Page 1

KOBOLD OME FLOWMETER

User Instructions

USA

1801 Parkway View Drive

Pittsburgh, PA 15205

PH 412-788-2830

www.koboldusa.com

Canada

9A Aviation

Point Claire, QC H9R 4Z2

PH 514-428-8090

OME_manual_10-16-2002

Page 2

Table of Contents

1.0 General .........................................................................................................1

2.0 Specifications .............................................................................................. 1

3.0 Installation instructions................................................................................. 4

4.0 Maintenance ................................................................................................ 5

5.0 Arrival of Damaged Equipment ................................................................. 5

6.0 Need Help With Your OME ......................................................................... 5

List of Diagrams

Diagram 2.3 Pressure Loss Data ........................................................... 2

Diagram 2.4 Dimensions ......................................................................... 3

Diagram 2.5 Electrical connections ......................................................... 3

List of Tables

Table 2.1 Technical Data ........................................................................1

Table 2.2 Model Specific Data .............................................................. 2

Page 3

OME

KOBOLD OME FLOWMETER

User Instructions

CAUTION: For safety reasons, please read the cautionary information located at

the end of the manual, before attempting installation.

1.0 General

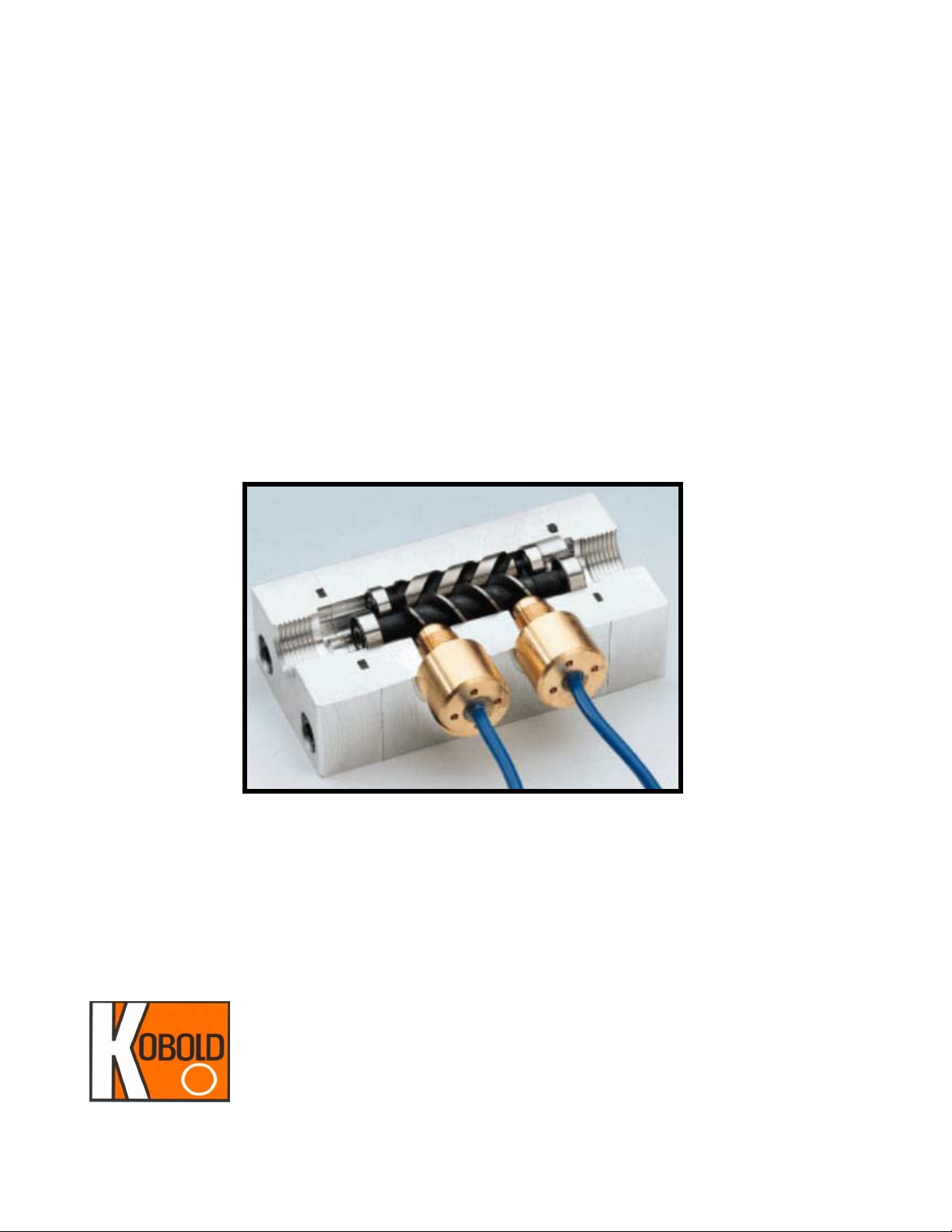

The KOBOLD OME helical gear positive displacement flowmeter is designed to measure

the volume flow rate of clean, non-abrasive, lubricating liquids whose viscosities lie in the

range of 1 to 5000 cSt. The measuring principle of this fowmeter can be described as follows:.

1. As the fluid to be measured is forced through the flowmeter by system

pressure, it causes the helical spindles (M) to rotate.

2. Each rotation of the spindle equates to an exact volume

of liquid which has passed through the flowmeter.

3. Permanent magnets are imbedded in the spindles; as

the spindle rotates, these magnets pass by a magnetic

pickup.

4. The pickup (I) generates a voltage pulse each time a magnet passes by.

These pulses can then be transmitted to a data acquisition device (A) where

the pulse frequency is translated into a rate of flow.

The helical gear design provides quiet operation, low pressure loss and few pulsations.

2.0 Specifications

Table 2.1; Technical Data

Operating Principle: Positive Displacement, helical gears

Dimensions: See Diagram 2.6

Range: 0.05 to 26.4 GPM

Accuracy: ± 0.3% of flow rate

Temperature range: -20° F to 212° F

Maximum operating Pressure

NPT: 580 PSIG

150 pound flange: 215 PSIG

300 pound flange: 560 PSIG

Max. differential: 75 PSIG

Filtration requirements: 300 micron (50 mesh) max.

FM Rev 10/02

Page 4

OME 2

Wetted parts:

Housing ...... Aluminum Gears ...... Nitrided steel

Bearings ...... Chrome steel Seals ...... FKM

Flanges ...... Carbon Steel

Sensor Data:

Power Supply

PNP: 10-30 VDC 50 mA Max.

NAMUR: 8.2 VDC ±0.1 VDC

Frequency Range: 0 to 5000 Hz.

Table 2.2; Model Specific Data

Table 2.23; Pressure Loss Diagram

FM Rev 10/02

Page 5

3OME

1

4

3

1

3

Diagram 2.4,Dimensions

Diagram 2.5 Electrical Connections

PNP Sensor NAMUR Sensor

+ V Supply

- V

Supply

1 = Brown

3 = Blue

4 = Black

Z

FM Rev 10/02

+ V supply (+8.2 VDC)

- V (Ri=1k Ohm)

Page 6

OME 4

3.0 Installation Instructions

CAUTION: For safety reasons, please read the cautionary information located at

the end of the manual, before attempting installation.

The following practices and guidelines should be applied when installing your flow

sensor. Proper installation will ensure the highest possible degree of measuring

accuracy and will maximize service life.

Orientation in the piping system: The flow sensor can be mounted in any orientation in

the piping system. There are no requirements for minimum straight piping runs at the

inlet or outlet of this unit.

Piping Alignment: The piping into and out of the flow sensor must be properly plumbed

and aligned such that no torsional or tensile stresses are placed on the sensor after it is

fastened into place.

Piping Supports: The piping at the inlet and outlet of the flow sensor must be rigidly

supported in order to prevent excessive piping vibration.

Flow Direction: The unit is capable of bi-directional flow. However; the sensor should be

mounted in the system such that during normal operation, flow moves in the direction of

the solid arrow on the nameplate.

System Pressure:The flow sensor requires a minimum back-pressure of 1.5 PSIG at

the sensor outlet. Under no circumstances should fluids be allowed the free flow

out of the sensor outlet. This will result in excessive bearing wear and reduce the

bearing service life.

Filtration Requirements: Solid particulates in the flow medium can result in damage to

the internal gears and failure of the sensor. Filtration of solids with a filter equivalent to

#50 mesh (300 micron) is required.

Over Pressure Protection: If the flow sensor becomes blocked or seized, system flow

will be stopped completely. This could cause pressure surges in the system resulting in

FM Rev 10/02

Page 7

5OME

damage to system components. For this reason it is recommended that a pressure relief

valve be installed upstream of the flowmeter.

4.0 Maintenance

Due to its construction, a positive displacement flowmeter, such as the OME, is nearly

maintenance-free.

Please note the filtration requirements in the specification section. Make sure the filter is

kept in proper functioning condition. The frequency of filter replacement and maintenance will depend on the level of cleanliness of the metered luquid.

The only wear component in the OME are the gear teeth, which will wear in time. The

rate of wear depends on the duration of operation and the abrasion/lubrication properties

of the measured liquid. It is recommended that a periodic check of the meter’s calibration

be conducted on a yearly basis - using a bucket, stopwatch and a reliable, calibrated

weigh scale.

5.0 Arrival of Damaged Equipment

Your instrument was inspected prior to shipment and found to be defect-free. If damage

is visible on the unit, we advise that you carefully inspect the packing in which it was

delivered. If damage is visible, notify your local carrier at once, since the carrier is liable

for a replacement under these circumstances. If your claim is refused, please contact

KOBOLD Instruments for further advisement.

6.0 Need help with your OME?

Call one of our friendly engineers at 412-788-2830.

FM Rev 10/02

Page 8

7OME

Caution

PLEASE READ THE FOLLOWING GENERAL FLOW METER/ MONITOR

WARNINGS BEFORE ATTEMPTING INSTALLATION OF YOUR NEW

DEVICE. FAILURE TO HEED THE INFORMATION HEREIN MAY

RESULT IN EQUIPMENT FAILURE AND POSSIBLE SUBSEQUENT

PERSONAL INJURY.

FM Rev 10/02

Page 9

OME 8

• User's Responsibility for Safety: KOBOLD manufactures a wide range of

process sensors and technologies. While each of these technologies are

designed to operate in a wide variety of applications, it is the user's

responsibility to select a technology that is appropriate for the application,

to install it per these installation instructions, to perform tests of the

installed system, and to maintain all components. The failure to do so could

result in property damage or serious injury.

• Proper Installation and Handling: Use a proper sealant with all

installations. Never overtighten fittings. Always check for leaks prior to

system start-up.

• Wiring and Electrical: Depending on the model, a supply voltage of

VDC (10-30 VDC)

or

8.2 VDC (NAMUR)

is used to power the OME. The

24

sensor systems should never exceed this rating. Electrical wiring of the

sensor should be performed in accordance with all applicable national,

state, and local codes.

• Temperature and Pressure: The OME is designed for use in application

temperatures from -20 to 212°F, and for use at pressures up to 580 PSIG

(215 PSIG with 150# flange, 560 PSIG with 300# flange). Operation

outside these limitations will cause damage to the unit and possible

personnal injury.

• Material Compatibility: Make sure that the wetted parts listed in Table 2.1

are chemically compatible with the application liquids. While the electronics

cable connections are rated NEMA 4 when installed properly,they are not

designed to be immersed. The OME should be mounted in such a way that

the housing does not normally come into continuous contact with fluid.

• Flammable, Explosive and Hazardous Applications: The OME is not of

an explosion proof design and should not be used in areas where an

explosion proof design is required.

• Make a Fail-Safe System: Design a fail-safe system that accommodates

the possibility of switch or power failure as well as operator error. In critical

applications, KOBOLD recommends the use of redundant backup systems

and alarms in addition to the primary system.

FM Rev 10/02

Loading...

Loading...