Page 1

Operating Instructions

for

Display Pressure Switch

Model: PSD

Page 2

PSD

We don’t accept warranty and liability claims neither upon this publication nor in

case of improper treatment of the described products.

The document may contain technical inaccuracies and typographical errors. The

content will be revised on a regular basis. These changes will be implemented in

later versions. The described products can be improved and changed at any time

without prior notice.

© Copyright

All rights reserved.

1. Contents

1. Contents ........................................................................................................ 2

2. Note .............................................................................................................. 3

3. Instrument Inspection .................................................................................... 3

4. Regulation Use .............................................................................................. 3

5. Operating Principle ........................................................................................ 4

6. Mechanical Connection ................................................................................. 4

7. Electrical Connection .................................................................................... 5

7.1 Output signal / supply voltage ................................................................ 5

8. Operating menu ............................................................................................ 6

9. Type label description ................................................................................... 8

10.Technical Information .................................................................................... 8

11.Terminology ................................................................................................ 11

12.Order Codes ............................................................................................... 13

13.Dimensions ................................................................................................. 13

14.EU Declaration of Conformance .................................................................. 14

Manufactured and sold by:

Kobold Messring GmbH

Nordring 22-24

D-65719 Hofheim

Tel.: +49(0)6192-2990

Fax: +49(0)6192-23398

E-Mail: info.de@kobold.com

Internet: www.kobold.com

page 2 PSD K02/0118

Page 3

PSD

2. Note

Please read these operating instructions before unpacking and putting the unit

into operation. Follow the instructions precisely as described herein.

The devices are only to be used, maintained and serviced by persons familiar

with these operating instructions and in accordance with local regulations

applying to Health & Safety and prevention of accidents.

When used in machines, the measuring unit should be used only when the

machines fulfil the EC-machine guidelines.

3. Instrument Inspection

Instruments are inspected before shipping and sent out in perfect condition.

Should damage to a device be visible, we recommend a thorough inspection of

the delivery packaging. In case of damage, please inform your parcel service /

forwarding agent immediately, since they are responsible for damages during

transit.

Scope of delivery:

The standard delivery includes:

Display Pressure Switch model: PSD

Operating Instructions

4. Regulation Use

Any use of the Display Pressure Switch, model: PSD, which exceeds the

manufacturer’s specification, may invalidate its warranty. Therefore, any resulting

damage is not the responsibility of the manufacturer. The user assumes all risk

for such usage.

PSD K02/0118 page 3

Page 4

PSD

5. Operating Principle

KOBOLD is a leading international supplier of high quality sensors and monitoring

instruments among other things for measurement of pressure and temperature.

The PSD is the ideal combination of pressure switch and transmitter with a

pressure display. The parameters can be set on the device. The settings in

combination with a comprehensive set of options make the PSD suitable for a

wide range of demanding applications.

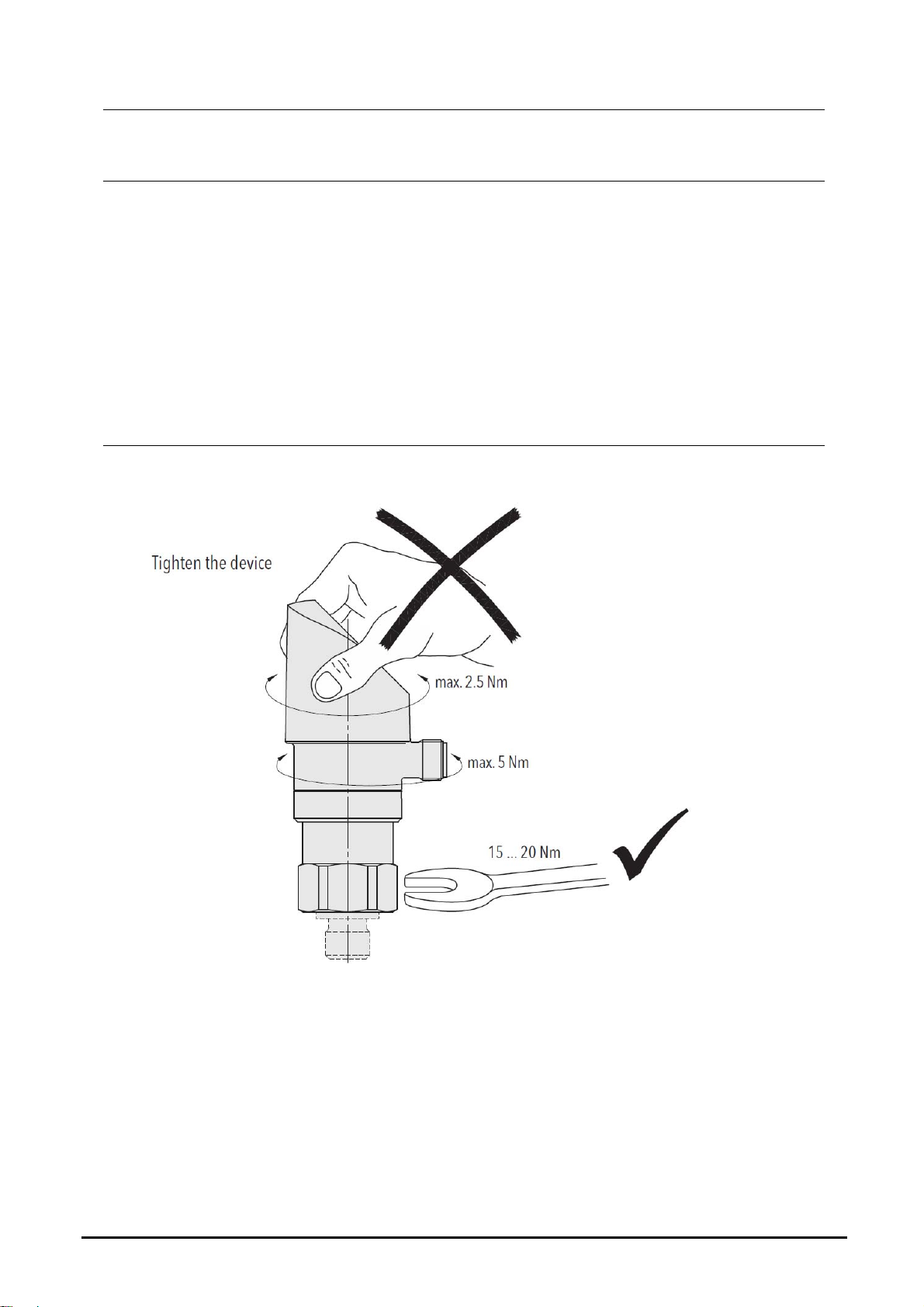

6. Mechanical Connection

page 4 PSD K02/0118

Page 5

PSD

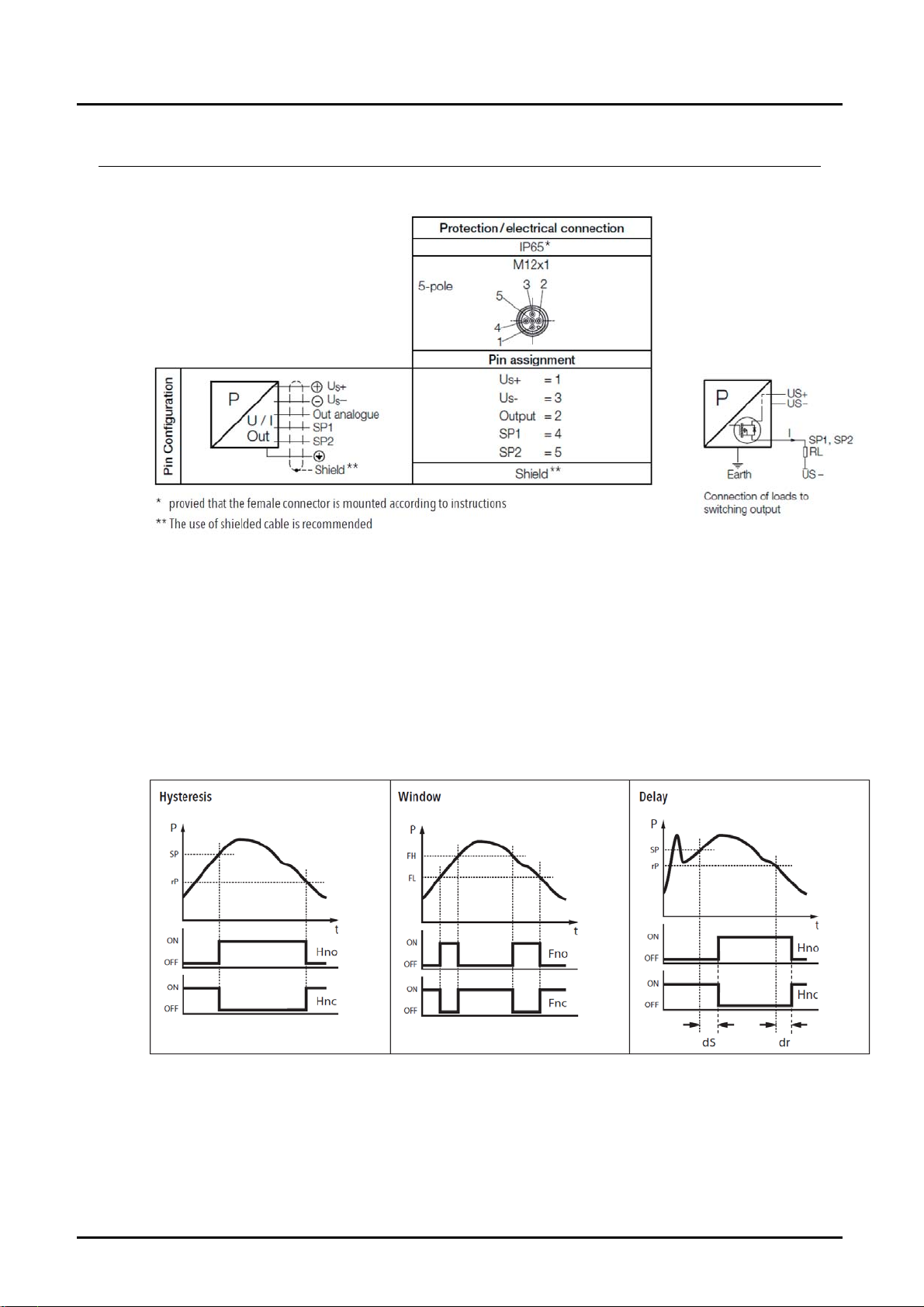

7. Electrical Connection

7.1 Output signal / supply voltage

Output I

4...20 mA ≤ 30 mA 15...30 VDC

0...10 VDC ≤ 30 mA 15...30 VDC

Switching output functions

SUPPLY

U

SUPPLY

PSD K02/0118 page 5

Page 6

PSD

8. Operating menu

page 6 PSD K02/0118

Page 7

PSD

Parameter

Name Standard setting

Switch point SP1 (hysteresis mode)

Upper switch point FH1 (window mode)

Reset point RP1 (hysteresis mode)

Lower switch point FL1 (window mode)

Switch point SP2 (hysteresis mode)

Upper switch point FH2 (window mode)

Reset point RP2 (hysteresis mode)

Lower switch point FL2 (window mode)

Switch point delay time SP1 (hysteresis

mode)

Switch point delay time FH1 (window

mode)

Switch point delay time RP1 (hysteresis

mode)

Switch point delay time FL1 (window

mode)

Switch point delay time SP2 (hysteresis

mode)

Switch point delay time FH2 (window

mode)

Switch point delay time RP2 (hysteresis

mode)

Switch point delay time FL2 (window

mode)

Functions switching output 1 Hysteresis, closer (Hno)

Functions switching output 2 Hysteresis, closer (Hno)

Pressure units bar bar, psi, MPa, kPa, mWC uni

Measuring range adjustment 100 % nominal pressure 50…100% nominal pressure P-EP

Damping (analogue output) 0.01 s 0.01…3.00 s (time constant) dAA

Display rotation no no, yes (180°) disr

Display mode Current pressure value

Display update 2 1, 2, 5, 20 Hz duPd

(accessory ZS)

75% measuring range

25% measuring range

75% measuring range

25% measuring range

0 0...99.99 s dS1

0 0...99.99 s dR1

0 0...99.99 s dS2

0 0...99.99 s dR2

Hysteresis NO (Hno), hysteresis NC (Hnc),

window NO (Fno), window NC (Fnc)

Hysteresis NO (Hno), hysteresis NC (Hnc),

window NO (Fno), window NC (Fnc)

current, highest, lowest, display off

decimal places selectable (max. 3)

Value range Short name

SP1RP1

FH1FL1

hysteresis≥1% FS

RP1<SP1

FL1<FH1

hysteresis ≥ 1% FS

SP2RP2

FH2FL2

hysteresis≥ 1% FS

RP2<SP2

FL2<FH2

hysteresis ≥ 1% FS

Pressure value:

Current value:

SP1

RP1

SP2

RP2

ou1

ou2

dis

PSD K02/0118 page 7

Page 8

PSD

9. Type label description

10. T echnical Information

Measuring principle: thin film on steel

Measuring range: -1...+1.5 to 0...600 bar

-14.5...+22 to 0...7500 psi

adjustable 50...100 % FS

Output signal: 4...20 mA

0...10 V

Switching output: 2 transistors PNP

Accuracy@ 25° C typ.: ±0.5 % FS typ.

Media temperature: -25° C...+85° C

Ambient temperature: -25° C...+85° C

Pressure unit for display: bar, psi, MPa, kPa, m WC, mm WC

Electrical data

Output/supply voltage: 4...20 mA: 24 or 0-10 V

Switch-on-delay: typ. 200 ms

Inverse-polarity protection,

Short-circuit strength

@ 25° C during 5 min.; integrated

Current consumption: ≤30 mA

24 (15...30) VDC

switchable mA or V

DC,

DC/

page 8 PSD K02/0118

Page 9

PSD

Environmental conditions

Media temperature: -25° C...+85° C

Ambient temperature: -25° C...+85° C

Protection1): IP65

Humidity: max. 95% relative

Vibration: 10 g (10...2000 Hz)

Shock: 50 g/ 3 ms

1)

see electrical connection

Analogue output

Output signal: switchable 4-20 mA or 0-10 V

Accuracy: TEB

2)

@ -25 °C...+85° C

[% FS typ.] ± 1.75

accuracy @ +25° C

[% FS typ.] ±0.5

2)

NLH

@ +25° C (BSL)

[% FS typ.] ±0.2

TC

2)

zero point and span

[% FS typ.] ±0.03

long term stability 1 year

[% FS typ.] ±0.1

Current limiting output signal: 4-20 mA (overload)

0...10 VDC: <40 mA (short-circuit)

Damping (rise-time): 0.01...3.00 s/10...90% nominal pressure

Switching output

Accuracy: accuracy@ +25° C

[% FS typ.] ± 0.5

TEB2) @ -25 °C...+85° C

[% FS typ.] ± 1.0

accuracy @ +25° C

long term stability 1 year

[% FS typ.] ±0.3

Adjustment range of

switchpoints: 0...100% FS

Switching hysteresis: ≥ 1% FS switchpoint reset point

Switching resistance: ≤ 3 Ω

Output function: hysteresis, window; normally open (NO),

normally closed (NC)

Switching current: ≤ 0.5 A each switching output

Current limiting: ≤ 2 A each switching output

Switching frequency: max. 200 Hz

Delay time: 0...99.99 s

2)

see »Terminology«

DC

PSD K02/0118 page 9

Page 10

PSD

Display

Display: 4-digit 7-segment display 180 °

flippable with disable function

standard decimal places:

≤9: 3 decimal places

10...99: 2 decimal places

100...999: 1 decimal place

Switching status indication: 2 LED, red

Operation: with 3 buttons and menu navigation

according to VDMA 24574-1

Display reduction: 0.1 % FS

Display range: -3...103% FS

Setting parameters: see table “Parameter”

Mechanical data

Sensor (wetted parts) 1.452 (AISI630)

Pressure connection

(wetted parts): 1.452 (AISI630)

Housing: steel, die cast metal galvanised,

display housing plastic

Connection: G¼ male,

adapter can be ordered as separate item

Sealing: FPM

Male electrical plug: PA-plug M12x1.5 pin

Mounting torque: 15...20 Nm

Housing alignment: display 335 ° rotatable, max. 2.5 Nm

electrical connection 343° rotatable, max. 5 Nm

Pressure peak

damping element: ø 0.4 mm

Weight: ~189 g

page 10 PSD K02/0118

Page 11

PSD

11. T erminology

Non-linearity

The largest deviation from the effective characteristic line of an ideal reference

line. The reference line can be defined as a limit point adjustment, a BSL or a

BSL through 0.

Specifications: Non-linearity, Hysteresis

BSL through Zero

As an additional requirement for the minimum value adjustment, the BSL

through zero (also BSL/0) must go straight through zero or the origin.

Specifications: Accuracy NLH (BSL through zero)

PSD K02/0118 page 11

Page 12

PSD

BSL Best Straight Line

The reference line according to the BSL or the minimum value adjustment is

placed in such a way that the maximum positive and negative deviations are as

small as possible.

Specifications: Non-linearity, Hysteresis

Specifications: Accuracy NLH (BSL)

NLH Non-linearity an d Hysteresis

Largest deviation from the ideal characteristic line (BSL, BSL/0 or limit point). In

pressure measuring instruments, the non-linearity and pressure hysteresis are

given together at a constant temperature.

Temperature Coefficient TC

Change of measured value for zero point and span as a result of changes in

temperature

Long-term Stability Long-term Drift

The change of accuracy due to aging under certain reference conditions

during a certain period of time, typically 1 year.

TEB Total Error Band

Total error (root from sum of the square of the deviations) due to measurement

deviations (accuracy) and temperature influence (temperature coefficient TC).

The temperature influence is usually given in the information across a range

larger than that given in the standard (-10 ... +60 °C). Whilst DIN 16086 also

continues to add to the long-term stability over a year, the information is subject

to ex-works conditions for obvious reasons.

page 12 PSD K02/0118

Page 13

PSD

12. Order Codes

Example: PSD-4 3 3 R2 B4 4

Model Version

4 = 2x PNP

switching

PSD-

* Other ranges on request

output,

analogue

output

4-20 mA

Electrical

connection

3 = M12 plug,

24 (15-30) V

13. Dimensions

Material Connection

3 = FPM

DC

o-ring,

st. steel

connection

R2 = G¼ male

Measuring range *

[bar]

A1 = -1...1.5

A4 = -1...9

B6 = 0...6

B7 = 0...10

B8 = 0...16

B9 = 0...25

C2 = 0...100

C3 = 0...160

C4 = 0...250

C5 = 0...400

Option

4 = pressure peak

damping element

D = 0.4 mm

Special

version

0 = none

Y = special

version

(specify in

clear text)

[mm]

PSD PSD...R2...

PSD K02/0118 page 13

Page 14

PSD

14. EU Declaration of Conformance

We, KOBOLD Messring GmbH, Hofheim-Ts, Germany, declare under our sole

responsibility that the product:

Display Pressure Switch Model: PSD

to which this declaration relates is in conformity with the standards noted below:

EN 61000-6-2: 2006 Electromagnetic compatibility (EMC) - Part 6-2: Generic

standards - Immunity for industrial environments

EN 61000-6-3:2007 + A1:2010 Electromagnetic compatibility (EMC) -

Part 6-3: Generic standards - Emission standard for residential, commercial and

light-industrial environments

Also the following EC guidelines are fulfilled:

2014/30/EU EMC Directive

2011/65/EU RoHS (category 9)

Hofheim, 12. Febr. 2018

H. Peters M. Wenzel

General Manager Proxy Holder

page 14 PSD K02/0118

Loading...

Loading...