Kobold NWS-5225 Installation & Operation Instructions

KOBOLD Instruments, Inc. 1801 Parkway View Drive, Pittsburgh PA 15205

p

Telephone: (412) 788-2830 · FAX: (412) 788-4890 www.koboldusa.com

Specifications

Power Requirements:

Two Wire Switching: 24 to 240 VAC/VDC 50-60 Hz.

Three Wire Switching: 24 VDC

SPDT Relay: 24 VDC or 110 VAC depending

on model number

Solid State Switch Characteristics:

Max. Current: 500 mA.

Min. Current: 7.5 mA.

Leakage Current: 3 mA.

Voltage Drop: 2.5 Volts @ 500 mA.

5.0 Volts @ 20 mA.

10 Volts @ 7.5 mA.

Installation

In order to ensure a leak tight seal, a thread sealant such as

Teflon tape should be used on the probe threads prior to installation.

Series NWS Fork Level switch

Installation/O

Description

KOBOLD’s Series NWS is a compact, vibrating

fork level switch which is suited for use with

non-viscous and viscous liquids as well as

many types of fine granular solids. The switch

employs an forked probe which vibrates at a

resonant frequency. When the probe is

immersed in a medium, the resonant frequency

is dampened. This frequency shift is sensed by

a detecting circuit and results in activation of a

solid state switch or SPDT relay depending on

the model.The Series NWS can be configured

either as a two wire or three wire controller and

is switchable from a normally open to normally

closed (wet-on or dry-on) switch function. Its

solid state design uses no moving parts in the

sensor or switch portions, making the switch

exceptionally reliable.

SPDT Relay Characteristics: 10A @ 110 VAC,

Switching Delay:

Wet to Dry: 500 mSec.

Dry to Wet: 50 mSec.

Fluid Temperature Range: -40 to 270°F

Max. Ambient Temp: 160°F with 200°F Fluid

Max. Operating Pressure: 1000 PSIG @-40 to 120°F

Electrical Protection: NEMA 4/IP 65

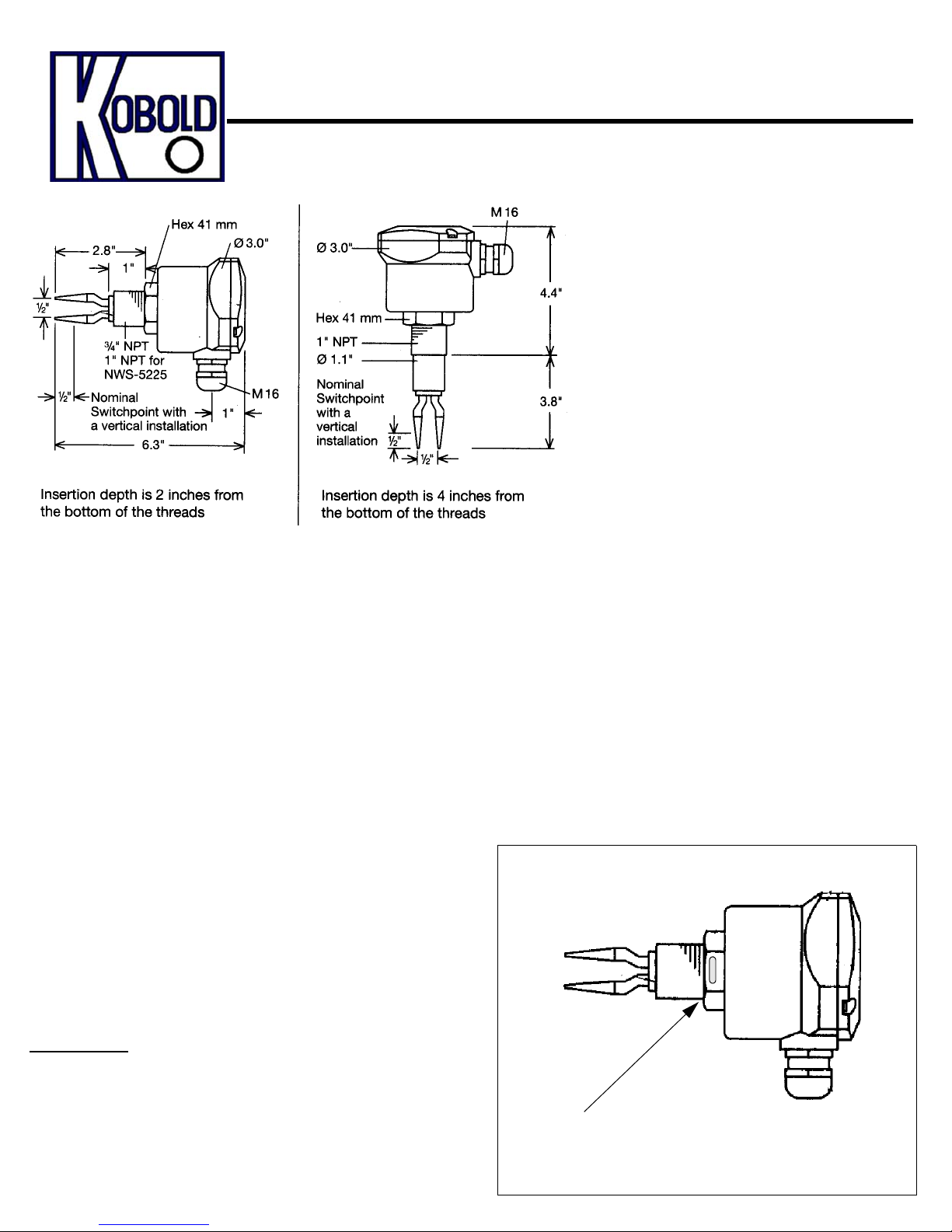

Fig. 2: Probe Orientation

eration Instructions

5A resistsive/2A inductive

@ 24 VDC

120°F with 270°F Fluid

760 PSIG @ 120 to 270°F

The NWS should be installed with the cable penetration facing downward. This will

prevent water from settling into the cable gland thereby minimizing leakage into

the electronics. After the unit is installed in its fitting the housing can be roatated to

achieve the proper cable gland orientation

Special Note:

To ensure reliable operation, the series NWS should be

installed in the vessel with the forks of the sensing probe in the

three o’clock and nine o’clock position. The Installation nut on

the NWS has a slotted positioning guide which can be used to

ensure that the probe is installed in the proper position (See

Fig. 2).

The guide slot on the probe installation

nut should be in the 12 O’clock or 6 O’clock

position to ensure that the probe is properly

oriented inside the tank

Electrical Connections

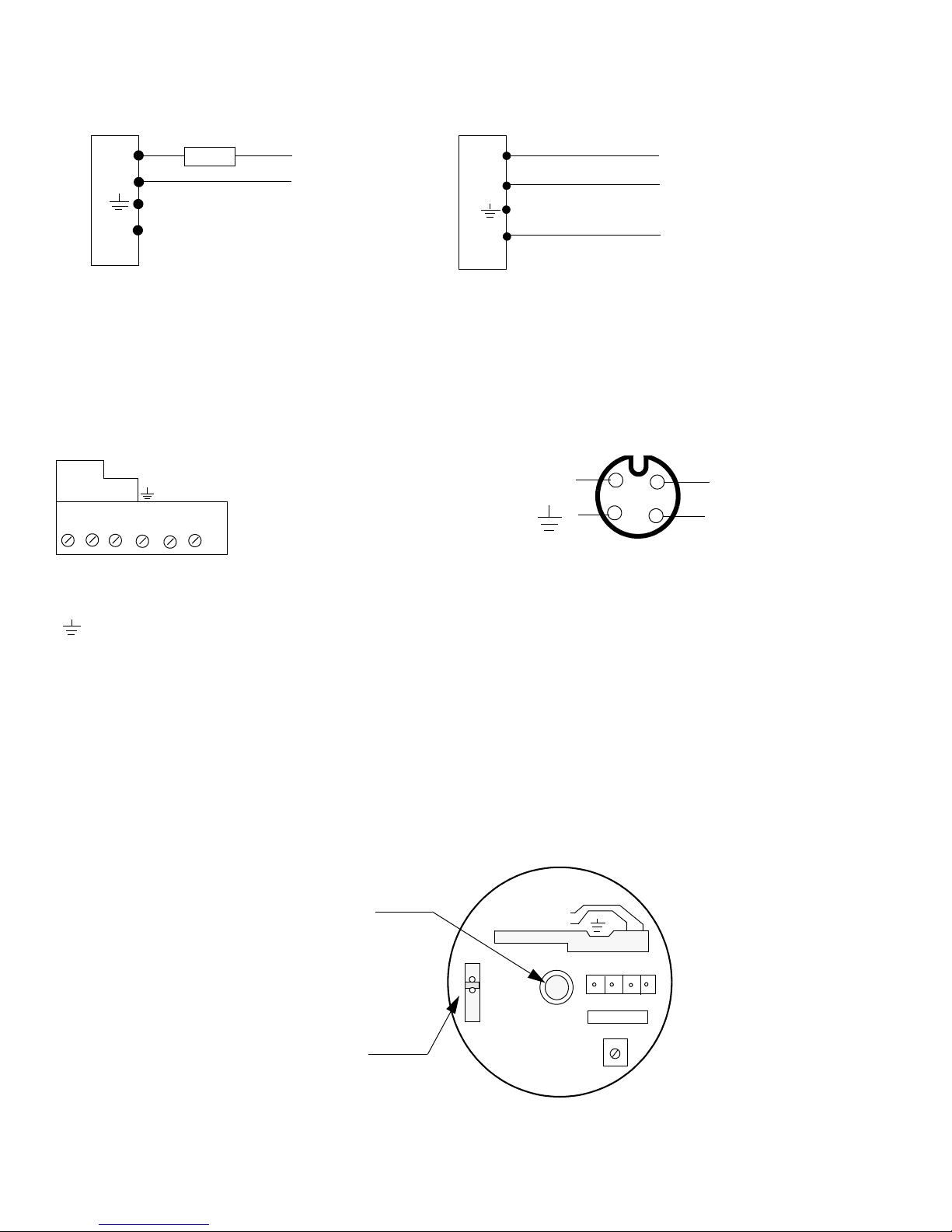

Fig. 3 Two Wire Connection

1

+VE

-VE

A

2

3

4

Load

24-240 VAC/VDC

Neut.

Line

The two wire connection switches line

voltage to the load device when switch

is activated. The load device is connected

in series with the NWS.

Fig. 5 Wiring for Relay Output ( R01 & R03)

V-

NC

C

NO

V+

Fig. 4 Three Wire Connection

+VE

-VE

1

A

2

3

4

Output

+

24 VDC In

-

The three wire configuration switches

24 VDC to the output when the NWS is

activated

Fig. 6 Plug Connector Pinout (option -M12) 24 VDC only

+VE

1

2

4

3

A

-VE

NO = Normally Open Contact

NC = Normally Closed Contact

= Safety Ground

V+

= Power, 110 VAC or 24 VDC

V-

depending on model

Operation

Status Indicator

Flashing: Switch not activated (open switch)

Steady: Switch activated (closed switch)

Logic Selector Switch

for normally open or

normally closed operation

Color Codes on Mating Connector

White = 1 = A

Blue = 2 = +VE

Black = 3 = Ground

Brown = 4 = -VE

LOAD/CHARGE/LAST

AC/DC 24-240 V

DRY-ON

VIOE

LEER

WET-ON

PLEIN

VOLL

-VE

+VE A

4

213

Rev. 10/05/01

Loading...

Loading...