Page 1

Operating Instructions

for

Viscosity Compensated

Flow Meter / Monitor

Model: VKM

Page 2

VKM

1. Contents

1. Contents ........................................................................................................ 2

2. Note .............................................................................................................. 3

3. Instrument Inspection .................................................................................... 3

4. Regulation Use .............................................................................................. 4

5. Use in Hazardous Areas ............................................................................... 5

5.1. General ................................................................................................ 5

5.2. Contacts and Ex-Contact N/O (code F) ............................................... 5

5.3. Potential Equalisation .......................................................................... 6

6. Operating Principle ........................................................................................ 6

7. Mechanical Connection ................................................................................. 7

8. Electrical Connection .................................................................................... 7

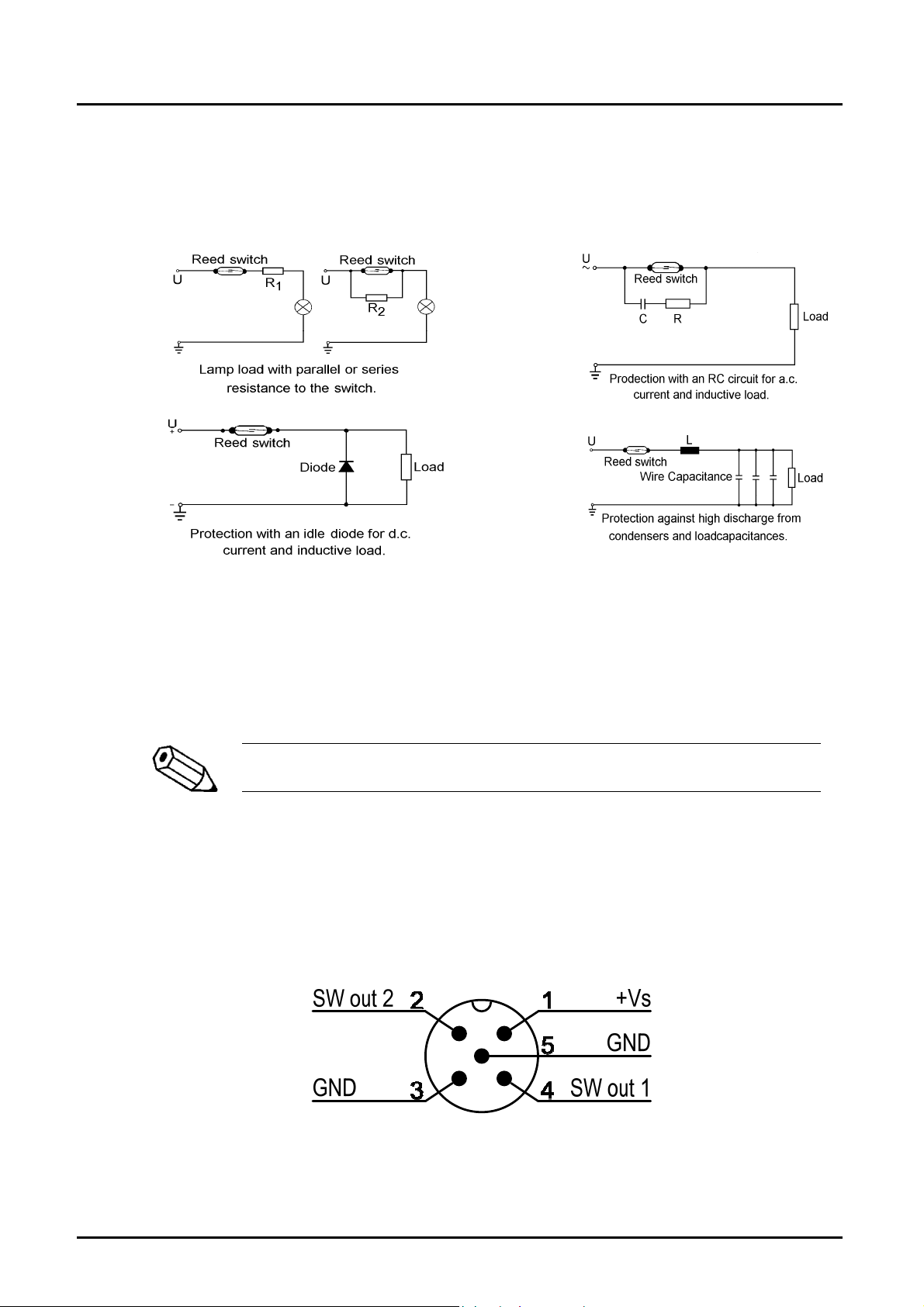

8.1. Switching Output VKM-1.. and VKM-3.. ............................................... 7

8.2. VKM-1... and VKM-3... with Ex-contact (cable connection).................. 8

8.3. Example for Contact Protective Measures ........................................... 9

8.4. ADI-Evaluation Electronics VKM-7.. .................................................... 9

8.5. Compact electronic VKM-8... ............................................................... 9

9. Commissioning ............................................................................................ 10

9.1. General .............................................................................................. 10

9.2. Switching Output VKM-1.. and VKM-3.. ............................................. 10

9.3. ADI-Electronic Analyser VKM-7.. ....................................................... 11

9.4. Compact electronic VKM-8... ............................................................. 11

10.Technical Information .................................................................................. 12

11.Order Codes ............................................................................................... 14

12.Maintenance ............................................................................................... 16

13.Dimensions ................................................................................................. 16

14.Recommended Spare-Parts ........................................................................ 18

15.Declaration of the Manufacturer (VKM) ....................................................... 19

16.Declaration of the Manufacturer (Ex RC...) ................................................. 21

17.EU Declaration of Conformance .................................................................. 22

18.EC-Type Examination Certificate Magnetic reed switch EEx RC ................ 23

Manufactured and sold by:

Kobold Messring GmbH

Nordring 22-24

D-65719 Hofheim

Tel.: +49(0)6192-2990

Fax: +49(0)6192-23398

E-Mail: info.de@kobold.com

Internet: www.kobold.com

page 2 VKM K11/0118

Page 3

VKM

2. Note

Please read these operating instructions before unpacking and putting the unit

into operation. Follow the instructions precisely as described herein.

The devices are only to be used, maintained and serviced by persons familiar

with these operating instructions and in accordance with local regulations applying to Health & Safety and prevention of accidents.

When used in machines, the measuring unit should be used only when the

machines fulfil the EC-machine guidelines.

as per PED 2014/68/EU

In acc. with Article 4 Paragraph (3), "Sound Engineering Practice", of the

PED 2014/68/EU no CE mark.

Diagram 8, Pipe, Group 1 dangerous fluids

3. Instrument Inspection

Instruments are inspected before shipping and sent out in perfect condition.

Should damage to a device be visible, we recommend a thorough inspection of

the delivery packaging. In case of damage, please inform your parcel service /

forwarding agent immediately, since they are responsible for damages during

transit.

Scope of delivery:

The standard delivery includes:

Viscosity Compensated Flow Meter / Monitor model: VKM

Operating Instructions

VKM K11/0118 page 3

Page 4

VKM

4. Regulation Use

The models VKM are used for measuring and monitoring of viscous liquid flows

(max. 540 mm2/s). They are suitable for measuring clean and homogeneous

fluids which are compatible with on the instrument materials used.

If using higher viscosity media, large deviations will occur to the measured values.

Large dirt particles may impede the movement of the float and cause false alarm

conditions.

Ferritic particles deposited on the float (with magnet) may lead to the same

effects.

The instruments are provided as follows:

Flow measurement (only for Model VKM-2.. and VKM-3..)

The actual flow rate may be read off the magnetically operated pointer indicator

mounted on the instrument. The scale indicates the flow rate directly in litres per

minute.

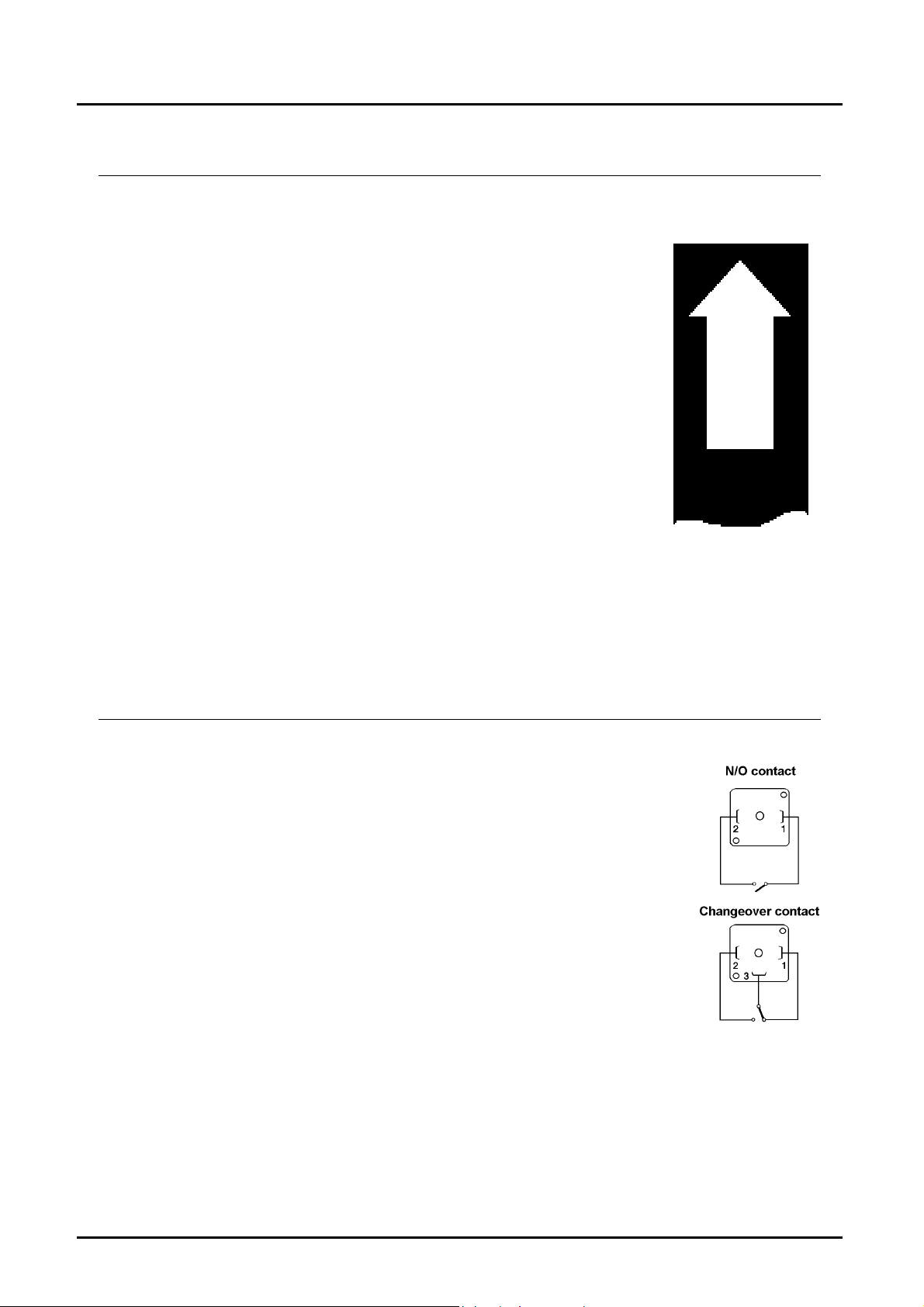

Limit Value Switches (only for Model VKM-1.. and VKM-3..)

The instrument is fitted with one or two adjustable limit value switches for the

monitoring of flow throughput values.

Type of contacts:

N/O contact (standard)

Changeover contact (standard)

N/O (cCSAus)

N/O II 2G Ex mb IIC T6 Gb

II 2D Ex mb IIIC T80°C Db IP67

Changeover (cCSAus)

II 2G Ex mb IIC T6 Gb

II 2D Ex mb IIIC T80°C Db IP67

page 4 VKM K11/0118

Page 5

VKM

5. Use in Hazardous Areas

5.1. General

The Flow Meter and Switch do not have a potential igniting source of its own as a

mechanical operating device; it does not get any identification according to the

guideline 2014/34/EU ("ATEX 100a”).

The attachable contact at the sides, being a component of the whole unit,

requires certificates and/or approvals.

The measurement units can be used as follows:

a) In the Zone 2 (Gas-Ex, Cat. 3G) in explosion group IIA, IIB and IIC

b) In the Zone 22 (Dust-Ex, Category 3D) with non-conductive dusts with a

minimum igniting energy of > 3 mJ

c) In the Zone 1 (Gas-Ex, Cat. 2G) in explosion group IIA, IIB and IIC

d) In the Zone 21 (Dust-Ex, Category 2D) with non-conductive dusts with a

minimum igniting energy of > 3 mJ

The Flow Meter and Switches are filled completely with medium in the normal

operation. Zone 2 or zone 1 conditions may be obtained for a short time.

The ambient temperature limit area is fixed as follows:

Execution

NBR-seal -20....+70 °C -20...+60 °C 250 bar

FPM-seal -10...+100 °C -10...+90 °C 350 bar

Medium

Temperature

Ambient

Temperature

Pmax

5.2. Contacts and Ex-Contact N/O (code F)

The VKM-1 and VKM-3 can be used in the Ex-area as follows:

Ex-Contact N/O (code F) according Category 2 G, 2D Group II,

Zone 1 and 21.

Standard-contacts (Code R, U, C or D) according Category 2G and 2D,

Group II, in zone 1 and 21 in connection with a switching amplifier for

protection type Ex II (2)GD [EEx ia] IIC (intrinsically safe)

The VKM-2 (without switching contact) can be used according Category 2G and

2D for the Group II in Zone 1 and 21.

The electrical connection is explained in section 8. Electrical Connection.

VKM K11/0118 page 5

Page 6

VKM

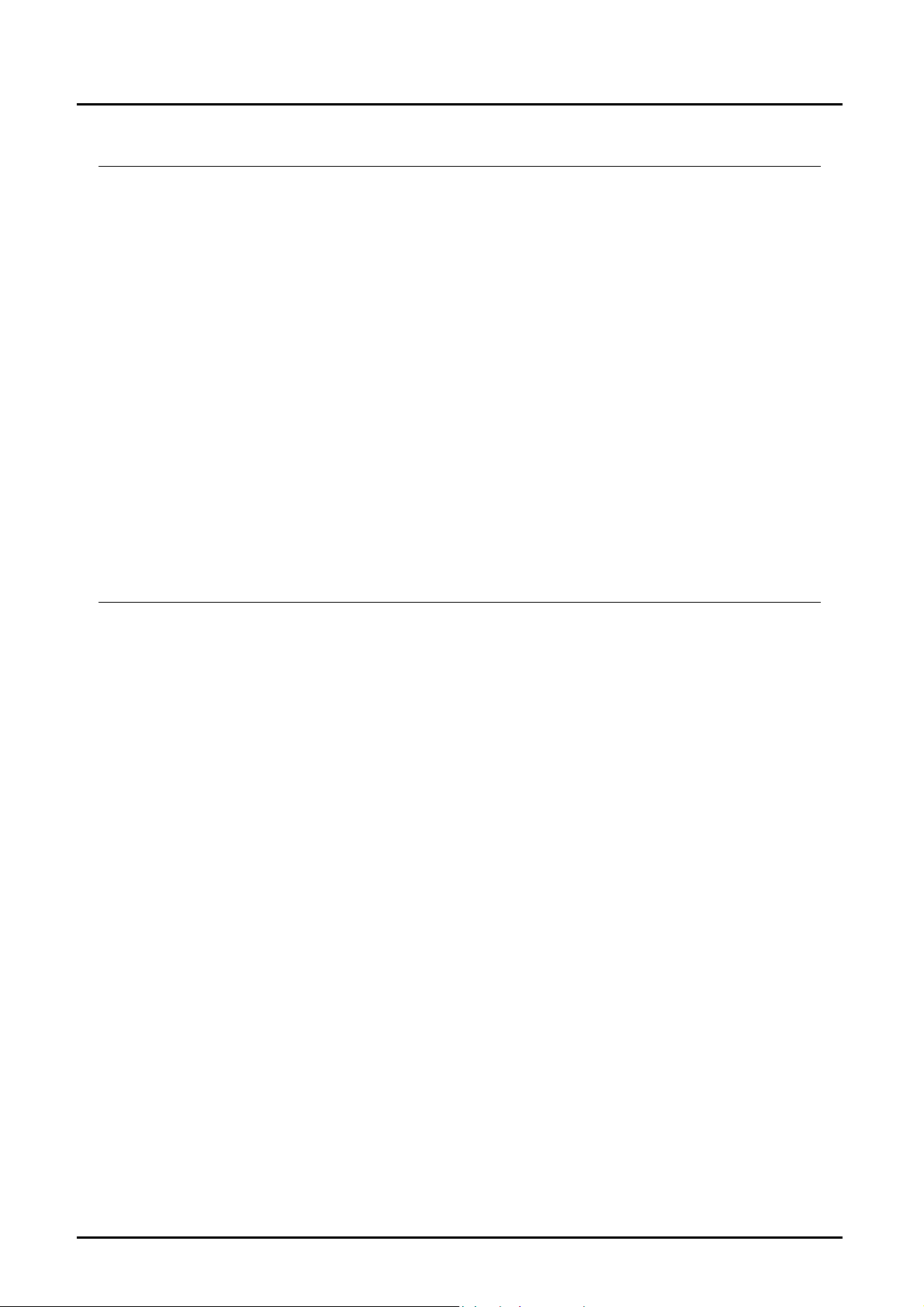

Read-out edge

Read-out edge

Flow Direction

5.3. Potential Equalisation

The All-metal Flow Meters have to be incorporated in the potential equalisation

system of the plant. This is accomplished through connection tube made of metal.

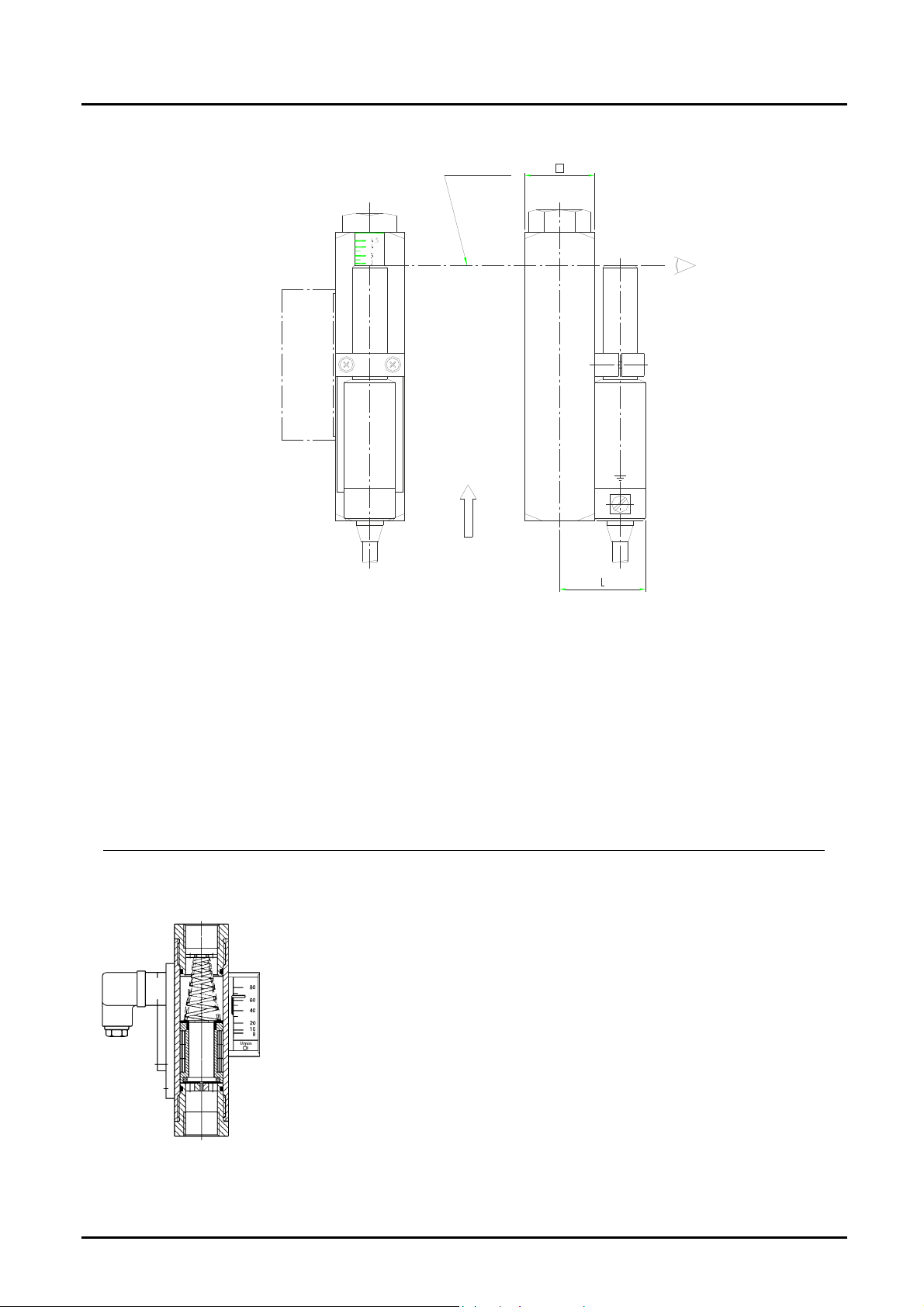

6. Operating Principle

A hollow float with a sharp-edged orifice is located within a

cylindrical bored metal housing. The flowing medium

raises the float against the spring force. The position of the

float corresponds to a particular flow rate which may be

read from the needle indicator mounted on the instrument.

Permanent magnets are fitted around the float which

operate reed contact switches external to the flowing

medium chamber.

The operation of the contacts is voltage free and works by

means of magnetic force. i.e.: the contact is hermetically

sealed from the flowing medium.

page 6 VKM K11/0118

Page 7

VKM

7. Mechanical Connection

Before installation:

It should be confirmed that the maximum allowed

operating pressures and operating temperatures of the

equipment are not exceeded.

(see table: standard material combinations).

The instruments may be mounted in any flow direction.

No recalibration is required when changing position.

The flow must always take place in the direction of the

arrow (see label).

Remove all transport packing and ascertain that no

packing material is left in the instrument.

Sealing of the connection threads should be carried

out with Teflon tape or similar.

The instruments must not be installed within an

induction field.

if possible, after the mechanical installation, it should

be checked that the connection thread to pipe is fully

sealed (see section 9 Commissioning).

8. Electrical Connection

8.1. Switching Output VKM-1.. and VKM-3..

Make sure that the supply wires are de-energized.

Loosen the holding screw of the plug and pull out the cap

from the socket.

Make connection inside the plug-cap according to the wiring

diagram.

If the contact switchpoint has not been adjusted yet, it would

be appropriate to do so at this point.

(see section 9 Commissioning).

Push the plug onto the socket, secure by using the locking

screw. (see section 9 Commissioning).

VKM K11/0118 page 7

Page 8

VKM

8.2. VKM-1... and VKM-3... with Ex-contact (cable connection)

Special requirements for a safety application

The connection of the magnetic switch has to take place in a housing’s, which

is in accordance with a norm ignition protection cat. acc. to EN 50014, 1.2.

The short-circuit current (Ik) of the supply source may not exceed 5 A.

The switch is suitable for an ambient temperature area of –20..+70 °C.

General

Make sure that the supply wires are de-energized.

Plug in the system according to the connecting diagrams.

If the contact switchpoint has not been adjusted yet, it would be appropriate to

do so at this point. (see section 9 Commissioning).

Ex-contact N/O

BN

BU

Attention! The given electrical specifications of reed switches must

never be exceeded, even for a short time. For higher switching

capacities we recommend the use of contact protection relays (e.g.

or model MSR) or any other contact protection device.

After your designated external units are connected to the limit contact and

adjustment of desired switching points is accomplished, then all the work

regarding connections is completed.

The unit can now be set in operation.

page 8 VKM K11/0118

Page 9

VKM

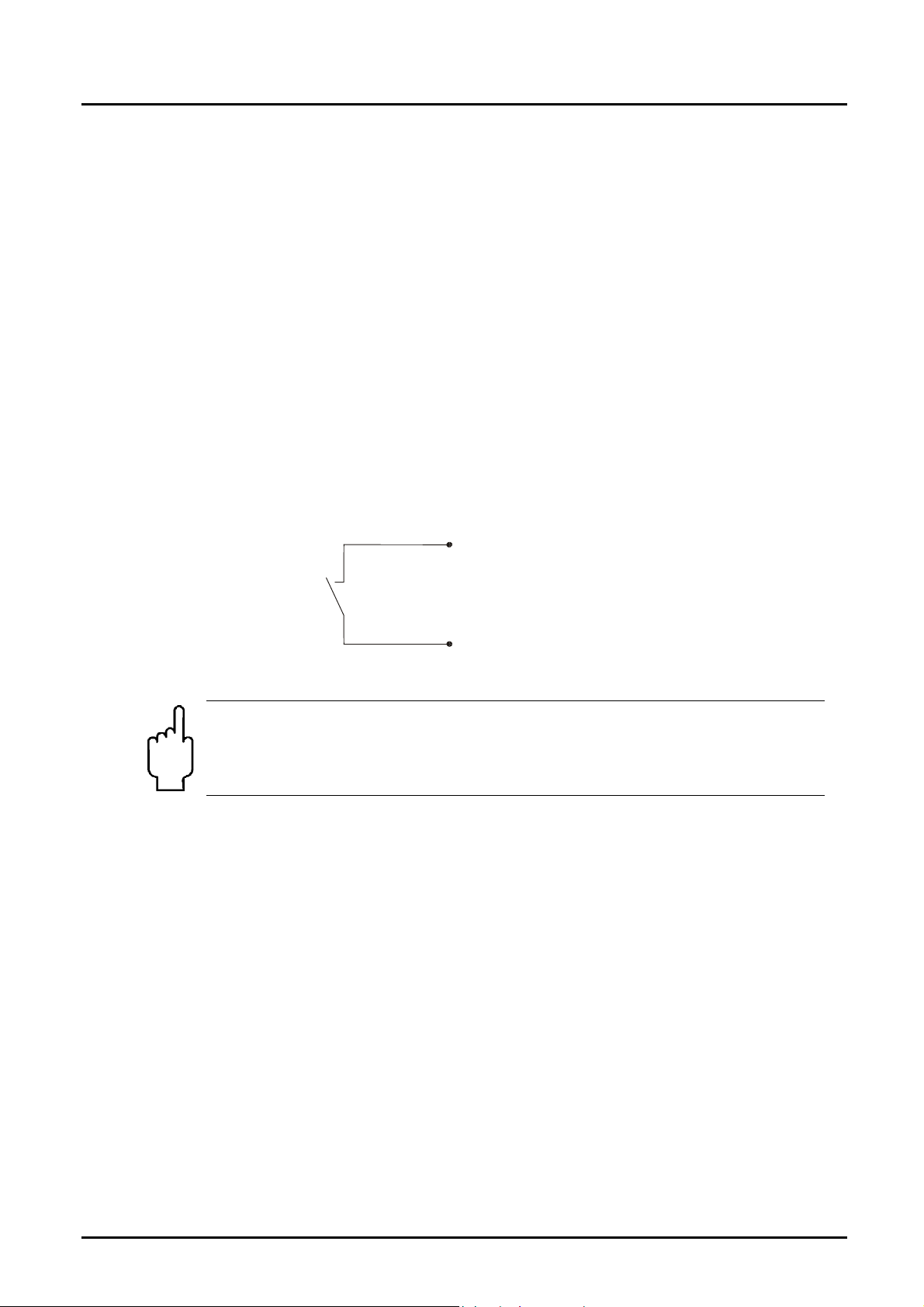

8.3. Example for Contact Protective Measures

For capacitive and inductive loads (long cables and relay/protection) we

recommend the following protective schemes.

8.4. ADI-Evaluation Electronics VKM-7..

For connection of the power supply and the output signals please check with the

operating instructions of the corresponding ADI electronic.

Information! The measuring input of the ADI is already factoryset.

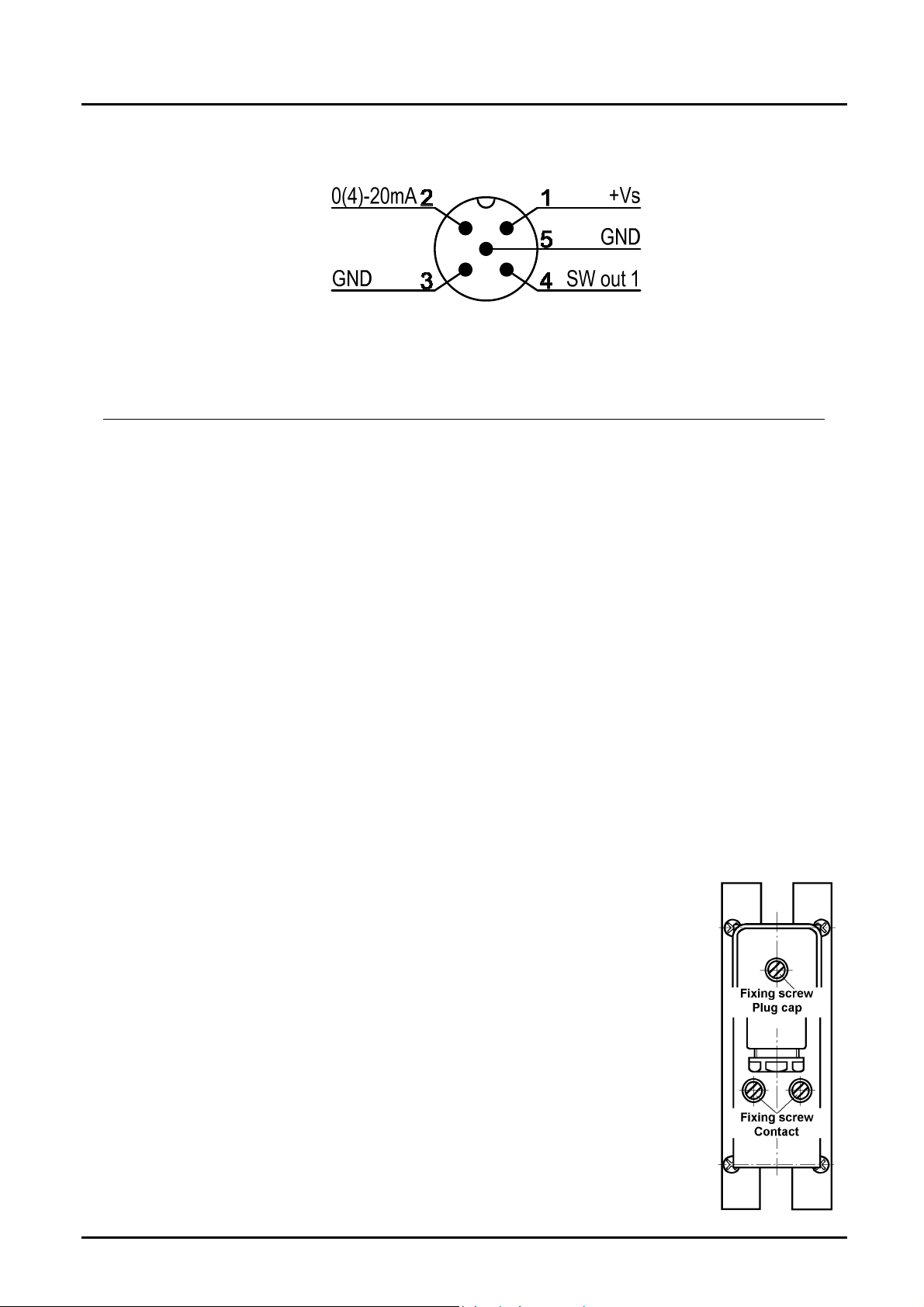

8.5. Compact electronic VKM-8...

Compact electronic: (..C30R, ..C30M)

VKM K11/0118 page 9

Page 10

VKM

Compact electronic: (..C34P, .. C34N)

9. Commissioning

9.1. General

Over-ranging

The flow range may be exceeded by a large margin with a non-pulsating flow.

Only a certain increase in pressure loss is experienced. (The permissible

maximum operating pressure must not be exceeded!).

Viscosity range

The instrument scale is suitable for a viscosity range of 1 - 540 mm2/s. Within this

range there is no need for recalibration.

9.2. Switching Output VKM-1.. and VKM-3..

Hysteresis (VKM-1.. and VKM-3..)

Hysteresis is characterised by the difference between the switching on and

switching off points of the contact. By matching the magnet and reed contact

strength (AW Number) a hysteresis of approx. 3.5 mm of float movement is

achieved. At the same time it may be assured that the contacts have a bistable

switching characteristic.

Adjustment of the limit values (VKM-1..)

Loosen the mounting screws on the contact.

Position the marking on the contact in line with the required

value on the housing scale.

Tighten the mounting screws at this position.

page 10 VKM K11/0118

Page 11

VKM

Adjustment of the limit values (VKM-3..)

With a screwdriver, loosen both mounting screws at the contact.

Move the switch housing to the lowest position.

After loosening the screws, remove the plug cap from the contact.

Connect a suitable multimeter to PIN 1 & 2

(SPDT: contact PIN 2 & 3); (see page 5).

When the instrument is already installed, open the inlet pipe and slowly allow

the medium to flow until the pointer indicator shows the required minimum flow

throughput. The reed switch is then closed (electrical continuity).

Move the switch housing upwards until the reed switch just opens (no electrical

continuity).

At this position tighten the mounting screws. Replace the plug cap. The

instrument is now ready for operation.

By correct adjustment of the limit switch, a bi-stable switch condition is

achieved, i.e.: even when exceeding the adjusted limit value, the contact

remains closed (PIN 1 + 2 or PIN 2 + 3 for changeover contact option).

9.3. ADI-Electronic Analyser VKM-7..

For adjusting the output parameters (analogue-, switching output) please check

with the operating instruction of the corresponding ADI-electronic. The electronic

of the ADI is already factory-set to the sensor.

9.4. Compact electronic VKM-8...

see Operating instructions supplement

for compact electronics without frequency output.

VKM K11/0118 page 11

Page 12

VKM

10. Technical Information

Body: VKM-x1...: Brass, nickel-plated

VKM-x2...: Stainless steel 1.4301

Screwed fitting: VKM-x1...: Brass, nickel-plated

VKM-x2...: Stainless steel 1.4301

Float: VKM-x1...: Brass, nickel-plated

VKM-x2...: Stainless steel 1.4301

Orifice: Stainless steel 1. 4310

Spring: Stainless steel 1. 4310

Magnet: Oxide ceramics

Seals: VKM-x1...: NBR

VKM-x2...: FPM

Max. temperature: +100 °C

(Attention! Note restrictions for the Ex-area. See section 5.)

Max. pressure: VKM-x1...: 250 bar

VKM-x2...: 350 bar

Installation position: arbitrary

Basic accuracy: ±4% f. s.

(with a viscosity of 105 mm2/s)

Measuring error due to

change in viscosity: For changes in viscosity within

1–540 mm2/s the additional

deviation is ± 5% f. s. maximum

Viscosity range: 1–540 mm2/s

Contacts: Optional with VKM-1..., VKM-3...

Electrical connection: 2 m cable (VKM-..F0...)

For all other types:

Connector DIN 43 650

Electrical switching values: N/O contact (standard)

max. 250 V

changeover contact (standard)

max. 250 V

N/O contact and changeover contact (cCSAus)

max. 230 VDC / 0,26 A / 60 W,

60 VDC / 1 A / 60 W,

max. 240 VAC / 0.42 A / 100 W,

100 VAC / 1 A / 100 W

N/O contact (Ex)

II 2G Ex mb IIC T6 Gb

II 2D Ex mb IIIC T80°C Db IP67

max. 250 VAC / 1.5 A /100 VA

Protection: IP 65 (electr. contact)

IP 54 (side display)

/ 1.5 A / 100 W / 100 VA

AC/DC

/ 1 A / 30 W / 60 VA

AC/DC

page 12 VKM K11/0118

Page 13

VKM

VKM-7..

Evaluating electronics: Digital indication, bargraph indication or

combined indication (digital/bargraph)

For technical information please see the operating instructions for ADI.

VKM-8..

display: 3-digit LED display

indication: semi conductor PNP or NPN

Analogue output: 4–20 mA, 3 wire version

max. 500 linear

Auxiliary power: 24 V

Max. temperature: +80° C

Electrical conn.: plug M12x1

+-20%

DC

VKM K11/0118 page 13

Page 14

VKM

11. Order Codes

Viscosity-compensated flow switches model: VKM-1...

Measuring

L/min oil

0.01…0.07 0.02 1.0

0.1...0.45 0.03 0.8

0.2...1.2 0.05 1.1

0.8...3.4 0.05 0.9

* Pressure loss refers to water

range

0.5...2 0.07 1.2

3...9 0.05 0.8

4...14 0.08 1.1

5...20 0.05 1.1

4...40 0.1 0.4

5...55 0.15 1.1

7...70 0.15 1.1

8...80 0.15 1.1

Pressure loss

P (bar) at

rated flow*

min. max.

VKM-1101... VKM-1201...

VKM-1102... VKM-1202...

VKM-1103... VKM-1203...

VKM-1104... VKM-1204...

VKM-1105... VKM-1205...

VKM-1106... VKM-1206...

VKM-1107... VKM-1207...

VKM-1108... VKM-1208...

VKM-1109... VKM-1209...

VKM-1110... VKM-1210...

VKM-1111... VKM-1211...

VKM-1112... VKM-1212...

Brass Stainless

steel

Contact Connection Option

..R0... = 1 N/O contact

..U0... = 1 changeover contact

..F0... = 1 EX N/O contact

..C0... = 1 N/O contact (cCSAus)

..D0... = 1 changeover contact

(cCSAus)

..RR... = 2 N/O contact

..UU... = 2 changeover contact

..CC... = 2 N/O contact (cCSAus)

..DD... = 2 changeover contact

(cCSAus)

Viscosity-compensated flow meters model: VKM-2...

Measuring

range

L/min oil

0.01…0.07 0.02 1.0

0.1...0.45 0.03 0.8

0.2...1.2 0.05 1.1

0.5...2 0.07 1.2

0.8...3.4 0.05 0.9

3...9 0.05 0.8

4...14 0.08 1.1

5...20 0.05 1.1

4...40 0.1 0.4

5...55 0.15 1.1

7...70 0.15 1.1

8...80 0.15 1.1

* Pressure loss refers to water

Pressure loss

P [bar] at

rated flow*

min. max.

Brass Stainless

steel

VKM-2101... VKM-2201...

VKM-2102... VKM-2202...

VKM-2103... VKM-2203...

VKM-2104... VKM-2204...

VKM-2105... VKM-2205...

VKM-2106... VKM-2206...

VKM-2107... VKM-2207...

VKM-2108... VKM-2208...

VKM-2109... VKM-2209...

VKM-2110... VKM-2210...

VKM-2111... VKM-2211...

VKM-2112... VKM-2212... ..R25= G 1 ..N25 = 1 NPT

Contact Connection Option

00..= without contact

Viscosity-compensated flow meters model: VKM-3...

Measuring

L/min oil

0.01…0.07 0.02 1.0

0.1...0.45 0.03 0.8

0.2...1.2 0.05 1.1

0.8...3.4 0.05 0.9

* Pressure loss refers to water

range

0.5...2 0.07 1.2

3...9 0.05 0.8

4...14 0.08 1.1

5...20 0.05 1.1

4...40 0.1 0.4

5...55 0.15 1.1

7...70 0.15 1.1

8...80 0.15 1.1

Pressure loss

P [bar] at

rated flow*

min. max.

VKM-3101... VKM-3201...

VKM-3102... VKM-3202...

VKM-3103... VKM-3203...

VKM-3104... VKM-3204...

VKM-3105... VKM-3205...

VKM-3106... VKM-3206...

VKM-3107... VKM-3207...

VKM-3108... VKM-3208...

VKM-3109... VKM-3209...

VKM-3110... VKM-3210...

VKM-3111... VKM-3211...

VKM-3112... VKM-3212... ..R25= G 1

Brass Stainless

steel

Contact Connection Option

...R0... = 1 N/O contact

...U0... = 1 changeover contact

...F0... = 1 EX N/O contact

...C0... = 1 N/O contact (cCSAus)

...D0... = 1 changeover contact

(cCSAus)

...RR... = 2 N/O contact

...UU... = 2 changeover contact

…CC... = 2 N/O contact (cCSAus)

...DD... = 2 changeover contact

(cCSAus)

..R08 = G 1/4 ..N08 = 1/4 NPT

..R08 = G 1/4

..R15 = G 1/2

..R15 = G 1/2

..R20 = G 3/4

..R20 = G 3/4

..R25 = G 1

..R25= G 1 ..N25 = 1 NPT

..R08 = G 1/4 ..N08 = 1/4 NPT

..R08 = G 1/4

..R15 = G 1/2

..R15 = G 1/2

..R20 = G 3/4

..R20 = G 3/4

..R25 = G 1

..R08 = G 1/4

..R08 = G 1/4

..R15 = G 1/2

..R15 = G 1/2

..R20 = G 3/4

..R20 = G 3/4

..R25 = G 1

..N08 = 1/4 NPT

..N15 = 1/2 NPT

..N15 = 1/2 NPT

..N20 = 3/4 NPT

..N20 = 3/4 NPT

..N25 = 1 NPT

..N08 = 1/4 NPT

..N15 = 1/2 NPT

..N15 = 1/2 NPT

..N20 = 3/4 NPT

..N20 = 3/4 NPT

..N25 = 1 NPT

..N08 = 1/4 NPT

..N08 = 1/4 NPT

..N15 = 1/2 NPT

..N15 = 1/2 NPT

..N20 = 3/4 NPT

..N20 = 3/4 NPT

..N25 = 1 NPT

..N25 = 1 NPT

special

connect.

0 = without

B = outlet

female

thread

inlet

BVB

manifold

special

connect.

0 = without

option

B = outlet

female

thread

inlet BVB

manifold

special

connect.

0 = without

option

B = outlet

female

thread

inlet

BVB

manifold

option

Flow

direction

B =

from bottom

T = from top

L = from left

R = from right

Flow

direction

B =

from bottom

T = from top

L = from left

R = from right

Flow

direction

B =

from bottom

T = from top

L = from left

R = from right

page 14 VKM K11/0118

Page 15

VKM

Viscosity-compensated flow meter with evaluating electronics model: VKM-7...

Measuring

range L/min

oil approx.

0.01-0.063 0.02 1.0

0.1...0.4 0.03 0.8

0.2...1.1 0.05 1.1

0.5...1.8 0.07 1.2

0.8...3.1 0.05 0.9

3...8.1 0.05 0.8

4...12.6 0.08 1.1

5...18 0.05 1.1

4...36 0.1 0.4

5...50 0.15 1.1

7...63 0.15 1.1

8...72 0.15 1.1

* Pressure loss refers to water

Viscosity-compensated flow meter with compact electronics model: VKM-8…

Measuring

range L/min

oil approx.

Pressure loss

P [bar] at

Brass Stainless

steel

Output Connection Flow

rated flow*

min. max. Standard Sonder

VKM-7101... VKM-7201...

VKM-7102... VKM-7202...

..R08 = G 1/4 ..N08 = 1/4 NPT

VKM-7103... VKM-7203...

VKM-7104... VKM-7204...

VKM-7105... VKM-7205...

VKM-7106... VKM-7206...

VKM-7107... VKM-7207...

VKM-7108... VKM-7208...

VKM-7109... VKM-7209...

VKM-7110... VKM-7210...

VKM-7111... VKM-7211...

…K04… = combination ind.

100-240 V

±10% (50-60 Hz)

AC/DC

…K34…= combination ind.

10-40 V

18-30 V

,

DC

50/60 Hz

AC

,

..R08 = G 1/4

..R15 = G 1/2

..R15 = G 1/2

..R20 = G 3/4

..R20 = G 3/4

..R25 = G 1

..N08 = 1/4 NPT

..N15 = 1/2 NPT

..N15 = 1/2 NPT

..N20 = 3/4 NPT

..N20 = 3/4 NPT

..N25 = 1 NPT

VKM-7112... VKM-7212... ..R25= G 1 ..N25 = 1 NPT

Pressure loss

P [bar] at

Brass Stainless

steel

Output Connection Flow

rated flow*

direction

B = from

bottom

T = from top

L = from left

R = from right

direction

min. max.

0.01-0.063 0.02 1.0

0.1...0.4 0.03 0.8

0.2...1.1 0.05 1.1

0.5...1.8 0.07 1.2

0.8...3.1 0.05 0.9

3...8.1 0.05 0.8

4...12.6 0.08 1.1

5...18 0.05 1.1

4...36 0.1 0.4

5...50 0.15 1.1

7...63 0.15 1.1

8...72 0.15 1.1

* Pressure loss refers to water

VKM-8101... VKM-8201...

VKM-8102... VKM-8202...

VKM-8103... VKM-8203...

VKM-8104... VKM-8204...

VKM-8105... VKM-8205...

VKM-8106... VKM-8206...

VKM-8107... VKM-8207...

VKM-8108... VKM-8208...

VKM-8109... VKM-8208...

VKM-8110... VKM-8210...

VKM-8111... VKM-8211...

VKM-8112... VKM-8212...

…C0R… = compact electr.

24 V

...C0M... = compact electr.

24 V

...C4P... = compact electr.

24 V

1xPNP

, 2x PNP

DC

, 2xNPN

DC

, 4-20 mA,

DC

...C4N... = compact electr.

24 V

DC

1x NPN

, 4-20 mA,

..R08 = G 1/4 ..N08 = 1/4 NPT

..R08 = G 1/4

..R15 = G 1/2

..R15 = G 1/2

..R20 = G 3/4

..R20 = G 3/4

..R25 = G 1

..N08 = 1/4 NPT

..N15 = 1/2 NPT

..N15 = 1/2 NPT

..N20 = 3/4 NPT

..N20 = 3/4 NPT

..N25 = 1 NPT

..R25= G 1 ..N25 = 1 NPT

B = from bottom

T = from top

L = from left

R = from right

VKM K11/0118 page 15

Page 16

VKM

12. Maintenance

In cases where the medium to be measured is uncontaminated, the models VKM

are almost maintenance-free. However where calcium or dirt deposits form in the

housing or other internal parts, the instruments should be regularly cleaned.

With a suitable open-ended spanner, remove the instrument from the pipe. After

removal of the uppermost threaded connection, the internal parts may be

removed for cleaning. The internal parts can be cleaned with a suitable brush.

After cleaning reassemble the instrument in the correct order of assembly.

Please note that the spring must be installed into the nipple of the upper threaded

connection and onto the float body. The lower end of the float with the inserted

orifice is located at the fluid inlet side.

13. Dimensions

Model

VKM-..01

VKM-..02

VKM-..03

VKM-..04

VKM-..05

VKM-..07

VKM-..08

VKM-..09

VKM-..10

VKM-..11

VKM-..12

* Weight valid for: VKM-1.., VKM-2... ** at G1 or 1 NPT

for model VKM-3... + 0,1 kg

for model VKM-7... + 1,4 kg

Square

(mm)

40x40 162 36 1,7

40x40 162 36 1,7

40x40 162 36 1,7

40x40 162 36 1,7

40x40 162 36 1,7

40x40 162 36 1,6

40x40 162 36 1,6

40x40 162 (186,5)** 36 (41)** 1,7

40x40 162 (186,5)** 36 (41)** 1,7

40x40 162 (186,5)** 36 (41)** 1,7

40x40 186,5 41 1,7

Length (mm)

Connection

SW (mm)

Connection

Weight*

(kg)

page 16 VKM K11/0118

Page 17

VKM

VKM-1.., VKM-2.., VKM-3..

VKM-7... VKM-8...

VKM K11/0118 page 17

Page 18

VKM

Ex contact for VKM-..F0..

Flow direc tion

Housing Meas. “L”

40x40 42

14. Recommended Spare-Parts

Only the instrument parts and material are listed. Depending on the instrument

type the parts are available in various sizes (when ordering please indicate

instrument type).

1.1) Float Brass 5.1) N/O contact (standard)

1.2) Float Stainless Steel 5.2) Changeover contact (standard)

2.1) Slotted-nozzle Brass 5.3) N/O contact Ex

2.2) Slotted-nozzle Stainless Steel 5.4) N/O contact (cCSAus)

3.1) Spring St. Steel 5.5) Changeover contact (cCSAus)

4.1) O-Ring set NBR

4.2) O-Ring set FPM

page 18 VKM K11/0118

Page 19

VKM

15. Declaration of the Manufacturer (VKM)

Declaration for equipment without a potential igniting source according to

the explosion protection guideline 2014/34/EU (ATEX 95).

We, KOBOLD Messring GmbH, herewith declare that the following units and/or

assembly groups:

Viscosity Compensated Flow Meter / Monitor model: VKM-***

according to guideline 2014/34/EU, article 1 paragraph 2 and 3 are

a. no safety, controlling and regulating equipment,

b. no devices,

c. no protection systems and

d. no components.

The All-Metal Flow Monitor does not have a potential igniting source of its own as

a mechanical operating device; it does not get any identification according to the

guideline 2014/34/EU ("ATEX 100a”).

The attachable contact at the sides is part and parcel of an own check and

requires certificates and/or approvals.

The units / assembly groups can be used as follows:

a. In the Zone 2 (Gas-Ex, Cat. 3G) in explosion group of IIA, IIB and IIC

b. In the Zone 22 (Dust-Ex, Category 3D) with non-conductive dusts with a

minimum igniting energy of > 3 mJ

c. In the Zone 1 (Gas-Ex, Cat. 2G) in explosion group of IIA, IIB and IIC

d. In the Zone 21 (Dust-Ex, Category 2D) with non-conductive dusts with a

minimum igniting energy of > 3 mJ

The heating is negligible, a limit value of 20 K must be accounted for the ambient

temperature and the temperature classification and/or the maximum surface

temperature.

The following harmonised norms were used in the current version applicable on

the date of signature.

EN 1127-1 Potentially Explosive Atmosphere, Explosion Protection, part 1:

Basics and Methodology

VKM K11/0118 page 19

Page 20

VKM

The operation instructions with the broader details listed therein and the

installation regulations for the potentially explosive atmosphere should be

observed. Some essential measures are:

a. The Flow Meter / -Switch has to involved in the potential equalisation

system.

b. Add-on control contacts can under application of EN 60079-14 article

12.2.1 be used as simple electrical equipment without any additional

marking in intrinsically safe equipment.

c. Add-on control contacts with an own EU type examination test can be

used, however, are not subject to this declaration.

Hofheim, 18. Oct. 2016 H. Peters M. Wenzel

General Manager Proxy Holder

page 20 VKM K11/0118

Page 21

VKM

16. Declaration of the Manufacturer (Ex RC...)

VKM K11/0118 page 21

Page 22

VKM

17. EU Declaration of Conformance

We, KOBOLD Messring GmbH, Hofheim-Ts, Germany, declare under our sole

responsibility that the product:

Flow Meter and Monitor Model VKM

to which this declaration relates is in conformity with the standards noted below:

EN 61010-1:2011-07

Safety requirements for electrical equipment for measuring control and laboratory

use

EN 60529:2014-09

Protection type through case (IP code)

EN 60079-0:2009

General Regulations

EN 60079-18:2009

Encapsulation „m“

EN 50581:2012

Technical documentation for the assessment of electrical and electronic products

with respect to the restriction of hazardous substances

Also the following EC guidelines are fulfilled:

2014/35/EU Low Voltage Directive

2014/34/EU Equipment and Protective systems intended for

use in a potentially Explosive Atmospheres (ATEX 100a)

Quality Management Production

Certificate number: BVS 15 ATEX ZQS/E110

Notified body: DEKRA Exam GmbH

Identification number: 0158

2011/65/EU RoHS (category 9)

Hofheim, 11. Jan. 2018

H. Peters M. Wenzel

General Manager Proxy Holder

page 22 VKM K11/0118

Page 23

VKM

18. EC-Type Examination Certificate Magnetic reed

switch EEx RC

VKM K11/0118 page 23

Page 24

VKM

page 24 VKM K11/0118

Page 25

VKM

VKM K11/0118 page 25

Page 26

VKM

page 26 VKM K11/0118

Page 27

VKM

VKM K11/0118 page 27

Page 28

VKM

page 28 VKM K11/0118

Page 29

VKM

VKM K11/0118 page 29

Page 30

VKM

page 30 VKM K11/0118

Page 31

VKM

VKM K11/0118 page 31

Page 32

VKM

page 32 VKM K11/0118

Page 33

VKM

VKM K11/0118 page 33

Page 34

VKM

page 34 VKM K11/0118

Loading...

Loading...