Page 1

Operating Instructions

for

Differential Pressure

Flow Meter / Monitor

Model: RCD-...

Page 2

RCD

1. Contents

1. Contents ........................................................................................................ 2

2. Note .............................................................................................................. 3

3. Instrument Inspection .................................................................................... 3

4. Regulation Use .............................................................................................. 4

5. Operating Principle ........................................................................................ 4

6. Mechanical Connection ................................................................................. 4

6.1. Check Service Conditions .................................................................... 4

6.2. Installation ............................................................................................ 5

7. Electrical Connection .................................................................................... 6

7.1. Mechanical Pointer Indication (..Z...) ................................................... 6

7.2. Compact Electronics: (..C30R, ..C30M, ..C34P, ..C34N) .................... 6

7.3. ADI Electronic ...................................................................................... 6

8. Commissioning .............................................................................................. 6

8.1. Mechanical Pointer Indication (..Z...) ................................................... 6

8.2. Setting Compact Electronics ................................................................ 6

8.3. Setting ADI Electronic .......................................................................... 6

9. Maintenance ................................................................................................. 7

10.Technical Information .................................................................................... 7

10.1. Sensor Data ......................................................................................... 7

10.2. Displays/Electronics ............................................................................. 7

11.Order Details ................................................................................................. 9

12.Dimensions ................................................................................................. 11

13.EU Declaration of Conformance .................................................................. 12

Manufactured and sold by:

Kobold Messring GmbH

Nordring 22-24

D-65719 Hofheim

Tel.: +49(0)6192-2990

Fax: +49(0)6192-23398

E-Mail: info.de@kobold.com

Internet: www.kobold.com

page 2 RCD K07/0818

Page 3

RCD

2. Note

Please read these operating instructions before unpacking and putting the unit

into operation. Follow the instructions precisely as described herein.

The devices are only to be used, maintained and serviced by persons familiar

with these operating instructions and in accordance with local regulations

applying to Health & Safety and prevention of accidents.

When used in machines, the measuring unit should be used only when the

machines fulfil the EC-machine guidelines.

as per PED 2014/68/EU

In acc. with Article 4 Paragraph (3), "Sound Engineering Practice", of the

PED 2014/68/EU no CE mark.

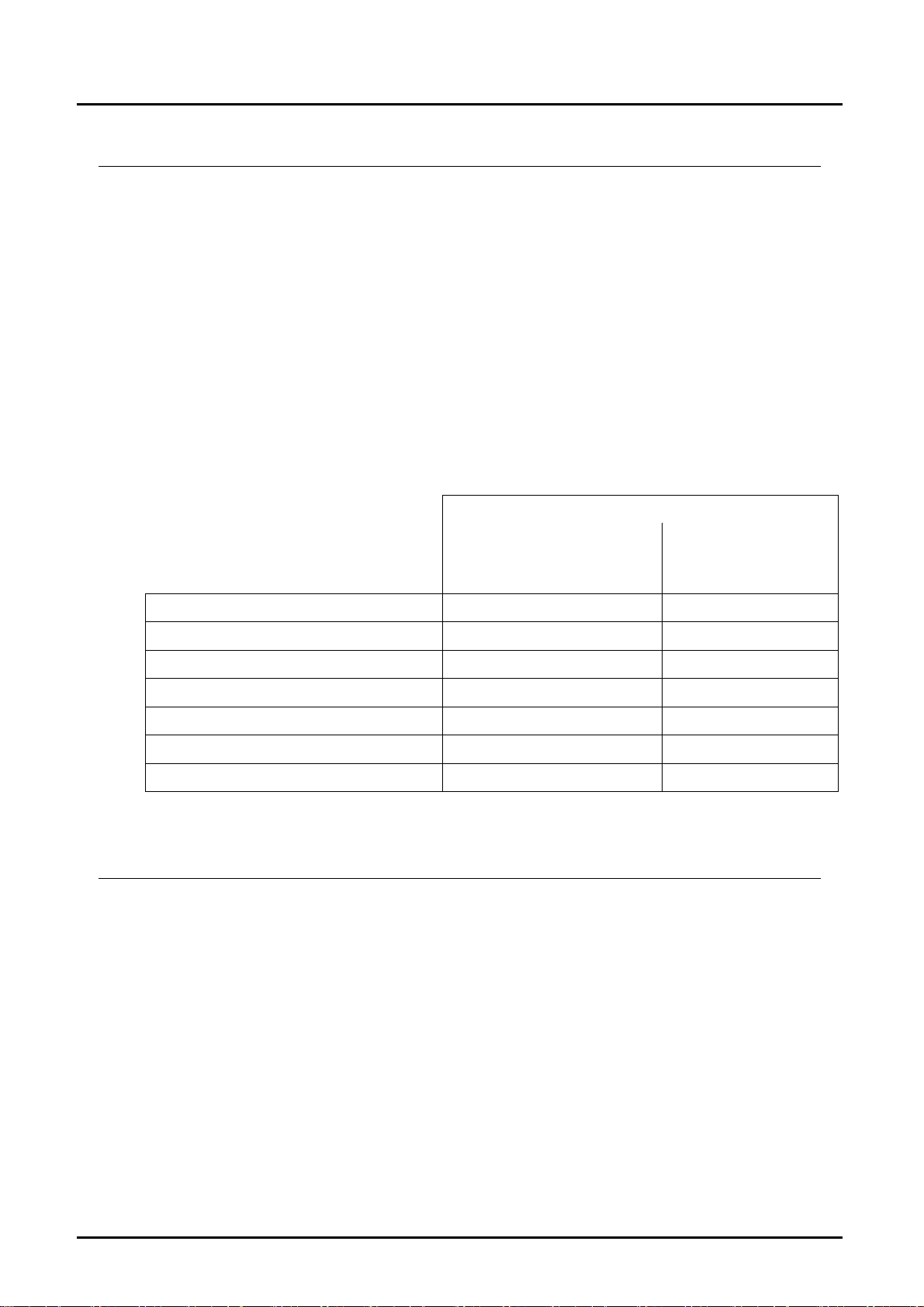

Pipe

Diagram 7

group 1

no dangerous fluids

RCD-..05 - RCD..30 Art. 4, § 3 Art. 4, § 3

RCD-1135, RCD-1140 Art. 4, § 3 Cat. I

RCD-1235, RCD-1240 Cat. I Cat. II

RCD-1145, RCD-1150 Art. 4, § 3 Cat. I

RCD-1245, RCD-1250 Cat. I Cat. II

RCD-1155, RCD-1160, RCD-1165 Cat. I not deliverable

RCD-1260, RCD-1265 Cat. I Cat. II

dangerous fluids

3. Instrument Inspection

Instruments are inspected before shipping and sent out in perfect condition.

Should damage to a device be visible, we recommend a thorough inspection of

the delivery packaging. In case of damage, please inform your parcel service /

forwarding agent immediately, since they are responsible for damages during

transit.

Scope of delivery:

The standard delivery includes:

Differential Pressure Flow Meter / Monitor model: RCD

Operating Instructions

Diagram 6

group 2

RCD K07/0818 page 3

Page 4

RCD

4. Regulation Use

Any use of the Differential Pressure Flow Meter / Monitor, model: RCD, which

exceeds the manufacturer’s specification may invalidate its warranty. Therefore

any resulting damage is not the responsibility of the manufacturer. The user

assumes all risk for such usage.

5. Operating Principle

The Kobold Flow Meter is used for measuring and monitoring the flow velocity of

liquids and gases. The device works in accordance with the well-known principle

of the Venturi nozzle. A small pressure difference proportional to the flow is

produced by the flowing medium at a cross-sectional constriction (nozzle) in the

device housing. The shape of the nozzle is based on the particular flow value

whereby flow characteristic remains constant over the entire measuring range.

Pressure sensing ports are located in the flow body to measure the resulting

differential pressure and send it to a differential-pressure measuring cell fitted in

the display case. If the flow is exceeded, the differential-pressure measuring cell

is protected by mechanical stops. In the case of mechanical displays the flow rate

measured by the differential pressure measuring cell is indicated on a pointer

element which is calibrated in l/min water or Nm3/h air. On electronic displays the

mechanical motion is converted to an electrical signal by a Hall sensor. The

electronics serves to display and monitor the volumetric flow.

6. Mechanical Connection

6.1. Check Service Conditions

Flow

Max. operating pressures

Max. operating temperature

Medium

Mounting position

When the medium is not in our substance database:

operating density

operating viscosity

page 4 RCD K07/0818

Page 5

RCD

6.2. Installation

Flow in direction of arrow (universal)

Avoid pressure and tensile loads

mount inlet and outlet piping at distances of 50 mm from the connections

Check connections for leaks

Pay attention to the inlet and outlet path (see drawings below)

2 x 90°- elbow

Control valve

P

3 - dimensional

P

2 x 90°- elbow

50 x D 5 x D

P

25 x D 5 x D

90°- elbow or

T - piece

40 x D

P

20 x D 5 x D

5 x D

P

Extention

P

18 x D 5 x D

Reduction

15 x D 5 x D

RCD K07/0818 page 5

Page 6

RCD

7. Electrical Connection

7.1. Mechanical Pointer Indication (..Z...)

without electrical connection

7.2. Compact Electronics:

(..C30R, ..C30M, ..C34P, ..C34N)

see

Operating instructions supplement

for compact electronics with frequency output

7.3. ADI Electronic

see

Operating instructions supplement

for ADI electronic display

8. Commissioning

8.1. Mechanical Pointer Indication (..Z...)

Attention! Remove transportation safety screw and screw in the

sealing screw from the bag into the thread M3.

8.2. Setting Compact Electronics

see

Operating instructions supplement

for compact electronics with frequency output

8.3. Setting ADI Electronic

see

Operating instructions supplement

for ADI electronic display

page 6 RCD K07/0818

Page 7

RCD

9. Maintenance

The measuring instrument requires no maintenance when the measured medium

leaves no deposits. To prevent fouling the flow meter pressure sensing ports, we

recommend that a filter is installed, for example the magnetic filter, model MFR.

Work on the sensor and electronics should only be carried out by the supplier,

otherwise the warranty is void.

10. Technical Information

10.1. Sensor Data

Measuring range: see name plate

Measuring accuracy: 3 % of F.S.

Reproducibility: 1 % of F.S.

Process temperature: RCD... mechanical: -20 °C…+100 °C

RCD... electronic: -20 °C…+80 °C

Ambient temperature: max. 80 °C

Max. operating pressure: 25 bar (RCD-1155, RCD-1160, RCD-1165)

40 bar (all others)

Protection: IP 65

Materials:

Flow housing: RCD-x1..: brass casting

RCD-x2..: stainless steel 1.4581

Differential pressure housing: RCD-x1..: brass casting

RCD-x2..: stainless steel 1.4571

Pressure measuring cell: stainless steel 1.4571

Venturi nozzle: stainless steel 1.4571

Gaskets: RCD-x1..: NBR

RCD-x2..: FPM

10.2. Displays/Electronics

Mechanical pointer indication:

Display: 270 °

Display case: aluminium / polyamide

Front cover: polycarbonate

Option: special scales for other gases and liquids.

Please specify medium, density, viscosity,

operating pressure and temperature

RCD K07/0818 page 7

Page 8

RCD

Compact electronics:

Display: 3-digit LED

Analogue output: (0) 4 - 20 mA adjustable, max. 500 Ω

Switching outputs: 1 (2) semiconductor PNP or

NPN, factory set

Contact operation: N/C / N/O frequency programmable

Setting: via 2 buttons

Supply: 24 V

± 20 %, 3-wire, approx. 100 mA

DC

Electrical connection: plug connector M12 x 1

ADI electronics

Display: bar graph and 5-digit digital display

Analogue output: (0)4-20 mA, 0-10 V

DC

Two switching outputs: relay/changeover contacts

max. 250 VAC/5 A resistive load,

max. 30 V

DC

/ 5 A

Setting: via 4 buttons

Power supply: 100...240 V

18...30 VAC/10...40 V

±10% or

AC

DC

Electrical connection: pluggable terminal block via cable gland

page 8 RCD K07/0818

Page 9

RCD

11. Order Details

Order details (example: RCD 1195H G4 K 0 0 0)

Meas.

range

water

[L/min]

0.5…3.3 2.80

0.5…4.2 3.15

0.5…5.2 3.50

1.0...6.8 4.00

1.0...8.6 4.50

1.0...10.6 5.00

2.0...13.2 5.60

2.0...16.8 6.30

2.0...21.4 7.10

3.0…27.0 8.00

5.0…34.5 9.00

5.0…42.4 10.00

10.0...58.0 11.20

10.0...66.0 12.50

10.0...85.0 14.00

20.0...118 16.00

20.0...132 17.50

20.0...148 18.00

20.0...168 19.20

30.0...275 26.00

50.0...350 28.00

50.0…435 31.00

100...700 40.00

100...910 43.50

100...1060 51.00

200...1540 60.00

300...2350 67.00

Orifice

[mm]

Model

Material

brass casting

RCD 1195H RCD 1295H

RCD 1100H RCD 1200H

RCD 1190H RCD 1290H

RCD 1191H RCD 1291H

RCD 1101H RCD 1201H

RCD 1192H RCD 1292H

RCD 1102H RCD 1202H

RCD 1103H RCD 1203H

RCD 1104H RCD 1204H

RCD 1106H RCD 1206H

RCD 1109H RCD 1209H

RCD 1110H RCD 1210H

RCD 1114H RCD 1214H

RCD 1115H RCD 1215H

RCD 1116H RCD 1216H

RCD 1117H RCD 1217H

RCD 1125H RCD 1225H

RCD 1126H RCD 1226H

RCD 1130H RCD 1230H

RCD 1135H RCD 1235H

RCD 1137H RCD 1237H

RCD 1139H RCD 1239H

RCD 1145H RCD 1245H G9 = G 2

RCD 1150H RCD 1250H GB = G 3

RCD 1155H RCD 1255H

RCD 1160H RCD 1260H

RCD 1165H RCD 1265H

Material

st. steel

G4 = G 1/2 N4 = 1/2 NPT

G4 = G 1/2

G5 = G 3/4

G4 = G 1/2

G5 = G 3/4

G6 = G 1

G5 = G 3/4

G6 = G 1

G6 = G 1

G8 = G 1 1/2

G8 = G 1 1/2

G9 = G 2

GB = G 3 NB = 3 NPT

Evaluating electronics

Mechanical pointer indication

Indication Flow direction Location of ind.

Z = pointer indicat., 270 °

ADI-electronics**

Indication Supply Output Contacts

0 = 100-240 V

K = bargraph /digital

Indication Supply Output/contacts

C = digital 3 = 24 V

** Please specify flow direction in the order (expect from top to bottom)

Please specify the operating conditions in the order

3 = 18-30 V

10-40 VAC

AC/DC

AC

Compact electronics**

DC

Connection

G-thread NPT

N4 = 1/2 NPT

N5 = 3/4 NPT

N4 = 1/2 NPT

N5 = 3/4 NPT

N6 = 1 NPT

N5 = 3/4 NPT

N6 = 1 NPT

N6 = 1 NPT

N8 = 1 1/2 NPT

N8 = 1 1/2 NPT

N9 = 2 NPT

N9 = 2 NPT

NB = 3 NPT

L = from left

R = from right

B = from bottom

0 = without

4 = (0)4-20 mA,

0-10 V

0R = 2 x Open Collector, PNP

0M = 2 x Open Collector, NPN

4P = 4-20 mA, 1 x Open Coll. PNP

4N = 4-20 mA; 1 x Open Coll. NPN

2 = 2 changeover contacts

L = left

R = right

T = top

B = bottom

RCD K07/0818 page 9

Page 10

RCD

Order details (example: RCD 1195L G4 K 0 0 0)

Range air Orifice

1 bar abs. / 20 °C

/h]*

[m³

N

[mm]

Material

Alu bronze

Model Connection

Material

st. steel

G-thread NPT

0.50...5.35 2.80

1.00...6.70 3.15

1.00...8.30 3.50

1.00...10.9 4.00

2.00...13.8 4.50

2.00...17.0 5.00

2.00...21.4 5.60

3.00...27.0 6.30

5.00...34.5 7.10

5.00...43.5 8.00

10.0...55.0 9.00

10.0...68.0 10.00

10.0...78.0 11.20

10.0...97.0 12.50

20.0...116 14.00

20.0...158 16.00

20,0...188 17.50

20.0...198 18.00

30.0...225 19.20

50.0...375 26.00

50.0...515 28.00

100...630 31.00

100...910 40.00

200...1160 43.50

200...1360 51.00

400...2000 60.00

300...2750 67.00

* m³N/h correspond to a flow rate at 0 °C; 1013 mbar

RCD 1195L RCD 1295L

RCD 1100L RCD 1200L

RCD 1190L RCD 1290L

RCD 1191L RCD 1291L

RCD 1101L RCD 1201L

RCD 1192L RCD 1292L

RCD 1102L RCD 1202L

RCD 1103L RCD 1203L

RCD 1104L RCD 1204L

RCD 1106L RCD 1206L

RCD 1109L RCD 1209L

RCD 1110L RCD 1210L

RCD 1114L RCD 1214L

RCD 1115L RCD 1215L

RCD 1116L RCD 1216L

RCD 1117L RCD 1217L

RCD 1125L RCD 1225L

RCD 1126L RCD 1226L

RCD 1130L RCD 1230L

RCD 1135L RCD 1235L

RCD 1137L RCD 1237L

RCD 1139L RCD 1239L

RCD 1145L RCD 1245L

RCD 1150L RCD 1250L

RCD 1155L RCD 1255L

RCD 1160L RCD 1260L

RCD 1165L RCD 1265L

G4 = G 1/2 N4 = 1/2 NPT

G4 = G 1/2

G5 = G 3/4

G4 = G 1/2

G5 = G 3/4

G6 = G 1

G5 = G 3/4

G6 = G 1

G6 = G 1

G8 = G 1 1/2

G8 = G 1 1/2

G9 = G 2

G9 = G 2

GB = G 3

GB = G 3 NB = 3 NPT

N4 = 1/2 NPT

N5 = 3/4 NPT

N4 = 1/2 NPT

N5 = 3/4 NPT

N6 = 1 NPT

N5 = 3/4 NPT

N6 = 1 NPT

N6 = 1 NPT

N8 = 1 1/2 NPT

N8 = 1 1/2 NPT

N9 = 2 NPT

N9 = 2 NPT

NB = 3 NPT

Evaluating electronics

Mechanical pointer indication

Indication Flow direction Location of ind.

L = from left

Z = pointer indicat., 270 °

ADI-electronics**

Indication Supply Output Contacts

0 = 100-240 V

K = bargraph /digital

Indication Supply Output/contacts

C = digital 3 = 24 V

** Please specify flow direction in the order (expect from top to bottom)

Please specify the operating conditions in the order

3 = 18-30 V

10-40 VAC

AC/DC

AC

Compact electronics**

DC

R = from right

B = from bottom

0 = without

4 = (0)4-20 mA,

0-10 V

0M = 2 x Open Collector, NPN

4P = 4-20 mA, 1 x Open Coll. PNP

4N = 4-20 mA; 1 x Open Coll. NPN

L = left

R = right

T = top

B = bottom

2 = 2 changeover contacts

0R = 2 x Open Collector, PNP

page 10 RCD K07/0818

Page 11

RCD

12. Dimensions

RCD...Z with mechanical display

RCD...C with compact electronics

Screw

thread

G 1/2 191 78 hex 27 143 ca. 2,0 kg

G 3/4 191 78 hex 41 143 ca. 2,3 kg

G1 191 78 hex 41 143 ca. 2,2 kg

G 1 1/2 206 78 hex 55 158 ca. 2,6 kg

G 2 204 81 hex 70 156 ca. 2,8 kg

G3 221 106 hex 100 173 ca. 5,1 kg

Screw

thread

G 1/2 191 78 hex 27 143 ca. 2,1 kg

G 3/4 191 78 hex 41 143 ca. 2,4 kg

G1 191 78 hex 41 143 ca. 2,2 kg

G 1 1/2 206 78 hex 55 158 ca. 2,6 kg

G 2 204 81 hex 70 156 ca. 2,9 kg

G3 221 106 hex 100 173 ca. 5,2 kg

A B C D Weight

(approx.)

A B C D Weight

(approx.)

RCD...K with ADI electronic

(same dimensions for RCD...D and RCD...K)

Screw

thread

G 1/2 191 78 hex 27 143 ca. 3,4 kg

G 3/4 191 78 hex 41 143 ca. 3,7 kg

G1 191 78 hex 41 143 ca. 3,6 kg

G 1 1/2 206 78 hex 55 158 ca. 3,9 kg

G 2 204 81 hex 70 156 ca. 4,2 kg

G3 221 106 hex 100 173 ca. 6,5 kg

A B C D Weight

(approx.)

RCD K07/0818 page 11

Page 12

RCD

13. EU Declaration of Conformance

We, KOBOLD-Messring GmbH, Hofheim-Ts, Germany, declare under our sole

responsibility that the product:

Differential Pressure Flow Meter / Monitor model: RCD -...

to which this declaration relates is in conformity with the standards noted below:

EN 61000-6-4:2011

Electromagnetic compatibility (EMC) - Part 6-4: Generic standards - Emission

standard for industrial environments

EN 61000-6-2:2005

Electromagnetic compatibility (EMC) - Part 6-2: Generic standards - Immunity for

industrial environments

EN 61010-1:2010

Safety requirements for electrical equipment for measurement, control and

laboratory use - Part 1: General requirements

EN 60529:2014

Degrees of protection provided by enclosures (IP Code)

EN 50581:2012

Technical documentation for the assessment of electrical and electronic products

with respect to the restriction of hazardous substances

in accordance with the general requirements of the guideline

2014/35/EU Low Voltage Directive

2014/30/EU EMC Directive

2011/65/EU RoHS (category 9)

2014/68/EU PED

Category III (IV) Diagram 1, vessel, group 1 dangerous fluids

Module D, marking CE0575

Notified body: DNV GL

Certificate No. PEDD000000R

Hofheim, 02. Aug. 2018

H. Peters M. Wenzel

General Manager Proxy Holder

page 12 RCD K07/0818

Loading...

Loading...