Kobold ZDM-XX08 Series, ZDM-XX02 Series, ZDM-XX09 Series, ZDM-XX10 Series, ZDM-XX20 Series User Instructions

...Page 1

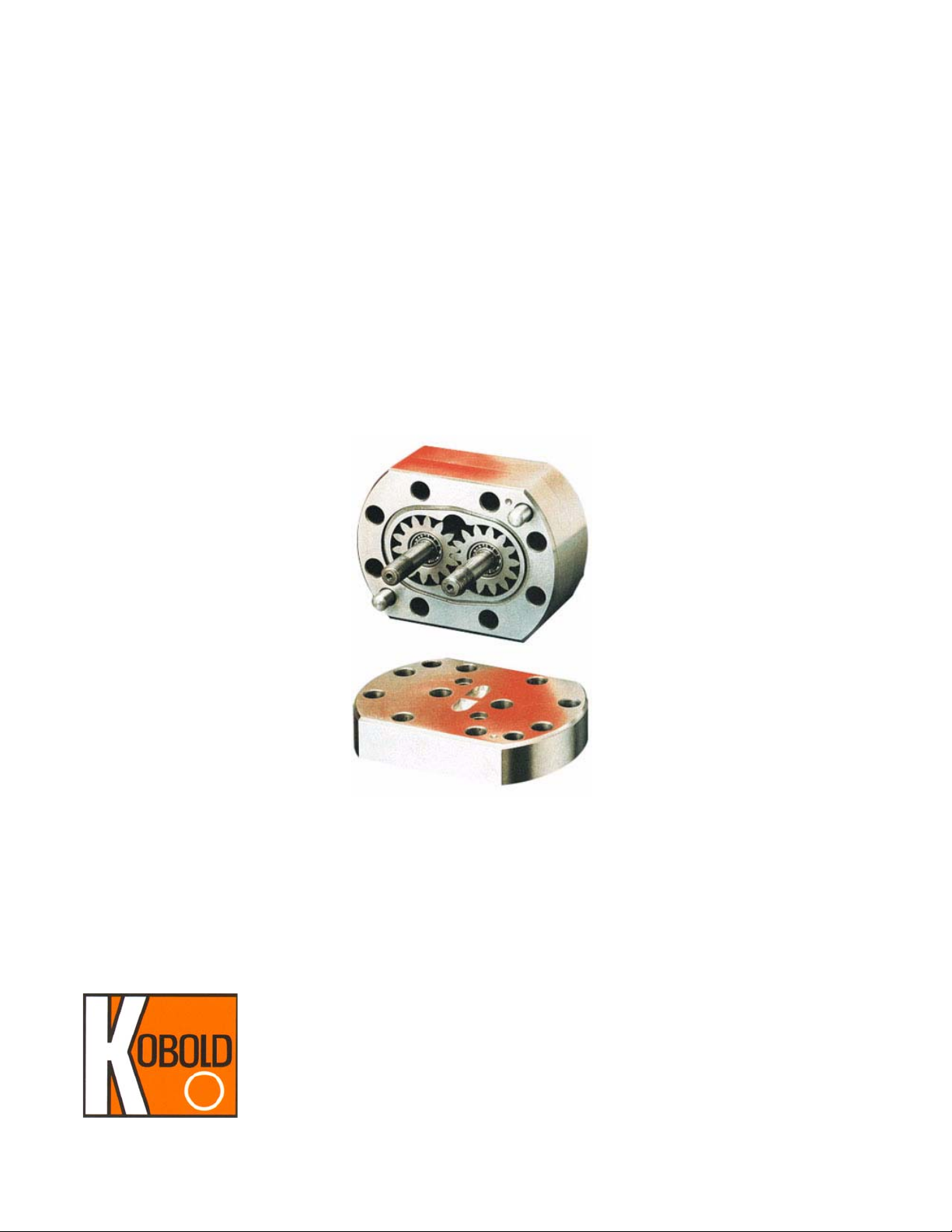

ZDM Positive Displacement Flow Meter

User Instructions

USA

1801 Parkway View Drive

Pittsburgh, PA 15205

PH 412-788-2830

www.koboldusa.com

Canada

9A Aviation

Point Claire, QC H9R 4Z2

PH 514-428-8090

ZDM_manual_11-10

Page 2

Table of Contents

Topic Page

1.0 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

2.0 Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

2.1 Principle of Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

2.2 Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

2.2.1 Mechanical Data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Filtration Requirements. . . . . . . . . . . . . . . . . . . . . . . . 3

Electrical Data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2.2.3 Accuracy. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2.2.2 Pressure Loss. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

3.0 Installation Instructions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

3.1 Mechanical Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

3.1.1 Installing the Mounting Plate. . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

3.1.2 Attaching the Flow Sensor to the Mounting Plate. . . . . . . . . . . . 4

3.1.3 Bolt Torque Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

3.1.4 Connecting Piping to the Sensor . . . . . . . . . . . . . . . . . . . . . . . . 5

3.2 Electrical Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

4.0 Operating Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

4.1 Turning the Unit On . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

4.2 Flow Measurement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

4.3 Turning the Unit Off . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

5.0 Arrival of Damaged Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

6.0 Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

7.0 Need Help with your ZDM Sensor? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Appendix A: Pressure Loss vs. Flow Rate at Various Viscosities . . . . . . . . . . . 9

List of Diagrams

Diagram 3.2.1 ZDM Wiring Schematic. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Diagram 4.2.1 ZDM Frequency Output Waveform. . . . . . . . . . . . . . . . . . . . . . . 6

List of Tables

Table 1: ZDM Wetted Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Table 2: Volume per Pulse for Various ZDM Ranges. . . . . . . . . . . . . . . . 7

Page 3

ZDM

KOBOLD ZDM POSITIVE DISPLACEMENT FLOWMETER

User Instructions

CAUTION: For safety reasons, please read the cautionary information located at

the end of this manual, before attempting installation.

1.0 General

Congratulations on your purchase of a Kobold ZDM Positive Displacement flowmeter.

The ZDM is one of the most precise and reliable low volume, liquid flow measuring

products available today.

The ZDM operates on the viscosity and density independent volumetric principle. Two

gears are brought into counter-rotation by the force of liquid moving past the gears along

the meter’s housing. Engagement of the gear teeth with the housing walls entraps a

defined volume in the cavity between the gear teeth. A detector counts the gear teeth as

the cavities empty into the exit port. The precision of the meter is defined by the gear

cavity volume. The ZDM can meter volumes as low as 0.02 CC (cubic centimeters.) This

ultra-high precision is coupled with bi-directional flow capability, viscosity compatibility to

100,000 cS t and a mechanical robustness ca pable of pressures to 6500 PSIG (450 BAR).

The ZDM is the ideal choice for difficult clean liquid applications involving media with

lubricating properties ranging from very slight, to extensive.

FM Rev. 11/10

Page 4

ZDM 2

2.0 Description

2.1 Principle of Operation

The ZDM operates on the volumetric displacement principle. The meter moves pocket s of

liquid from the inlet port to the exit port in discrete segments of known volume. These

pockets are defined by the space between adjacent gear teeth and the internal housing

wall.

As liquid enters the meter, the inlet cavity fills. The liquid pressure forces the meter’s

gears to rotate from the gear mesh-point inwards. The ge ar teeth ca vities fill with liqu id in

the inlet side of the meter and remain filled as the teeth come into near-contact with the

meter’s interior walls. The gear teeth then drag the liquid to the exit cavity at the opposite

side of the meter. This process causes the exit cavity to fill since the liquid is squeezed

out of the spaces between the teeth at the gear mesh point. The liquid then flows out the

exit port of the meter.

A proximity sensor in the housing senses the passage of individual gear teeth. Since the

passage of a tooth signals the passage of its trailing space (filled with liquid), the system

as a whole signals with an electrical pulse every time a displaced amount is emptied into

the exit port. The resolution of the ZDM is, therefore, determined by the volume between

the gear teeth.

This entire procedure is completely independent of the properties of the liquid, making the

system applicable to a wide variety of media (even liquids with dynamically changing

characteristics.) The only limitations to the system are mechanical ones. Since metal to

metal contact is involved, the liquid must have some lubricating properties in order to

prevent excessive wear of the gear teeth. If the gear teeth wear down, liquid will leak p ast

them excessively. This excess leakage will degrade the meter’s accuracy. The required

amount of media lubricity is very slight. For example, leaded gasoline (such as jet fuel)

will work, while unleaded gasoline will not.

Another limitation is caused by the relatively high pressure loss inherent to positive

displacement technology. The pressure loss through the ZDM becomes unacceptable if

the media viscosity exceeds 100,000 cSt.

2.2

Specifications

2.2.1 Mechanical Data

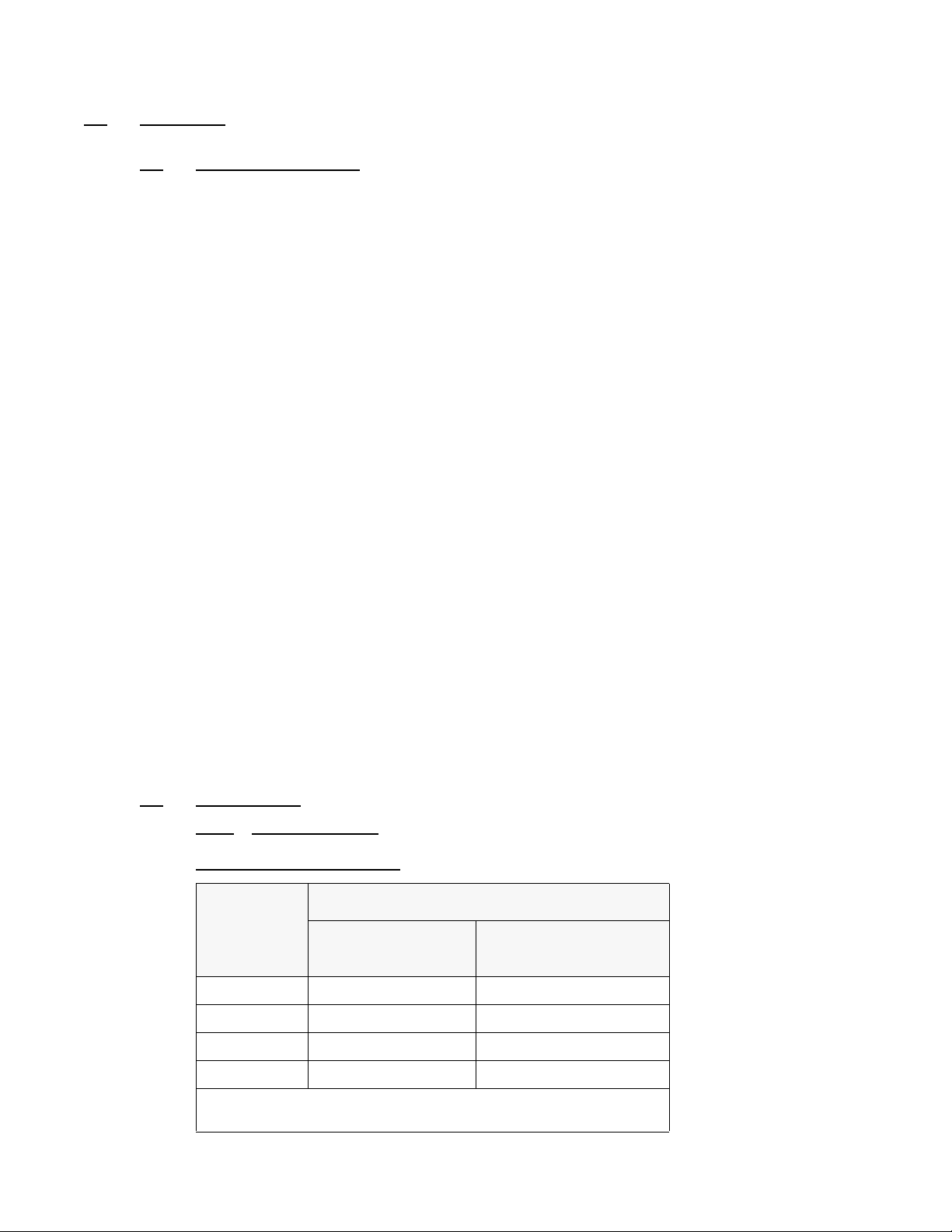

Table 1: ZDM Wetted Parts

Nominal Construction Material

Wetted

Component

Housing Cast Iron 316 Ti SS (DIN 1.4571)

Cast Iron

(ZDM-X1XX)

316 Stainless Steel

(ZDM-X3XX)

FM Rev. 11/10

Gears SS* (DIN 1.4122) 316 Ti SS (DIN 1.4571)

Seals

Bearings Carbon Steel Tungsten Carbide

* Alloy content of DIN 1.4122 SS: X 35 Cr Mo 17. No direct AISI equivalent. Similar

to 400 series SS.

FKM (EPDM Optional) FKM (EPDM Optional)

Page 5

3ZDM

Filtration Requirements

ZDM-XX02, -XX04, -XX07: 10 µM (1600 mesh)

ZDM-XX08, -XX09: 20 µM (750 mesh)

ZDM-XX10, -XX20, -XX40: 50 µM (250 mesh)

Maximum Pressure Rating: Cast Iron: 4500 PSIG

St. Steel: 6500 PSIG

Maximum Temperature Rating

Standard: -40 to 248°F

Accuracy: ±0.3% of reading with

viscosity >20 cSt.

Repeatability: ±0.05% of reading

Electrical Data

Sensor Type: Qty. 2 Push-Pull Outputs (Channels A & B)

A & B Signals are 90° out of phase.

Phase difference can be used to determine

flow direction using suitable receiving equipment.

Power Requirements

Voltage (V

): 10-28 VDC

cc

Current: 80 mA max. @ 24 VDC

Power: 1.92 W max. @ 24 VDC

Output Signal

Type: DC voltage pulse

Form: Square wave

Amplitude: Low = GND, High = V

- 1.0 VDC

cc

FM Rev. 11/10

Page 6

ZDM 4

2.2.2 Pressure Loss

Pressure loss is a function of the viscosity of the liquid being metered, and

its rate of flow. Detailed pressure loss information may be found in

Appendix A of this manual.

3.0

Installation Instructions

CAUTION: For safety reasons, please read the cautionary information located at

the end of this manual, before attempting installation.

3.1 Mechanical Installation

The ZDM is shipped from the factory in two pieces (not counting the electrical

connecting cable or the sensor-mounting plate fastening bolts) consisting of the

mounting plate and the sensor body. We recommend that you install the mounting

plate first, then attach the sensor and finally connect the piping.

3.1.1

3.1.2

Installing the Mounting Plate

The sensor may be rigidly held in place on your installation through use of

the four threaded holes in the base of the mounting plate. These holes are

metric and sized as follows:

ZDM-XX02 to ZDM-XX08: M6 (6 mm metric)

ZDM-XX09 to ZDM-XX40: M8 (8 mm metric)

Attaching the Flow Sensor to the Mounting Plate

The sensor comes supplied with a set of four steel bolts and O-rings for

fastening the sensor to the mounting plate.

3.1.2.1 Install the O-rings into the grooves in the body of the sensor.

3.1.2.2 Position the sensor on the mounting plate so that the bolt holes in

the sensor line up with the bolt holes in the mounting plate.

3.1.2.3 Insert the bolts into the bolt holes and thread into mounting plate

until they are finger tight.

3.1.2.4 With an appropriately sized wrench, tighten the bolts to the specified torque in a diagonal bolt tightening pattern.

3.1.3

Bolt Torque Specifications

The following are the nominal torque specifications for all ZDM bolts.

Meter Model

ZDM-XX02 to ZDM-XX08:40 29.5

ZDM-XX09 to ZDM-XX20:70 51.6

ZDM-XX40: 120 88.5

Torque (N-m) Torque (lb.-ft.)

FM Rev. 11/10

Page 7

5ZDM

3.1.4 Connecting Piping to the Sensor

The procedure for attaching piping to the sensor depends on the type of

thread that was ordered with the sensor. The most common thread in

North America is NPT (series ZDM-3XXX and ZDM-4XXX sensors.)

Occasionally, the European pipe thread (BSP) is ordered because of its

superior leak resistance. Series ZDM-1XXX and ZDM-2XXX sensors all

have BSP threaded fittings.

If the fittings on your ZDM are incorrect for your application, you can

correct the situation by purchasing a different mounting plate.

3.1.4.1 If you have NPT threads, coat the threads with a paste type pipe

sealant before threading into the mounting plate.

We recommend that PTFE tape NOT be used since pieces of it

may find their way into the sensor, possibly causing the gears to

bind. Should you have no alternative to PTFE t ape, make sure tha t

it is properly trimmed and does not extend beyond the first thread

on your pipe fittings.

3.1.4.2 If you have BSP threads, place the sealing gaskets over the ends

of your pipe fittings and thread fittings into the mounting plate.

3.2

Electrical Connections

The standard ZDM operates on a power supply of: 10-28 VDC.

Diagram 3.2.1:

ZDM Wiring Schematic

FM Rev. 11/10

Page 8

ZDM 6

4.0 Operating Instructions

4.1 Turning the Unit On

Supply power.

4.2

Flow Measurement

The ZDM transmits a frequency based electronic signal in response to flow

through its mechanism. This signal takes the form of a square wave, the

amplitude of which is the supply voltage (V

) minus 1.0 VDC. A representation of

cc

the waveform is given in Diagram 4.2.1, "ZDM Frequency Output Waveform", on

page 6. Each pulse in the transmitted signal represents a fixed quantity of liquid

passing through the meter. The exact amount of liquid represented by each pulse

is a function of the range of the meter. To determine the sensitivity of your meter,

consult Table 2, "Volume per Pulse for Various ZDM Ranges", on page 7.

Diagram 4.2.1:

ZDM Frequency Output Waveform

FM Rev. 11/10

Page 9

7ZDM

Table 2: Volume per Pulse for Various ZDM Ranges

ZDM Model Number Range (GPM) Frequency(Hz) Pulses per Gallon

ZDM-XX02 0.0005 - 0.53 1.577-1671. 90 189,272

5.0

ZDM-XX04 0.0011 - 1.

ZDM-XX07 0.0026- 2.

ZDM-XX08 0.0053 - 4.

ZDM-XX09 0.0079 - 10.57 1.

ZDM-XX10 0.0132 - 2

ZDM-XX20 0.0

ZDM-XX40 0.

264

2642

-

-

06

64

76

1.13

31.70

66.00

1.

735

-1671.

90

1.640-1665.

1.672-1501.

246

0.833-1333.

0.833-1

4.167-1041.

59

56

-1667.17 9,463.

11

000.00

00

94,63

37,854

18,927

3,785.4

1,892.7

946.3

6

.4

.2

6

4

2

6

4.3 Turning the Unit Off

Remove power.

Arrival of Damaged Equipment

Y our in strument was inspected prior to shipment and found to be defect-free. If damage is

visible on the unit, we advise that you carefully inspect the packing in which it was

delivered. If damage is visible, notify your local carrier at once. The carrier is liable for a

replacement under these circumstances. If your claim is refused, please contact

KOBOLD Instruments.

6.0

7.0

Maintenance

The ZDM is continuously lubricated by the medium flowing through its internal

components, so no extra lubrication is required.

Please note the following typical filtration requirements:

ZDM-XX02 to ZDM-XX07: 10 um

ZDM-XX08 to ZDM-XX09: 20 um

ZDM-XX10 to ZDM-XX40: 50 um

Make sure that the filter is kept in proper functioning condition. The frequency of filter

replacement and maintenance will depend on the level on cleanliness of the metered

liquid.

The only wear component in the ZDM are the gear teeth. The gear teeth will wear with

time. The rate of wear depends on the time of operation and the abrasion/lubrication

properties of your measured liquid. We recommend that users perform a periodic (every

six months is suggested) check of the meter calibration. The most effective way to do this

is to use a calibrated container, a timer and accurate weight scale.

Need Help with your ZDM Sensor?

Call one of our friendly engineers at 412-788-2830.

FM Rev. 11/10

Page 10

9ZDM

Appendix A:

Pressure Loss vs. Flow Rate

at Various Viscosities

FM Rev. 11/10

Page 11

ZDM 10

FM Rev. 11/10

Page 12

11 ZDM

FM Rev. 11/10

Page 13

ZDM 12

FM Rev. 11/10

ZDM-0010 Pressure Loss

Page 14

13 ZDM

FM Rev. 11/10

Page 15

15 ZDM

CAUTION

PLEASE READ THE FOLLOWING WARNINGS BEFORE ATTEMPTING

INSTALLATION OF YOUR NEW DEVICE. FAILURE TO HEED THE

INFORMATION HEREIN MAY RESULT IN EQUIPMENT FAILURE AND

POSSIBLE SUBSEQUENT PERSONAL INJURY.

FM Rev. 11/10

Page 16

ZDM 16

• User's Responsibility for Safety: KOBOLD manufactures a wide range of

process sensors and technologies. While each of these technologies are

designed to operate in a wide variety of applications, it is the user's

responsibility to select a technology that is appropriate for the application,

to install it per these installation instructions, to perform tests of the

installed system, and to maintain all components. The failure to do so could

result in property damage or serious injury.

• Proper Installation and Handling: Use a proper sealant with all

installations. Never overtighten fittings. Always check for leaks prior to

system startup.

• Wiring and Electrical: A supply voltage of: 10-28 VDC is used to power

the ZDM. The sensor systems should never exceed this rating. Electrical

wiring of the sensor should be performed in accordance with all applicable

national, state, and local codes.

• Temperature and Pressure: The ZDM is designed for use in media

temperatures from -40 to 248°F, and for use at pressures up to 6500 PSIG,

depending on model. Operation outside these limitations will cause

damage to the unit and possible personal injury.

• Material Compatibility: Check your model number with the wetted

materials specifications of this manual. Make sure that the model which

you have selected is chemically compatible with the application liquids.

While the electronics housing is liquid resistant when installed properly, it is

not designed to be immersed. It should be mounted in such a way that it

does not normally come into contact with fluid.

• Flammable, Explosive and Hazardous Applications: The ZDM with

option Ex or EXA are intrinsically safe and are the only units which are to

be used in hazardous locations. Other ZDM models should not be used in

areas where an explosion proof design is required.

• Make a Fail-Safe System: Design a fail-safe system that accommodates

the possibility of switch or power failure as well as operator error. In critical

applications, KOBOLD recommends the use of redundant backup systems

and alarms in addition to the primary system.

FM Rev. 11/10

Loading...

Loading...