Page 1

Operating Instructions

for

Polysulfone Paddle Monitor

Model: PPS-..

Page 2

PPS

page 2 PPS K02/0416

1. Contents

1.

Contents ........................................................................................................ 2

2. Note .............................................................................................................. 3

3. Regulation Use .............................................................................................. 3

4. Operating Principle ........................................................................................ 3

5. Instrument Inspection .................................................................................... 4

6. Mechanical Connection ................................................................................. 4

7. Electrical Connection .................................................................................... 6

8. Technical Information .................................................................................... 8

9. Order Codes ................................................................................................. 8

10.Maintenance ................................................................................................. 8

11.Recommended Spare Parts .......................................................................... 9

12.Dimensions ................................................................................................... 9

13.EU Declaration of Conformance .................................................................. 10

Manufactured and sold by:

Kobold Messring GmbH

Nordring 22-24

D-65719 Hofheim

Tel.: +49(0)6192-2990

Fax: +49(0)6192-23398

E-Mail: info.de@kobold.com

Internet: www.kobold.com

Page 3

PPS

PPS K02/0416 page 3

2. Note

Please read these operating instructions before unpacking and putting the unit

into operation. Follow the instructions precisely as described herein.

The devices are only to be used, maintained and serviced by persons familiar

with these operating instructions and in accordance with local regulations

applying to Health & Safety and prevention of accidents.

By usage in machines, the measuring unit should be used only when the

machines fulfil the EC-machine guidelines.

3. Regulation Use

The Model PPS-.. is installed for the purposes of monitoring flow throughputs of

liquids in nominal pipe sizes greater than NW 32. The paddle switch is available

with a factory set limit switch (N/O or N/C). It is suitable for low viscosity fluids

which have no effects on the instrument materials used. The flow throughput

switching point is determined by the length of the paddle. During installation the

paddle length may be reduced by cutting to adjust the set point.

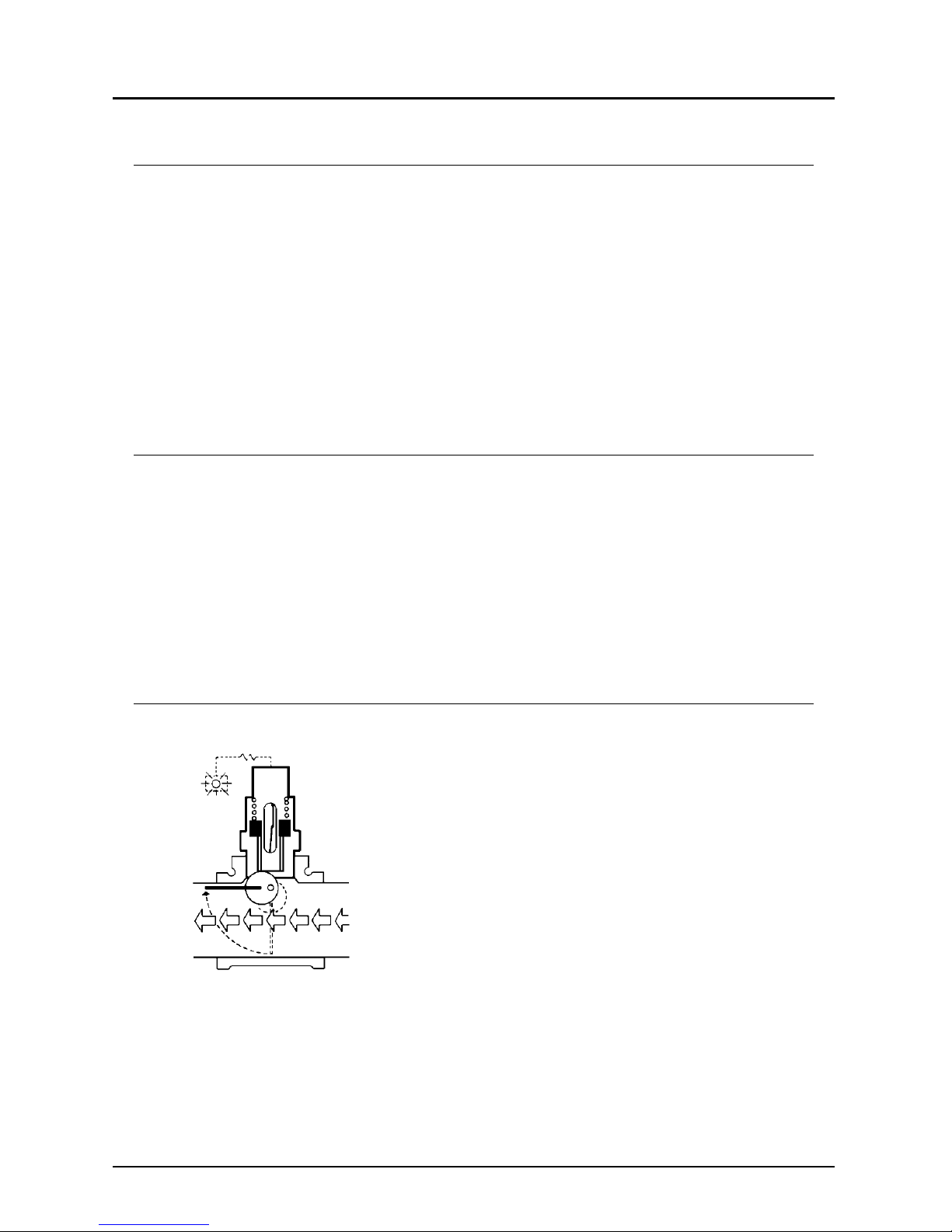

4. Operating Principle

Media flowing in any direction moves the paddle,

which rotates an eccentric, which in turn raises an

assembly within the unit. The assembly has a

permanent magnet mounted within it. This enables

the magnet to activate a hermetically sealed reed

switch. The signal from the reed switch can be used

to trigger an alarm or indicator. With the appropriate

relay, it is possible to automatically control pumps,

motors or valves.

Page 4

PPS

page 4 PPS K02/0416

5. Instrument Inspection

Instruments are inspected before shipping and sent out in perfect condition.

Should the damage to a device be visible, we recommend a thorough inspection

of the delivery packing. In case of damage, please inform your parcel service /

forwarding agent immediately, since they are responsible for damages during

transit.

Scope of delivery:

Paddle Monitor model: PPS

Operating Instructions

6. Mechanical Connection

Before installation:

Check the nominal pipe size and adapt by cutting at the paddle marking

according the following table the paddle monitor to your nominal pipe size and

the determined switching point.

Shorter paddle as specified in the table = higher switching point

Longer paddle as specified in the table = lower switching point

(Please note that the paddle length is not allowed to be longer than the

nominal pipe size).

Please ascertain whether the allowable maximum operating pressure and

operating temperature of the instruments will not be exceeded.

Remove all transport packing and ascertain that no packing material is left in

the instrument.

Nominal pipe size

(customer side)

Cutting mark (L)

approx. mm

Switching point

L/min rising

Switching point

L/min falling

32 28 36 18

40 35 54 36

50 47 72 36

65 60 90 54

80 73 108 72

Page 5

PPS

PPS K02/0416 page 5

Installation:

For mounting in a horizontal pipe line you need a vertical G 1" (1" NPT) socket.

Sealing of the connection threads should be carried out with Teflon tape or

similar. The paddle must be able to swing in the inner pipe and should not hit

against the inside wall of the sleeve. Therefore we recommend a max. length

of the socket of 20 mm.

Please take care that the broad dimension of the paddle has to show against

the flow direction. The arrow must show into the flow direction.

To reduce the influence of dirt we recommend to mount the instrument on the

top side of the pipe. This prevents a deposit of dirt. If a mounting on the top is

not possible, we recommend to check and to clean the instrument in regular

intervals (see maintenance).

If possible, check right after the mechanical installation that the connection

thread to the pipe is fully sealed.

Page 6

PPS

page 6 PPS K02/0416

7. Electrical Connection

Caution! Make sure that the voltage and current values of your

system correspond with the voltage values of the measuring unit

(see name plate). Possibly make shroud arrangements.

Make sure that the supply wires are de-energised.

Loosen the screw of the plug cap and remove the cap.

Connect the connection cable with the power supply

cable in accordance with the connection diagram

alongside.

Plug the plug on to the plug socket and tighten the

screw.

After connection of your external equipment at the connection points the

instrument is ready for operation.

1

2

1

2

1

3

2

Page 7

PPS

PPS K02/0416 page 7

Contact types

Model PPS-1201, Normally closed

The contact is opened when the flow increases and the set point value is

reached or exceeded. The switch closes again with falling flow at the minimum

value influenced by the switch hysteresis.

Model PPS-1202, Normally open

The contact is closed when the flow increases and the set point value is

reached or exceeded. The switch opens again with falling flow at the minimum

value influenced by the switch hysteresis.

Model PPS-1203 and model PPS-3203, changeover contact

The contact 1-2 is closed and the contact 1-3 is opened when the flow

increases and the set point value is reached or exceeded. The switch

backspaces again with falling flow at the minimum value influenced by the

switch hysteresis

Hysteresis

Defined as the difference between the opening and closing flow values of a

contact.

For example, the model PPS-1202 in tube with 11/4" ID, set at about 36 L/min

increasing set point will reset at about 18 L/min decreasing. Contact hysteresis =

18 L/min.

Contact protection

The reed contact may be damaged if the switch ratings are exceeded, especially

while switching inductive or capacitive loads. This can cause dangerous

situations. By the use of a contact protection relay, this problem can be overcome

and the lifespan and switch rating of the reed contact can be greatly increased.

(e. g. model MSR 10).

Page 8

PPS

page 8 PPS K02/0416

8. T echnical Information

Material housing / paddle: polysulfone, transparent

case: PSU or PTFE

spring: stainless steel 1.4310

safety pin: stainless steel 1.4305

magnet: oxide ceramic

Connection: G 1 (1“ NPT)

Medium temperature: max. 105 °C

Operating pressure: max. 10 bar

Max. pressure drop: max. 0,1 bar

Adjustment accuracy: ± 20%

Repeat accuracy: ± 3%

Other materials that

are exposed to the medium: stainless steel, ceramic magnet

Electrical connection: plug according to DIN 43 650

Protection: IP 65

Mounting Position: vertical

Switch: N/C, N/O or changeover contact

hermetically sealed reed-contact

Max. switching capacity: 230 V

AC/DC

; 2 A; 40 W / VA (N/O / N/C)

100 VDC;0,5 A; 5 W (changeover contact)

9. Order Codes

Contact operation

(with rising flow rate)

Order number

G 1 external thread

Order number

1 NPT external thread

N/C contact PPS-1201 PPS-3205

N/O contact PPS-1202 PPS-3202

changeover contact PPS-1203 PPS-3203

10. Maintenance

In cases where the flow medium is uncontaminated, the PPS will remain

maintenance-free. In particular, any ferritic particles present in the medium may

be deposited on the magnet, which can lead to problems. Large dirt particles can

lead to clamping of the paddle and of the magnet ring.

be deposited on the beam.

Depending on the amount of dirt present in the medium, we recommend that the

instrument is checked at regular intervals.

Page 9

PPS

PPS K02/0416 page 9

11. Recommended Spare Parts

1) Replacement paddle made of polysulfone

12. Dimensions

Page 10

PPS

page 10 PPS K02/0416

13. EU Declaration of Conformance

We, Kobold Messring GmbH, Hofheim-Ts, Germany, declare under our sole

responsibility that the product:

Polysulfone Paddle Monitor Model: PPS-..

to which this declaration relates is in conformity with the standards noted below:

EN 61010-1:2011

Safety requirements for electrical equipment for measurement, control and

laboratory use.

EN 60529:2014

Protection type through case (IP code)

Also the following EC guidelines are fulfilled:

2014/35/EU Low Voltage Directive

2011/65/EU RoHS (category 9)

Hofheim, 27. April 2016

H. Peters M. Wenzel

General Manager Proxy Holder

Loading...

Loading...