Koch Ultravac 250 Owner's Manual

Ultravac® 250

Vacuum Chamber Packaging Machine

860108 Revision Q

Date 01/2009

TABLE OF CONTENTS

MAIN: 816-753-2150

TOLL FREE: 800-777-5624

INTERNET: kochequipment.com

E-MAIL: info@kochequipment.com

General ...............................................III

Specifications ....................................... IV

SAFETY

Personal Safety ....................................1.1

Food Safety ........................................1.2

General Safety Guidelines ....................1.2

STARTUP

Unpacking ..........................................2.1

Power Requirements .............................2.1

Grounding Instructions.........................2.1

Vacuum Pump .................................... 2.2

Gas Flush Connection ........................ 2.3

Air-Assist Connection .......................... 2.3

Checking Vacuum Pump Rotation ........ 2.3

OPERATION

Placement of Product ...........................3.1

Operation with Analog Control Panel ... 3.2

Operation with Digital Control Panel .... 3.3

Operator Menu on Digital Panel .......... 3.4

Selecting a New Program .................... 3.6

Sealing with Air-Assist ......................... 3.7

Gas Flush Option ............................... 3.7

Double Seam Seal Option .................. 3.7

MAINTENANCE

Prior to Cleaning .................................4.1

Cleaning Recommendations .................4.1

Vacuum Pump Maintenance ................ 4.2

Seal Bar Maintenance ......................... 4.2

Reading the Indicators ........................ 4.3

Troubleshooting ................................. 4.4

Supervisor Menu on Digital Panel ........ 4.6

Opening Chamber Machine ............... 4.11

Changing Vacuum Pump Oil .............. 4.11

Replacing Power Cord .......................4.12

Replacing Potentiometer ..................... 4.12

Maintenance Log .............................. 4.13

Service Log .......................................4.13

SCHEMATICS

Designation and Function of Controls....5.1

110 Volt, Single Phase ......................... 5.2

220 Volt, Single Phase ........................ 5.3

110 Volt, Double Seal Bar ................... 5.4

220 Volt, Double Seal Bar ................... 5.5

Non-Gas Flush Pneumatic Diagram ..... 5.6

Gas Flush Pneumatic Diagram ............. 5.7

PARTS

Recommended Spare Parts ...................6.1

Pump and Chassis .............................. 6.2

Seal Bar ............................................ 6.4

Lid and Hinge System ......................... 6.6

Gas Flush Components....................... 6.8

Analog Control Panel ........................6.10

Digital Control Panel .........................6.12

Mebner Valve ....................................6.13

Miscellaneous Machine Parts ..............6.14

Pump Filter Option ............................6.15

REFERENCE MANUALS

R5 Series Vacuum Pumps .....................7.1

INDEX .............................................. 8.1

860108•Q

INTRODUCTION •

PAGE I

Specifications

MAIN: 816-753-2150

TOLL FREE: 800-777-5624

INTERNET: kochequipment.com

E-MAIL: info@kochequipment.com

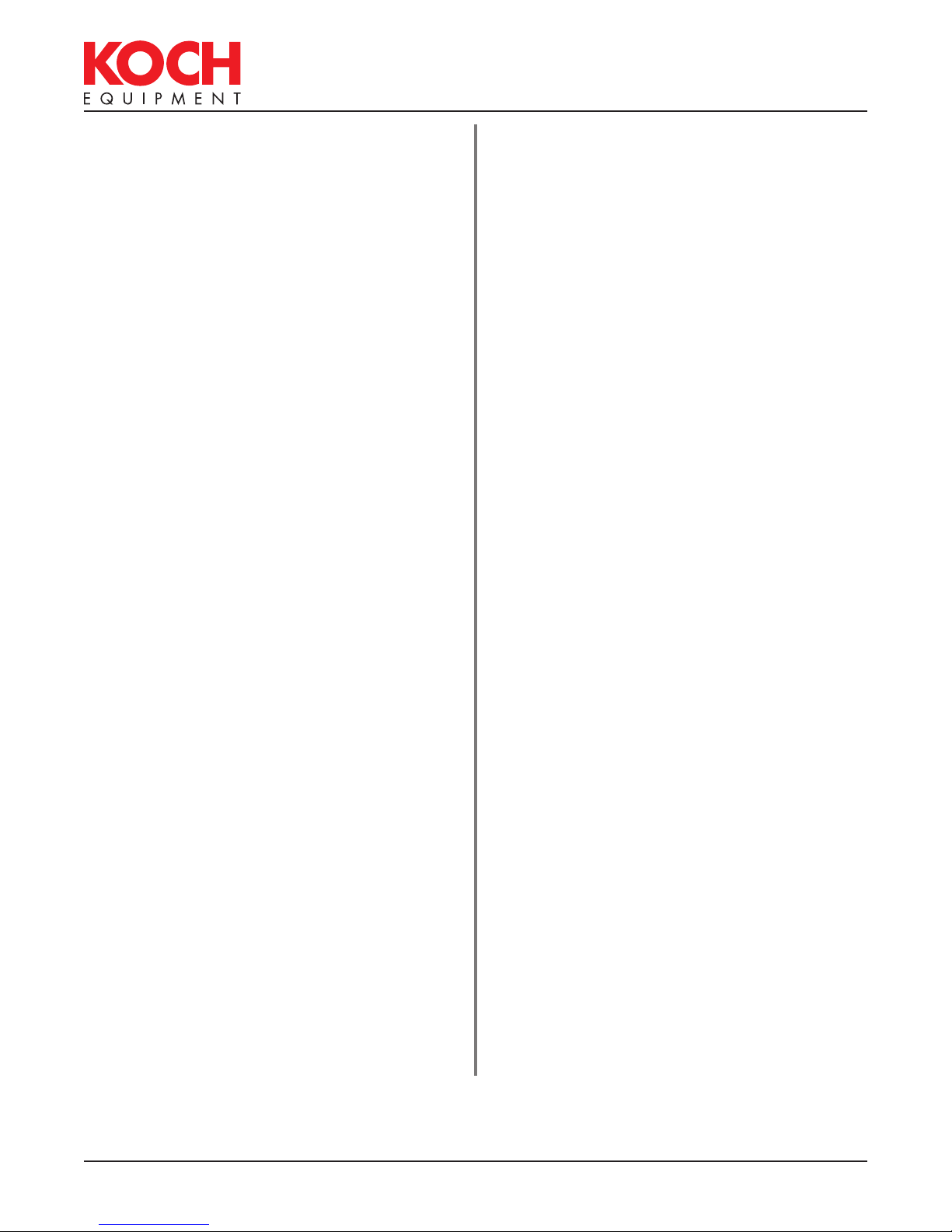

Figure 0.1

Length (A): 483mm (19-in.)

Width (B): 625mm (24.625-in.)

Maximum Height (C): 826mm (32.5-in.)

Working Height (D): 365mm (14.375-in.)

Seal Bar Length: 406mm (16-in.)

Chamber Length (E): 505mm (19.875-in.)

Chamber Width (F): 422mm (16.625-in.)

Chamber Height (G): 171mm (6.75-in.)

Between Seal Bar and Back of Chamber (H): 451mm (17.75-in.)

Between Seal Bars (double seal bar option): 416mm (16.375-in.)

Vacuum Pump: 25m

3

/h (15cfm) 0.95kW (1.25-hp)

Net Weight: 81-kg, 178-lbs.

Electrical Connection: See Power Requirements in Section 2

Capacity: 20-30 seconds per cycle

860108•Q

INTRODUCTION •

PAGE IV

MAIN: 816-753-2150

WARNING

WARNING

CAUTION

CAUTION

TOLL FREE: 800-777-5624

INTERNET: kochequipment.com

E-MAIL: info@kochequipment.com

SAFETY

Personal Safety

The procedures and guidelines herein must be followed precisely to avoid problems that can

result in property damage, personal injury, or death. If you have any questions related to

this information, please contact Koch Equipment Services Inc. at (800) 777-5624.

DANGER

Disconnect and lockout power before servicing machine or cleaning. Do not remove panels

unless power has been disconnected, locked out, and tagged out at risk of electric shock

hazard.

Hazardous voltage.

DANGER

Improper connection of the equipment-grounding conductor can result in a risk of electric

shock.

WARNING

Read and understand owner’s manual before using this machine. Failure to follow operating

instructions could result in personal injury or damage to equipment.

WARNING

Do not use a gas with an oxygen content greater than 22% with gas flush option.

CAUTION

Only let the front foot of the chassis hang over the edge of the table.

CAUTION

Do not get the cleaning agents in eyes, on skin, or on clothing. Always wear rubber gloves,

goggles, and protective clothing when contact is likely. Consult product manufacturer for

specific details.

Hazardous voltage.

Explosion hazard.

Tip over hazard.

Cleaning agents.

Signal words used in classification of potential hazards are defined as follows:

DANGER: Indicates an imminently hazardous situation, which, if not avoided, may result in death or

serious injury.

WARNING: Indicates a potentially hazardous situation, which, if not avoided, could result in death or

serious injury.

CAUTION: Indicates a potentially hazardous situation, which, if not avoided, may result in minor or

moderate injury. Caution also indicates actions that may cause property damage.

860108•Q

SAFETY •

P A G E 1.1

MAIN: 816-753-2150

TOLL FREE: 800-777-5624

INTERNET: kochequipment.com

E-MAIL: info@kochequipment.com

Food Safety

Food Packaging

While this machine is often used for food packaging and vacuum cooking, there are

inherent risks associated with this packaging technique that could cause serious illness

or death to the consumer of the food product. If you are using this machine for a food

application, you must consult with a reputable food technologist or specialist in vacuum/

modified atmosphere packaging (M.A.P.) to review the safety of your application.

Gas Flush

In order to ensure proper shelf life of the food product packaged in this machine, you

must contact a reputable food technologist or specialist in vacuum/modified atmosphere

packaging (M.A.P.) to review and develop the appropriate gas mixture for your package,

and you must perform quality control and gas analysis on your finished M.A.P. packages.

General Safety Guidelines

Obvious safety guidelines should be observed.

¾ Be sure to turn off power to your packaging machine before any maintenance work is

performed.

¾ Follow approved Lockout/Tagout procedures.

¾ Place machine on a flat, stable surface.

¾ Do not place tools, parts, or other objects on or inside machine while operating.

860108•Q

SAFETY •

P A G E 1.2

MAIN: 816-753-2150

TOLL FREE: 800-777-5624

INTERNET: kochequipment.com

E-MAIL: info@kochequipment.com

STARTUP

Unpacking

1. Carefully remove crate from the skid.

2. Remove machine from skid.

3. Wipe down outside of the machine.

Power Requirements

The owner must supply the correct single phase power source in accordance with the

National Electric Code. The machine is rated at 110 volt, 60 Hz, 15 amps; or 220 volt, 50

Hz, 8 amp. Do not use an extension cord to connect the machine to the wall outlet.

Grounding Instructions

The Ultravac® 250 must be grounded. In the event of malfunction or breakdown, grounding

provides a path of least resistance for electric current to reduce the risk of electric shock.

The unit is equipped with a equipment-grounding conductor cord and a grounding plug.

The plug must be plugged into an appropriate outlet that is properly installed and grounded

in accordance with all local codes and ordinances.

DANGER

Improper connection of the equipment-grounding conductor can result in a risk of electric

shock.

The equipment-grounding conductor outer surface is green with or without yellow

stripes. If repair or replacement of the cord or plug is necessary, do not connect the

equipment-grounding conductor to a live terminal. Check with a qualified electrician or

Koch Equipment Services Inc. technician if the grounding instructions are not completely

understood, or if there is doubt as to whether the unit is properly grounded. Do not modify

the plug provided with the unit – if it will not fit the outlet; have a proper outlet installed by

a qualified electrician.

Hazardous voltage.

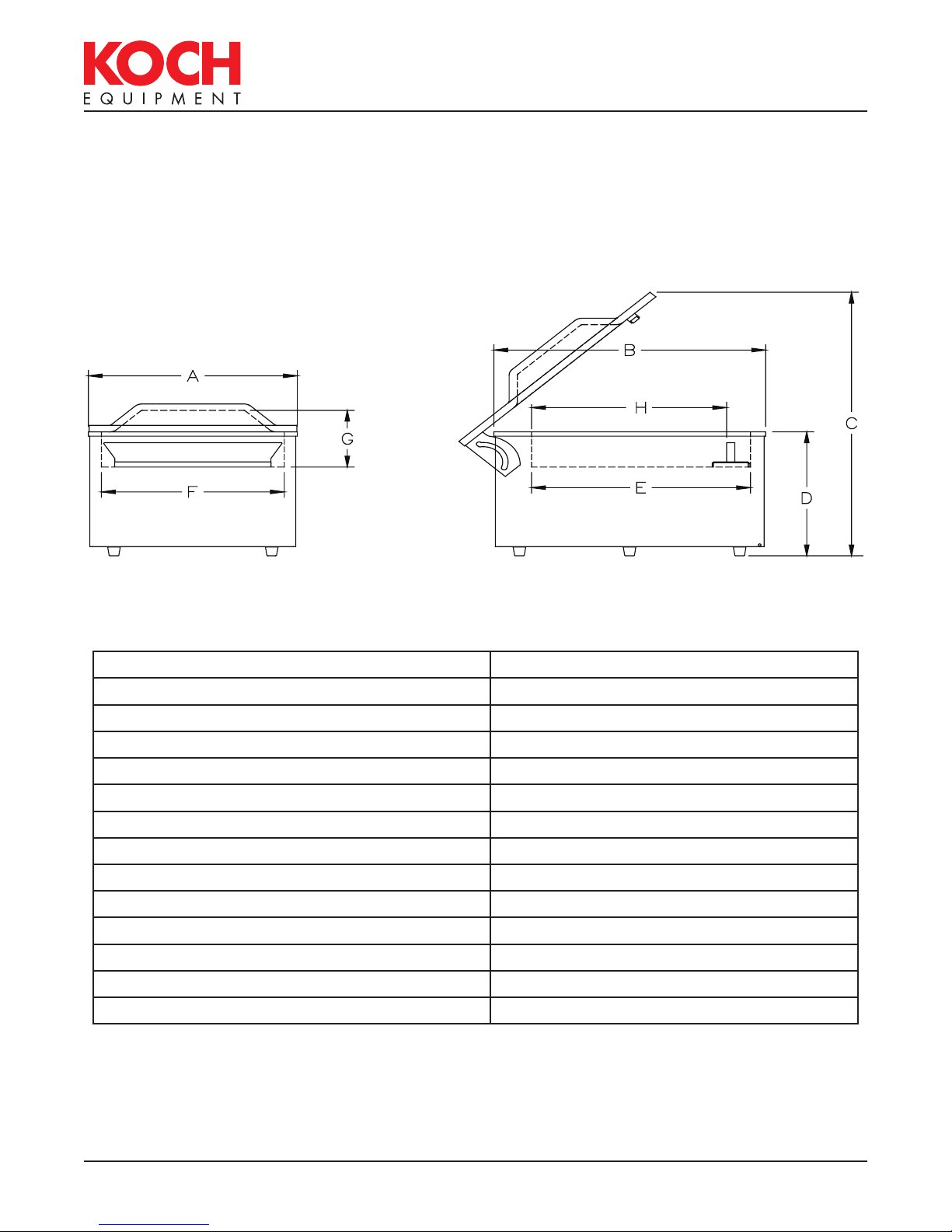

For 110 Volt Units

This unit is for use on a nominal 110V circuit, and has a factory equipped grounding plug

(see Figure 2.2A on page 2.2). A temporary adaptor (see Figure 2.2C on page 2.2), may

be used to connect this plug to a two-pole receptacle (see Figure 2.2C on page 2.2) if a

properly grounded outlet is not available. The temporary adaptor should be used only until

a properly grounded outlet (see Figure 2.2B on page 2.2) can be installed by a qualified

electrician. The green rigid ear extending from the adaptor must be held in place by the

metal screw on a properly grounded outlet box cover.

860108•Q

STARTUP •

PAGE 2.1

MAIN: 816-753-2150

TOLL FREE: 800-777-5624

INTERNET: kochequipment.com

E-MAIL: info@kochequipment.com

Grounding Instructions

For 220 Volt Units

This unit is for use on a nominal circuit having a rating more than 110V; or is rated more

than 15 amps and used on a nominal 110V circuit, and has a factory equipped grounding

plug. No adapter should be used with this unit. If the unit must be reconnected for use on

a different type of electric circuit, the reconnection should be made by qualified service

personnel; and after the reconnection, the appliance should comply with all local codes and

ordinances.

Temporary Adaptor

Metal Screw

Cover of Grounded

Outlet Box

Grounding Pin

A

B

C

Figure 2.1

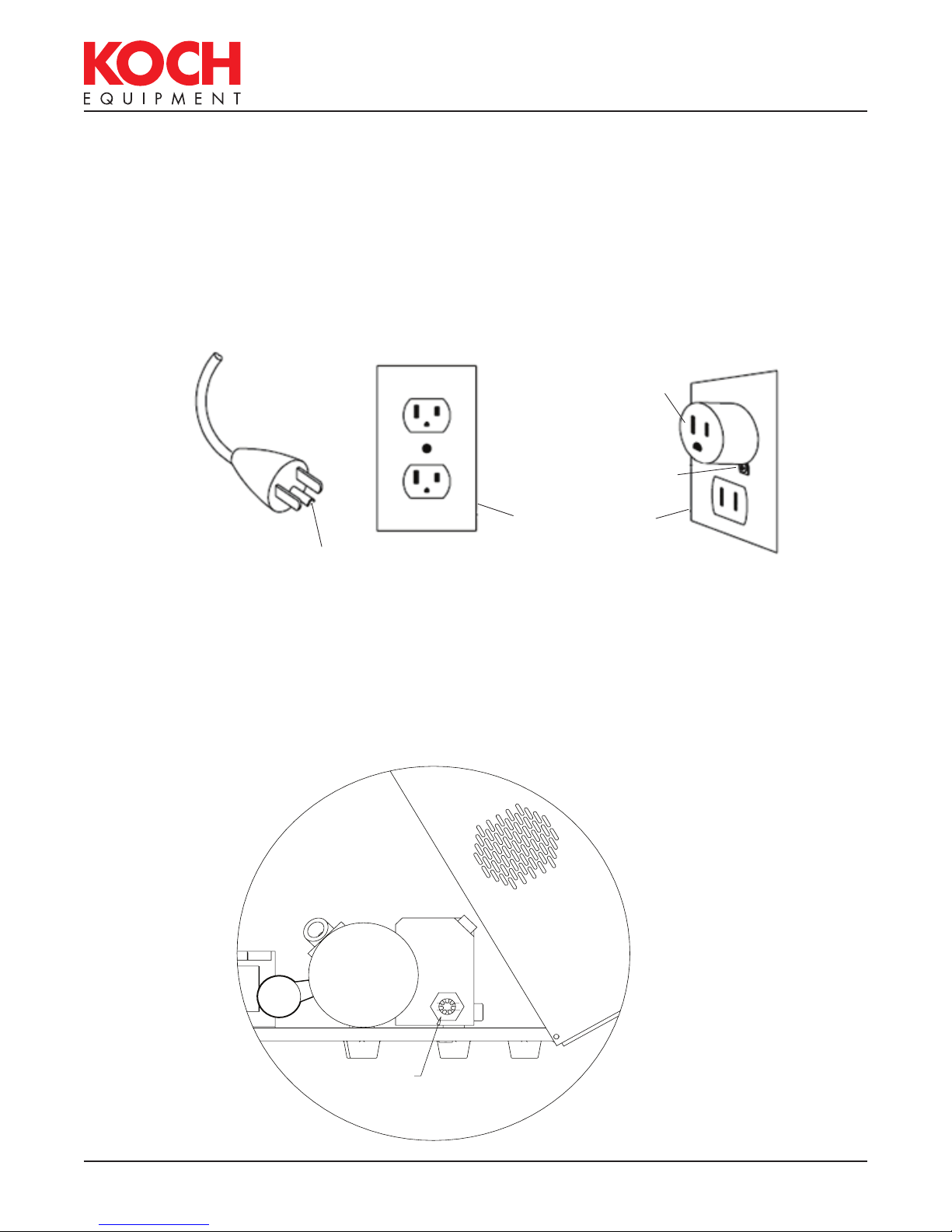

Vacuum Pump

It is essential to check the oil level daily and to change the oil after every 500 hours of

operation. Read the oil level with the machine turned off. Oil may be added until the level

reaches the MAX level shown in the sight glass on the pump. Refer to the pump manual

supplied with the machine for details on changing the oil.

860108•Q

MAX

MIN

OIL SIGHT HOLE

STARTUP •

Figure 2.2

PAGE 2.2

MAIN: 816-753-2150

TOLL FREE: 800-777-5624

INTERNET: kochequipment.com

E-MAIL: info@kochequipment.com

Gas Flush Connection

The owner must supply a suitable regulator with a range of 0 to 60 p.s.i. We recommend

using food-grade flexible hose with a 1/4-in. I.D. and a maximum length of 15-ft. Maximum

regulator pressure is 15 p.s.i.

Air-Assist Connection

The machine is equipped with a regulator for air-assisted sealing. The hose barb will

accept 1/4-in. I.D. hose. The recommended air supply is 75 p.s.i. at 6 c.f.m. The maximum

regulator setting is 40 p.s.i.

Checking Vacuum Pump Rotation

Caution: Check oil level of pump before starting pump (please refer to pump manual).

To check the direction of the pump rotation, briefly engage the “POWER ON” switch and

observe the motor fan at the end of the pump. The fan should rotate as indicated by the

arrow on the fan cover. To correct the rotation, switch any two phases in the plug.

860108•Q

STARTUP •

PAGE 2.3

MAIN: 816-753-2150

TOLL FREE: 800-777-5624

INTERNET: kochequipment.com

E-MAIL: info@kochequipment.com

OPERATION

Placement of Product

For best sealing results, it is important to:

Check the pump oil level daily.

•

• Select a pouch that fits the product.

• Carefully load the product into the pouch.

• Keep the product and the product residue away from the seal area of the pouch.

• Place the product as far into the pouch as possible.

• Maintain an equal amount of the product above and below the seal bar (see figure 3.1,

below on use of filler plates).

Use Filler Plates for raising the height of the product.

•

• Lay the pouch flat on the seal area, keeping the pouch free of wrinkles.

• Place the pouch so that the open end is inside the chamber when the lid is closed.

PRODUCT HALF HEIGHT

EVEN WITH TOP OF

SEAL BAR

Figure 3.1

860108•Q

OPERATION •

PAGE 3.1

MAIN: 816-753-2150

TOLL FREE: 800-777-5624

INTERNET: kochequipment.com

E-MAIL: info@kochequipment.com

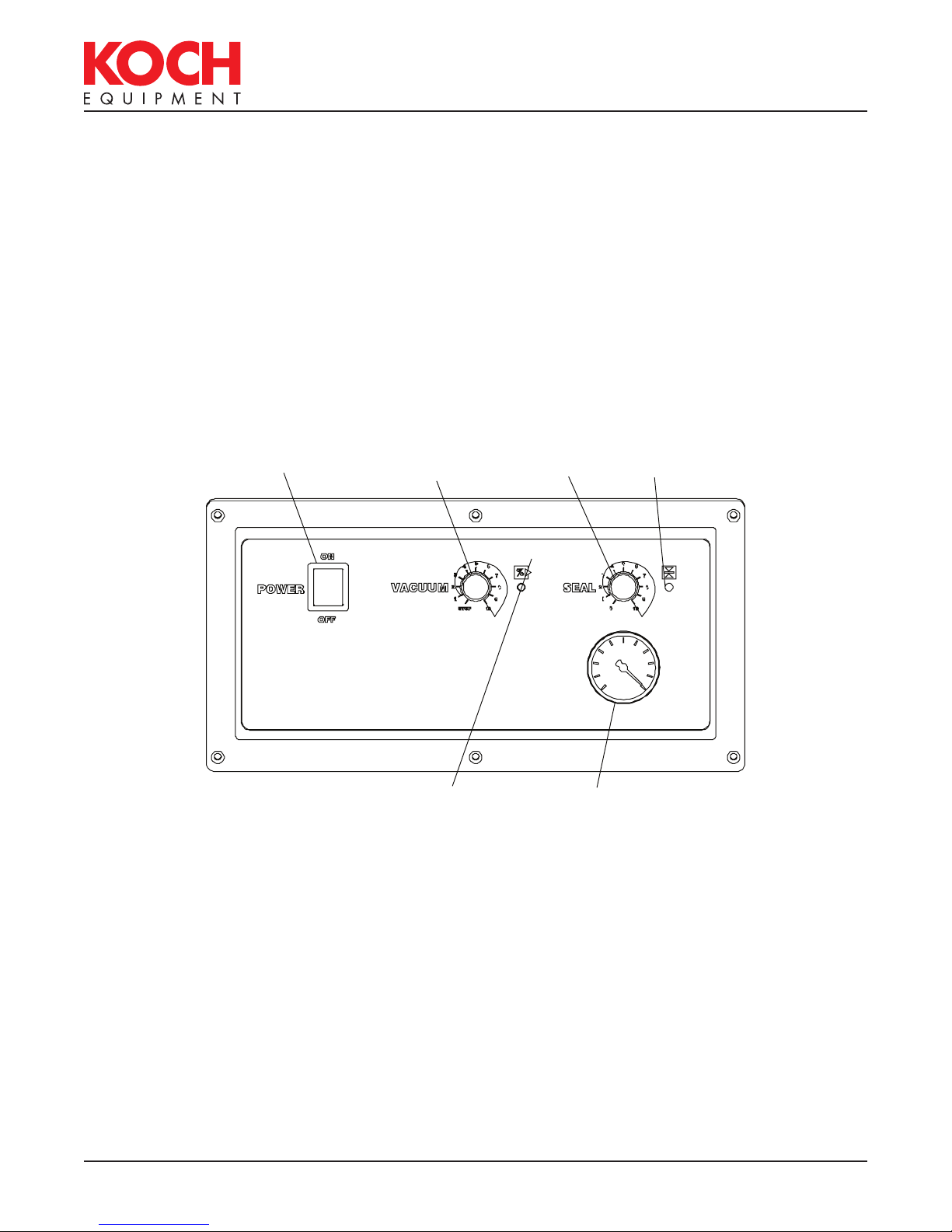

Operation with Analog Control Panel

The analog control panel is shown below, figure 3.2.

The range for timed vacuum is 0 to 55 seconds and is controlled by the Vacuum

Potentiometer. We suggest an initial setting of “3” on the dial.

Seal impulse is the length of time the seal bar is turned on and can range from 0 to

2 seconds. The impulse time is controlled by the Seal Potentiometer. Koch Equipment

recommends an initial setting of “6” on the potentiometer. This setting will vary according

to the thickness of the pouch. Thinner pouches will require a lower setting while thicker

pouches will require a higher setting.

Experiment with both settings to achieve the best results.

Figure 3.2

POWER SWITCH

VA CUUM

POTENTIOMETER

VACUUM LIGHT

(GREEN)

SEAL

POTENTIOMETER

VACUUM

INDICATOR

SEAL LIGHT

(RED)

860108•Q

OPERATION •

PAGE 3.2

MAIN: 816-753-2150

TOLL FREE: 800-777-5624

INTERNET: kochequipment.com

E-MAIL: info@kochequipment.com

Operation with Digital Control Panel

The digital control panel allows the user more options than the standard control panel. The

embedded microprocessor controls each sequence of the packaging operation. Settings for

the vacuum, gas, and sealing are entered as parameters through the keypad. This allows

the user to custom program every step of the packaging process. The precise vacuum

and gas pressures are controlled by a pressure based sensor. The vacuum pressure, gas

pressure, and seal time are displayed on a large 16-character LCD backlit readout, which

is easily readable in all lighting conditions. As each sequence is performed, the real-time

pressure level or cycle time is displayed.

The digital front panel can save up to 100 pre-programmed routines, which can be

retrieved at any time for specific packaging applications. With the supervisor security feature

turned on, these programs cannot be inadvertently changed.

The VACPLUS option allows the operator to run the pump from 0 to 20 seconds after the set

vacuum level is achieved.

The Gas Flush option allows the operator to introduce an inert gas into the chamber after

the vacuum stage. This option can be used as a filler to prevent crushing of the product

after sealing, as a means to prolong shelf life or as a means to maintain desirable product

appearance.

The digital front panel has an auto stop, which will automatically seal if the preset vacuum is

not reached. This feature decreases the cycle time and optimizes the vacuum level of each

product.

The digital front panel, which includes the keypad, illuminated display, and microprocessor,

uses sealed components and is conformal coated in a moisture-proof coating. The digital

front panel meets or exceeds the requirements of NEMA 4. The front of the digital display is

sealed and flush for easy cleaning.

The digital control has both pulsed vacuum and pulsed venting options for fragile product.

The digital control has a maintenance screen for testing valves and a special loop option for

multiple vacuum/gas cycles before sealing.

Figure 3.3

860108•Q

OPERATION •

PAGE 3.3

MAIN: 816-753-2150

TOLL FREE: 800-777-5624

INTERNET: kochequipment.com

E-MAIL: info@kochequipment.com

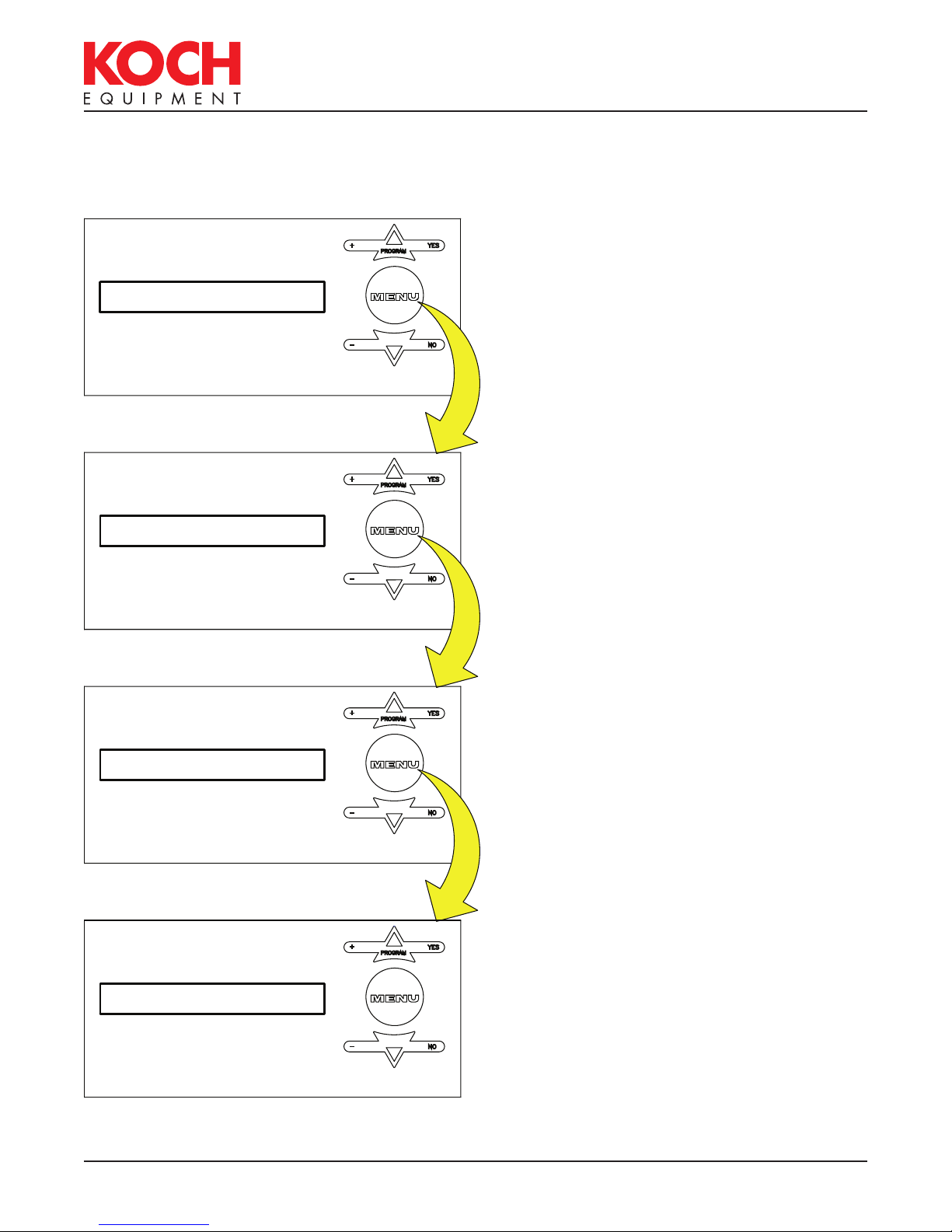

Operator Menu on Digital Panel

NOTE: if the supervisor has set security on, these settings cannot be changed.

RUNNING PROG: 1

VACUUM: 98

+

PROGRAM

YES

machine starts up, the last program that was

run will be the current program shown in

the window. To set the operating parameters

for the program shown press the MENU key.

This is the Main Menu screen. When the

-

+

PROGRAM

NO

YES

VACUUM is set to % vacuum using the UP

and DOWN Arrow Keys.

The range is 30% to 99%.

Press the MENU key.

-

NO

VACPLUS: 4.0

SEAL: 1.2

Figure 3.4

+

PROGRAM

YES

A setting greater than 0 allows the pump

to continue evacuating the chamber (for

the specified number of seconds) after the

pressure in the chamber has reached the %

VACPLUS may be set from 0 to 20 seconds.

-

NO

vacuum set in the vacuum menu.

Press the MENU key.

The SEAL setting is in seconds. Use the UP

+

PROGRAM

YES

and DOWN arrow keys to change the seal

time. The range is 0 to 2 seconds.

Press the MENU key.

-

NO

860108•Q

OPERATION •

PAGE 3.4

INTERNET: kochequipment.com

WARNING

E-MAIL: info@kochequipment.com

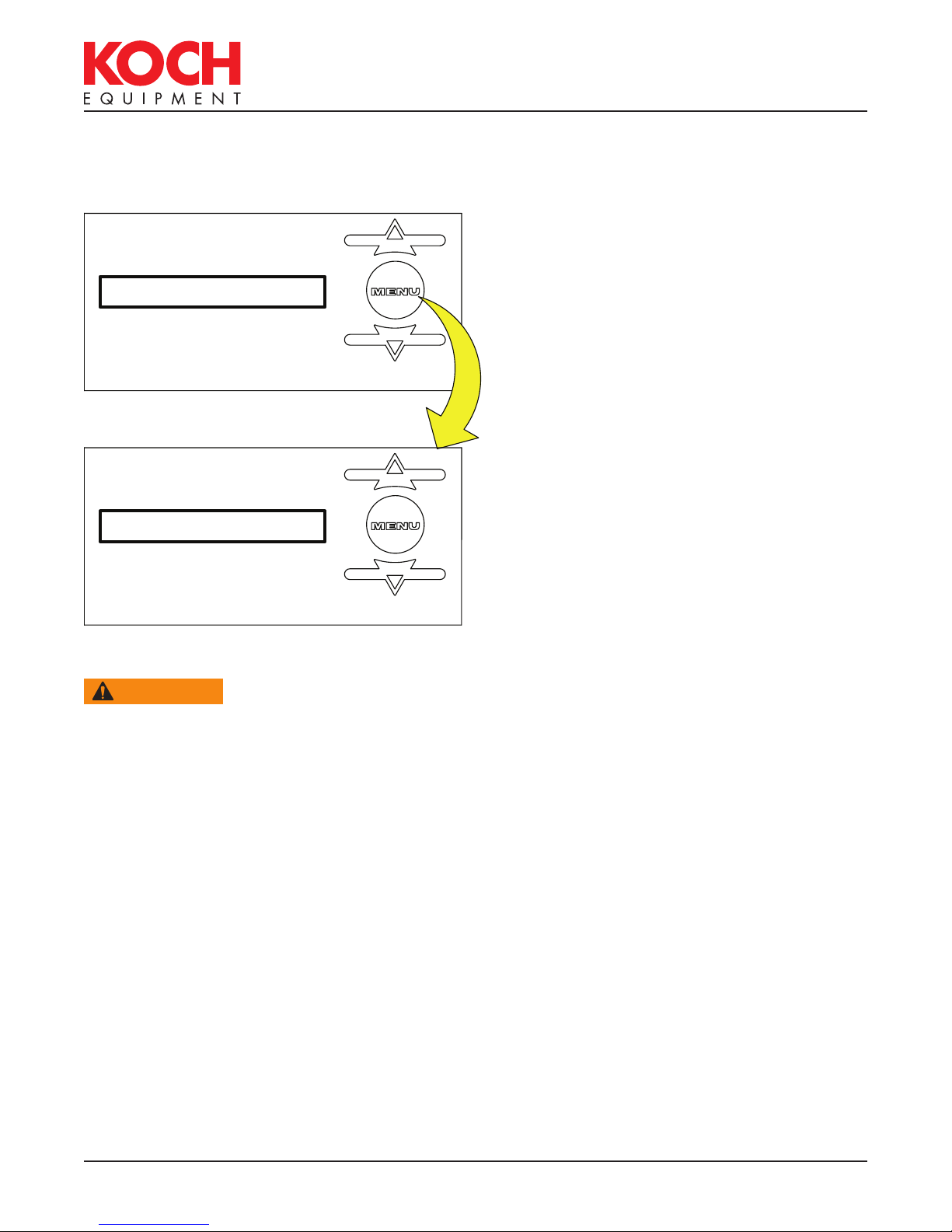

Operator Menu on Digital Panel (continued)

MAIN: 816-753-2150

TOLL FREE: 800-777-5624

GAS: YES

GAS: 75

Figure 3.5

+

PROGRAM

YES

If the machine is equipped with the gas

option, it can be turned on or off by pressing

the UP or DOWN arrow keys.

Press the MENU key.

-

NO

Gas is set to % gas using the UP and DOWN

+

PROGRAM

YES

Arrow Keys. This value also corresponds to

the vacuum reading inside the chamber. It

is recommended to use pulse vent when gas

flushing to a low % vacuum. The range is

-

NO

98% to 30%.

Press the MENU key.

WARNING

Explosion hazard.

Do not use a gas with an oxygen content greater than 22% with gas flush option.

860108•Q

OPERATION •

PAGE 3.5

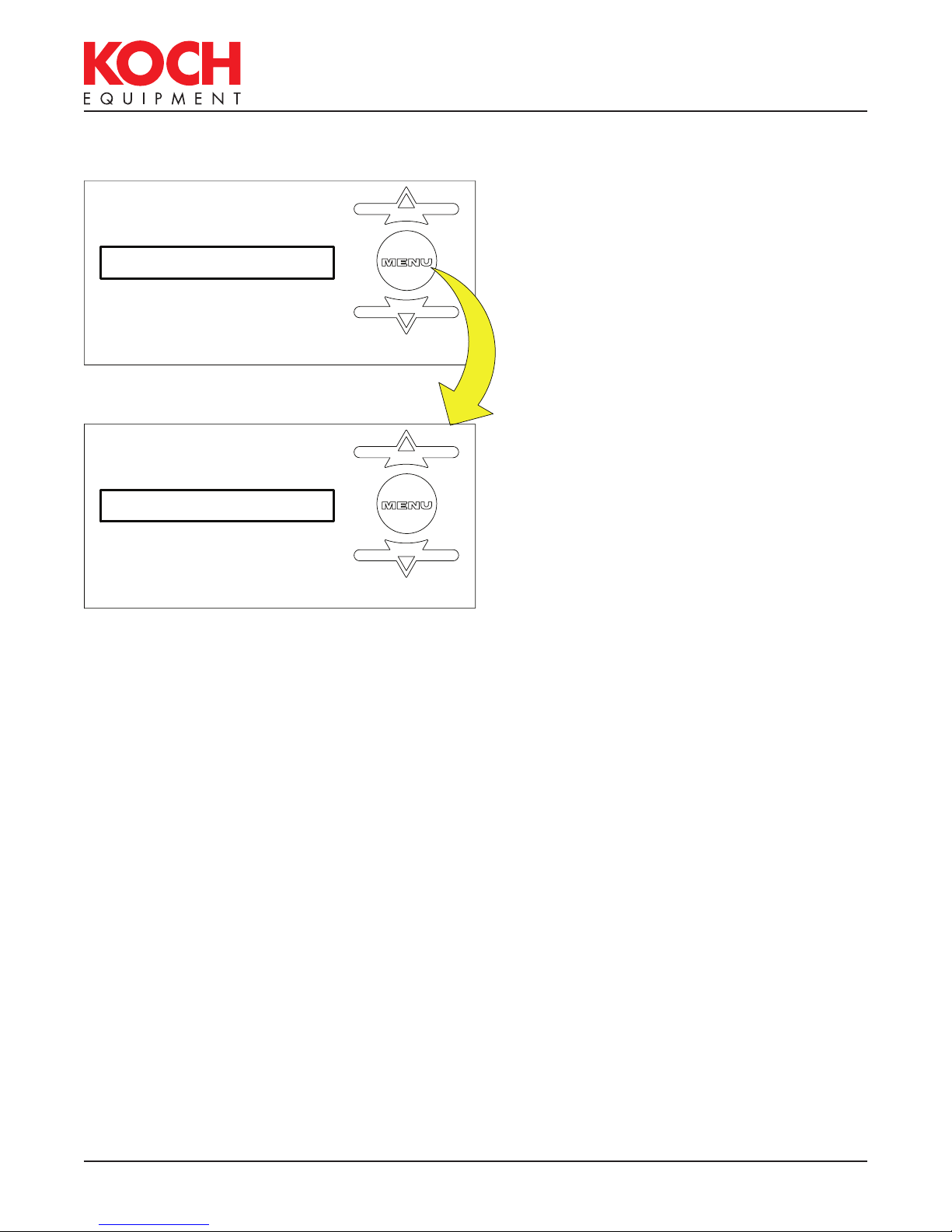

Selecting a New Program

+

PROGRAM

MAIN: 816-753-2150

TOLL FREE: 800-777-5624

INTERNET: kochequipment.com

E-MAIL: info@kochequipment.com

From the Main Menu, use the UP and

YES

DOWN Arrow Keys to select a new program.

RUNNING PROG: 1

ENTER PROGAM: 2

Figure 3.6

Press the UP Arrow to switch to program 2

(or any of the ten programs.)

-

NO

New parameters may be set for vacuum,

+

PROGRAM

YES

seal time and gas for program 2 (following

the procedure described in the previous

example) or simply close the lid on the

machine and run program 2.

-

NO

860108•Q

OPERATION •

PAGE 3.6

MAIN: 816-753-2150

WARNING

TOLL FREE: 800-777-5624

INTERNET: kochequipment.com

E-MAIL: info@kochequipment.com

Sealing with Air-Assist

All machines are equipped with regulators for air-assisted sealing. Set the air pressure

regulator to 20 p.s.i. increasing to a maximum of 40 p.s.i. While a good seal can be

obtained without air-assist, use air-assist when:

• Gas back-flushing above average pressure.

• Using shrink pouches.

• Packaging a product that easily contaminates the seal area of the pouch.

• Trying to overlap pouches.

• Wrinkles cannot be avoided in the seal area.

•

Using the Double Seam Seal Option.

Gas Flush Option

Gas flushing is the introduction of an inert gas into the chamber after the vacuum stage

is finished. Gas can be used as a filler to prevent crushing of the product after sealing, as

a means to prolong shelf life or as a means to maintain desirable product appearance.

Commonly used gasses include nitrogen, carbon dioxide, or a mixture of both. Consult your

local gas supplier to select the proper gas for your product.

WARNING

Explosion hazard.

Do not use a gas with an oxygen content greater than 22% with gas flush option.

Double Seam Seal Option

All machines are equipped with standard seal bars having a single seal element per seal

bar. The double seam seal bars have two seal elements per seal bar. We recommend using

air-assisted sealing with this option to achieve best results.

860108•Q

OPERATION •

PAGE 3.7

MAIN: 816-753-2150

TOLL FREE: 800-777-5624

INTERNET: kochequipment.com

E-MAIL: info@kochequipment.com

THIS PAGE LEFT BLANK INTENTIONALLY.

860108•Q

OPERATION •

PAGE 3.8

MAIN: 816-753-2150

CAUTION

TOLL FREE: 800-777-5624

INTERNET: kochequipment.com

E-MAIL: info@kochequipment.com

MAINTENANCE

Prior to Cleaning

Every environment and application is different; therefore, Koch Equipment LLC cannot

provide cleaning instructions to guarantee microbiological sanitation. Koch Equipment

requests that the owner of this machine consult with sanitation experts to review the

unit working in their particular environment to develop a robust cleaning schedule and

methodology, followed by bacterial testing to ensure satisfactory cleaning procedures are

followed.

Cleaning Recommendations

Before cleaning the machine, turn power off; disconnect the main power, and lockout the

connection.

DANGER

Disconnect and lockout power before servicing machine or cleaning. Do not remove panels

unless power has been disconnected and locked out at risk of electric shock hazard.

Check with the detergent and sanitizer manufacturers that their products are compatible

with the listed materials.

CAUTION

Do not get the cleaning agents in eyes, on skin, or on clothing. Always wear rubber gloves,

goggles, and protective clothing when contact is likely. Consult product manufacturer for

specific details.

Never hose down the machine. Damage caused by hosing or high pressure washing is not

covered under warranty.

1. Filler Plates: Remove filler plates. The filler plates are made from polyethylene. Clean,

sanitize, and dry. High pressure water spray can be used on the filler plates.

2. Lid and Backup Strip: The lid is constructed of acrylic. Use only nonabrasive soap and

water. Do not use window sprays or kitchen scouring compounds. The backup strip is

made of silicone. Clean, sanitize, and dry.

3. Seal Bars: Remove the seal bars by first lifting them up off of the guide rods. Remove

the wire connectors from the adapter clips on the seal bar and remove the seal bar from

the machine. The seal bars are made of aluminum and phenolic. Clean, sanitize, and

dry.

4. Chamber and Base: The chamber is made of 304 stainless steel and the base is made

from polyurethane. Clean, sanitize, and dry, including under the seal bar bladder (not

removable).

5. Clean under the machine.

6. Reinstall the seal bar.

7. Use bacteriological testing to insure cleaning process.

Hazardous voltage.

Cleaning agents.

860108•Q

MAINTENANCE •

P A G E 4.1

MAIN: 816-753-2150

TOLL FREE: 800-777-5624

INTERNET: kochequipment.com

E-MAIL: info@kochequipment.com

Vacuum Pump Maintenance

Consult the pump manufacturer’s manual provided with the machine for detailed

information.

Seal Bar Maintenance

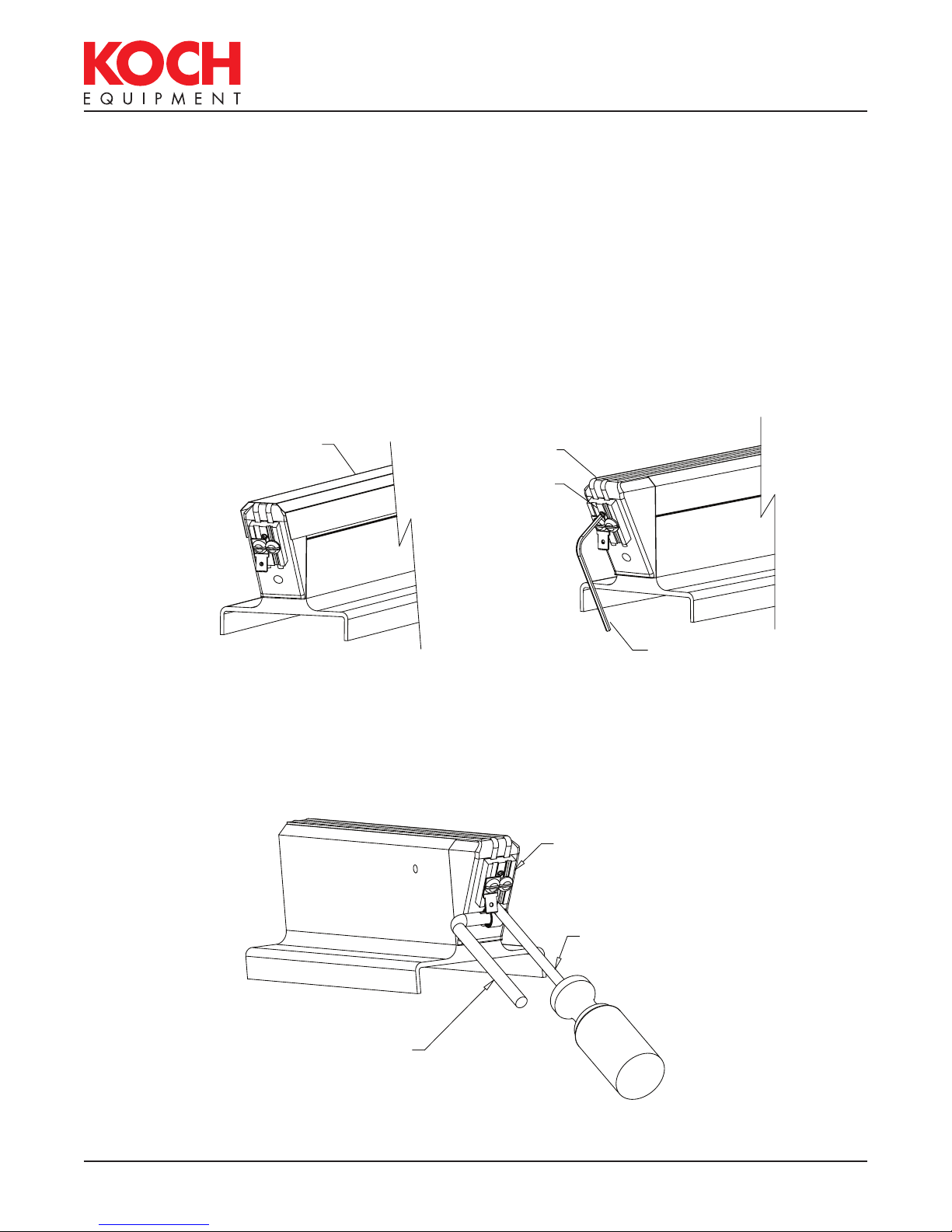

The following illustrations show replacement of the seal elements for the seal bars.

Step 1.

Remove the seal bars from the machine. Pull

off the Teflon

off any remaining Teflon

®

tape strip and discard. Clean

®

tape adhesive

using acetone or an equivalent solvent.

Teflon® tape

TEFLON TAPE

Figure 4.1

Step 2.

Using a 2mm Allen wrench, loosen the set

screws for the cut-off wire and the seal

element on both ends of the seal bar and

discard.

Seal element

SEAL ELEMENT

Set screw

SET SCREW

2mm ALLEN

Figure 4.2

2mm Allen

WRENCH

wrench

Step 3.

If you are replacing the L-shaped spring retainer and the spring at this time, loosen the set

screw and remove the old spring retainer and spring and install the new ones. Adjust the

spring retainer to allow a 1/8-in. gap between the spring retainer and the seal bar. This will

allow the seal element to remain under tension after tightening the seal element.

TIGHTENING TOOL

Figure 4.3

860108•Q

MAINTENANCE •

BRASS CONTACT

SLOTTED TIP

SCREWDRIVER

P A G E 4.2

MAIN: 816-753-2150

TOLL FREE: 800-777-5624

INTERNET: kochequipment.com

E-MAIL: info@kochequipment.com

Reading the Indicators

If your machine is controlled by a digital control module (with touch pad), this design to aids

in troubleshooting. The digital panel has indicator lights mounted on the front below the

ON/OFF switch. The indicator lights correspond to the operating devices and should turn on

and off in the following sequence when the machine lid is closed:

1. Vacuum Pump [C-1]

2. Gas Flush Valve [SOL-3] (optional)

3. Seal Bladder Valve [SOL-2]

(stays on until completion of cycle)

4. Seal Impulse Contactor [C-2]

5. Ventilation Valve [SOL-1]

The device should be operating when the light is illuminated. If the lights illuminate in the

proper sequence, but there is still a problem, look for the problem in the operating device

itself. If the lights do not sequence properly, look for a problem in the control module.

860108•Q

MAINTENANCE •

P A G E 4.3

E-MAIL: info@kochequipment.com

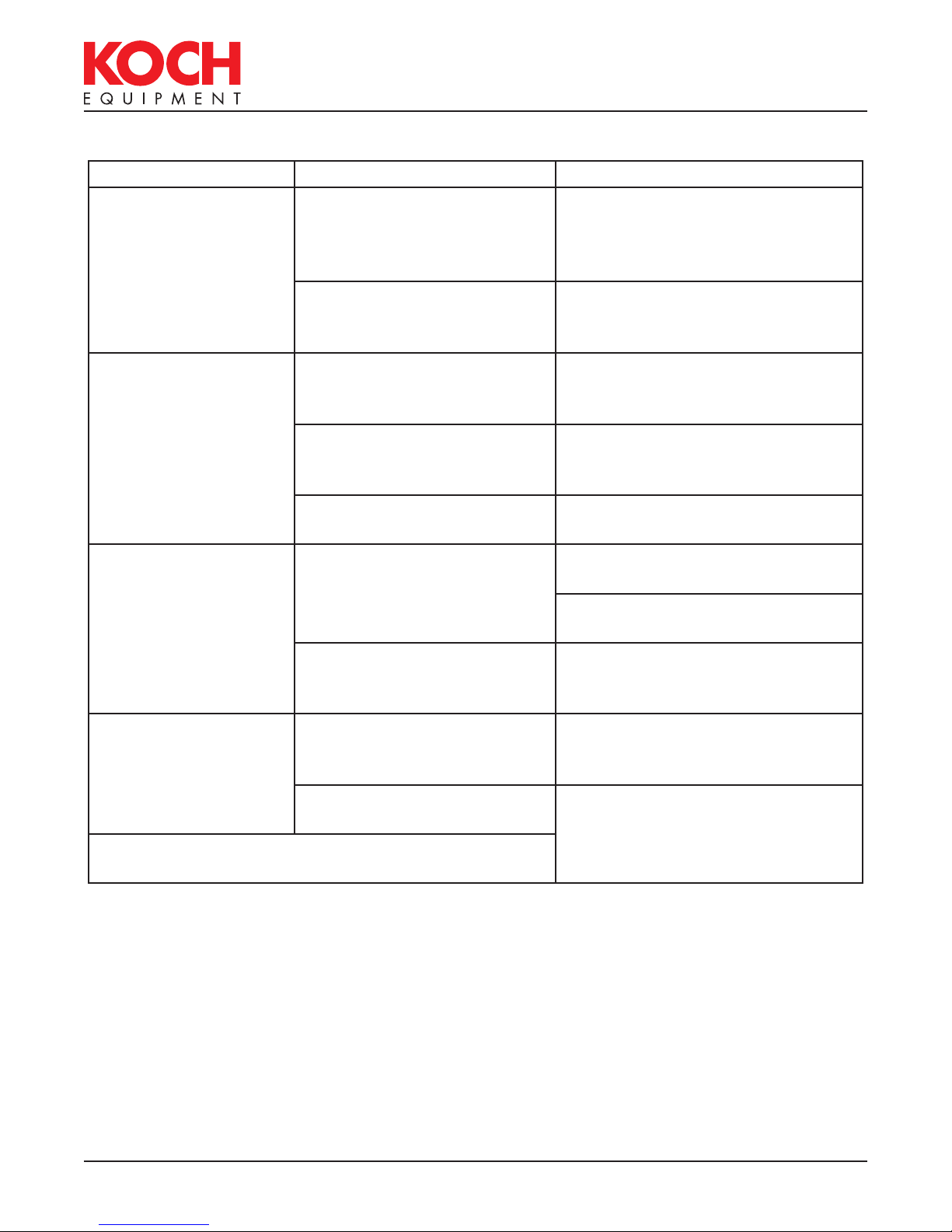

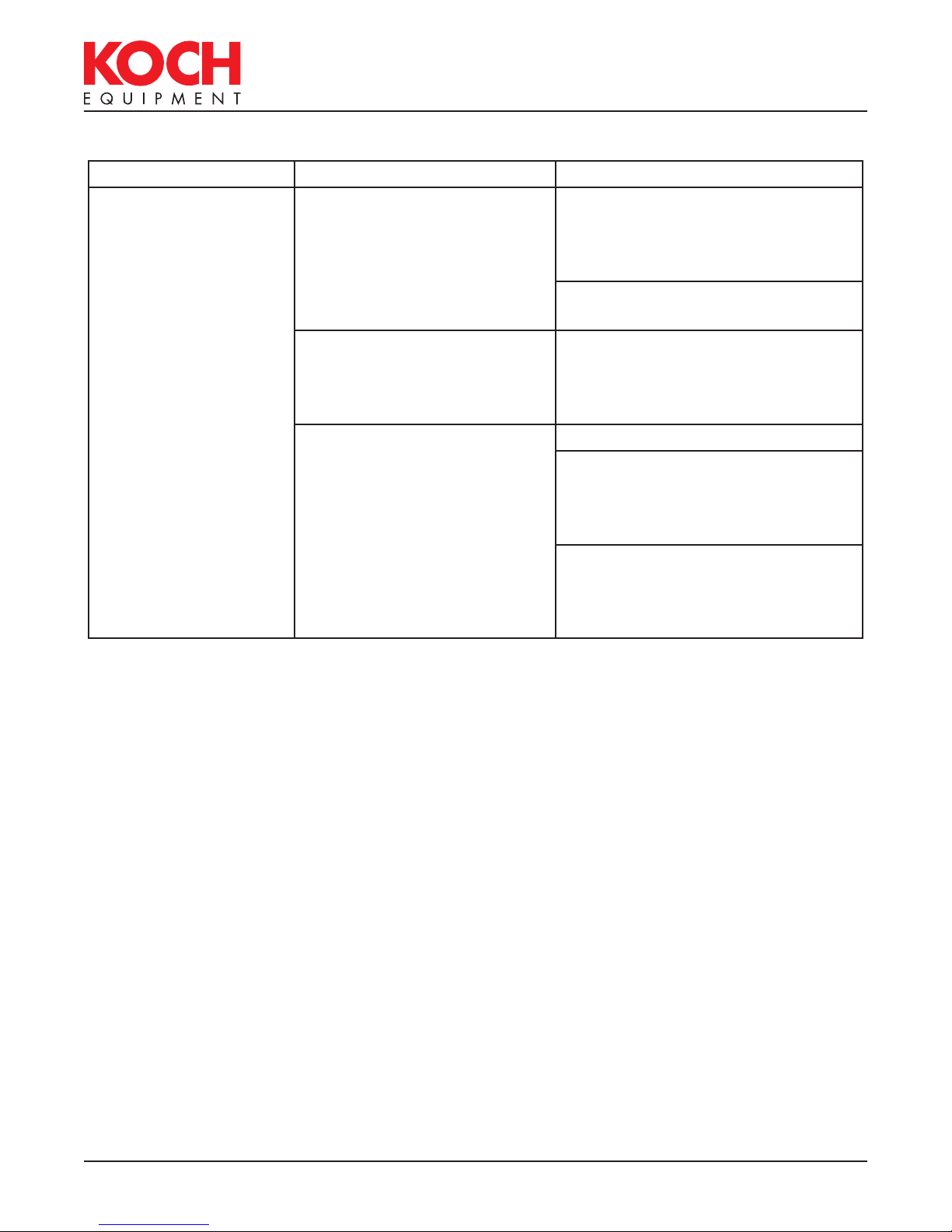

Troubleshooting

Problem Indications Remedy

MAIN: 816-753-2150

TOLL FREE: 800-777-5624

INTERNET: kochequipment.com

Machine will not start Green power “ON” light not

lit when switch is turned on

Make sure that the power

requirements match those given

on the nameplate. Also, check

fuse F-2; replace if blown.

Vacuum pump does not run Make sure that the power

requirements match those given

on the nameplate

No vacuum When lid is closed, indicator

light (VAC) is “OFF” on the

Check lid switches LS-1 for proper

adjustment

control module

Vacuum not pulling lid down Check intake screen in vacuum

pump hose barb for blockage,

pieces of bags, labels, bone, etc.

Longer vacuum cycle times Check intake screen in vacuum

pump hose barb for blockage

No gas flush (optional) If indicator light (GAS) is lit Check for proper gas pressure

going into gas inlet

Check for proper operation of gas

flush valve (SOL-3)

If indicator light (GAS) is not

lit

Chamber not venting

(lid will not open)

Lid will not open and red

indicator light “VENT” on

control module is lit

“VENT” indicator light is not

lit

NOTE: Lid can be released by pulling the hose off of

the vacuum gauge to remove product.

Check gas flush potentiometer on

analog control module or possible

defective digital control panel

Check ventilation valve SOL-1 for

proper operation

Check cool down potentiometer

on analog control module or

possible defective digital control

panel

860108•Q

MAINTENANCE •

P A G E 4.4

E-MAIL: info@kochequipment.com

Troubleshooting

Problem Indications Remedy

MAIN: 816-753-2150

TOLL FREE: 800-777-5624

INTERNET: kochequipment.com

Improper or no

sealing

Seal bladder light on control

module is lit, but the seal bar

does not go up

The seal bar is not heating

up even though the red

seal light on the front panel

comes on

The red seal light on the

front panel either does not

light for the proper length of

time (½ to 1 second) or does

not light at all

Check to make sure that the

regulator knob is turned fully

clockwise or, if air-assist is used,

set to the recommended pressure

Check seal bladder valve SOL-2

for proper operation

Check seal bar connection points

and clips for corrosion and proper

tension

Check for broken seal element

Check seal bar fuse F-1 located on

the analog or digital panel. If the

machine is 110VAC with two seal

bars, F-1 is located on the chassis.

Make sure the seal impulse

potentiometer is set high enough

or check for possible defective

digital control panel

NOTE: For proper sealing, three things must occur:

1. The seal bar must come down and place adequate pressure between the seal bar and

the backup strip.

2. The seal element must heat up sufficiently to fuse the pouch.

3. The pouch must be allowed to cool for a time to ensure a good “set.”

860108•Q

MAINTENANCE •

P A G E 4.5

Loading...

Loading...