Kobold NQ series Installation & Operation Instructions

Specifications

Series NQ Ultrasonic Level Switch

Installation/Operation Instructions

Power Requirements:

Two Wire Switching: 24 to 240 VAC/VDC 50-60 Hz.

Three Wire Switching: 24 VDC

KOBOLD Instruments, Inc. 1801 Parkway View Drive, Pittsburgh PA 15205

Telephone: (412) 788-2830 · FAX: (412) 788-4890 www.koboldusa.com

Description

KOBOLD’s Series NQ level switch is a compact, ultrasonic

gap level switch which is suited for use with low-viscosity,

non-coating liquids. The switch employs an ultrasonic

transmitter and receiver in the switch probe. When the probe

is immersed in liquid, the gap fills, resulting in the ultrasonic

transmitter being acoustically coupled to the receiver. This

acoustic coupling is sensed by a detection circuit and results

in the activation of the integral, solid-state switch. The solidstate switch can be configured either as a two-wire or threewire controller. The unit is adjustable from a normally-open

to normally-closed (wet-on or dry-on) switch function via an

internal selector switch. Its solid-state design uses no

moving parts in the sensor or switch portions, making the

NQ level switch exceptionally reliable.

Solid State Switch Characteristics:

Max. Current: 500 mA.

Min. Current: 7.5 mA.

Leakage Current: 3 mA.

Voltage Drop: 4.5 Volts @ 500 mA.

10 Volts @ 7.5 mA.

Installation

1.) In order to ensure a leak-tight seal, a thread sealant such as

Teflon tape (or other appropriate thread sealant) should be used on

the probe threads prior to installation.

2.) The NQ must always be installed with the cable penetration facing

downward (between the 5 O’Clock to 7 O’Clock position) and creating

a drip loop with the cable. This will minimize the possibility of water

entering the cable gland thereby minimizing the possibility of water

migration into the electronics. After the unit is installed into the

process fitting, the housing may be rotated to achieve the proper

cable gland orientation.

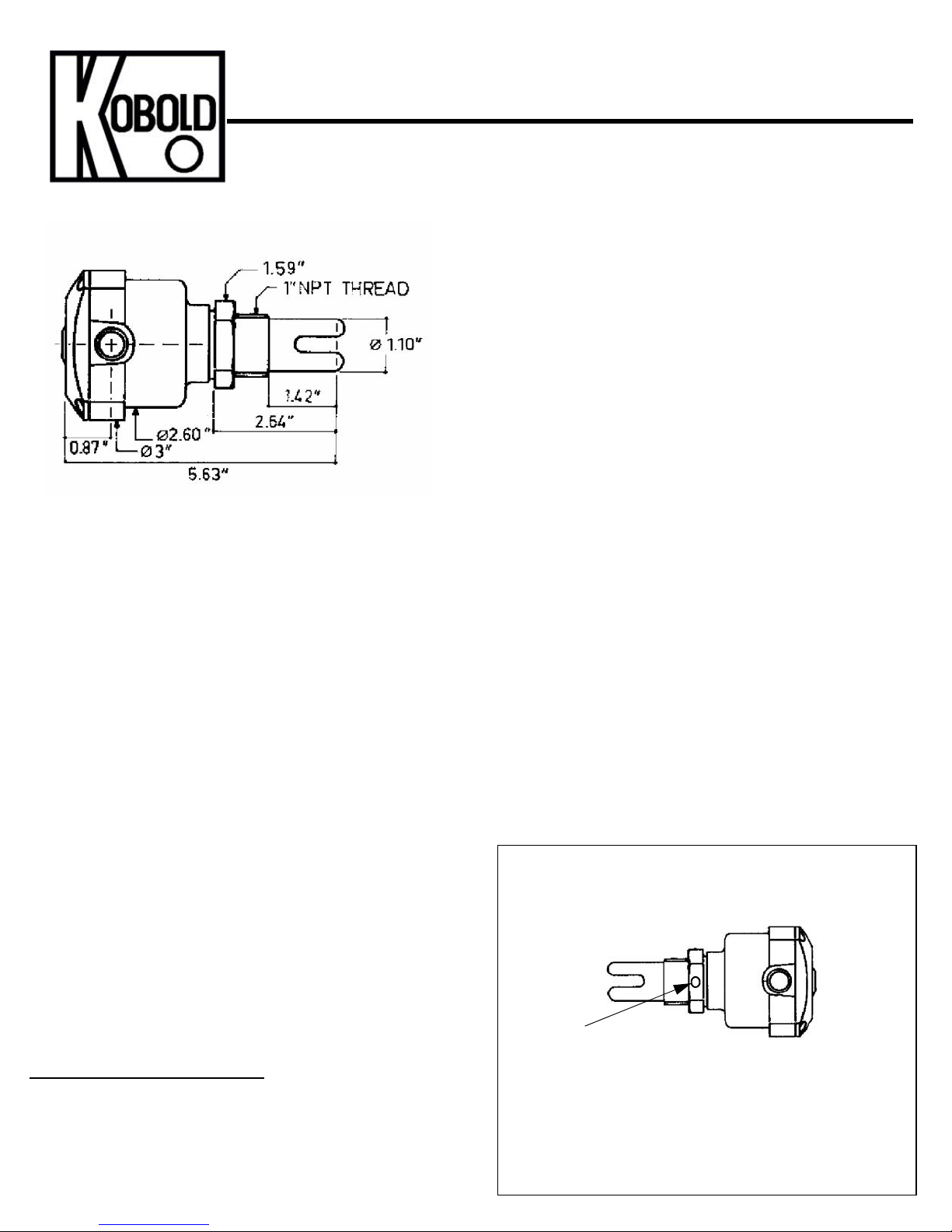

Probe Orientation Installation Note:

To ensure reliable operation, the NQ-2000 must be installed into the

vessel with the forks of the sensing probe in the 3 O’Clock and 9

O’Clock position. This will minimze any air bubbles that could collect

in the gap and interfere with the acoustic coupling. The installation

nut on the NQ has a guide dot or drilling which can be used to ensure

that the probe is installed in the proper position (See Fig. 2).

Switching Delay:

Wet to Dry: 500 mSec.

Dry to Wet: 150 mSec.

Fluid Temperature Range: -40 to 250°F

Max. Ambient Temp: 120°F with 250°F Fluid

Max. Operating Pressure: 290 PSIG @-40 to 250°F

Electrical Protection: IP 65

Fig. 2: Probe Orientation

Guide Dot

(Bottom View)

The guide dot or drilling on the probe installation

nut should be located in the 12 O’Clock or 6 O’Clock

position to ensure that the probe is properly

oriented inside the tank.

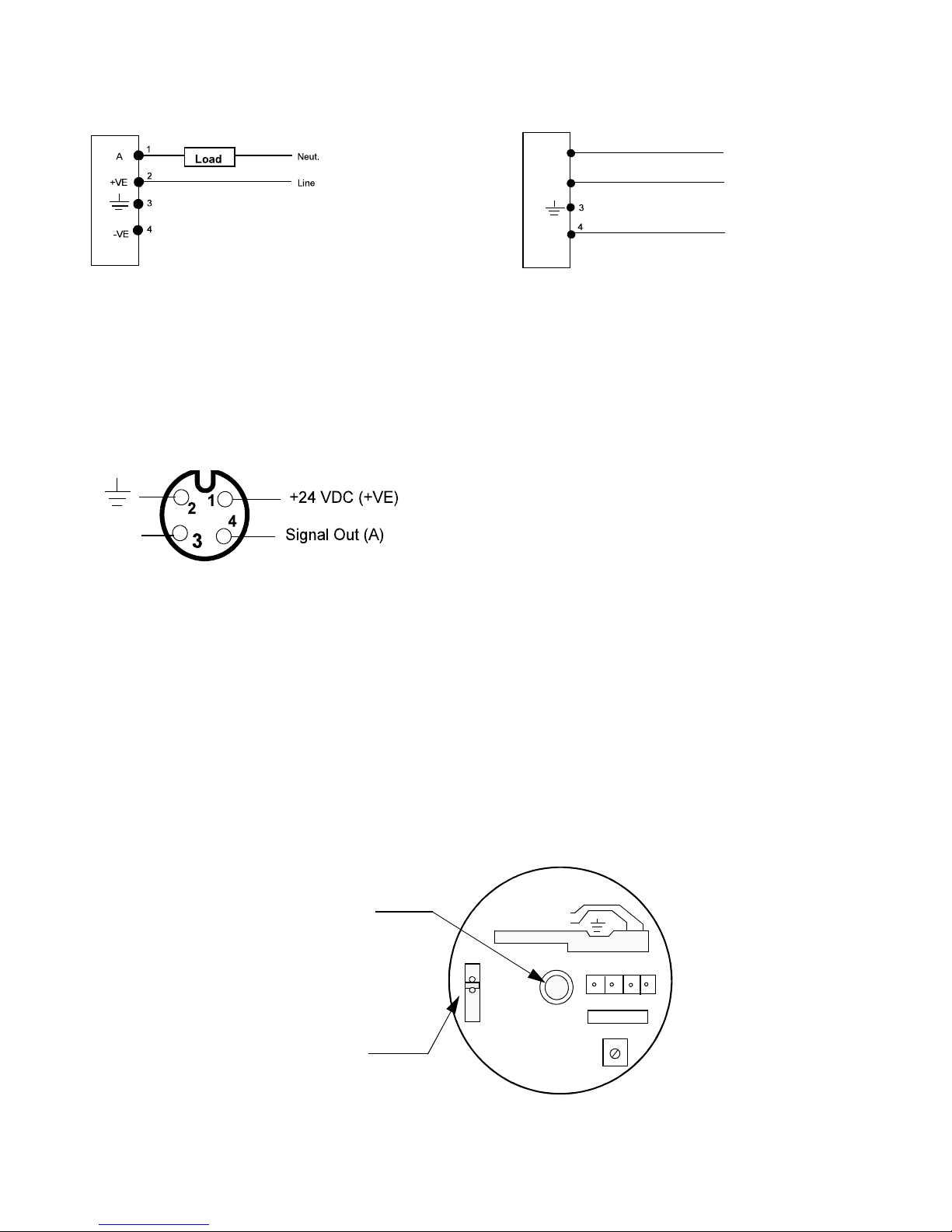

24-240 VAC/VDC

Wire Color Codes on Mating Connector

Brown = 1 = +24 VDC (+VE)

White = 2 = Equipment Ground

Blue = 3 = -DC Ground (-VE)

Black = 4 = Signal Out (A)

Electrical Connections

-DC Gnd. (-VE)

Fig. 3 Two-Wire Connection

The two-wire configuration switches line

voltage to the load device when switch

is activated. The load device is connected

in series with the NQ.

WARNING: ALWAYS CONNECT THE LOAD PRIOR TO

APPLYING POWER OR DAMAGE TO THE NQ WILL RESULT!

Fig. 5 Plug Connector Pinout (option -M12) 24 VDC only!

Fig. 4 Three-Wire Connection

+VE

-VE

1

A

2

Output

+

24 VDC In

-

The three-wire configuration switches

+24 VDC to the output when the NQ is

activated.

Operation

Status Indicator

Flashing: Switch not activated (open switch)

Steady: Switch activated (closed switch)

Logic Selector Switch

for normally open or

normally closed operation

LOAD/CHARGE/LAST

AC/DC 24-240 V

DRY-ON

VIOE

LEER

WET-ON

PLEIN

VOLL

-VE

+VE A

4

2 13

Rev. 1/12/15

Loading...

Loading...