Page 1

Viscosity Compensated

Flowmeter and Switch

measuring

•

monitoring

•

analyzing

VKG

● ±5% Full Scale Accuracy

● For High and Low Viscosity Liquids

● Viscosity-Compensated up to Δv=540 cSt

(No Scale Recalibration Necessary)

● Density-Compensated up to Δp=30 lb/ft

● Direct Reading Scales for Oil

● Universal Mounting Positions

● In-line Connections for Easy Installation

● Max. Pressure: 175 PSI

● Brass or Stainless Steel Construction

Available

KOBOLD companies worldwide:

ARGENTINA, AUSTRALIA, AUSTRIA, BELGIUM, BULGARIA, CANADA, CHILE, CHINA, COLOMBIA,

CZECH REPUBLIC, EGYPT, FRANCE, GERMANY, HUNGARY, INDIA, INDONESIA, ITALY, MALAYSIA,

MEXICO, NETHERLANDS, PERU, POLAND, REPUBLIC OF KOREA, ROMANIA, SINGAPORE, SPAIN,

SWITZERLAND, TAIWAN, THAILAND, TUNISIA, TURKEY, UNITED KINGDOM, USA, VIETNAM

05/07-15-2019

3

KOBOLD Instruments, Inc.

1801 Parkway View Drive

Pittsburgh, PA 15205

Main Ofce:

1.800.998.1020

1.412.788.4890

info@koboldusa.com

www.koboldusa.com

Page 2

Viscosity Compensated Flowmeter and Switch Model VKG

Description

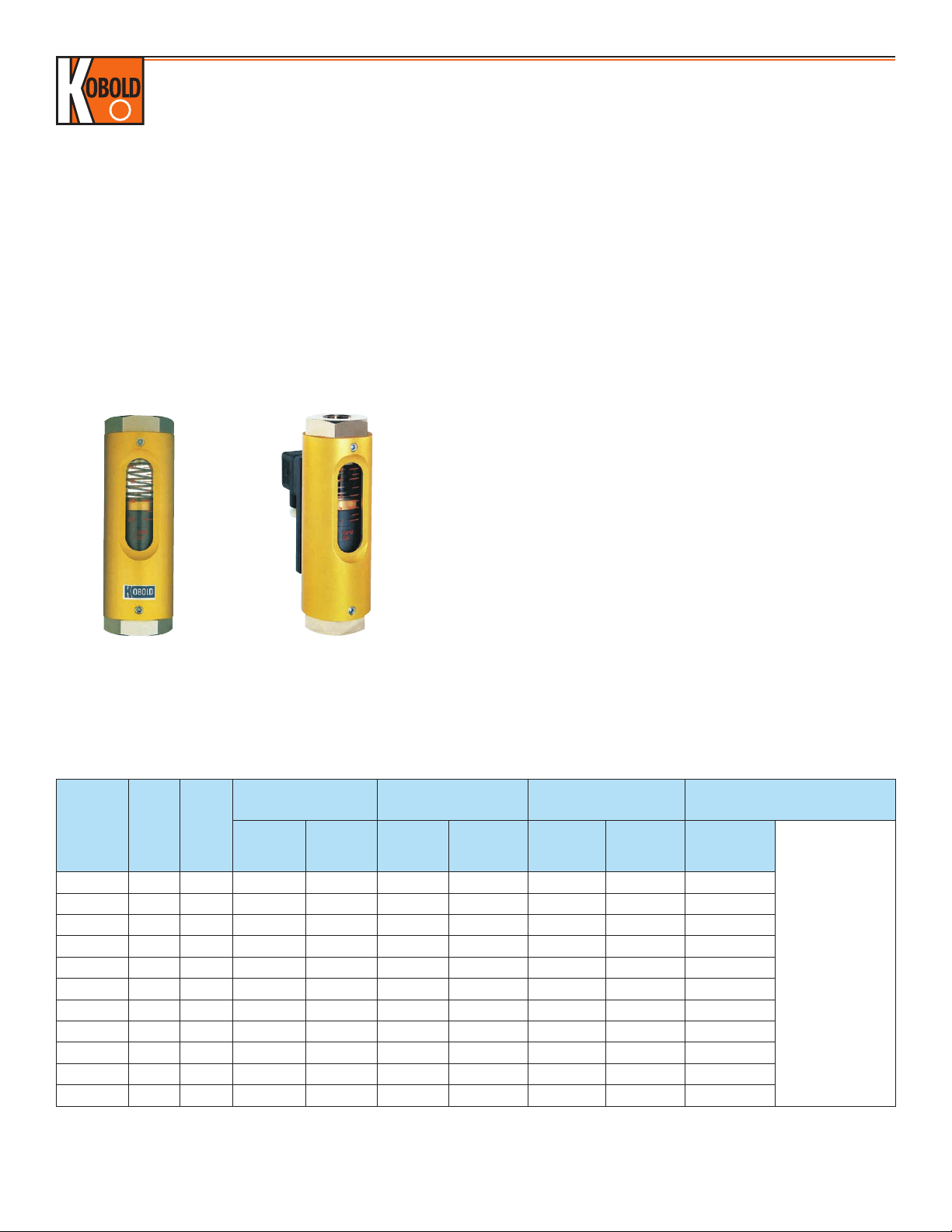

KOBOLD flowmeter and switches type VKG-6000, VKG

-7000, and VKG-8000 fill an important gap in the high

viscosity media measurement field. Using KOBOLD’s

patented viscosity compensation system, these instruments

are largely insensitive to viscosity and density changes during

operation. This development in flow and measurement control

technology has resulted in an extremely versatile instrument

for almost any application.

VKG-7107VKG-6105

Specifications

Base Accuracy: ±5% Full Scale

(Add ±5% Max. for Viscosity

Changes Over a 1...540 cSt Range)

Flow Media: Oil, Water, and Other Liquids

Mounting: Universal, without Recalibration

Measuring Principle: With Float, Spring Loaded

Max. Temperature: 212 °F

Max. Pressure: 175 PSI

Viscosity-Compensated: Up to Δv = 540 cSt with Same

Scale

Density-Compensated: Up to Δp = 30 lbs/ft3 with Same

Scale

Housing: Anodized Aluminum (non-wetted)

Glass: Borosilicate

Fittings: Ni-plated Brass or SS 304

Float: Ni-plated Brass or SS 304

Orifice: SS 301

Spring: SS 301

Seals: NBR for Brass Units, FKM

for SS Units

Elect. Switch Housing: Plastic

Reed Contact: Standard: N/O, Optional: SPDT

max. 230 VDC/0.26 A/60 W

60 VDC/1 A/60 W

max. 240 VAC/0.42 A/100 W

100 VAC/1 A/100 W

cCSAus Approved

Electrical Connection

Standard: DIN 43 650 w/Cable Gland

Optional: DIN 43 650 w/1/2" NPT Conduit

Ingress Protection: IP65 (Electrical Switch)

Order Details (Example: VKG-7104B)

Range

Oil

(GPM)

0.03...0.12 1/4" 13.1 VKG-6101 VKG-6201 VKG-7101 VKG-7201 VKG-8101 VKG-8201 -

0.05...0.3 1/4" 14.5 VKG-6102 VKG-6202 VKG-7102 VKG-7202 VKG-8102 VKG-8202 1/2"

0.1...0.5 1/4" 14.5 VKG-6103 VKG-6203 VKG-7103 VKG-7203 VKG-8103 VKG-8203 1/2"

0.2...0.9 1/4" 13.1 VKG-6104 VKG-6204 VKG-7104 VKG-7204 VKG-8104 VKG-8204 1/2"

0.5...2.0 1/4" 14.5 VKG-6105 VKG-6205 VKG-7105 VKG-7205 VKG-8105 VKG-8205 1/2"

1.0...4.0 1/2" 14.5 VKG-6106 VKG-6206 VKG-7106 VKG-7206 VKG-8106 VKG-8206 3/4"

1.0...5.0 1/2" 14.5 VKG-6107 VKG-6207 VKG-7107 VKG-7207 VKG-8107 VKG-8207 3/4"

0.5...12 3/4" 5.8 VKG-6108 VKG-6208 VKG-7108 VKG-7208 VKG-8108 VKG-8208 1"

1.0...14 3/4" 14.5 VKG-6109 VKG-6209 VKG-7109 VKG-7209 VKG-8109 VKG-8209 1"

0.5...18 3/4" 16.0 VKG-6110 VKG-6210 VKG-7110 VKG-7210 VKG-8110 VKG-8210 1"

2.0...21 1" 14.5 VKG-6111 VKG-6211 VKG-7111 VKG-7211 VKG-8111 VKG-8211 -

* Not for VKG-8000 Series

2

Stand.

Conn.

(NPT)

Press.

Drop

Max.

(PSI)

Flowmeter

Oil Scale

Brass SS Brass SS Brass SS

Flowmeter and Switch

1 N/O Contact Oil Scale

www.koboldusa.com

Flowmeter and Switch

2 N/O Contacts Oil Scale

Options

Spec. Conn.

(NPT)

Suffix "B"

..C = ½" NPT

Conduit

Fitting

..U = SPDT Switch

Contact

..V* = Special

Inlet Fitting

for BVB

Manifold

Mount

No responsibility taken for errors;

subject to change without prior notice.

Page 3

Viscosity Compensated Flowmeter and Switch Model VKG

Description

KOBOLD VKG flowmeters and switches with a side mounted

pointer indicator fill an important gap in the high viscosity

media measuring field, especially when dark color media

is to be measured. Using KOBOLD’s patented viscosity

compensation system, these instruments are largely

insensitive to viscosity and density changes during operation.

This development in flow and measurement control

technology has resulted in an extremely versatile instrument

for almost any application.

VKG-9101

VKG-9105 R

Specifications

Base Accuracy: ±5% Full Scale

(Add ±5% Max. for Viscosity

Changes Over a 1...540 cSt Range)

Flow Media: Oil, Water, and Compatible Liquids

Mounting: Universal, without Recalibration

Measuring Principle: With Float, Spring Loaded

Max. Temperature: 212 °F

Max. Pressure: 175 PSI

Viscosity-Compensated: Up to Δv = 540 cSt with Same

Scale

Density-Compensated: Up to Δp = 30 lbs/ft3 with Same

Scale

Housing: Anodized Aluminum (non-wetted)

Glass: Borosilicate

Fittings: Ni-plated Brass or SS 304

Float: Ni-plated Brass or SS 304

Orifice: SS 301

Spring: SS 301

Seals: NBR for Brass Units, FKM

for SS Units

Elect. Switch Housing: Plastic

Reed Contact: Standard: N/O, Optional: SPDT

max. 230 VDC/0.26 A/60 W

60 VDC/1 A/60 W

max. 240 VAC/0.42 A/100 W

100 VAC/1 A/100 W

cCSAus Approved

Electrical Connection

Standard: DIN 43 650 w/Cable Gland

Optional: DIN 43 650 w/1/2" NPT Conduit

Ingress Protection: IP54 (Side Indicator)

IP65 (Electrical Switch)

Order Details* (Example: VKG-9101R)

Range

Oil

(GPM)

0.03...0.12 1/4" 13.1 VKG-9101 VKG-9201 -

0.05...0.3 1/4" 14.5 VKG-9102 VKG-9202 1/2"

0.1...0.5 1/4" 14.5 VKG-9103 VKG-9203 1/2"

0.2...0.9 1/4" 13.1 VKG-9104 VKG-9204 1/2"

0.5...2.0 1/4" 14.5 VKG-9105 VKG-9205 1/2"

1.0...4.0 1/2" 14.5 VKG-9106 VKG-9206 3/4"

1.0...5.0 1/2" 14.5 VKG-9107 VKG-9207 3/4"

0.5...12 3/4" 5.8 VKG-9108 VKG-9208 1"

1.0...14 3/4" 14.5 VKG-9109 VKG-9209 1"

0.5...18 3/4" 16.0 VKG-9110 VKG-9210 1"

2.0...21 1" 14.5 VKG-9111 VKG-9211 -

* When submitting your order, please also include the flow direction: right to left, left to right, vertical up, or vertical down.

No responsibility taken for errors;

subject to change without prior notice.

Standard

Connection

(NPT)

Pressure

Drop

Max.

(PSI)

Brass SS

www.koboldusa.com

Flowmeter

Oil Scale

Options

Special Connection

(NPT)

Suffix "B"

..C = ½" NPT Conduit

Fitting

..R = N/O Switch

Contact

..U = SPDT Switch

Contact

3

Page 4

Viscosity Compensated Flowmeter and Switch Model VKG

Dimensions

Viscosity Compensated Flowmeter: VKG-6...

Order Number

Brass SS Standard Suffix "B" Standard Special

VKG-6101 to

VKG-6105

VKG-6106 to

VKG-6107

VKG-6108 to

VKG-6111

U.S. Patent Number. 4,573,361

VKG-6201 to

VKG-6205

VKG-6206 to

VKG-6207

VKG-6208 to

VKG-6211

HEX D

1.61" 1.89" 5.63" 5.63" 1.89 1.76

1.61" 1.89" 5.63" 6.02" 1.76 1.76

1.61" 1.89" 6.02" 6.02" 1.76 -

L

Weight Approx.

(lbs)

Viscosity Compensated Flowmeter and Switch with N/O Contact: VKG-7...

Order Number

Brass SS Standard Suffix "B" Standard Special

VKG-7101 to

VKG-7105

VKG-7106 to

VKG-7107

VKG-7108 to

VKG-7111

U.S. Patent Number. 4,573,361

VKG-7201 to

VKG-7205

VKG-7206 to

VKG-7207

VKG-7208 to

VKG-7211

HEX D

1.89" 1.61" 5.63" 5.63" 2.09" 2.20 1.98

1.89" 1.61" 5.63" 6.02" 2.09" 1.98 1.76

1.89" 1.61" 6.02" 6.02" 2.09" 1.98 1.76

L

B

Weight Approx.

(lbs)

VKG-6...

VKG-7...

Viscosity Compensated Flowmeter and Switch with 2 N/O Contacts: VKG-8...

Order Number

Brass SS Standard Suffix "B"

VKG-8101 to

VKG-8105

VKG-8106 to

VKG-8107

VKG-8108 to

VKG-8111

U.S. Patent Number. 4,573,361

VKG-8201 to

VKG-8205

VKG-8206 to

VKG-8207

VKG-8208 to

VKG-8211

HEX D

1.61" 1.89" 5.63" 5.63" 2.09" 2.65

1.61" 1.89" 5.63" 6.02" 2.09" 2.65

1.61" 1.89" 6.02" 6.02" 2.09" 2.43

L

B

Viscosity Compensated Flowmeter with Additional Pointer Indicator: VKG-9...

Order Number

Brass SS Standard Suffix "B"

VKG-9101 to

VKG-9105

VKG-9106 to

VKG-9107

VKG-9108 to

VKG-9111

U.S. Patent Number. 4,573,361

4

VKG-9201 to

VKG-9205

VKG-9206 to

VKG-9207

VKG-9208 to

VKG-9211

HEX

1.61" 1.81"x1.81" 5.63" 5.63" 2.09" 0.87" 2.43

1.61" 1.81"x1.81" 5.63" 6.02" 2.09" 0.87" 2.20

1.61" 1.81"x1.81" 6.02" 6.02" 2.09" 0.87" 2.20

D

Suffix "B"

L

www.koboldusa.com

B E

Weight

Approx.

(lbs)

VKG-9...

Weight

Approx.

(lbs)

VKG-9... R

No responsibility taken for errors;

subject to change without prior notice.

Loading...

Loading...