Page 1

Heavy Duty

Differential Pressure

Transmitter

measuring

•

monitoring

•

analyzing

PAD

●● Span: 0.3" W.C. … 6" W.C. to 60 … 6000 PSIG

●● Static Pressure: Max. 4500 PSIG

●● t

: 248 °F

max

●● Process Connection: ½" NPT, ¼" NPT, or Various

Diaphragm Seals Available upon Request

●● Material: Stainless Steel

●● Various Outputs: 4 ... 20 mA or Frequency Output

●● Sensor Inputs: Differential, Gauge, or Absolute Pressure

●● Digital Communication with HART

KOBOLD companies worldwide:

ARGENTINA, AUSTRALIA, AUSTRIA, BELGIUM, BULGARIA, CANADA, CHILE, CHINA, COLOMBIA,

CZECH REPUBLIC, EGYPT, FRANCE, GERMANY, HUNGARY, INDIA, INDONESIA, ITALY, MALAYSIA,

MEXICO, NETHERLANDS, PERU, POLAND, REPUBLIC OF KOREA, ROMANIA, SINGAPORE, SPAIN,

SWITZERLAND, TAIWAN, THAILAND, TUNISIA, TURKEY, UNITED KINGDOM, USA, VIETNAM

01/03-18-2019

®

Protocol

KOBOLD Instruments, Inc.

1801 Parkway View Drive

Pittsburgh, PA 15205

Main Ofce:

1.412.788.2830

1.412.788.4890

info@koboldusa.com

www.koboldusa.com

Page 2

Heavy Duty Differential Pressure Transmitter Model PAD

Description

The KOBOLD Differential Pressure Transmitter model PAD

is a microprocessor based high performance transmitter.

It has flexible pressure calibration and output, automatic

compensation of ambient temperature and process variables,

configuration of various parameters, and communication with

HART® protocol. It measures pressure, flow and level by an

application method. All data is input, modified and stored in

EEPROM.

The KOBOLD Pressure Transmitter is also available as a flow

meter. The flowmeter model PAD-F has an added totalizing

function. It is able to check the flow rate and the totalizing flow.

It measures the flow rate by using differential pressure without

compensation for the temperature and static pressure. The

shape of the PAD-F is the same as the standard device.

Only the terminal block is different, since there are two more

terminals for the display of the pulse output.

Features

Superior Performance

●● High Reference Accuracy

●● Long-term Stability (0.125 % URL for 3 Years)

●● High Rangeability (100:1) for Range 4-0

Flexibility

●● Data Configuration with HART

●● Zero Point Adjustment

®

Communicator

Reliability

●● Continuous Self-diagnostic Function

●● Automatic Ambient Temperature Compensation

●● EEPROM Write Protection

●● Fail-mode Process Function

●● CE EMC Conformity Standards (EN 50081-2, EN 50082-2)

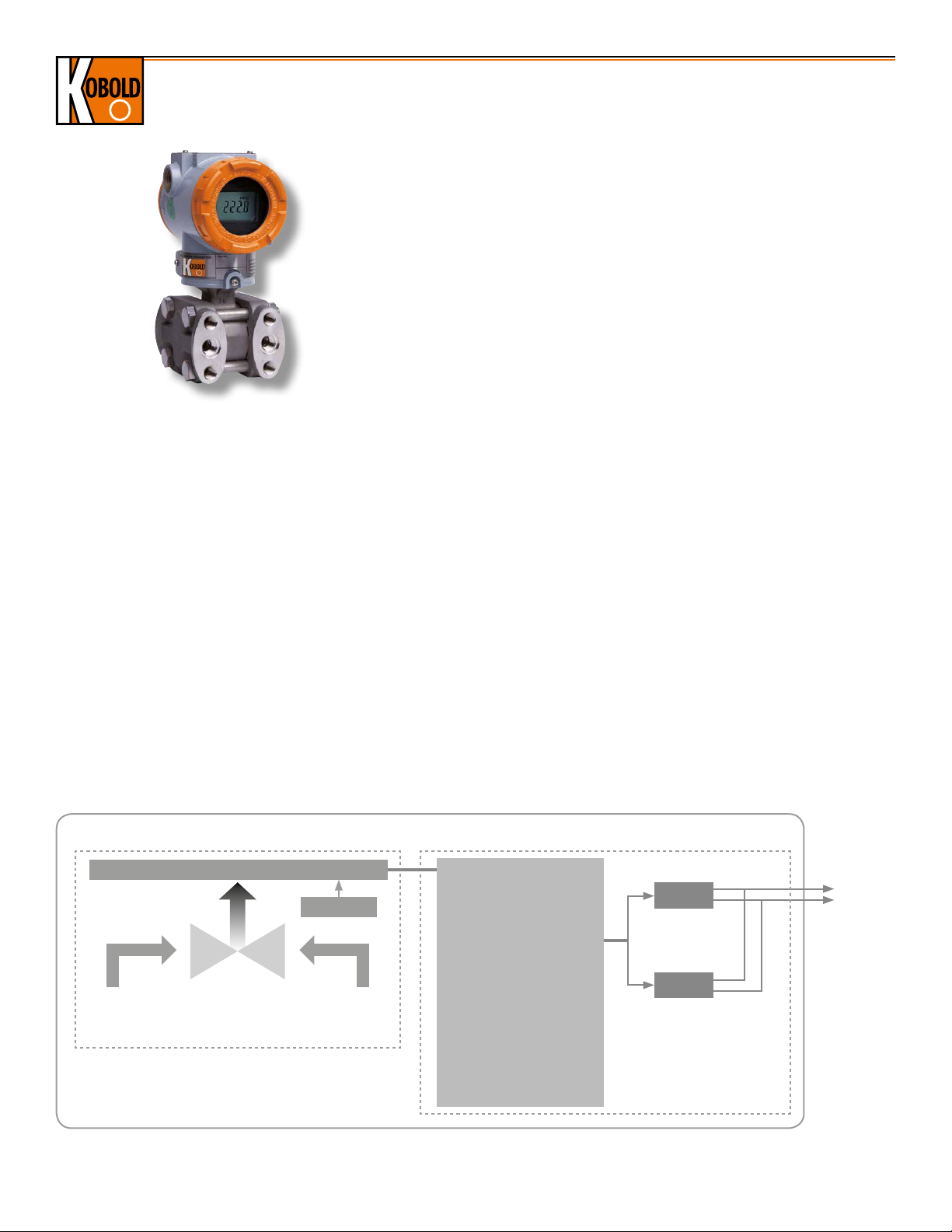

Transmitter Description

Electronics module

The Electronics module consists of a circuit board sealed in

an enclosure. There is an MCU module. an analog module,

an LCD module and a terminal module within the transmitter.

The MCU module acquires the digital value from the analog

module and applies correction coefficients selected from

EEPROM. The output section of the MCU module converts

the digital signal to a 4…20 mA output. The MCU module

communicates with the HART®-based communicator or

control system such as DCS. The power section of the MCU

module has a DC-to-DC power conversion circuit and an

input/output isolation circuit. The LCD module plugs into

the MCU module and displays the digital output in a userconfigured unit.

Functional Block Diagram

High

Pressure

User-Selectable Input

• - D /- G /- H /- A

• Measuring Range

2

Sensor Part MCU Part

A/D Conversion

Capacitive

Sensor

EEPROM

Low

Pressure

Microprocessor

· Input Sensor Value

· Engineering Units

· Re–range (Zero / Span)

· Sensor Trimming

· Zero Point Adjustment

· DA Trimming

· Damping / Filtering

· Transfer Function

· LCD Engineering Mode

· Diagnostics

· Self Compensation

· Communications

· LCD Display

· Configuration Data

www.koboldusa.com

4~20mA

DAC

®

HART

HART® Protocol

with Host

No responsibility taken for errors;

subject to change without prior notice.

Page 3

Heavy Duty Differential Pressure Transmitter Model PAD

Sensor Inputs

The models PAD-D, PAD-G, and PAD-H are available in a

capacitance type differential pressure sensor. It measures

differential and gauge pressure and is commonly used in flow

and level applications. Both sides in the capacitance sensor

transmit process pressure from the process isolators to the

sensor. The model PAD-A is also available in a piezoresistive

type absolute pressure sensor. The sensor module converts

the capacitance or the resistance to the digital value. The

MCU module calculates the process pressure based on the

digital value.

The sensor modules include the following features

• The software of the transmitter compensates thermal

effects, improving performance.

• Precise Input Compensation during operation is achieved

with temperature and pressure correction coefficients that

are characterized over the range of the transmitter and

stored in the sensor module EEPROM memory.

• EEPROM stores sensor information and correction

coefficients separately from MCU module, allowing for easy

repair, reconfiguration and replacement.

Basic Setups

The following settings can be easily configured from any host

that supports the HART® protocol:

• Operational Parameters

• 4-20 mA Points (Zero/Span)

• Engineering Units

• Damping Time: 0.25...60 sec

• Tag: 8 Alphanumeric Characters

• Descriptor: 16 Characters

• Message: 32 Characters

• Date: Day/Month/Year

Self-Diagnosis and others

• CPU & Analog Module Fault Detection

• Communication Error

• Fail-mode Handling

• LCD Indication

• Temperature Measurement of Sensor Module

Multi Planar Process Connection

When the pressure transmitter should be vertically installed irrespective

of the orientation of the process connection lines, modified flanges

(as shown above) are required in addition to the basic flanges. Multiplanar pressure transmitters have been made in an effort to solve

the problems occurring in these types of installation. The object of

this is to provide a pressure transmitter, capable of being vertically

installed, without separate adapters or various types of brackets.

This is regardless of the position of the process connection lines.

Calibration and Adjustment

• Lower/Upper Range (Zero/Span)

• Sensor Zero Trimming

• Zero Point Adjustment

• DAC Output Trimming

• Transfer Function

• Self-Compensation

No responsibility taken for errors;

subject to change without prior notice.

Process Connection Via Diaphragm Seals

When connecting the differential pressure transmitter model PAD to

all different process connections, diverse diaphragm seal versions

are necessary. They can be connected to the differential pressure

transmitter by direct mounting or via a capillary tube. Depending on

the application, different combinations of diaphragm seals, capillary

tubes and fill fluids are available. To clarify those options, the special

connections via diaphragm seals should be specified separately for

the differential pressure transmitter.

www.koboldusa.com

3

Page 4

Heavy Duty Differential Pressure Transmitter Model PAD

Technical Details

Measuring Principle: Capacitance Sensor (PAD-D, -F, -G, -H)

Piezo-resistive (PAD-A)

Measuring Span: 0.3" W.C..6" W.C. to 60…6,000 PSIG

bar (Depending on Instrument Version)

Zero and Span Values can be set

anywhere within the Range Limits.

Span must be Greater than or Equal

to the Minimum Span.

Accuracy

Range 2: ±0.25 % of Span for

0.1 URL ≤ Span ≤ URL

±[0.24 + (0.008 x (URL/Span)) % of

Span for 0.05 URL ≤ Span ≤0.1 URL

Range 3: ±0.075 % of Span for

0.1 URL ≤ Span ≤ URL

±[0.25 + (0.005 x (URL/span))] % of

Span for 0.02 URL ≤ Span ≤0.1 URL

Range 4 to 0: ±0.075 % of Span for

0.1 URL ≤ Span ≤ URL

±[0.025+(0.005x(URL/Span))] % of

Span for 0.01 URL ≤ Span ≤0.1 URL

Stability: ± 0.125% URL for 36 Months

Static Press. Effect: ± 0.1% URL per 70 bar (Zero Error)

± 0.2% of Reading per 70 bar (Span Error)

Turndown Ratio: Ranges 4 ~ 0 = 100 : 1

Range 3 = 50 : 1

Range 2 = 20 : 1

Process Temp.: -40…248 °F

(Approval Codes may Affect Limits.

Max. Ambient Temperature at

LCD = 176 °F.)

Ambient Temp.: -22…176 °F

Ambient Temp.

Effect: ± (0.019% URL + 0.125% Span) /28 °C

Storage Temp.: -40…185 °F (Non-condensing)

Humidity Limit: 5 %...100 % RH

Power Supply Effect: ± 0.005% of span per Volt

Mounting Pos. Effect: Zero Shift up to 350 Pa, no span effect

Pressure Limits (with Silicone Oil)

(Valid for stand-alone instruments only without assembled

diaphragm seals.)

Model D and G: 0…1999.6 PSIG (for Range 2...8)

Model G: 0…5800 PSIG (for Range 9)

0...10875 PSIG (for Range 0)

Model H: 0…4495 PSIG (for Range 4...7)

Model A: 0…72.5 PSIG (for Range 4)

0…435 PSIG (for Range 5)

0…754 PSIG (for Range 6)

Burst Pressure

Model D, G and H: 9990.5 PSIG

11600 PSIG (for Model G, Range 0)

Model A: 145 PSIG (for Range 4)

580 PSIG (for Range 5)

1015 PSIG (for Range 6)

4

Wetted Materials

Isolating Diaphragms: 316L SS

Drain/Vent Valves: 316 SS

Flanges/Adapters: 316 SS

O-ring: FKM, PTFE as an Option

Non-Wetted Materials

Fill Fluid: Silicone Oil

Bolts: Stainless Steel

Housing: Aluminum or SS, Flameproof (Ex d) and

Waterproof (lP67)

Cover O-ring: NBR

Paint: Epoxy-polyester or Polyurethane

Mounting Bracket: For 2-inch Pipe, 304 SS,

with 304 SS U-bolt

Nameplate: 304 SS

Process

Connections: ¼" NPT with 54.0 mm Center

Distance for Standard Flanges,

½" NPT with Process Adapter

(Option)

Mount Position: Upright (Process Connection more

Flexible by using Multi-planar Flange)

Display: 5 Digit LCD

Power Supply: 12…45 VDC

17.5…45 VDC -HART® Communication

Maximum Load: 250 Ω at 17.5 VDC

550 Ω at 24 V

Max. Loop Resistance =

Loop Load: 0...1500 Ω - Operation

250...550 Ω - HART® Communication

Failure Mode: Fail High: Current ≥ 21.1 mA

Fail Low: Current ≤ 3.78 mA

Electrical

Connection: ½" NPT Conduit with M4 Screw

Terminals (G½ Option)

Output: • Two Wire 4…20 mA, Configurable

for Linear or Square Root Output, Digital

Process Value Superimposed on

4…20 mA Signal, Available to any Host

that Conforms to the HART® Protocol

• Frequency Output for Flowmeter

Model PAD-F with Pulse Width of 10,

50 or 100 ms (Selectable, Negative

Going Pulse)

Output Type: Open Collector, 30 V,

500 mA max.

Pulse Rate: 49 pulses/sec max.

Turn-On Time: 3 seconds

Protection: IP 67 for Standard (Code S)

Weight: 8.6 lb (Excluding Options) Standard

11.8 lb (SS Housing - Excl. Options)

ATEX Approval

(Option): II 2G Exd IIC T6 ... T5

II 1G or 2G Ex ia IIC T5 or

T4 Ga or Gb

www.koboldusa.com

DC

(U - 12 VDC)

0.022 A

No responsibility taken for errors;

subject to change without prior notice.

Page 5

Heavy Duty Differential Pressure Transmitter Model PAD

Order Details (Example: PAD-D EE 2 S 2 N S 0 0)

Model Version

..D.. = Differential Pressure Transmitter

(Static Pressure 2000 PSI)

..F..1) = Differential Pressure Transmitter with

Pulse Output and Totalizer for

PAD-

Flow Measurement

..H.. = Differential Pressure Transmitter for High

Line Pressure (Static Pressure 4495 PSI)

..G.. = Gauge Pressure Transmitter

..A.. = Absolute Pressure Transmitter

Material

Body/Vent Plug/

Diaphragm

..EE.. = 316 SS / 316 SS / 316L SS

Calibrated Span

(Measuring Range Limits for PAD-D,

-F, -G and -H in Separate Table)

Calibrated Span for

PAD-D, -F, -G, -H

..2..3) = 0.3"...6" W.C.

..3.. = 0.6"...30" W.C.

..4.. = 1.5"...150" W.C.

..5.. = 7.5"...750" W.C.

..6.. = 1...100 PSIG

..7.. = 3...300 PSIG

..8..3) = 10 ...1000 PSIG

3)4)

..9..

..0..

= 30...3000 PSIG

3)4)

= 60...6000 PSIG

Calibrated Span for PAD-A

..4.. = 10"...1000" W.C.

..5.. = 1.5...217 PSIA

..6.. = 3...362 PSIA

Order Details Continued

Fill Liquid Process Connection

..S.. = Silicone

1)

Specify flow rate engineering unit, ∆ p and flow rate

at URV (Upper Range Value), ∆ p and flow rate (generally '0')

at LRV (Lower Range Value)

pulse scale (choose only one value from

0.001, 0.01, 0.1, 1, 10, 100, 1 000, 10 000 m³/pulse) and

pulse width (choose only one value from

10 ms, 50 ms, 100 ms), while ordering so that max.

duty cycle is 49 pulses/sec

..2..6) = ¼" NPT

Female

Electrical

Connection

..N.. = ½" NPT

Epoxy Polyester

Painted

Aluminum

..G.. =G ½ Epoxy Polyester

Painted

Aluminum

Approvals Options

..S0.. = Standard

(Waterproof

IP67)

..F0.. = ATEX,

Flameproof, Ex d

..E0.. = ATEX,

Intrinsically Safe, Ex i

3)

Not for PAD-H

4)

Not for PAD-D and PAD-F

5)

Diaphragm seal model and application data to be specified in clear text.

The online application guide on the PAD product page of the website must be

completed for any PAD ordered with a DRM. For summary of

diaphragm seal models and possible ranges, see page 11 onwards. For

dimensional details see DRM data sheet.

6)

1/2" NPT connection via an adapter is available, see page 6

..0 = without

..C = Engineering Unit (must be

chosen when using the

differential transmitter as a

flowmeter)

..D = PTFE O-ring (Wetted Part)

..E = Oil Free Finish

..F = Side Vent / Drain Bottom

..G = Side Vent / Drain Top

..H = Multi-Planar

Process Connection

..M = Housing in Stainless Steel

..N5) = Mounting of PAD onto

Diaphragm Seal

No responsibility taken for errors;

subject to change without prior notice.

www.koboldusa.com

5

Page 6

Heavy Duty Differential Pressure Transmitter Model PAD

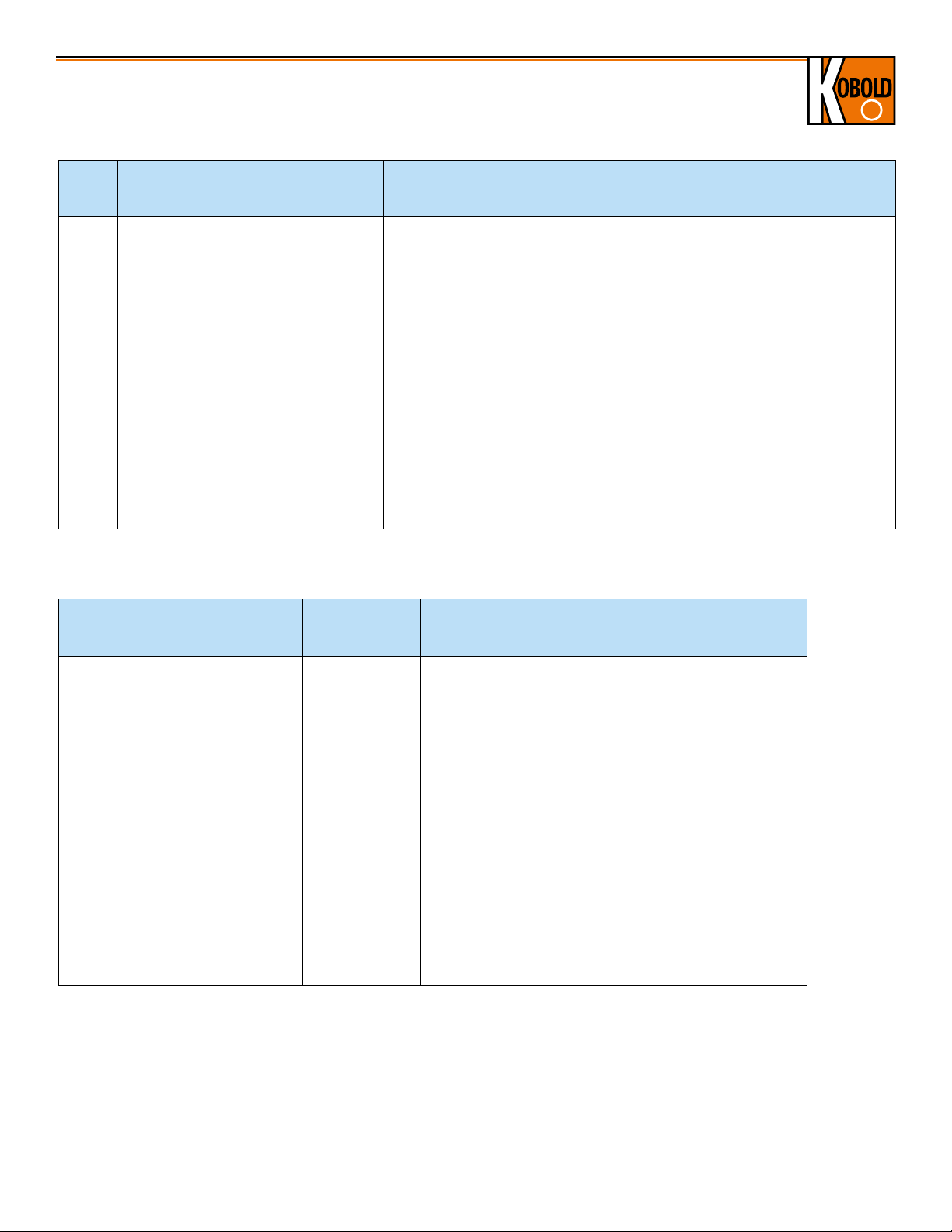

Order Details: Oval Flange Adapter

Description Order Number

1/2" NPT Oval Flange Adapter

ZUB-PAD-OVF

Technical Details

Material: 316 Stainless Steel

Seal: PTFE

Bolts: 2 x Mounting Screws 7/16"-20 UNF

Connection: ½" NPT Female

Dimensions

1.63"

Order Details: Mounting Brackets

Description Order Number

Angle Type Bracket for PAD/PAS

Vertical Pipe Mounting for PAS

Vertical Pipe Mounting for PAD

Incl. U-Clamp for 2“ Pipe Mounting Bracket and 2 x Mounting Nuts/Washers

Incl. 4 x Mounting Screws for PAS

Incl. 4 x Mounting Screws for PAD

Flat Type Bracket for PAD/PAS

Horizontal Pipe Mounting for PAS

Vertical Pipe Mounting for PAD

Incl. U-Clamp for 2“ Pipe Mounting Bracket and Mounting Nuts/Washers

Incl. 4 x Mounting Bolts and Washers for PAS

Incl. 4 x Mounting Bolts for PAD

Order Details: Manifold Valves

Description Order Number

3-way Manifold Valve, Remote Mount, Machined

5-way Manifold Valve, Remote Mount, Machined

2-way Manifold Valve, Direct Mount, Machined

2-way Compact Manifold Valve, Direct Mount, Machined

3-way Compact Manifold Valve, Direct Mount, Machined

5-way Compact Manifold Valve, Direct Mount, Machined

3-way Manifold Valve, Direct Mount, Forged

0.98"

ZUB-PAD/PAS-K

ZUB-PAD/PAS-L

ZUB-PAD-3WMR

ZUB-PAD-5WMR

ZUB-PAD-2WMD

V-2003CDADABAA

V-3151CHHHIBAA

V-5050CDAHIBAA

V-3454CHHHHBAA

6

www.koboldusa.com

No responsibility taken for errors;

subject to change without prior notice.

Page 7

Heavy Duty Differential Pressure Transmitter Model PAD

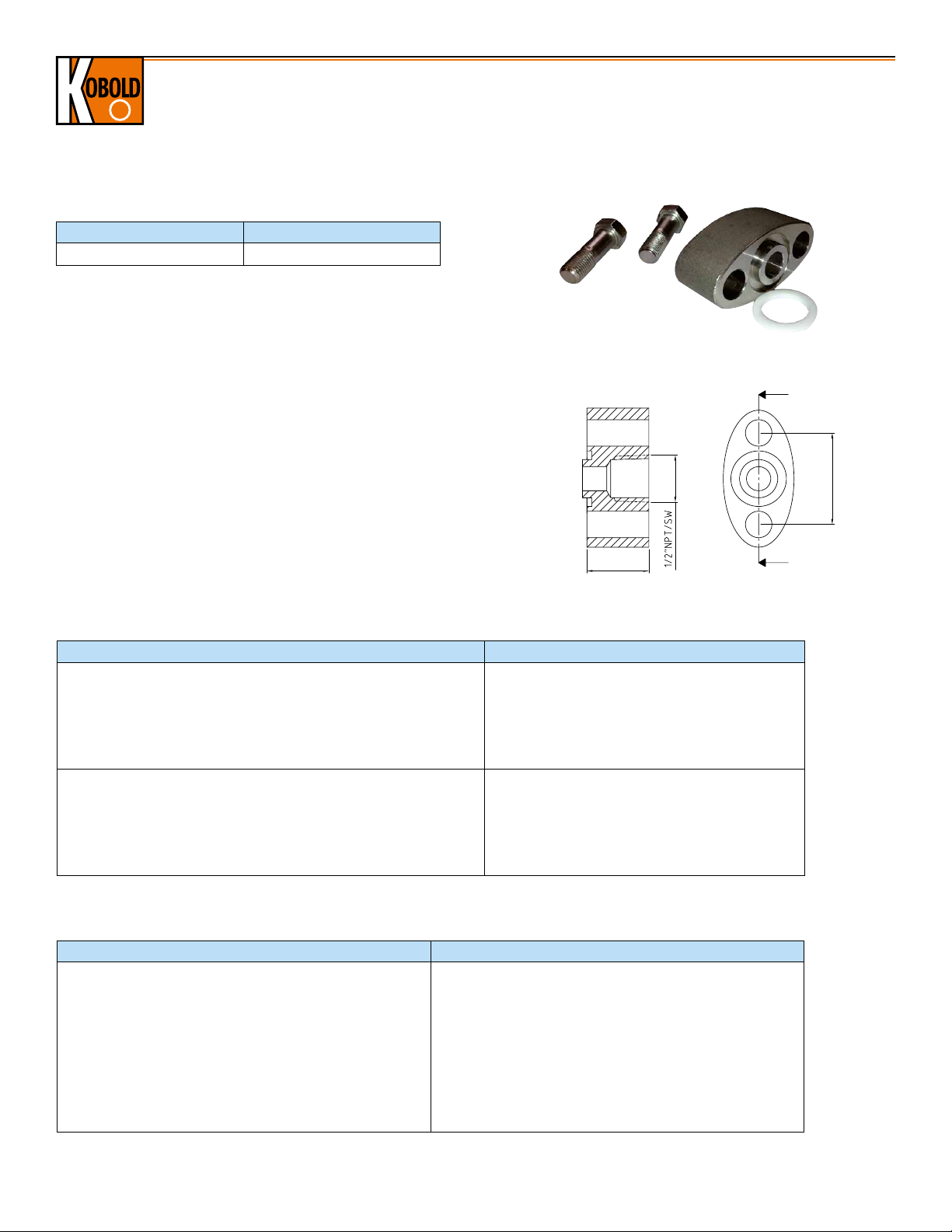

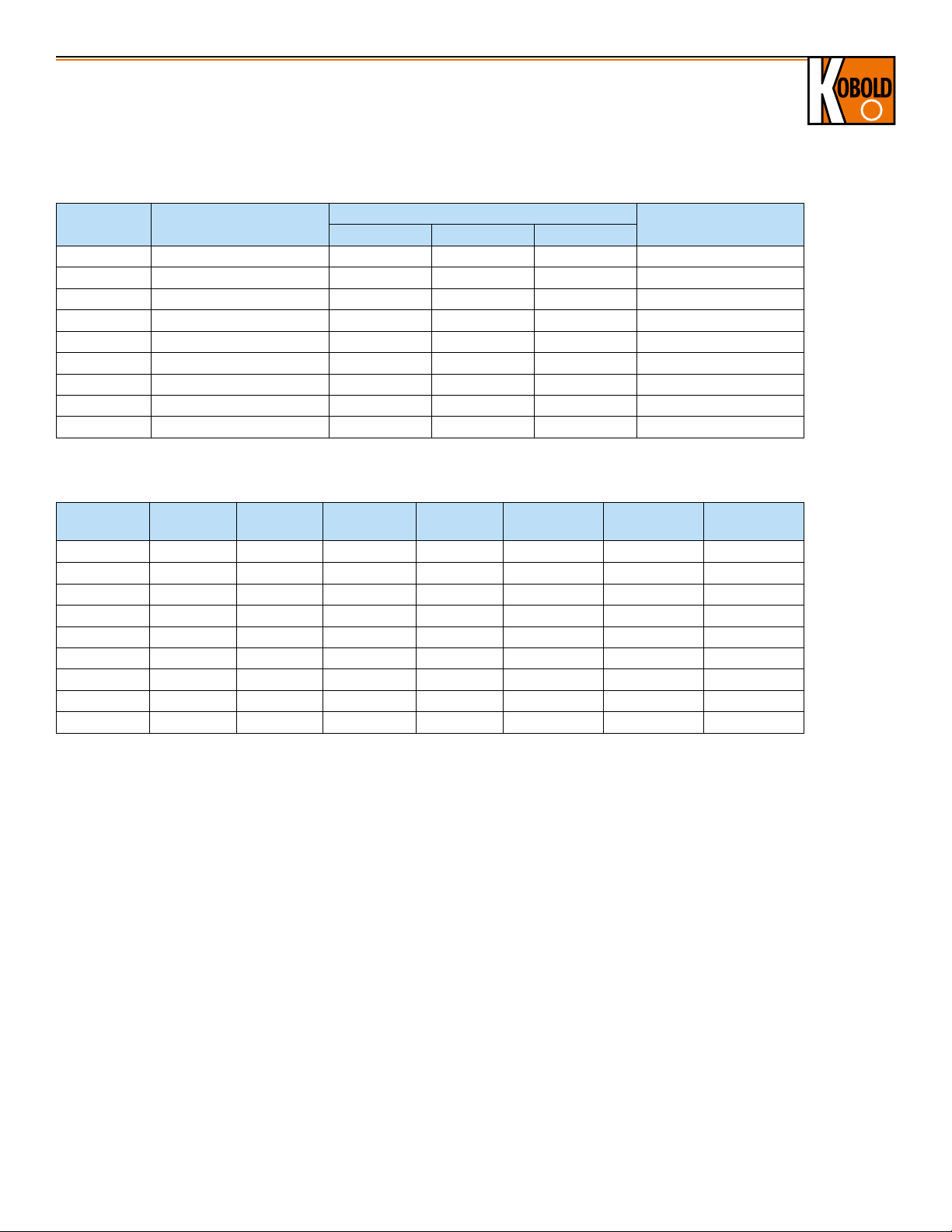

Measuring Range Limits for PAD-D, -F, -G and -H

Range Code Calibrated Span

PAD-D, -F PAD-G PAD-H

Lower Range Limit (LRL)

Upper Range Limit (URL)

2 0.3...6" W.C. -6" W.C. -6" W.C. - 6" W.C.

3 0.6...30" W.C. -30" W.C. -30" W.C. - 30" W.C.

4 1.5...150" W.C. -150" W.C. -150" W.C. -150" W.C. 150" W.C.

5 7.5...750" W.C. -750" W.C. -14.5 PSIG -750" W.C. 750" W.C.

6 1...100 PSIG -100 PSIG -14.5 PSIG -100 PSIG 100 PSIG

7 3...300 PSIG -300 PSIG -14.5 PSIG -300 PSIG 300 PSIG

8 10...1000 PSIG -1000 PSIG -14.5 PSIG - 1000 PSIG

9 30...3000 PSIG - -14.5 PSIG - 3000 PSIG

0 60...6000 PSIG - -14.5 PSIG - 6000 PSIG

* Special measuring span, with adequate lower and upper range limits, on request.

Range Code Unit Conversion

Range Code bar kg/cm² KPa psi in H2O at 39 °F

2 0.015 0.015 1.5 0.217 6 152 0.422

3 0.075 0.076 7.5 1.087 30 765 2.215

4 0.373 0.38 37.3 5.410 149 3804 11.014

5 1.865 1.902 186.5 27 749 19018 55.072

6 6.900 7.036 690 100 2773 70361 203.750

7 20.681 21.088 2068 300 8310 210878 610.660

8 68.950 70.309 6895 1000 27708 703097 2036.025

9 206.800 210.876 20680 3000 83105 2108781 6106.597

0 413.700 421.856 41370 6000 166085 4218566 12216.550

mm H2O at

39 °F

in Hg at 32 °F

No responsibility taken for errors;

subject to change without prior notice.

www.koboldusa.com

7

Page 8

Dimensions

LOCK

LOCK

FIELD

TERMINALS

s

112

73 39

79.5

113

192.5

LOCK

LOCK

FIELD

TERMINALS

s

316

CF8MXXXX

112

73 39

89.5

113

202.5

LOCK

LOCK

FIELD

TERMINALS

s

316

CF8MXXXX

112

122

324.5

210

PAD Standard*

Heavy Duty Differential Pressure Transmitter Model PAD

PAD Multi-Planar Process Connection*

4.41"*/4.69"**

112

2.87"*/3.15"**

1.54"

73 39

s

TERMINALS

FIELD

LOCK

LOCK

* For Ex d and Standard

113

4.45"

79.5

3.13"

7.58"

192.5

42

1.65"

E

N

E

E

L

G

R

I

H

D

E

Z

I

W

N

E

3.39"

86

U

A

C

-

P

O

T

O

54

2.13"

T

I

O

N

D

O

N

-

I

N

E

X

P

L

O

S

I

V

E

A

T

M

O

S

P

H

E

R

E

7/16-20 UNF

** For Ex i

PAD with Multi-Planar Flange and Angle Type Bracket*

3.39"

R

E

N

E

E

L

I

D

E

Z

I

G

H

W

N

E

86

U

A

C

-

P

O

T

O

N

4.33"

110

T

I

O

N

-

I

N

E

X

P

L

O

S

I

V

E

A

T

M

O

S

P

H

E

R

E

D

O

* For Ex d and Standard

** For Ex i

4.41"*/4.69"**

112

s

LOCK

TERMINALS

FIELD

LOCK

CF8MXXXX

316

122

4.80"

324.5

12.78"

4.41"*/4.69"**

112

2.87"*/3.15"**

1.54"

73 39

s

TERMINALS

FIELD

LOCK

LOCK

CF8MXXXX

316

* For Ex d and Standard

113

4.45"

89.5

3.52"

202.5

7.97"

42

1.65"

E

N

E

E

L

R

I

H

D

E

Z

I

G

W

N

E

3.39"

86

U

A

C

-

P

O

T

O

54

2.13"

T

I

O

N

-

I

N

E

X

P

L

O

S

I

V

E

A

T

M

O

S

P

H

E

R

E

D

O

N

** For Ex i

PAD Standard with Flat Type Bracket (Vertically Mounted)*

4.41"*/4.69"**

112

s

LOCK

TERMINALS

FIELD

LOCK

323.5

12.74"

G

R

E

N

E

E

L

I

H

3.39"

D

E

Z

I

W

N

E

P

3.70"

86

I

T

O

U

N

A

-

C

-

I

N

E

X

P

L

O

S

I

V

E

A

T

M

O

S

P

H

E

R

O

E

T

D

O

O

N

* For Ex d and Standard

** For Ex i

94

47

1.85"

210

8.27"

PAD Standard with Flat Type Bracket (Horizontally Mounted)*

8.27"

4.72"

120

I

T

O

U

N

A

-

C

-

I

N

D

E

E

X

Z

I

P

L

G

O

R

S

E

I

N

V

E

E

E

A

* For PAD-G/A, the low pressure port 'L' is always closed

8

L

I

T

M

H

W

O

S

N

P

H

E

E

P

R

O

E

T

D

O

O

N

www.koboldusa.com

4.41"*/4.69"**

112

s

TERMINALS

FIELD

LOCK

LOCK

* For Ex d and Standard

** For Ex i

205.5

8.09"

47

1.85"

No responsibility taken for errors;

subject to change without prior notice.

Page 9

Static

Process side Block valve Sied

Block valve

Equalize valve

Flow schematic

Technical Specications:

Material: 316SS

Connection & Size: ½" NPT (F)

Pressure rating: 6,000 psig at 38°C (≈410 bar)

Heavy Duty Differential Pressure Transmitter Model PAD

Process side Block valve Sied

Block valve

Equalize valve

Flow schematic

228.0 (open, approx.)

Process side

Instrument side

Block valve

½" NPT

4 places

¼" NPT

Static vent

2 places

Block valve

44.0

Ø 7.0 DIA

Mounting holes

2 places

side

24.0

54.0

86.0

31.0

Technical Specications:

Material: 316SS

Connection & Size: ½" NPT (F)

Pressure rating: 6,000 psig at 38°C (≈410 bar)

Temperature range: -54°C ... +232°C

Weight: 2 kg

Technical Specications:

Material: 316SS

Connection & Size: ½" NPT (F)

Pressure rating: 6,000 psig at 38°C (≈410 bar)

Temperature range: -54°C ... +232°C

Weight: 2.2 kg

Process side

Instrument side

228.0 (open, approx.)

Block valve

86.0

43.0

24.0

Instrument Instrument

Process Vent port Process

Static

(test)

Static

(test)

Equalize Equalize

Block/

Isolate

Block/

Isolate

Flow schematic

Vent

Instrument Instrument

Process Vent port Process

Static

(test)

Static

(test)

Equalize Equalize

Block/

Isolate

Block/

Isolate

Flow schematic

Vent

PAD-G/A Mounted with 2-way Manifold Valve*

3.39"

4.41"*/4.69"**

4.80"

* For PAD-G/A, the low pressure port 'L' is always closed.

Manifold Valves (Remotely Mounted)

Technical Specifications

Material: 316 SS Body with PTFE Packing

Connection: ½" NPT (F)

Pressure Rating: 6000 PSIG at 100 °F (≈410 bar)

Temperature Range: -65...449 °F

* For Ex d and Standard

** For Ex i

7.58"

3-way Manifold Valve

Equalize valve

104.5 (open, approx.)

4.11"

33.3

1.31"

5-way Manifold Valve

Equalize valve Equalize valve

85.0 (open, approx.)

3.35

No responsibility taken for errors;

subject to change without prior notice.

¼" NPT

Static port

2 places

3.07"

78.0

Bleed valve

2.13"

54.0

¼" NPT

Vent port

½" NPT

4 Places

33.3

1.31"

Block valve

Ø 7.0 DIA

0.28"

Mounting holes

2 places

side

Process side

228.0 (open, approx.)

8.98"

½" NPT

4 places

Block valve

www.koboldusa.com

1.22"

31.0

24.0

0.95"

Instrument side

8.98"

8.98"

228.0 (open, approx.)

1.73"

44.0

3.39"

86.0

1.69"

43.0

0.95"

24.0

Process side

Block valve

Instrument side

54.0

2.13"

¼" NPT

Static vent

2 places

86.0

3.39"

Block valve

Block valve

Equalize valve

Process side Block valve Sied

Instrument

side

Weight: 4.41 lbs

Instrument Instrument

Equalize Equalize

Static

(test)

Block/

Isolate

Vent

Block/

Isolate

Process Vent port Process

Weight: 4.85 lbs

(test)

9

Page 10

Heavy Duty Differential Pressure Transmitter Model PAD

Vent

Bleed

Block

Process

1/4" NPT vent port

28.4

47.8

7.8

41.4

16

Bleed valve

50.8

50.8

92.60 (open)

Instrument

Vent

Bleed

Block

Process

Instrument

Manifold Valves (Direct Mount)

Technical Specifications:

Material: 316 SS Body with PTFE Packing

Pressure Rating: 3000 PSIG at 449 °F (≈210 bar)

Connection: ½" NPT (F) to Flange

Temperature Range: -65...449 °F

2-way Manifold Valve

1.77"

Block valve

45

1/4" NPT vent port

28.4

1.12"

47.8

1.88"

2.00"

50.8

Vent

Instrument side

0.48"

Ø 12.2 for

7/16" bolts

63.5 (open)

2.50"

31

1.22"

41.3

1.63"

3.81"

96.8

1/2" NPT

2 places

Process side

92.60 (open)

3.65"

41.4

1.63"

7.8

16

0.63" 0.31"

Bleed valve

50.8

2.00"

Bleed

Instrument

Weight: 3.53 lbs

Block

Process

10

www.koboldusa.com

No responsibility taken for errors;

subject to change without prior notice.

Page 11

Heavy Duty Differential Pressure Transmitter Model PAD

IN

Drain

Manifold Valves (Direct Mount, Machined)

Technical Details

Material: AISI 316L

Pressure Rating: 6 000 psi

Temperature Range: -99...410 °F (PTFE Packing), Standard

-65... 950 °F (GRAPHOIL Packing), On Request

Weight: 1.94 lbs

2-way Manifold Valve: V-2003CDADABAA (PTFE Packing)

(Inlet: ½" NPT Female / Outlet: ½" NPT Male)

VENT.

5.83"

148

IS

O

A

L

E

T

4.73"

120

OUT IN

30

1.18"

Ø

Drain

IN

Included Accessories: Plug

No responsibility taken for errors;

subject to change without prior notice.

Drain 1/4" NPT-F with plug

www.koboldusa.com

11

Page 12

Heavy Duty Differential Pressure Transmitter Model PAD

ND

OUT

32

Ø

12

IN

IN

D

IN

P

DRAINDRAIN

E

QU

A

L

I

S

E

Flanged Type

IEC 61518/A

70

OUT

41.4

32

124

54

224

N°4 fori Ø12

IN

106

IN

D

IN

P

DRAINDRAIN

84

DRAIN 1/4" NPT-F

EQUALISE

ISOLATE

ISOLATE

E

QU

A

L

I

S

E

30

N°2 fixing

holes M10

Flanged Type

IEC 61518/A

70

Manifold Valves (Direct Mount, Machined)

Technical Details

Material: AISI 316L

Pressure Rating: 6 000 psi

Temperature Range: -99...410 °F (PTFE Packing), Standard

-65...950 °F (GRAPHOIL Packing), On Request

Weight: 4.78 lbs

3-way Manifold Valve: V-3151CHHHIBAA (PTFE Packing)

(Inlet: Flanged / Outlet: Flanged According to IEC 61518 Type B / Type A)

8.82"

N°4 holes

Ø12

4.88"

2.76"

DRAI

D

P

RAIN

IN

IN

1.18"

2.13"

3.31"

4.17"

Included Accessories:

4 Carbon Steel Screws (Stainless Steel On Request)

2 Plugs

2 PTFE Gaskets

Mounting Options 3-way Manifold Valve with PAD

Description Process Connection Illustration

Valve Mounted Upside Down on Front Side of PAD Flanged According to IEC 61518 Type A

Valve Mounted Upside Down on Front Side of PAD

including Oval Flange Adapter Model ZUB-PAD-OVF

1.26"

½" NPT Female

7/16"-20 UNF

2¾"

1/4" NPT

7/16" UNF

Valve Mounted on Front Side of PAD, Head of PAD

Rotated 90° Clockwise

Valve Mounted on Front Side of PAD including Oval

Flange Adapter Model ZUB-PAD-OVF, Head of PAD

Rotated 90° Clockwise

12

Flanged According to IEC 61518 Type A

½" NPT Female

www.koboldusa.com

No responsibility taken for errors;

subject to change without prior notice.

Page 13

Heavy Duty Differential Pressure Transmitter Model PAD

IN

32

70

IN

DRAIN 1/4" NPT-F

DRAIN DRAIN

142

41.4

54

N°2 fixing holes M10

D

P

260

IN

ISOLATE

VENT. EQUALISE VENT.

ISOLATE

V

E

N

T

.

30

102

10.5

16

Ø

12 holes

OUT

Flanged Type

IEC 61518/A

IN

32

70

IN

T-F

DRAIN DRAIN

D

P

IN

V

E

N

T

.

30

102

10.5

16

OUT

Flanged Type

IEC 61518/A

IN

IN

DRAIN DRAIN

D

P

IN

IN

DRAIN DRAIN

D

P

Manifold Valves (Direct Mount, Machined)

Technical Details

Material: AISI 316L

Pressure Rating: 6 000 psi

Temperature Range: -99...410 °F (PTFE Packing), Standard

-65...950 °F (GRAPHOIL Packing), On Request

Weight: 6.17 lbs

5-way Manifold valve: V-5050CDAHIBAA (PTFE Packing)

(Inlet: ½" NPT / Outlet: Flanged According to IEC 61518 Type A)

10.24"

260

VENT. EQUALISE VENT.

124

4.88"

ISOLATE

ISOLATE

41.4

D

P

IN

1.18"

4.02"

30

102

IN

16

0.63"

DRAIN DRAIN

0.41"

10.5

Flanged Type

IEC 61518/A

OUT

70

2.76"

V

E

N

T

.

IN

N°4 Ø12 holes

N°4 12 holesN°4 12 holes

Included Accessories:

4 Carbon Steel Screws (Stainless Steel On Request)

2 Plugs

2 PTFE Gaskets

Mounting Options for 5-way Manifold Valve with PAD

Valve Mounted Upside Down on Front Side of PAD ½" NPT Female

Valve Mounted on Front Side of PAD after Rotating

the Head of PAD 90° Clockwise

Description Process Connection Illustration

2.13"

54

5.59"

142

DRAIN 1/4" NP

N°2 fixing holes M10

½" NPT Female

1.26"

32

7/16"-20 UNF

1/4" NPT

1¾"

7/16" UNF

No responsibility taken for errors;

subject to change without prior notice.

www.koboldusa.com

13

Page 14

Heavy Duty Differential Pressure Transmitter Model PAD

IN

32

70

IN

DRAIN 1/4" NPT-F

DRAIN DRAIN

142

41.4

54

N°2 fixing holes M10

D

P

260

IN

ISOLATE

V

E

N

T

.

30

102

10.5

16

OUT

Flanged Type

IEC 61518/A

Manifold Valves (Direct Mount, Forged)

Technical Details

Material: 316L Stainless Steel

Pressure Rating: 6 000 psi

Temperature Range: -99...410 °F (PTFE Packing), Standard

-65...950 °F (GRAPHOIL Packing), On Request

Weight: 4.96 lbs

3-way Manifold Valve: V-3454CHHHHBAA (PTFE Packing)

(Inlet: Flanged Oval/ Outlet: Flanged According to IEC 61518 Type B)

0.51"

0.81" ± 0.004"

2.13" ± 0.01"

7.68"

3.39"

1.63" ± 0.008"

3.98"

4.41"

2.13"

0.47"

1.63" ± 0.008"

3.66"

2.09"

0.81" ± 0.004"

Included Accessories:

4 Carbon Steel Screws (Stainless Steel On Request)

2 PTFE Gaskets

14

www.koboldusa.com

7/16" UNF

1¾"

No responsibility taken for errors;

subject to change without prior notice.

7/16"-20 UNF

Page 15

Heavy Duty Differential Pressure Transmitter Model PAD

Δ L (min. 150 mm max. 500 mm)

welded

Example of PAD Direct Assembed with an Extended Diaphragm Seal (not available as ATEX-Version)

(for Dimensional Details, see DRM Data Sheet)

Fig. 1

Dimensions: Examples for DN50 / DN 80/DN100 / 2" ANSI / 3" ANSI/4"ANSI

Flange Type D k d

2

b f d

DN50 PN16 6.50" 4.92" 0.71" 0.71" 0.08"

DN50 PN40 6.50" 4.92" 0.71" 0.79" 0.08" 0.16" 1.89"

2" ANSI Cl. 150 6.00" 4.75" 0.75" 0.75" 0.08"

2" ANSI Cl. 300 6.50" 5.00" 0.75" 0.88" 0.08" 0.31" 1.89"

DN80 PN16 7.87" 6.30" 0.71" 0.79" 0.08"

DN80 PN40 7.87" 6.30" 0.71" 0.94" 0.08" 0.31" 2.99"

3" ANSI Cl. 150 7.50" 6.00" 0.75" 0.94" 0.06"

3" ANSI Cl. 300 8.25" 6.63" 0.87" 1.12" 0.06" 0.31" 2.99"

DN100 PN16 8.66" 7.09" 0.71" 0.79" 0.08" 5.87" 0.31" 3.50"

DN100 PN40 9.25" 7.48" 0.87" 0.94" 0.08" 5.87" 0.31" 3.50"

4" ANSI Cl. 150 9.00" 7.50" 0.75" 0.94" 0.06" 6.19" 0.31" 3.50"

4" ANSI Cl. 300 10.00" 7.87" 0.87" 1.26" 0.06" 6.19" 0.31" 3.50"

4

4.02"

3.62"

5.43"

5.00"

X d

0.16" 1.89"

0.16" 1.89"

0.31" 2.99"

0.16" 2.99"

5

100 mm (4")/

150 mm (6")/

200 mm (8")/

R

L

50 mm (2")/

(customer

specified)

Example of PAD Assembed with Remote Diaphragm Seals and Capillaries

(for Dimensional Details, see DRM Data Sheet)

Dimensions: Examples for DN50 / DN 80 /DN100 / 2" ANSI / 3" ANSI/4"ANSI

Flange Type D k d

DN50 PN16 6.50" 4.92" 0.71" 0.71" 0.08"

DN50 PN40 6.50" 4.92" 0.71" 0.79" 0.08" 0.16"

2" ANSI Cl. 150 6.00" 4.75" 0.75" 0.75" 0.08"

2" ANSI Cl. 300 6.50" 5.00" 0.75" 0.88" 0.08" 0.31"

DN80 PN16 7.87" 6.30" 0.71" 0.79" 0.08"

DN80 PN40 7.87" 6.30" 0.71" 0.94" 0.08" 0.31"

3" ANSI Cl. 150 7.50" 6.00" 0.75" 0.94" 0.06"

3" ANSI Cl. 300 8.25" 6.63" 0.87" 1.12" 0.06" 0.31"

DN100 PN16 8.66" 7.09" 0.71" 0.79" 0.08" 5.87" 0.31"

DN100 PN40 9.25" 7.48" 0.87" 0.94" 0.08" 5.87" 0.31"

4" ANSI Cl. 150 9.00" 7.50" 0.75" 0.94" 0.06" 6.19" 0.31"

4" ANSI Cl. 300 10.00" 7.87" 0.87" 1.26" 0.06" 6.19" 0.31"

Fig. 2

No responsibility taken for errors;

subject to change without prior notice.

www.koboldusa.com

2

b f d

4.02"

3.62"

5.43"

5.00"

4

X

0.16"

0.16"

0.31"

0.16"

15

Page 16

Heavy Duty Differential Pressure Transmitter Model PAD

Example of PAD-G Remote Assembled with (Extended) Diaphragm Seal and Capillary

(for Dimensional Details, see DRM Data Sheet)

Fig. 3

Dimensions: Examples for DN50 / DN 80 /DN100 / 2" ANSI / 3" ANSI/4"ANSI

Flange Type D k d

2

b f d

DN50 PN16 6.50" 4.92" 0.71" 0.71" 0.08"

DN50 PN40 6.50" 4.92" 0.71" 0.79" 0.08" 0.16" 1.89"

2" ANSI Cl. 150 6.00" 4.75" 0.75" 0.75" 0.08"

2" ANSI Cl. 300 6.50" 5.00" 0.75" 0.88" 0.08" 0.31" 1.89"

DN80 PN16 7.87" 6.30" 0.71" 0.79" 0.08"

DN80 PN40 7.87" 6.30" 0.71" 0.94" 0.08" 0.31" 2.99"

3" ANSI Cl. 150 7.50" 6.00" 0.75" 0.94" 0.06"

3" ANSI Cl. 300 8.25" 6.63" 0.87" 1.12" 0.06" 0.31" 2.99"

DN100 PN16 8.66" 7.09" 0.71" 0.79" 0.08" 5.87" 0.31" 3.50"

4

4.02"

3.62"

5.43"

5.00"

X d

0.16" 1.89"

0.16" 1.89"

0.31" 2.99"

0.16" 2.99"

5

R

L

50 mm (2")/

100 mm (4")/

150 mm (6")/

200 mm (8")/

(customer

specified)

DN100 PN40 9.25" 7.48" 0.87" 0.94" 0.08" 5.87" 0.31" 3.50"

4" ANSI Cl. 150 9.00" 7.50" 0.75" 0.94" 0.06" 6.19" 0.31" 3.50"

4" ANSI Cl. 300 10.00" 7.87" 0.87" 1.26" 0.06" 6.19" 0.31" 3.50"

16

www.koboldusa.com

No responsibility taken for errors;

subject to change without prior notice.

Page 17

Heavy Duty Differential Pressure Transmitter Model PAD

Diaphragm Seal Models (Remote Assembly)

(Standard device without additional options (e.g. coatings, special materials etc.).

For dimensions/technical data, see DRM data sheet. Accuracy: 0.075% of calibrated span + influence of seal).

Over and under ranges of the min./max. span may be possible, but must be verified by KOBOLD for each application.

The indicated min./max. spans do not consider any coating of diaphragm seals. For additional information contact KOBOLD.

Model DRM Size Code Size Note

DRM-601 R15 G ½

R20 G ¾ Ø 23.8 0 ... 36.3 14500

R25 G 1 Ø 29.5 0 ... 23.2 8700

R32 G 1 ¼ Ø 38 0 ...14.5 8700

DRM-603

DIN 11851

DRM-605

IDF

R40 G 1 ½ Ø 40 0 ...14.5 8700

N15 ½" NPT Ø 18 0 ... 87 14500

N20 ¾" NPT Ø 18 0 ... 87 14500

N25 1" NPT Ø 23.8 0 ... 36.3 8700

N32 1 ¼" NPT Ø 34.5 0 ... 23.2 8700

M20 M20 x 1.5 Ø 18 0 ... 87 8700

M48 M 48 x 3 Ø 40 0 ...14.5 8700

R20 DN 20

R25 DN 25 Ø 23.8 0 ... 36.3 580

R32 DN 32 Ø 29.5 0 ... 23.2 580

R40 DN 40 Ø 38 0 ...14.5 580

R50 DN 50 Ø 45.5 0 ... 8.7 362.5

R65 DN 65 Ø 64 0 ... 5.8 362.5

R80 DN 80 Ø 64 0 ... 5.8 362.5

R1H DN 100 Ø 64 0 ... 5.8 362.5

R25 1"

R40 1 ½" Ø 42 0 ... 14.5 580

R50 2" Ø 56 0 ... 8.7 580

Fixed Male Thread with

Capillary

Dairy Connection, Capillary

IDF Socket with Union Nut,

Capillary

Ø Diaphragm

(mm)

Ø 18

Ø 18

Ø 29.5

Max. Media

Temperature

392 °F

392 °F

392 °F

Min. Span

(PSIG)

0 ... 87 14500

0 ... 87 580

0 ... 23.2 580

Max. Span

(PSIG)

DRM-606

R20 G ¾

Capsule Seal with Rotable

Male, Capillary

R28 M 28 x 1,5 0 ...145 8700

DRM-608/1

DRM-611

SMS

* Note: Threaded diaphragm seal only available with PAD-G/A. For PAD-D only flange, clamp connections or union nut are possible

No responsibility taken for errors;

subject to change without prior notice.

R20 G ¾

R25 G 1

R40 1 ½"

R50 2" Ø 45.5 0 ... 8.7 580

Capsule Seal with Union Nut,

Capillary

Capsule Seal with Union Nut,

Capillary

SMS Socket with Union Nut,

Capillary

www.koboldusa.com

Short capsule 662 °F

Long capsule

662 °F

Long capsule 0 ... 23.2 8700

Ø 34.5

392 °F

0 ...145 8700

0 ... 23.2 8700

0 ... 23.2 580

17

Page 18

Heavy Duty Differential Pressure Transmitter Model PAD

Diaphragm Seal Models (Remote Assembly)

(Standard device without additional options (e.g. coatings, special materials etc.).

For dimensions/technical data, see DRM data sheet. Accuracy: 0.075% of calibrated span + influence of diaphragm seal).

Model DRM Size Code Size Note

DRM-613

Clamp

R25 1"

F40 1 ½" Ø 35.5 0 ...23.2 232

Ø Diaphragm

(mm)

Ø 18

Max. Media

Temperature

Min. Span

(PSIG)

0 ...87 232

Max. Span

(PSIG)

DRM-615

APV-RJT

DRM-617

DRM-620

DRM-620/1

F50 2" Ø 45.5 0 ...8.7 232

R65 2 ½" Ø 52 0 ...8.7 232

R80 3" Ø 64 0 ...5.8 145

R20 1"

R40 1 ½" Ø 42.5 0 ... 14.5 1450

R50 2" Ø 56 0 ... 8.7 1450

R45 M 45 x 2 Union-nut, Capillary Ø 23.8 248 °F 0 ... 36.3 23200

R20 G ¾ Union-nut, Capillary Ø 23.8 662 °F 0 ... 36.3 8700

R20 G ¾ Union-nut, capillary Ø 23.8 662 °F 0 ... 36.3 8700

Tri-Clamp, Capillary

Ø 29.5

Union-nut, Capillary

392 °F

0 ... 36.3 1450

392 °F

DRM-622/1

DRM-624/1

DRM-625/1

* Note: Threaded diaphragm seal only available with PAD-G/A. For PAD-D only flange, clamp connections or union nut are possible

18

F48 Ø 48 mm

F48 1 Ø 48 mm Ø 48 0 ...8.7 580

F48 2 Ø 48 mm Ø 48 0 ...8.7 580

F1H Ø 100 mm Flange, Capillary Ø 63.5 482 °F 0 ... 5.8 580

R15 G ½

N15 ½" NPT 0 ... 5.8 580

I15 G ½ male 0 ... 5.8 580

Flange, Capillary

Fixed male, Capillary Ø 63.5 482 °F

www.koboldusa.com

Ø 48

392 °F

0 ...8.7 580

0 ... 5.8 580

No responsibility taken for errors;

subject to change without prior notice.

Page 19

Heavy Duty Differential Pressure Transmitter Model PAD

Diaphragm Seal Models (Direct or Remote Assembly)

(Standard device without additional options (e.g. coatings, special materials etc.).

For dimensions/technical data, see DRM data sheet. Accuracy: 0.075% of calibrated span + influence of diaphragm seal).

Model DRM Size Code Size Note

DRM-627

PN 25

DRM-627

PN 100

DRM-627

PN 250

R08A025 G ¼ male Fixed Male, Capillary Ø 56

R08I025 G ¼ female Fixed Female, Capillary Ø 56 0 ... 8.7 362.5

R15A025 G ½ male Fixed Male, Capillary Ø 56 0 ... 8.7 362.5

R15I025 G ½ female Fixed Female, Capillary Ø 56 0 ... 8.7 362.5

N15A025 ½" NPT male Fixed Male, Capillary Ø 56 0 ... 8.7 362.5

R08A100 G ¼ male Fixed Male, Capillary Ø 56

R08I100 G ¼ female Fixed Female, Capillary Ø 56 0 ... 8.7 1450

R15A100 G ½ male Fixed Male, Capillary Ø 56 0 ... 8.7 1450

R15I100 G ½ female Fixed Female, Capillary Ø 56 0 ... 8.7 1450

N15A100 ½" NPT male Fixed Male, Capillary Ø 56 0 ... 8.7 1450

R08A250 G ¼ male Fixed Male, Capillary Ø 56

R08I250 G ¼ female Fixed Female, Capillary Ø 56 0 ... 8.7 3625

R15A250 G ½ male Fixed Male, Capillary Ø 56 0 ... 8.7 3625

R15I250 G ½ female Fixed Female, Capillary Ø 56 0 ... 8.7 3625

N15A250 ½" NPT male Fixed Male, Capillary Ø 56 0 ... 8.7 3625

Ø Diaphragm

(mm)

Max. Media

Temperature

482 °F

482 °F

482 °F

Min. Span

(PSIG)

0 ... 8.7 362.5

0 ... 8.7 1450

0 ... 8.7 3625

Max. Span

(PSIG)

DRM-629

PN 06

DRM-629

PN 16

DRM-629

PN 40

DRM-630/1

PVC

F25P06 DN 25

F32P06 DN 32 Ø 30 0 ... 36.3 87

F40P06 DN 40 Ø 38 0 ... 14.5 87

F50P06 DN 50 Ø 48 0 ... 8.7 87

F65P06 DN 65 Ø 64 0 ... 5.8 87

F80P06 DN 80 Ø 64 0 ... 5.8 87

F1HP06 DN 100 Ø 64 0 ... 5.8 87

F25P16 DN 25

F32P16 DN 32 Ø 30 0 ... 36.3 232

F40P16 DN 40 Ø 38 0 ... 14.5 232

F50P16 DN 50 Ø 48 0 ... 8.7 232

F65P16 DN 65 Ø 64 0 ... 5.8 232

F80P16 DN 80 Ø 64 0 ... 5.8 232

F1HP16 DN 100 Ø 64 0 ... 5.8 232

F25P40 DN 25

F32P40 DN 32 Ø 30 0 ... 36.3 580

F40P40 DN 40 Ø 38 0 ... 14.5 580

F50P40 DN 50 Ø 48 0 ... 8.7 580

F65P40 DN 65 Ø 64 0 ... 5.8 580

F80P40 DN 80 Ø 64 0 ... 5.8 580

F1HP40 DN 100 Ø 64 0 ... 5.8 580

R08 G ¼ female

R15 G ½ female Ø 64 0 ... 5.8 145

N15 ½" NPT female Ø 64 0 ... 5.8 145

Flange to EN1092-1,

Capillary

Flange to EN1092-1,

Capillary

Flange to EN1092-1,

Capillary

Fixed Female, Capillary

Ø 24

Ø 24

Ø 24

Ø 64

0 ... 36.3 87

482 °F

0 ... 36.3 232

482 °F

0 ... 36.3 580

482 °F

0 ... 5.8 145

104 °F

DRM-631/1

PP

DRM-632/1

PVDF

* Note: Threaded diaphragm seal only available with PAD-G/A. For PAD-D only flange, clamp connections or union nut are possible

No responsibility taken for errors;

subject to change without prior notice.

R08 G ¼ female

R15 G ½ female Ø 64 0 ... 5.8 145

N15 ½" NPT female Ø 64 0 ... 5.8 145

R08 G ¼ female

R15 G ½ female Ø 64 0 ... 5.8 232

N15 ½" NPT female Ø 64 0 ... 5.8 232

Fixed Female, Capillary

Fixed Female, Capillary

www.koboldusa.com

Ø 64

104 °F

Ø 64

122 °F

0 ... 5.8 145

0 ... 5.8 232

19

Page 20

Heavy Duty Differential Pressure Transmitter Model PAD

Diaphragm Seal Models (Direct or Remote Assembly)

(Standard device without additional options (e.g. coatings, special materials etc.).

For dimensions/technical data, see DRM data sheet. Accuracy: 0.075% of calibrated span + influence of diaphragm seal).

Model DRM Size Code Size Note

DRM-633/1

F50 DN 50

F1H DN 100 Ø 64 0 ... 3.6 580

Flange to DIN2527 Form C,

Capillary

Ø Diaphragm

(mm)

Ø 64

Max. Media

Temperature

482 °F

Min. Span

(PSIG)

0 ... 3.6 580

Max. Span

(PSIG)

DRM-635

150 lbs

DRM-635

300 lbs

DRM-635

600 lbs

DRM-635

1500 lbs

A25P150 1"

A32P150 1¼" Ø 38 0 ... 14.5 145

A40P150 1 ½" Ø 38 0 ... 14.5 145

A50P150 2" Ø 48 0 ... 8.7 145

A65P150 2 ½" Ø 48 0 ... 8.7 145

A80P150 3" Ø 64 0 ... 5.8 145

A90P150 3 ½" Ø 64 0 ... 5.8 145

A1HP150 4" Ø 64 0 ... 5.8 145

A25P300 1"

A32P300 1¼" Ø 38 0 ... 14.5 290

A40P300 1 ½" Ø 38 0 ... 14.5 290

A50P300 2" Ø 48 0 ... 8.7 290

A65P300 2 ½" Ø 48 0 ... 8.7 290

A80P300 3" Ø 64 0 ... 5.8 290

A90P300 3 ½" Ø 64 0 ... 5.8 290

A1HP300 4" Ø 64 0 ... 5.8 290

A25P600 1"

A32P600 1¼" Ø 38 0 ... 14.5 580

A40P600 1 ½" Ø 38 0 ... 14.5 580

A50P600 2" Ø 48 0 ... 8.7 580

A65P600 2 ½" Ø 48 0 ... 8.7 580

A80P600 3" Ø 64 0 ... 5.8 580

A90P600 3 ½" Ø 64 0 ... 5.8 580

A1HP600 4" Ø 64 0 ... 5.8 580

A25P1K5 1"

A32P1K5 1¼" Ø 38 0 ... 14.5 1450

A40P1K5 1 ½" Ø 38 0 ... 14.5 1450

A50P1K5 2" Ø 48 0 ... 8.7 1450

A65P1K5 2 ½" Ø 48 0 ... 8.7 1450

A80P1K5 3" Ø 64 0 ... 5.8 1450

A90P1K5 3 ½" Ø 64 0 ... 5.8 1450

A1HP1K5 4" Ø 64 0 ... 5.8 1450

Flange to ASME B16.5,

Capillary

Flange to ASME B16.5,

Capillary

Flange to ASME B16.5,

Capillary

Flange to ASME B16.5,

Capillary

Ø 30

Ø 30

Ø 30

Ø 30

0 ... 36.3 145

482 °F

0 ... 36.3 290

482 °F

0 ... 36.3 580

482 °F

0 ... 36.3 1450

482 °F

DRM-638

PN 06

DRM-638

PN 16

* Note: Threaded diaphragm seal only available with PAD-G/A. For PAD-D only flange, clamp connections or union nut are possible

20

F25P06 DN25

F32P06 DN32 Ø 30 0 ... 14.5 87

F40P06 DN40 Ø 38 0 ... 14.5 87

F50P06 DN50 Ø 48 0 ... 8.7 87

F65P06 DN65 Ø 64 0 ... 8.7 87

F80P06 DN80 Ø 64 0 ... 5.8 87

F1HP06 DN100 Ø 64 0 ... 5.8 87

F25P16 DN25

F32P16 DN32 Ø 38 0 ... 14.5 232

F40P16 DN40 Ø 38 0 ... 14.5 232

F50P16 DN50 Ø 48 0 ... 8.7 232

F65P16 DN65 Ø 48 0 ... 8.7 232

F80P16 DN80 Ø 64 0 ... 5.8 232

F1HP16 DN100 Ø 64 0 ... 5.8 232

Flange to EN1092-1,

Capillary

Flange to EN1092-1,

Capillary

www.koboldusa.com

Ø 24

482 °F

Ø 24

482 °F

0 ... 36.3 87

0 ... 36.3 232

No responsibility taken for errors;

subject to change without prior notice.

Page 21

Heavy Duty Differential Pressure Transmitter Model PAD

Diaphragm Seal Models (Direct or Remote Assembly)

(Standard device without additional options (e.g. coatings, special materials etc.).

For dimensions/technical data, see DRM data sheet. Accuracy: 0.075% of calibrated span + influence of diaphragm seal).

Model DRM Size Code Size Note

DRM-638

PN 40

DRM-640

150 lbs

DRM-640

300 lbs

DRM-640

600 lbs

DRM-640

1500 lbs

* Note: Threaded diaphragm seal only available with PAD-G/A. For PAD-D only flange, clamp connections or union nut are possible

F25P40 DN 25

F32P40 DN 32 Ø 38 0 ... 14.5 580

F40P40 DN 40 Ø 38 0 ... 14.5 580

F50P40 DN 50 Ø 48 0 ... 8.7 580

F65P40 DN 65 Ø 48 0 ... 8.7 580

F80P40 DN 80 Ø 64 0 ... 5.8 580

F1HP40 DN 100 Ø 64 0 ... 5.8 580

A25P150 1"

A32P150 1¼" Ø 38 0 ... 14.5 145

A40P150 1 ½" Ø 38 0 ... 14.5 145

A50P150 2" Ø 48 0 ... 8.7 145

A63P150 2 ½" Ø 48 0 ... 8.7 145

A75P150 3" Ø 64 0 ... 5.8 145

A85P150 3 ½" Ø 64 0 ... 5.8 145

A1HP150 4" Ø 64 0 ... 5.8 145

A25P300 1"

A32P300 1¼" Ø 38 0 ... 14.5 290

A40P300 1 ½" Ø 38 0 ... 14.5 290

A50P300 2" Ø 48 0 ... 8.7 290

A63P300 2 ½" Ø 48 0 ... 8.7 290

A75P300 3" Ø 64 0 ... 5.8 290

A85P300 3 ½" Ø 64 0 ... 5.8 290

A1HP300 4" Ø 64 0 ... 5.8 290

A25P600 1"

A32P600 1¼" Ø 38 0 ... 14.5 580

A40P600 1 ½" Ø 38 0 ... 14.5 580

A50P600 2" Ø 48 0 ... 8.7 580

A63P600 2 ½" Ø 48 0 ...8.7 580

A75P600 3" Ø 64 0 ... 5.8 580

A85P600 3 ½" Ø 64 0 ... 5.8 580

A1HP600 4" Ø 64 0 ... 5.8 580

A25P1K5 1"

A32P1K5 1¼" Ø 38 0 ... 14.5 1450

A40P1K5 1 ½" Ø 38 0 ... 14.5 1450

A50P1K5 2" Ø 48 0 ... 8.7 1450

A63P1K5 2 ½" Ø 48 0 ... 8.7 1450

A75P1K5 3" Ø 64 0 ... 5.8 1450

A1HP1K5 4" Ø 64 0 ... 5.8 1450

Flange to EN1092-1,

Capillary

Flange to ASME B16.5,

Capillary

Flange to ASME B16.5,

Capillary

Flange to ASME B16.5,

Capillary

Flange to ASME B16.5,

Capillary

Ø Diaphragm

(mm)

Ø 30

Ø 30

Ø 30

Ø 30

Ø 30

Max. Media

Temperature

482 °F

482 °F

482 °F

482 °F

482 °F

Min. Span

0 ... 36.3 580

0 ... 36.3 145

0 ... 36.3 290

0 ... 36.3 580

0 ... 36.3 1450

(PSIG)

Max. Span

(PSIG)

No responsibility taken for errors;

subject to change without prior notice.

www.koboldusa.com

21

Page 22

Heavy Duty Differential Pressure Transmitter Model PAD

Diaphragm Seal Models (Direct or Remote Assembly)

(Standard device without additional options (e.g. coatings, special materials etc.).

For dimensions/technical data, see DRM data sheet. Accuracy: 0.075% of calibrated span + influence of diaphragm seal).

Model DRM Size Code Size Note

DRM 501

ISO Sterile

DRM 503

Clamp

ISO 2852

* Note: Threaded diaphragm seal only available with PAD-G/A. For PAD-D only flange, clamp connections or union nut are possible

D15 DN 15

D20

D25 DN 25 Inline 0 ... 14.5 580

D32 DN 32 Inline 0 ... 14.5 580

D40 DN 40 Inline 0 ... 8.7 580

D50 DN 50 Inline 0 ... 8.7 580

D15

D20 DN 20 Inline 0 ... 23.2 580

D25 DN 25 Inline 0 ... 8.7 580

D32 DN 32 Inline 0 ... 8.7 580

D40 DN 40 Inline 0 ... 5.8 580

D50 DN 50 Inline 0 ... 5.8 580

DN 20

Inline, Capillary

DN 15

Inline, Capillary

Ø Diaphragm

(mm)

Inline

Inline 0 ... 36.3 580

Inline

Max. Media

Temperature

176 °F

176 °F

Min. Span

(PSIG)

0 ... 36.3 580

0 ... 23.2 580

Max. Span

(PSIG)

22

www.koboldusa.com

No responsibility taken for errors;

subject to change without prior notice.

Loading...

Loading...