Kobold NSV Series, NSV-8200G800, NSV-8201G800 Operating Instructions Manual

Operating instructions

For

Vibration level switch

Model NSV

NSV

1. Content

1. Content ......................................................................................................... 2

2. Note .............................................................................................................. 3

3. Instrument Inspection .................................................................................... 3

Regulation use .............................................................................................. 3

4.

5.

Operating Principle ........................................................................................ 4

6. Mechanical Connection ................................................................................. 5

7. Electrical connection ..................................................................................... 7

8. Commissioning .............................................................................................. 7

Maintenance ................................................................................................. 8

9.

10.

Technical information .................................................................................... 9

11.Order Codes ............................................................................................... 10

12.Dimensions, standard models ..................................................................... 10

13.Safety Instructions (ATEX) .......................................................................... 11

14.Installation in classified zone (ATEX) .......................................................... 12

15.Label Description (ATEX) ............................................................................ 13

16.Dimensions, ATEX models ......................................................................... 13

17.Declaration of conformance (ATEX) ............................................................ 14

18.Declaration of conformance ........................................................................ 15

19.ATEX Certificate .......................................................................................... 16

20.Notes ........................................................................................................... 19

Manufactured by:

Kobold Mesura S.L.U

Avda. Conflent 68, nave 15

08915 Badalona

Tel.: +34 93 460 38 83

Fax: +34 93 460 38 76

E-Mail: info.es@kobold.com

Internet: www.kobold.com

june 2017

Page 2 DT0335

NSV

2. Note

Please read these operating instructions before unpacking and putting the unit

into operation. Follow the instructions precisely as described herein.

The devices are only to be used, maintained and serviced by persons familiar

with these operating instructions and in accordance with local regulations

applying to Health & Safety and prevention of accidents.

When used in machines, the measuring unit should be used only when the

machines fulfil the EC-machine guidelines.

3. Instrument Inspection

Instruments are inspected before shipping and sent out in perfect condition.

Should damage to a device be visible, we recommend a thorough inspection of

the delivery packaging. In case of damage, please inform your parcel service /

forwarding agent immediately, since they are responsible for damages during

transit.

Scope of delivery:

The standard delivery includes:

- Level Monitor for Bulk model: NSV

- Operating instructions

4. Regulation use

The Level Monitor is designed for the selective level monitoring of bulk materials,

especially for bulk material with low bulk density. This level monitor is not

sensitive to material dampness and can be employed regardless of the

composition of the bulk material.

Any use of the Level Monitor for Bulk, model: NSV, which exceeds the

manufacturer’s specification may invalidate its warranty. Therefore, any resulting

damage is not the responsibility of the manufacturer. The user assumes all risk

for such usage.

DT0335 Page 3

NSV

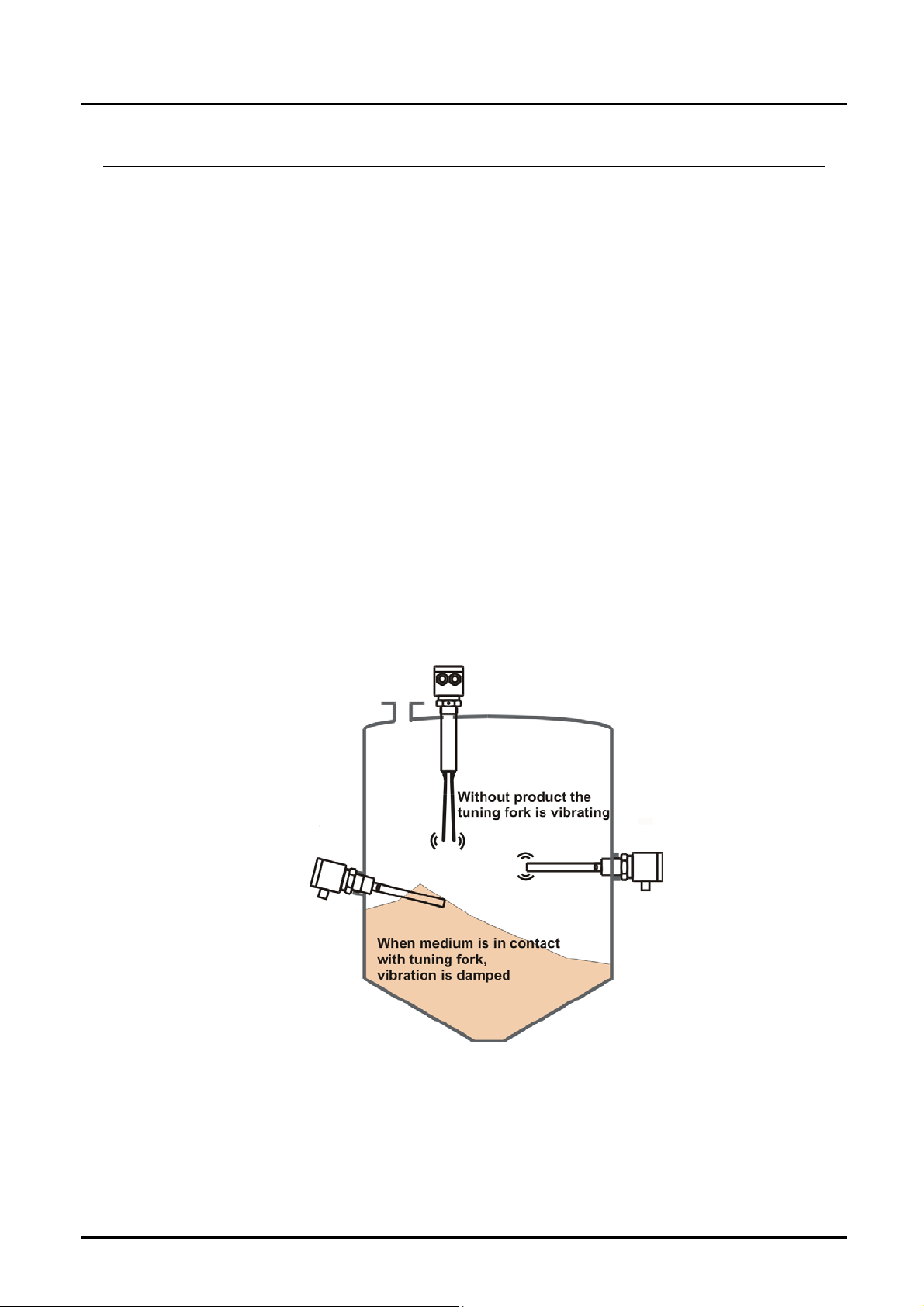

5. Operating Principle

The Level Monitor model NSV has decisive advantages, especially with bulk

goods with low bulk density.

The sensor consists of a connecting head, which contains the electronics, and an

adaptor with an oscillating fork. The latter is responsible for the direct contact with

the bulk material. Two piezoelectric crystals start the fork vibrating at about 100

Hz. As soon as the fork is covered with the bulk material its vibration is

dampened. This damping is detected in a pluggable evaluation module and

transformed into a potential-free limit contact. With the aid of a selector switch (A

and B) the relay can be switched on or off with every contact of the fork with the

bulk material. At the same time, the electronics in the connecting head triggers

the output relay. The electronics in the connecting head consists of a

maintenance-friendly plug-in module that is fitted with an LED voltage supply

indicator and an additional LED that lights up whenever the fork touches the

medium.

In addition to the standard version NSV-8200, the devices can also be provided

for vertical installation with an extended neck pipe (NSV-8201). The maximum

length of the neck pipe is 3000 mm. The plug-in evaluation module can be

changed easily so that the devices are really easy to maintain.

Page 4 DT0335

NSV

6. Mechanical Connection

Before installation:

Remove all packing materials and transport retainers and ensure that no

such materials remain in the device.

Make sure that the permitted max. operational pressure and temperature

limits are not exceeded (see chapter 10 Technical Information)

The units may not be installed at a location within an inductive field.

If possible, check directly after mechanical installation whether the

connection thread to the pipe is fully sealed.

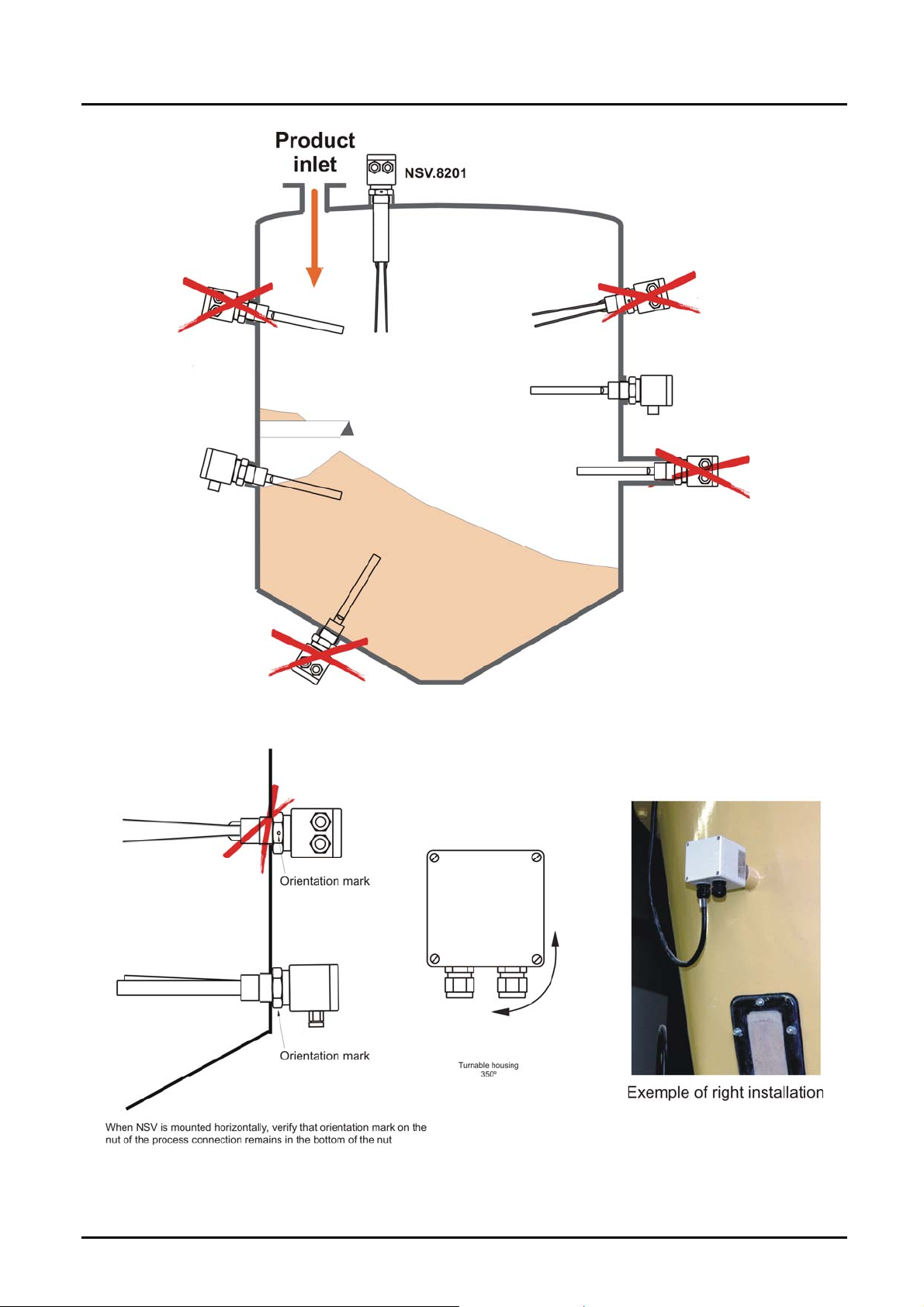

INSTALLATION OF THE NSV VIBRATION LEVEL MONITOR

The NSV series vibration level monitor is physically connected with a 1 ½” male

thread. For installation you should use the hexagonal adaptor (60 mm spacing) of

a suitable wrench.

THE FOLLOWING MUST BE OBSERVED UNDER ALL CIRCUMSTANCES:

When the bulk material container is being filled, the NSV level monitor

must not come into contact with the inflowing medium.

If this is however not possible, the vibrating fork must be fitted with a

suitable protective covering.

Make sure that the fork is always positioned correctly inside the bulk

container and that no bulk material deposit is formed on it, since this can

result in incorrect readings. If the NSV level monitor is built in laterally you

must ensure that the markings on the adaptor are vertical in relation to the

side of the container.

When the NSV vibration level monitor is installed vertically a minimum

distance must be maintained between the fork and the container wall

otherwise this area could be filled with a deposit of the bulk material.

Whenever possible the NSV level monitor should be fitted with a slight

downward inclination. This prevents bulk material sticking to the vibrating

fork when the container is being emptied.

The level monitor should also be installed in such a position that there are

no parts in its immediate vicinity that could trigger vibrations in the inside of

the container, since this can also lead to incorrect readings or damage.

For correct positioning the connection head (resp. cable bushing) is 350º

rotatable.

DT0335 Page 5

NSV

Page 6 DT0335

Loading...

Loading...