Kobold TDD Series, TDD-5 Series, TDD-1 Series, TDD-3 Series, TDD-153 Operating Instructions Manual

...Page 1

Operating Instructions

for

Electronic Temperature Switch

Model: TDD

Page 2

TDD

page 2

TDD K06/0416

1. Contents

1. Contents ........................................................................................................ 2

2. Note .............................................................................................................. 3

3. Instrument Inspection .................................................................................... 3

4. Regulation Use .............................................................................................. 3

5. Operating Principle ........................................................................................ 4

6. Mechanical Connection ................................................................................. 4

7. Electrical Connection .................................................................................... 5

7.1. Connector pin assignment TDD-153, TDD-353 ................................... 5

7.2. Connector pin assignment TDD-553, TDD-753 ................................... 6

8. Commissioning .............................................................................................. 7

8.1. Button function ..................................................................................... 7

9. Adjustments .................................................................................................. 8

9.1. Value setting ........................................................................................ 8

10. Set- up Mode ................................................................................................ 9

10.1. Adjustments for TDD-1... and TDD-3... ................................................ 9

10.2. Adjustments for TDD-5...; TDD-7... .................................................... 10

11. Main Menu Options ..................................................................................... 12

11.1. Switching point ................................................................................... 12

11.2. Hysteresis .......................................................................................... 12

11.3. Window point (Double Point), (only for TDD-1… and TDD-3…) ........ 12

11.4. Switching behaviour ........................................................................... 13

11.5. Filter (only for TDD-1… and TDD-3…)............................................... 14

11.6. Transient response (only for TDD-5… and TDD-7…) ........................ 14

11.7. Contact model .................................................................................... 15

11.8. Change Code ..................................................................................... 15

12. Maintenance ............................................................................................... 15

13. Technical Information .................................................................................. 16

14. Order Codes ............................................................................................... 17

15. Dimensions ................................................................................................. 18

16.

Declaration of Conformance..................................................................… .. 19

Manufactured and sold by:

Kobold Messring GmbH

Nordring 22-24

D-65719 Hofheim

Tel.: +49(0)6192-2990

Fax: +49(0)6192-23398

E-Mail: info.de@kobold.com

Internet: www.kobold.com

Page 3

TDD

TDD K06/0416

page 3

2. Note

Please read these operating instructions before unpacking and putting the unit

into operation. Follow the instructions precisely as described herein.

The devices are only to be used, maintained and serviced by persons familiar

with these operating instructions and in accordance with local regulations

applying to Health & Safety and prevention of accidents.

When used in machines, the measuring unit should be used only when

the machines fulfil the EC-machine guidelines.

3. Instrument Inspection

Instruments are inspected before shipping and sent out in perfect condition.

Should damage to a device be visible, we recommend a thorough inspection of

the delivery packaging. In case of damage, please inform your parcel service /

forwarding agent immediately, since they are responsible for damages during

transit.

Scope of delivery:

The standard delivery includes:

• Electronic Temperature Switch model: TDD

• Operating Instructions

4. Regulation Use

Any use of the Electronic Temperature Switch, model: TDD, which exceeds the

manufacturer’s specification may invalidate its warranty. Therefore any resulting

damage is not the responsibility of the manufacturer. The user assumes all risk

for such usage.

Page 4

TDD

page 4

TDD K06/0416

5. Operating Principle

The KOBOLD Model TDD temperature sensor is used for economical measuring

and monitoring of temperature. It can be used for any application in which

temperatures must be monitored with great accuracy.

The sensor element is a semiconductor that outputs a digital signal to the

electronic processor in 0,5 °C steps. The measured values are shown on a 3-digit

LED display. The switch setpoint can be adjusted as required within the

measuring range.

6. Mechanical Connection

Before installation:

• Please check, if the switching temperature and switching function of TDD

device is in agreement with your system requirements (specifications).

• Ensure that the maximum operating pressure or temperature for the device is

not exceeded.

Installation:

• This device is installed in a matching sleeve. Use sealing tape (i.e. Teflon tape)

or a flat gasket to seal the threaded connections.

• The mounting position should be selected so that the sensor tip is always

immersed in the liquid being monitored, thus ensuring optimal heat exchange

between the liquid and the temperature sensor.

• Note that deposits that build up on the sensor tip or dirty liquids can have an

insulating effect and cause invalid measurements.

• Whenever possible, after the mechanical installation is complete, the joint at

the threaded connector and the supply piping should be checked to ensure

that it is tight and does not leak.

Page 5

TDD

TDD K06/0416

page 5

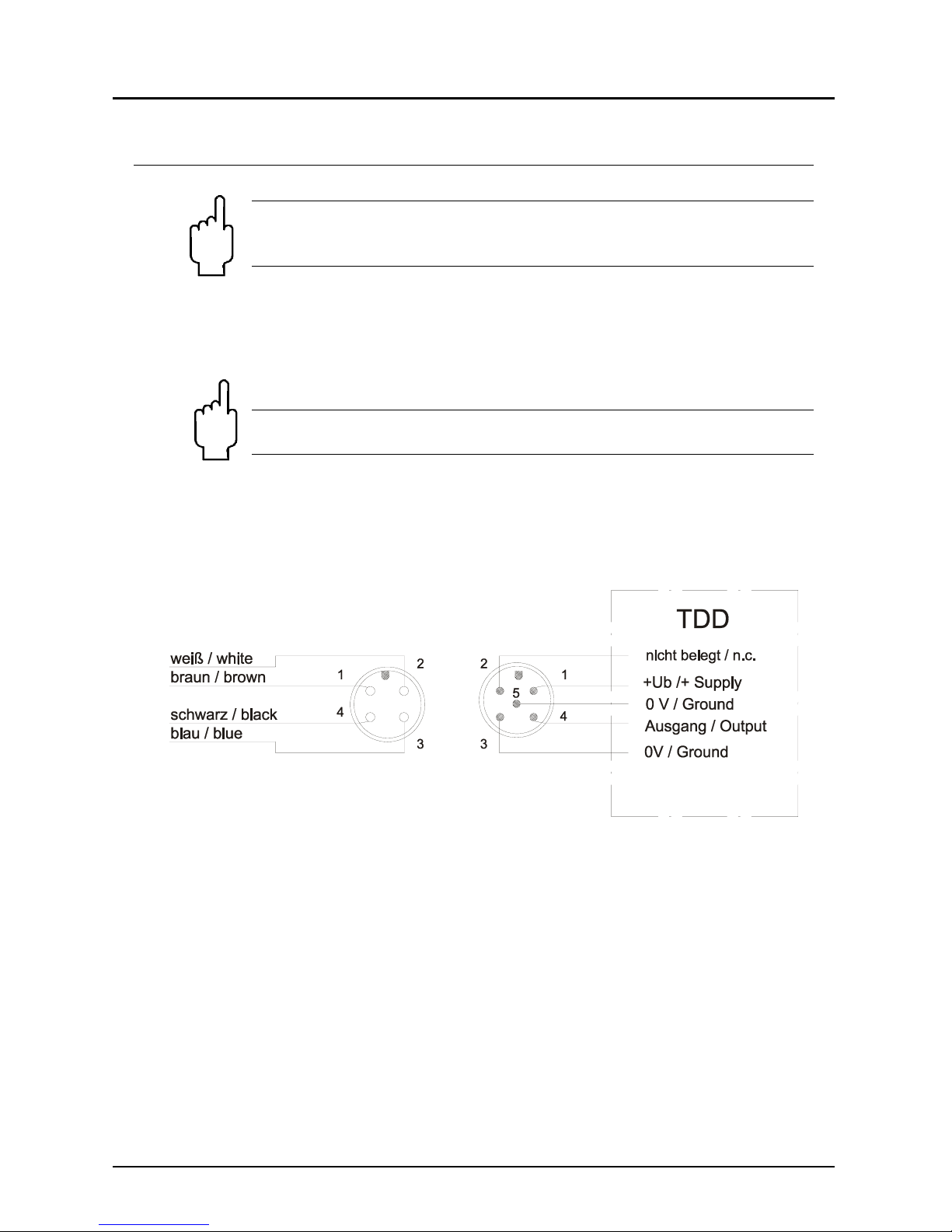

7. Electrical Connection

Attention! Make sure that the supply voltage of your system

correspond with the voltage of the measuring unit specified on the

nameplate.

• Make sure that the electrical supply lines are de-energised.

• Make the connection using the M 12x1 connector socket, as shown in the

accompanying diagram.

• Appropriate connectors with different cable lengths are optionally available.

Attention! Incorrect wiring will lead to damage of the unit’s

electronics.

7.1. Connector pin assignment TDD-153, TDD-353

Option:

plug with cable ZUB-KAB-12K002

Plug

Page 6

TDD

page 6

TDD K06/0416

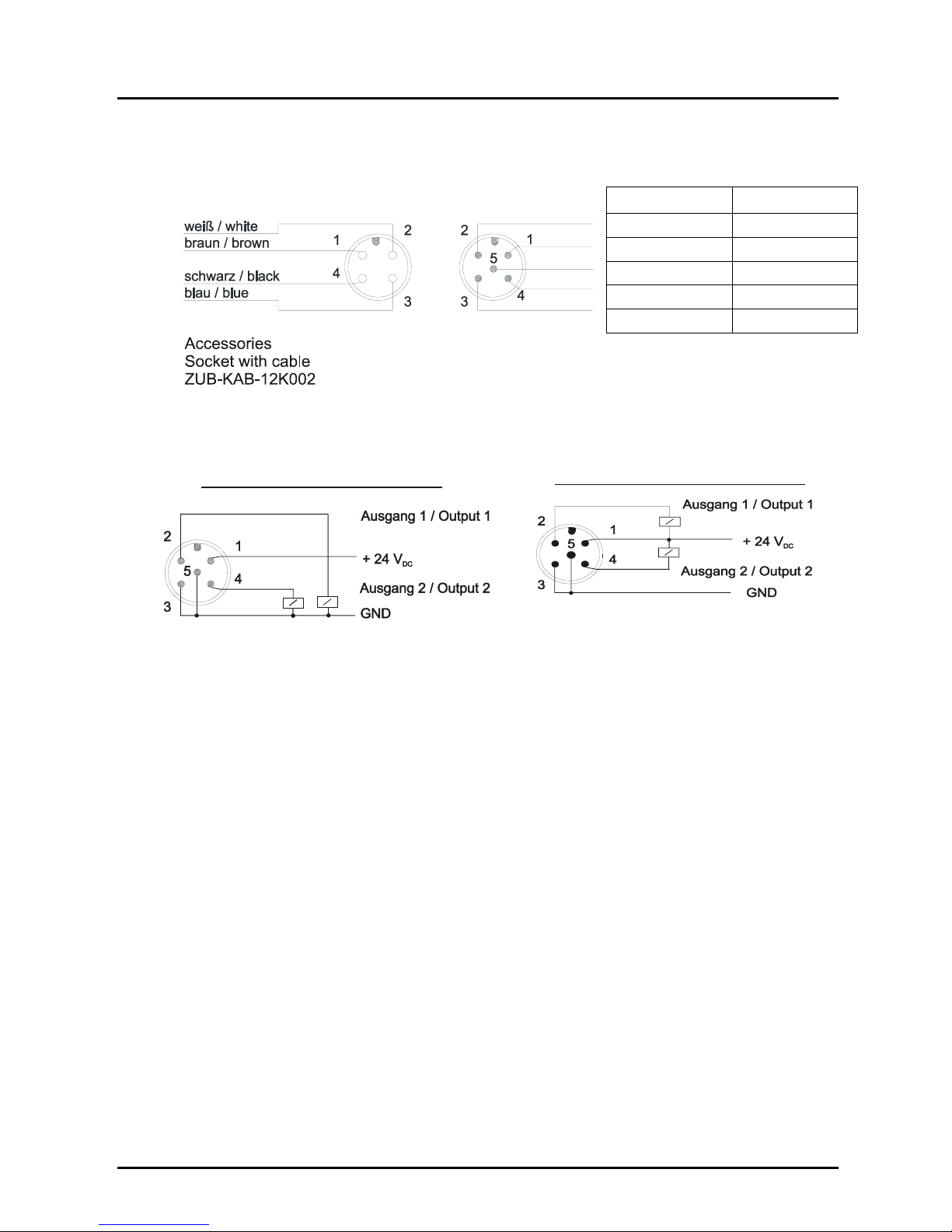

7.2. Connector pin assignment TDD-553, TDD-753

TDD-...553 TDD-...753

PNP-Output 1 NPN-Output 1

+24 VDC +24 VDC

0 V / GND 0 V / GND

PNP-Output 2 NPN-Output 2

0 V / GND 0 V / GND

Plu

g

PNP connection scheme

Plug

NPN Connection Scheme

Plug

Page 7

TDD

TDD K06/0416

page 7

3 sec

Normal Mode

Anytime:

or 20 sec

Don’t press any key

8. Commissioning

Attention! Please take note that during operation at high

temperatures, the surface and the elements within the unit may

become very hot!

Connect the temperature switch according to the figure shown on the previous

page, and supply the device with the specified voltage.

8.1. Button function

In the normal mode (measurement mode)

: Press 3 sec set-up mode

: Switch point/display window point

: Switch point/display hysteresis

In adjustment mode

: Next level

: Change values

TDD-1

TDD-5 and TDD-7

Page 8

TDD

page 8

TDD K06/0416

9. Adjustments

The following values can be changed at the temperature transmitter:

Display range Factory pre-set

Switching point (SPo, set-point)

-199...999 50.0

Hysteresis (HYS)

-199...0 000

Window point (double)

Switching point ...999 --- (inactive)

Filter (Filt)

1/2/4/8/16/32/64 1

Contact-Type (Con) Contact (N/O) or (N/C) N/O Contact

Code (CCo, change code)

000...999 000

9.1. Value setting

From main menu option (e.g. Switching point, "SPo"), press "" key in order to

go to Parameter Adjustment. The following structure shows the sequence of

steps required to change a single parameter.

[From main menu option]

1. Set position

2. Set position

3. Set position

Adjust decimal point

Save selected value

or key-in new value

[to next main menu option]

Save

Page 9

TDD

TDD K06/0416

page 9

10. Set- up Mode

10.1. Adjustments for TDD-1... and TDD-3...

3 sec

Normal Mode

Anytime:

or 20 sec

Don’t press any key

: Next level

: Change value

Contact type

N/O contact

N/C contact

Save

Off-delay

Setting parameter

Setting parameter

On-delay

Duo-point

Hysteresis

Switch point

Code input

3 sec

Code=

Setting parameter

Code change

Setting parameter

Setting parameter

Setting parameter

Setting parameter

Page 10

TDD

page 10

TDD K06/0416

10.2. Adjustments for TDD-5...; TDD-7...

Setting parameter

On-delay 2

On-delay 1

Setting parameter

Setting parameter

Hysteresis 2

Hysteresis 1

Switch pt. 2

Setting parameter

Switch pt. 1

Code input

3 sec

Code=

Setting parameter

Page 11

TDD

TDD K06/0416

page 11

Change code

Setting parameter

Contact type 2

N.O. contact

N.C. contact

Save

Contact type 1

N.O. contact

N.C. contact

Save

Off-delay 2

Off-delay 1

Setting parameter

Page 12

TDD

page 12

TDD K06/0416

11. Main Menu Options

11.1. Switching point

In menu option "SP0", “SP1” and “SP2” the switching point is entered. A setting

value between -199 and 999 can be selected. This value can also include a

decimal point. The decimal point can be set at two points (e.g. 10.0 or 100). If the

measuring value is the set switch point, the temperature switch is activated and is

signalised by a lightning LED.

If the hysteresis is zero and the window point is inactive, the temperature switch

will be reacted if the temperature is below the switch point.

11.2. Hysteresis

After the setting of switching point, the hysteresis can be entered as a negative

value in the "HYS", “HY1” and “HY2” menu. The standard hysteresis value is

zero. In operation condition this can lead to ambiguous switching behaviour if the

reading fluctuates around the switching point or window point. Aid can be given

here by increasing the hysteresis. The hysteresis relates to the switching point

and the window point (switching point minus hysteresis; window point plus

hysteresis).

Example: Switching point 100 °C; Hysteresis: -2.5 °C

The temperature switch switches when 100 °C is exceeded and

switches back when the reading drops below 97.5 °C.

11.3. Window point (Double Point), (only for TDD-1… and TDD-3…)

As well as the switching point, it is also to define a "duo" (duo-point), the window

point. This must be higher than the switching point. Using the window point and

the switching point it is possible to monitor the measurement value in a certain

range. The switching point limits the measurement range to smaller values and

the window point to larger values.

If the window point (duo-point) is less than or equal to the switching

point, an error report (Er4) will be indicated on the display and its

value is deleted and its function is invalid (in the case that the

window point and switching point out of adjustment).

The value is set in the same way as the switching point.

The window point is needed for process, monitoring of a certain temperature

range.

Page 13

TDD

TDD K06/0416

page 13

Example: Switching point: 50 °C; window point: 70 °C; hysteresis: -2 °C

The temperature contact switches when 50 °C is exceeded.

If the temperature remain between 48 °C (50-2) and 72 °C (70+2), the contact will

also remain in active switching condition (LED on). If it exceeds 72 °C or drops

below 48 °C the temperature switch switches back.

11.4. Switching behaviour

The following diagram clarifies the switching behaviour of the temperature switch.

The contact closes (contact type: no) when it drops below the switching point or

the window point. It only opens again if the window point plus hysteresis is

exceeded or if it drops below the switching point minus hysteresis. An LED

indicates the switching condition of the switching point.

time/ t

Display

bar (°C)

Switching pt.

Hysteresis

LED ON

time / t

Display

bar (°C)

Switching pt.

Hysteresis

LED ON

Hysteresis

Window point

LED ON

Page 14

TDD

page 14

TDD K06/0416

11.5. Filter (only for TDD-1… and TDD-3…)

The filter function "Filt" makes the measured value for switching purposes the

running average from the measured value samples. The following values can be

adjusted (see section 9. Adjustments):

1 / 2 / 4 / 8 / 16 / 32 / 64 samples

The filter value determines the dynamic behaviour of the display value. The larger

the Filt value, the more dampened the display response. With the adjustment of

the filter value " 1 " the filter is switched off, i.e. the display value is equal to the

unfiltered measured value.

The integrated overshoot detector reacts to a step change of approx. 6.25% of

the measurement range (full scale). During a detected measured value overshoot

of >6.25%, the instantaneous measured value is transferred directly to the display

without filtering.

11.6. Transient response (only for TDD-5… and TDD-7…)

Using the menu items “dS1”, “dS2”, “dr1” and “dr2” it is possible to set the

delay set and the delay reset.

The delay set causes delayed switching of the output if the switching threshold is

exceeded.

The delay reset causes a delayed resetting of the output if it drops below the

switching threshold – hysteresis.

The setting range for both parameters is 0.0 ... 99.5 seconds. The step rate is 0.5

seconds.

With these two functions it is also possible to suppress temporary disturbances.

Page 15

TDD

TDD K06/0416

page 15

11.7. Contact model

In menu option "Con", “Co1” and “Co2” the transistor switching output function

is set. The switching function changes from

N/O contact

to

N/C contact, and back.

N/O contact means: Contact closes on exceeding the switching point.

N/C contact means: Contact opens on exceeding the switching point.

11.8. Change Code

The code change "CCo" protects the device against unauthorised changes in

adjusted device parameters. If the code is different from 000, the user must input

the adjusted code in order to perform any programming changes.

12. Maintenance

This device is maintenance-free when properly installed. However, deposits from

dirty liquids can lead to invalid measured values.

Page 16

TDD

page 16

TDD K06/0416

13. Technical Information

Housing cover: St. steel 1.4305

Housing: St. steel 1.4404 (compact version)

St. steel 1.4305 (separate version)

Connection compact version:

G 1/2 or G 3/4 male thread

St. steel 1.4404

Option: 1/2 NPT or 3/4 NPT

Connection separate version:

Sensor: 100 mm, 6 mm; st. st. 1.4404

Cable: 2,5 m PTFE with M 12x1 plug

Housing: M 25x1,5 with counter nut

Principle of measurement: Semiconductor

Display: TDD-1,-3,-5,-7: 3-digit LED, digit-height: 7mm;

Resolution: TDD-1,-3,-5,-7: 0.5 °C to 100 °C

1 °C up to 100 °C

Max. temperature:

of measured medium: -20...+120 °C (compact version)

-50...+125 °C (separate version)

Max. ambient temp.: -20...+50 °C

Max. pressure: 80 bar

Power supply: 24VDC ± 20%

Current intake: TDD-1,-3,-5,-7: approx. 50 mA

(without switching output);

(without switching output)

Electrical connection: Plug M12x1 or

PVC-cable (cable t

max

: 90 °C)

Switching output: Semiconductor

PNP or NPN (factory set),

max. 300 mA, short-circuit proof

Contact function: N/O / N/C, window, adjustable

Switch. point adjustment: programmable

Switching display: programmable

Switching state display: 1 (2) LED

Hysteresis: programmable

ON/ OFF- switching delay: 0.5....99.5 (separately adjustable)

(only TDD-5, TDD-7)

Measuring cycle: 0.5 s

Accuracy (sensor): ± 0.5 °C (between –10...+85 °C)

± 2 °C (between +85...125 °C)

± 2 °C (between -50...-10 °C)

Protection cat: IP 65

Page 17

TDD

TDD K06/0416

page 17

14. Order Codes

(Example: TDD-153 R4H2 00) Please specify cable length with order!

Electrical

Connection

Model

Version

Sensor

length*

Switching

output

1x PNP

Switching

output

1x NPN

Switching

output

2x NPN

Switching

output

2x NPN

Plug

M12x1

TDD-153 TDD-353 TDD-553 TDD-753

R4H2 =G 1/2; -20...+120°C

R5H2 =G 3/4; -20...+120°C

N4H2 =1/2 NPT; -

20...+120°C

N5H2 =3/4 NPT; -

20...+120°C

D6H3 =separate version;

smooth sensor; -50...+125°C

00 =short

10 =100 mm

20 =200 mm

*Separate version only with 100 mm sensor; maximum length at NPT-threads is 184 mm instead 200 mm

Accessories: Electrical connection

Description Model

M12x1 box with terminal

ZUB-KAB-12D500

M12x1 box with 2 m cable

ZUB-KAB-12K002

M12x1 box with quickon-plug

ZUB-KAB-12Q000

Page 18

TDD

page 18

TDD K06/0416

15. Dimensions

Compact version short

Compact version long Separate version

Page 19

TDD

TDD K06/0416

page 19

16.

Declaration of Conformance

We, KOBOLD Messring GmbH, Hofheim-Ts, Germany, declare under our sole

responsibility that the product:

Electronic Temperature Switch

Model: TDD-1…, TDD-3…, TDD-5… and TDD-7…

to which this declaration relates is in conformity with the standards noted below:

EN 61326-1:2013

Electrical equipment for

measurement, control and laboratory use -

EMC requirements

- Part 1: General requirements

EN 61010-1:2011

Safety requirements for electrical equipment for measurement, control and

laboratory use -

Part 1: General requirements

Also the following EEC guidelines are fulfilled:

2014/30/EU Electromagnetic Compability

2011/65/EU RoHS (category 9) industrial monitoring and control instruments,

compliant, no CE-marking for the transitional period until 2017

Hofheim, 27. Apr. 2016

H. Peters M. Wenzel

General Manager Proxy Holder

Loading...

Loading...