Page 1

T

T

e

e

c

c

h

h

nii

n

c

c

all

a

Trr

T

aii

a

nii

n

n

n

g

g

G

Pre-site Inspection……………………… Page 2

Printer Features………………………… Page 4

Printer Installation…………………....... Page 7

Printer Calibrations……………………………… Page 14

Networking………………………………………. Page 18

Print Mode/Dryer Guidelines…………………... Page 23

G

uii

u

d

d

e

e

Printer Operation Tips…………………. Page 27

Software Control Tips…………………. Page 30

Printer Maintenance…………………. Page 31

Bulletin Reference List………………… Page 40

Error Message Codes…………………. Page 41

Printer Grounding/Static Control……. Page 65

Technical Training Guide

Page 2

KODAK 1200i WIDE-FORMAT PRINTING SYSTEM

PPrreessiittee IInnssppeeccttiioonn

Installation Requirements

The Kodak 1200i wide-format printing system requires approximately 15’ x 20’ (4 x 6

meters) square space available for the printer un-boxing and setup. Additionally, vice

grips/pliers may be needed to aid in support bracket removal. Four (4) people will need

to be available to assist in the setup.

((pprree--iinnssttaallllaattiioonn)

)

Operational Space Requirements

Ensure printer is placed onto a level floor surface – use a

fluid level to verify printer is properly leveled.

Printer footprint dimensions are illustrated below:

Technical Training Guide 2

Page 3

KODAK 1200i WIDE-FORMAT PRINTING SYSTEM

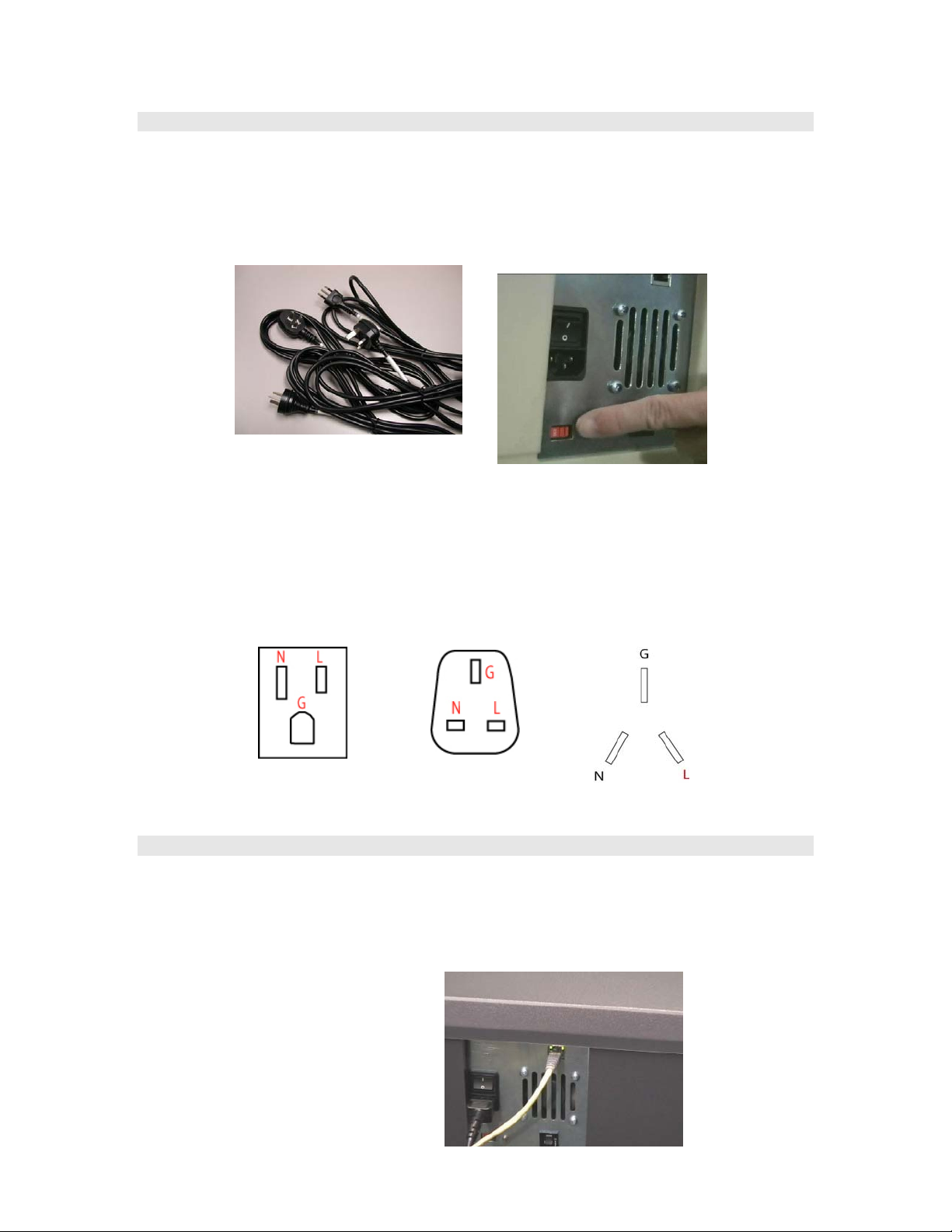

Power Requirements

Either 115 or 230 volt, 50/60Hz source power is required for the printer. All major power

cord standards are supplied with each printer. The voltage selector switch is positioned

to the 230 volt position during shipping; ensure selector switch is set to either 115 or 230

for the appropriate region. The printer typically uses 1100 watts of power during normal

operation (when dryer is engaged) –a dedicated 20 amp circuit is ideal.

NOTE: The printer must be properly grounded in accordance with regional and general

equipment/electrical grounding guidelines or improper print operation may result and

personnel hazards may result if inadequate grounding is provided. Verify a ground line

(G) is present at power receptacle or power strip prior to installing the printer, refer to

receptacle examples below.

US/Canada

UK/Singapore/

Hong Kong

China

Connectivity Requirements

The printer can be connected directly to a computer via an Ethernet crossover cable or

via a regular Ethernet cable (RJ-45) connected to a 100BaseT HUB/Switch/Router

placed on the network. For DHCP (Dynamic Host Control Protocol) networks a static IP

address (dedicated address for printer) must be made available; consult a network

administrator to verify system setup.

Technical Training Guide 3

Page 4

KODAK 1200i WIDE-FORMAT PRINTING SYSTEM

PPrriinntteerr FFeeaattuurreess

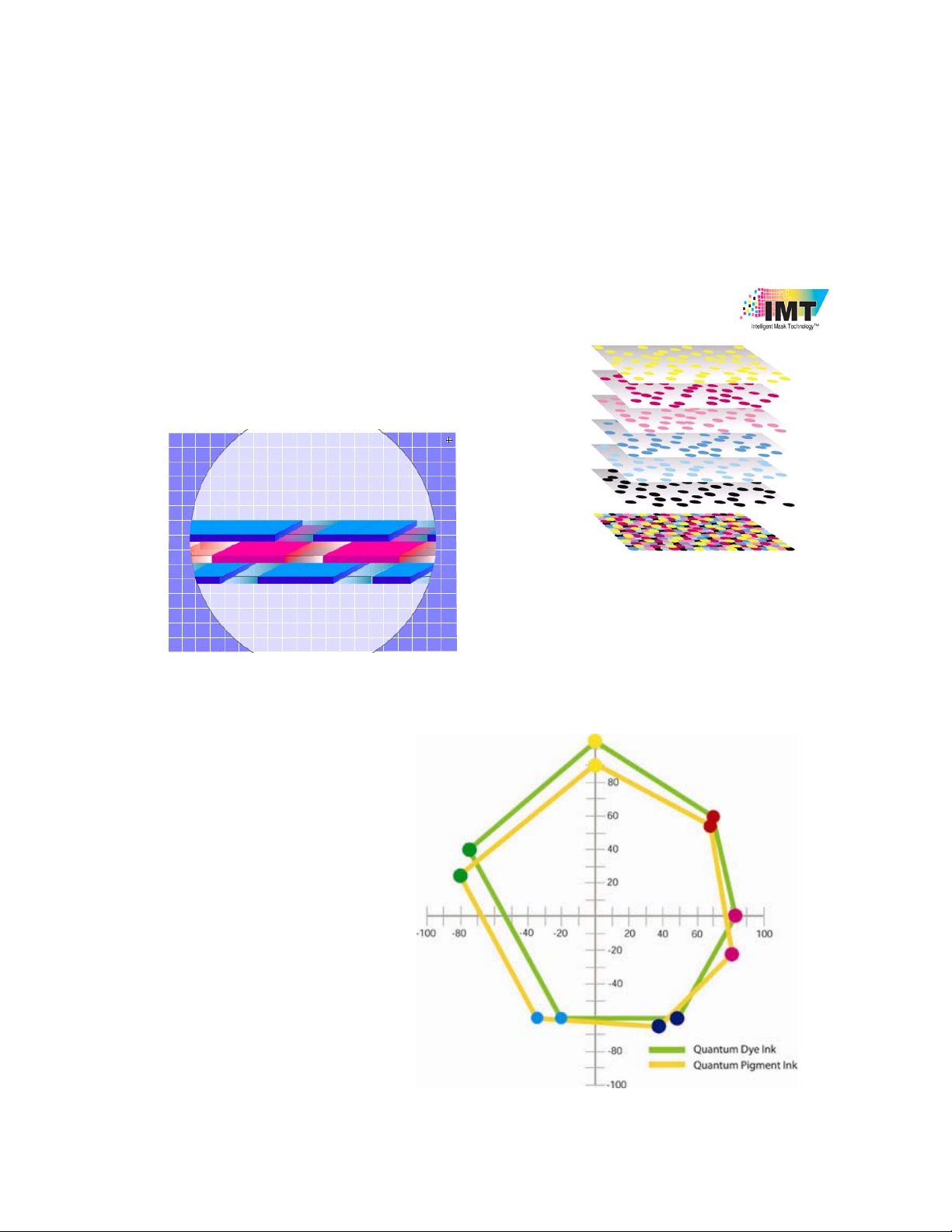

1. Intelligent Mask Technology (IMT)

- A simple screen that is applied to image

files by the printer to determine which dots

are printed during each swath (or print pass)

in a particular print mode selection. A

different print mask is applied for each color

plane.

- Two thermal-based ink types are available with the Kodak 1200i Wide-Format Printing

system: Quantum-Dye (Qi-Dye) and Qi-Pigment (Qi-Pig). The typical color range of the

Qi-Dye ink is approximately

17,500 and offers outstanding

color pop and with the majority of

inkjet-coated media types in the

industry. This ink is particularly

strong in the backlit applications

market. Qi-Pigment ink color is

near the16,500 range and offers

exceptionally brilliant color for a

thermal-based ink, particularly

on the Rapid Dry and

indoor/outdoor media sets.

Technical Training Guide 4

Page 5

KODAK 1200i WIDE-FORMAT PRINTING SYSTEM

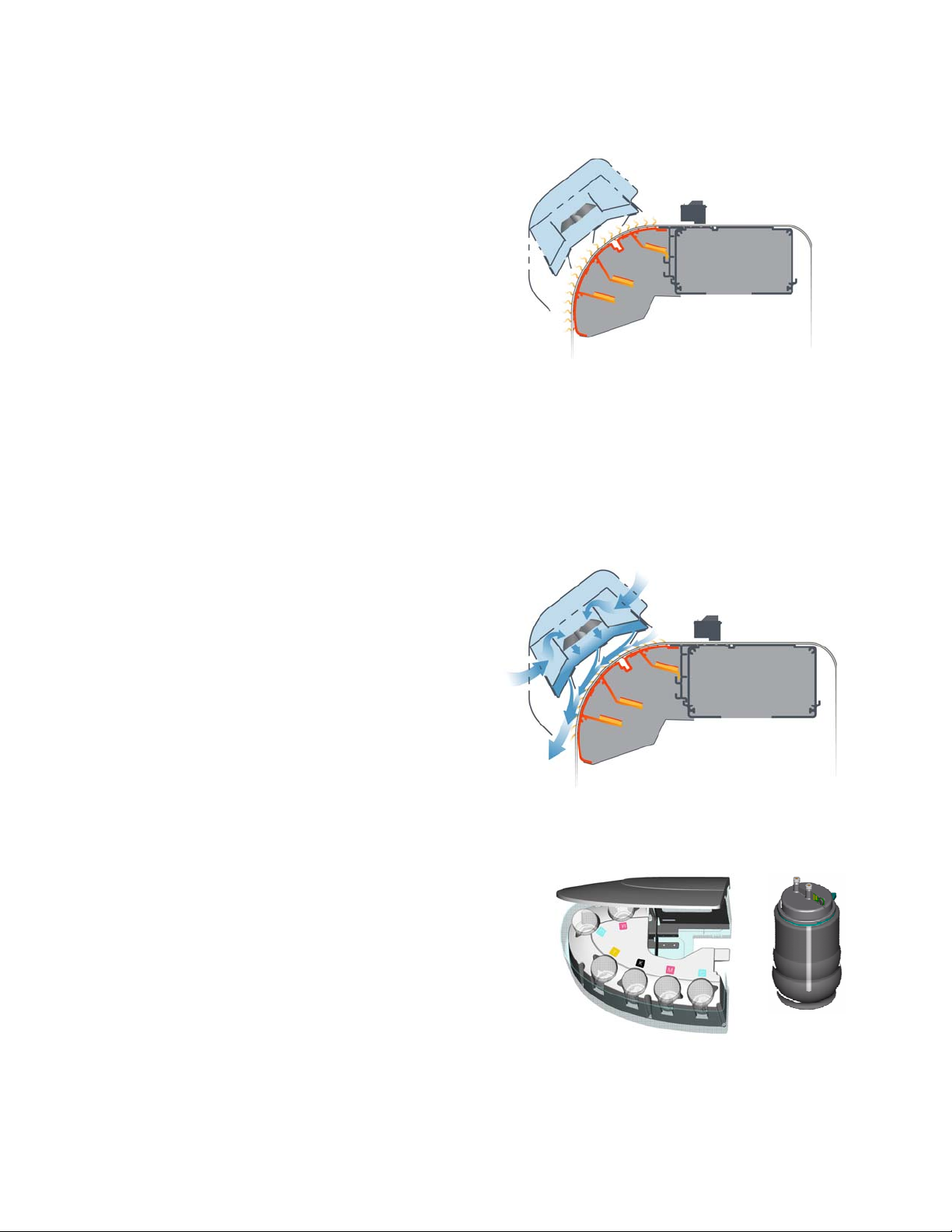

2. Rapid Dryer Technology

The advanced dual-component drying system

uses the principle of conducted heat to dry

printed images with much greater efficiency

than can be achieved with hot air dryers. The

media web is fed over a heated aluminum

nose that is curved to maintain intimate

contact with the back of the web for effective

heat transfer. The nose is an isolated

extrusion that incorporates three longitudinal

fins with an electrical heating strip mounted to

each fin inside the curve (each of the three

electrical heating strips provide up to 323 watts of power). This design evens out heat

flow to minimize cold spots under high density printed areas across the web without

the long warm-up time of a much thicker section. Ambient air flow is used to pull away

moisture and improve drying efficiency by another 30% over that achieved with the

heated nose alone. The application of ambient air flow also allows the system to apply

more drying power at a lower peak temperature for reduced risk of media damage.

Overall the drying system uses approximately 25% less energy over other drying

systems.

An ambient fan driven air plenum is used

to distribute air flow evenly across the

print width. Air flow is downward, carrying

heat away from the print zone to improve

nozzle reliability and to reduce the risk of

edge curl. An intelligent control system

regulates electrical power to achieve and

maintain temperature set points between

35 and 55 degrees C.

The air plenum may be lowered by

removing two locking pins to perform

printer maintenance.

3. Ink System

a. Ink Reservoir:

- 6 ink reservoirs (ML, CL, Y, K, M, C)

- Ink bottles are easy to replace

- Encrypted for ink monitoring (700 ml)

- One set of ink lines; switch over capability

(Dye or Pigment)

- Plug and Play ink refill bottle (700 ml) with

septum/needle interface

- Clean-hands installation

- Mechanical color keying of bottle

Technical Training Guide 5

Page 6

KODAK 1200i WIDE-FORMAT PRINTING SYSTEM

c. Intermediate Reservoir:

- Intermediate reservoir located below ink bottle

- Provides consistent ink supply pressure (50 ml capacity)

- Replace ink on-the-fly (30 seconds); prevents job interruptions

- Optical sensor monitors reservoir ink levels [ink level LOW

warning sensor (<30ml; ~10-30 minutes) and ink level OUT stop

(<20ml), protects cartridge]

d. Ink Supply Dampers and Septum

Valve System:

- Ink flows through damper into a septum

assembly (spring actuated ball valve to

shutoff ink when cartridges are removed)

Note: ink is filtered at the cartridge only.

e. Carriage Assembly:

- Robust carriage bushing design; thick bushings with 2 shims for better

dimensional stability. Bushings are secured by bushing retainers.

- Bushings are grooved to minimize the effect of dirt and debris.

- Cartridge doors secure and bias print heads into proper position.

- One-step cartridge installation process; remove tape and install.

f. Cartridge / Printhead:

- Increased productivity with 640 nozzle print

heads.

- Clean hands shipping and installation.

- Foam filled, eliminate tubing and needles.

- Ink filter.

- 700 ml warranty; 2800 ml shutoff.

- 1400 ml average print head life.

Technical Training Guide 6

Page 7

KODAK 1200i WIDE-FORMAT PRINTING SYSTEM

g. Service Station:

- Clean hands cartridge maintenance through service station

(Cartridge cleaning/System Prime).

- Ink is deposited into a waste disposal bottle.

h. Auto Clean Unit:

- Door Magnet

- Suction pump/motor (used for priming ink lines)

- Bottle full sensor (IR)

- Ink waste bottle

- Bottle present/empty sensor ((IIRR))

Technical Training Guide 7

Page 8

KODAK 1200i WIDE-FORMAT PRINTING SYSTEM

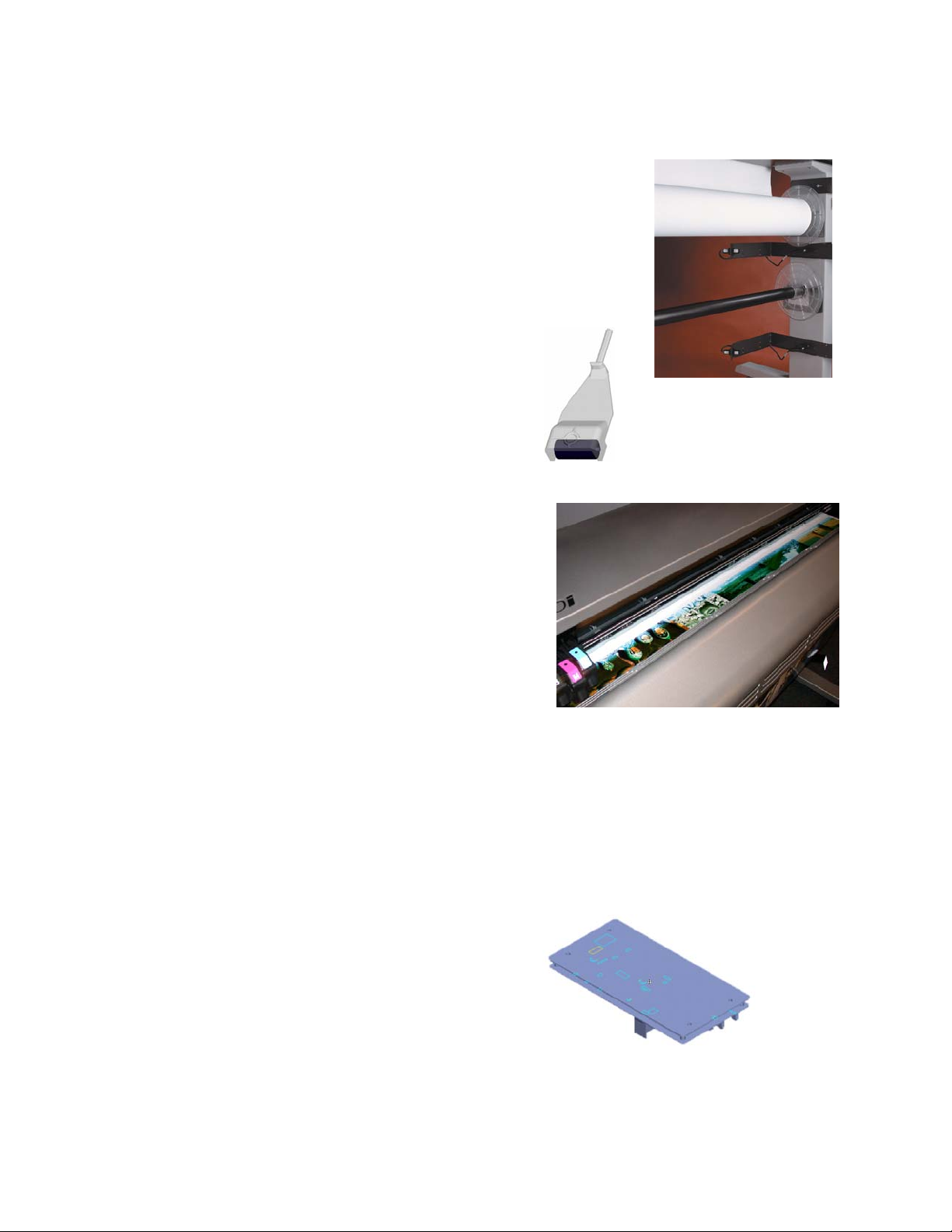

4. Media Handling System

- Four media supply modes are available: Sheet, Roll, Roll 2 and

TakeUp

- Media rolls can be easily exchanged with the removable media

spindles

- The Autoload paper sensor has a 6 second delay when media

is manually loaded at rear of printer

- The Roll 2 mode allows for a second roll of media to be loaded

onto the lower roller (no takeup mode available)

- The lower roller, new heavy duty stepper motor,

and new pinch roller design help better control

feed, paper travel and line length accuracy.

5. Print Speeds:

60 inch printer

High Speed Mode (2 pass): 220 sfph (20.4 smph)

Productivity Mode (3 pass): 150 sfph (14 smph)

Fine Mode (4 pass): 115 sfph (10.7 smph)

Enhanced Mode (6 pass): 75 sfph (7.0 smph)

8-Pass Print Mode 58 sfph (5.39 smph)

12-Pass Print Mode 37 sfph (3.44 smph)

High Quality (16 pass): 26 sfph (2.8 smph)

42 inch printer

High Speed Mode (2 pass): 195 sfph (18.1 smph)

Productivity Mode (3 pass): 140 sfph (13.0 smph)

Fine Mode (4 pass): 104 sfph (9.6 smph)

Enhanced Mode (6 pass): 70 sfph (6.5 smph)

High Quality (16 pass): 23 sfph (2.5 smph)

Note: printer ships with 64 MB SDRAM and is not up gradable; 32 MB RAM on Main PWA; HPGL/2 (vector file formats) is not supported

6. Power Supply:

Input Operating Range

90 – 132 and 180 – 264 VAC

Input Operating Frequency Range

43 – 67 Hz

Power Consumption

Typical: 1035 W; Idle: 20 W; Maximum: 1225 W

Output Voltage

24 VDC

Output Current

8.3 Amp. Maximum

Technical Training Guide 8

Page 9

KODAK 1200i WIDE-FORMAT PRINTING SYSTEM

Printer Installation

(Quick Steps)

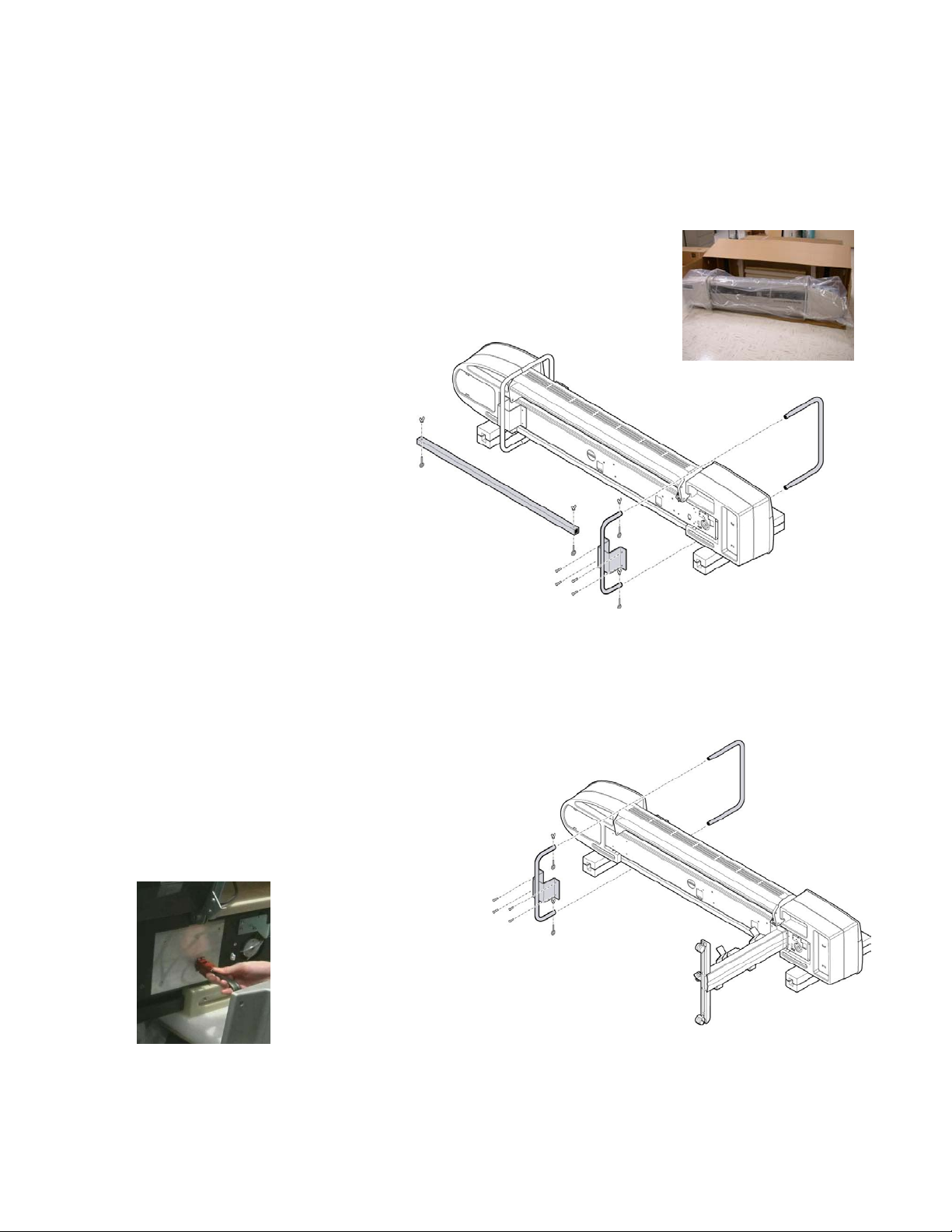

Step 1: Shipping Brackets Removal

- Rotate printer head box 90 degrees onto one side and remove

printer from large shipping box by pulling out and away from box.

- Before removing the shipping support brackets ensure the printer

is properly placed and balanced

on two or three strips of packing

foam provided.

- Remove the two (2) bolts

securing the metal crossbeam

between the support brackets.

- Remove upper and lower

shipping support brackets (four

bolts total) and install

appropriate stand leg to balance

the printer. Remove wing nut,

retaining bolt, and 4 screws.

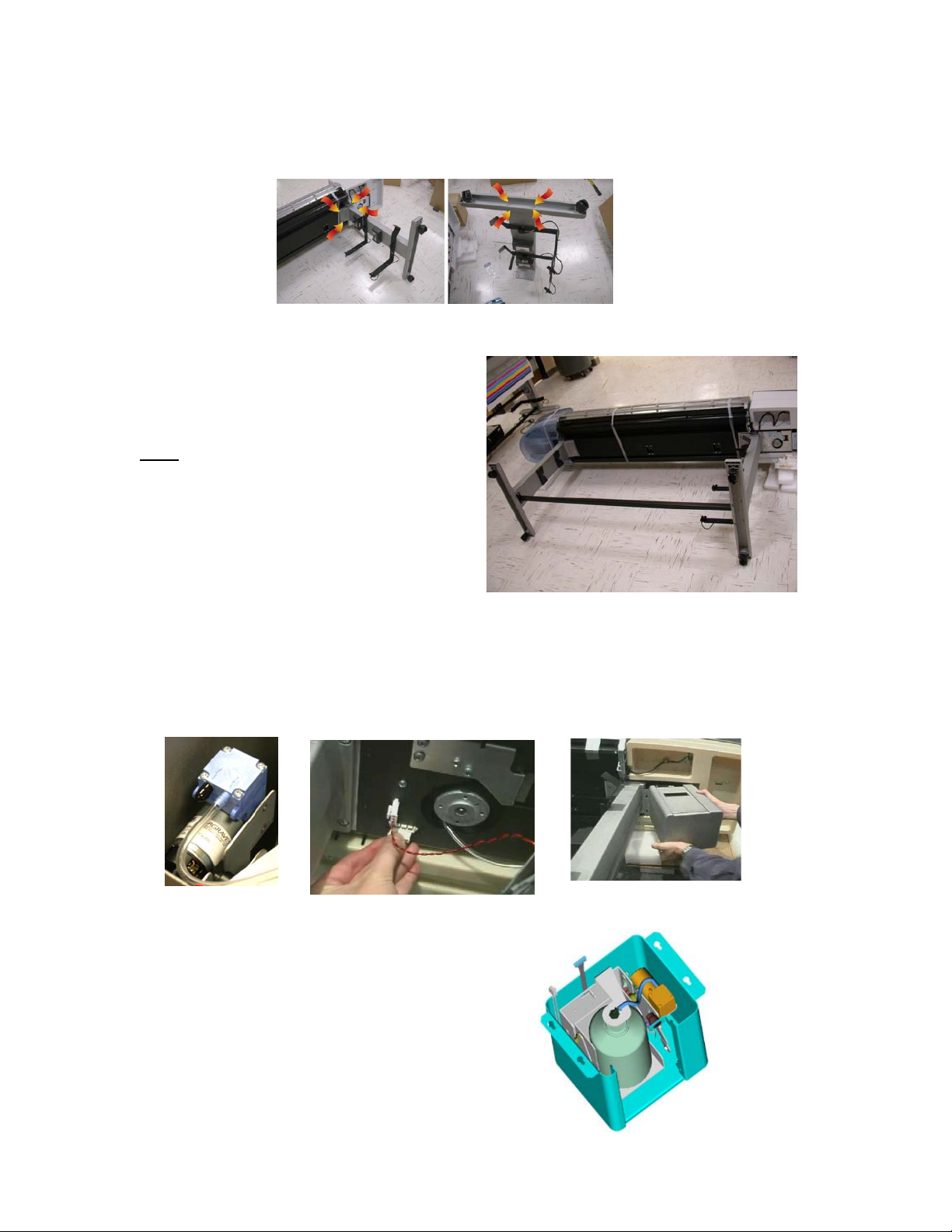

Step 2:

- When installing the right stand leg attach electrical plug connection to printer base;

ensure the plug is aligned straight and square onto the connector to prevent damage to

the electrical pins. CAUTION: plug pins

are extremely fragile; ensure restraining

clips are secure.

- ‘Loosely’ attach the eight (8) stand leg

screws to the printer base; this will allow

for proper installation of the stand’s

crossbar.

Media System Installation (1 electrical connection)

CAUTION:

Avoid pushing

plug into the

platen assembly.

Technical Training Guide 9

Page 10

KODAK 1200i WIDE-FORMAT PRINTING SYSTEM

NOTE: It is suggested to assemble the right stand leg first, then attach the assembly to

the printer. Repeat with left stand leg assembly. Do not ‘completely’ tighten the screws

between stand legs and platen – only perform after the crossbar has been installed.

Step 3: Crossbar Installation

- Install crossbar between stand legs and

tighten four (4) securing screws.

- Tighten the eight (8) stand leg screws

after

the crossbar has been properly

installed.

Step 4:

- To attach the auto clean unit first connect the ink tube line to the pump nipple. Attach

both electrical plug connections to respective jacks. Angle the assembly at a 45 degree

angle to connect over the 4 securing screws. Tighten four (4) securing screws.

Auto Clean Unit System (2 electrical connections/1 tubing connection)

- Verify the disposal bottle is installed and tubing

connections to bottle are intact.

Technical Training Guide 10

Page 11

KODAK 1200i WIDE-FORMAT PRINTING SYSTEM

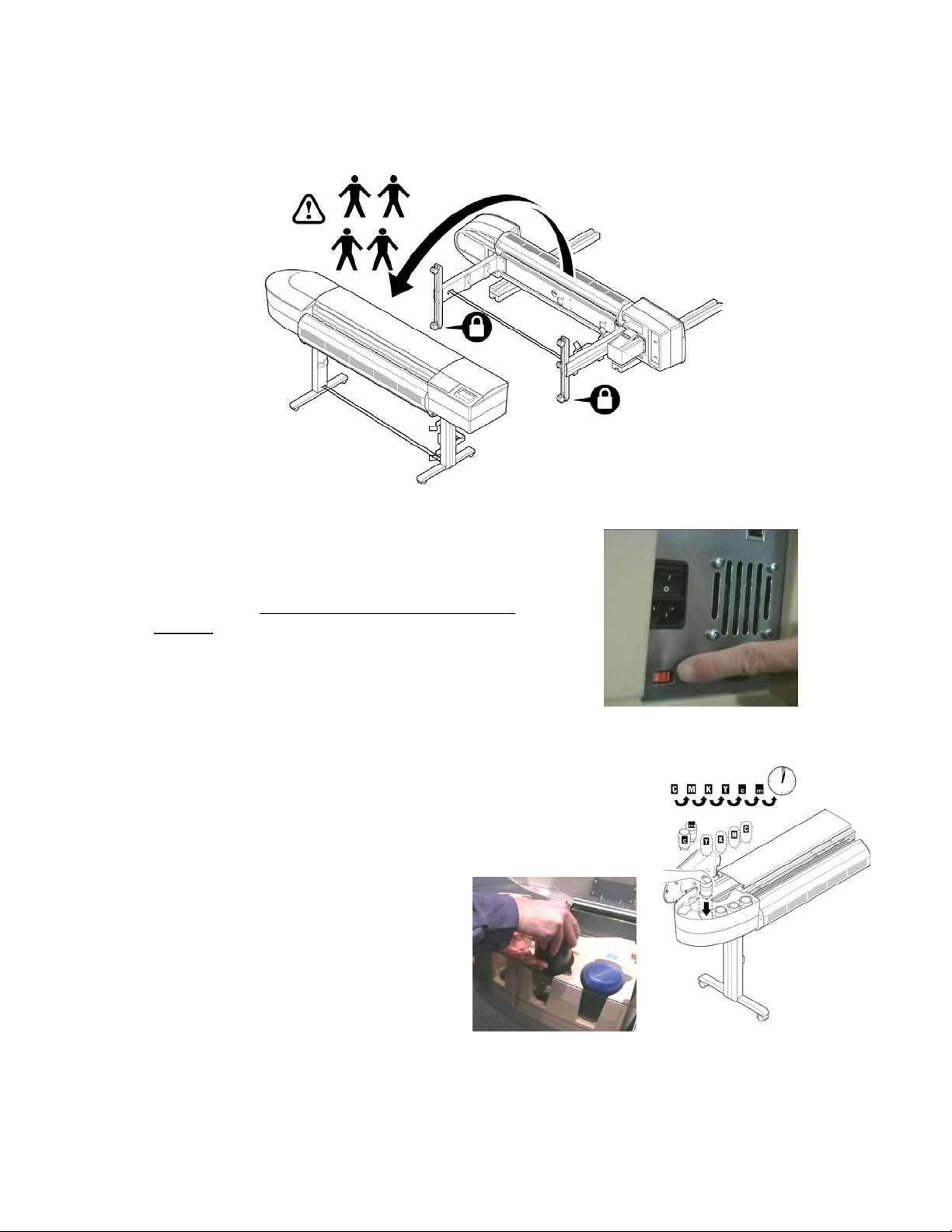

Step 5: Raise Printer

- Using a four (4) person lift gently raise printer to the standing position.

Step 6: Voltage Configuration (for dryer system)

Prior to powering on printer ensure the voltage selector

switch is set to either 115V or 230V depending on line

source.

NOTE 1: The voltage selector ships in the 230V

position.

NOTE 2: the circuit beaker will ‘pop’ out in an over-

current condition and will need to be replaced if this

occurs.

Step 7:

Reservoir Installation

When installing the six (6) ink bottles ensure each bottle is

installed straight up and down to avoid damaging pins at

intermediate reservoir (located at base).

Firmware Note:

C1 = C

M1 = M

Note: wait 5 minutes prior to

conducting line filling operation (using

‘Pump On’ from the control panel or

ink line may not fill properly.

L

L

NOTE: during normal operation you will have only 30 seconds to change ink

bottles during print operations or a printer STOP error will occur.

Technical Training Guide 11

Page 12

KODAK 1200i WIDE-FORMAT PRINTING SYSTEM

Step 8: Ink Line Filling

- After installing the 6 ink bottles and waiting 5 minutes, select

‘Access Cartridges’.

- Install the Cartridge with Tube Assembly into the first stall

position; attach tube needle to right side plate septum fitting

(under access cover).

NOTE: the cartridge with tube

assembly (+plug bar) ships in a

small box within the printer

head box.

- Activate tube fill by selecting and holding

Prime Menu – Service Station Menu – ‘Pump On’

Utility Menu -

.

- The fill process takes approximately 4-16 seconds per

color. When ink reaches the cartridge tube release the

‘Pump On’ selection. Repeat procedure for remaining colors.

NOTE:

To flush the ink system refer to

Technical Bulletin 2. Only use the

authorized Flush Kit (part number

221984-00) to evacuate ink lines and clean the system of ink

prior to printer transport.

Step 9: Cartridge Installation

Open cartridge door by pulling up on door at a 45 degree angle.

Remove tape from cartridge. Slide cartridge into cartridge stall and

close cartridge door until it locks.

Note: door must be closed to properly bias cartridge position.

Technical Training Guide 12

Page 13

KODAK 1200i WIDE-FORMAT PRINTING SYSTEM

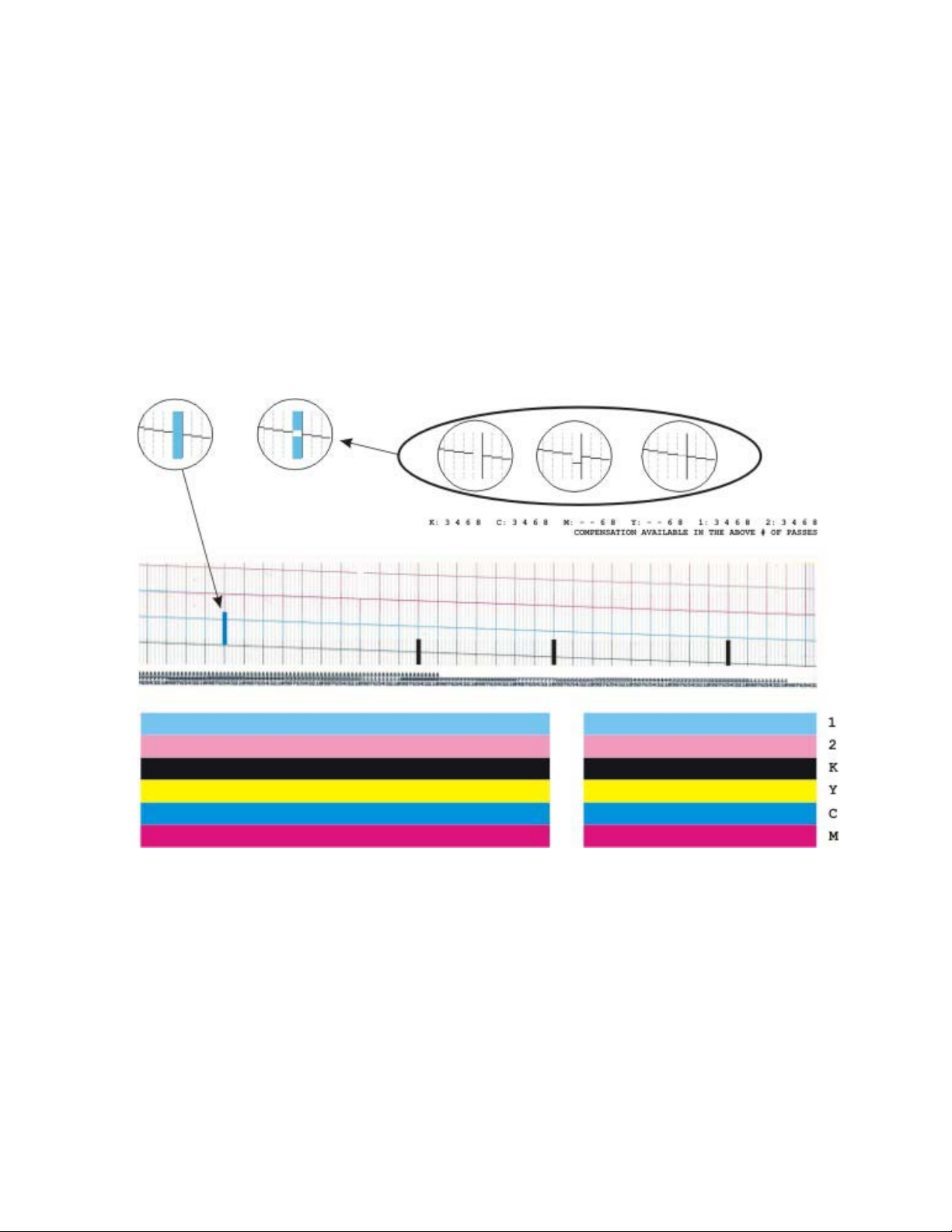

Step 10: Activate ‘Prime All’ Test Pattern

- To print the Prime pattern select Utility Menu - Prime Menu - Prime All. Verify

print head nozzle performance - ensure diagonal lines are smooth and clogged jets are

not present.

- If necessary perform Manual Jet Bypass for clogged or misfiring jets. Select

Menu – Calibration Menu – Open Jet Menu – Edit List Menu.

Scroll to particular

jet number which has the clog/problem and toggle off. Select Ok to save selection.

NOTE: A few ‘streaks’ or lines may appear in the pre-prime pattern area, this is

considered normal due to the unique 640 jet pattern printed.

Utility

Technical Training Guide 13

Page 14

KODAK 1200i WIDE-FORMAT PRINTING SYSTEM

Step 11:

Printer Calibrations

NOTE: Refer to Technical Bulletin 1 for the specific printing application required. Most

customers should use the following procedure to obtain the best print quality output.

A. Activate the dryer system to warm the printer up for optimum calibration

performance. Wait approximately 5 minutes after completing steps 1a and 1b below

before proceeding to Step 2.

a) Set dryer to a heat setting of 4 (Low Heat, Fans). At control panel select

Dryer Menu - Dryer Setting.

Select Next or Prev to a setting of 4 and press Ok.

Setup Menu –

b) Activate the dryer. At control panel select

Menu – Accessory Menu – Dryer Status.

Utility Menu – Service Menu – Diagnostics

The T1 and T2 (temperature sensors) will begin

to slowly climb to the target temperature value (i.e. 40 degrees C).

NOTE: the new calibration menu structure is different from the previous firmware

version; please review the 3 calibration paths available:

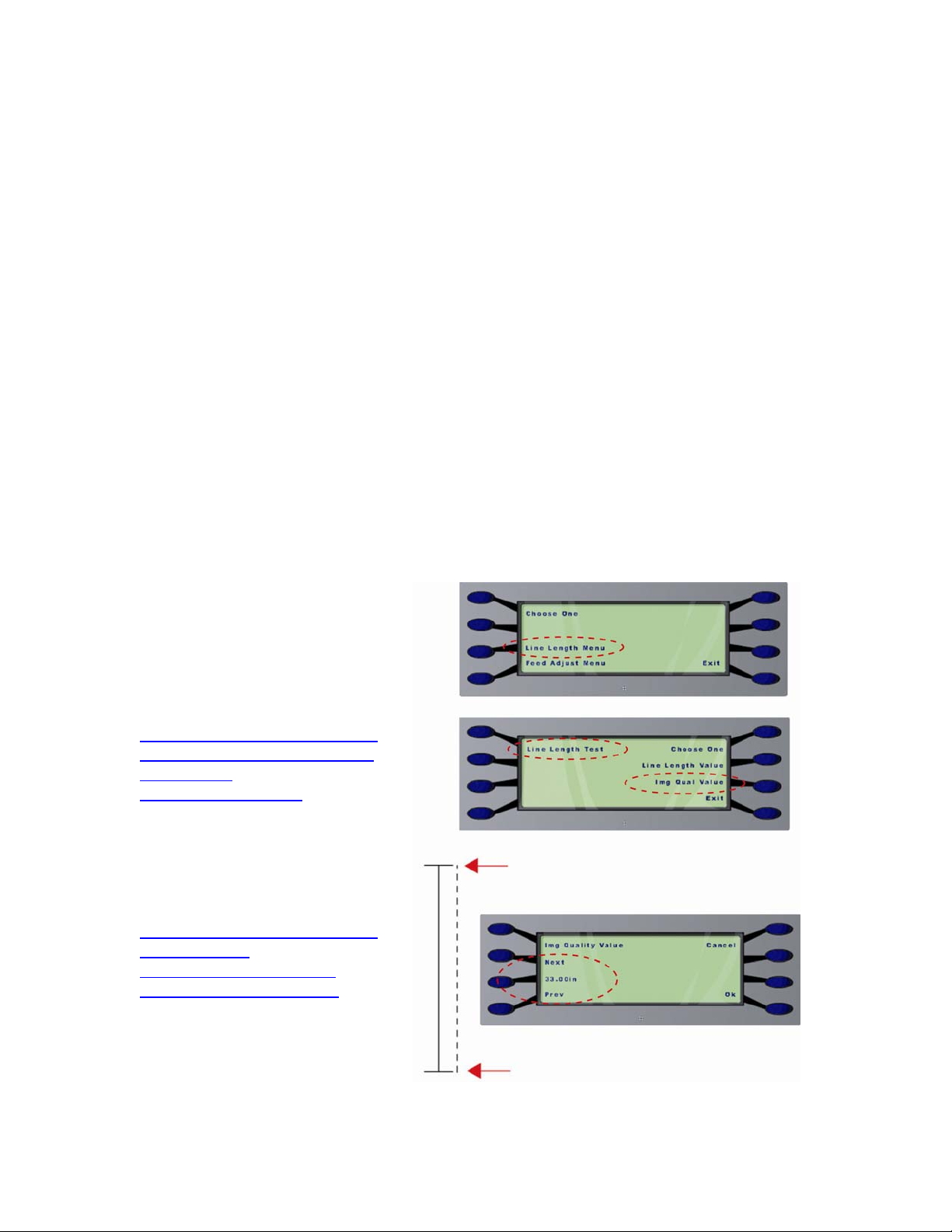

B. Activate the Line Length Test under Line Length Menu (

Menu – Paper Calib Menu - Line Length Menu – Line Length Test

Utility Menu – Calibration

), using a draftsman

ruler, measure and enter exact

value under

Image Quality Value

(i.e. 33.02 inches/83.90 cm).

NOTE: a 35 inch ruler print file

is provided on the System CD or

may be downloaded from the

Encad support web site

http://www.encad.com/Support/

Tech-Support-Resources/RTLTest-ImageDownloads/index.asp

The file can be printed using the

EFPU program supplied on

System CD (load software

utilities) or can be obtained from

the following link:

http://www.encad.com/Support/

Tech-SupportResources/ENCAD-TechSupport-Utilities/index.asp

Technical Training Guide 14

Page 15

KODAK 1200i WIDE-FORMAT PRINTING SYSTEM

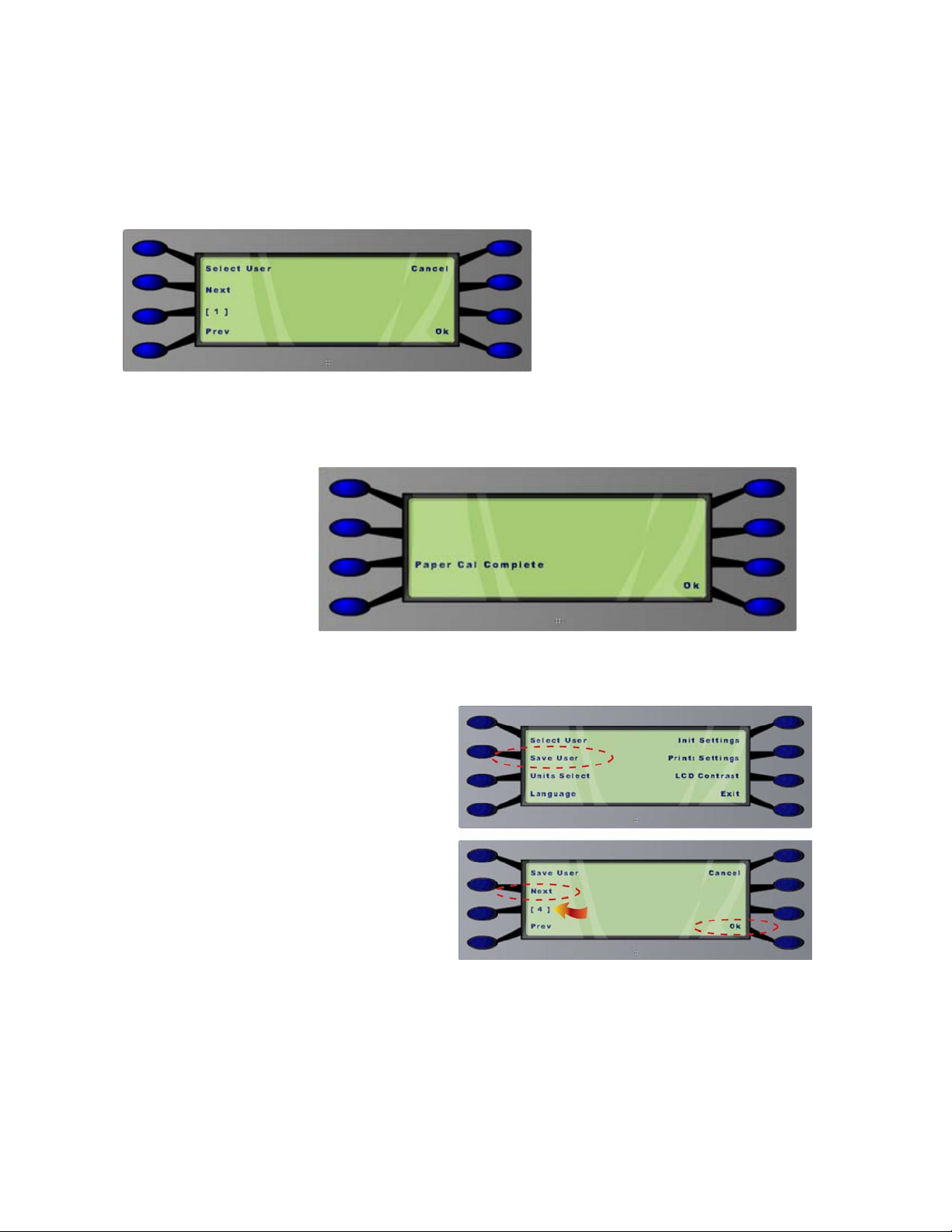

C. When printer calibration is complete the printer will display the Save User screen.

Select a save user number (i.e. 1 through 8) to be assigned for the media type currently

loaded. Select Ok.

Example Assignments:

User 1: Photo Satin, 180 g

User 2: Premium Backlit, 7 mil

User 3: PP Gls, 8 mil

User 4: Rapid Dry Gls, 190 g

User 5: Photo Gls, 160 g

User 6: Water Res Vinyl

A calibration complete message will be displayed on the control panel display. Select

Ok.

NOTE 1: do not select

‘Select User’ or any

previously entered data

will be overwritten.

Technical Training Guide 15

Page 16

NOTE 2: When new media is loaded (or changed) the unique user setting

assigned must be chosen, select

Select the user

User.

number (1 through 8) that

was assigned for a

particular media type.

Select Ok.

Example Assignments:

User 1: Photo Satin, 180 g

User 2: Premium Backlit, 7 mil

User 3: PP Gls, 8 mil

User 4: Rapid Dry Gls, 190 g

User 5: Photo Gls, 160 g

User 6: Water Res Vinyl

NOTE 3: If the printer is powered off and on, User Setting 1 is

automatically initialized as a default operational setting. Refer to NOTE 2

above to “set” the proper calibration value for the media type loaded. If

the incorrect user setting is used then banding in printed output may

result due to the incorrect paper feed value being utilized. Media Feed

Adjust controls are better optimized and controlled from the Kodak 1200i

software suite.

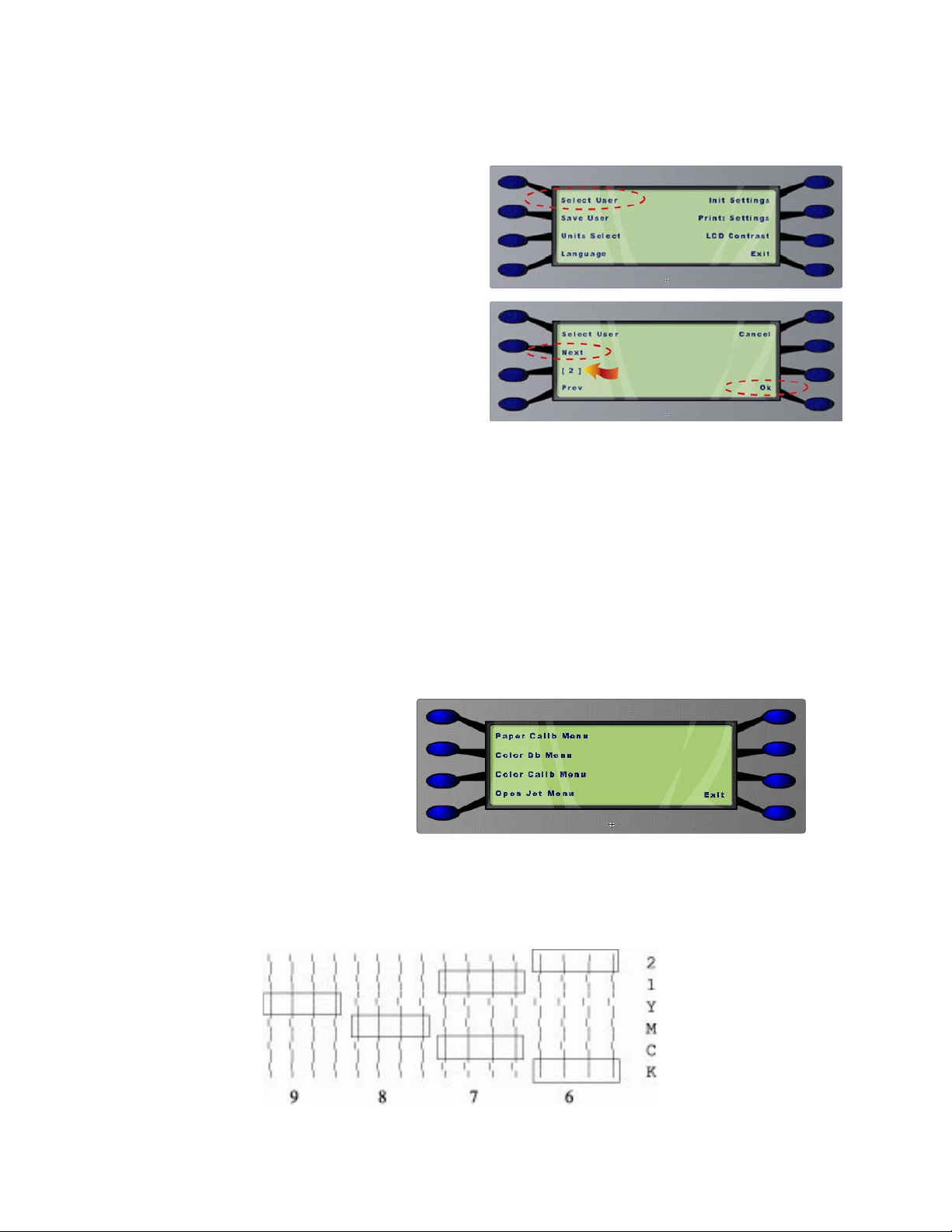

D. Perform the other 3

calibrations as normal (Color

Deadband, Color Calibration

Horizontal, and Color Calibration

Vertical):

a) Color Db. Select Utility

Choose best group of aligned bars for each color. Perform whenever a new

Test.

Menu – Calibration Menu – Color Db Menu – Color Db

cartridge is installed.

KODAK 1200i WIDE-FORMAT PRINTING SYSTEM

Setup Menu – User Setup Menu – Select

Technical Training Guide 16

Page 17

b) Color Cal Horizontal. Select

Horiz. Calib Test.

Choose best group

Utility Menu – Calibration Menu – Color Calib Menu -

of aligned bars for each set of colors.

Perform whenever a cartridge is

removed.

c) Color Cal Vertical. Select

– Calibration Menu – Color Calib

Menu - Vert. Calib Test.

Utility Menu

Choose best

group of aligned bars for each set of

colors. Perform whenever a

cartridge is removed or if the feed

adjust value is adjusted.

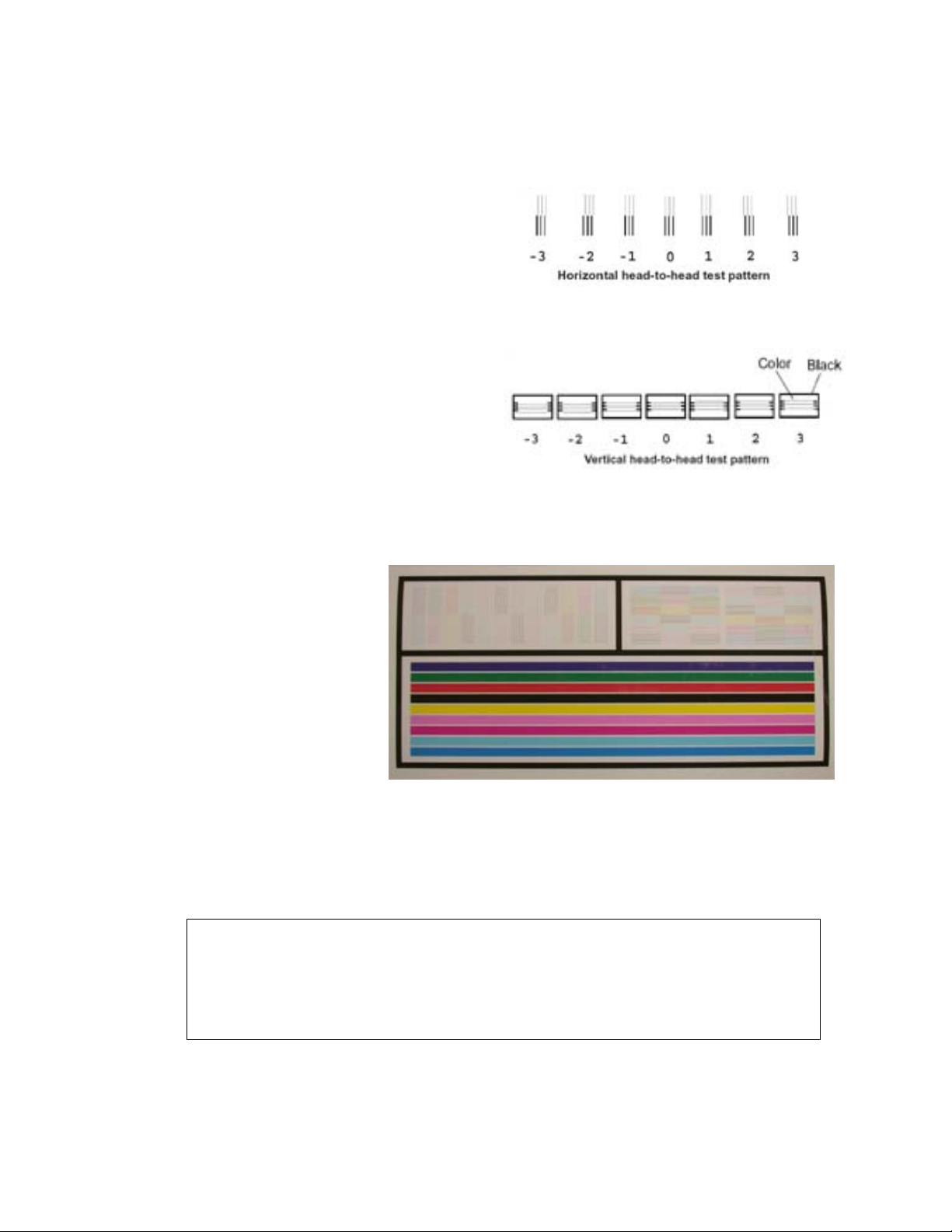

E. Activate the Internal Test Print. Select

will help verify the printer

calibrations are correct.

Inspect the vertical and

horizontal alignment between

all colors in the upper two

sections of the test print. If

vertical or horizontal

alignment is not achieved

then repeat step D.

KODAK 1200i WIDE-FORMAT PRINTING SYSTEM

Utility Menu – Service Menu – Test Print. This

Step 12: Best Quality Mode

To obtain the highest or optimum print quality mode from the printer place the print pass mode to 16.

To set the print-pass mode. Print pass mode will impact image output quality – refer to the

guidelines in the chart below:

Print Pass Modes: 2, 3, 4, 6, 8, 10, 12, 16

High speed print modes shown in BLACK

Default print mode shown in RED

Quality print modes shown in BLUE

Technical Training Guide 17

Page 18

KODAK 1200i WIDE-FORMAT PRINTING SYSTEM

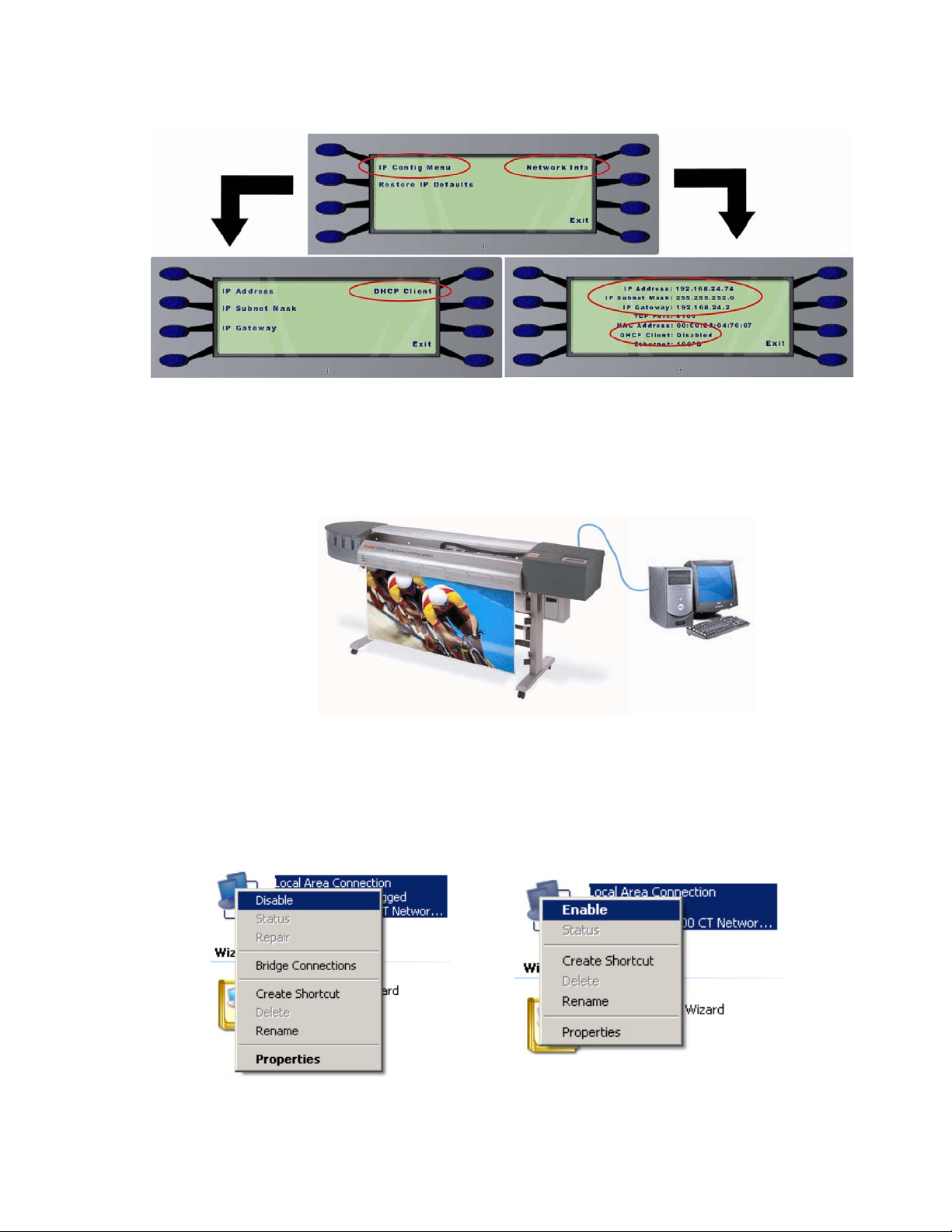

Step 13. Networking (Peer-to-peer - Windows 2000/XP example)

The basic printer networking process is generally a 7-step process, but may vary

depending on network configuration/support. Refer to User System CD for additional

networking information as necessary.

1). At the host computer (i.e. RIP workstation) assign network address settings.

a) At desktop right click on ‘My Network Places’ and select ‘Properties’. At

Local Area Connection window right click and select ‘Properties’. At local area

connection window select Internet Protocol and select ‘Properties’. If a TCP/IP

protocol is not listed then go ahead and install a TCP/IP protocol.

b) Assign workstation IP address (this

address should be one number different,

or very close to, from the printer’s address

for best results, i.e. 192.168.24.73).

Assign the Subnet mask and Default

gateway address (these addresses will

match the printer). DNS addresses are not

required unless internet/web access is

going to be assigned and available.

2). Assign IP address at printer (i.e.

192.168.24.74) – stay in the same ‘range’

as host computer from step 1 (i.e. one

number different from host workstation).

Select Setup Menu – Network Menu – IP

Address. Assign the Subnet mask and

Default Gateway addresses, these addresses must be exactly the same as

the host workstations. (see example above). Ensure DHCP (Dynamic Host

Control Protocol) is disabled unless advised by a network administrator that it

is required (a static IP address will need to be available in these types of

configurations).

Technical Training Guide 18

Page 19

KODAK 1200i WIDE-FORMAT PRINTING SYSTEM

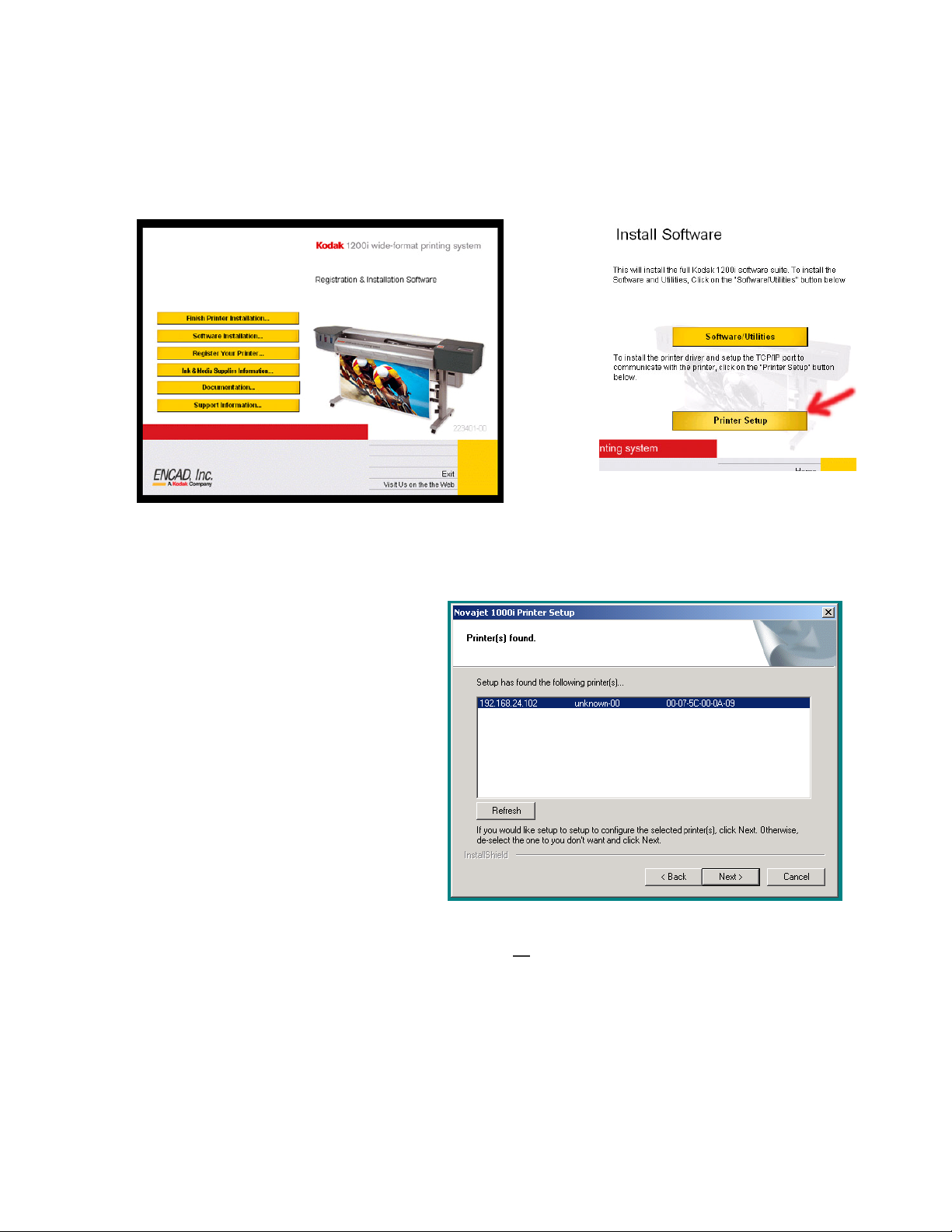

3). Connect Ethernet ‘crossover’ cable between the host workstation and the

printer for direct connections (or an RJ-45 Ethernet patch cable from

HUB/switch to printer if indirectly connected).

4). At desktop right click on ‘My Network Places’ again and select ‘Properties’. At

Local Area Connection window select ‘Disable’. Then select ‘Enable’; this will

ensure the IP addressing has been refreshed (sometimes required on Win

2000/XP systems).

Technical Training Guide 19

Page 20

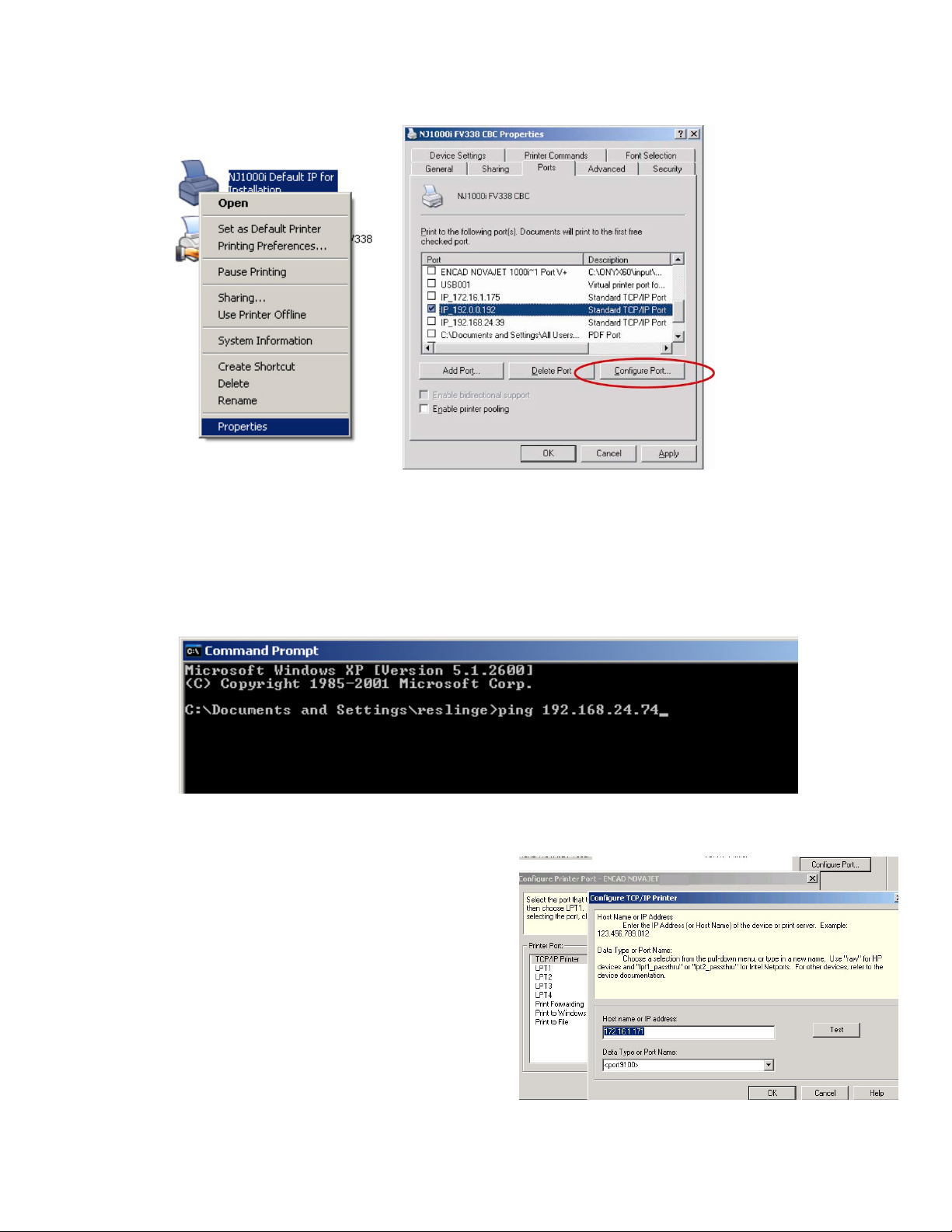

5). Load Windows Driver

a) Load the Kodak 1200i System CD into CD-ROM drive (CD should launch

automatically). Select Software Installation, then Printer Setup.

b) A Windows driver will be loaded (just follow the default button selections). If

configuration is successful the printer will be automatically detected across the

new network (Note: the

picture at right is an

example only; printer name

and IP address should be

displayed correctly). If the

printer is not located

perform steps 1-5 again.

NOTE: Ensure Subnet

mask and Default Gateway

addresses are assigned

and are the same at both

the printer and the

workstation.

c) NOTE: If steps a. and b. above are unsuccessful then install a standard

TCP/IP printer port driver and configure or

existing NJ1000i/Kodak 1200i printer driver (or TCP/IP port) to match the

printers IP address. If necessary add a Standard TCP/IP driver (load Generic

text only driver) if not already installed. Open up Printers (START – SETTINGS

– PRINTERS). Select an existing TCP/IP port and choose ‘Configure Port’ if

making a modification; please note the port name will stay the same.

KODAK 1200i WIDE-FORMAT PRINTING SYSTEM

assign an IP address to an

Technical Training Guide 20

Page 21

KODAK 1200i WIDE-FORMAT PRINTING SYSTEM

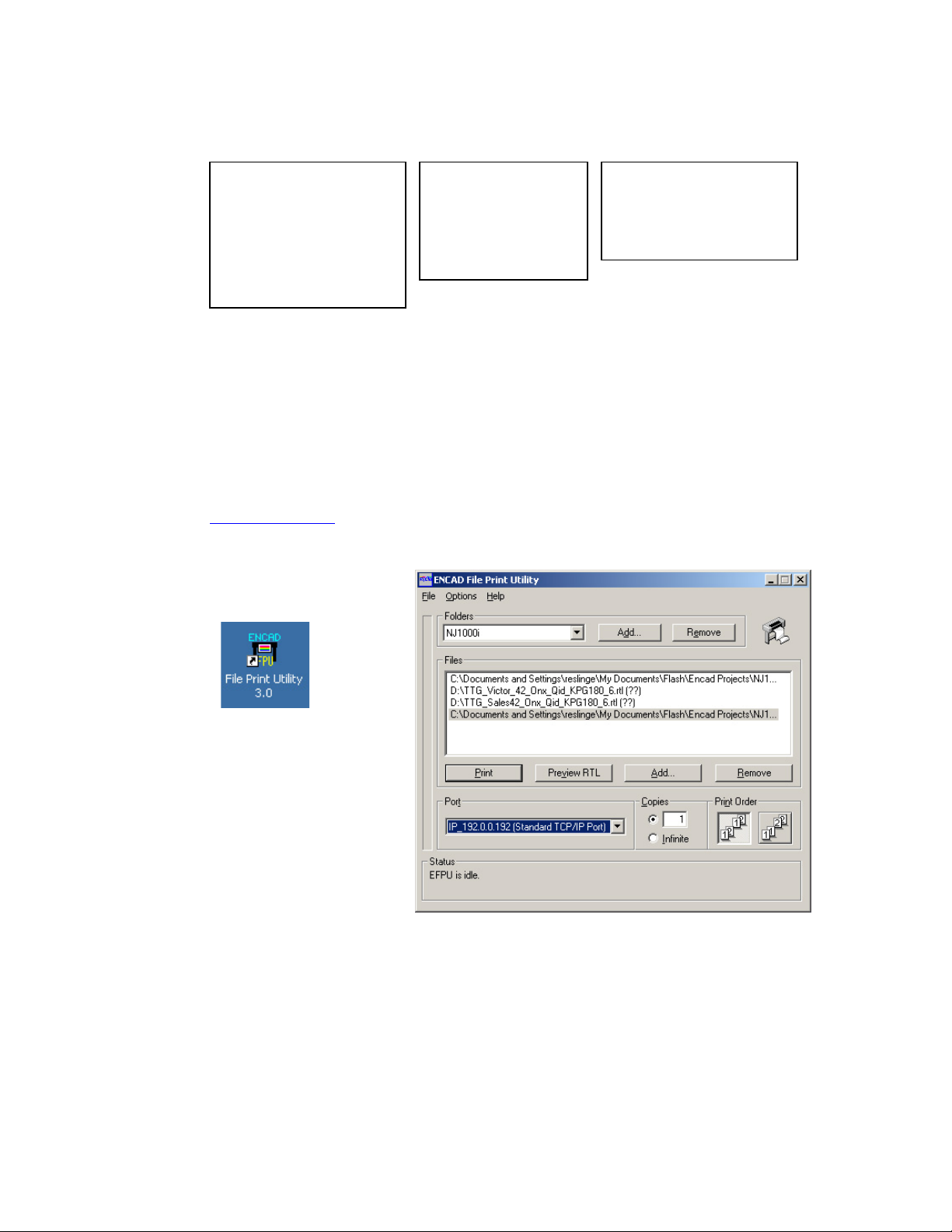

6). At Command Prompt, ping the printer to verify connectivity between computer

and the printer. At computer select START – PROGRAMS – ACCESSORIES –

COMMAND PROMPT (or similar). Type: ping 192.168.24.74 (as an example)

and select ENTER. Four (4) ‘REPLY …..’ messages should appear. If

‘REQUESTED TIME OUT….’ messages appear then connectivity is incorrect –

verify steps 1 through 6 again.

7). Assign IP address at RIP (host

workstation) and set data type. The

IP address will be the same as the

printer’s IP address (i.e.

192.168.24.74). Data type must be

set to <9100> for proper data

transfer to occur. Pictured below is

ONYX’s printer port setup splash

screen; a port test may be activated

once values are set – a ‘Valid IP

Address!’ message should appear.

RIP and print operations may begin

at this point.

Technical Training Guide 21

Page 22

KODAK 1200i WIDE-FORMAT PRINTING SYSTEM

8). Configuration Double-check

(example only):

Workstation/Server:

IP: 192.168.24.73

Subnet: 255.255.255.0

Gateway: 192.168.24.2

- Windows Driver

Loaded

RIP:

IP: 192.168.24.74

- uses Windows

driver printer port

Printer:

IP: 192.168.24.74

Subnet: 255.255.255.0

Gateway: 192.168.24.2

9). To further verify connectivity either send a test file to printer via RIP or from the

EFPU (Encad File Print Utility). Launch EFPU (if previously loaded) or load

EFPU (from User System CD, select Software Utilities, located EFPU utility and

load). Select port previously configured (normally identified by a default IP

address the first time loaded). Select the printer test file (link and open an

xxxxxx.rtl file from System CD images subfolder) and select ‘PRINT’. Printer

should start printing within 30 seconds if sending pre-ripped files to printer. To

download printer firmware (product enhancements/bug fixes) perform same

procedure with a firmware file (.rom file; may be obtained from

www.encad.com

); printer will sound a beep after approximately 60 seconds

and reboot power automatically.

NOTE: To function, the

EFPU utility may

require a LPT port be

available. Add a printer

port and assign to a

local LPT port if

necessary.

Technical Training Guide 22

Page 23

KODAK 1200i WIDE-FORMAT PRINTING SYSTEM

Step 14: Print Mode & Dryer Guidelines

NOTE: Go here for the most up-to-date information: http://www.encad.com/Printers/Kodak1200i/index.asp

Qi Dye

Photographic Papers

Kodak Premium Rapid-Dry Photographic Glossy / 260g (9 mil) 2 Production (3 Bi 10)

Kodak Premium Rapid-Dry Photographic Lustre / 260g (9 mil) 2 Production (3 Bi 10)

Kodak Rapid-Dry Photographic Glossy Paper / 190g (7 mil) 2 Production (3 Bi 10)

Kodak Rapid-Dry Photographic Satin Paper / 190g (7 mil) 2 Production (3 Bi 10)

Kodak Premium Photographic Glossy Paper / 270g (10 mil) 4 Production (3 Bi 10)

Kodak Premium Photographic Glossy Paper / 180g (8 mil) 4 Production (3 Bi 10)

Kodak Premium Photographic Satin Paper / 180g (8 mil) 6 Production (3 Bi 10)

Kodak Premium Photographic Matte Paper / 180g (8 mil) 4 Production (3 Bi 10)

Kodak Production Photographic Glossy Paper / 170g (7 mil) 10 Production (3 Bi 10)

Kodak Production Photographic Satin Paper / 170g (7 mil) 10 Production (3 Bi 10)

Photographic Films

Kodak Premium Backlit Film / 7 mil 10 (No Fans) Production (3 Bi 10)

Kodak Universal Backlit Film / 8 mil 2 Production (3 Bi 10)

Kodak Production Backlit Film / 7 mil Fans Only Enhanced (6 Bi 10)

Kodak Production Reverse Print Backlit Film / 5 mil 4 Enhanced (6 Bi 10)

Kodak Premium White Film / 5 mil 6 Production (3 Bi 10)

Kodak Production Glossy Poly Poster Plus / 8 mil 10 Production (3 Bi 10)

Kodak Production Satin Poly Poster Plus / 8 mil 10 Production (3 Bi 10)

Kodak Production Self-Adhesive Glossy Poly Poster Plus / 6 mil 10 Production (3 Bi 10)

Kodak Production Self-Adhesive Satin Poly Poster Plus / 6 mil 10 Production (3 Bi 10)

Kodak Self-Adhesive Glossy Poly Poster / 120g 10 Production (3 Bi 10)

Kodak Self-Adhesive Matte Poly Poster / 120g 10 Production (3 Bi 10)

Coated Papers

Kodak Coated Matte Print Paper / 140g (6 mil) (1) Fans Only Fine (4 Bi 10)

Kodak Coated Matte Print Paper / 90g (4 mil) (1) Fans Only Fine (4 Bi 10)

Kodak Self-Adhesive Coated Matte Print Paper / 100g (7 mil) (1) Fans Only Production (3 Bi 10)

Vinyl & Banners

Kodak Water-Resistant Removable Vinyl / 6 mil 2 User Defined (8 Bi 10)

Kodak GO Water-Resistant Self-Adhesive Vinyl / 6 mil 2 Enhanced (6 Bi 10)

Kodak Water-Resistant Scrim Banner / 17 mil 6 Enhanced (6 Bi 10)

Kodak Water-Resistant Poly Poster Matte / 8 mil 2 User Defined (8 Bi 10)

Kodak Water-Resistant Self-Adhesive Poly Poster Matte / 9 mil 2 User Defined (8 Bi 10)

Kodak Production Removable Glossy Vinyl / 6 mil 10 Production (3 Bi 10)

Kodak Production Removable Satin Vinyl / 6 mil 10 Production (3 Bi 10)

Canvas

Kodak Artists’ Semigloss Canvas / 20 mil (1) Fans Only Production (3 Bi 10)

Kodak Matte Canvas / 19 mil (1) Fans Only Production (3 Bi 10)

Recommended Printer

Heater Setting (1)

Recommended Print

Mode*

(1): Based on room conditions of 23C/50% RH. *: Recommended mode for photo

image quality 3 Bi 10 = 3 pass, bidirectional, 10 speed 4 Bi 10 = 4 pass,

bidirectional, 10 speed 6 Bi 10 = 6 pass, bidirectional, 10 speed 8 Bi 10 = 8 pass,

bidirectional, 10 speed

Technical Training Guide 23

Page 24

KODAK 1200i WIDE-FORMAT PRINTING SYSTEM

Qi Pigment

Photographic Papers

Kodak Premium Rapid-Dry Photographic Glossy / 260g (9 mil) 2 Fine (4 Bi 10)

Kodak Premium Rapid-Dry Photographic Lustre / 260g (9 mil) 2 Fine (4 Bi 10)

Kodak Rapid-Dry Photographic Glossy Paper / 190g (8 mil) 2 Fine (4 Bi 10)

Kodak Rapid-Dry Photographic Satin Paper / 190g (8 mil) 2 Fine (4 Bi 10)

Photographic Films

Kodak Universal Backlit Film / 8 mil 2 Production (3 Bi 10)

Coated Papers

Kodak Coated Matte Print Paper / 140g (6 mil) Fans Only Enhanced (6 Bi 10)

Kodak Self-Adhesive Coated Matte Print Paper / 100g (7 mil) Fans Only Fine (4 Bi 10)

Vinyl & Banners

Kodak Water-Resistant Removable Vinyl / 6 mil 2 User Defined (8 Bi 10)

Kodak GO Water-Resistant Self-Adhesive Vinyl / 6 mil 2 Enhanced (6 Bi 10)

Kodak Water-Resistant Scrim Banner / 17 mil 6 Enhanced (6 Bi 10)

Kodak Water-Resistant Poly Poster Matte / 8 mil 2 Enhanced (6 Bi 10)

Kodak Water-Resistant Self-Adhesive Poly Poster Matte / 9 mil 2 Enhanced (6 Bi 10)

Canvas

Kodak Artists’ Semigloss Canvas / 20 mil 2 Production (3 Bi 10)

Kodak Matte Canvas / 19 mil Fans Only Fine (4 Bi 10)

Recommended Printer

Heater Setting (1)

Recommended Print

Mode*

(1): Based on room conditions of 23C/50% RH. *: Recommended mode for photo image quality 3

Bi 10 = 3 pass, bidirectional, 10 speed 4 Bi 10 = 4 pass, bidirectional, 10 speed 6 Bi 10 = 6 pass,

bidirectional, 10 speed 8 Bi 10 = 8 pass, bidirectional, 10 speed

NOTE: If dryer temperature is too high on certain backlit media vertical banding

(swaths) may be observed in printed output. Lower the dryer temperature if this occurs.

Technical Training Guide 24

Page 25

KODAK 1200i WIDE-FORMAT PRINTING SYSTEM

)

Step 15: Lamination Guidelines

Kodak Media Lamination Reference for Kodak 1200i Printer

Qi Dye

Lamination Compatibility#

Heat

Activated

Thermal

Heat Activated

Low

Temperature

Heat

Assisted

Pressure

Sensitiv e

Ambient

Photographic

Kodak Rapid-Dry Photographic Glossy Paper / 200g (8 mil) Yes Yes Yes Yes

Kodak Rapid-Dry Photographic Satin Paper / 200g (8 mil) Yes Yes Yes Yes

Kodak Premium Photographic Glossy Paper / 270g (10 mil) Yes Yes Yes Yes

Kodak Premium Photographic Glossy Paper / 180g (8 mil) Yes Yes Yes Yes

Kodak Premium Photographic Satin Paper / 180g (8 mil) Yes Yes Yes Yes

Kodak Premium Photographic Matte Paper / 180g (8 mil) Yes Yes Yes Yes

Kodak Economy Photographic Glossy Paper / 160g (6 mil) No No No Yes

Kodak Economy Photographic Satin Paper / 160g (6 mil) No No No Yes

Coated

Kodak Coated Matte Print Paper / 140g (6 mil) No No Yes Yes

Kodak Coated Matte Print Paper / 90g (4 mil) No No Yes Yes

Kodak Self-Adhesive Coated Matte Print Paper / 100g (7 mil) No Yes Yes Yes

Film

Indoor:

Kodak Premium Backlit Film (7 mil) Yes Yes Yes Yes

Kodak Premium White Film (5 mil) Yes Yes Yes Yes

Reverse Print Backlit VS (5 mil) No No Yes Yes

Kodak Poly Poster Glossy (7 mil) No No No Yes

Kodak Poly Poster Satin (7 mil) No No No Yes

Indoor/Outdoor:

Kodak Reverse Print Backlit Film (6 mil) Yes No No Yes

Kodak Water-Resistant Backlit Film (8 mil) Yes No Yes Yes

Kodak Water-Resistant Poly Poster Matte (8 mil) Yes Yes Yes Yes

Kodak Water-Resistant Self-Adhesive Poly Poster Matte (9 mil

Kodak Self-Adhesive Glossy Poly Poster (120g) No No No Yes

Kodak Self-Adhesiv e Matte Poly Poster (120g) No No No Yes

Yes Yes Yes Yes

Vinyl

Kodak GO Water-Resistant Scrim Vinyl No

Kodak GO Water-Resistant Self-Adhesive Vinyl No Yes Yes Yes

KODAK W ater-Resistant Removable Vinyl No Yes Yes Yes

KODAK Water-Resistant Scrim Banner

No No No Yes

NA NA

Yes

Specialty

Fine Art:

Kodak Artists’ Semigloss Canvas (20 mil) NA NA NA NA

Kodak Matte Canvas (19 mil) No No No Yes

Indoor/Outdoor:

Kodak GO Banner/Dupont Tyvek material (9 mil)

Kodak GO Wet Strength Paper (11 mil) Yes Yes Yes Yes

Kodak GO Polyethylene Banner (10 mil) Yes Yes Yes Yes

Kodak Water-Resistant Reinforced Flex Banner (15 mil) Yes Yes Yes Yes

NA = Not Applicable

#: Check with laminate manufacturer for suitability of outdoor use

*: Recommended mode for photo image quality

Yes Yes Yes Yes

Technical Training Guide 25

Page 26

KODAK 1200i WIDE-FORMAT PRINTING SYSTEM

)

Kodak Media Lamination Reference for Kodak 1200i Printer

Qi Pigment

Lamination Compatibility#

Heat

Activated

Thermal

Heat Activated

Low

Temperature

Heat

Assisted

Pressure

Sensitive

Ambient

Photographic

Kodak Rapid-Dry Photographic Glossy Paper / 200g (8 mil) Yes Yes Yes Yes

Kodak Rapid-Dry Photographic Satin Paper / 200g (8 mil) Yes Yes Yes Yes

Coated

Kodak Coated Matte Print Paper / 140g (6 mil)

Kodak Self -Adhesiv e Coated Matte Print Paper / 100g (7 mil)

No No Yes Yes

No No

Yes Yes

Film

Indoor/Outdoor:

Kodak Reverse Print Backlit Film (6 mil) Yes

Kodak Water-Resistant Backlit Film (8 mil) Yes Yes Yes Yes

Kodak Water-Resistant Poly Poster Matte (8mil) Yes Yes Yes Yes

Kodak Water-Resistant Self-Adhesive Poly Poster Matte (9 mil

Yes Yes Yes Yes

No

Yes Yes

Vinyl

Kodak GO Water-Resistant Scrim Vinyl

Kodak GO Water-Resistant Self-Adhesive Vinyl No Yes Yes Yes

KODAK W ater-Resistant Remov able Vinyl No Yes Yes Yes

KODAK W ater-Resistant Scrim Banner

No

No No No Yes

NA NA

Yes

Specialty

Fine Art:

Kodak Artists’ Sem igloss Canv as (20 mil)

Kodak Matte Canvas (19 mil)

NA NA NA NA

No No No

Yes

Indoor/Outdoor

Kodak GO Banner/Dupont Tyvek material (9 mil)

Kodak GO W et Strength Paper (11 mil) Yes Yes Yes Yes

Kodak GO Polyethylene Banner (10 mil) Yes Yes Yes Yes

Kodak Water-Resistant Reinforced Flex Banner (15 mil) Yes Yes Yes Yes

NA = Not Applicable

#: Check with laminate manufacturer for suitability of outdoor use

*: Recommended mode for photo image quality

Yes Yes Yes Yes

Technical Training Guide 26

Page 27

KODAK 1200i WIDE-FORMAT PRINTING SYSTEM

PPrriinntteerr OOppeerraattiioonn TTiippss

1. Media Load and Verification

- Install media onto spindle and attach the media guide

and tighten the blue locking nut. Verify spindle gears

mesh properly. Ensure left media guide is locked next

to the white alignment mark. Adjust right media guide

to within 2 mm of media edge. Load media into the rear

of printer, align with white alignment mark.

NOTE: paper will be automatically advanced following

a 6 second delay and then measured. Verify load was

successful under

- Install the front left and right Paper Guides (these help guide media under the air plenum)

and install the magnetic media holders

directly above the left and right edges of the media surface

below; parts are actually black or white in color).

Utility Menu - Display Settings.

(help prevent media head strike) onto the Y-Arm

(NOTE: illustrated in yellow

NOTE: After loading media a friendly reminder control panel message ‘Warning – Adjust

Rear Paper Guides…’ will appear.

- Ensure both rear paper guides are not touching media edges (2

mm offset minimum on both sides). This is very important as

media drag may occur at either the left or right sides (causes left

or right side micro-banding). Also ensure media is not rubbing or

‘climbing’ over guides at any time during printing.

CAUTION: once media has been aligned and guides

have been set, typically the media may "glide" against

one guide or the other but not to the point where media

jumps on top of the guide (see picture at left). Verify

media is initially loaded with the offset to ensure that

the media is not wedged between the two guides. This

can lead to left or right side horizontal banding on

printed output.

Technical Training Guide 27

Page 28

KODAK 1200i WIDE-FORMAT PRINTING SYSTEM

2. The ‘Perfect’ Media Load

- After loading media in the normal routine, it is best to perform a ‘perfect media load’.

Hold the feed roller guide (round plastic guide) at

right side with one hand and then simultaneously

press the

media forward until it pulls against the media roll,

keep holding (do not allow guide to rotate) for

another 10 seconds or so - resistance is the key

to pull the media straight.

NOTE: the media guides should be pulled all the

way out when loading media (see Caution

above). Also, once the media is tight, driving media ‘forward’ aids in alignment.

Feed Media - Forward button. Drive

3. Dryer Modes

To activate the drying system, select Setup Menu -

Dryer Menu

modes are available; refer to dryer matrix label affixed to

printer’s top cover or Installation Step #14 above

specific modes of operation.

NOTE 1: The air plenum may be lowered to the maintenance position by removing 2

locking pins and gently lowering plenum. The air plenum should be only be lowered

when performing printer calibrations and replacing cartridges.

NOTE 2: The air plenum may also be completely removed for certain media print

applications (i.e. 50” bond media) where the media becomes obstructed by the air

plenum. Contact technical support for assistance with removal.

. Scroll through available selections. 12 dryer

0 = OFF

1 = Fans Only

2 = Minimum, Fans On

3 = Minimum

4 = Heat Low, Fans On

5 = Heat Low

6 = Heat Medium, Fans On

7 = Heat Medium

8 = Heat High, Fans On

9 = Heat High

10 = Maximum, Fans On

11 = Maximum

for

Technical Training Guide 28

Page 29

KODAK 1200i WIDE-FORMAT PRINTING SYSTEM

4. Humidity Control

Ideal humidity for printing is between 45 and 55 percent, at a temperature of 68-72

degree F. (20-22.2 degrees C.)

Low Humidity problems:

1) Media warping and edge curl problems leads to visible

carriage head strike on media surface.

2) Inconsistent print quality is normally observed in severe

low humidity environments. To compensate more ink must

be used to balance the color loss (need for color profiling).

High humidity problems:

1) Dry time drastically increases with high humidity levels.

2) Lamination issues often result; increasing time required to finish jobs. Refer to

Installation Step #15 above

These problems can be avoided by maintaining proper temperature and humidity levels

(RH) in both storage and operational areas. The use of humidifiers will add water to the

air, resulting in a humidity level increase. This will help prevent normal heating season

problems caused by dry air.

General Environmental Conditions

Controlling the print location and surrounding humidity is key toward maintaining good

color output no matter what environment or region the printer is located in.

for lamination guidelines.

5. Edge Band mode

To eliminate instances of ‘First Drop’ (color change at print edges) from occurring ensure

the Edge Band mode is turned on. Select

Margins

vertical bar of 6 colors will be printed along both media edges. This will force the

cartridges to warm up by

printing data outside the

page layout, thus

decreasing the chances of

‘First Drop’ from appearing

along printed edges.

. By selecting Edge Band the printer will be forced into Normal Margins and a

Setup Menu – Paper Option Menu –

Technical Training Guide 29

Page 30

KODAK 1200i WIDE-FORMAT PRINTING SYSTEM

SSooffttwwaarree CCoonnttrrooll TTiippss

1. Typical Server Installation (one per subnet)

- For most installations perform the ‘typical’ installation of the Kodak 1200i software

suite. This is ideal for most environments including those using a single computer

single printer configuration. Note: this software only runs on Windows®

2000/2000/2003 Pro/Server and XP/XP Pro.

NOTE: Verify another Microsoft SQL database is not loaded or being used by customer

on same subnet – do not load the software suite or conflicts may be encountered.

- For peer-to-peer connections use an Ethernet crossover cable otherwise use a

regular Ethernet patch cable through a Switch (100FD capable). Configure the

TCP/IP address either through the software installation instructions or directly at

the printer under Setup Menu – Network Menu.

2. Client Installation (one per workstation)

- Install the Client Installation package onto additional workstations that will be

printing to the printer (in addition to the server workstation). Note: the database

program (MSDE) should only be installed onto the primary server workstation (one

subnet per server).

NOTE: While the software suite is not required to run the RIP or drive the printer, the NJ1000i

driver will normally need to be loaded for most RIPs to communicate properly with the printer (one

exception is NT 4.0). The primary advantage of loading the printer software is easy setup on the

network, job accounting features,

media feed calibration (best

operational feature!), ink usage

and allowing remote control over

the printer settings. If the software

is not registered the job

accounting elements will become

disabled after 90 plot hours –

perform product registration via

the Client software under Help.

Technical Training Guide 30

Page 31

KODAK 1200i WIDE-FORMAT PRINTING SYSTEM

PPrriinntteerr M

Maaiinntteennaannccee

WWhheenn aa PPrriinntt HHeeaadd iiss RReeppllaacceedd::

A. Check for air bubbles in the ink delivery line after replacing a print head:

- Perform an “Access Cartridge”

- Check for air segments of more than 5mm in length in the ink tubes; air bubbles are

acceptable but LARGE air segments are NOT acceptable.

Perfect Air bubbles acceptable NOT ACCEPTABLE

- If necessary, perform an ink load on ink lines which contain large air segments. Air

bubbles will be removed by a System Prime (must have new service station and f/w

1.5.0 or greater already installed).

- Select

Utility Menu - Prime Menu - Serv. Station Menu – System Prime. The System

Prime will take approximately 60 seconds to complete; all bubbles should be removed.

B. If air segments remain or ink line is completely empty:

- Install the Plug Bar and attach the ink line fitting to right side plate septum fitting;

remove the Print head and replace it with the Ink Load cartridge.

- Select

Utility Menu - Prime Menu - Serv. Station Menu - Pump On (hold button for 15

seconds).

- If this problem appears frequently after removing

and installing multiple print heads, then septum may need replacement (contact

Technical Training Guide 31

Page 32

KODAK 1200i WIDE-FORMAT PRINTING SYSTEM

service).

C. After replacing a print head, it is a good practice to run the System Prime. This will

improve ink flow through the ink system and reduce print head errors.

NOTE: ensure printer is placed on a level

floor surface to avoid ink starvation (which

could cause ‘MAX INK TEMP EXCEEDED’

error messages) and related ink flow

problems. Check printer levelness by

placing a standard level on the platen

surface (remove media from platen).

Perform the following:

- A System Prime:

Select Utility Menu - Prime Menu - Serv. Station Menu - System Prime

- Print a Prime Test to check that all nozzles are properly firing

Select Utility Menu - Prime Menu - Prime Single - Prime

- Perform Print head alignments:

Bi-directional alignment:

Color Db Test

Geometric print heads alignment: Utility Menu / Calibration Menu / Color

Calib Menu / Vert. Calib Test / Horiz. Calib Test

Prime Test Color Dead Band Vertical Calibration

Utility Menu / Calibration Menu / Color Db Menu /

Horizontal Calibration

Technical Training Guide 32

Page 33

KODAK 1200i WIDE-FORMAT PRINTING SYSTEM

RRoouuttiinnee MMaaiinntteennaanncce

e

IMPORTANT: It is suggested to perform a weekly cleaning action on the printer (i.e.

every Monday morning for 20 minutes) instead of attempting to remember the user

guide cleaning intervals.

A. Clean the following assemblies:

1. Encoder Strip (lint-free swabs dampened with Windex® or a mild dish soap and

water solution). Thoroughly clean the top and bottom surfaces of the entire length

of the encoder strip (including the area near the service station; access cartridges

to move carriage out). Repeat procedure with new swabs until no ink residues are

observed on swab surfaces.

NOTE: Windex solution should be mainly used on printers running pigment inks.

2. Service Station (lint-free towel/lint-free swab dampened with a mild dish soap &

water solution). Gently clean service station seals & wipers; ensure the outside

edges of the wipers are thoroughly cleaned.

CAUTION: do not remove the service station to clean (only Authorized Service

Providers should remove the service station when necessary).

3. Slide Shaft (lint-free towel dampened with Windex solution or isopropyl alcohol).

Thoroughly clean the entire length of the slide shaft, including the portion near the

service station zone.

NOTE: do not apply solutions directly on the

carriage bushings; allow shaft to dry before

moving carriage assembly.

Technical Training Guide 33

Page 34

KODAK 1200i WIDE-FORMAT PRINTING SYSTEM

4. Platen Surface & Cutter Groove (lint-free swab/lint-free towel dampened with

Windex or a mild dish soap & water solution). Remove media from printer and wipe

down platen and cutter groove until ink residues are no longer visible on cleaning

swab/towel. Using a toothpick or paperclip, gently remove paper fibers or similar

debris from the cutter groove.

5. Carriage Belt (lint-free towel dampened with Windex or a mild dish soap & water

solution). Thoroughly clean the entire length of the inside surface of carriage belt).

6. Flex Driver Cables (lint-free towel or lint-free swab

dampened with Windex solution or isopropyl alcohol).

Remove all print heads from carriage assembly. Thoroughly

clean all 6 (six) carriage flex driver cables; ensure no lint

fibers or ink residues remain on cable surfaces.

NOTE: Routine cleaning of the flex driver cables is very

important when the printer is running in certain print

modes [print pass modes 2, 3, 4 and GB Mode available in firmware >2.1.0].

NOTE 2: If ink residue is observed on cable surfaces at any time printing should

be immediately suspended and a flex cable and rear cartridge cleaning

maintenance actions should be performed. Also refer to section B below.

CAUTION: Print heads may become damaged if media is allowed to scrape

against the lower jet plate surface during printing or through direct contact with

ink residues on service station seals when the carriage is at the home position.

Technical Training Guide 34

Page 35

KODAK 1200i WIDE-FORMAT PRINTING SYSTEM

7.

Carriage Guide and Carriage Slider (lint-free towel dampened with Windex or a

mild dish soap & water solution). Thoroughly clean the printer rear plate carriage

guide (horizontal shelf) and carriage slider. A dirty carriage guide and/or slider can

lead to carriage vibration and printer banding.

8. Lower Roller/Pinch Rollers (lint-free towel dampened with a mild dish soap &

water solution). To clean, apply power to the printer. Advance rollers using the

control panel’s Feed Media menu, depress the Forward or

Backward function. Ensure all rollers (6 or 8) are thoroughly

cleaned.

NOTE: certain 3rd party vinyl media adhesive glues and print

environments exposed to smoke and other contaminants

have been found to adhere to roller surfaces.

B. Clean the following items as required:

1. Cartridge (lint-free towel/foam swab dampened with a mild soap & water solution

or isopropyl alcohol). Thoroughly wipe the print head rear electrical contacts of ink

residues. Gently blot the jet plate surface (center strip) with a dampened lint-free

towel to remove ink debris/build-up (DO NOT WIPE JET PLATE!)

NOTE: The lower surfaces of the print head (adjacent to the jet plate center strip)

should be thoroughly cleaned of all ink residues with a lint-free towel.

Technical Training Guide 35

Page 36

KODAK 1200i WIDE-FORMAT PRINTING SYSTEM

2. Auto Clean Unit (Disposal) Bottle (prompted by ‘Empty Waste Bottle Now’

control panel/software suite message). Open Auto Clean Unit door, remove bottle

and dispose of ink in accordance with local guidelines).

3. Encoder Sensor. The carriage encoder sensor

and will need to be cleaned or image shifted output may be observed (see samples

below). Typically, random horizontal bands will first appear in the printed output,

followed by gradual image shift, then eventual data shift.

will likely get dirty ~600 plot hours

Cleaning Procedure:

- Remove power from printer.

- Manually move the carriage assembly to the

extreme left side of the printing surface.

- Place absorbent towels around base of carriage

assembly.

- Obtain Windex cleaning fluid and attach spray

tube (internal tube may need to be cut to allow for

inverted spray operation).

NOTE: Windex solution is strongly suggested for printers running the pigment ink

set as the ink can be difficult to clean from surfaces.

Technical Training Guide 36

Page 37

KODAK 1200i WIDE-FORMAT PRINTING SYSTEM

- Spray three (3) quick bursts of solution onto the encoder sensor spray zone (do

not over saturate the carriage!). Refer to the illustration below.

- Obtain canned air and blow area clean for one second.

- Allow printer to dry for 10 minutes.

- Apply power to printer and resume printer operations.

4. Carriage Paper Sensor (lint-free/foam swab dampened with Windex solution or

isopropyl alcohol). The carriage paper sensor recognizes the presence of media

and measures media width and location. The sensor is located at the rear of the

carriage assembly directly behind the magenta print head and is in line or above

the cutter groove.

Cleaning Procedure:

- Remove the media from the platen.

- Perform “Access Cartridge” and remove the magenta print head.

- Apply Windex or isopropyl alcohol to a lint-free/foam swab and clean the paper

sensor (located approximately 4 mm behind the magenta flex cable) by gently

dabbing swab up toward sensor. Repeat procedure with a second swab.

NOTE: while the carriage paper sensor

will not be visible, the photo below

depicts the reverse angle view for

assistance in cleaning.

- Replace the print head and follow the print head

replacement procedures on page 2.

- Perform “Access Cartridge” to return the carriage to

the home position.

- Reload the media.

Technical Training Guide 37

Page 38

KODAK 1200i WIDE-FORMAT PRINTING SYSTEM

C. Replace the following item as required:

1. Cutter (when smooth cuts are no longer observed when media is cut or if ‘Internal

Shutdown - Carriage Axis Failures’ occur and are determined to be caused by the

cutter assembly). Remove cutter assembly by

gently pushing down on upper tab; pull

assembly out and to the left to remove.

Technical Training Guide 38

Page 39

KODAK 1200i WIDE-FORMAT PRINTING SYSTEM

PPrreevveennttiivvee MMaaiinntteennaannccee

Periodic Maintenance is required at the following intervals; this type of service should

only be performed by authorized service providers.

1. Replace carriage bushings every 1000 plot hours or when vertical

banding or ‘Internal Error - Carriage Axis’ errors are observed

(bushings will typically last between 630 and 2200 plot hours

depending on the print environment conditions, cleanliness, routine

maintenance practices and type of actual printing performed).

NOTE: it is possible for bushings to become dirty prior to

500 plot hours causing horizontal banding and/or

shuddering of the carriage assembly during movement.

Remove bushings from carriage (3 screws at each side)

and clean lint/debris from bushings with dry lint-free towel.

- Inspect and verify bushing shims (2 per bushing) are present

or vertical banding may result due to carriage chatter.

2. Replace the service station every 2000 plot hours

(station wipers may require frequent replacement

depending on customer maintenance).

3. Replace the idler, frame

tensioner, spring and

carriage belt every 2000

plot hours.

4. Replace the servo motor every 4000 plot hours.

Technical Training Guide 39

Page 40

KODAK 1200i WIDE-FORMAT PRINTING SYSTEM

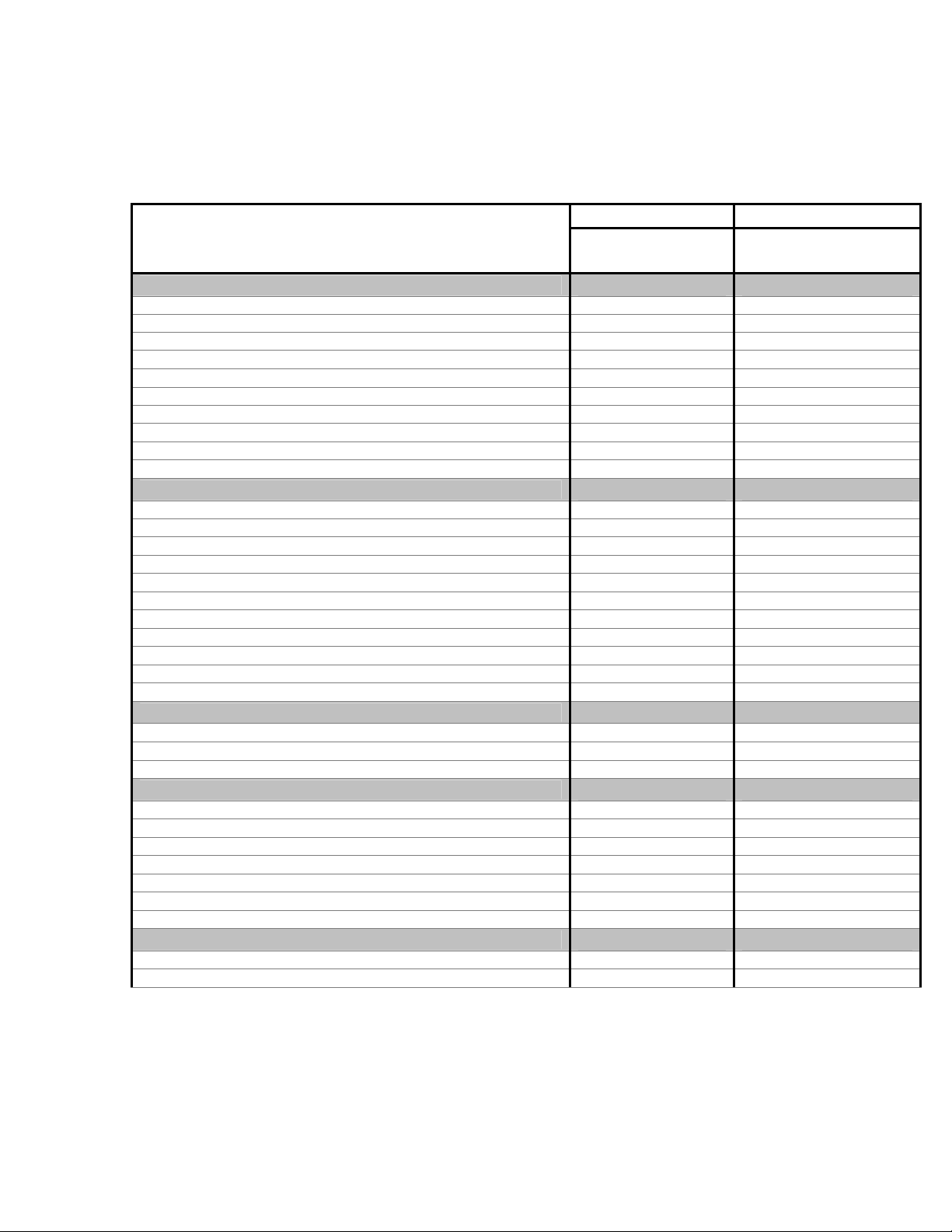

BBuulllleettiinn RReeffeerreennccee LLiisstt

Bulletin Type Topic Revision Prerequisite

Actions

KODAK 1200i

Technical Bulletin 1

KODAK 1200i

Technical Bulletin 2

KODAK 1200i

Technical Bulletin 3

KODAK 1200i

Technical Bulletin 4

KODAK 1200i

Technical Bulletin 5

KODAK 1200i

Technical Bulletin 6

KODAK 1200i

Technical Bulletin 7

KODAK 1200i

Technical Bulletin 8

KODAK 1200i

Technical Bulletin 9

KODAK 1200i

Technical Bulletin 10

KODAK 1200i

Technical Bulletin 11

KODAK 1200i

Technical Bulletin 12

Printer

Calibration

Procedure

Printer

Repacking

Instructions

- Video Procedure

Available; partial

Encoder Strip &

Encoder Sensor

Cleaning

- Video Procedure

Available

Print and

Lamination

Guidelines

- Video Procedure

Available; partial

Tiling Guidelines

- Video Procedure

Available; partial

Printer

Networking – Win

2000/XP

Kodak Software

Suite Locating

Password Info

Operator

Cleaning &

Maintenance

- also available in

French and Spanish

Printer Error

Message &

Troubleshooting

Printer

Grounding, ESD

Control & Output

Symptoms

Premature File

Terminations

Routine &

Preventive

Maintenance

05/24/2005 - None

05/24/2005

05/24/2005

06/23/2005

12/02/2005

08/22/2005 - None

09/16/2005 - None

5/30/2006

3/30/2006 - TB3, 10 and 12

12/06/2005

02/21/2006 - TB 10

06/29/2006 - None

- None

- TB12

- TB1 and 8

- TB1, 5, and 6

- TB3 and 12

- TB 9

Technical Training Guide 40

Page 41

KODAK 1200i WIDE-FORMAT PRINTING SYSTEM

EErrrroorr M

Meessssaaggee CCooddeess

Errors are listed into four general groups:

¾ Cartridge Error Messages/Cartridge Failures

¾ Ink System (Refill Bottle/Intermediate Reservoir) Error Messages

Dryer System Error Messages

¾

Miscellaneous Error Messages

¾

NOTE: service related actions should only be performed by qualified personnel.

1. Cartridge Error Messages/Cartridge Failures:

Review the explanation for ink system/cartridge error messages and the appropriate

recovery process – additional error message/code information is provided at the end of

this document. Make sure you report the following information completely and

accurately:

1. The initial screen error message.

2. The message displayed after pressing the MORE INFO key.

3. The message displayed after pressing the failed cartridge associated

error key (e.g., F1 = Black, F2 = Cyan, F3, = Magenta, etc.).

Background Info - Error Classifications:

There are three basic types of cartridge errors:

1. ID-chip communication errors.

2. ID-chip data errors.

3. Internal cartridge errors (or insufficient ink delivery).

Type 1: ID-chip communication errors (Example: "Pen Error – Code 4”).

This type of error is identified by a special code and it usually indicates there is a

fault or bad connection with the ID-chip. The suggested course of action is to

inspect the ID-chip and its connection to make sure the chip is making contact.

Try reseating the cartridge - if no problems are detected, you should replace the

cartridge and retest the system to verify valid ID-chip response with the new chip.

Note: Additional information is available (but not necessary) if you press the

associated error key (F1, F2, etc.) after navigating to the “Cart Info” display.

If a communication problem cannot be resolved through cartridge replacement

then check flex driver cable and trailing cable connectivity. Replace flex driver

cable; replace trailing cable.

Type 2: ID-chip data errors (Example: "Pen Error – Invalid Ink Type!”).

This type of error indicates the data recorded in the cartridge ID-chip is incompatible with

the requirements specified in the printer setup. In this particular case, the cartridge ink

type does not match the ink types of the other cartridges and, therefore, is incompatible.

Correct this error by simply replacing the cartridge with one having the proper ink type.

Technical Training Guide 41

Page 42

KODAK 1200i WIDE-FORMAT PRINTING SYSTEM

Under INK STATUS MENU, at the CART INFO screen ensure ink type matches (i.e. QiD or Qi-Pig) across all cartridge stall positions. The printer will not print unless ink type is

the same for each cartridge. Other examples of data type errors include the following:

1. “Pen Error – End of Jet Life!”… [use (ml) is over limit; typically 2800 ml]

2. “Pen Error – Invalid OEM ID!”… (chip OEM# doesn’t match printer OEM)

3. “Pen Error – Ink Warranty Mismatch!”… (chip warranty data error)

4. “Pen Error – Invalid Chip ID”… (chip serial # is invalid)

As with the Type 1 errors, your best bet with all of these type 2 errors is to replace

the cartridge with a qualified replacement.

Type 3: Internal cartridge errors.

These errors generally indicate there is a major flaw or breakdown within the

cartridge or ink is not being supplied to the cartridge properly. The error recovery

procedure is slightly different for each instance:

Example 1: <color> PEN ERROR – MAX INK TEMP. EXCEEDED!

MAX INK TEMP cartridge errors are a response to jet plate temperature exceeding a set

maximum value. This is generally an indication that ink is not being fed to the jet plate

area to keep it cool while printing.

An insufficient factory prime (leaking cartridge – typically observed with a new cartridge

that has leaked into the cartridge foil packaging) or an ink delivery system problem

(blockage or leakage) can be the cause of observing this error. Typically the cartridge

will need to be replaced, but the following actions/checks can be made to help revive the

cartridge.

1. Ensure the ink delivery system is feeding ink to the cartridge

(ink line should be full of ink from intermediate reservoirs to the

carriage dampers – only ‘very small’ bubbles are permitted to be

observed in ink line at any time). In the photo at right note the

Light Magenta ink tubing line does not have any ink visible.

CAUTION: Do not repeatedly plug and up-plug a cartridge into

the septum connector, this will cause the cartridge to

eventually deprime. The ink line will typically need to be reprimed using either the standard Cartridge with tubing needle (and Plug bar) or

via the System Prime feature (>2.1.0 firmware). For complete ink line depletion

problems, Access Cartridges and install Cartridge with Tubing Assembly tool.

NOTE: the plug bar must be installed into service station to cap off service

station to establish proper vacuum for the ‘Pump On’ feature.

Technical Training Guide 42

Page 43

KODAK 1200i WIDE-FORMAT PRINTING SYSTEM

2. For visible ink starvation (resembling large horizontal areas of ink dropout; no

error condition displayed on control panel) first verify ink system flow and

pressure are adequate (no bubbles greater than 1 cm in size within ink tubing

should be visible) and check general cartridge health (via color test & prime

pattern). Perform ‘System Prime’ (must have firmware version 2.1.0 loaded and

the new service station must be installed), select:

UTILITY MENU – PRIME MENU – SERVICE STATION MENU – SYSTEM

PRIME. Activation of the System Prime will fully recharge the entire ink system in

~60 seconds (also assumes factory set service station height is correct and the

service station shim is installed properly) and helps correct ‘MAX INK TEMP

errors’ and general cartridge ink depletion problems 90% of the time.

Technical Training Guide 43

Page 44

KODAK 1200i WIDE-FORMAT PRINTING SYSTEM

3. Replace cartridge if ‘intermittent’ ink dropout occurs (no error displayed – see

sample image problems below); the cartridge has an internal jetting problem and

must be replaced. The customer will need to determine which color is

dropping out by inspecting the bands along bottom edge of print.

NOTE: the ‘MAX INK TEMP error’ message may not be displayed

when the ink dropout occurs in the examples below; this symptom has

been observed with cartridges greater than 700 ml ink throughput).

4. Activate an All Color Test (UTILITY MENU – SERVICE MENU –

DIAGNOSTICS – COLOR TEST MENU – ALL COLOR TEST) in the default 6pass printer mode to fire all cartridges and check overall cartridge performance

and ink flow to cartridges.

5. As a preventive measure against future ‘MAX INK TEMP’ errors (and even

help recover a cartridge which has already suffered a MAX INK TEMP error) try

using the suggested System Prime procedure (refer to step 2 above).

6. If cartridge recovery is not possible then proceed to replace the cartridge

(cartridge may have an internal air leak which is causing the ink pressure

integrity problem; multiple cartridge failures typically indicate a septum failure).

The alarm message will be cleared when you send a new print job or power cycle the

printer. The steps involved to clear the alarm without a power cycle are:

1 - cancel the print job at the host

2 - navigate to the keypad main menu and press RESET

3 - navigate to the alarm display by pressing ALARM

4 - press the MORE INFO key

5 - determine the offending cartridge

6 - access carriage and replace offending cartridge

7 - access carriage back to home position

8 - send a new print job to clear the alarm (a prime printing test or calibration plot will

clear the alarm)

Technical Training Guide 44

Page 45

KODAK 1200i WIDE-FORMAT PRINTING SYSTEM

7. For a more advanced analysis (i.e. for technicians) of the ‘MAX INK TEMP’ error

please refer to pages 21–24.

Example 2: <color> PEN ERROR – OVERCURRENT CARTRIDGE SHUTDOWN!

A cartridge OVERCURRENT error indicates the detection of an electrical short internal

to the cartridge – the cartridge must be replaced. This error is often the result of not

correcting a MAX INK TEMP. EXCEEDED error as described in Example 1 above.

All OVERCURRENT cartridge errors require replacement of the cartridge and recycling

of the printer power. The steps involved to restart the printer and replace the cartridge

are:

1 - cancel the print job at the host

2 - press the MORE INFO key on the keypad display to show

which cartridge is defective

3 - turn the printer power OFF

4 - replace the defective cartridge

5 - turn the printer power ON

For the following error message (examples):

Internal error shutdown

Image Manager

VFIRE VALUE=1 (or 5)

RETRY=3 (or 0)

If newer firmware is loaded (i.e. >2.1.0) and the error message remains, then the carriage board

is likely faulty. Replace carriage board to correct symptom.

Example 3: <color> Pen Error – Invalid Pen ID!

The message indicates that the ID of the cartridge itself is not correct or is not being

read. This could be a contact problem between the cartridge ID chip contacts and the

carriage flex or it could be that the cartridge ID is not the correct type (programming

problem), misaligned or even missing completely from cartridge. You can verify this

condition by going to the CART INFO screen (Utility Menu – Service Menu – Ink Status

Menu – Cart Info) and you will see something similar to:

K: BLACK

XXXmL

If you then press the F1 key on the display you should see:

604 K: BLACK QiD TSR: XXX

MFGl X-X-XXX OEM: 1 ID: 6

XXXXXXXXXXXXX

TSR FOUND +

Technical Training Guide 45

Page 46

KODAK 1200i WIDE-FORMAT PRINTING SYSTEM

ID: 0 is typically an indication that the cartridge ID is wrong. This field will equal 6 (will be

0 until you have printed at least 0.10mL of ink through the cartridge). This is assuming

you have printed and the error has occurred. TSR (Target Sensing Resistor) values are

typically between 450 and 540; displayed message should also indicate ‘TSR FOUND

+’. For TSR errors try reseating the cartridge or replace the cartridge. If one or all TSR

cartridge levels are at error condition (out of range) then load firmware version 2.1.0 (or

higher) to help correct. This will place the identified cartridge (s) in open loop mode and

may affect specific color output slightly however. For persistent TSR errors check

connectivity between flex driver cable to carriage PWA and/or replace the cartridge.

NOTE: the OEM field is read from the ID chip. 1 = Kodak 1200i, 4 = POS, 5 =

special, 6 = Xerox 8142/8160. The MB (i.e. MB:01) version under the ABOUT

menu should ‘always’ match the cartridges and bottles.

The alarm message will be cleared when you send a new print job or power cycle the

printer. The steps involved to clear the alarm without a power cycle are:

1 - cancel the print job at the host

2 - navigate to the keypad main menu and press RESET

3 - navigate to the alarm display by pressing ALARM

4 - press the MORE INFO key

5 - determine the problem cartridge

6 - access carriage and replace the problem cartridge

7 - access carriage back to home position

8 - send a new print job to clear the alarm (a prime printing test or calibration plot will

clear the alarm)

APC UNAVAILABLE, ABORT JOB?

APC stands for Auto Pass Correction. There are three possible selections from the

menu for PASS CORRECTION: AUTO, PAUSE, and OFF. Default is AUTO.

If you receive this error with APC set to AUTO this indicates that the printer is not able to

compensate in any print mode. Your only option is to abort the current print job or

continue. You can abort the job, try reseating the cartridge, print a PRIME pattern to help

you understand the extent of the electrically defective jets. The prime pattern will print a

message at the end of the pattern indicating which modes can be compensated, if any.

If you receive this error with APC set to PAUSE this indicates that the printer is able to

compensate at a higher pass mode but is needing your input to proceed.

NOTE: APC errors will not be receive if PASS CORRECTION is set to OFF. Also, prior to

firmware version 2.0.7 there is no automatic APC correction above the 8 print-pass mode

(i.e. for 12 and 16 pass). It is suggested to load firmware 2.1.0 or higher for this condition.

This is typically a cartridge failure. Items 1- 7 below can be verified prior to cartridge

replacement to help isolate problem. If problem does not clear following cartridge

replacement perform items d. through f. below:

1. Thoroughly clean flex driver cable surfaces, rear electrical surfaces of

cartridge and jet plate.

Technical Training Guide 46

Page 47

2. Ensure cartridge is completely seated and firmly pressed against the flex

driver cable surface. Ensure cartridge door and door pusher is properly

engaging and locking cartridge in place.

3. Cycle printer power to verify fault clears.

4. Replace cartridge.

5. Reseat appropriate flex driver cable and trailing cable (both ends).

6. Replace appropriate flex driver cable.

7. Replace trailing cable.

JETS BAD: ALLOW 3-PASS APC? (N/A)

JETS BAD: ALLOW 4-PASS APC?

JETS BAD: ALLOW 6-PASS APC?

JETS BAD: ALLOW 8-PASS APC?

If you receive any of these errors (APC set to PAUSE) this indicates that the

printer is able to compensate at a higher pass mode. Select YES to give

permission to proceed to this new higher pass mode or select NO to stay at the

current pass mode. One line of the display will show the cartridge colors with the

problem cartridge(s) flashing.

PEN ERROR - JOB PAUSED!

This pen alarm provides the top-level error status only. Additional information

about the specific error is available if the operator presses the “More Info” button.

The following is a list of all possible (color-generic) “More Info” specific error

messages that follow “Pen Error”:

If the Pen Error is related to an ID-chip data validation error, one the following

messages will be displayed:

[<color>] Pen Error – Ink Record Mismatch!

Translation: The system was unable to update pen ID-chip ink count.

[<color>] Pen Error – Invalid Pen ID!

Translation: The pen Cartridge Body ID is invalid. Ensure the cartridge is properly

mating to the flex driver cable. Clean flex driver cable and retest.

[<color>] Pen Error – End of Jet Life!

Translation: The pen ink count is greater than maximum (2800ml).

[<color>] Pen Error (#10) – Invalid Ink Type!

Translation: The pen ink type does not match the other installed pen ink types

(i.e. Qi-Dye versus Qi Pigment). Verify OEM configuration by checking Cartridge.

Could also be an improperly programmed ID chip.

[<color>] Pen Error – TSR Failure!

Translation: The Cartridge Body TSR value is out of range. If this error is

occurring for all cartridges then the firmware (i.e. version 2.0.7) may be detecting

a faulty carriage board voltage level. It is suggested to load firmware version

2.1.0 (or higher) bypass the error and resume print operations (the specific

cartridge will run in open loop thermal control and may affect output color

however). Average TSR values are normally 460-490 (480 to 510 is optimum),

KODAK 1200i WIDE-FORMAT PRINTING SYSTEM

Technical Training Guide 47

Page 48

KODAK 1200i WIDE-FORMAT PRINTING SYSTEM

system wide acceptable range is between 450 and 540 (go to Cartridge Status –

press outside keys to view individual cartridge status/information, refer to bottom

of page 8).

[<color>] Pen Error – Invalid OEM ID!

Translation: The pen OEM ID does not match the main-board OEM ID. For

ENCAD cartridge all OEM values should be 1. Replace cartridge under warranty

if one cartridge is different than the rest.

[<color>] Pen Error – Ink Warranty Mismatch!

Translation: The system was unable to update pen warranty status (ID-chip).

[<color>] Pen Error – Invalid Chip ID!

Translation: The pen ID chip serial number is invalid. Reseat or replace cartridge

under warranty.

For the above error messages replace the cartridge with a qualified

replacement. If cartridge replacement does not solve the issue then check

flex driver cable and trailing cable connectivity. Replace appropriate flex

driver cable. Replace trailing cable. Replace carriage board (defective jack

connector).

If the Pen Error is related to an ID-chip communication failure, the error message

format changes to the following:

[<color>] Pen Error – Code < # > (# ranges from 2 to 7)

Where:

2 = “<color> Pen Error - Pri CRC Failed!”

3 = “<color> Pen Error - Sec CRC Failed!”

4 = “<color> Pen Error - No Response!”

5 = “<color> Pen Error - Write Protected!”

6 = “<color> Pen Error - Copy Failed!”

7 = “<color> Pen Error - MAC Mismatch!”

Translation: The ID-chip or its connection is faulty.

These communication error messages are displayed in the “Cart Info” secondary

menu. This display menu is made visible by pressing the associated cartridge

color button (F1-F6).

604 K: BLACK QiD TSR: XXX

MFGl X-X-XXX OEM: 1 ID: 6

XXXXXXXXXXXXX

TSR FOUND +

NOTE: the TSR range is normally between 450 and 540; cartridges operate the

‘best’ between TSR levels between 480 and 510 however.

Technical Training Guide 48

Page 49

KODAK 1200i WIDE-FORMAT PRINTING SYSTEM

2. Ink System (Refill Bottle/Intermediate Reservoir) Error Messages:

BOTTLE ERROR - JOB PAUSED!

This bottle alarm provides the top-level error status only.

Additional information about the specific error is available if the

operator presses the “More Info” button. The following is a list of

all possible (color-generic) “More Info” specific error messages

that follow “Bottle Error”:

If the Bottle Error is related to an ID-chip data validation error,

one the following messages will be displayed:

[<color>] BOTTLE ERROR – INK RECORD MISMATCH!

Translation: The system was unable to update bottle ID-chip ink count.

[<color>] BOTTLE ERROR – INK LIMIT REACHED!

Translation: The bottle ink count is greater than maximum (700ml).

[<color>] BOTTLE ERROR – INVALID INK TYPE!

Translation: The bottle ink type does not match other installed bottle ink types.

[<color>] BOTTLE ERROR – INVALID OEM ID!