Kobold NBK, NBK-01, NBK-04, NBK-06, NBK-03 Operating Instructions Manual

...

Operating Instructions

for

Bypass Level Indicator

Model: NBK

NBK

page 2 NBK K01/0906

1. Contents

1. Contents........................................................................................................2

2. Note ..............................................................................................................3

3. Instrument Inspection....................................................................................4

4. Regulation Use..............................................................................................4

4.1. Bypass Measuring Tube System .........................................................4

4.2. Electrical Limit Switches (option) .........................................................5

4.3. Remote Sensor with Reed Contact Chain of Resistors

(option ..M.. / option ..W..) ...................................................................5

4.4. Remote Sensor with Magnetostrictive Pick-Up (option ..T..)................ 5

5. Operating Principle........................................................................................5

6. Mechanical Connection.................................................................................7

7. Electrical Connection ....................................................................................9

7.1. Limit contacts NBK-R, NBK-RT ...........................................................9

7.2. Remote Sensor: Reed Contact Chain of Resistors (option ..W..) ......10

7.3. Remote Sensor: Chain of Resistors with 2-wire Transmitter

(option ..M..).......................................................................................11

7.4. Remote Sensor: Magnetostrictive Sensor with 4-wire Transmitter

(option ..T..) .......................................................................................12

8. Commissioning............................................................................................13

9. Trouble Shooting.........................................................................................14

10. Maintenance ...............................................................................................14

11. Technical Information..................................................................................15

12. Options........................................................................................................ 17

13. Order Codes ...............................................................................................18

14. Dimensions .................................................................................................19

15. Declaration of Conformance .......................................................................20

Manufactured and sold by:

Kobold Messring GmbH

Nordring 22-24

D-65719 Hofheim

Tel.: +49(0)6192-2990

Fax: +49(0)6192-23398

E-Mail: info.de@kobold.com

Internet: www.kobold.com

NBK

NBK K01/0906 page 3

2. Note

Please read these operating instructions before unpacking and setting the unit

into operation. Follow the instructions precisely as described herein.

The devices are only to be used, maintained and serviced by persons familiar

with these operating instructions and in accordance with local regulations applying to Health & Safety and prevention of accidents.

When used in machines, the measuring unit should be used only when the machines fulfil the EWG-guidelines.

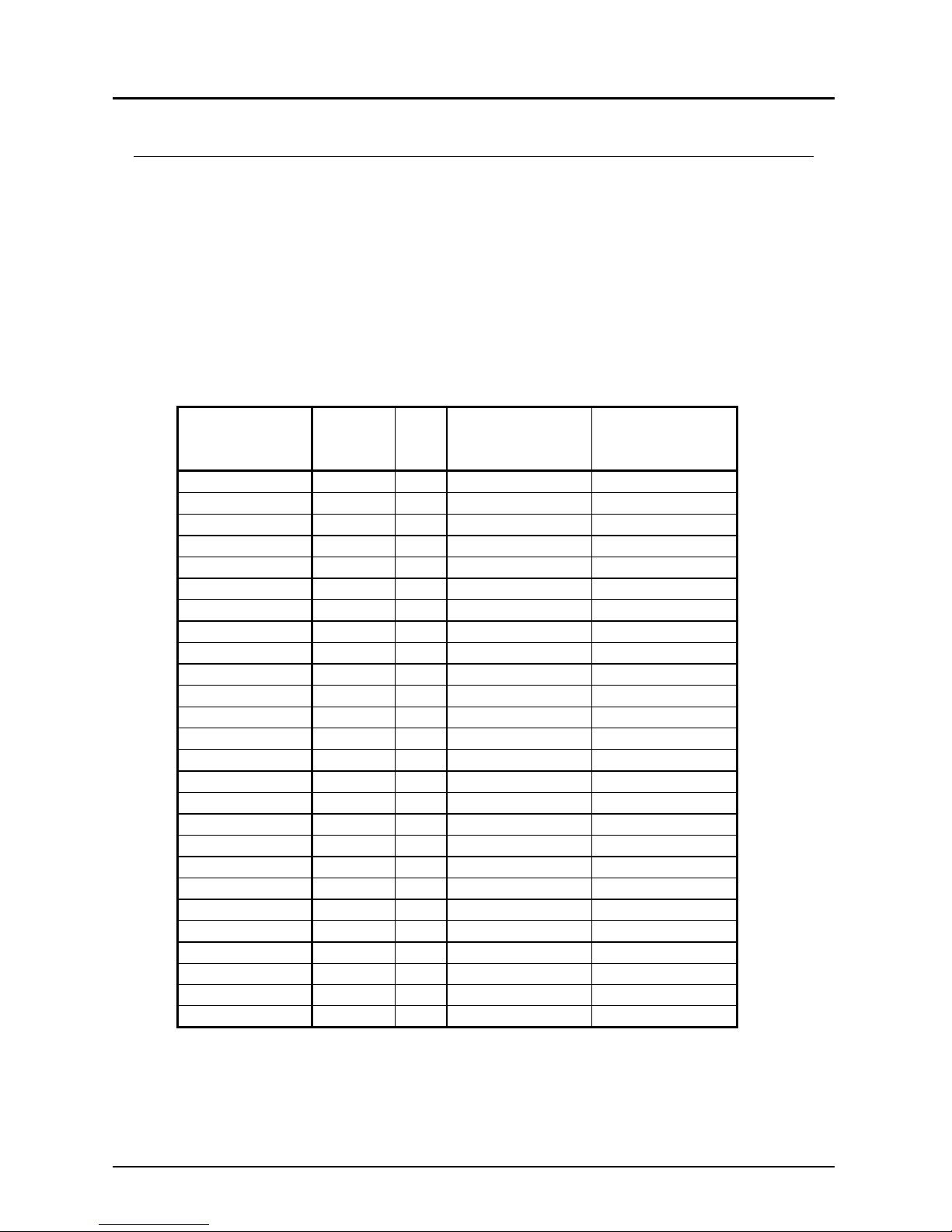

as per PED 97/23/EG

Model

Total bypasslength

p

max

[bar]

Medium non

dangerous

(Diagr. 2)

Medium dangerous

(Diagr. 1)

NBK-01 <= 645 16 Art.3, Para.3 Art.3, Para.3

NBK-01 <= 1270 16 Art.3, Para.3 I

NBK-01 <= 5040 16 I II

NBK-01 >= 6420 16 II III

NBK-03 <= 645 16 Art.3, Para.3 Art.3, Para.3

NBK-03 <= 1270 16 Art.3, Para.3 I

NBK-03 <= 5040 16 I II

NBK-03 >= 6420 16 II III

NBK-04 <= 645 16 Art.3, Para.3 Art.3, Para.3

NBK-04 <= 1270 16 Art.3, Para.3 I

NBK-04 <= 5040 16 I II

NBK-06 <= 250 40 Art.3, Para.3 Art.3, Para.3

NBK-06 <= 500 40 Art.3, Para.3 I

NBK-06 <= 2000 40 I II

NBK-06 <= 6500 40 II III

NBK-07 <= 167 64 Art.3, Para.3 Art.3, Para.3

NBK-07 <= 335 64 Art.3, Para.3 I

NBK-07 <= 1341 64 I II

NBK-07 <= 6500 64 II III

NBK-10 <= 107 100 Art.3, Para.3 Art.3, Para.3

NBK-10 <= 215 100 Art.3, Para.3 I

NBK-10 <= 858 100 I II

NBK-10 <=4292 100 II III

NBK-10 <= 6500 100 III IV

NBK-12; 13; 14 <= 1470 6 Art.3, Para.3 Art.3, Para.3

NBK-12; 13; 14 <= 2974 6 Art.3, Para.3 I

NBK

page 4 NBK K01/0906

3. Instrument Inspection

Instruments are inspected before shipping and sent out in perfect condition.

Should damage to a device be visible, we recommend a thorough inspection of

the delivery packaging. In case of damage, please inform your parcel service /

forwarding agent immediately, since they are responsible for damages during

transit.

Scope of delivery:

The standard delivery includes:

• Bypass Level Indicator model: NBK

• Operating Instruction

4. Regulation Use

Any use of the Bypass level Indicator, model: NBK, which exceeds the

manufacturer’s specification may invalidate its warranty. Therefore, any resulting

damage is not the responsibility of the manufacturer. The user assumes all risk

for such usage.

The NBK Bypass Level Indicator is used for continuous measurement, indication,

and monitoring of liquids in tanks, vessels, reservoirs, basins etc. The indication

occurs via a magnetically coupled roller indicator.

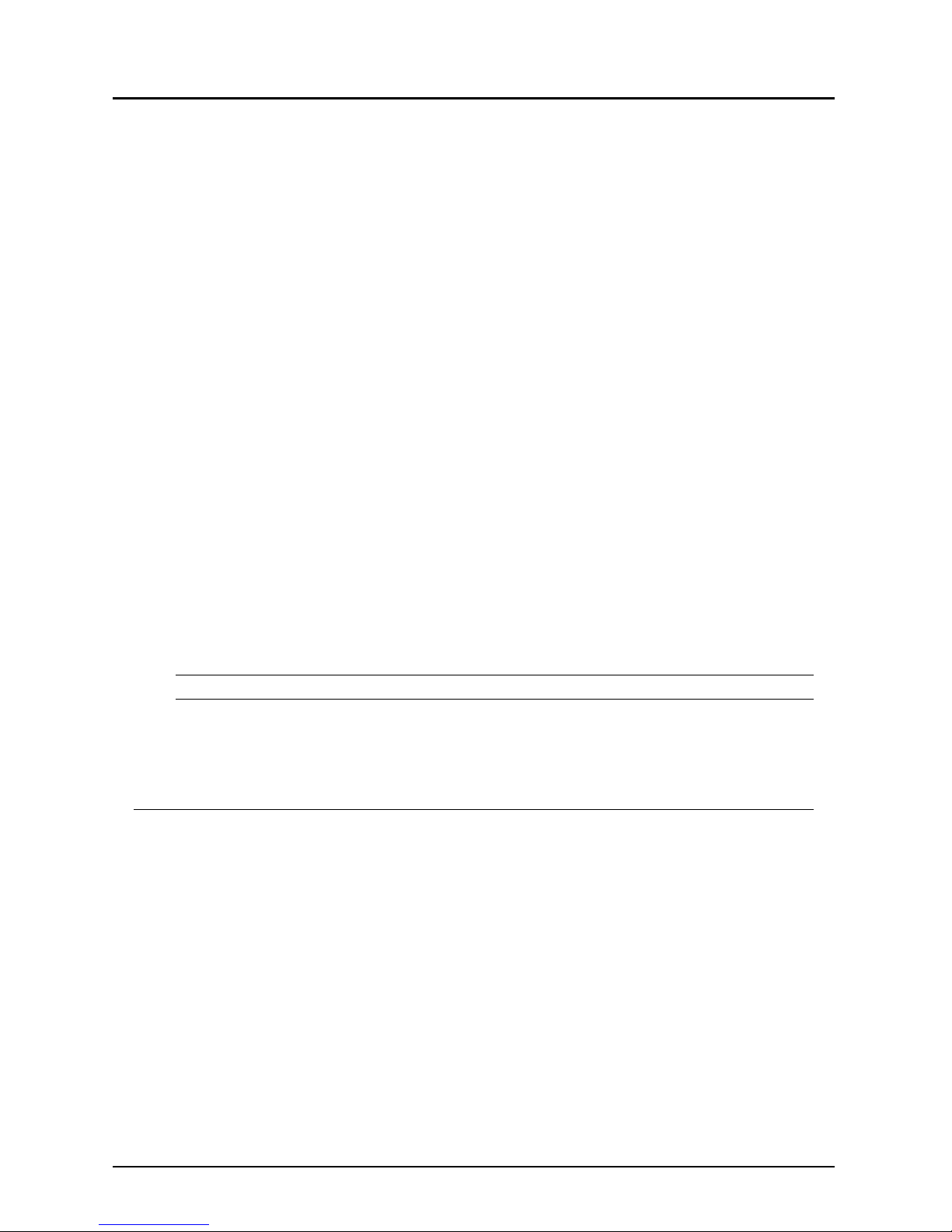

4.1. Bypass Measuring Tube System

The bypass tube is attached at the side of the vessel with a connecting flange or

a threaded pipe. The installation position is always vertical. The NBK should only

be used for liquids with the medium density specified on the nameplate.

Otherwise the indication will deviate (float too high or submerged).

Vessel inner pressure and medium temperature should not exceed the specified

maximum values, as this can lead to the destruction and malfunction of the

bypass system. It is imperative that the materials used are compatible with the

liquid being measured.

Proper operation is also impaired by:

• High degree of soiling

• Suspended solids

• Crystallisation

• Ferrite particles

NBK

NBK K01/0906 page 5

4.2. Electrical Limit Switches (option)

The optional electrical limit switches serve to signal a preset level.

NBK-R: Bistable changeover contact fitted in a polycarbonate housing with 3m

connection cable

NBK-RT200/-RT400: Bistable changeover contact fitted in an aluminium die cast

housing with terminal connectors

4.3. Remote Sensor with Reed Contact Chain of Resistors

(option ..M.. / option ..W..)

The optional remote electrical sensor converts the liquid level to a resistance

value, which serves to transmit the level as a varying electrical signal. Downstream control electronics transform the signal to a standard analogue value

(e.g., 4–20 mA), or control the level.

4.4. Remote Sensor with Magnetostrictive Pick-Up

(option ..T..)

Remote level transmission can be achieved by mounting a magnetostrictive

sensor outside the bypass tube. A continuous standard 4 to 20 mA signal is

obtained with a built-in transmitter. This signal can then be displayed on analogue

or digital indicators.

Please pay attention to the maximum medium and ambient temperatures.

5. Operating Principle

Kobold Bypass Level Indicators are used for continuous measurement, display

and monitoring of liquid levels. The bypass tube is attached onto the side wall of

the vessel. According to the law of communicating tubes the level in the bypass

tube equals the level in the vessel. A float with embedded circular magnets in the

bypass tube follows the liquid level and transfers it in a non-contacting manner to

a display fitted outside the tube or to a monitoring device. The following indication

and monitoring devices are available:

NBK

page 6 NBK K01/0906

Magnetic roller indicator

As the float passes by, the red/white rollers are rotated in succession by 180°

around their own axes. The rollers change from white to red as the level rises and

from red to white as the level falls. The level in a tank or a mixer is continuously

displayed as a red column, even when the power fails.

Transmitter

To remotely transmit the level a transmitter with a chain of resistors or a magnetostrictive transducer can be mounted outside the bypass tube.

The contacts of a reed contact chain are connected or disconnected via the float

movement in a non-contacting manner. Depending on the level, the number of

connected resistors changes and as a consequence the output of the total

resistor value.

A continuous standard signal of 4 to 20 mA is generated by means of a fitted

transmitter. This standard signal can then be displayed on analogue or digital

indicating devices.

Universal indicating unit

A universal indicating unit of type series ADI can be mounted on the bypass to

display and evaluate the standard signal (4–20 mA) generated by the transmitter.

Limit contacts

One or more reed contacts for limit-value acquisition or also for level control can

be attached to the bypass tube.

ATEX version

The bypass level indicators can be supplied with ATEX approval. As an option

limit contacts and a reed contact chain with ATEX approval are available for level

measurement and monitoring.

ATEX approval:

Bypass-level indicator: Ex II 1G /2GD (mechanical)

Limit contact NBK-RA: Ex II 2G EEx m II T6 / T5

Immersible magnetic probe

(Reed contact chain): Ex II 1G EEx ia IIC T6

Transmitter for Reed chain: Ex II (1) G [EEx ia] IIC

GL version

In the pressure stages PN 16 (NBK-03) and PN 40 (NBK- 06) the bypass level

indicators are available with GL approval (Germanischer Lloyd). The magnetic

roller indication as well as limit contacts and a reed contact chain can be

delivered for level indication and evaluation .

Certificate-No. GL: 79 786-95 HH

NBK

NBK K01/0906 page 7

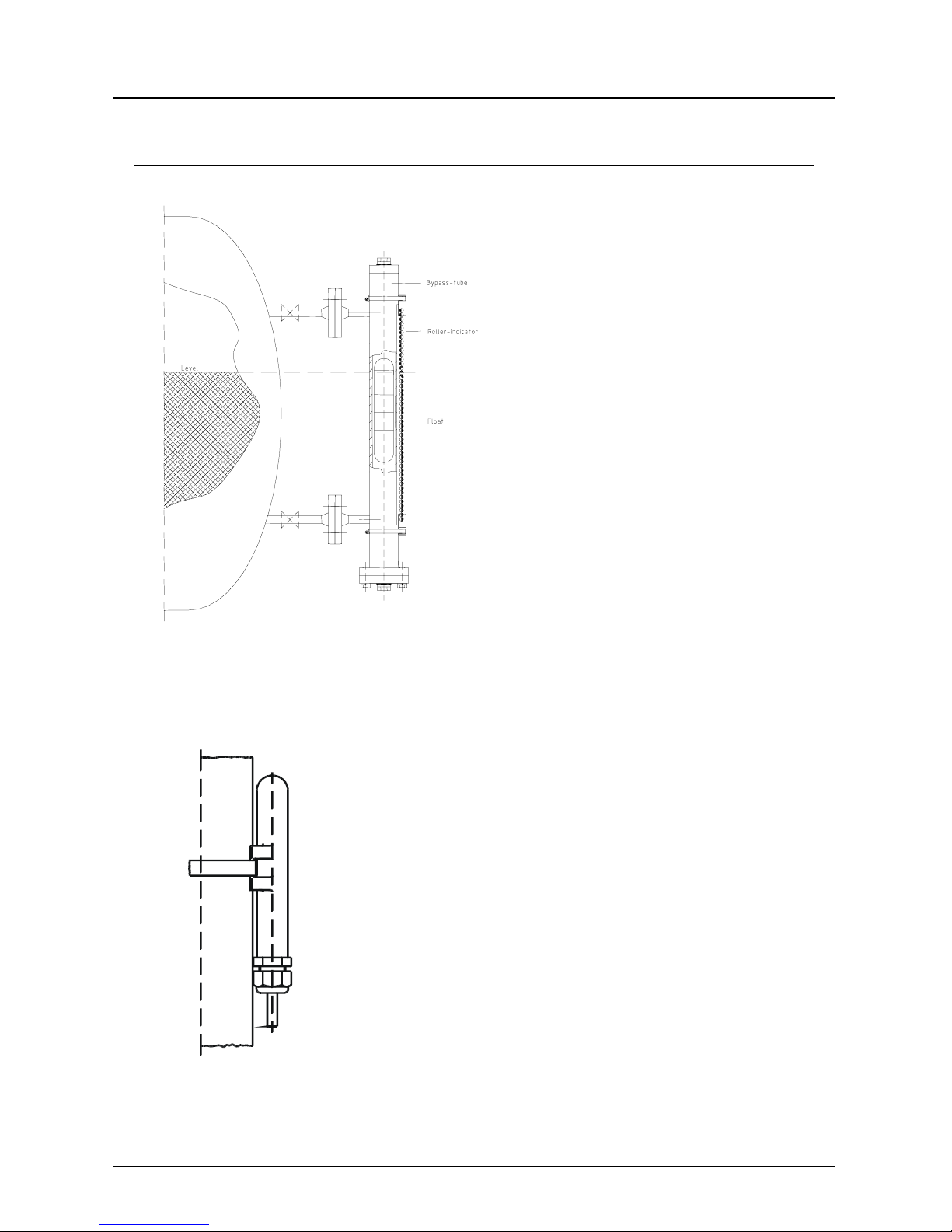

6. Mechanical Connection

Remove bottom flange from bypass

tube, and insert the cylindrical float in

the NBK bypass tube with the designation "TOP" at the top. Re-position the

gasket and close the bottom flange

again; firmly tighten with screws.

Mount the bypass tube to the vessel to

be monitored via the process

connection and seal with an

appropriate device. Normally it is

sufficient to fix the complete NBK with

both process connections. However

should the NBK be subjected to

constant shock or strong vibrations it

is recommended that the instrument is

secured with rubber-damped tube

clips. No welding is allowed on the

bypass tube.

Mount and tighten the magnetic roller

indicator - if not already mounted - on

the bypass tube with the two provided

ribbon clamps.

Mount and tighten the reed switch - if available.- on the

bypass tube at the opposite side of the roller indicator with

the provided ribbon clamps (ex contact: two ribbon

clamps). The height of the switch contacts may be selected

at will. The cable connection must point downwards. The

switch must be attached close to the bypass tube. The

switching function of the switch is impaired by an enlarged

air gap.

Loading...

Loading...