Koci Elektromaschinen KC 100, KC 200 Operating Instruction

O R I G I N A L

Operating Instruction

Compressor unit with direct current motor

KC 100 and KC 200

Manufacturer:

Koci Elektromaschinen GbR

Zittauer Straße 12

02796 Kurort Jonsdorf

Germany

Edition: 07.2016

Kontakt:

Zittauer Straße 12 Tel. + 49 35844/ 70234 www.elektromaschinen-koci.de

D – 02796 Kurort Jonsdorf Fax + 49 35844/ 72103 koci.lachmann@t-online.de

List of content

1. Introduction .................................................................................................................................. 1

1.1 Owner’s responsibility .............................................................................................................. 1

1.2 Copyright .................................................................................................................................. 1

1.3 General advices ....................................................................................................................... 1

EC – Declaration of Conformity ..................................................................................................... 1

2. Warranty and complaints ............................................................................................................ 2

3. Reference of utilization ................................................................................................................ 2

3.1 conventional utilization ............................................................................................................. 2

3.2 unconventional utilization ......................................................................................................... 2

4. Technical information about the compressor unit ................................................................... 3

4.1 Components account ............................................................................................................... 3

4.2 Technical description ............................................................................................................... 3

4.3 Technical Data ......................................................................................................................... 4

5. Commissioning ............................................................................................................................ 5

5.1 Location and assembly references .......................................................................................... 5

5.2 Installation – electrical ............................................................................................................. 6

6. Maintenance.................................................................................................................................. 8

General reference notes ................................................................................................................ 9

Compressor block .......................................................................................................................... 9

Cylinder head and valves .............................................................................................................. 9

Clean and replace air filter ............................................................................................................. 9

Maintenance of the bearings and carbon brushes of the DC motor .............................................. 9

Checking the safety valve ............................................................................................................ 10

Pressure container (accessory if requested) ............................................................................... 10

Performance check ...................................................................................................................... 10

Torque specification ..................................................................................................................... 10

Reference notes to anti-freeze pump .......................................................................................... 11

7. Safety regulations – environment protection .......................................................................... 11

7.1 Safety regulations .................................................................................................................. 11

7.2 Environment protection .......................................................................................................... 11

8. Troubleshooting ......................................................................................................................... 12

9. Storing & Transport ................................................................................................................... 13

10. Replacement parts ................................................................................................................... 13

Kontakt:

Zittauer Straße 12 Tel. + 49 35844/ 70234 www.elektromaschinen-koci.de

D – 02796 Kurort Jonsdorf Fax + 49 35844/ 72103 koci.lachmann@t-online.de

1

1. Introduction

These operating instructions are applicable for the compressor units KC 100 and KC 200.

Description: compressor unit with direct current motor

Type: ___________________________________

Machine no.: ___________________________________

Please read these operating instructions carefully to enable a safe operation.

1.1 Owner’s responsibility

These operating instructions are part of the product. The owner/ operator has to consider on own authority:

Operating and maintenance staff has access to these operating instructions always.

All advices and safety regulations have to be fulfilled during shutdown and operating.

These operating instructions have to be retained for further utilization.

1.2 Copyright

The duplication of text, technical data, drawings or similar is prohibited and demands the agreement of the

manufacturer.

Technical changes at the compressor unit stay reserved for the manufacturer.

1.3 General advices

The company Koci Elektromaschinen GbR determined that requirements regarding to spare parts and their

delivery, information for reparation or questions about technical issues of the compressor can be handled

only with the correct type or machine number.

If you did not purchase the compressor directly from the manufacturer please first contact your provider.

Additionally it is prohibited to remove the appliance rating plate.

EC – Declaration of Conformity

Kontakt:

Zittauer Straße 12 Tel. + 49 35844/ 70234 www.elektromaschinen-koci.de

D – 02796 Kurort Jonsdorf Fax + 49 35844/ 72103 koci.lachmann@t-online.de

2

2. Warranty and complaints

The legal foundation of our guarantee management is the German Civil Code. But please consider the

following regulations:

Work carried out on our compressors under guarantee is only done in our workshop as a matter of

principle because the machines are classified as easy to transport. In case of contact by others any

guarantee claim cannot be asserted.

Equally guarantee does not apply, if the compressor has been modified or altered without

consultation and approval by our company.

The guarantee is limited to the compressor only and includes material and manufacturing faults.

Faults resulting from natural wear and tear, improper use, installation or insufficient maintenance are

disregarded. Wear and tear elements are:

Solenoid discharge valve

Non-return valve

Pressure switch

Air filter

Fuse

Furthermore the tube cooler is excluded from guarantee in case of traceable use as carry handle,

what is not allowed and results destruction of itself.

We reserve the right to determine how and by whom the repairs are to be made.

Costs that may arise as an after-effect of the compressor’s breakdown will not be accepted by our

company.

3. Reference of utilization

3.1 conventional utilization

The compressor units with DC motor are designed for versatile applications in which a compressed air

supply is needed to permanent disposition.

The compressor is provided solely for production of compressed air. Any other use is considered improper.

The manufacturer is not responsible for any damages resulting from improper utilization – the risk carries

the operator by himself.

Correct use includes also the compliance with the manufacturer’s regulations of installation, operating and

maintenance.

3.2 unconventional utilization

The compressor unit must not be used in hazardous areas - it is not protected against explosions.

Without additional air treatment compressed air from oil lubricated compressors is not suitable for the filling

of breathing air equipment and use in dentistry or for operations where compressed air comes directly into

contact with food.

Compressed air must never be directed at people. The concentrated energy causes a life-threatening

situation.

Kontakt:

Zittauer Straße 12 Tel. + 49 35844/ 70234 www.elektromaschinen-koci.de

D – 02796 Kurort Jonsdorf Fax + 49 35844/ 72103 koci.lachmann@t-online.de

3

4. Technical information about the compressor unit

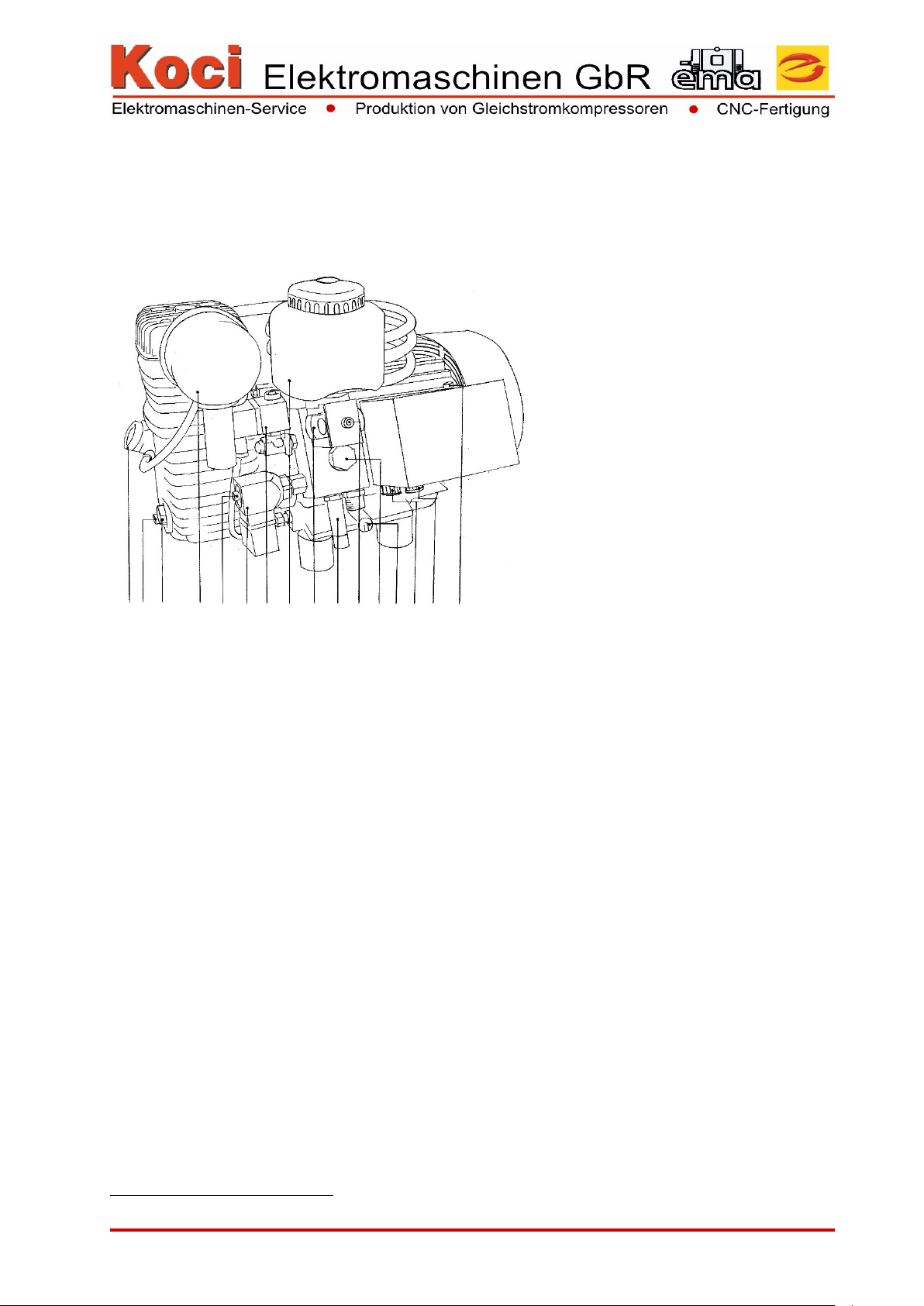

4.1 Components account

1 oil filler neck

2 oil drain plug

3 oil level eye

4 air filter and intake manifold

5 pressure – adjustment screw

6 pressure switch

7 solenoid discharge valve1

8 antifreeze reservoir1

9 switch summer/ winter operation of

the antifreeze pump1

10 safety valve

11 adjustment screw for antifreeze1

12 non-return valve

13 cable entry for battery 31 14 main terminal negative 30 +

15 cable entry

16 fine-wire fuse 12 V or 24 V

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16

4.2 Technical description

The compressor unit with DC motor and control unit is a compact, powerful unit in block manner, which is

composed of two main parts, the single cylinder – compressor and the DC motor as a drive source.

Furthermore, we would like to mention following principal technical details that are integrated into the

compressor and contribute to increased safety and functionality.

General area: Area control block: Field electric machine:

intake silencer with air filter

4 rubber mounts for vibration

damping

tube cooler

compressed air tank/ pressure

container (delivery on request)

To ensure the electrical connection security and the corresponding control over the compressor, a control

light outside the device signals the respective operating.

An integrated momentum balance in the engine reduces vibration and provides a quiet and low-wear run.

For further noise reduction the compressor units are fixed on four rubber mounts and completed with an

intake silencer and an exhaust box on the discharge valve.

solenoid discharge valve1

pressure switch

non-return valve

safety valve

silencer for the discharge air

antifreeze pump with

antifreeze reservoir(installation

on request)

power relay

suppression equipment

thermostats

low voltage protection

operating voltage independent

of the control voltage

ensure a low control current

security protection by circuit

board against false engaging

from the outside of the

compressor

1

only compressors with antifreeze pump

Kontakt:

Zittauer Straße 12 Tel. + 49 35844/ 70234 www.elektromaschinen-koci.de

D – 02796 Kurort Jonsdorf Fax + 49 35844/ 72103 koci.lachmann@t-online.de

Loading...

Loading...