Page 1

KOBOLD Instruments Inc.

1801 Parkway View Drive

Pittsburgh, PA 15205

PH: 412-788-2830

FAX: 412-788-4890

www.koboldusa.com

Series TWR

Temperature Switch

Precautions

• User's Responsibility for Safety: KOBOLD manufactures

a wide range of process sensors and technologies. While

each of these technologies are designed to operate in a

wide variety of applications, it is the user's responsibility to

select a technology that is appropriate for the application,

to install it properly , to perform tests of the installed system,

and to maintain all components. The failure to do so could

result in property damage or serious injury.

• Proper Installation and Handling: Use a proper thread

sealant with all installations. Never overtighten the sensor

within its fitting. Always check for leaks prior to system

start-up.

• Wiring and Electrical: Because this is an electrically

operated device, only properly trained personnel should

install and maintain this product. Review the specifications

for maximum electrical switch ratings. Do not exceed these

ratings. Electrical wiring of the sensor should be performed

in accordance with all applicable national, state and local

codes.

• T emperature and Pressure: The TWR is designed for use

in process temperatures from -30°C to +125°C. Operation

outside these limitations will cause damage to the unit.

Specifications

Accuracy: ±5-7°C (±9-13°F)

Hysteresis: Max. 20°C (36°F)

Wetted Parts: Nickel-plated brass or 1.4301 (304)

SS depending on model

Fitting: 3/4” NPT

Max. Pressure: 64 Bar (928 PSIG)

Temperature Range: -30°C to +125°C (-22°F to +257°F)

• Material Compatibility: The TWR’s process wetted parts

are nickel-plated brass or stainless steel depending on th e

model. Make sure that the TWR is chemically compatible

with the application liquids. While the sensor’s outer

housing is liquid resistant when installed properly, it is not

designed to be immersed. It should be mounted in such a

way that it does not normally come into contact with fluid.

• Flammable, Explosive and Hazardous Applications:

The TWR is considered a simple apparatus per the U.S.

National Electric Code. It can be made intrinsically safe if

properly installed with an intrinsic safety barrier per the

requirements of the National Code.

• Make a Fail-Safe System: Design a fail-safe system that

accommodates the possibility of sensor or power failure.

In critical applications, KOBOLD recommends the use of

redundant backup systems and alarms in addition to the

primary system.

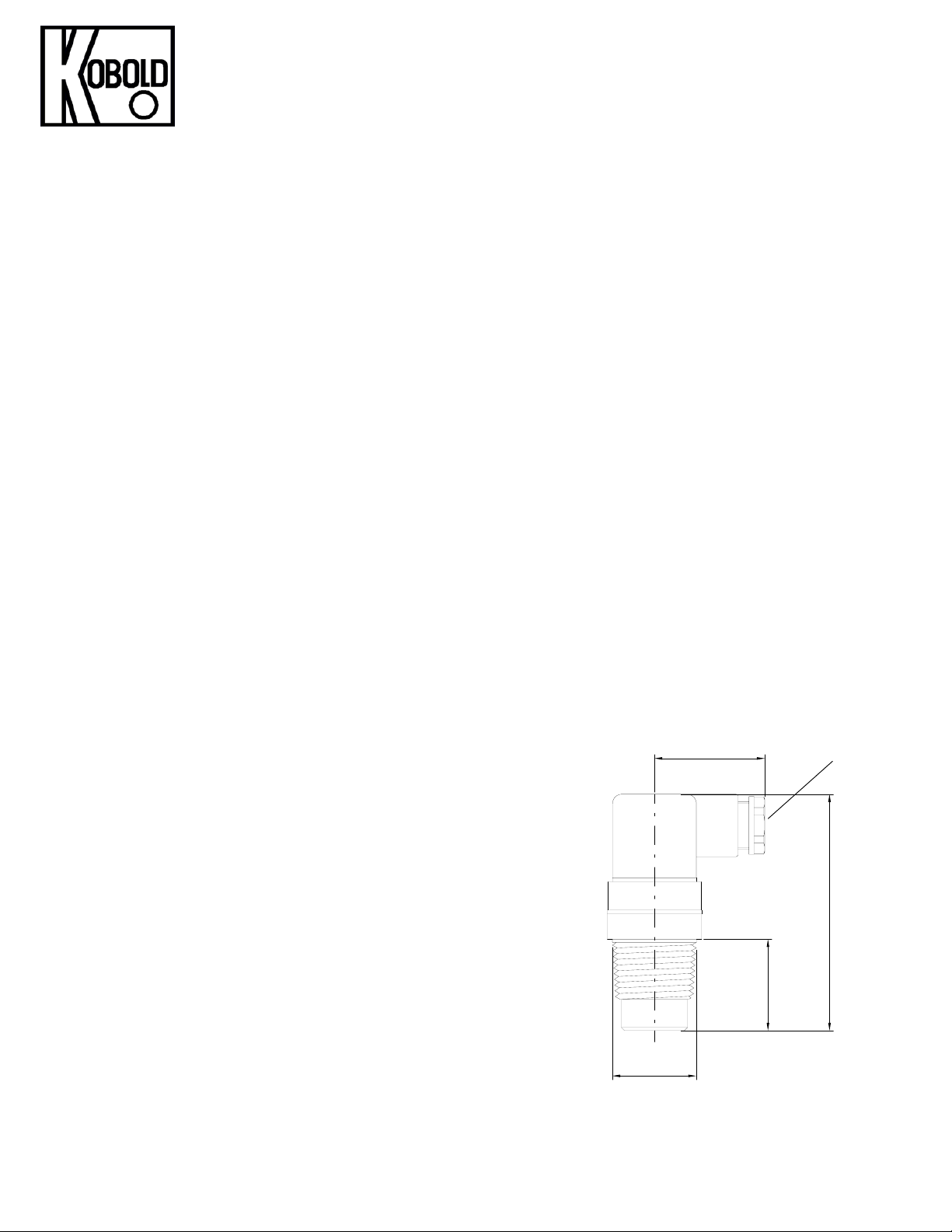

Dimensions

1.38”

PG 9

Electrical Specifications:

Switch Type: SPST normally open (N/O) or

normally closed (N/C) based on

model

Switch Rating

Standard: Max. 250 VAC, 30 VDC, 4 A

Option LED: 24 VDC

Option GLP: 110 VAC

Electrical Connection: DIN 43 650

Electrical Protection: IP 65

2.95”

(3.23” with signal lamp)

1.15”

¾” NPT

All dimensions in inches unless otherwise noted

FM Rev. 4/29/11

TWR_datasheet_man

Page 2

Order Codes

Con-

tact

Type

N/O TWR-5101 TWR-5201

N/C TWR-5102 TWR-5202

Part Number Options

Brass Stainless Switch status signal lamp

Electrical Connections

(add to part number)

-LED = 24 VDC Lamp

-GLP = 110 VAC Lamp

Switch Point Options in °C (°F)

switchpoint is stamped on TWR body

(add to base p/n as suffix):

30( 86), 35( 95)

40(104), 45(113)

50(122), 60(140)

70(158), 80(176)

90(194), 100(212)

110(230), 120(248)

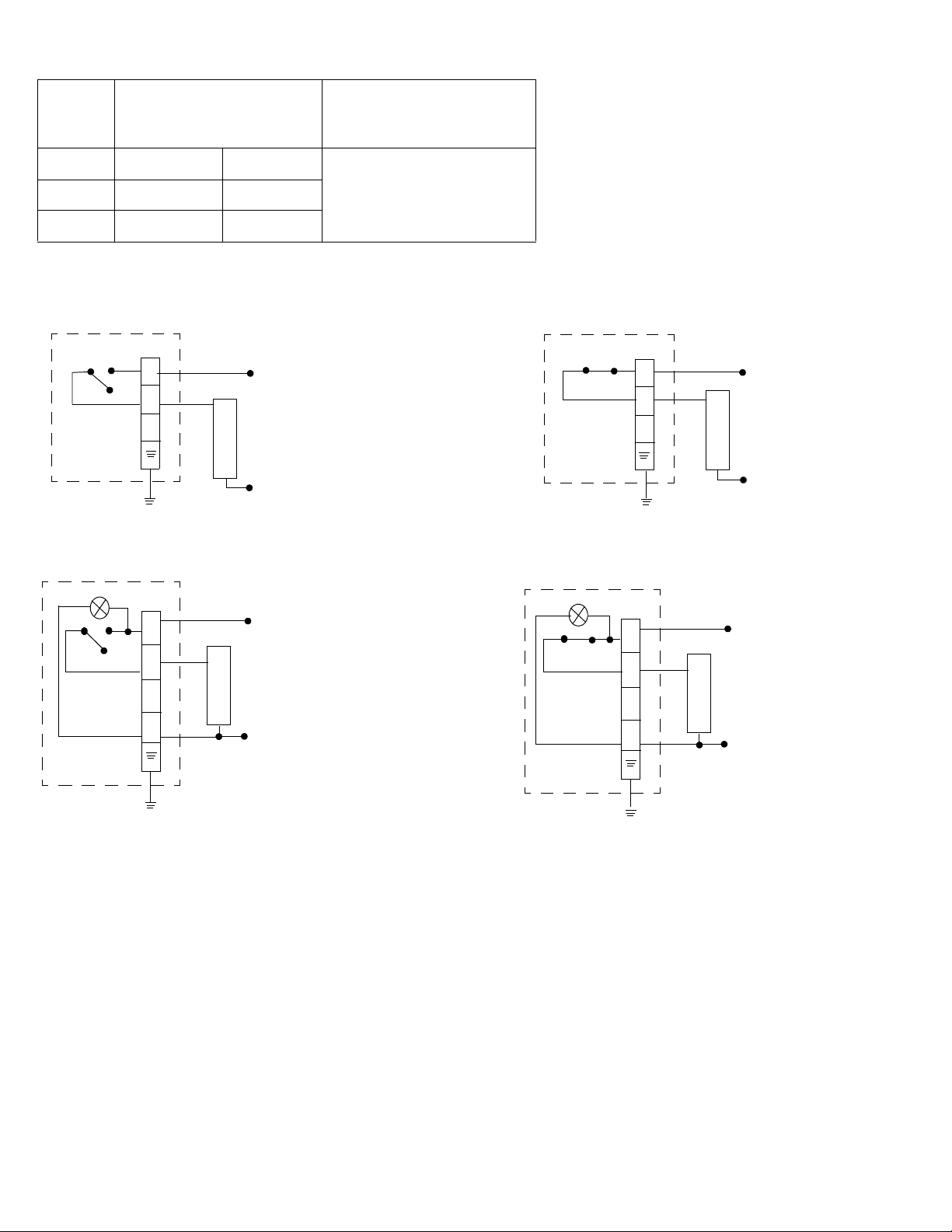

TWR

TWR

1

2

3

N/O Function

1

2

3

N

L

O

A

D

Line / +VDC

L

O

A

D

Neutral / -VDC

Line / +VDC

Neutral / -VDC

TWR

TWR

1

2

3

N/C Function

1

2

3

N

Line / +VDC

L

O

A

D

Neutral / -VDC

Line / +VDC

L

O

A

D

Neutral / -VDC

N/O Function with Lamp

Note: for versions with signal lamp, the lamp is lit when switch is open

Mechanical Installation

1. Use a proper thread sealant to install the switch in its

fitting

2. Ensure that the sensing bulb is immersed in the liquid

to be monitored. If the switch is installed in an air pocket

slow response or malfunction of the switch will occur.

3. If installing into a horizontal pipe, do not install at the

top (12 O’clock) position on the pipe. Air bubbles which

form in the top of the pipe will insulate the switch sensing

bulb and result in slow operation or switch malfunction.

4. If installing into a horizontal pipe, do not install at the

bottom (6 O’clock) position. Sediments may deposit on the

sensing bulb causing slow response or switch malfunction.

5. Ensure that the coupling used to install the TWR is

short enough to allow the sensing bulb to extend past the

pipe or tank wall and into the liquid to be monitored. If the

switch sensing bulb is recessed into the coupling, a

stagnant liquid pocket will form around the sensing bulb.

The liquid temperature in this stagnant area may not be

representative of the bulk liquid temperature, resulting in

errors or false switching.

N/C Function with Lamp

Loading...

Loading...