Page 1

Operating Instructions

for

Level Switch

Tuning Fork Principal

Model: NWS

Page 2

NWS

Page 2 NWS K06/0214

1. Contents

1. Contents ........................................................................................................ 2

2. Note .............................................................................................................. 3

3. Instrument Inspection .................................................................................... 3

4. Regulation Use .............................................................................................. 3

5. Operating Principle ........................................................................................ 4

6. Use in Hazardous Areas (NWS-2E) .............................................................. 4

6.1 Device function .................................................................................... 4

6.2 Commissioning/Installation .................................................................. 5

6.3 Designation .......................................................................................... 5

6.4 Temperature resistance ....................................................................... 6

7. Mechanical Connection ................................................................................. 6

8. Electrical Connection .................................................................................... 7

8.1 NWS-...200 .......................................................................................... 7

8.2 NWS-...23/24; NWS-...2W/2H; NWS-...2E (ATEX certification) ........... 9

9. Settings ....................................................................................................... 10

9.1 Settings for NWS-...200.. ................................................................... 10

9.2 Settings for NWS-...23/24/2W/2H and NWS-2E ................................ 12

10.Technical Information .................................................................................. 15

11.Order Codes ............................................................................................... 17

12.Service and Maintenance ............................................................................ 17

13.Trouble Shooting ......................................................................................... 17

14.Recommended Spare Parts ........................................................................ 18

15.Disposal ...................................................................................................... 18

16.Dimensions ................................................................................................. 19

17.Declaration of Conformance ....................................................................... 21

18.Supplement to the EC-Type Examination certificate ................................... 22

19.IECEx Certificate ......................................................................................... 25

Manufactured and sold by:

Kobold Messring GmbH

Nordring 22-24

D-65719 Hofheim/Germany

Tel.: +49(0)6192-2990

Fax: +49(0)6192-23398

E-mail: info.de@kobold.com

Internet: www.kobold.com

Page 3

NWS

NWS K06/0214 Page 3

2. Note

Please read these operating instructions before unpacking and putting the unit

into operation. Follow the instructions precisely as described herein.

The devices are only to be used, maintained and serviced by persons familiar

with these operating instructions and in accordance with local regulations

applying to Health & Safety and prevention of accidents.

When used in machines, the measuring unit should be used only when the

machines fulfil the EWG-machine guidelines.

3. Instrument Inspection

Instruments are inspected before shipping and sent out in perfect condition.

Should damage to a device be visible, we recommend a thorough inspection of

the delivery packaging. In case of damage, please inform your parcel service /

forwarding agent immediately, since they are responsible for damages during

transit.

Scope of delivery:

The standard delivery includes:

Level Switch model: NWS

Operating instructions

4. Regulation Use

Kobold model NWS Liquid-Level Switches are designed to be wired as 2-wire or

3-wire switches and can be universally installed in any position in containers and

piping. They can be used in many types of liquids including oils, water, paints and

varnishes, sauces, milk, carbonated liquids and foamy oils. The liquid may have a

maximum viscosity of 5000 cSt. At higher viscosities, the response time may

increase. NWS Liquid-Level Switches are ideally suited for use in hygienic and

sterile applications and designed to withstand CIP cleaning methods at temperatures up to 150 °C.

Any use of the device which exceeds the manufacturer’s specification may

invalidate its warranty. Therefore any resulting damage is not the responsibility of

the manufacturer. The user assumes all risk for such usage.

Page 4

NWS

Page 4 NWS K06/0214

5. Operating Principle

The KOBOLD liquid level switch NWS is designed as a 2 and 3-wire switch and

can be universally used in vessels and pipelines. The NWS operates on the

tuning fork principle in air at resonance frequency. A piezoelectric crystal is used

for excitation of oscillations and for monitoring the actual oscillation frequency.

When the fork is immersed in liquid, the frequency changes: this change is

detected electronically and the output signal is changed. The NWS operates as a

two-wire switch in series with the load. The simple electronic switch is operated

by the liquid. The NWS can also be connected to a PLC through a third terminal.

Special Features:

The NWS has a switch status indicator with LED, which can be seen continuously

through a lens in the cover. The LED flashes approximately once every second,

when the NWS has switched off and goes onto a permanent light, when the NWS

is switched on. The LED is a visible confirmation that the NWS is working

correctly and that the condition of the wet side is correctly indicated. With a

selector switch the NWS can be set either as an upper limiter or as a lower

limiter.

6. Use in Hazardous Areas (NWS-2E)

6.1 Device function

The intrinsically safe NAMUR oscillating fork sensor is used to detect the fill

levels of combustible and non-combustible liquids. The sensor is supplied with

current from a switching amplifier with an intrinsically safe output circuit in

accordance with the NAMUR specification and behaves accordingly when the

oscillating fork is dampened by liquid or can oscillate freely. The sensor can be

used in all zones in gaseous hazardous areas.

Page 5

NWS

NWS K06/0214 Page 5

6.2 Commissioning/Installation

The devices may be installed in zones 0, 1 and 2. The intrinsically safe

circuits must be installed (by specialists) in conformance with the

applicable installation requirements (certification document of installer,

protected routing of the intrinsically safe circuits, etc.).

The devices are constructed in accordance with protection type IP 65. If

applicable, they must be protected against adverse environmental

conditions.

The EU model test certificates must be complied with. Any “special

regulations” contained in them must be followed.

The device should only be used for its intended use.

The connection with the associated and/or intrinsically safe equipment

must be separately checked.

The sensors must be grounded to discharge accumulated electrostatic

charge.

At an ambient temperature area of - 5 .. + 70 °C the connected electrical

cable may be mechanically moved. Furthermore at an ambient

temperature area of - 20 .. + 70 °C the electrical cable must be mounted in

a fixed and static manner.

The tuning fork should be protected against external hits.

The connection area of the plug connection version and the connection

cable should be protected against electrostatic charges during its use in

zone 0.

The sensors are by default produced with 1.5 m long cable or with a plug.

In this case a Ci of 8 pF should be taken into account, the internal

inductance is negligible.

o For longer cable length an additional Lc value of 0.14 nF m

-1

and LI

value of 0,65 µH m

-1

per each meter of supplied cable should be

considered.

6.3 Designation

Model: NWS***2E* ****

II 1 G Ex ia IIC T6 Ga

BVS 03 ATEX E 119

IECEx BVS 13.0004

Identification number: 0158

Production-No.: SN: E999999 (consecutively numbered)

Page 6

NWS

Page 6 NWS K06/0214

6.4 Temperature resistance

The values for ambient temperatures ranging from -20 °C up to the values

indicated in the following table apply to this sensor, depending on the max.

temperature of the oscillating forks in the sensor:

Ambient temperature 70 °C 70 °C

Medium temperature 75 °C 90 °C

Temperature class T6 T5

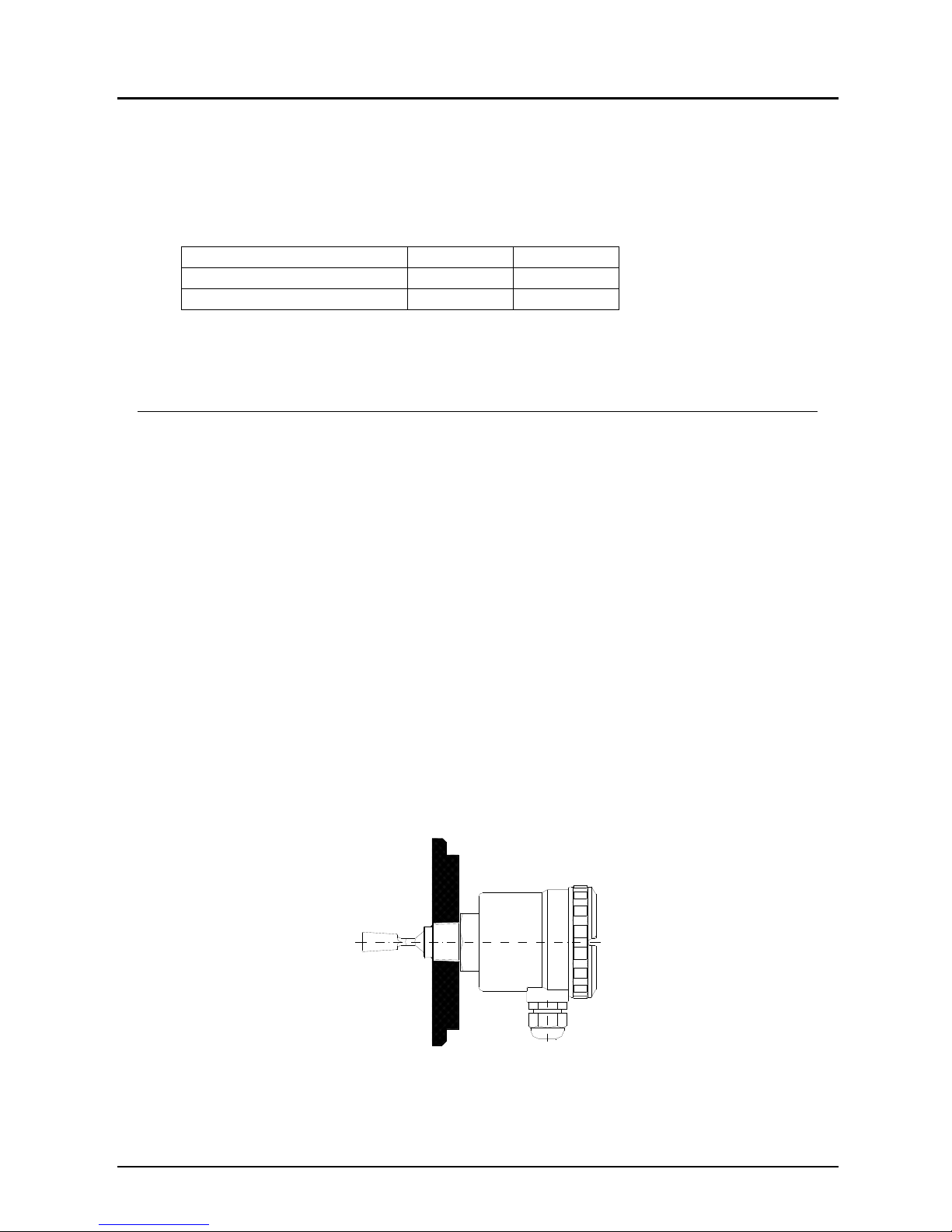

7. Mechanical Connection

During installation and removal, recognised and applicable engineering practices

and regulations shall be observed. When working on electrical and pneumatic

plants, the special safety requirements shall be observed.

The NWS switch can be installed in containers or piping by screwing it into a

threaded mounting flange or other type of mounting device. The threaded connection must be sealed with Teflon (PTFE) tape. Be sure to turn the switch at the

hexagonal drive; do not install the switch by turning it at the housing.

After installation, the NWS-...200 can be rotated up to 330° to locate the M16

cable connection (supplied with the device) in a suitable position.

If the switch is installed in a horizontal position, the tuning fork gap should be

positioned vertically so that the liquid can drain from it. If the liquid being monitored is of high viscosity, the switch should be installed so that it extends the

maximum distance into the container or piping in order to prevent the thick liquid

from sticking and accumulating between the fork and the container or pipe wall. If

the switch is installed in piping, the tuning fork gap should be positioned so that it

is parallel to the pipe axis.

Page 7

NWS

NWS K06/0214 Page 7

8. Electrical Connection

Attention! Be sure that the supply voltage of your system is the

same as that specified on the device nameplate. Make sure that the

electrical supply lines are de-energised when connecting the device!

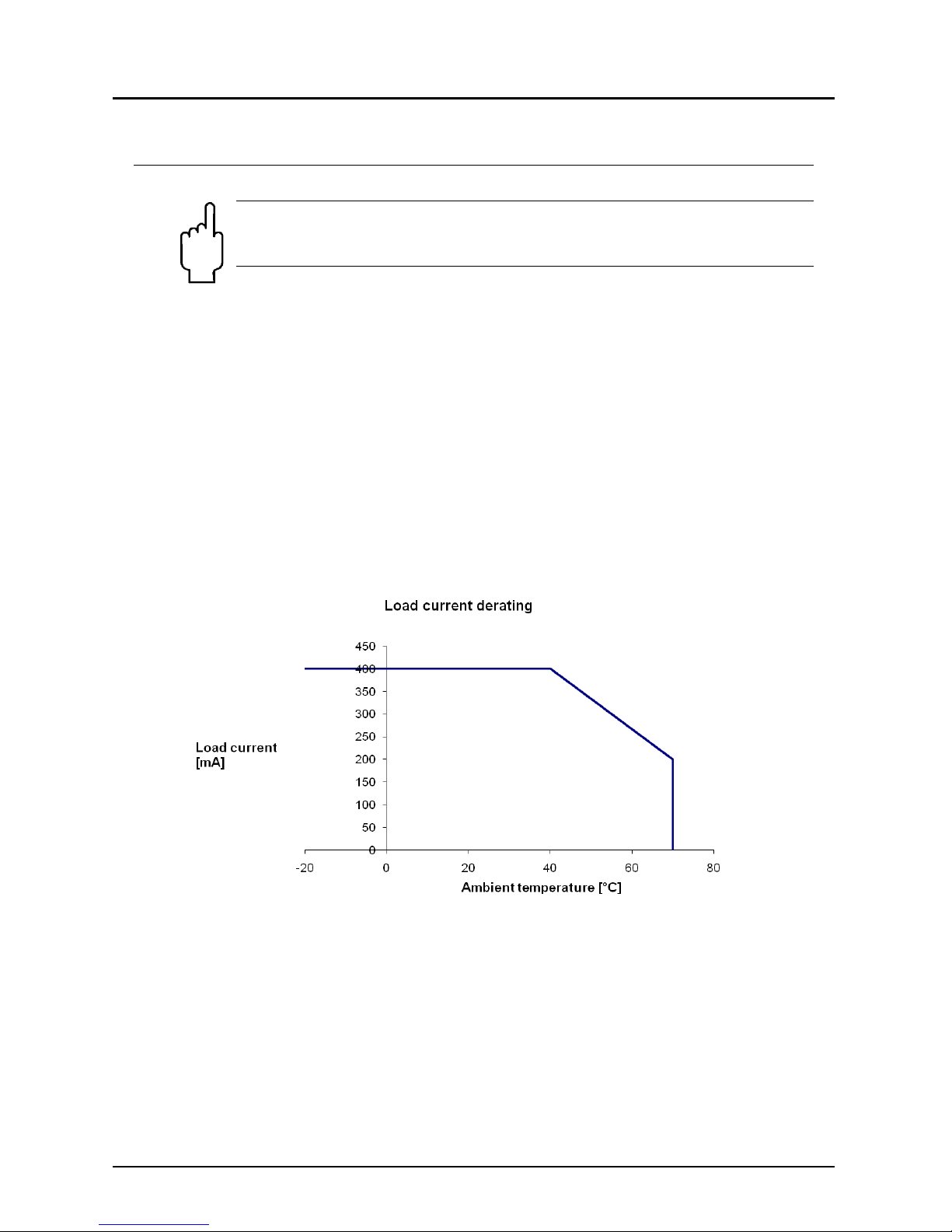

8.1 NWS-...200

Series wiring with a 2-wire connection

Please note:

The switch must always be operated in series with a load.

The switch must be grounded at terminal 1.

The switch draws a continuous operating current of less than 3.5 mA (even

when it is "off"). For this reason, it cannot be used for loads that do not allow

an “off” current (such as for gas discharge lamps).

The maximum load current for the switch is 500 mA. The user must provide

suitable protective measures to ensure that this load limit is not exceeded.

Page 8

NWS

Page 8 NWS K06/0214

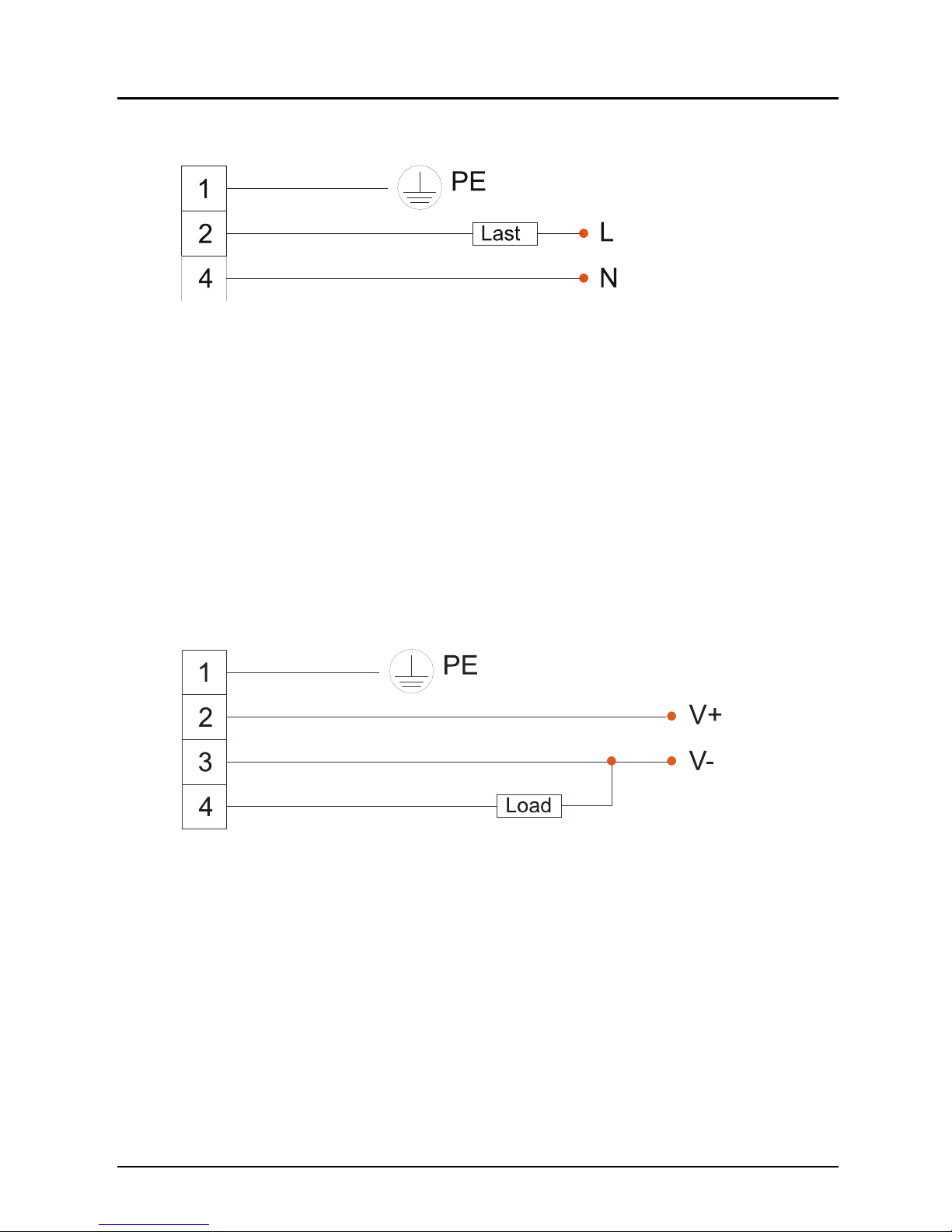

Wiring diagram: 2-wire 24-240V

AC/DC

, series load, I

max

≤ 400mA

PLC connection with 3-wire connection

Please note:

An integral series resistance is used in the 3-wire circuit to generate a

PLC-compliant voltage signal.

The signal can be picked up at terminal 4.

PLC programming devices or computers from various manufacturers will have

different "OFF" threshold voltages. If you should have problems with this setting, please contact us for assistance.

Wiring diagram: 3-wire, VS = 24 VDC,

output PNP: U

HIGH

~ 20 V; U

LOW

~ 3.5 V; I

max

≤ 400 mA

Page 9

NWS

NWS K06/0214 Page 9

8.2 NWS-...23/24; NWS-...2W/2H; NWS-...2E (ATEX certification)

Make sure that the electrical supply lines are de-energised.

Connect the device using the M12x1 plug or a connection cable as shown in

the wiring diagram below.

Matching connectors with different cable lengths are optionally available.

Make sure that the installation is properly performed and that the IP protection

level is maintained.

Wiring diagram NWS-...23/24 (24 VDC) Wiring diagram NWS-...2W/2H

1

2

3

4

+Vs (n.o.)

Switch

Out

GND (n.o.)

GND (n.c.)

+Vs (n.c.)

Wiring diagram NWS-2ES.. (NAMUR, ATEX)

1

2

3

4

+S (n.o.)

+S

(n.c.)

E

-S

Cable pin assignment

Strand colour NWS-...23/24 NWS-...2W/2H

brown +Vs(n.o.) / GND +Vs

blue GND / +Vs (n.c.) GND

black Switch Out Switch Out

Lead-/Pinnumber NWS-...2EF

1 +S (n.o.)

2 ground

3 -S

4 +S (n.c.)

1

2

3

4

+Vs

Switch

Out

GND

Page 10

NWS

Page 10 NWS K06/0214

9. Settings

9.1 Settings for NWS-...200..

9.1.1 Signalling the operating status

The NWS has an output status indicator with an LED monitor that can be viewed

continuously through a lense in the cover. The LED flashes approximately once

every second when the NWS is off. It is continuously illuminated when the NWS

is switched on. The LED provides visual confirmation that the NWS is operating

correctly and that the status of the wet side is correctly displayed. With its operating mode switch, the NWS can be set to operate as either an N/C contact or an

N/O contact.

9.1.2 Operating mode selector switch

The operating mode switch is positioned on the circuit board on the right about

the LED. If the switch is operated as an N/C contact (upper limiter), the operating

mode must be set to DRY-ON, in order to obtain the maximum fail-safe

behaviour. The device completes the circuit in the dry state (empty state) so that

a fault at the device or in the wiring results in a voltage drop that causes an alarm

to be triggered (break circuit). Conversely, if the switch is to WET-ON, the device

operates as an N/O contact (lower limiter) in fail-safe mode, in which case the

fork is normally immersed in liquid.

Page 11

NWS

NWS K06/0214 Page 11

9.1.3 Calibration mode

Each appliance is adjusted by the

factory to record fluids with density 1,0

kg/l (water). It is not usually necessary

to alter this pre-adjustment. In extreme

situations, however, such as with very

light fluids at high temperatures or

highly viscous fluids, which produce a

significantly extended reaction time from

dry to wet, it can be advantageous to

alter the pre-adjustment. In order to

attain the calibration mode the Setup

button must be activated and held, then

the supply voltage must be switched on.

After approximately 1 second the LED

goes on, after 2 seconds the LED goes

out, then let go of the Setup button – the

appliance stays now in the main menu

of the calibration mode.

There is a choice of options in the main menu - Switchpoint Calibration,

Hysteresis Level and LED Mode. The LED indicates the selected option:

Switchpoint Calibration: LED flashes briefly 1x, then LED 2 seconds off.

Hysteresis Level: LED flashes briefly 2x, then LED 2 seconds off.

LED Mode: LED flashes briefly 3x, then LED 2 seconds off.

The option points are repeated in an infinite loop.

In order to get access to an option the Setup button must be activated briefly

when the LED has signalled the requested option point.

Switchpoint Calibration:

The "Switchpoint Calibration Mode" is signalled by: LED 1x briefly off, then LED 2

seconds on.

Dip the tuning fork as far as the required switchpoint (1/2 – 2/3 of the fork length)

in the medium and activate the Setup button. The calibration is made.

A successful calibration is signalled by the LED flashing quickly three times.

Hysteresis and LED Mode are set back to default! After calibration the switch

back to the main menu takes place.

Hysteresis Level:

The "Hysteresis Level Mode" is signalled by: LED 2x briefly off, then LED 2

seconds on. Briefly activate the Setup button to get to the submenu.

Hysteresis Level 1(approx. 1-1.5mm): LED flashes briefly 1x, then LED 2

seconds off.

Hysteresis Level 2 (approx. 3-4.5mm, Standard): LED flashes briefly 2x, then

LED 2 seconds off.

Hysteresis Level 3 (approx. 5-7.5mm): LED flashes briefly 3x, then LED 2

seconds off.

Page 12

NWS

Page 12 NWS K06/0214

The choice of options is repeated in an infinite loop. To select an Hysteresis

Level, the Setup button must be activated after the flashing of the relevant LED.

Three quick flashes of the LED signal that an option has been selected, then the

switch back to the main menu is made.

LED Mode:

The "LED Mode" is signalled by: LED briefly 3x off, then LED 2 seconds on.

Briefly activate the Setup button in order to attain the option menu LED Mode.

LED Mode 1 (Standard): LED flashes briefly 1x, then LED 2 seconds off. LED

shows the status of the switch output

LED Mode 2: LED flashes briefly 2x, then LED 2 seconds off. LED indicates

whether the tuning fork is wetted or not

The choice of options is repeated in an infinite loop. In order to select an "LED

Mode" the button must be briefly activated after the relevant flashing of the LED.

Three quick flashes of the LED signal that an option has been selected. When the

LED Mode has been successfully selected, the switch back to the main menu is

made.

In order to leave the calibration mode, the appliance must be separated from the

voltage supply for approx. 10 seconds

9.1.4 Test Function NWS-20

Through the pressing and holding of the setup button, independent of the state of

NWS, the switching output can be temporarily switched off.

During the test phase, the LED blinks rapidly.

Releasing the button returns the NWS after ca. 3 sec. to the current operating

condition.

9.2 Settings for NWS-...23/24/2W/2H and NWS-2E

9.2.1 Signalling the operating status

The NWS has an output status indicator with an LED monitor that can be viewed

continuously through a lense in the cover. The LED flashes approximately once

every second when the NWS is off. It is continuously illuminated when the NWS

is switched on. The LED provides visual confirmation that the NWS is operating

correctly and that the status of the wet side is correctly displayed. With its operating mode switch, the NWS can be set to operate as either an N/C contact or an

N/O contact.

Page 13

NWS

NWS K06/0214 Page 13

9.2.2 Selecting operating mode

By reversing the polarity of the power supply, the switching function of the NWS...23/24 can be changed from a N/C contact to a N/O contact.

In the case of the NWS-...2W/2H (WHG), the switching function cannot be

changed for reasons of safety. This electronic switch opens in case of wetting, a

faulty sensor or a power failure.

For the NWS-2E the operating modus is selected by connecting the

corresponding connector (plug connector or cable pin assignment) (see 8.2).

Function Signalling NAMUR-output fork

N/C

LED on ≥ 2.1 mA uncovered

LED flashes quickly ≤ 0.8 mA covered

N/O

LED on ≥ 2.1 mA covered

LED flashes quickly ≤ 0.8 mA uncovered

9.2.3 Calibration mode NWS-23/24/2W/2H and NWS-2E

Each appliance is adjusted by the factory to record fluids with density 1,0 kg/l

(water). It is not usually necessary to alter this pre-adjustment. In extreme

situations, however, such as with very light fluids at high temperatures or highly

viscous fluids, which produce a significantly extended reaction time from dry to

wet, it can be advantageous to alter the pre-adjustment. In the calibration mode

for NWS-2E, the NAMUR loop current changes with the state of the LED signal.

Therefore, the subsequent signal evaluation should be suppressed during the

calibration process. In order to attain the calibration mode the test magnet must

be placed at the label marking and held, then the supply voltage must be

switched on. After approximately 1 second the LED goes on, after 2 seconds the

LED goes out, then remove the test magnet – the appliance stays now in the

main menu of the calibration mode.

There is a choice of options in the main menu - Switchpoint Calibration,

Hysteresis Level and LED Mode (not NWS-2E). The LED indicates the selected

option:

Switchpoint Calibration: LED flashes briefly 1x, then LED 2 seconds off.

Hysteresis Level: LED flashes briefly 2x, then LED 2 seconds off.

LED Mode: LED flashes briefly 3x, then LED 2 seconds off (not NWS-2E).

The option points are repeated in an infinite loop.

In order to get access to an option the test magnet must be placed briefly when

the LED has signalled the requested option point.

Page 14

NWS

Page 14 NWS K06/0214

Switchpoint Calibration:

The "Switchpoint Calibration Mode" is signalled by: LED 1x briefly off, then LED 2

seconds on.

Dip the tuning fork as far as the required switchpoint (1/2 – 2/3 of the fork length)

in the medium and activate by placing the test magnet briefly. The calibration is

made.

A successful calibration is signalled by the LED flashing quickly three times.

Hysteresis and LED Mode are set back to default! After calibration the switch

back to the main menu takes place.

Hysteresis Level:

The "Hysteresis Level Mode" is signalled by: LED 2x briefly off, then LED 2

seconds on. Activate by placing the test magnet briefly to get to the submenu.

Hysteresis Level 1(approx. 1-1.5mm): LED flashes briefly 1x, then LED 2

seconds off.

Hysteresis Level 2 (approx. 3-4.5mm, Standard): LED flashes briefly 2x, then

LED 2 seconds off.

Hysteresis Level 3 (approx. 5-7.5mm): LED flashes briefly 3x, then LED 2

seconds off.

The choice of options is repeated in an infinite loop. To select an Hysteresis

Level, the test magnet must be placed briefly after the flashing of the relevant

LED. Three quick flashes of the LED signal that an option has been selected,

then the switch back to the main menu is made.

LED Mode (not NWS-2E):

The "LED Mode" is signalled by: LED briefly 3x off, then LED 2 seconds on.

Briefly activate the Setup button in order to attain the option menu LED Mode.

LED Mode 1 (Standard): LED flashes briefly 1x, then LED 2 seconds off. LED

shows the status of the switch output

LED Mode 2: LED flashes briefly 2x, then LED 2 seconds off. LED indicates

whether the tuning fork is wetted or not

The choice of options is repeated in an infinite loop. In order to select an "LED

Mode" the test magnet must be placed briefly after the relevant flashing of the

LED. Three quick flashes of the LED signal that an option has been selected.

When the LED Mode has been successfully selected, the switch back to the main

menu is made.

In order to leave the calibration mode, the appliance must be separated from the

voltage supply for approx. 10 seconds

9.2.4 Test function

The magnet supplied with the device can be used to switch off the electrical

output of the NWS- independent of status of the tuning fork. In this case, the

magnet must be placed on the location indicated on the device nameplate. After

approximately 2 seconds, the NWS- switches the output off and the LED begins

blinking. After the magnet is removed, the output returns after 3 seconds to its

previous state.

Page 15

NWS

NWS K06/0214 Page 15

9.2.5 Selecting operating mode

The choice of plug connector or cable pin assignment determines whether the

level switch is operated as an N/C contact or an N/O contact (see the section

“Electrical connection” below).

10. Technical Information

Fork: stainless steel 1.4404

Process connection: stainless steel 1.4404

Electronic housing: NWS-...200: PAG, glass-fibre-reinforced

cover with window, 330° rotatable

all other types:

stainless steel 1.4301

Process connections: Pipe thread DIN EN 10226-1,

NPT thread, Tri-Clamp,

Pipe connection DIN 11851

(sanitary connection),

Aseptic-connection DIN 11864,

DRD flange,

Flange B 25 PN 40 DN 2527,

Flange B 50 PN 40 DN 2527,

Flange ANSI B 16.5 - 1", 300 lbs,

Flange ANSI B 16.5 - 2", 300 lbs

Protection: plastic housing: IP 65

(NWS-...200)

stainless steel housing, plug connection: IP 67

stainless steel housing, cable connection: IP 68

Max. operating pressure: 45 bar

Flange connection: see pressure steps

Max. medium temp.: 130 °C (NWS-..200..)

90 °C (for all other NWS)

short-time 150 °C for CIP

(valid for all models NWS)

Min. medium density 0.8 kg/L (lower on request)

Ambient temperature: -20 °C...+70 °C

Power supply

NWS-...200..: 24...240 VDC/ AC (50/ 60 Hz);

2-wire; 24 VDC, 3-wire

NWS-...23/24/2W/2H..: 24 VDC, 3-wire

NWS-...2E..(ATEX): Isolation Switching Amplifier to IEC 60947-5-6

(Namur) necessary (for example: REL-6)

Delay: 1 s wet /dry

1 s dry / wet

Viscosity: 5000 mm2/s max. at 25 °C

(influence on the response time)

Page 16

NWS

Page 16 NWS K06/0214

Hysteresis: 4 mm vertical, 1 mm horizontal

Repeatability: ± 1 mm at ambient temperature

Weight: 0.5 kg (for R ¾ and ¾ NPT)

Electrical Connection:

NWS-...200...: cable connection: M 16 x 1.5

terminal: max. 1.5 mm2 (26-14 AWG)

capacity: 0.4 A max. at room temp.

min. switching current: 7.5 mA

leakage current in off-state: < 3.5 mA constant

voltage drop: ca. 6 V (2-wire connection)

NWS-...23/24/2W/2H..: connector M12x1, 4-pole or 1.5 m

fixed cable, 3-pole

switching output: O. C. PNP or NPN (factory

set), max. 300 mA, short-circuit-proof

contact function: N/C or N/O adjustable

by switching polarity of supply voltage

(only NWS...23/24)

Overload cut-off (NWS-2x): In case of thermal overload or excessive current,

the unit cust off the load. The triggering of

overload protection is indicated by fast blinking of

the LED.

NWS-...2E.. (ATEX): connector M12x1, 4-pole or 1.5 m cable

2-wire NAMUR output

N/C or N/O selectable

N/C: ≥ 2.1 mA discovered

≤ 0.8 mA covered

N/O: ≤ 0.8 mA discovered

≥ 2.1 mA covered

Page 17

NWS

NWS K06/0214 Page 17

11. Order Codes

Example: NWS-R20 20 0 0000

Connection Model Electrical connection Sensor version

R ¾ male thread

NWS-R20...

Plastic housing

200 = 24...240 V

AC/DC

cable gland/terminal connect.

St. steel housing/plug connect.

23S = 24 V

DC

, PNP, plug M12x1

24S = 24 V

DC

, NPN, plug M12x1

2WS*** = 24 V

DC

, WHG, PNP, plug M12x1

2HS*** = 24 V

DC

, WHG, NPN, plug M12x1

2ES = ATEX-approval, plug M12x1

St. Steel housing/cable connect.

23F = 24 V

DC

, PNP, 1.5 m cable

24F = 24 V

DC

, NPN, 1.5 m cable

2WF*** = 24 V

DC

, WHG, PNP, 1.5 m cable

2HF*** = 24 V

DC

, WHG, NPN, 1.5 m cable

2EF = ATEX-approval, 1.5 m cable

0060 = 60 mm (only for

NWS-T / NWS-L / NWS-H)

0070 = 70 mm

standard version, short

(not for NWS-T / NWS-L)

0117** = 117 mm

extended

0300** = 300 mm sensor

0500**= 500 mm sensor

1000** = 1000 mm sensor

XXXX** = please specify

special length 4-position

in mm (max. 3000 mm)

R 1 male thread

NWS-R25...*

¾ NPT male thread

NWS-N20...

1 NPT male thread

NSW-N25...*

DIN-flange DN 25

NWS-F25...

DIN-flange DN 50

NWS-F50...*

1“ ANSI-flange

NWS-A25...

2“ ANSI-flange

NWS-A50...*

Tri-Clamp DN 40

NWS-T40...

Tri-Clamp DN 50

NWS-T50...

Sanitary DN 40 (DIN 11851)

NWS-L40...

Sanitary DN 50 (DIN 11851)

NWS-L50...

Aseptic connection

DN 50 (DIN 11864)

NWS-H50...

DRD Ø 125 mm flange

NWS-D1Z...

Special connection

NWS-YYY...

**only models marked with *are available with sensors in extended version.

***WHG-approval in preparation.

12. Service and Maintenance

The functional behaviour of these devices is stable, even over long periods or

time. Regular adjustments or similar procedures are not required. No

maintenance of any type is required.

In the event that device faults are noted, this device should be immediately

removed from service. The device contains no user-serviceable parts. Return the

device to the manufacturer for examination.

13. Trouble Shooting

Devices that are operated in hazardous areas must not be modified in any way.

Repairs must be performed by trained, qualified service personnel only. Defective

devices should normally be returned to the manufacturer for examination.

Page 18

NWS

Page 18 NWS K06/0214

14. Recommended Spare Parts

There are no recommended spare parts.

If the device becomes defective, it usually means that there is a fault in the device

electronics that must be diagnosed and repaired.

In this case, we recommend that the device be returned to the manufacturer for

servicing.

15. Disposal

Disposal of packaging and used parts shall be done in conformance with the

regulations of the country in which the device is installed.

Page 19

NWS

NWS K06/0214 Page 19

16. Dimensions

Ø 40

6

5

70

Ø 40

NWS-...23S/24S

NWS-...2WS/2HS

24 VDC

Plug connection

NWS-...23F/24F

NWS-...2WF/2HF

24 VDC

NWS-...2ES

ATEX

Plug connection

NWS-...2EF

ATEX

Cable connection

NWS-...200

24...V

AC/DC

Plastic housing

Page 20

NWS

Page 20 NWS K06/0214

L2 L3

DN 25 /PN 40 18 approx. 47

DN 50 / PN 40 20 approx. 95

ANSI 1“ 300 lbs 17,5 approx. 41

ANSI 2“ 300 lbs 22,4 approx. 92

NWS-R20/N20

(Standard, short)

NWS-R25/N25

NWSN25...0117

(Standard, long)

NWS-F../NWS-A..

Flange version

NWS-T..

Tri-clamp

NWS-L..

Sanitary connection

(DIN 11851)

NWS-H..

Aseptic connection

(DIN 11864)

Page 21

NWS

NWS K06/0214 Page 21

17. Declaration of Conformance

We, KOBOLD Messring GmbH, Hofheim-Ts, Germany, declare under our sole

responsibility that the product:

Level Switch model: NWS -..

to which this declaration relates is in conformity with the standards noted below:

EN 61010-1 Safety requirements for electrical equipment for

measurement, control and laboratory use 2002

EN 61326-A2 Electrical equipment for measurement, control and

laboratory use - EMC requirements, industrial area, 2006

Additional for model NWS-***2E* ****

EN 60079-0:2012

EN 60079-11:2012

EN 60079-26:2007

Also the following EEC guidelines are fulfilled:

2004/108/ EC (Electromagnetic compatibility)

2006/95/EC (Low voltage guideline)

94/9/EC Equipment and Protective systems intended for

use in a potentially Explosive Atmospheres (ATEX 100a)

Quality Management Production

Certificate number: BVS 09 ATEX ZQS/E110

Notified body: DEKRA Exam GmbH

Identification number: 0158

Hofheim, 30. Jan. 2014

H. Peters M. Wenzel

General Manager Proxy Holder

Page 22

NWS

Page 22 NWS K06/0214

18. Supplement to the EC-Type Examination

certificate

Page 23

NWS

NWS K06/0214 Page 23

Page 24

NWS

Page 24 NWS K06/0214

Page 25

NWS

NWS K06/0214 Page 25

19. IECEx Certificate

Loading...

Loading...