Page 1

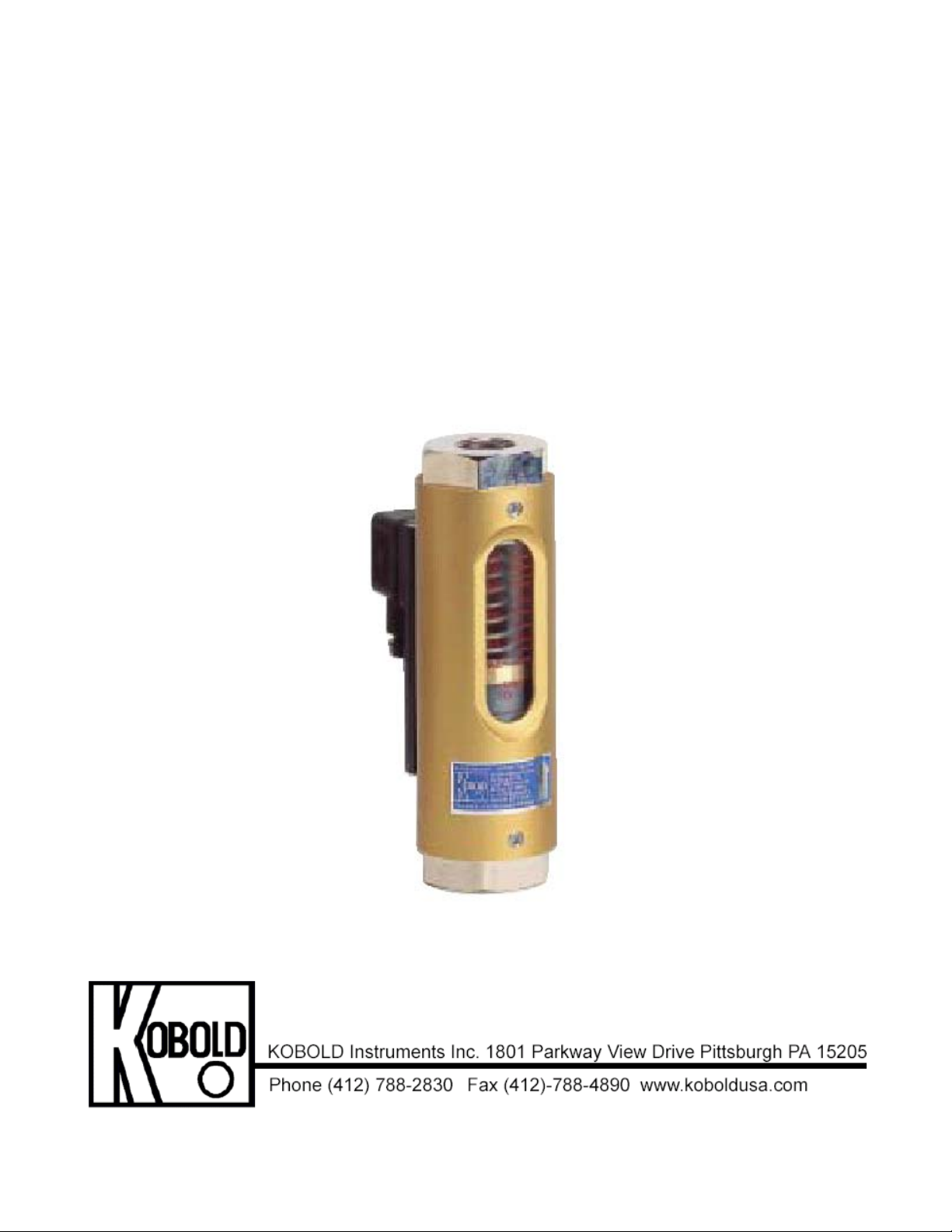

KOBOLD VKG FLOWMETER/SWITCH

User Instructions

Manual-VKG_8-16

Page 2

Table of Contents

1.0 General . . . . . . . . . . . . . .. . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . 1

2.0 Specifications . . . . . . . . . . .. . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . 2

3.0 Principle of Operation . . . .. . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . 5

4.0 Installation Instructions. . . .. . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . 5

4.1 Mounting . . . . . . . . . . . . .. . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . 5

4.2 Adjusting the Set point for Increasing Flow. . . . . . . . . . . . . . . . . . . . 6

4.3 Adjusting the Set point for Decreasing Flow . . . . . . . . . . . . . . . . . . 6

4.4 Contact Protection . . . . . . .. . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . 7

5.0 Arrival of Damaged Equipment . . . . . . . .. . . . . . . . . . . . . . . . . . . . . 7

6.0 Need help with your VKG? . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . 7

VKG

List Of Diagrams

Diagram 2.3 Dimensions . . . . . . .. . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . 3

Diagram 2.4 Wiring of the Reed Switch . . . . . . .. . . . . . . . . . . . . . . . . . . . . 4

Diagram 2.6 Contact Protection . .. . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . 7

List of Tables

Table 2.1 Material Composition. . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . 2

Table 2.2 Operational Limits . .. . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . 2

Table 2.5 Electrical Data and Operational Limits. . . . . . . . . . . . . . . . . . 4

PDF Rev. 8/16

Page 3

1VKG

KOBOLD VKG FLOWMETER

User Instructions

CAUTION: For safety reasons, please read the cautionary information located at

the end of the manual, before attempting installation.

1.0 __General

The KOBOLD VKG is a viscosity compensated flowmeter intended for use in

applications where changing viscosities of the measured media make flow determination

difficult.

The VKG offers viscosity independent behavior for fluids in the range of 1-540 cSt (full

compensation). Ordinary float-type flow meters experience measurement errors of up to

1000% with this type of a viscosity change in the medium.

At a glance, the special features of the VKG are:

• Viscosity compensated for ∆v = 540 cSt (mm²/s) enabling use of same scale - no

need for recalibration.

• Density compensated for ∆p = 0.5 kg/l, enabling use of same scale - no recalibration

needed.

• Can be installed in any position.

• Can accurately measure flow of a wide range of media without recalibration.

• Compact.

• A large number of flow set points available (3 reed contacts and/or 5 electronic

contacts).

• Hermetic separation between media and indicator/ electronics.

• Suitable for dark and turgid liquids (with side indicator).

• Easy installation.

• Reliable.

PDF Rev. 8/16

Page 4

VKG 2

2.0 __ Specifications

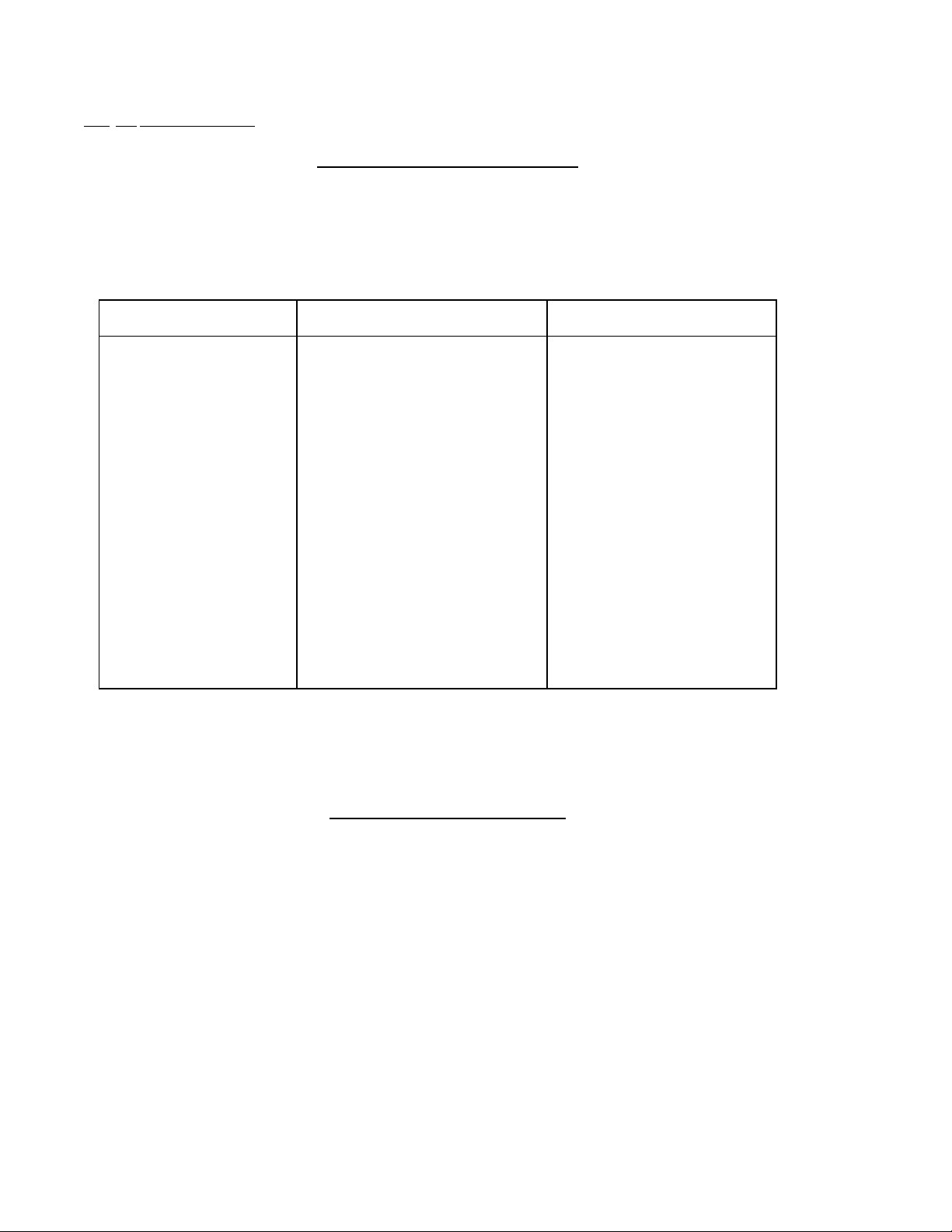

Table 2.1; Material Composition

Material: Brass Material: Stainless Steel

Outer Castings

Spring

Orifice

Magnet

Connections

Float

Measuring Tube

O-ri ngs NBR FKM

A lum inum, ano di ze d

301 Stainless Steel

301 Stainless Steel / Brass

Ceramic oxide

Brass

Brass

Borosilica te Glass

Aluminum, anodized

301 Stainless Steel

301 Stainless Steel

Ceramic oxide

304 Stainless Steel

304 Stainless Steel

Borosilicate Glass

Viscosity Range:

Maximum Medium Temperature:

Maximum Internal Pressure:

PDF Rev. 8/16

Table 2.2; Operational Limits

v = 1 - 540 cSt (mm²/s)

212° F

175 PSIG

Page 5

3VKG

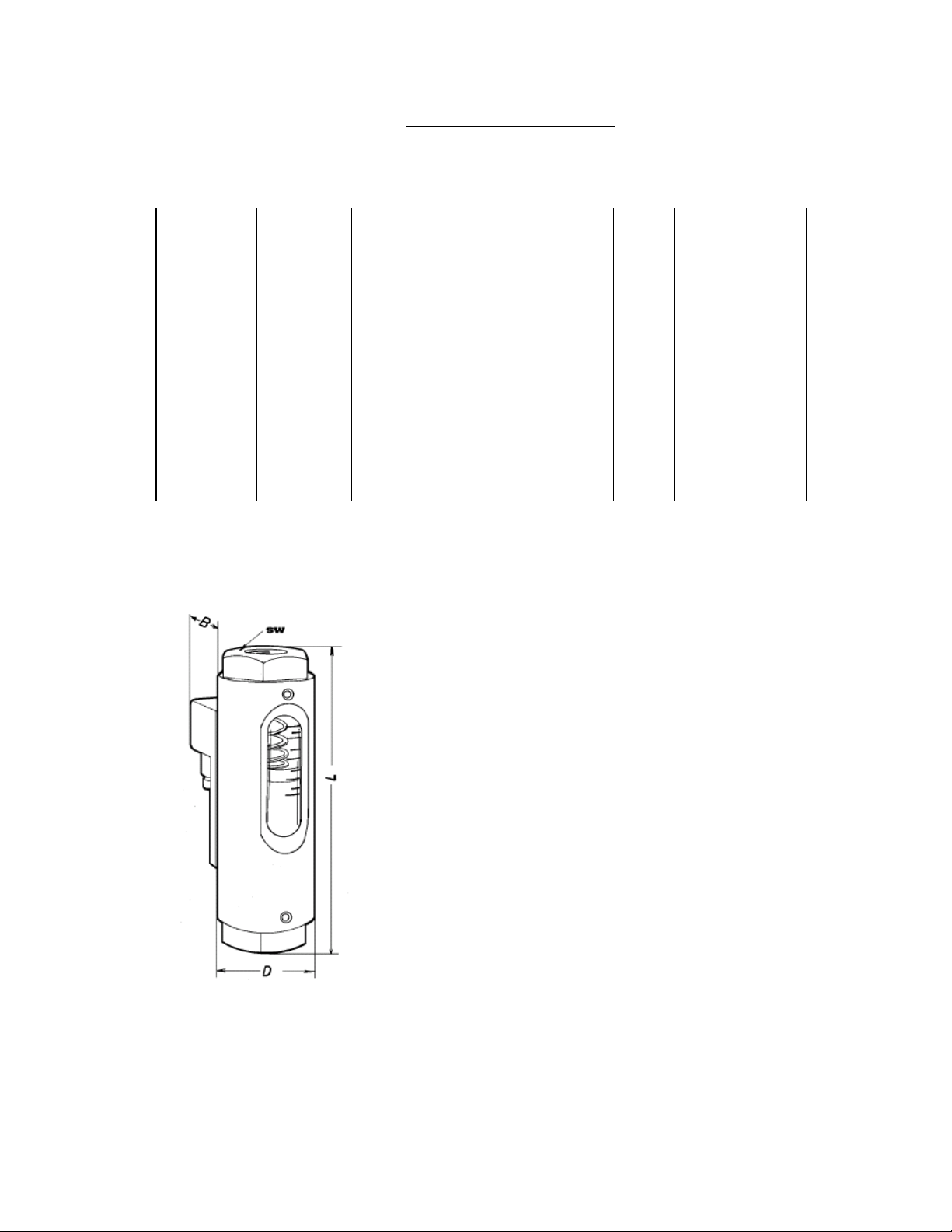

Diagram 2.3; Dimensions

HEX ( mm) NPT L (in) B (in) D (in) Weight (lb)

VKG-..01

VKG-..02

VKG-..03

VKG-..04

VKG-..05

VKG-..06

VKG-..07

VKG-..08

VKG-..09

VKG-..10

VKG-..11

41

41

41

41

41

41

41

41

41

41

41

1/4

1/4 (1/2)*

1/4 (1/2)*

1/4 (1/2)*

1/4 (1/2)*

1/2 (3/4)*

1/2 (3/4)*

3/4 (1)*

3/4 (1)*

3/4 (1)*

1

5.63

5.63

5.63

5.63

5.63

5.63 (6.02)*

5.63 (6.02)*

6.02

6.02

6.02

6.02

2.09

2.09

2.09

2.09

2.09

2.09

2.09

2.09

2.09

2.09

2.09

1.89

1.89

1.89

1.89

1.89

1.89

1.89

1.89

1.89

1.89

1.89

1.55

1.55 (1.77)**

1.55 (1.77)**

1.55 (1.77)**

1.55 (1.77)**

1.77

1.77

1.77 (2.0)**

1.77 (2.0)**

1.77 (2.0)**

2.0

* Larger fitting size listed in parenthesis is optional.

** Weight in parenthesis is for the VKG series with

optional larger fitting size.

PDF Rev. 8/16

Page 6

VKG 4

Diagram 2.4; Wiring of Reed Switch

N/O Contact SPDT Contact

Table 2.5; Electrical Data and Operational Limits

Reed Contact:

Electrical Connection

Standard:

Optional:

Environmental Protection:

Standard: N/O, Optional: SPDT

max. 230 VDC/0.26 A/60 W

60 VDC/1 A/60 W

max. 240 VAC/0.42 A/100 W

100 VAC/1 A/100 W

cCSAus Approved

DIN 43 650 w/Cable Gland

DIN 43 650 w/1/2" NPT Conduit

IP65 (Electrical Switch)

PDF Rev. 8/16

Page 7

5VKG

3.0 __Principle of Operation

The KOBOLD VKG flowmeter has a spring-loaded float which slides within a cylindrical

measuring tube. Our patented process for achieving viscosity compensation hinges on

the use of the nonlinear behavior of the float spring in combination with a unique orifice

integral to the float itself. A large amount of medium density compensation is provided

simultaneously.

Should flow monitoring be desired, limit switches may be added to the device easily.

Permanent magnets on the float actuate an electrically isolated, sealed contact (reed

switch) mounted on the outside of the instrument housing. This arrangement guarantees

hermetic separation of the medium and the electrical system. The contact is embedded

within a plastic housing to prevent damage to the contacts by mechanical action or

aggressive atmospheres. The contact housing is mounted in slides to enable set point

changes to be effected.

The flowing media raises the float against the spring force. When the magnetic field

reaches the contact reeds of the reed switch, the contact actuates. As the flow increases,

the float rises until it reaches its stop. This prevents the float from going beyond the

contact range of the magnetic switch, i.e., the contact remains activated. The result is

bistable switching without a latching relay as normally required.

The magnetic field may be used to couple to an external (i.e., hermetically separated)

indicator. This configuration provides clear indication, even with dark media.

The magnetic field and the indicator are so designed that response to sudden surges in

flow is almost immediate.

4.0 __Installation Instructions

CAUTION: For safety reasons, please read the cautionary information located at

the end of the manual, before attempting installation.

4.1 - Mounting

1. The VKG may be mounted in any orientation without effecting accuracy.

2. The medium must flow through the instrument from inlet to outlet. Note that

reverse flow or backflow can damage the device, thus a check valve is

recommended where this condition may occur. The inlet fitting can be

identified as the fitting where the float rests in a no flow condition.

3. The medium must not contain any solids or contaminants prone to precipitate

out of solution and deposition on the instrument's inner walls, which would

prevent proper operation of the device. Unclean media should be filtered

upstream of the VKG. KOBOLD offers a magnetic/screen filter for such

PDF Rev. 8/16

Page 8

VKG 6

purposes (Type MFR).

4. Do not install the meter on large masses of ferritic materials or in areas where

strong electric fields are present, as this will hamper proper operation of the

reed contact.

5. The media flow rate is referenced at the top edge of the float where it contacts the spring.

- Adjusting the Set point for Increasing Flow

4.2

The set point may be adjusted as follows:

1. Loos

2. Slide the contact upwards along its rail until it reaches its stops.

3. Open the media feed line and set flow to desired volume.

4. Slide the reed contact downwards until the contact actuates.

5. Tighten the hold-down screws.

4.3

- Adjusting the Set point for Decreasing Flow

Adjust the set point as follows:

1. Loosen the hold-down screws on the reed contact housing.

2. Slide the contact downwards (toward inlet) along the rail until it reaches its

3. Open the feed line and introduce flow until the reed contact de-actuates, then

en the hold-down screws on the reed contact housing.

stops. The reed contact will be actuated at this point.

lower the flow value to the desired minimum.

4. Slide the contact upwards (toward outlet) until the reed contact actuates again.

5. Tighten the hold-screws.

PDF Rev. 8/16

Page 9

7VKG

4.4 - Contact Protection

Maximum values of current and voltage must not be exceeded with the reed switch.

When driving inductive or capacitive loads, we recommend protecting the contact as

diagrammed below. If continuous load values exceed contact rating, we recommend the

use of an isolation relay. KOBOLD provides a line of relays for such instances.

Diagram 2.6; Contact Protection

5.0 __Arrival of Damaged Equipment

Your instrument was inspected prior to shipment and found to be defect-free. If damage

is visible on the unit, we advise that you carefully inspect the packing in which it was

delivered. If damage is visible, notify your local carrier at once, since the carrier is liable

for a replacement under these circumstances. If your claim is refused, please contact

KOBOLD Instruments for further advisement.

6.0 __Need help with your VKG?

Call one of our friendly engineers at 412-788-2830.

PDF Rev. 8/16

Page 10

Page 11

9VKG

Caution

PLEASE READ THE FOLLOWING GENERAL FLOW METER/ MONITOR

WARNINGS BEFORE ATTEMPTING INSTALLATION OF YOUR NEW

DEVICE. FAILURE TO HEED THE INFORMATION HEREIN MAY

RESULT IN EQUIPMENT FAILURE AND POSSIBLE SUBSEQUENT

PERSONAL INJURY.

PDF Rev. 8/16

Page 12

Page 13

11 VKG

• KOBOLD manufactures a wide range of process sensors and technologies. While

each of these technologies are designed to operate in a wide variety of applications, it

is the user's responsibility to select a technology that is appropriate for the

application, to install it properly, to perform tests of the installed system, and to

maintain all components. The failure to do so could result in property damage or

serious injury.

• Inspect instrument for damage upon arrival. Cracked, fractured, bent or otherwise

damaged instruments must not be put into use, since the device is weakened to an

unknown extent. (The operations and installation guide will explain how to make a

claim on damaged instruments.)

• Make sure that the model which you have selected is chemically compatible with the

application liquids. While the meter is liquid and spray resistant when installed

properly, it is not designed to be immersed.

• Under NO circumstances must the maximum tolerances (temperature and pressure)

be exceeded.

• The maximum tolerances of the device have been determined using water, air and/or

oil. If using other media, especially corrosive ones, it is critically important that the

user determine chemical compatibility with our instruments. A list, detailing material

composition of our instruments, is available from KOBOLD Instruments Inc. upon

request. KOBOLD Instruments Inc. cannot accept responsibility for failure and

consequences resulting from use of media other than water, mineral oil, air, and

nitrogen.

• Install the device in a fully supported position within your flow system. This avoids

excessive stresses which may damage the instrument. In particular:

a. Ensure that the plumbing leading to and from the instrument is fully supported

and that the instrument does not perform the physical function of a joint.

b. When calculating stress on the device caused by plumbing, the weight of the

medium in the pipes must be considered as well.

c. Misaligned runs of rigid piping can cause large stresses when connected to

the instrument. Do not connect in such a fashion.

• During installation, avoid stresses on the instrument by following guidelines given

below:

a. When connecting fittings, hold the instrument fittings rigid with a correctly

sized wrench. Do not install by twisting the instrument into the pipe fittings.

b. Do NOT install by holding the device housing to provide counter-torque to the

pipe fitting.

PDF Rev. 8/16

Page 14

VKG 12

Use an appropriate amount of PTFE tape on male threads of fitting. This

c.

reduces the twisting stresses produced by tightening the fittings into each

other.

d. Do not use pliers or wrenches on the housing, as this may damage it.

e. Do not overtighten, as this may fracture the fittings.

• During operation there are a number of situations to avoid:

a. The sudden cessation of fluid flow causes what is typically referred to as

“water hammer”. Most people are familiar with this phenomenon from their

home experience - it is the cause behind the loud clank of water pipes which

occurs when faucets are turned off too suddenly. The cause behind this “water

hammer” is quite easy to visualize. Water is fairly massive. The amount of

water in long runs of pipe is quite substantial. When the faucets are turned off

suddenly, especially from a full on condition, the water has considerable

momentum and does not want to stop flowing. The situation is similar to

stopping a car by running into a wall, rather than by applying brakes. Both are

sudden rather than gradual. The damage to the wall can be substantial (not to

mention the car). The “water hammer” causes surges in fluid pressure which

could cause the measurement instrument's pressure limit to be exceeded,

resulting in failure and possible personal injury.

b. Fluid surges, as well as the water hammer, can be particularly damaging to

empty flowmeters since there is no back pressure in the device. The damage

is caused, once again, by momentary excess pressure. To avoid these surges,

fluid lines should remain full (if possible) and water flow should be introduced

to the device slowly.

c. If the instrument is isolated with inlet and outlet valves, the flowmeter must be

completely drained when said valves are both closed. Failure to do so could

result in damage to the device caused by thermal expansion of fluid.

d. Freezing of water in the instrument must be avoided since the resultant

expansion will damage the flowmeter and make it unsafe for use.

e. Design a fail-safe system that accommodates the possibility of switch or

power failure. In critical applications, KOBOLD recommends the use of

redundant backup systems and alarms in addition to the primary system.

PDF Rev. 8/16

Loading...

Loading...