Page 1

Operating Instructions

for

Level Switch for Liquids

Model: RFS

Page 2

RFS

page 2 RFS K02/0118

1. Contents

1. Contents ........................................................................................................ 2

2. Note .............................................................................................................. 3

3. Instrument Inspection .................................................................................... 3

4. Regulation Use .............................................................................................. 3

5. Operating Principle ........................................................................................ 4

6. Use in Hazardous Areas ............................................................................... 4

7. Mechanical Connection ................................................................................. 5

8. Electrical Connection .................................................................................... 6

9. Technical Information .................................................................................... 8

10.Order Codes ................................................................................................. 9

11.Dimensions ................................................................................................. 10

12.EU Declaration of Conformance .................................................................. 11

13.ATEX-Certificate ......................................................................................... 12

Manufactured and sold by:

Kobold Messring GmbH

Nordring 22-24

D-65719 Hofheim

Tel.: +49(0)6192-2990

Fax: +49(0)6192-23398

E-Mail: info.de@kobold.com

Internet: www.kobold.com

Page 3

RFS

RFS K02/0118 page 3

2. Note

Please read these operating instructions before unpacking and putting the unit

into operation. Follow the instructions precisely as described herein.

The devices are only to be used, maintained and serviced by persons familiar

with these operating instructions and in accordance with local regulations

applying to Health & Safety and prevention of accidents.

When used in machines, the measuring unit should be used only when the

machines fulfil the EC-machine guidelines.

3. Instrument Inspection

Instruments are inspected before shipping and sent out in perfect condition.

Should damage to a device be visible, we recommend a thorough inspection of

the delivery packaging. In case of damage, please inform your parcel service /

forwarding agent immediately, since they are responsible for damages during

transit.

Scope of delivery:

The standard delivery includes:

Level Switch model: RFS

Operating Instructions

4. Regulation Use

Model RFS devices are used for when monitoring liquid levels. The device should

only be used with liquids that are compatible with the unit’s materials of

construction.

Level control is often accomplished with at least two level switches - one acting to

sense the minimum level and the other for maximum level detection.

Any use of the Level Switch, model: RFS, which exceeds the manufacturer’s

specification, may invalidate its warranty. Therefore, any resulting damage is not

the responsibility of the manufacturer. The user assumes all risk for such usage.

Page 4

RFS

page 4 RFS K02/0118

5. Operating Principle

The Level Switch RFS is designed for economical control of liquids in vessels.

The following three versions are available: A device with plug connection and two

devices with aluminium housing connection of which one is an ATEX-version for

the use in environment with gas explosion hazards. The switch is remarkable for

its maintenance-free design and small dimensions. The switch is mounted on the

side of the vessel. A hinged stainless steel float with a magnet floats up and down

through the liquid level. In the end position a potential-free reed contact is

operated by the magnet. The switching function (N/O contact / N/C contact) is

determined by the mounting position. The switching function is reserved by

simply rotating the switch through 180°.

6. Use in Hazardous Areas

With the approval the Level Switch, model RFS, can be used within hazardous

areas. Thereby the aluminium housing is applicable outside the process in zone

of category 2D. The float is appropriate for the use within the process in zone of

category 2D and 1D.

The approvals are as follows:

II 1 GD Ex ia IIC T6 Ga

-20≤Ta≤+60 °C

An additional intrinsically safe relay is required in environment with gas explosion

hazards (KFA…and respectively KFD).

For a correct and professional potential equalization, the ground terminal on the

housing of the RFS must be connected in applications in hazardous areas.

Page 5

RFS

RFS K02/0118 page 5

7. Mechanical Connection

The Level Switch should be mounted so that the float can move freely over its

entire path without hitting the walls, floor or roof of the container. Avoid fitting the

switch where agitators or inlet valves could expose it to excessive turbulence.

Make sure that the medium does not contain solids or ferrite particles, as they

could collect on the float magnet and interfere with the switching operation. If the

liquid does contain sediment or suspended matter, you must be sure they do not

come into contact with the float system.

Mount the switch in a way that it is easily accessible for installation and

maintenance.

Make sure that the allowed max. operational pressure and service temperature

for the device is not exceeded.

The installation position must be horizontal.

If possible, examine all the connection joints for proper sealing, just after

mechanical installation.

The engraved arrow on the hexagon must point up or down depending on the

desired contact function. In any case the marked hexagon surface must always

be mounted vertically.

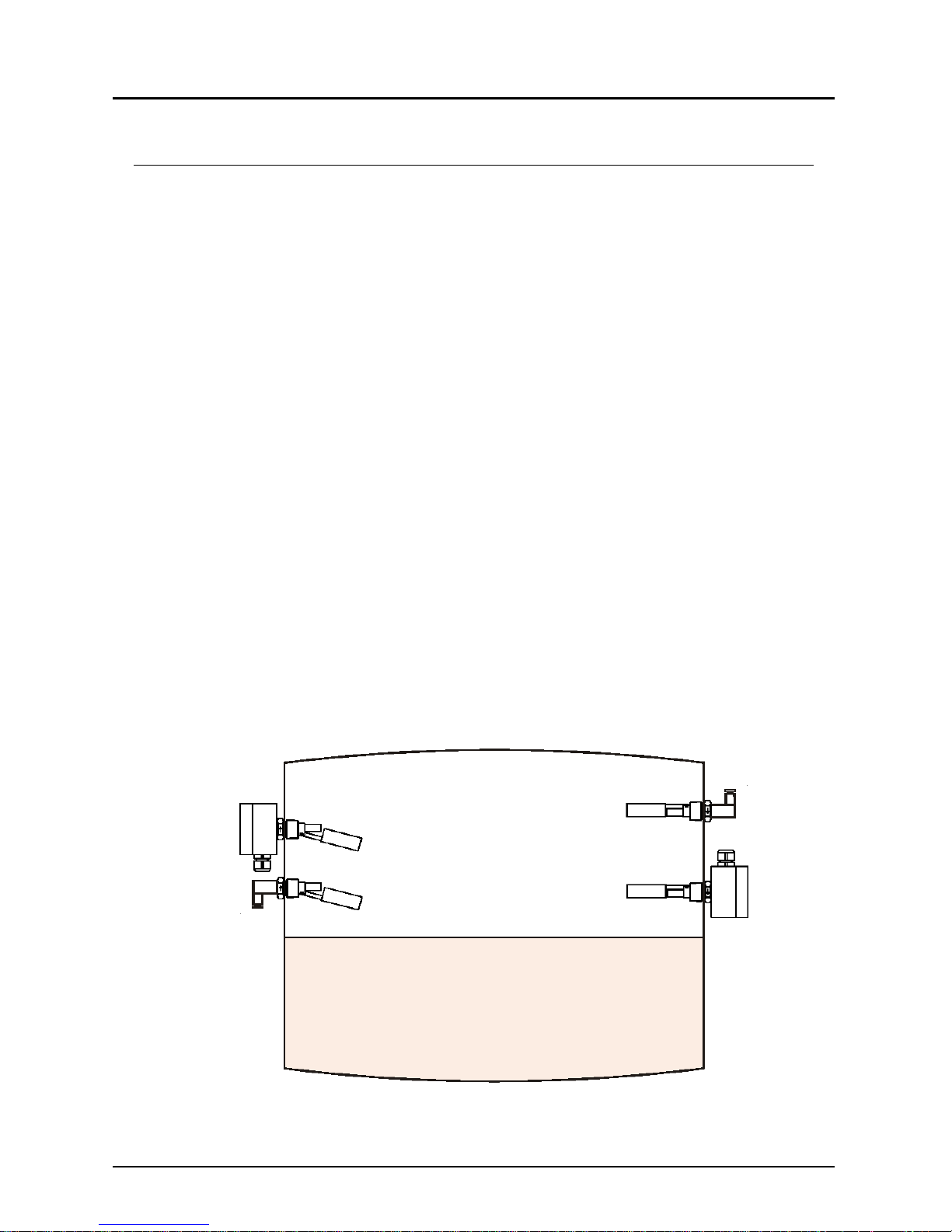

Mounting position

Depending on the mounting position of the device, the contact function (N/O or

N/C contact) of the level switch will be defined.

Mounted as

N/O contact

Mounted

as N/C

Page 6

RFS

page 6 RFS K02/0118

8. Electrical Connection

Caution! Make sure that the voltage values of your system

correspond with the voltage values of the level switch.

Make sure that the supply wires are de-energised.

Connect your connection cable to the terminal of the aluminium housing or the

plug of the RFS level switch.

The level switch has a protective insulation; a separate protection wiring for the

standard version is not necessary.

For the RFS version for ATEX applications, the connection of the potential

terminal is mandatory.

An additional intrinsically safe relay is required in environment with gas

explosion hazards (KFA…and respectively KFD).

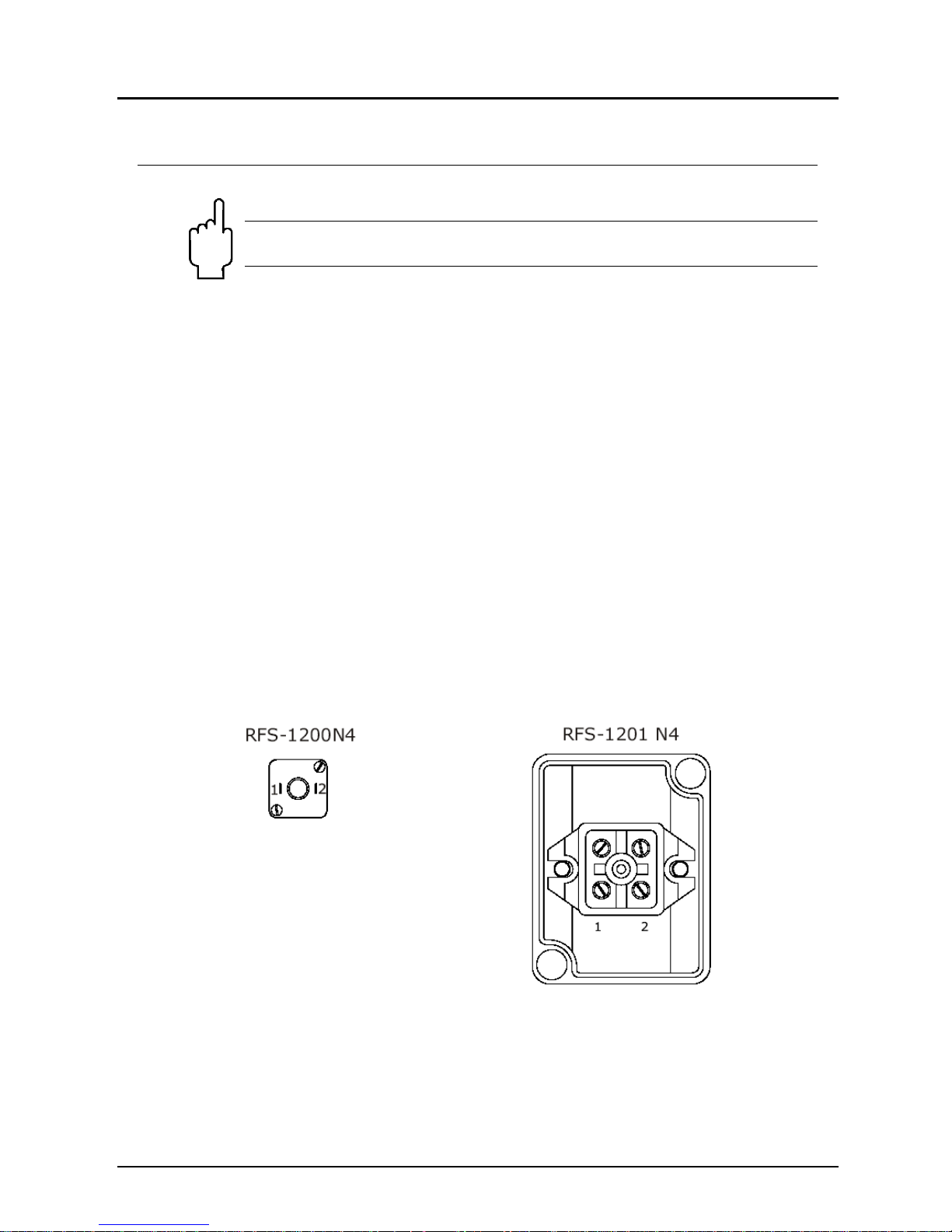

Pin assignment for RFS Level Switch

RFS-1200N4 and RFS-1201N4

There are only two connection terminals which can be connected by choice and

which do not have any influence on the contact function (N/C / N/O). The contact

function is defined by the mounting position of the instrument.

Page 7

RFS

RFS K02/0118 page 7

RFS-12EXN4

There are three connection terminals of which one terminal is clearly marked as a

ground terminal. The two other terminals are connected in the same way as the

standard devices RFS-1200N4 and RFS-1201N4 respectively.

After the connection of any other from your designated external instruments to

the limit contact, the device is ready for operation.

Page 8

RFS

page 8 RFS K02/0118

9. Technical Information

Medium temperature: - 40...+120 °C

Ambient temperature: -20...+80 °C

(RFS-1200 N4 and RFS-1201 N4)

-20...+ 60 °C

(RFS-12Ex N4)

Operating pressure: max. 5 bar

mounting position: horizontal

Materials

• Housing / plug: plastic with RFS-1200 N4

aluminium with RFS-1201 N4

and RFS-12Ex N4

• Float: stainless steel 1.4301

• Connection: stainless steel 1.4301

Process connection: 1/2 NPT

Electr. connection: for RFS-1200 N4: DIN plug

for RFS-1201 and RFS-12Ex:

terminals in the aluminium connection

Contacts: N/O or N/C contact,

depending on the mounting

position of the device

Switching voltage: max. 240 V

AC / 300 VDC

with RFS-1200 and RFS-1201

max. 40 VDC with RFS-12Ex

Switching current: max. 0.5 A

Switching capacity: max. 15 VA

with RFS-1200 and RFS-1201

max. 4 VA with RFS-12Ex

Medium density: >0.7 g/cm

3

Contact resistance: max. 150 kΩ

Protection: IP65

ATEX marking

for RFS-12Ex: II 1 GD Exia IIC T6 Ga

-20°C ≤ Ta ≤ +60 °C

Page 9

RFS

RFS K02/0118 page 9

10. Order Codes

Example: RFS-1200 N4

Model Description

RFS-1200 N4

Standard version with

plug connection

RFS-1201 N4

Standard version with

housing connection

(aluminium)

RFS-12Ex N4*

ATEX version for use in

environments with explosion

hazards

*an additional relay is required for the use

in environment with gas explosion hazards

Page 10

RFS

page 10 RFS K02/0118

11. Dimensions

RFS-1201 N4, RFS-12Ex N4

4719.5

8

.5

17.5

1/2 NPT

2

8

1

7

50

65

M16

RFS-1200 N4

4719.5

8

.5

17.5

1/2 NPT

2

8

1

7

Page 11

RFS

RFS K02/0118 page 11

12. EU Declaration of Conformance

DECLARACIÓN DE CONFORMIDAD EU

EU DECLARATION OF CONFORMITY

EU-KONFORMITÄTSERKLÄRUNG

DÉCLARATION DE CONFORMITÉ

DICHIARAZIONE DI CONFORMITÀ EU

KOBOLD MESURA SLU

Avda. Conflent 68 nave 15 08915 Badalona (España)

Declara, bajo la propia responsabilidad, que el producto

Declares under our sole responsibility, that the product

Erklärt in alleiniger Verantwortung, dass das Produkt

Déclare sous sa seule responsabilité, que le produit

Dichiara sotto la propia responsabilità, che il prodotto

Magnetic level switch

RFS-12Ex N4

A los cuales se refiere esta declaración, son conformes a las siguiente Directivas Europeas:

To which this declaration relates is in conformity with the following European Directives:

Mit folgenden Euroäischen Richtlinien Konform ist:

À auxquels se réfère cette déclaration, ils sont conformes aux Directives Européennes suivant :

A ai quali si riferisce questa dichiarazione, sono conformi alle direttive europee seguente:

EMC2014/30/EU LVD2014/35/EU ATEX2014/34/EU RoHS2011/65/EU

Normas armonizadas y documentos de la normativa aplicados:

Applied harmonised standards and normative documents:

Angewandte harmonisierte Normen und normative Dokumente:

Normes harmonisées et documents normatifs appliqués

Norme armonizzate e documenti normativi applicati:

EN61010-1 :2011 EN60079-0:2012 (acc. EN60079-0:2013)

EN61000-6-2 :2006 EN60079-11:2012 (acc. EN60079-11:2013)

Certificado de examen CE de tipo Marcado

EC-type examination certificate Marking

EG-baumusterprüfbescheinigung Kennzeichnung

Attestation d´examen CE de type Inscription

Certificazione per esame di tipo CE Marcatura

LOM06ATEX2054X

II 1 GD Ex ia IIC T6 Ga

-20≤Ta≤+60ºC

Fabricado en: KOBOLD MESURA SLU Avda. Conflent 68 nave 15 08915 BADALONA (Spain)

Made in:

Hergestellt in:

Fabriqué dans:

Fabbricato in:

Organismo notificado

: LOM 0163 Número notificación : LOM 05ATEX9070

Notified organism Notification number

Zertifizierungsstelle Zertifikatsnummer

Organization annoncée Nombre notification

Organismo informato Notifica di numero

Badalona april. 2016

DT0497

Gerente

Page 12

RFS

page 12 RFS K02/0118

13. A TEX-Certificate

Page 13

RFS

RFS K02/0118 page 13

Page 14

RFS

page 14 RFS K02/0118

Page 15

RFS

RFS K02/0118 page 15

Page 16

RFS

page 16 RFS K02/0118

Page 17

RFS

RFS K02/0118 page 17

Page 18

RFS

page 18 RFS K02/0118

Loading...

Loading...