Page 1

Series TNS/TNF Thermometers

Installation/Operation

KOBOLD Instruments Inc. 1801 Parkway View Drive Pittsburgh, PA 15205

Phone (412) 788-2830 • Fax (412) 788-4890

Precautions

• Please read the entire manual prior installing this

product. These instructions include information on

the TNS/TNF series capillary and rigid stem thermometers. Refer to the part number label on the

instrument housing to verify the exact model number.

• User’s responsibility: The TNS/TNF series thermometer are designed for use in a wide variety of

applications. It is however, the user’s responsibility to

ensure the suitability of the device with respect to a

specific application. Additionally, it is the user’s

responsibility to ensure the unit is properly installed

and tested prior to operation.

• Proper Installation and Sealing: Always use a

proper thread sealant with all installations. Be sure

not to overtighten fittings. Test for leaks prior to operating the instrument.

Instructions

• Wiring and Electrical: For units with switches,

check the current and voltage requirements for

the load to be controlled. Ensure that they do not

exceed the maximum specified switch ratings.

• Temperature and Pressure: Under no circum-

stances should the maximum ratings of operating

temperature and pressure be exceeded. Doing so

can result in equipment damage and personnel

injury.

• Material Compatibility: Ensure that the media

contacted parts are made of a material which is

chemically compatible with the process media.

Ensure that the housing material is compatible

with the ambient environment. Failure to do so

can result in equipment damage caused by chemical attack.

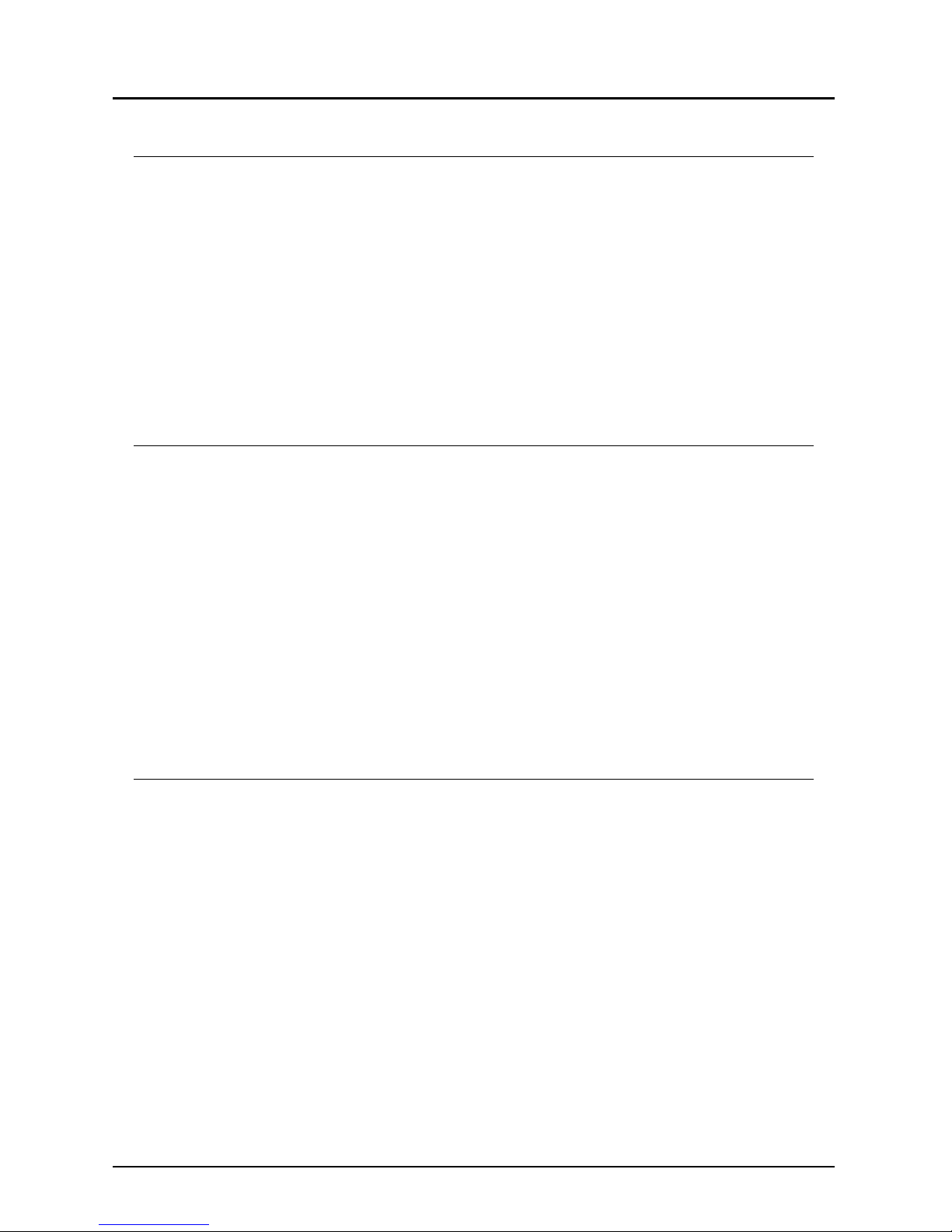

Electrical Connections:

For units with optional adjustable switches, all electrical connections are made via a weather proof 90° angle connector plug on

the side of the indicator housing. Connections are made via numbered screw terminals inside the connector. It is recommended

that a multi-conductor jacketed cable be used. The outside diameter of the jacket should be large enough to ensure that the

weather-tight cable gland on the plug can be tightened down

snugly.

Table 1 (back of page) lists all of the switch type codes and the

functional descriptions for each switch type. The switch type

code is stamped on the dial of the thermometer and is on the wiring diagram which appears on the thermometer housing. Consult

the wiring diagram on the thermometer housing for pin assignments for each switch.

5

6

4

3

1

2

TNS/TNF Terminal Housing

Setpoint Adjusting Tool

Switch Adjustment:

For units which have optional switches, adjust the switch setpoint as follows:

• Remove the switch adjusting tool by pulling it from the center of the 90° angle electrical connector.

• Insert the tool into the adjusting stub at the center of the dial crystal. The setpoint indicators are the ones with the red tips.

Push the adjusting tool in against spring tension and rotate until the adjusting lever contacts the setpoint indicator at its

base.

• Use the tool to rotate the setpoint indicator to the desired setpoint.

• Re-install the adjusting tool into the rear of the electrical connector.

FM Rev 02/27/04

Manual-TNS/TNF

Page 2

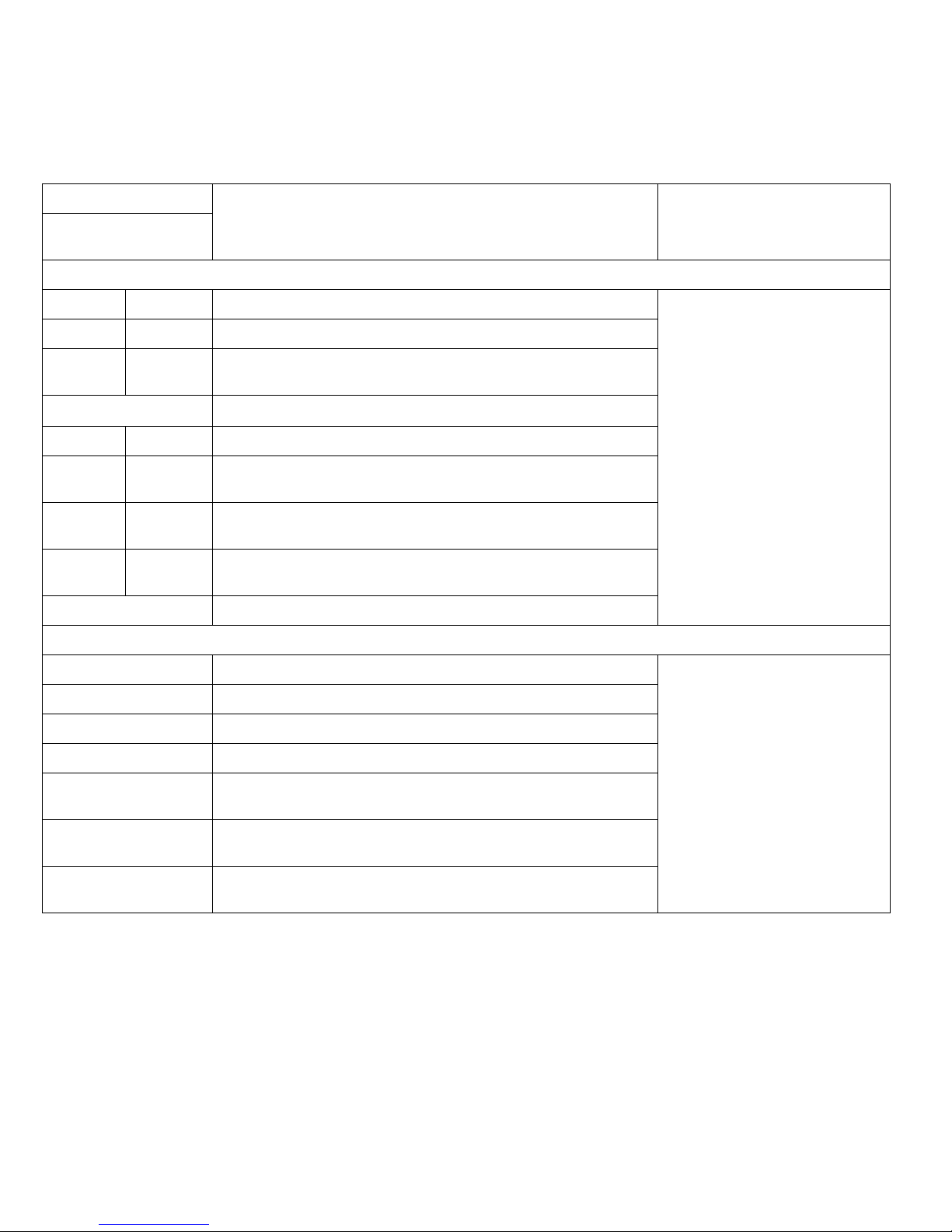

Table 1: Switching Options and Wring Terminal Numbers

Contact Type Code Functional Description

Sliding & Magnetic

Contacts

Single Contact

S10 M10 Single contact closes when temperature is above setpoint Sliding Contact Ratings

S20 M20 Single contact opens when temperature is above setpoint

S30 M30 Changeover (SPDT) contact switches over when temperature is

above setpoint

Max. Voltage: 250 VAC/VDC

Max. Power: 10 Watts

Max. Current: 0.6 Amps

Elec. Protection: NEMA 4X/ IP65

Two Contacts

S11 M11 Both contacts closed when temperature is above setpoint

S12 M12 First contact closed when temperature is above setpoint

Second contact open when temperature is above setpoint

S21 M21 First contact open when temperature is above setpoint

Second contact closed when temperature is above setpoint

S22 M22 First contact open when temperature is above setpoint

Second contact open when temperature is above setpoint

Inductive Contacts

Single Contacts

I10 Single switch activated when temperature is above setpoint Inductive Switch Rating

I20 Single switch de-activated when temperature is above setpoint

Two Contacts

I11 Both contacts activated when temperature is above setpoint

I12 First contact activated when temperature is above setpoint

Second contact de-activated when temperature is above setpoint

I21 First contact de-activated when temperature is above setpoint

Second contact activated when temperature is above setpoint

Magnetic Contact Ratings

Max. Voltage: 250 VAC/VDC

Max. Power: 30 Watts

Max. Current: 0.6 Amps

Elec. Protection: NEMA 4X/ IP65

Output: NAMUR Per DIN 19234

Elec. Protection: NEMA 4X/ IP65

I22 Both contacts de-activated when temperature is above setpoint

Mechanical Specifications

Materials of construction:

Measuring probe

2.5”, 3” and 10” dials: 304 stainless steel

4” and 6” dials: 316 stainless steel

Housing

3” and 10” dials: Painted steel or stainless

steel

4” and 6” dials: Aluminum or stainless steel

Capillary (TNF series only): 316 stainless steel

Capillary armor (option): 304 stainless steel

FM Rev 02/27/04

Maximum Pressure: 350 PSIG

Maximum Temperature: 1.3X measuring range

Page 3

Operating Instructions

for

Nitrogen Filled Thermometers

Model: TNS/ TNF

Page 4

TNS/TNF

page 2 TNS/TNF K01/0707

1. Contents

1. Contents ........................................................................................................ 2

2. Note .............................................................................................................. 3

3. Instrument Inspection .................................................................................... 3

4. Regulation Use .............................................................................................. 3

5. Operating Principle ........................................................................................ 4

6. Electrical Connection (Option)....................................................................... 4

6.1. Contacts ............................................................................................... 5

6.2. Switching Function Contacts ................................................................ 7

7. Installation ..................................................................................................... 8

8. Maintenance and Storage ............................................................................. 8

9. Technical Information .................................................................................... 9

10. Order Codes ............................................................................................... 10

Manufactured and sold by:

Kobold Messring GmbH

Nordring 22-24

D-65719 Hofheim

Tel.: +49(0)6192-2990

Fax: +49(0)6192-23398

E-Mail: info.de@kobold.com

Internet: www.kobold.com

Page 5

TNS/TNF

TNS/TNF K01/0707 page 3

2. Note

Please read these operating instructions before unpacking and putting the unit

into operation. Follow the instructions precisely as described herein.

The devices are only to be used, maintained and serviced by persons familiar

with these operating instructions and in accordance with local regulations

applying to Health & Safety and prevention of accidents.

When used in machines, the measuring unit should be used only when the

machines fulfil the EWG-machine guidelines.

3. Instrument Inspection

Instruments are inspected before shipping and sent out in perfect condition.

Should damage to a device be visible, we recommend a thorough inspection of

the delivery packaging. In case of damage, please inform your parcel service /

forwarding agent immediately, since they are responsible for damages during

transit.

Scope of delivery:

The standard delivery includes:

• Nitrogen Filled Thermometer, model: TNS/TNF

• Operating Instructions

4. Regulation Use

Any use of the Nitrogen Filled Thermometer, model: TNS/TNF, which exceeds

the manufacturer’s specifications, may invalidate its warranty. Therefore any

resulting damage is not the responsibility of the manufacturer. The user assumes

all risk for such usage.

Page 6

TNS/TNF

page 4 TNS/TNF K01/0707

5. Operating Principle

The measuring system of the gas pressure thermometer comprises probe,

capillary tube and Bourdon tube in a casing. These parts form a unit. The

complete measuring system is filled with pressurised nitrogen. A change in

temperature causes a change in inner pressure in the immersion shaft. The

resulting deflection of the Bourdon tube is transferred to the pointer through a

pointer element.

For the model TNF, the display and probe are connected by a capillary tube

separated by a distance up to 100 m.

A version filled with glycerine is available as an option for service at measuring

points exposed to strong vibrations. The fill dampens the measuring system when

exposed to mechanical vibrations and thus enables steady indication; it also

provides good lubrication for moving parts.

We recommend our robust aluminium casing for rough field service conditions.

These thermometers can also be used with aggressive measuring substances

when fitted with a suitable thermowell.

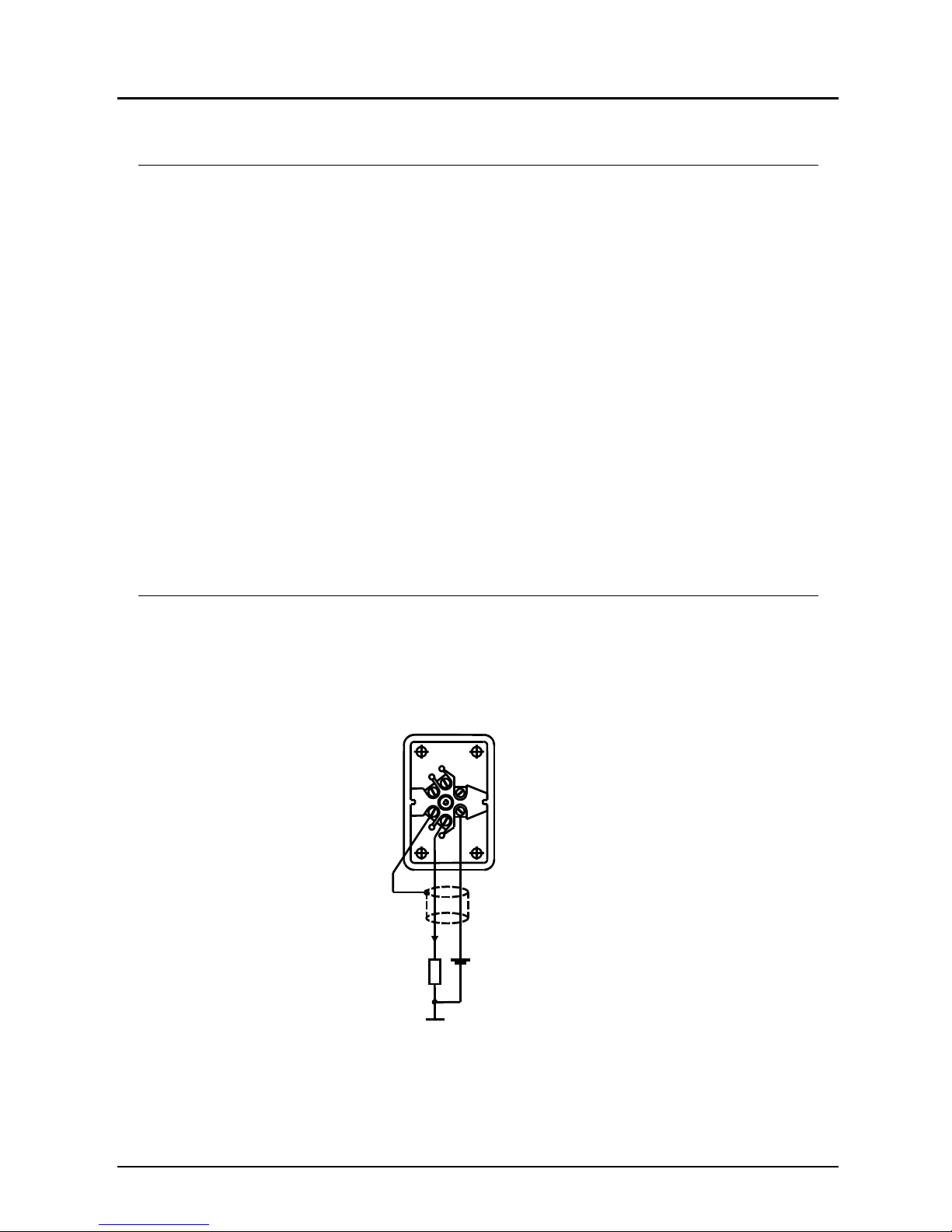

6. Electrical Connection (optional)

The electrical wiring diagram for the incorporated 2-wire transmitter with

4...20 mA output is given below. For all electrical parameters please see section

9. Technical Information: Transmitter.

4

5

3

2

6

1

24 VDC

R

+

-

GND

Screened twisted pair

Pin 1 = Power Supply

Pin 2 = GND (4... 20 mA)

Pin 3 = cable screen

4...20 mA

Page 7

TNS/TNF

TNS/TNF K01/0707 page 5

6.1. Contacts

(only for case diameters 100 and 160 mm )

Description

Electromechanical and electronic limit monitors serve to open and close electrical

switching circuits depending on the position of the instrument display. They are

suitable for fitting in casings with 100, 160 mm Ø.

The limit values are adjusted from outside with a setting lock. The limit monitor

is set with a detachable key to the value at which the switching operation is to be

carried out.

The construction of the limit monitor is such that the instrument can continue

operating past the setting pointer after successful contact operation.

The maximum setting range is approximately 270 degrees. Ambient

temperatures of –20 °C to +70 °C have no effect on the reliability performance.

We strongly recommend the use of our contact protection relays in applications

with high breaking capacities or vibrations, or for service in damping liquids (oil).

These relays have been specially designed for electromechanical limit monitors

and their use is mandatory.

The following contacts are available:

• Slow-action contacts

• Magnetic spring contacts

• Inductive contacts

6.1.1. Magnetic spring contacts

Magnetic spring contacts are suitable for service under almost all operating

conditions. They are almost completely insensitive to vibrations. The contact pin

carrier of the setting pointer is fitted with an adjustable magnet which pulls in the

wiper shortly before the set value is reached. Arcing is thus avoided and the pin is

prevented from being scorched. Because the magnetic force becomes effective

during the switching operation with this construction, the setting pointer must be

advanced or retarded by a differential gap of approximately 3–6% of full scale

value.

Switching voltage: max. 250 VAC/VDC

Breaking capacity: max. 30 W/50 VA

Switching current: max. 0.6 A

with standard contact material silver-nickel (Ag 80 Ni20)

Others on request.

Page 8

TNS/TNF

page 6 TNS/TNF K01/0707

6.1.2. Slow-action contacts

These contacting devices switch free of delay in the same way as the motion of

the actual-value pointer. They should be used where no contact loading is

required and the instruments are not exposed to vibrations. Due to sparking, the

contacting devices should not be used where there is a danger of explosion. Care

should also be taken that the contacting devices are not exposed to the effects of

aggressive vapours.

Switching voltage: max. 250 VAC/VDC

Breaking capacity: max. 10 watt / 18 VA

Switching current: max. 0.6 A

with standard contact material silver-nickel (Ag 80 Ni20)

6.1.3. Inductive contacts according to DIN 19234 (Namur)

The inductive contact device comprises mainly the control head (initiator)

attached to the setpoint pointer with its completely assembled encapsulated

electronics and mechanical assembly with moving control vane. The control vane

is moved by the instrument pointer (setpoint pointer). The control head is supplied

with DC voltage.

When the control vane is immersed in the air gap of the control head, its inner

resistance increases (damped condition, the initiator is high-resistive). The

resulting change in current intensity is the input signal for the switching amplifier

in the control unit.

Inductive contacts are suitable for service where explosion protection and high

reliability and switching rate, that is, long service life, are required.

Advantages of the inductive contact device:

• Long service life with non-contact switching

• Negligible reaction on the display

• Insensitive to aggressive environments (encapsulated electronics)

• Explosion protection, with control unit for service in zone 1 and 2 areas

Nominal voltage: 8 V

DC

(Ri = 1 kΩ)

6.1.4. Ex-protection

Thermometers with inductive contacts and external control unit can be used in

hazardous areas (zone 1 and 2). The necessary control unit should be installed

outside the ex-area.

Please refer to our brochure Z2 for details on control units.

Page 9

TNS/TNF

TNS/TNF K01/0707 page 7

6.2. Switching Function of Contacts

Magnetic spring contacts/slow-action contacts

Limit monitor with one contact

Switching

operation

Switching function

(when the limit value is exceeded)

Order code

Magnetic spring

contact

Order code

Slow-action

contact

Contact closes

..M10 ..S10..

Contact opens

Contact switches over, that is, contact

opens contact closes

..M20

..M30

..S20..

..S30..

Limit monitor with two contacts

First and second contact closes

..M11 ..S11..

1. Contact closes

2. Contact opens

..M12 ..S12..

1. Contact opens

2. Contact closes

..M21 ..S21..

First and second contact opens

..M22 ..S22..

Inductive contacts

Limit monitor with one contact

Switching

operation

When the thermometer pointer

moves clockwise and when the set

limit value is exceeded it causes the

following action:

Control action

Order code

inductive contact

moves the control vane out of the

control head

Control circuit is

closed

..I10..

moves the control vane into the control

head

Control circuit is

opened

..I20..

Limit monitor with two contacts

moves the control vane of the first and

second contact out of the control head

Control circuits

are closed

..I11..

moves the control vane of the first

contact out of the control head - moves

the control vane of the second contact

into the control head

Control circuits

are closed

..I12..

moves the control vane of the first

contact into the control head - moves

the control vane of the second contact

out of the control head

First control circuit

opens Second control

circuit closes

..I21..

moves the control vane of the first and

second contact into the control head

Control circuits are

opened

..I22..

Up to three contacts (up to four contacts in the aluminium case) can be delivered upon

request. The devices are delivered with lateral connecting box as standard. Other connectors

upon request.

Page 10

TNS/TNF

page 8 TNS/TNF K01/0707

7. Installation

Care must be taken to ensure that the bulb is not damaged during installation. Do

not attempt to bend bulb. The sensing bulb should be totally immersed in the

medium which is being measured. If a thermowell is being used, the heat transfer

delay can be improved by filling the thermowell with heat transfer substance (i.e.

graphite). When fitting bulb into a thermowell it is essential the bulb is not forced

against the bottom of the thermowell when tightening the nut. This can lead to

increase in pressure within the bulb and cause incorrect readings. The bulb

should be inserted into the thermowell until it bottoms and then withdrawn

approximately 5 mm before tightening compression nut to hand tight plus quarter

turn.

Check capillary is correct length by laying along proposed route. Never attempt to

stretch capillary as this will lead to fracture of the system.

The capillary should be securely supported and clipped to wall or other solid

surface and must be free from buckling and twists and have a minimum bending

radius of 60mm. Particular care should be taken at the points where the capillary

enters the case and the bulb. Excess capillary should be coiled and arranged in

free swinging loops between the last fixing point and the bulb.

Do not tighten instrument into the system by grasping the case, as any distortion

created will lead to calibration errors.

Instrument heads should be mounted in the vertical position unless otherwise

agreed with the manufacturer.

8. Maintenance and Storage

The function of the gauge does not require any special maintenance procedures

but frequent checks must be made to ensure that the instrument is still working

correctly and accurately. Any shift in temperature readings greater than twice the

tolerance of the instrument must be investigated and the immediate replacement

of the gauge if it is faulty.

Instruments should be stored in dry, clean conditions and care should be taken to

ensure the ambient temperature does not exceed or fall below the measuring

range of the instruments.

They must be protected against any impact damage.

Page 11

TNS/TNF

TNS/TNF K01/0707 page 9

9. Technical Information

Casing: Stainless steel 1.4301 with bayonet lock

aluminium (100 or 160 mm) with steel

ring cover, stainless steel or brass

chromium plated profile

casing: black steel, noryl black

Window: instrument glass 4 mm

with aluminium case: plexiglass

option: safety glass

Protection: IP 65

IP 54 with black steel

Dial: aluminium, white with black inscription

Pointer: aluminium, black

Pointer element: brass, option for 100 or 160 mm

casing: stainless steel

Measuring range: -40 to +40 – 0 to 600°C

Overload protection: full scale value, option 1.3 x full scale

Accuracy class: Ø 63 and Ø 80 category 1.6

Ø 100, Ø 160 and Ø 250 category 1

Nominal sizes: Ø 63, 80, 100, 160 and 250 mm

Probe: stainless steel 1.4301

with 100 or 160 mm casing

stainless steel 1.4571

Probe diameter: standard: 12 mm

option: 8, 9 or 10 mm

Probe length: to customer specification

Thread: stainless steel 1.4301

Capillary tube (for model TNF): stainless steel 1.4571

steel with PVC jacket

stainless steel 1.4571 with flexible

reinforced protective hose made of

1.4301 red copper

(not for 100 and 160 mm Ø)

Transmitter (optional):

Measuring range: See temperature range

Current output: 4 – 20 mA, 2-wire

Current output limit: max. 33 mA

Max. error F.S.: < 0.5%

Power supply: 13...25 VDC

Loop Resistance:

L

R =

(

)

mA20/V13V

plysup

−

Operating temperature: -20...+70 °C

Storage temperature: -20...+110 °C

Connection type: IP65

Protected against reversed polarity

Wiring: please see section 6.

Page 12

TNS/TNF

page 10 TNS/TNF K01/0707

10. Order Codes

For model: TNS

TNS- 1D 1 24 0A1 M12 Y

Model

Case material

Indicating range

Probe/ material /connection

Type of contact / function

Special version

For model: TNF

TNF-

1D 1 24 E A1 M12 Y

Model

Case material

Indicating range

Capillary material

Probe/material/connection

Type of contact/function

Special version

Please specify bulb and length of capillary tube (mm) in writing.

Page 13

TNS/TNF

TNS/TNF K01/0707 page 11

Design / case diameter for model: TNF

Case diameter

Design

63 80 100 160 250

TNF-0D TNF-0E TNF-0F TNF-0G TNF-0I

TNF-1D TNF-1E TNF-1F TNF-1G TNF-1I

TNF-2D TNF-2E TNF-2F TNF-2G TNF-2I

TNF-5D TNF-5E TNF-5F TNF-5G* TNF-5I

TNF-8D TNF-8E TNF-8F TNF-8G TNF-8I

TNF-6D TNF-6E TNF-6F** TNF-6G** -

Profile casing

96 x 96 mm 72 x 144 mm

TNF-Q91..

steel, black finish

TNF-R71..

noryl black

* with 160 mm high-grade steel case eccentric probe exit

** 100 and 160 mm casing in aluminium only

Page 14

TNS/TNF

page 12 TNS/TNF K01/0707

Design / case diameter

Case diameter

Design 63 80 100 160 250

TNS-0D TNS-0E TNS-0F TNS-0G TNS-0I

TNS-1D TNS-1E TNS-1F TNS-1G TNS-1I

TNS-AD

TNS-BD

TNS-CD

TNS-DD

TNS-AE

TNS-BE

TNS-CE

TNS-DE

TNS-AF

TNS-BF

TNS-CF

TNS-DF

TNS-AG

TNS-BG

TNS-CG

TNS-DG

TNS-AI

TNS-BI

TNS-CI

TNS-DI

TNS-8D TNS-8E TNS-8F* TNS-8G* TNS-8I

* with 100/160 mm st. steel case off-centre probe mounting

Case material

..2.. = stainless steel

..3.. = aluminium ring cover steel, black (for 100/160 mm casing only)

..A.. = aluminium ring cover stainless steel (for 100/160 mm casing only)

Scale ranges

°C °C °C

..24.. = -20 ... +40

..26.. = -20 ... +60

..35.. = -30 ... +50

..44.. = -40 ... +40

..46.. = -40 ... +60

..06.. = 0 ... +60

..08.. = 0 ... +80

..10.. = 0 ... +100

..12. .= 0 ... +120

..16.. = 0 ... +160

..20.. = 0 ... +200

..25.. = 0 ... +250

..30.. = 0 ... +300

..40.. = 0 ... +400

..50.. = 0 ... +500

..60.. = 0 ... +600

Special measuring ranges: upon request min. ∆ T = 60°C

Page 15

TNS/TNF

TNS/TNF K01/0707 page 13

Capillary tube (only for model: TNF)

..E..= stainless steel 1.4571 (standard) (1.4541 with 63, 80, 250 mm case

diameters)

..P.. = steel with PVC sheathing (only NG 100 / 160)

..F.. = stainless steel with flexible stainless steel reinforced hose (1.4301)

Please specify length of capillary tube (mm) when ordering.

Standard probe / material / connection (probe diameter: 12 mm)

for model: TNF

Description Material Thread Order code

Smooth probe Stainless steel Without

..A0..

Union nut Stainless steel

G 1/2

G 3/4

G 1

..B1..

..B2..

..B3..

Rotatable nipple

for DIN sleeve

Stainless steel

G 1/2

G 3/4

G 1

..41..

..42..

..43..

Union nut and

shoulder nipple

Stainless steel

G 1/2

G 3/4

G 1

1/2 NPT

3/4 NPT

1 NPT

..11..

..12..

..13..

..1A..

..1B..

..1C..

Sliding screwing

on extension

tube/probe

Stainless steel

G 1/2

G 3/4

G 1

1/2 NPT

3/4 NPT

1 NPT

..91..

..92..

..93..

..9A..

..9B..

..9C..

Sliding screwing

on capillary tube

Stainless steel

G 1/2

G 3/4

G 1

1/2 NPT

3/4 NPT

1 NPT

..81..

..82..

..83..

..8A..

..8B..

..8C..

Helix probe for

gases

Stainless steel Smooth probe

..H0..

Page 16

TNS/TNF

page 14 TNS/TNF K01/0707

Standard probe / meterial / connection (probe diameter: 12 mm)

for model: TNS

Description Material Thread Order code

Smooth probe Stainless steel without

..0A0..

Union nut Stainless steel

G 1/2

G 3/4

G 1

..0B1..

..0B2..

..0B3..

Simple nipple, rigid Stainless steel

G 1/2

G 3/4

G 1

1/2 NPT

3/4 NPT

1 NPT

..0C1..

..0C2..

..0C3..

..0CA..

..0CB..

..0CC..

Rotatable nipple for

DIN sleeve

Stainless steel

G 1/2

G 3/4

G 1

..041..

..042..

..043..

Union nut and

shoulder nipple

Stainless steel

G 1/2

G 3/4

G 1

1/2 NPT

3/4 NPT

1 NPT

..011..

..012..

..013..

..01A..

..01B..

..01C..

Sliding screw

on probe

Stainless steel

G 1/2

G 3/4

G 1

1/2 NPT

3/4 NPT

1 NPT

..0S1..

..0S2..

..0S3..

..0SA..

..0SB..

..0SC..

DIN 11851 with

polished probe,

for the milk and

food industry

Stainless steel

1" NW 25

1 1/2" NW 40

2" NW 50

3" NW 75

ANSI auf Anfrage

..0M3..

..0M5..

..0M6..

..0M7..

TRI-CLAMP

ISO 2852

with polished probe

Stainless steel

1" NW 25

1 1/2" NW 40

2" NW 50

ANSI auf Anfrage

..0T3..

..0T5..

..0T6..

Tuchenhagen®

with polished probe

Stainless steel

NW 10-15: Ø 31 mm

NW 25-32: Ø 50 mm

NW 40-50: Ø 68 mm

..0V3..

..0V5..

..0V6..

Helix probe

for gases

Stainless steel

..0H0..

Page 17

TNS/TNF

TNS/TNF K01/0707 page 15

Bulb length

Please specify when ordering. Minimum length 50 mm from the sealing collar of

the thread.

Special version (Please specify in writing when ordering)

Probe diameter 9 or 10 mm

Test certificate (5 measuring points)

Overtemperature protection (1.3 x)

Safety glass

Dual scale (°C/°F)

Measuring mechanism made of stainless steel (with 100 and 160 mm casing

only)

Max. pointer

Red gliding mark pointer

Casing filled with glycerine or oil

Knife edge pointer with fine graduation

Plug according to DIN 43650 with junction box (for unfilled casings only)

Tuchel-plug

Loading...

Loading...