Page 1

Operating instructions

for

Capacitive level transmitter

Model NMC

2 Wire (4 to 20mA)

Page 2

NMC

1. Content

1. Content ......................................................................................................... 2

2. Note .............................................................................................................. 3

3. Instruments inspection .................................................................................. 3

4. Description ................................................................................................... 3

5. Application .................................................................................................... 3

6. Current simulation ........................................................................................ 4

7. Installation .................................................................................................... 4

8. Electrical connection ..................................................................................... 5

9. Programming ................................................................................................ 6

9.1 Calibrating probe ................................................................................. 6

9.2 Output Adjustment .............................................................................. 7

9.3 Output simulate ................................................................................... 8

9.4 Language ............................................................................................ 9

10. Technical Data............................................................................................ 10

11. Safety Instructions (ATEX) ......................................................................... 11

11.1 Validity ............................................................................................... 11

11.2 General considerations ..................................................................... 11

11.3 Protection against ESD (electro static discharges) ........................... 11

11.4 Chemical resistance .......................................................................... 12

12. Installation in classified zone (ATEX) ......................................................... 12

13. Label Description (ATEX) ........................................................................... 12

14. Declaration of conformance ATEX ............................................................. 13

15. Declaration of conformance ........................................................................ 14

16. ATEX Certified ............................................................................................ 15

17. Models ........................................................................................................ 20

18. Order details. .............................................................................................. 21

19. Notes .......................................................................................................... 22

Manufactured by:

Kobold Mesura S.L.U

Avda Conflent Nº68 Nave 15

08915 Badalona

Tel.: +34 93 460 38 83

Fax: +34 93 460 38 72

E-Mail: info.es@kobold.com

Internet: www.kobold.com

Edition: june 2017

Páge 2 DT0305

Page 3

NMC

2. Note

Please read these operating instructions before unpacking and putting the unit into

operation. Follow the instructions precisely as described herein.

The devices are only to be used, maintained and serviced by persons familiar with

these operating instructions and in accordance with local regulations applying to

health & safety and prevention of accidents.

3. Instruments inspection

Instruments are inspected before shipping and sent out in perfect condition.

Scope of delivery

The standard delivery includes:

Capacitive Level Transmitter NMC

Cable gland M20

Operating Instructions

4. Description

The NMC transmitter is a two wire capacitance level transmitter for measuring

continuous level in tanks containing liquids.

5. Application

The probe of the NMC and the wall of the tank, forms an electric capacitor. The

dielectric of this capacitor when the tanks is empty, is the air.

When the liquid reaches the probe, the dielectric constant formed by the unit and

tank, changes.

An electronic circuit sited in the connecting module of NMC, converts this capacity

change in a variable current and proportional to the height of the liquid.

Due to each application is different, given that the kind and the measures of the

tank and the products that it contains change, every unit has to be adjusted to be

adapted to each tank and product.

Using the menus of the NMC , this operation is very easy.

The circuit, controled by microprocessor, stores all data and does the calculation. A

display LCD guides us in the calibration process.

The output current signal is 4 to 20 mA. These values can be sited where we want

in the probe.

DT0305 Page 3

Page 4

NMC

6. Current simulation

Using this option the NMC generates in the supply loop, a 4 to 20 mA current, in

steps of 1 mA. This function is very useful to make tests with independence of the

level of the tank.

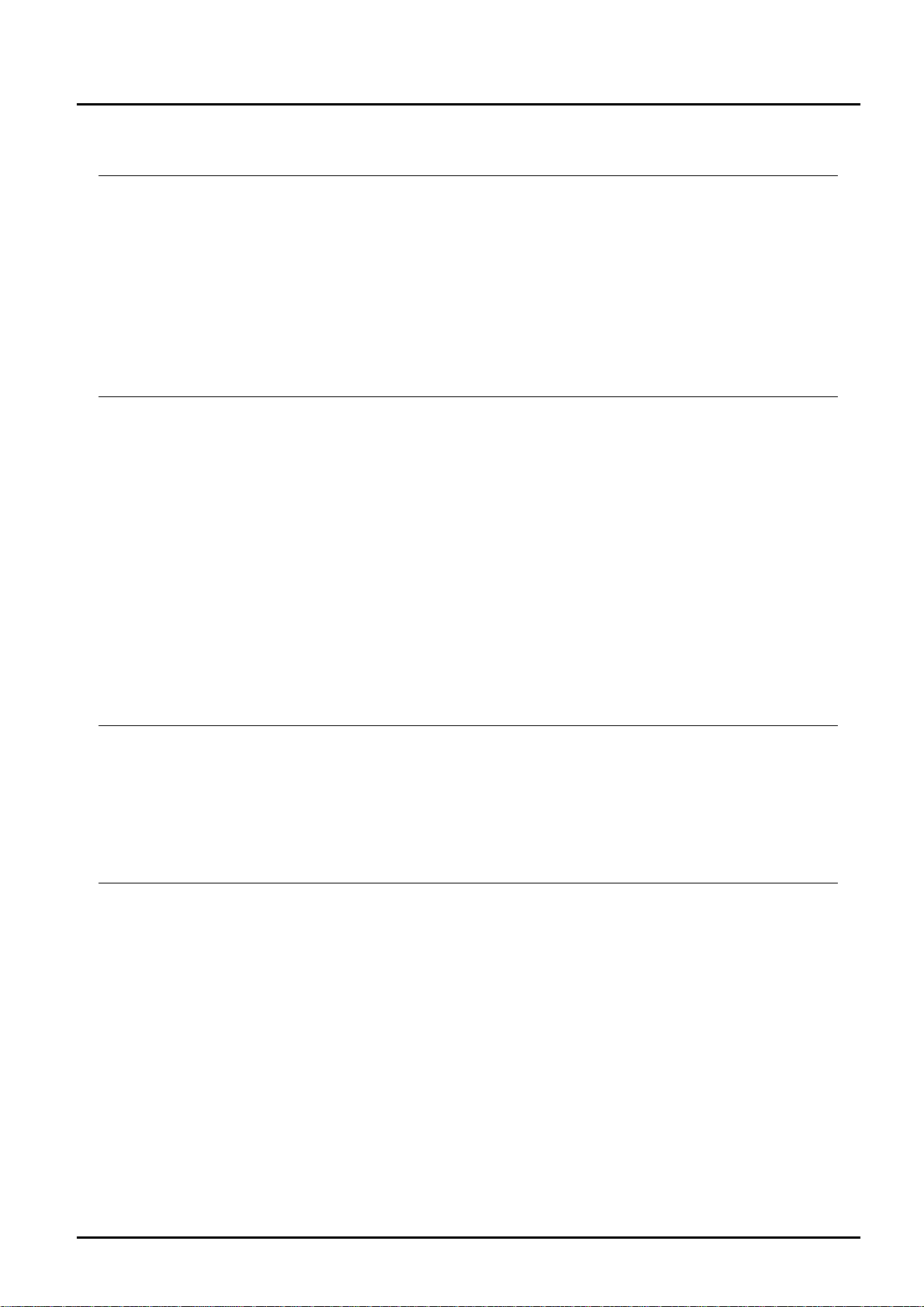

7. Installation

The NMC is installed using a G1” (G2” in DS version).

The probe must be installed avoiding a good contact between the probe and the

tank’s wall.

Electronic of the NMC unit should be protected with shelter against development of

too high temperature by direct sunshine.

Be ensured that the connection to the tank has been done properly. The NMC ’s

thread should not been forced.

The electrical connection between the thread and the tank has to be good.

Páge 4 DT0305

Page 5

NMC

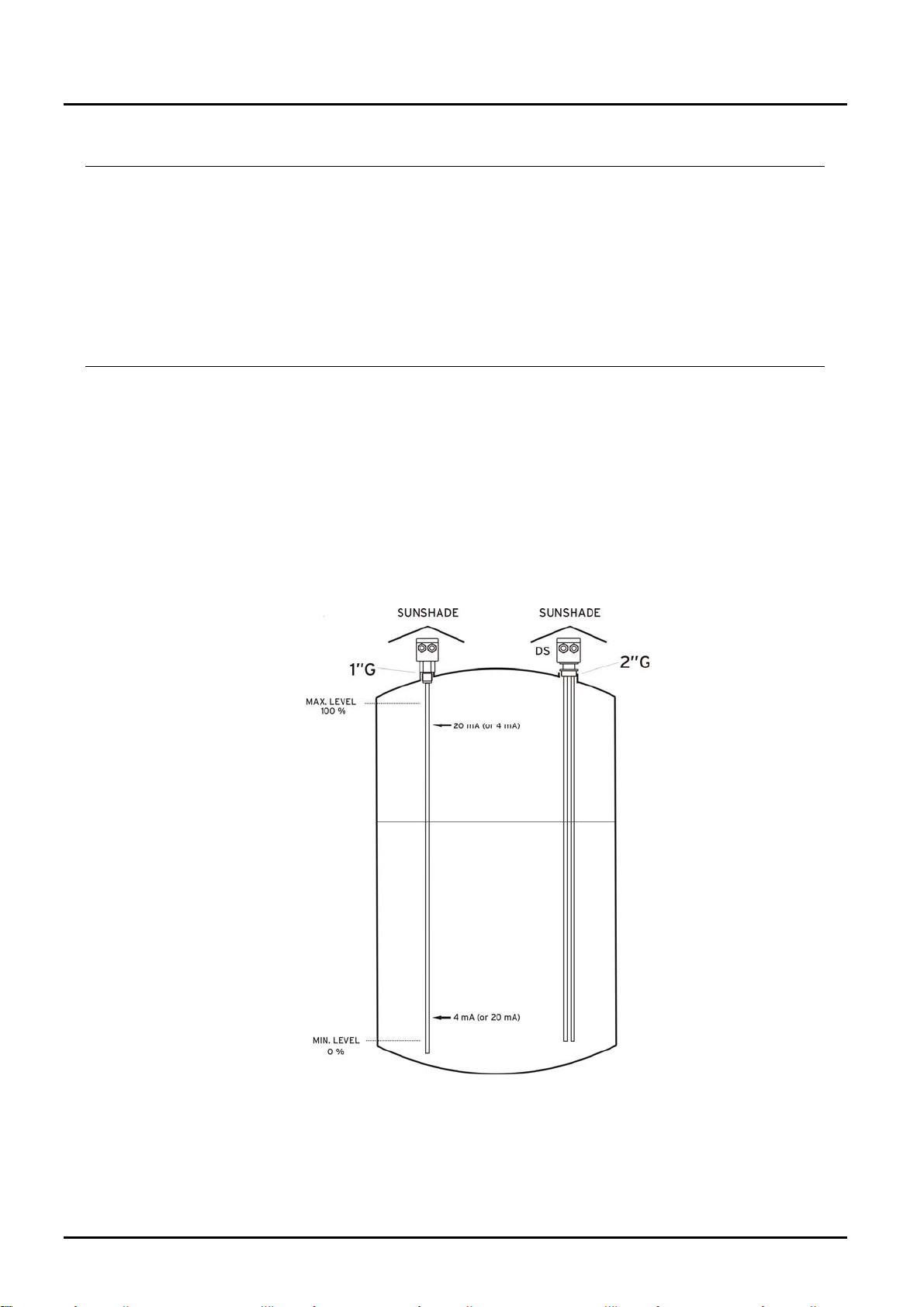

8. Electrical connection

The maximum resistance of the line in serial depends on the power supply. These

values have to be bear in mind for the good run of the NMC.

DT0305 Page 5

Page 6

NMC

9. Programming

9.1 Calibrating probe

Calib.Probe OK

Output +

Language Back ESC

CALIBRATION

¿SURE?

YesOK NoESC

CALIBRATION

Low Level OK

High Level +

LOW LEVEL ADJUST

Enter the actual level in probe.

+And-: 010.0 % OK

Calibrating

PROBE

For low level

….WAIT….

***PROBE

CALIBRATED**

Calib.Probe OK

Output +

Language -

Back ESC

1. Pressing any key, you enter in the main menú.

Press (OK) to enter in calibration probe.

2. To avoid mistakes, asks again if you are sure that

you want to calibrate the unit. Press (OK) another

time to enter.

3. If the level in the tank is low, we will choose the

(OK) option to adjust the unit with the lowest level

4. If, for example, when you adjust the low level, the

level of the tank is the 10 % of the capacitance, we

will indicate it in the display using the ( + ) and ( - )

keys. Confirm with ( OK ).

5. In this moment the microprocessor makes the

operations to choose the best measurement range.

This operations takes some seconds.

6. When this operation is finished, the display shows

the message “PROBE CALIBRATED”.

7. Automatically the display shows the main menu.

Now need calibrate the High Level, then pressing

(OK) another time to enter in the calibration probe

menu.

Páge 6 DT0305

Page 7

NMC

CALIBRATION

¿SURE?

Yes OK No ESC

CALIBRATION

Low Level OK

High Level +

HIGH LEVEL ADJUST

Enter the actual level

In probe

+ and - :080.0 % OK

Calibrating

PROBE

For low level

…. WAIT ….

*** PROBE

CALIBRATED ***

Calib.Probe OK

Output +

Language Back ESC

8. To avoid mistakes, asks again if you are sure that

you want to calibrate the unit. Press ( OK ) another

time to enter.

9. Pressing (+) we enter in High level calibration.

10. If when you adjust the high level, the liquid in the

tank is 80 % of the capacitance, we will indicate it in

the display using the (+) and (-) keys. Confirm with

(OK).

11. The microprocessor makes the operations to

calibrate the maximum level of the unit. This

operation takes some seconds.

12. The display shows this message to indicate NMC

has finished the calibration internal process.

When the liquid level will be in the minimum point, it

will indicate 000.0 % and when the liquid level will

be in the maximum, 100.0 %.

13. Automatically, the display shows the main menu.

Pressing ESC the unit returns to read state.

Pressing (+) we can enter in output adjustment

menu and simulation mode.

9.2 Output Adjustment

Calib.Probe OK

Output +

Language Back ESC

OUTPUT

Output SIM -

Output Adj +

Back ESC

DT0305 Page 7

1. Pressing any key, you enter in the main menu.

Press (+) to enter in Output.

2. Pressing (+), we enter in Output adjustment menu.

Page 8

NMC

¿Where do you want the 4

¿Where do you want the 20

+ and - : 1 OK

Output SIM -

Output Adj +

Back ESC

OUTPUT ADJUST

mA output?

+ and - : 005.0 % OK

OUTPUT ADJUST

mA output?

+ and - : 095.0 % OK

MEASURE FILTER

Enter filter’s level

0 to 5

OUTPUT

049.8%

12.04 mA

3. This asks, where do you want the NMC gives us 4

mA. If you want it in 5 % of the probe. Using (+) and

(-) we indicate this value in the display. Confirm with

(OK)

4. We do the same for the 20 mA. In this case, if we

want this current in the 95 % of the probe, we will

indicate this value using (+) and (-).

Confirm with (OK)

5. Finished the adjustment, we can incorporate a filter

to avoid oscillations caused by quick movements of

the liquid’s surface. This value between 0 and 5

(maximum filter). Confirm with (OK)

6. Automatically return to output menu.

Pressing ESC return to measuring mode.

7. In this point, the NMC is adjusted. The number in

% indicates the height that reaches the level in the

probe (0 to 100). The value of the current will

depends f the adjustment of the points 3 and 4 of this

section, and it can be in any point of the probe. It

can be in maximum point and in the 20 mA at the

minimum.

9.3 Output simulate

Calib.Probe OK

Output +

Language Back ESC

OUTPUT

Output SIM -

Output Adj +

Back ESC

Páge 8 DT0305

1. Pressing any key, you enter in the main menu.

Press (+) to enter in Output.

2. Pressing (-), we enter in simulate output menu.

Page 9

NMC

SIMULATE OUTPUT

Back ESC

+ and - : 04 mA OK

9.4 Language

Calib.Probe OK

Output +

Language Back ESC

LANGUAGE

+&- : English OK

3. In this screen, using the (+) and (-) keys, the loop

current (2 wire) will change in steps of 1mA. With this

option, you can do current testes without generator.

Pressing (OK) returns to menu show in point 2.

Pressing (ESC) returns to read mode.

1. Pressing any key, you enter in the main menu.

Press (-) to enter in Language.

2. Pressing (+) or (-) we can choose the language for

the display.

Language available: Spanish, English, German,

Italian, French, Portuguese and Catalan.

Pressing (OK) return to main menu in language

selected.

DT0305 Page 9

Page 10

NMC

10. Technical Data

Note: Kobold Mesura makes every attempt to ensure the accuracy of these

specifications but reserves the right to change them at any time.

Measuring principle: Capacitive (for liquids up to 1000 pF)

Probe length: 265…4000 mm (shorter versions on request)

Accuracy: ±2 mm

Medium temp.: max. 90 ºC, NMC-H max.125 ºC

Max. pressure: 30 bar at 20 ºC, 10 bar at 90 ºC

Media DC-value: ε

Materials: Housing: Polycarbonate

Connection: St.steel 1.4305 (NMC-N,NMC-T,NMC-H)

PVDF (NMC-S)

Probe: - St.steel with PTFE coating (NMC-N, NMC-T)

- PVDF coating (NMC-S)

- St.steel probe 1.4305 with internal sensor

(st.steel with PTFE coating) (NMC-T)

Mech.Connection: G1 male (NMC-N,NMC-H,NMC-T)

G2 male (NMC-S)

Supply voltage: 10…35 Vdc

12…30 Vdc for ATEX

Electr.connection: via 1 (2) cable gland M20

Output: 4-20mA, two wire

Protection: IP 65

= min. 1.5

r

ATEX Ex II 2/1 GD Ex ia IIC T4 Gb/Ga

Ex ia IIIC T85ºC Db/Da

-20ºC<Ta<+60ºC

Páge 10 DT0305

Page 11

NMC

11. Safety Instructions (ATEX)

11.1 Validity

These safety instructions must be applied to the capacitive level transmitters series

NMC...E when used in explosive atmospheres.

11.2 General considerations

Working principle of NMC..E is capacitive and these instruments are used to

measure and control the level on a liquid of any zone. Including zones with

explosion risk.

Level instruments NMC..E have an analogue output 4-20 mA two wires, and are

used to measure the level in a tank. They can be used in explosive atmospheres

group IIA, category 1/2GD

NMC..E have a housing with the electronic module and a probe that can be rigid

(one or two roads) or flexible.

The probe can be installed in explosion risk areas 1/2GD.

The process connection element and the housing must be installed in area 2GD.

When installing these instruments in explosive zones, all general instructions and

recommendations regarding installations in explosive zones, as well as the

instructions of this safety manual must be followed.

Verify that all data in the label of the instrument fits the installation requirements.

EN60079-0, EN60079-11, EN60079-26, EN60079-31 must be followed.

Switch off power supply before open housing or be sure there is no explosion risk.

Verify that housing is closed before switch on the instrument.

It is very important to verify that ground terminal of the instrument is connected to

ground of the installation.

Installation in hazardous zones must be done by trained people.

11.3 Protection against ESD (electro static discharges)

Instruments with plastic parts that can produce electro static discharges, have a

label for it.

It is important to follow some rules to avoid ESD:

-Avoid frictions.

-Do not clean the instrument with a dry cloth.

-Do not install in locations close to pneumatic flow of materials or close to steam

exhaust systems.

11.4 Chemical resistance

Materials in touch with the instrument must be chemically resistant specially when

used in hazardous zones category 1/2GD.

DT0305 Page 11

Page 12

NMC

12. Installation in classified zone (ATEX)

In classified zones, NMC EX version, must

be installed with the housing in zone 21, 22

dust and 1, 2 for Gas (category 2) or NOT

CLASSIFIED.

Process connection is mounted in the border

wall between areas of category 2 and 1.

Probe can be mounted in ZONE 20,21 or 0,1

(category 1).

Installation must be done by people trained

in ATEX environments.

13. Label Description (ATEX)

Páge 12 DT0305

Page 13

NMC

14. Declaration of conformance ATEX

DT0164

DECLARACIÓN DE CONFORMIDAD EU

EU DECLARATION OF CONFORMITY

EU-KONFOMITÄTSERKLÄRUNG

DÉCLARATION DE CONFORMITÉ

DICHIARAZIONE DI CONFORMITÀ EU

KOBOLD MESURA SLU

Avda. Conflent 68, nave 15 08915 Badalona (España)

Declara, bajo la propia responsabilidad, que el producto

Declares under our sole responsibility, that the product

Erklärt in alleiniger Verantwortung, dass das produkt

Déclare sous sa seule responsabilité, que le produit

Dichiara sotto la propia responsabilità, che il prodotto

NMC…E

A los cuales se refiere esta declaración, son conformes a las siguiente Directivas Europeas:

To which this declaration relates is in conformity with the following European Directives:

Mit folgenden Richtlinien konform ist:

À auxquels se réfère cette déclaration, ils sont conformes aux Directives Européennes suivant :

A ai quali si riferisce questa dichiarazione, sono conformi alle direttive europee seguente:

EMC2014/30/EU LVD2014/35/EU Atex2014/34/EU RoHS2011/65/EU

Normas armonizadas y documentos de la normativa aplicados:

Applied harmonised standards and normative documents:

Angewandte harmonisierte Normen und normative Dokumente:

Normes harmonisées et documents normatifs appliqués

Norme armonizzate e documenti normativi applicati:

EN61010-1 :2011 EN60079-0:2006 (acc. EN60079-0:2013)

EN61000-6-2 :2006 EN60079-26:2007 (acc. EN60079-26:2015)

EN60079-11:2007 (acc. EN60079-11:2013)

Certificado de examen CE de tipo

EC-type examination certificate Marking

EG-baumusterprübescheinigung Kennzeichnung

Attestation d´examen CE de type Inscription

Certificazione per esame di tipo CE Marcatura

Marcado

LOM07ATEX2032X

II 2/1 GD Ex ia IIC T4 Gb/Ga

Ex ia IIIC T85ºC Db/Da

-20ºC <

Ta < +60ºC

Fabricado en: KOBOLD MESURA SLU Avda. Conflent 68, nave 15 08915 BADALONA (Spain)

Made in:

Hergestellt in:

Fabriqué dans:

Fabbricato in:

Organismo notificado

Notified organism Number notification

Zertifizierungsstelle Zertifikatsnummer

Organization annoncée Nombre notification

Organismo informato Notifica di numero

: LOM 0163 Número notificación : LOM 05ATEX9070

Badalona june 2017 Gerente

DT0305 Page 13

Page 14

NMC

15. Declaration of conformance

DECLARACIÓN DE CONFORMIDAD EU

EU DECLARATION OF CONFORMITY

EU-KONFOMITÄTSERKLÄRUNG

DÉCLARATION DE CONFORMITÉ

DICHIARAZIONE DI CONFORMITÀ EU

KOBOLD MESURA SLU

Avda. Conflent, 68 nave 15 08915 Badalona (España)

Declara, bajo la propia responsabilidad, que el producto

Declares under our sole responsibility, that the product

Erklärt in alleiniger Verantwortung, dass das produkt

Déclare sous sa seule responsabilité, que le produit

Dichiara sotto la propia responsabilità, che il prodotto

NMC…

A los cuales se refiere esta declaración, son conformes a las siguiente Directivas Europeas:

To which this declaration relates is in conformity with the following European Directives:

Mit folgenden Richtlinien konform ist:

À auxquels se réfère cette déclaration, ils sont conformes aux Directives Européennes suivant :

A ai quali si riferisce questa dichiarazione, sono conformi alle direttive europee seguente:

EMC2014/30/EU LVD2014/35/EU RoHS2011/65/EU

Normas armonizadas y documentos de la normativa aplicados:

Applied harmonised standards and normative documents:

Angewandte harmonisierte Normen und normative Dokumente:

Normes harmonisées et documents normatifs appliqués

Norme armonizzate e documenti normativi applicati:

EN61010-1 :2011 EN61000-6-2 :2006

Fabricado en

Made in:

Hergestellt in:

Fabriqué dans:

Fabbricato in:

: KOBOLD MESURA SLU Avda. Conflent, 68 nave 15 08915 BADALONA (Spain)

Badalona June 2017 Gerente

DT0490

Páge 14 DT0305

Page 15

NMC

16. ATEX Certified

DT0305 Page 15

Page 16

NMC

Páge 16 DT0305

Page 17

NMC

DT0305 Page 17

Page 18

NMC

Páge 18 DT0305

Page 19

NMC

DT0305 Page 19

Page 20

NMC

17. Models

Páge 20 DT0305

Page 21

NMC

18. Order details

Version Probe length* Mechanical

ATEX Supply

connection

NMC-N

NMC-H

NMC-T

NMC-S 9G9 = G2, PVDF

…1 = up to 1 meter

…2 = up to 2 meter

…3 = up to 3 meter

….4 = up to 4 meter

2G6 = G1, st. steel

0 = without

E= ATEX

* Please specify in writing length.

3 = 10…35 Vdc

DT0305 Page 21

Page 22

NMC

19. Notes

Páge 22 DT0305

Page 23

NMC

DT0305 Page 23

Page 24

KOBOLD MESURA S.L.U

Avda Conflent Nº68 Nave 15

08915 Badalona

Tel.: +34 93 460 38 83

Fax: +34 93 460 38 76

E-Mail: info.es@kobold.com

www.kobold.com

Technical data

Subject to change without prior notice

Loading...

Loading...