Page 1

NM

LIQUID LEVEL TRANSDUCER

Flow

Pressure

Level

Temperature

measurement

monitoring

control

Model:

NM

Visit KOBOLD Online at

www.kobold.com

KOBOLD Instruments Inc.

1801 Parkway View Drive

USA-Pittsburgh, PA 15205

☎

+1 412-788-2830

Fax +1 412-788-48 90

E-mail: info@koboldusa.com

USA

CANADA

KOBOLD Instruments Canada Inc.

9A Aviation

Pointe-Claire, QC H9 R 4Z2

☎

+1 514-428-8090

Fax +1 514-428-8899

E-mail: kobold@kobold.ca

N2

Rev 4/12

● Continuous Level Measurement

● Undisturbed by Foam

● Vapor Insensitive

● Liquid Interface Detection

● Range of Wetted Parts

Page 2

NM - Liquid Level Transducer

Rev 4/12 Subject to change without prior notice.

The NM series of level transducers is

applicable to a wide variety of industrial

level indicating applications. A reed chain

and travelling float design allow the

system to function independently of

liquid electrical properties, temperature,

pressure, foaming or the presence of

vapors. With proper float weighting, the

system can be constructed to detect the

interface level of two liquids with

dissimilar specific gravities. A selection

of materials ranging from stainless steel,

to plastic, to PTFE, provide

compatibility with a large variety of

process liquids.

Typical NM applications include waste

water and sewage treatment plants,

charging and mixing bins, containers for

chemicals, beverages or vegetable oils,

remote level indication for rivers or

reservoirs. High reliability is assured by

keeping the moving part count down to a

single, non-friction component (the float.)

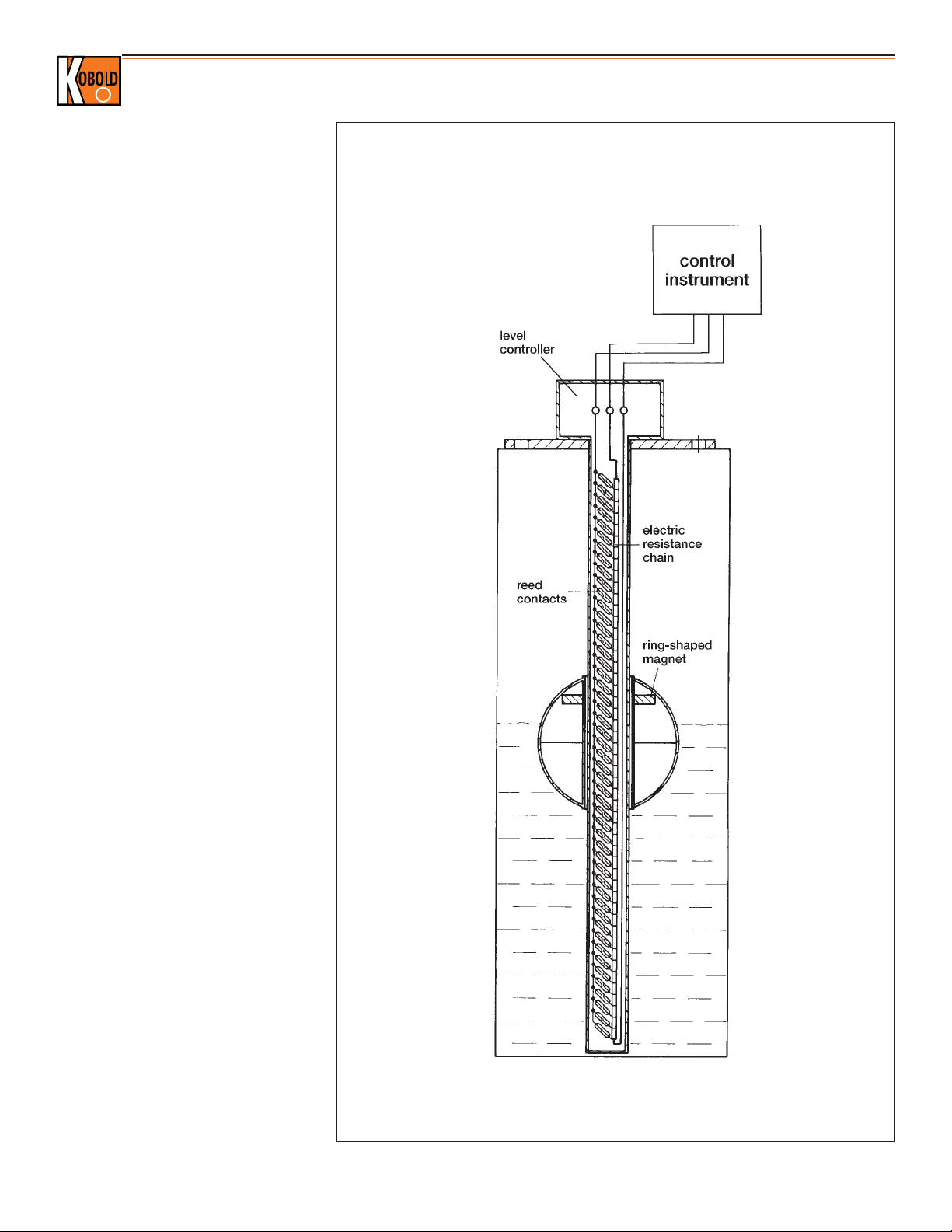

Function

The transducer consists of a guide tube

onto which a float is inserted. A magnet

inside the float actuates a series of reed

switches inside the tube. One contact of

the reed switches is connected to a

resistance chain every fraction of an

inch, and the other contact to a common

terminal. The entire system functions as

a three-tap potentiometer whose

resistance is determined by the location

of the float on the guide tube. An optional

electronic signal converter module

(suffix code:"RT") uses this variable

resistance as part of a Wheatstone Bridge

circuit and converts the resistance to an

4-20 mA, 2-wire analog signal for use with

an external display or PLC input.

This module can be specified for any unit

with an integral junction box.

.

.

The accuracy of the system is a function

of the reed switch spacing. This spacing

varies from 10 mm (0.4 inches) to 20 mm

(0.8 inches) depending on transducer

model and overall length. The magnet

closes either one or two switches at all

times. Interpolation allows accuracies of

1

/2the switch spacing.

NM Series Level Gauge

Page 3

Subject to change without prior notice. Rev 4/12

N2

NM - Liquid Level Transducer

The NM-298 and NM-299 are stainless

steel level transducers which are

installed upwards into a threaded fitting.

This arrangement requires access to the

interior of the vessel into which the units

are installed.

Each transducer comes standard with

3.3 feet (1 meter) of pigtail cable. Extra

cable lengths are available.

The NM-298 is ideal for installations 6.6

feet (2 meters) and shorter. The NM-299

can be obtained in lengths to 19.8 feet

(6 meters).

Specifications

Maximum Length

NM-298: 6.6 feet

NM-299: 19.8 feet

Fittings

NM-298:

3

/8" NPT male

NM-299:

1

/2" NPT male

Wetted Parts: 316-Ti SS

Accuracy: ± 15 mm (0.6 in.)

Minimum Liquid Specific Gravity

Standard: 0.8

Optional: 0.7

Temperature Range:– 4 to 250 °F

Max. Pressure

NM-298: 210 PSIG

NM-299: 290 PSIG

Electrical Data

Sensing Voltage: 20 VDC max.

Sensing Current: 100mA max.

Total Resistance

Standard: Approx. 5,000 Ω

Cable Length: 3.3 feet standard

(longer available)

Protection: NEMA 4X/IP65

NM-298 NM-299

Models NM-298 and NM-299: Stainless Steel

Model Number

Series Number Fittings Length

NM-298 -N

3

/8":3/8" NPT -L =: Specify Length

-R 3/8":3/8" bsp

NM-299 -N

1

/2":1/2" NPT

-R 1/2":1/2" bsp

NM-298 and NM-299 Ordering Information

Example: NM-298-N 3/8"-L 40"

Page 4

NM - Liquid Level Transducer

Rev 4/12 Subject to change without prior notice.

The NM-301 and NM-302 are stainless

steel level transducers with flanged or

threaded fittings. Use of the 1

1

/2" NPT

fitting or flange allows the units to be

installed from the top of your vessel or

mounting bracket. These larger fittings

will accommodate the floats with which

the transducers are equipped. Each

transducer comes standard with a

NEMA 4 terminal box.

The NM-302 is intended for installations

6.6 feet (2 meters) and shorter. The

NM-301 can be obtained in lengths to

19.8 feet (6 meters.)

Specifications

Minimum Length: 12 inches

Maximum Length

NM-301: 19.8 feet

NM-302: 6.6 feet

Fittings

NM 301:

1

/2" NPT male

4" ANSI flange

NM-302: 1

1

/2" NPT male,

2", 2

1

/2" 3" or 4"

ANSI flange

Wetted Parts: 316-Ti SS

Accuracy

NM-302: ± 10 mm (0.6 in.)

NM-301

L< 6.6 feet: ± 10 mm (0.4 in.)

L> 6.6 feet: ± 20 mm (0.8 in.)

Minimum Liquid Specific Gravity

Standard: 0.8

Optional: 0.7

Temperature Range: – 4 to 250 °F

Max. Pressure

NPT Threads

NM-301: 290 PSIG

NM-302: 210 PSIG

Electrical Data

Sensing Voltage: 20 VDC max.

Sensing Current: 100 mA max

Total Resistance

Standard: Approx. 5,000 Ω

Terminal Box: Polyamide

Protection: NEMA 4X/IP65

Optional Transmitter: 2-wire, 4-20 mA,

16-32 VDC input power

NM-301 NM-302

Models NM-301 and NM-302: Stainless Steel

Model Number

Series Number Fittings Length

NM-301 -N

1

/2":1/2" NPT -L =: Specify Length

-FL 4": 4" 150 lb ANSI flange

NM-302 -N 1

1

/2": 11/2" NPT

-FL 2": 2" 150 lb ANSI flange

-FL 2

1

/2": 21/2" 150 lb ANSI flange

-FL 3": 3" 150 lb ANSI flange

-FL 4": 4" 150 lb ANSI flange

Options

-RT Integral 2-wire 4-20 mA Transmitter

NM-301 and NM-302 Ordering Information

Example: NM-302-FL 3", L = 128"

Page 5

Subject to change without prior notice. Rev 4/12

N2

NM - Liquid Level Transducer

The NM-300 and NM-308 are PVC,

polypropylene (PP) or PTFE

level transducers with flanged or threaded

fittings. PVC floats and flanges are

unavailable. Polyethylene (PE) floats and

polypropylene (PP) flanges will be provided

with PVC units. PVC threaded fittings are

available.

Each transducer comes with a NEMA 4

terminal box.

Specifications

Maximum Length

NM-300: 3.3 feet

NM-308: 19.8 feet

Fittings

NM-300: 2 NPT male

2

1

/2ANSI flange

NM-308: 1" NPT male

3" ANSI flange

Wetted Parts

NM-300:

Stem: PVC or

Polypropylene (PP)

Float: Polyethylene with

PVC stem or PP

with PP stem

NPT Fittings: PVC or PP

Flanged: PP only

NM-308:

Stem: PVC, PP or PTFE

Float: Polyethylene with

PVC stem, PP or

PTFE

NPT Fittings: PVC, PP or PTFE

Flanged: PP or PTFE

Accuracy

NM-300: ± 10 mm (0.4 in.)

NM-308

Below 6.6 feet: ± 10 mm (0.4 in.)

Above 6.6 feet: ± 20 mm (0.8 in.)

Minimum Liquid Specific Gravity

NM-300: 0.5

NM-308: 0.8

Operating Temperature Range

PVC/PE: – 4 to 140 °F

Polypropylene: – 4 to 190 °F

PTFE: – 4 to 250 °F

Max. Pressure: 85 PSIG

NM-300 NM-308

Models NM-300 and NM-308: Synthetic

Model Number

Series Number

Fittings

Length

Tube & Float

(PVC Units w. PP Flange) Material

NM-300 -N 2": 2 NPT -L =: -PVC: PVC (Poly-

(PVC or PP) -FL 21/2": 21/2" 150 lb ANSI flange Specify ethylene float)

Length

-PP: Polypropylene

NM-308 -N 1

1

/2": 11/2" NPT

(PVC, PP or PTFE) -FL 2": 2" 150 lb ANSI flange -PTFE : PTFE

-FL 2

1

/2": 21/2" 150 lb ANSI flange (NM-308 only)

-FL 3": 3" 150 lb ANSI flange

-FL 4": 4" 150 lb ANSI flange

Options

-RT Integral 2-wire 4-20 mA Transmitter

NM-300 and NM-308 Ordering Information

Example: NM-300-FL 21/2"PVC, L=23”

Electrical Data

Sensing Voltage: 24 VDC max.

Total Resistance

Standard: Approx. 5,000 Ω

Terminal Box: Polyamide

Protection: NEMA 4X/IP65

Optional Transmitter: 2-wire, 4-20 mA,

16-32 VDC

Loading...

Loading...