Page 1

KOBOLD Instruments Inc. 1801 Parkway View Drive Pittsburgh PA 15205

Phone (412) 788-2830 • Fax (412)-788-4890 • www.koboldusa.com

KOBOLD TDD Series Digital Temperature Switch

TDD-153 and TDD-3 53 Seri es

User Instructions

Manual-TDD_8-01

Page 2

Page 3

Table Of Contents

FM Rev . 8/6/01

TDD

KOBOLD TDD Series Digital Temperature Switch

1.0 General . . . . . . . . . . . . . .. . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . 1

2.0 Specifications . . . . . . . . . . .. . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . 1

3.0 Mechanical Installation . . . .. . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . 3

4.0 Electrical Installation . . . . .. . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . 4

5.0 Operation . . . . . . . . . . . . .. . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . 5

5.1 Programming Functions . . .. . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . 5

5.2 Programming Menu Item Descriptions . . .. . . . . . . . . . . . . . . . . . . . . . 8

6.0 Maintenance . . . . . . . . . . .. . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . 10

List Of Diagrams

Diagram 2.1 Dimensions . . . . . . .. . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . 3

Diagram 3.1 Electrical Connections . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . 4

Diagram 5.1 Displays and Controls . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . 5

Diagram 5.2 Program ming Functio ns . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . 5

Diagram 5.3 Sequence to C hange a Val ue . . . .. . . . . . . . . . . . . . . . . . . . . . 6

Diagram 5.4 Program ming Flowchar t . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . 7

List of Tables

Table 2.1 Part Number Identification . . . . . . .. . . . . . . . . . . . . . . . . . . . . . 2

Page 4

Page 5

TDD

FM Rev. 8/6/01

CAUTION: For safety reaso ns, please read the cautionary informati on located at

the end of the manual, before attempting installation.

1.0 General

The KOBOLD TDD Series is a solid state, electronic temperature switch which employs

a Pt-100 R TD as the heart of the sensing system. The measuring p robe and hou sing ar e

constructed of 316L stainless steel providing excellent corrosion resistance. The TDD’s

microprocessor based electr onics allow the user to program a setpoint, adjust switching

hysteresis, dampening and switch logic. There is virtually no calibration drift over its

service life.

In addition to the switch output, t he TDD has a d i g ital display for local indicati on of

temperature.

2.0 Specifications

Available Switching Ranges: 0°F to 250°F or -20°C to

120°C

Display Ty pe: 3 Digit LED

Resolution: ±0.5° below 100°

±1° for 100° and above

Switch Status: Red LED on when

Temperature is above setpo int

Accuracy (worst case)

32°F to 160°F: ±1°F

0°F to 31°F: +6°F/-2°F

161°F to 230°F: +2°F/-4°F

231°F to 250°F: +2°F/-5°F

Sensor Element: Pt-100 RTD

Maximum Pressure: 1 150 PSIG

sensing Probe Material: 316L Stainless steel

Housing Material: 316L Stainless steel

Electrical Data

Switch Type: Open collector, NPN or PNP

based on model number,

programmable N/O or N/C

Switch Rating: Max. 300 mA, short circuit

protected

Response Time: 50 mSec.

Power Supply Requirement: 24 VDC ±20%, 40 mA Max.

Electrical Connection: M-12 male, Micro-DC

Electrical Protecti on: NEMA 4X/IP 65

Page 6

TDD 2

FM Rev. 8/6/01

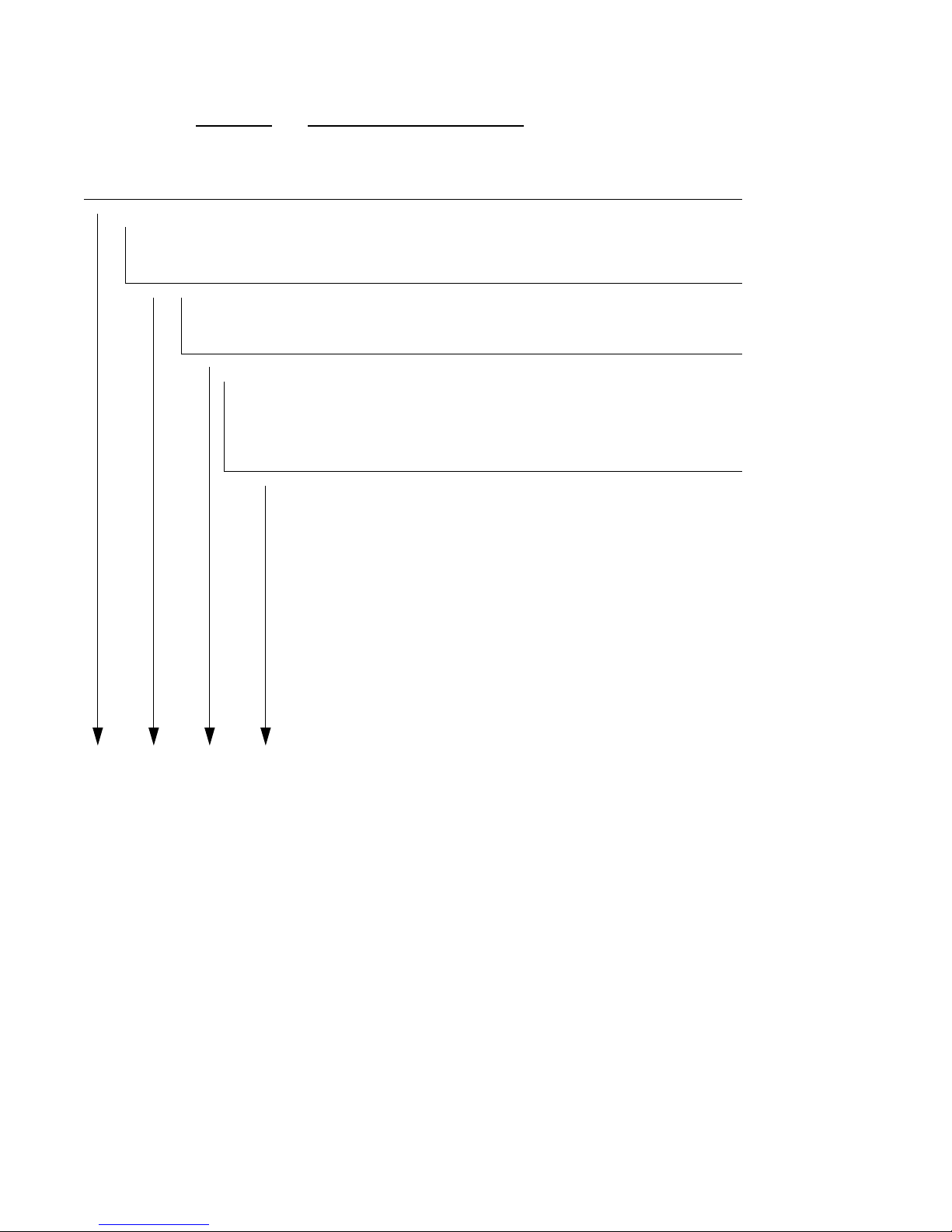

Table 2.1 Part Number Identification

TDD = Compact Electronic Temperature Switch

153 = PNP transistor switch Output Type

353 = NPN transistor switch

N4 = 1/2” NPT Fitting

N5 = 3/4” NPT

Range

TDD - 353 - N4 - F2 Example

F2 = 0 to 250°F

H2 = -20 to 120°C

Page 7

3TDD

FM Rev. 8/6/01

Diagram 2.1 Dimensions

3.0 Mechanical Installation

The following genera l installa tion instructions and pr ecautio ns must be followed to in sure

proper, reliable switch operation:

1. Select a suitable location on the piping system for installation. Installation in a

location where sediments can collect on the switch’s temperature sensing

probe (such as the underside of a horizontal piping run) will cause sluggish or

faulty operation.

2. The switch should not be installed directly on top of a horizontal pipi ng run (12

O’clock position). Air pockets which can form at the top of the pipe will prevent

the measuring probe from obtaining accurate temperature measurement.

Mounting at the 2 O’clock to 5 O’clock or the 7 O’c lock to 10 O’clock position is

best.

3. The ambient temperature range which the switch can withstand is -4°F to

+140°F. If the switch is located outdoors in a cold environment the switch must

be protected from excessively cold temperatures with insulated heat tracing or

by other suitab le means. In hot environments the switch should be located in

an area where the ambient temperature does not exceed 140°F.

4. In order to obtain an accurate measurement of the bulk flui d temperature in a

pipe, the fitting into which the switch is installed must allow the sensing probe

tip to protrude past the ID of the pipe and into the flow stream. The turbulent

fluid flow will then promote mixing and yield an accurate measurement.

1.75

0.93

1.68

1.56

41 mm

Std. connec t or

M-12 x 1

1.89

.47

.45

.28

A

B

1/2” NPT

2.76

3/4” NPT

2.78

Dimensions in inches unless otherwise noted

Page 8

TDD 4

FM Rev. 8/6/01

4.0 Electrical Installation

The following electrical installation instructions and precautions must be followed to

insur e proper switch and analog output operation. Failure to follow these instructions

may result in irreparable damage to the switch:

1. The unit employs an open collector NPN or PNP transistor switch. To verify

which model you are installing, check the model number codes in Section 2.0,

Specifications. When the PNP version activates, it connects the DC supply

voltage to the switch output pin. When the NP N version activates, it connects

the DC ground to the switch output pin.

2. This switch can only switch fixed polarity DC loads with a maximum current

draw of 300 mA. To switch higher current DC loads or AC loads use an

appropriately sized relay.

3. In order to minimize electromagnetic noise pickup, a jacketed instrument and

control cable with shield should be used. The shield should be connected to

the power system earth ground at one end of the cable only.

Diagram 4.1 Electrical Connectio ns

Typical Wiring

1

2

3

4

Switch Out

Not

Connected

-DC

+ DC Supply

24 VDC ±20%

Optional Mating Connector

Brown = 1 = +DC

White = 2 = Not Connected

Blue = 3 = -DC

Black = 4 = Switch Out

TDD-153...

1

4

3

+DC

Switch Out

-DC

Load

PNP Switch Version

+

-

TDD-253...

1

4

3

+DC

Switch Out

-DC

Load

+

-

NPN Switch Version

Page 9

5TDD

FM Rev. 8/6/01

5.0 Operation

Diagram 5.1 Displays and Controls

5.1 Programming Functions

The TDD digital Temperature switch is programmed via membrane push-buttons on the

faceplate of the switch as shown in the following figure:

Diagram 5.2 Programming Functions

.

Switch Status LED

On = Temperature Above Setpoint

Off = Tem perature Below Setpoint

Press to enter a menu

program m ing bran ch,

or change a display v al ue

Hold for 3 seconds

to enter programm ing

me nu. Press to step

through menu

During Normal Operation

:

:

Press for 3 Sec to Enter Setup Mode

Display Switch Point/ Window Point

During Setup Mode

: Next Step

: Change Values

Press 3 sec

Exit Setup

Orfor20sec

Press no buttons

Page 10

TDD 6

FM Rev. 8/6/01

5.1.1 Changing Values in Setup Mode

When in the S etu p Mode the actual values of setpoint, hysteresis, switch logic and other

functions are adjusted as required by the user . Fro m the main menu (e.g. switching point

“SPo”), press the “▼” button to adjus t tha t functions value . The follow i ng diagram shows

the sequence of steps required to change a value:

Diagram 5.3 Sequence to Change a Value

Speichern

Save Value

Press “▼” to get from the main menu

Set the fi rst digit

Set the second digit

Set the third digit

Set the decimal point

location

reset value

or

Page 11

7TDD

FM Rev. 8/6/01

5.1.2 Programming Flow Chart

Diagram 5.4 Programming Flowchart

7 Steps

Switch Logic

Filter

Window Point

Hysteresis

Setpoint

N/O

3 sec

C

o

d

e

=

N/C

Save

Enter Code

Change Code

Change Value

Change Value

Change value

Change Value

(Enter Code)

Enter New Code

Page 12

TDD 8

FM Rev. 8/6/01

5.2 Programming Menu Item Descriptions

After the “▼” Button is depressed for three seconds to enter the setup mode, and the

lockout code is entered (if lockout is en abled) , the programmi ng menu may be accessed.

Diagram 5.3 provides a flowchart of the programming menu. Section 5.1.1 and di agram

5.2 provide details on how to change the value of each menu item parameter. The

following is a detailed description of each menu item.

5.2.1 Cod - Code

If the lockout featu re was enabled during a prior setup , the user cod e which was sele cted

at that time mu st be entered. Section 5.1.1 ‘Changing Values in Setup Mode’ on page 6

provides steps required to enter the value.

5.2.2 SPo - Switchpoint

This menu ite m allow s the user to input t he desired switching point. Any number between

-199 and 999 can be entered. Additionally, a decimal point can be added if desired.

Section 5.1.1 ‘Changing Values in Setup Mode’ on page 6 provides steps required to

change a value. If the measured temperature exceeds the switchpoint value, the switch

will activate.

5.2.3 HYS - Hysteresis

This menu item allows the user to set a deadband value bel o w the switchpo int such tha t

the switch will not de-activate until the measured temperature falls below the setpoint,

minus the hysteresis va lue. The hysteresis value will always be a negative value an d can

be set as any number between 0 and -199. Additionally, a decimal point can be added if

desired. Section 5.1.1 ‘Changing Values in Setup Mode’ on page 6 provides steps

required to change a value.

Example: Switchpoint Value (SPo) is set at 50.0

Hysteresis Value (HYS) is set at -5

The switch will activate (LED on) when measured temperature is above

50.0 and will de-activate (LED off) when measured temperature is below

45.0.

Temperature

Switch

On

Off

Temperature

Switch

On

Off

Case 1:

Case 2:

Switch set as Switch set as

Normally Open Normally Closed

45.0

50.0

45.0

50.0

Page 13

9TDD

FM Rev. 8/6/01

5.2.4 duo - Window Point

This menu item allows the user to set a value above the switchpoint such that a

temperature band, or window can be monitored.

Note: The duo value must be a positive number and it must be a larger value that the

SPo value. If it is not, an error message is displayed. If the error occurs both the

SPo value and the duo values are cleared and must be re-entered.

Additionally, a decimal point can be added if desired. Section 5.1.1 ‘Changing Values in

Setup Mode’ on page 6 provides steps required to change a value. When the measured

temperature is above the switchpoint, the switch will activate. The switch will de-activate

when the measured Temperature either increases to above the window point value or

decreases to below the switchpoint value. The window point can also used with the

hysteresis function if desire d.

Example: Switchpoint Value (SPo) is set at 50

Window Point (duo) value is set at 75

Hysteresis Value (HYS) is set at -5

The switch will activate (L ED on) when measured Temperature is above

50.0 and will de-activate (LED off) when meas ured Tempera ture is above 80

(75 + 5) or below 45 (50 - 5).

5.2.5 Filt - Filtering

This menu item allows the user to average the measured output over 1, 2, 4, 8, 16, 32 or

64 samples. Section 5.1.1 ‘Changing Values in Setup Mode’ on page 6 provides steps

required to change a value. Adding filtering provides a more stable display and prevents

false switching for systems in which spurious temperatu re fluctuations are a prob lem. The

larger the number of samples the more stable the display and switch. A Filt value of “1”

shuts off the filtering.

When filtering is being used, the TDD series employs an integrated overshoot function

which detects any overshoot above 6.25% and processes that measured value without

filtering. This feature allows the switch to differentiate between spurious fluctuations and

Temperature

Switch

On

Off

Temperature

Switch

On

Off

Case 1: Switch set as

Case 2: Switch set as

Normally Open

Normally Closed

45

50 75

80

45

50

75

80

Page 14

TDD 10

FM Rev. 8/6/01

actual system tempera ture changes and process the tempera ture change signals without

filtering. This greatly enhances the switch’s response time when the filtering function is

being used.

5.2.6 Con - Switch Logic

This menu item allows the user to select the output switch logi c as either normally closed

(nc), or normally open (no):

Normally Open: Switch activates when measured temperature is above the

switchpoint.

Normally Closed: Switch activ ates when mea sured temperature is below the

switchpoint.

5.2.7 CCo - Change Code

This menu item allows the user to set a pass code which will lock out the programming

functions. This protects the devi ce from un-authorized access to the setup men u. Section

5.1.1 ‘Changing Values in Setup Mode’ on page 6 provides steps required to change a

value. The code can be any value from 000 to 999. A code of 000 disables the lockout

function. A value other than 000 will require entry of that code to access the setup menu.

6.0 Maintenance

The TDD series temperature switches have no moving parts and are therefore virtually

maintenance free. Depending on the type of media, the temp erat ure sensing pro be may

become coated over time. Sluggish response to changes in system temperature would

be evidence of this. If coating occurs, remove the switch from the system and clean the

temperature sensing probe.

Page 15

CAUTION

PLEASE READ THE FOLLOWING WARNINGS BEFORE AT TEMPTING

INSTALLATION OF YOUR NEW DEVICE. FAILURE TO HEED THE

INFORMATION HEREIN MAY RESULT IN EQUIPMENT FAILURE AND

POSSIBLE SUBSEQUENT PERSONAL INJURY.

Page 16

TDD 12

FM Rev. 8/6/01

• User's Responsib ility f or Safe ty: K OBOLD manufactur es a wide range of

process sensors and technologies. While each of these technologies are

designed to operate in a wide variety of applications, it is the user's

responsibility to select a technology that is appropriate for the application,

to install it p roperly, to perfo rm tests of the installed system, and to maintain

all components. The failure to do so could result in property damage or

serious injury.

• Proper Installation and Han dling: Use a proper thread sealant with all

installations. Take care not to overtighten the fittings. Always check for

leaks prior to system start-up.

• Wiring and Electrical: Section 2.0, Specifications and Section 4. 0,

Electrical Connections, provide the voltage and current limitations and the

wiring for the various sensor types. The sensor electrical ratings should

never be exceeded. Electrical wiring of the sensor should be performed in

accordance with all applicable national, state and local codes.

• Pressure and Temperature: Section 2.0, Specifications, provides the

pressure and temperature limits for each model. Operation out side these

limitations will cause damage to the unit and can potentially cause personal

injury.

• Material Compatibility: Make sure that the model which you have

selected is chemically compatible with the application liquids. While the

meter is liquid and spray resistant when installed pr operly, it is not

designed to be immersed.

• Flammable, Explosive and Hazardous Applications: The TDD series is

not an intrinsically safe or explosion proof design. They should not be used

in installations in which an instrinsically safe or explosion proof design is

required.

• Make a Fail-safe System : Design a fail-safe system that accommodates

the possibility of switch or power failure. In critical applications, KOBOLD

recommends the use of redundant backup systems and alarms in addition

to the primary system.

Page 17

Page 18

Loading...

Loading...