Kobold SEN-87 Series, SEN-8640 Series, SEN-8600 Series, SEN-8630 Series, SEN-8650 Series Operating Instructions Manual

...Page 1

Operating Instructions

for

Pressure Sensors

Heavy Duty Compact

Model: SEN-86../ SEN-87..

Page 2

SEN-86../87..

page 2 SEN-86../87.. K04/0618

1. Contents

1. Contents ........................................................................................................ 2

2. Note .............................................................................................................. 3

3. Instrument Inspection .................................................................................... 3

4. Regulation Use .............................................................................................. 3

5. Operating Principle ........................................................................................ 4

6. Mechanical Connection and Putting to Operation ......................................... 4

7. Electrical Connection .................................................................................... 5

8. Maintenance ................................................................................................. 7

9. Trouble shouting ........................................................................................... 7

10.Technical Information .................................................................................... 8

11.Order Codes ................................................................................................. 9

12.Dimensions ................................................................................................. 11

13.EU Declaration of Conformance .................................................................. 12

Manufactured and sold by:

Kobold Messring GmbH

Nordring 22-24

D-65719 Hofheim

Tel.: +49(0)6192-2990

Fax: +49(0)6192-23398

E-Mail: info.de@kobold.com

Internet: www.kobold.com

Page 3

SEN-86../87..

SEN-86../87.. K04/0618 page 3

2. Note

Please read these operating instructions before unpacking and putting the unit

into operation. Follow the instructions precisely as described herein.

The devices are only to be used, maintained and serviced by persons familiar

with these operating instructions and in accordance with local regulations applying to Health & Safety and prevention of accidents.

When used in machines, the measuring unit should be used only when the

machines fulfil the EC-machine guidelines.

3. Instrument Inspection

Instruments are inspected before shipping and sent out in perfect condition.

Should damage to a device be visible, we recommend a thorough inspection of

the delivery packaging. In case of damage, please inform your parcel service /

forwarding agent immediately, since they are responsible for damages during

transit.

Scope of delivery:

The standard delivery includes:

Pressure Sensors Heavy Duty Compact model: SEN-86../87..

Operating Instructions

4. Regulation Use

Pressure sensors transmit the mechanical pressure signal into an electrical

output signal. The media’s which are in contact with the instrument should have

no effects on the instrument materials used. Do not use standard units in

hazardous areas and for oxygen applications.

Page 4

SEN-86../87..

page 4 SEN-86../87.. K04/0618

G 1/2 A

R 16

z

* min.

S

ealing acc. DIN 16288 Sealing with flat gasket

7

+0,2

G 1/2 A

R 16

z

* min.

7

+0,2

21,3

-0,2

G 1/4 A

R 16

z

* min.

7

20,5

14,5

14,5

19

24,5

24,5

13

16,5

9

+0,2

- 0,5

- 0,5

- 0,5

+1

+1

+1

5. Operating Principle

KOBOLD Pressure sensors model SEN-86 are inexpensive pressure sensors

with thick film ceramic pressure element. With their accuracy, reliability and

compact design, they are perfectly suitable for OEM applications in medium to

high quantities.

The materials and technology used make these pressure sensors insensitive to

chemically aggressive media and mechanical load.

Particularly hydraulics systems with their high and fast pressure peaks are thus

preferred applications.

6. Mechanical Connection and Putting to Operation

The place where pressure is taken should be prepared according the following

specifications for the screw-in threads.

For sealing, please use sealing discs acc. DIN 16258 or profile washers. The

maximum initial tension depends on the material, the shape of the used sealing

and the mechanical connection of the pressure sensor.

There should be no vibrations and/or no radiation of heat near the mounting

position of the sensors. Please pay attention that the given technical data’s are

not exceeded. After the mechanical and electrical connection the sensor works

immediately.

Page 5

SEN-86../87..

SEN-86../87.. K04/0618 page 5

7. Electrical Connection

Ensure that the power is disconnected during connection of the cable.

The electrical connection is made either via plug and pin or by cable.

The exact wiring scheme is shown on the sketches hereafter or at the type

plate of your sensor.

Meaning of the different connector markings

UB+ positive pole of the supply voltage

OV negative pole of the supply voltage

S+ positive pole of the output signal

S- negative pole of the output signal

Shielding Cable protection enclosure-earth

The sensor can be supplied with a non stabilised DC source with the given voltage range. The minimum supply voltage for pressure sensors with current output

should be the minimum UB plus the minimum voltage, which is needed for the

external indicator:

Current output

2-wire system 3-wire system

Output signal 4...20 mA 0...20 mA

Supply voltage UB= 15 ... 32 VDC

Permissible load RA[Ohm] = (UB[V] - 15 V) / 0,02 A

Wiring see schematic

Voltage output

3-wire system 3-wire system

Output signal 0...5 V 0...10 V

Supply voltage UB= 15 ... 32 VDC

Permissible load

R

A >5 k RA >10 k

Wiring see schematic

Page 6

SEN-86../87..

page 6 SEN-86../87.. K04/0618

Electrical connection, principle drawings

pin assignment, cable marking

0V/S-

0V/S-

U

B

+

U

B

+

U

B

+/S+

U

B

+/S+

Supply

U

B

(DC)

Supply

U

B

(DC)

Supply

U

B

(DC)

Supply

U

B

(DC)

Supply

UB (DC)

Supply

U

B

(DC)

Indicator Indicator

Indicator

Indicator

Indicator

Indicator

1

2

3

green 0V/S-

green

0V/S-

white S+

DIN 43650 plug

5 - pin plug (Binder)

With free cable

brown U

B

+blue UB+

0V/S-

S+

3

2

1

5

4

3

2

1

5

4

S+

1

2

3

shielding

shilding

2-wire-system

3-wire-system

2-wire-system 3-wire-system

Attention! Incorrect wiring will lead to damage of the unit’s electronics.

Page 7

SEN-86../87..

SEN-86../87.. K04/0618 page 7

8. Maintenance

The pressure sensors described in this manual are maintenance free! They do

not contain any components which may be repaired or exchanged locally.

Repairs are not possible other than in our factory.

9. Trouble shouting

Trouble Possible reason What's to do

No signal no supply voltage

broken wire

Check your power supply and

wiring. lf necessary replace

defective parts

Sensor has been wired faulty Check the wiring according to

the sketches, adjust wiring if

necessary.

No pressure Check your tubing , valves

open?

Defective electronics

caused by to high supply

voltage or by external voltage

Return sensor to us for repair

Unchanged signal by Pressure port is clocked Clean the pressure port

changing pressure Defective electronic caused

by to high supply voltage or

by external voltage

Return sensor to us for repair

Pressure sensor over pressurized

Return sensor to us for repair

To high, even on changing

pressure unchanged signal

Defective electronics caused

by to high supply voltage or

by external voltage

Return sensor to us for repair

Span of signal to small Supply voltage to low

Resistance to high

Adjust supply voltage Adhere

to max. allowable resistance

Zero signal to high Mechanical overburden Return to us for repair

Output signal non linear Mechanical overburden Recalibrate sensor resp. re-

turn to us for repair

Page 8

SEN-86../87..

page 8 SEN-86../87.. K04/0618

10. T echnical Information

Model

SEN-86x0 SEN -87x0

Technology internal diaphragm

Pressure type gauge pressure

Housing stainless steel 1.4305

Connection:

G ½ male; stainless steel

1.4301 (NPT, UNF on

request)

G ¼ male; stainless steel

1.4301 (NPT, UNF on

request)

Sensor element ceramic (Al2O3)

Measuring principle thick film techn. (DMS)

O-Ring NBR

Max. Temperature

Storage: -30...+100 °C

Medium: -20...+125 °C

Ambient: -30...+100 °C

Storage: -30...+100 °C

Medium: -20...+ 85 °C

Ambient: -30...+100 °C

Pressure limitation

< 60 bar: 2 x range

≥ 60 bar: 1.5 x range

Accuracy class 0.5 f.s.d.)

Repeatability

± 0.15 % (f.s.d.)

Characteristic deviation

± 0.3 % (f.s.d.)

Stability (annual)

± 0.2 % of full scale

in rated conditions

Electrical connection

Plug DIN 43 650 A / Plug M12x1

Cable connection

Power supply 15...32 VDC

Output signal 4 – 20 mA, (2-wire), 0 – 10 VDC

Load () (UB – 15 V)/0.02 A (for 4 – 20 mA)

Response time

1 ms (within 10 – 90% of full scale)

Temp. comp. range -25...+85 °C

Temperature drift Zero:

± 0.02% full scale/K

Measuring span:

± 0.01% full scale/K

Protection

IP 65 (SEN-860..; SEN-863..)

IP 68 (SEN-865..)

Options Absolute pressure for ranges 1.0...25 bar

Oil- and free of grease for oxygen

Silicone- and LABS free

Connection with 50 mm cooling fins t

max

125 °C

Connection and housing SS 1.4539

1)

instead of 1.4305

Connection and housing SS 1.4571 instead of 1.4305

O-ring FPM instead of NBR

O ring PTFE (Kalrez) instead of NBR <100 bar

½” NPT thread instead of “G”

G¼ DIN385-E inclusive seal

ring

3)

Special connection2) on request

1)

Seawater resistant

2)

Please specify in writing

3)

Adapter of PSD usable

Page 9

SEN-86../87..

SEN-86../87.. K04/0618 page 9

11. Order Codes

Sensor (Example: SEN-8600 C315)

Electrical

connection

Class Model Output Measuring range Options

DIN-plug;

IP 65

0.5

SEN-8600..

without =

4 – 20 mA

/2 = 0 –10 V

C305 = -0.6...0 bar

C315= -1 ...0 bar

C505 = -1...0.6 bar

C515 = -1…1.5 bar

C525 = -1…3 bar

C535 = -1…5 bar

C545 = -1…9 bar

C555 = -1...15 bar

B015 = 0…0.6 bar

B025= 0...1 bar

B035= 0…1.6 bar

B045= 0…2.5 bar

B055= 0…4 bar

B065= 0…6 bar

B075= 0…10 bar

B085= 0...16 bar

A095= 0...25 bar

A105= 0...40 bar

A115= 0...60 bar

A125= 0...100 bar

A135= 0...160 bar

A140 = 0...200 bar

A145= 0...250 bar

A155= 0...400 bar

A165 = 0...600 bar

A170 = 0...700 bar

A175 = 0...800 bar

H 315= -30...0 Hg

P 020 = 0...10 psi g

P 025= 0...15 psi g

P 045= 0...30 psi g

P 055= 0...50 psi g

P 060 = 0...60 psi g

P 065= 0...100 psi g

P 075= 0...150 psi g

P 085= 0...200 psi g

P 090 = 0...300 psi g

P 095= 0...350 psi g

P 100 = 0...500 psi g

P 105= 0...600 psi g

P 115= 0...1000 psi g

P 125= 0...1450 psi g

P 130 = 0...2000 psi g

P 135= 0...2300 psi g

P 140 = 0...300 psi g

P 145= 0...3600 psi g

P 150 = 0...500 psi g

P 155= 0…5800 psi g

P 160 = 0…7500 psi g

P 165 = 0…10000 psi g

YYY= special range,

please specify in

writing

Thread

without = G ½ male

Y = absolute

pressure for

ranges

1.0…25 bar

Y = oil- and free of

grease for

oxygen

Y = silicone- and

LABS-free

Y = connection with

50 mm cooling

fins t

max

125 °C

Y = connection and

housing SS

1.4539 (seewater

resistant) instead

of 1.4305

Y = connection and

housing SS

1.4571 instead

of 1.4305

Y = O-ring FPM

instead of NBR

Y = O-ring PTFE

(Kalrez) instead of

NBR <100 bar

Y = special

connection on

request, please

specify in writing

N = ½” NPT male

M12-plug;

IP 67

0.5

SEN-8630..

Cable connection;

IP67

Standard cable 1 m

(other length on

request)

SEN-8640..

Cable connection;

IP 68

Standard cable 1 m

(other length on

request)

0.5

SEN-8650..

Page 10

SEN-86../87..

page 10 SEN-86../87.. K04/0618

Sensor (Example: SEN-8700 C315)

1)

Seawater resistant

2)

Please specify in writing

3)

Adapter of PSD usable

Electrical

connection

Class Model Output

Measuring

range

Options

DIN-plug;

IP 65

0.5

SEN-8700..

without =

4 – 20 mA

/2 = 0 –10 V

C305 = -0.6...0 bar

C315= -1 ...0 bar

C505 = -1...0.6 bar

C515 = -1…1.5 bar

C525 = -1…3 bar

C535 = -1…5 bar

C545 = -1…9 bar

C555 = -1...15 bar

B015 = 0…0.6 bar

B025= 0...1 bar

B035= 0…1.6 bar

B045= 0…2.5 bar

B055= 0…4 bar

B065= 0…6 bar

B075= 0…10 bar

B085= 0...16 bar

A095= 0...25 bar

A105= 0...40 bar

A115= 0...60 bar

A125= 0...100 bar

A135= 0...160 bar

A140 = 0...200 bar

A145= 0...250 bar

A155= 0...400 bar

A165 = 0...600 bar

A170 = 0...700 bar

A175 = 0...800 bar

H 315= -30...0 Hg

P 020 = 0...10 psi g

P 025= 0...15 psi g

P 045= 0...30 psi g

P 055= 0...50 psi g

P 060 = 0...60 psi g

P 065= 0...100 psi g

P 075= 0...150 psi g

P 085= 0...200 psi g

P 090 = 0...300 psi g

P 095= 0...350 psi g

P 100 = 0...500 psi g

P 105= 0...600 psi g

P 115= 0...1000 psi g

P 125= 0...1450 psi g

P 130 = 0...2000 psi g

P 135= 0...2300 psi g

P 140 = 0...300 psi g

P 145= 0...3600 psi g

P 150 = 0...500 psi g

P 155= 0…5800 psi g

P 160 = 0…7500 psi g

P 165 = 0…10000 psi g

YYY= special range,

please specify in

writing

Thread

without = G ¼ male

Y = absolute

pressure for

ranges

1.0…25 bar

Y = oil- and free of

grease for

oxygen

Y = silicone- and

LABS-free

Y = connection with

50 mm cooling

fins t

max

125 °C

Y = connection and

housing SS

1.4539

1)

(seewater

resistant) instead

of 1.4305

Y = connection and

housing SS

1.4571 instead

of 1.4305

Y = O-ring FPM

instead of NBR

Y = O-ring PTFE

(Kalrez) instead of

NBR <100 bar

Y = G ¼ DIN 385-E

inclusive seal ring

Y = special

3)

connection

2)

on

request, please

specify in writing

N = ½” NPT male

M12-plug;

IP 67

0.5

SEN-8730..

Cable

connection; IP67

Standard cable

1 m (other length

on request)

0.5

SEN-8740...

Cable

connection;

IP 68

0.5

SEN-8750..

Page 11

SEN-86../87..

SEN-86../87.. K04/0618 page 11

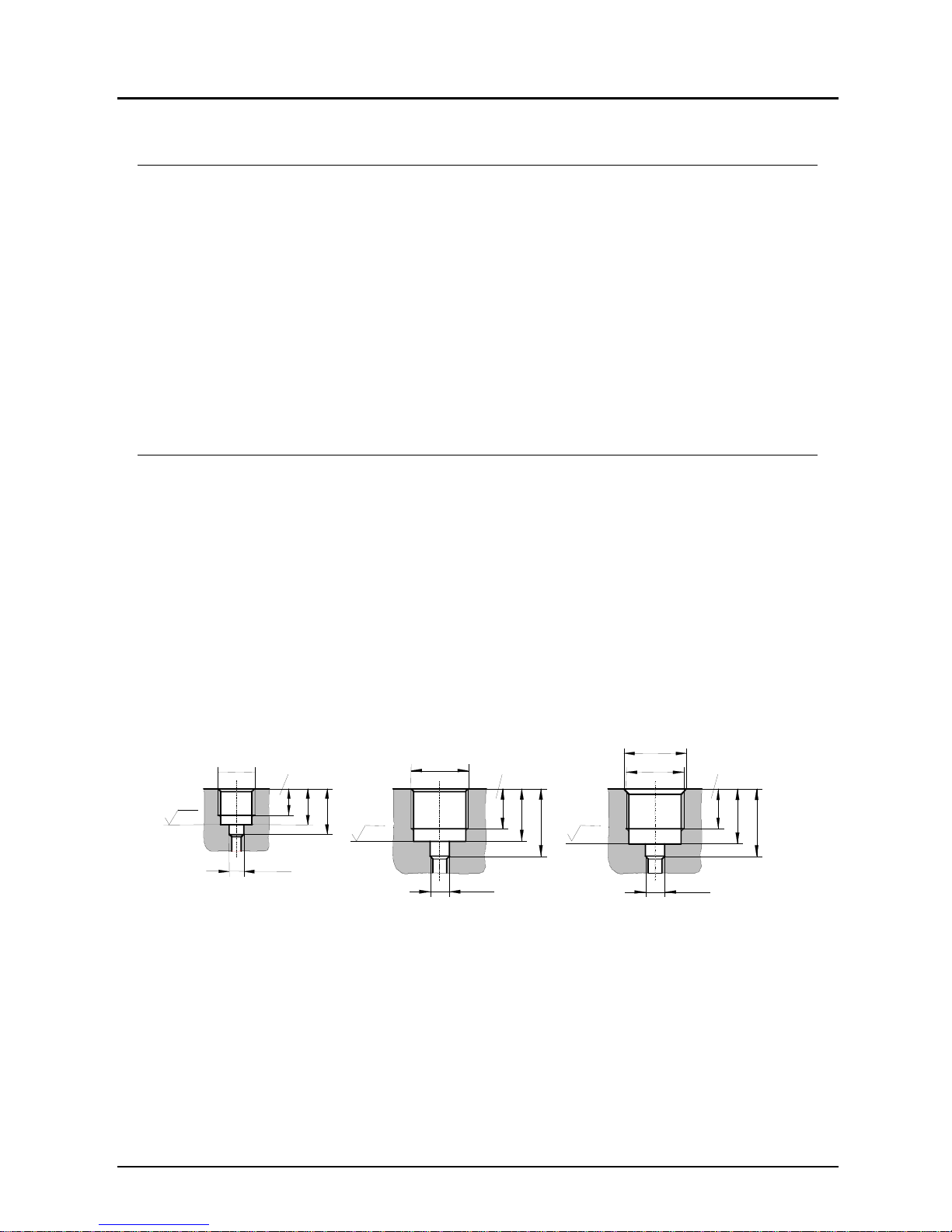

12. Dimensions

[in mm]

SEN-86

SEN-87

Page 12

SEN-86../87..

page 12 SEN-86../87.. K04/0618

13. EU Declaration of Conformance

We, KOBOLD-Messring GmbH, Hofheim-Ts, Germany, declare under our sole

responsibility that the products:

Pressure Sensors models: SEN-86... and SEN-87...

to which this declaration relates in conformity with the standards noted below:

EN 61326-1:2013 Electrical equipment for measurement, control and

laboratory use - EMC requirements - Part 1: General requirements

EN 61326-2-3:2013 Electrical equipment for measurement, control and

laboratory use - EMC requirements - Part 2-3: Particular requirements - Test

configuration, operational conditions and performance criteria for transducers

with integrated or remote signal conditioning

EN 50581:2012 Technical documentation for the assessment of electrical

and electronic products with respect to the restriction of hazardous substances

Also the following EC guidelines are fulfilled:

2014/30/EU EMC Directive

2014/68/EU PED

PS200 bar; module A, pressure accessory

2011/65/EU RoHS (category 9)

Hofheim, 23. Jan. 2018

H. Peters M. Wenzel

General Manager Proxy Holder

Loading...

Loading...