000 (3-Stop Push Process)

XTOL 13 111⁄

4

101⁄

4

—8NR11

75°F

1

⁄

4

51⁄

2

3

⁄

4

3

⁄

4

2

Large Tank

75°F

3

⁄

4

1

⁄

2

65°F

(18°C)

68°F

(20°C)

70°F

(21°C)

72°F

(22°C)

NR NR NR NR 61⁄

1

⁄

4

61⁄

97

93⁄

4

81⁄

—121⁄

2

10 9 — 7

—143⁄

65°F

(18°C)

68°F

(20°C)

2

3

⁄

4

4

76

71⁄

4

111⁄

4

131⁄

2

70°F

(21°C)

65

1

⁄

2

—5

4

—8

2

—101⁄

72°F

(22°C)

NR NR NR NR 53⁄

103⁄

4

91⁄

4

81⁄

2

—6

1

⁄

4

101⁄

4

—8

75°F

(24°C)

4

51⁄

2

3

⁄

4

3

⁄

4

75°F

(24°C)

4

1

⁄

2

2

KODAK

Developer or

Developer and

Replenisher

65°F

(18°C)

68°F

(20°C)

T-MAX NR 8

T-MAX RS NR 71⁄

D-76 9 7

XTOL 93⁄

4

81⁄

XTOL (1:1) — 121⁄

XTOL 111⁄

2

10 9 — 7 111⁄

XTOL (1:1) — 14

NR = Not Recommended.

Rotary Tube

Development Time (Minutes)

135 Film 120 Film

70°F

(21°C)

72°F

(22°C)

75°F

(24°C)

65°F

(18°C)

68°F

(20°C)

EI 500 (2-Stop Push Process)

3

⁄

4

4

3

⁄

4

4

61⁄

71⁄

4

111⁄

87

2

76

2

1

⁄

4

61⁄

4

NR 83⁄

65NR7

1

⁄

2

51⁄

—5

4

—8

2

3

⁄

4

3

⁄

4

97

93⁄

—121⁄

4

1

⁄

4

3

⁄

4

4

81⁄

4

EI 1000 (3-Stop Push Process)

2

10 9 — 7

3

⁄

4

131⁄

2

—101⁄

2

—143⁄

70°F

(21°C)

87

61⁄

76

71⁄

4

111⁄

4

131⁄

72°F

(22°C)

2

2

4

2

75°F

(24°C)

1

⁄

4

61⁄

4

65

1

⁄

2

51⁄

2

—5

—8

—101⁄

3

⁄

4

3

⁄

4

2

KODAK PROFESSIONAL PLUS-X 125 Film / 125PX • F-4018 5

Page 6

FINAL STEPS

65 to 75°F (18 to 24°C).

Step/Solution Time (min:sec)

Rinse—with agitation:

KODAK Indicator Stop Bath 0:30

KODAK EKTAFLO Stop Bath 0:30

Fix—with frequent agitation:

KODAK Fixer 5:00 to 10:00

KODAK Rapid Fixer 2:00 to 4:00

KODAFIX Solution 2:00 to 4:00

KODAK POLYMAX T Fixer (1:3) 2:00 to 4:00

Wash:

Running Water

—OR—

Rinse with water

KODAK Hypo Clearing Agent

Running water

Final Rinse:

KODAK PHOTO-FLO Solution 0:30

Dry—in a dust-free place

20:00 to 30:00

0:30

1:00 to 2:00

5:00

MACHINE PROCESSING

Roller-Transport Processors

KODAK VERSAMAT Film Processors

Y o u can process this f ilm in roller -transport pro cessors, such

as the KODAK VERSAMAT Film Processor, Model 5, 11,

or 411, with KODAK DURAFLO RT Developer Starter,

KODAK DURAFLO RT Developer Replenisher, and

KODAK Rapid Fixer.

Processing Steps and Conditions for KODAK

VERSAMAT Film Processors

KODAK PROFESSIONAL PLUS-X 125 Films

Step

Develop 2

Fix 3 12 ft (3.8 m) 6 ft (1.9 m)

Wash 2 8 ft (2.4 m) 4 ft (1.2 m)

Dry 8 ft (2.4 m) 4 ft (1.2 m)

No. of

Racks

The recommended machine speeds for processing

KODAK PROFESSIONAL PLUS-X 125 Film to a contrast

index of 0.56 is as follows:

Processor PLUS-X 125 Film

KODAK VERSAMAT Film Processor,

Models 5 and 411

KODAK VERSAMAT Film Processor,

Model 11

Path Length

Model 11

8.5 ft

(2.6 m)

Models 5

and 411

4 ft (1.2 m)

4.0 ft (1.2 m) per

8.5 ft (2.6 m) per

Temperature

80 ± 0.5°F

(26.5 ± 0.3°C)

80°F (26.5)

nominal

70 to 75°F

(21 to 24°C)

105 to 140°F

(40.5 to 60°C)

minute

minute

You may need to use higher dryer temperatures (135 to

°F[57 to 60°C]) to dry several sheet films processed in

140

succession. If you are processing only roll films, a lower

temperature will be adequate.

Processing Conditions for Other Roller-Transport

Processors

Adjust the machine speed so that the development time for

normally exposed film is approximately 60 seconds. The

development time is measured from the time the film enters

the developer to the time it enters the fixer. Differences in

machine design that affect agitation and crossover times

from one tank to the next may require development-time

adjustments.

Replenishment Rates

Developer—Because most film loads will consist of a

variety of film types, use an average replenishment rate of

0.20 mL per squar e inch of film processed.

Fixer—Use 0.55 mL per square inch.

Large Tank Rack-and-Tank Processors

The development times for large-tank rack-and-tank

processors are based on a machine speed that transfers the

film every 2 minutes. The times given below are

starting-point recommendations. Make tests to determine if

results are acceptable for your needs.

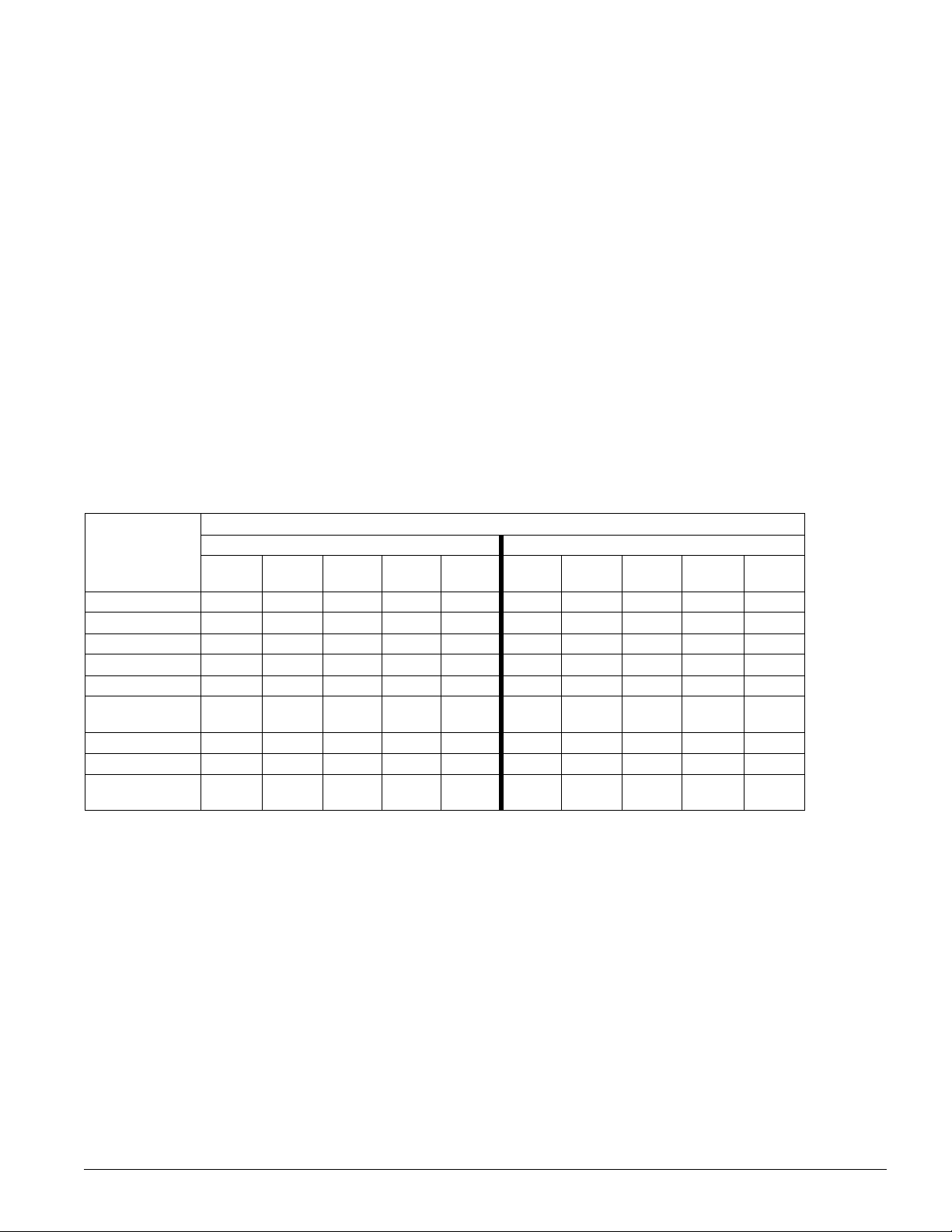

Large-Tank Rack-and-Tank Processing

EI

125/22°

250/25°

125/22°

250/25°

125/22°

250/25°

KODAK Developer or

Developer and

Replenisher

T-MAX RS 3

D-76 4 to 6

XTOL 4 to 6

Replenishment Rates

Stir or recirculate the solution after each addition of

replenisher solution.

T-MAX RS Developer—Add 45 mL (1.5 ounces) of

replenisher solution for each 135-36 or 120 roll of film

processed.

Note: Do not use T-MAX RS Developer and R eplenisher t o

replenish T-MAX Developer. They are not desi gned to work

together.

D-76 and XTOL Developers—Add 70 mL (2.4 ounces)

of replenisher solution for each 135-36 or 120 roll of film

processed.

Note: Refer to KODAK Publication No. J-78,

KODAK PROFESSIONAL Developer D-76, for modified

replenisher mixing instruction s .

Time (min) at

72°F (22°C)

1

⁄2 to 6

6 KODAK PROFESSIONAL PLUS-X 125 Film / 125PX • F-4018

Page 7

Push Processing: Roller T r ansport Processors

To process pushed PLUS-X 125 Film in a machine with

DURAFLO RT Developer, use a normal machine process

with the machine speed shown in the appropriate table

below.

EI Machine Speed

KODAK VERSAMAT Film Processor, Models 5 and 411

250/25° 4.0 ft (1.2 m)/min (normal)

500/28° 3.0 ft (0.9 m)/min

KODAK VERSAMAT Film Processor, Model 11

250/25° 8.5 ft (2.6 m)/min (normal)

500/28° 6.4 ft (1.9 m)/min

Other Roller-Transport Processors

EI Develop ment Time at

250/25°

500/28° 80 seconds

80°F (27°C)

60 seconds

(normal)

IMAGE STRUCTURE

The data in this section is based on development in KODAK

HC-110 Developer (Dilution B), 70

a large tank, with manual agitation at 1-minute intervals.

Resolving Power

ISO RPL

TOC 1.6:1)

50 125 10 (extremely fine)

*

Read at a net diffuse density of 1. 0, using a 48-micrometre aperture, 12X

magnification.

ISO RPL

TOC 1000:1)

°F (21°C), 5 minutes in

Diffuse rms

Granularity

*

CURVES

3.0

2.0

DENSITY

1.0

0.0

3.5

3.0

2.0

DENSITY

Characteristic Curves

Exposure:

KODAK PROFESSIONAL Developer D-76

Small Tank

20 C (68 F)

Diffuse Visual

Exposure:

KODAK PROFESSIONAL T-MAX Developer

Small Tank

20 C (68 F)

Diffuse Visual

Daylight

= 11 minutes

= 7 minutes

= 5 minutes

2.5

3.0 2.0 1.5 1.0 0.5 0.0 0.5

LOG EXPOSURE (lux-seconds)

Daylight

1.0

1.0

0.0

3.5

3.0

LOG EXPOSURE (lux-seconds)

= 11 minutes

= 7 minutes

= 6 minutes

0.50.00.51.01.52.02.5

1.0

KODAK PROFESSIONAL PLUS-X 125 Film / 125PX • F-4018 7

Page 8

Contrast Index Curves

)

)

CO

S

(

)

CO

S

1.1

Small Tank 68 F (20 C)

1.0

0.9

0.8

0.7

0.6

CONTRAST INDEX

0.5

0.4

0.3

46

8 10 12 14 16 18 20 22 24 26 28

1.1

Small Tank 68 F (20 C)

1.0

0.9

D-76

D-76 (1:1)

T-MAX

T-MAX RS

HC-110 (B)

Microdol-X

Microdol-X 1:3

DEVELOPMENT TIME (MINUTES

XTOL

XTOL 1:1

1.1

Large Tank 68 F (20 C)

1.0

0.9

0.8

T INDEX

0.7

NTRA

0.6

0.5

0.4

0.3

30

64

DEVELOPMENT TIME (MINUTES)

1.1

Large Tank 68 F (20 C)

1.0

0.9

D-76

D-76 (1:1)

T-MAX RS

HC-110 (B)

Microdol-X

Microdol-X 1:3

282624222018161412108

XTOL

30

0.8

0.7

0.6

CONTRAST INDEX

0.5

0.4

0.3

0.8

T INDEX

0.7

NTRA

0.6

0.5

0.4

12108 16 18 22 24 26

DEVELOPMENT TIME (MINUTES

201464

30

28

0.3

46

14 20

DEVELOPMENT TIME

NOTICE: The sensitometric curves and data in this publication represent product tested

under the conditions of exposure and processing specified. They are representative of

production coatings, and therefore do not apply directly to a particular box or roll of

photographic material. They do not represent standards or specifications that must be met

by Eastman Kodak Company. The company reserves the right to change and improve

product characteristics at any time.

MINUTES

28

30

26242218168 10 12

8 KODAK PROFESSIONAL PLUS-X 125 Film / 125PX • F-4018

Page 9

Spectral Sensitivity Curve

3.0

Effective Exposure:

Diffuse Visual

2.0

*

1.0

LOG SENSITIVITY

0.0

-1.0

250 300 350 400 450 500 550 600 650 750700

*Sensitivity = reciprocal of exposure (erg/cm ) required

1.4 seconds

WAVELENGTH (nm)

to produce specified density

D = 0.30>min

D = 1.00>min

2

KODAK PROFESSIONAL PLUS-X 125 Film / 125PX • F-4018 9

Page 10

KODAK PROFESSIONAL PLUS-X 125 Film / 125PX

MORE INFORMATION

Kodak has many publications to assist you with information

on Kodak products, equipment, and mate rials.

The following publications are available from dealers who

sell Kodak p roducts, or you can conta ct Kodak in your

country for more information.

E-30 Storage and Care of Photographic Materials—

ED-1 Processing KODAK Black-and-White Films and

E103BF KODAK PROFESSIONAL Black-and-White Films

E103BP KODAK PROFESSIONAL Black-and-White

E103CF Chemicals for KODAK PROFESSIONAL

F-2 Pathways to Black and White

G-10 KODAK AZO Paper

G-16 KODABROME II RC Paper

G-21 KODAK POLYCONTRAST III RC Paper

G-23 Toning KODAK Black-and-White Materials

G-24 KODAK POLYMAX Fine-Art Paper

G-26 KODAK POLYMAX II RC Paper

G-27 KODAK PANALURE SELECT RC Paper

G-28 KODAK P-MAX Art RC Paper

J-24 KODAK HC-110 Developer

J-78 KODAK Developer D-76

J-86

J-87 KODAK T-MAX 100 Direct Positive Film Developing

J-109 KODAK XTOL Developer

Before and After Processing

Papers

Papers

Black-and-White Films

KODAK T-MAX Developers

Outfit

For the latest version of tech ni cal support publication s fo r

KODAK PROFESSIONAL Products, visit Kodak on-line at:

http://www.kodak.com/go/professional

If you have questions about KODAK PROFESSIONAL

Products, call Kodak.

In the U.S.A.:

1-800-242-2424, Ext. 19, M onday–Friday

9 a.m.–7 p.m. (Eastern time)

In Canada:

1-800-465-6325, Mon day–Friday

8 a.m.–5 p.m. (Eastern time)

Note: The Kodak materials described in this publication for

use with KODAK PROFESSIONAL PLUS-X 125 Films are

available from dealers who supply KODAK

PROFESSIONAL Products. You can use other materials,

but you may not obtain similar results.

The following books are available from photo-specialty

dealers who sell Kodak products:

F-5 KODAK Professional Black-and-White Films

R-20 KODAK Black-and-White Darkroom DATAGUIDE

KODAK PROFESSIONAL PLUS-X

125 Film / 125PX

KODAK Publication No. F-4018

Kodak, D-76, Duraflo, HC-110, Microdol -X, Phot o-Flo, T-Max, T-Max RS, Tri-X,

Versamat, Wratten , an d X tol are trademarks.

New 2-02

Printed in U.S.A.

Loading...

Loading...