Kobold NRF Instruction Manual

NRF-100_KM Rev. : 1.0 16/04/2002

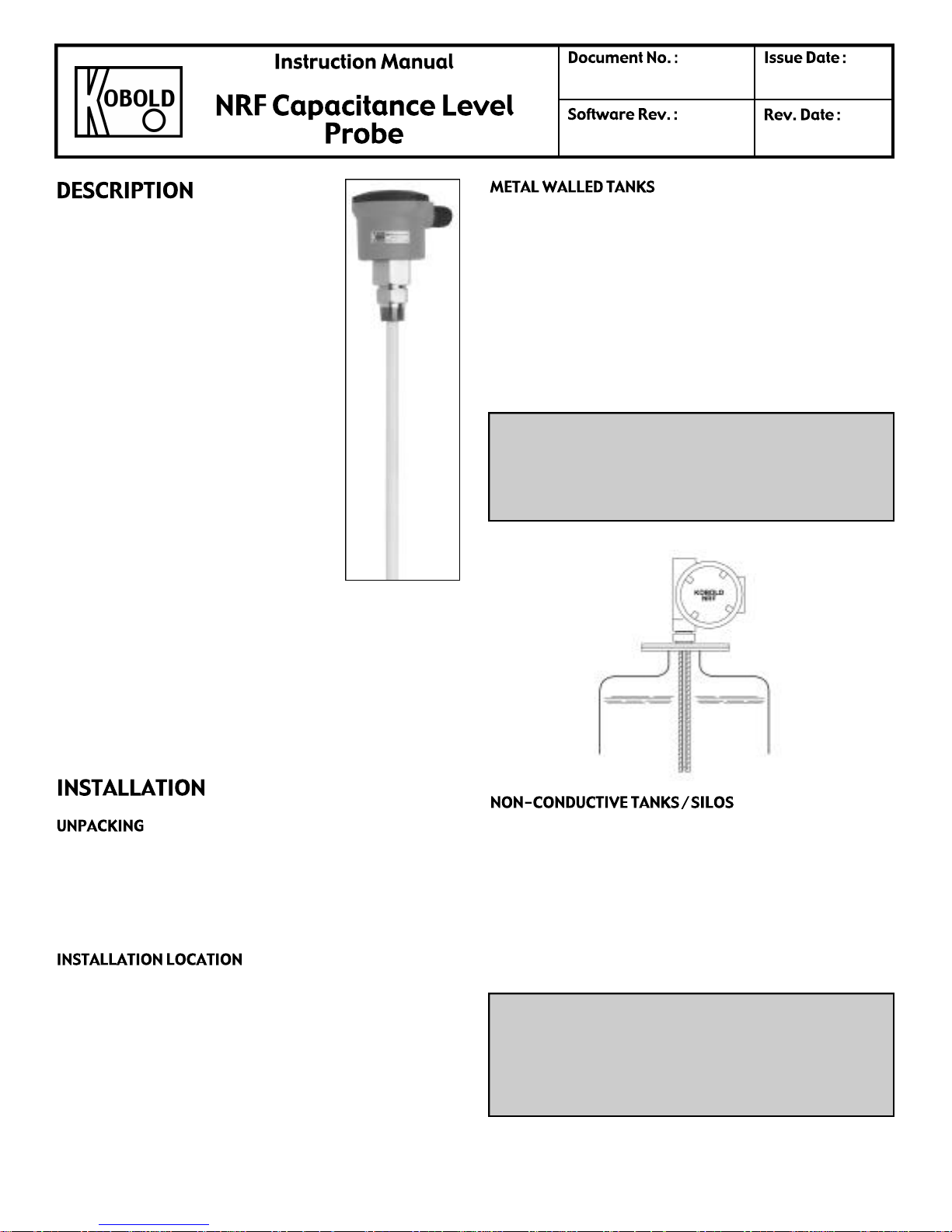

Kobold two-wire NRF level transmitters

are designed to measure either liquid or

certain dry bulk media. The 12-36 VDC

4mA base current is the supply to the

unit. The NRF monitors level change by

converting movement of media UP or

DOWN the probe into pulse wave form

which is proportional to changes in

level. The amplifier converts this pulse

wave into 4 to 20 mA output signal. The

conversion of level movement to an

electrical signal is due to changes in

electrical capacitance. The probe and a

ground reference electrode, usually the

metal tank wall, have a certain capacitance in air. As the medium displaces

the air, a change occurs because of the

difference in the dielectric constants of

the medium and air.

Fig 1.

aran_v02 or higher

01/12/2002

It is a common practice to use the metal tank wall as the

reference electrode. In such cases, it is required that the

probe housing makes a good electrical connection to the

tank wall. If there is any doubt about this connection due

to the use of PTFE thread tape, gaskets, paint, rust, or

any other reason, a separate grounding wire should be

installed between the probe and the tank housing. In case

the probe housing is non-metalic, or if the connection

fitting is non-metalic, a grounding wire must be connected

from the tank to the G terminal on the transmitter.

CAUTION: This unit contains CMOS electronics which

may be damaged by static electricity. Electronics may

be accessed by removing the top cover of the enclosure

(head). Do not remove the transmitter face plate (and

touch the electronics). There are no servicable parts.

The NRF comes complete with the transmitter mounted in

an enclosure, fitting and probe (Fig. 1). Micro-processor

based electronics are protected and potted within a metal

housing. Calibration is made via four push buttons

(Fig. 3) as explained later. Variety of options including

Stainless or PVC housings, rigid or flexible probes (bare

or jacketed), NPT, sanitary or flange connections are

available.

Unpack the instrument carefully. Inspect all components

for damage. Report any damage to Kobold within 24

hours. Check the contents of the packing slip and report

any discrepencies to Kobold.

The Kobold NRF level sensor should be located for easy

access for service, calibration and monitoring. Sensors

should not be exposed to ambient temperatures below

- 4 0°C (- 4 0° F) or above +70°C (+ 1 6 0° F). Special precau tion

should be made to prevent exposure to corrosive

atmosphere, excessive vibration, shock or physical

damage. It is preferable that the NRF is not installed in

proximity to high voltage wires or other sources of high

electrical noise.

Fig 2.

With plastic, concrete, wood, or any other non-conductive

walled vessels a reference electrode must be inserted

into a tank. Most commonly, this electrode will be in the

form of a concentric, ground tube (i.e. stilling well, Fig. 2)

or a metal rod installed in parallel with the probe. In all

cases, a good electircal connection must be made

between the ground reference electrode and the G

terminal of the transmitter (or probe housing).

CAUTION: When installing units with PTFE (or plastic)

coated rods or cables, be careful not to damage the

insulation. NPT threads have very sharp corners and

PTFE (or plastic) can be easily cut. In acidic and/or

conductive liquids damaged units may malfunction and

the metal rods can corrode

Page 1

NRF-100_KM Rev. : 1.0 16/04/2002

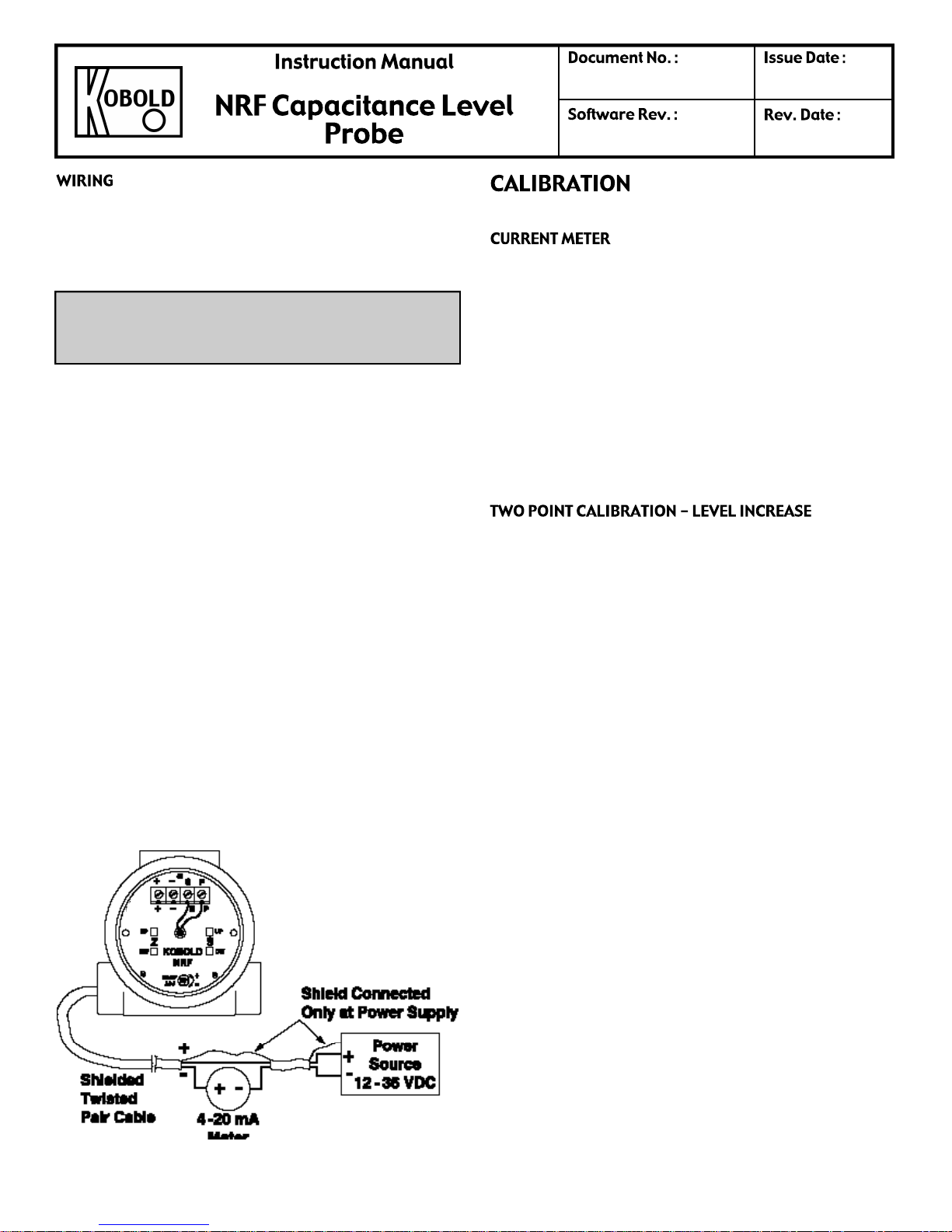

All wiring between the power supply and the transmitter

should be done with 18 AWG to 22 AWG shielded twisted

pair. The connection is made at the terminal strip within

the transmitter enclosure.

CAUTION: Units are designed to operate on the 12 to

36 VDC power only. Application of 110 VAC will destroy

the instrument.

1. Make sure the power source is turned off.

2. Pull power supply wires through conduit connection.

3. Connect the positive supply wire to the (+) terminal,

and the negative supply to the (-) terminal.

Note: Leave shield unattached at transmitter.

Connect the shield to ground at the power source.

4. Replace the transmitter enclosure (head) cover until

time to calibrate.

5. Connect positive supply wire to the positive terminal

of the transmitter. See Fig. 3.

6. Connect the loop current meter in series with the

negative supply wire as follows:

a. Negative transmitter wire to positive meter

terminal. See Fig. 3.

b. Negative meter terminal to negative power

source termianl. See Fig.3.

7. Turn ON the power. The meter may read anywhere

on the scale at either end. This is normal until calibra

tion has been completed. Proceed to the calibration

Instructions.

aran_v02 or higher

01/12/2002

In order to calibrate the transmitter, you must use the loop

current meter. It should read currents in the range of 1.00

to 25.00 mA, with a resolution of .01 mA. Using a meter

of less resolution will somewhat reduce the calibration

accuracy. To calibrate the instrument :

1. Remove enclosure (head) cover.

2. Connect the loop current meter as per instructions in

WIRING section(Fig. 3).

3. The loop current should now be in the range of 1.5

mA to 38 mA, which is normal at this point.

Three calibration procedures are described. Follow the

one which fits your application. Note the following definitions used in the calibration procedures, referring to Fig 4.

L = the level of material which corresponds to 4.00 mA of

loop current, i.e., the 0%

L1 = a material level higher than L

H1 = a material level higher than L1, but less than H.

H = the level of material in the vessel which corres-

ponds to 20.00 mA of loop current, i.e., the 100% level.

Note: To avoid the possibility of a “dead zone”, L must be

at least two (2) inches above the end of the probe for (4)

conductive media and four inches above for nonconductive media.

Page 2

CALIBRATION L- H = when material in tank can be set

to L (0%) and H (100%).

CALIBRATION L - H1 = when material in tank can be set

to L (0%) and H1 (less than 100 %).

CALIBRATION L1 - H1 = when material in tank can be

set to L1 (greater than 0 %) and H1 (less than 100%).

NOTE: Calibration procedure L-H gives the most

accurate results and is the recommended procedure in

all cases.

Fig. 3

Loading...

Loading...